Lightweight Aggregates with Special Microstructure for Use in Rooftop Garden Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials Used

2.1.1. The Associated Clay Bełchatów (Poland)

2.1.2. Post-Process Clay, Dubna Skala (Slovakia)

2.2. Aggregate Preparation and Analytical Techniques

2.2.1. Granulation of the Material

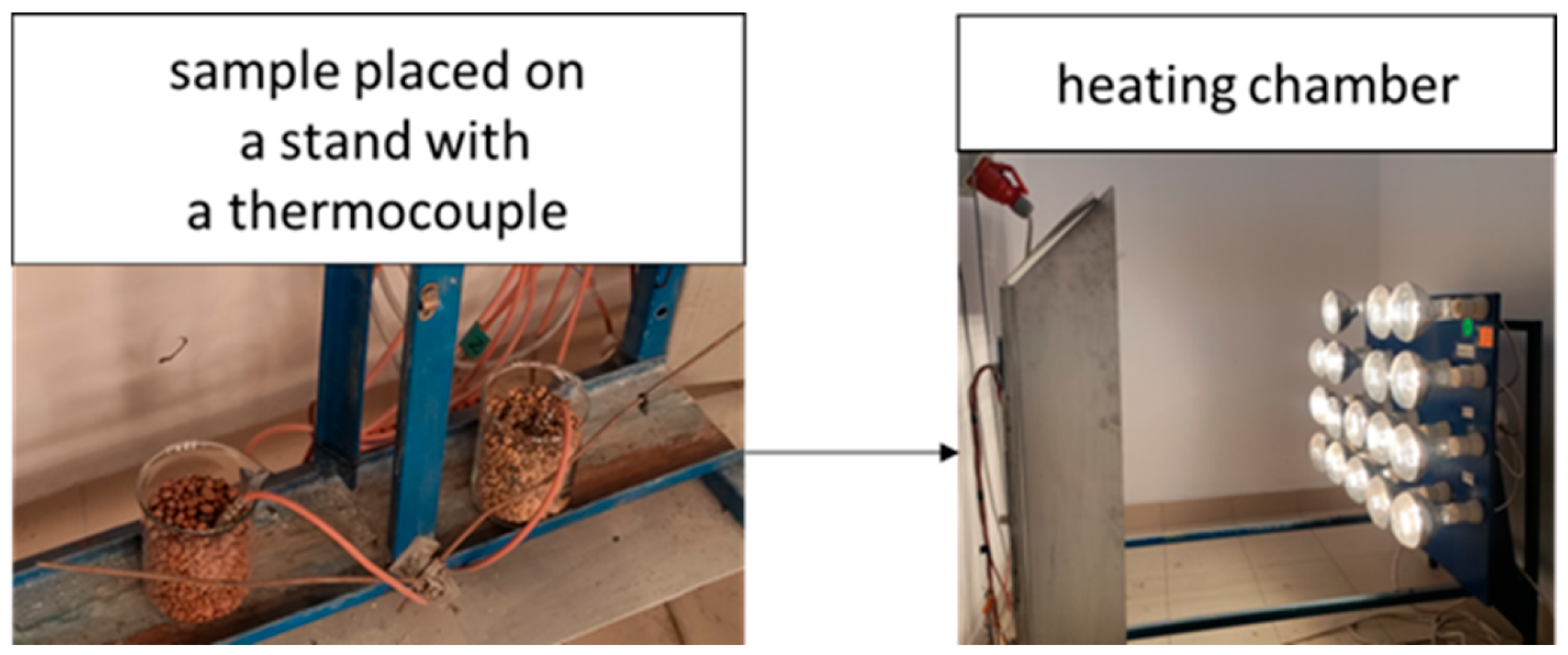

2.2.2. Sintering

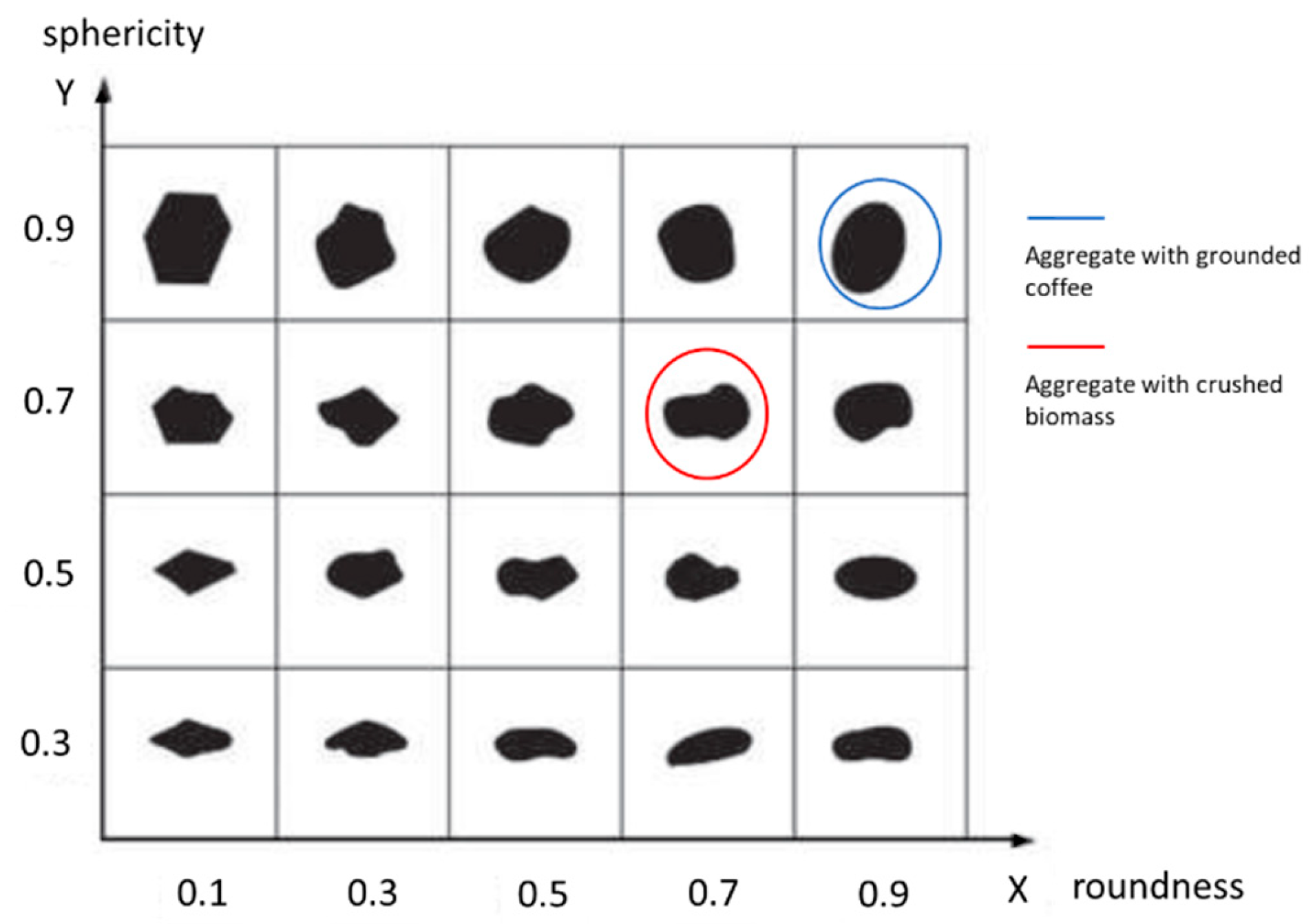

2.2.3. Imaging Analysis

2.2.4. Strength Tests

2.2.5. Determination of the Basic Physical, Chemical, and Hydrometric Parameters

2.2.6. Heating and Cooling Tests

2.2.7. Methodology of Vegetation Test

3. Results and Discussion

3.1. Achievement of Sintered Aggregate

3.2. Analysis of Selected Properties of Sintered Aggregates

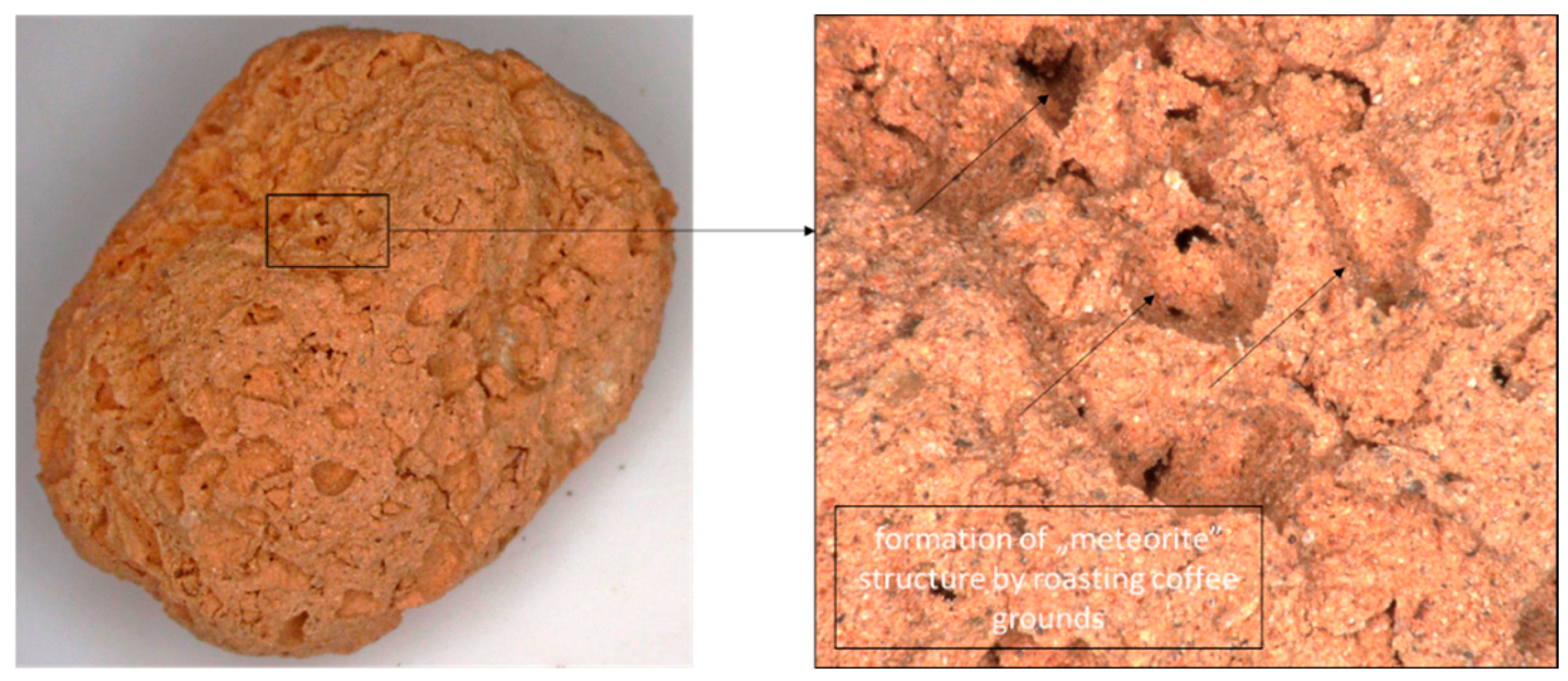

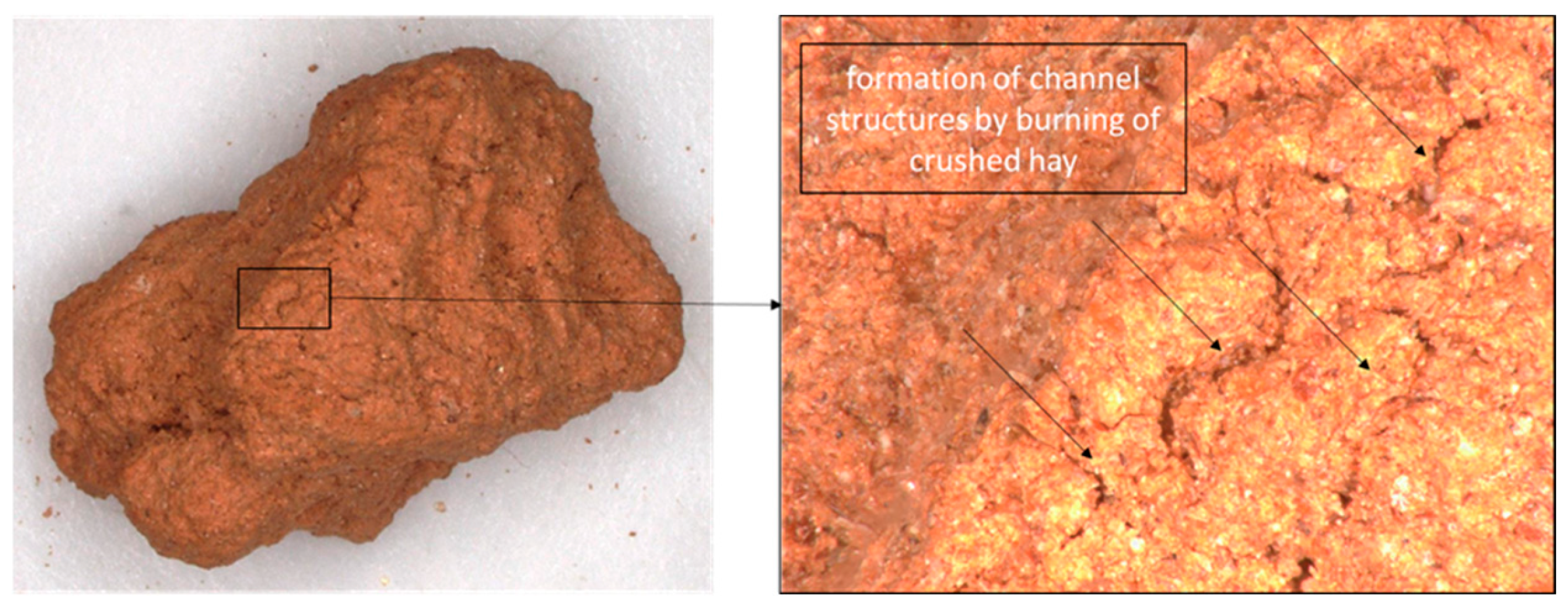

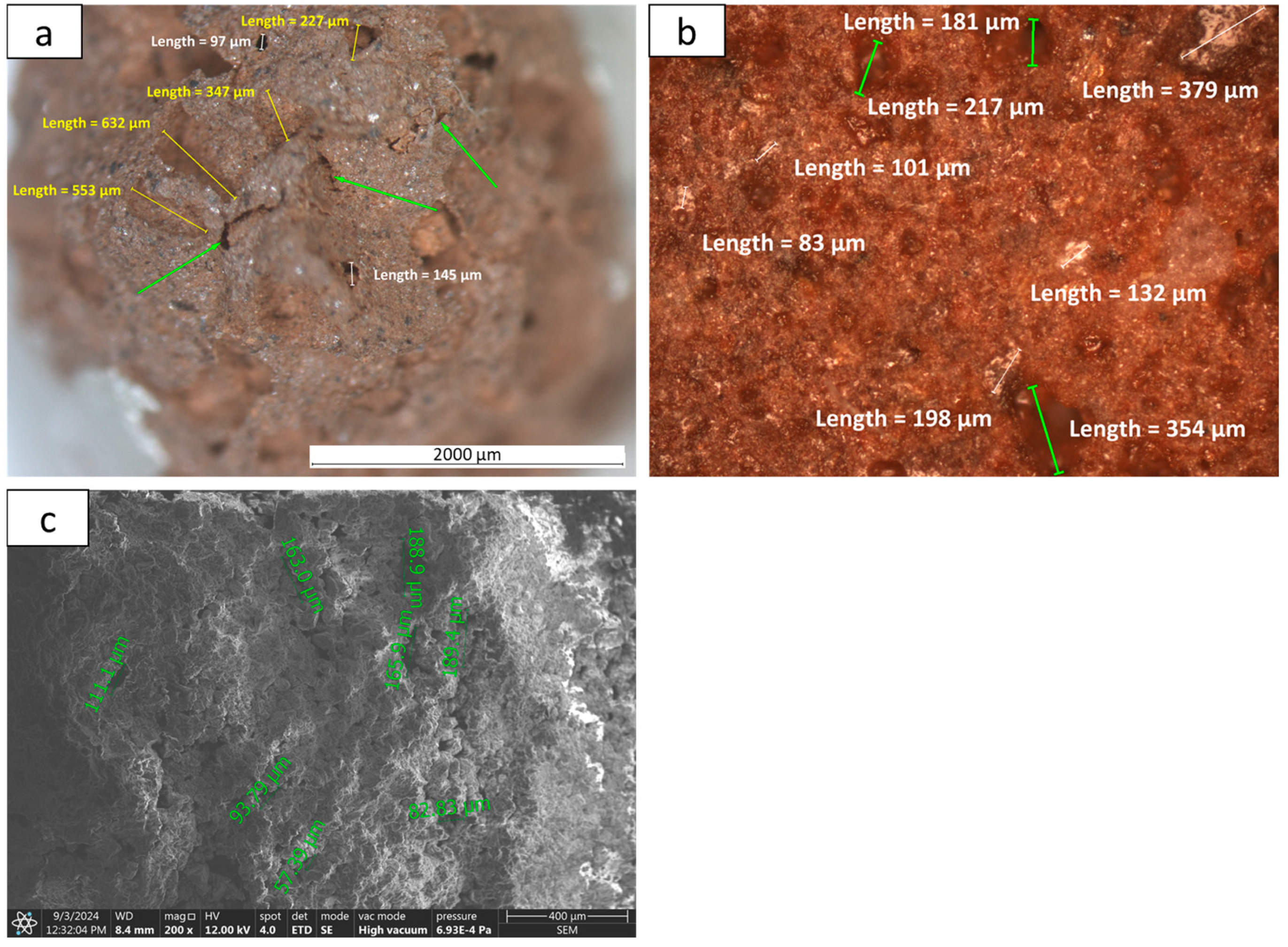

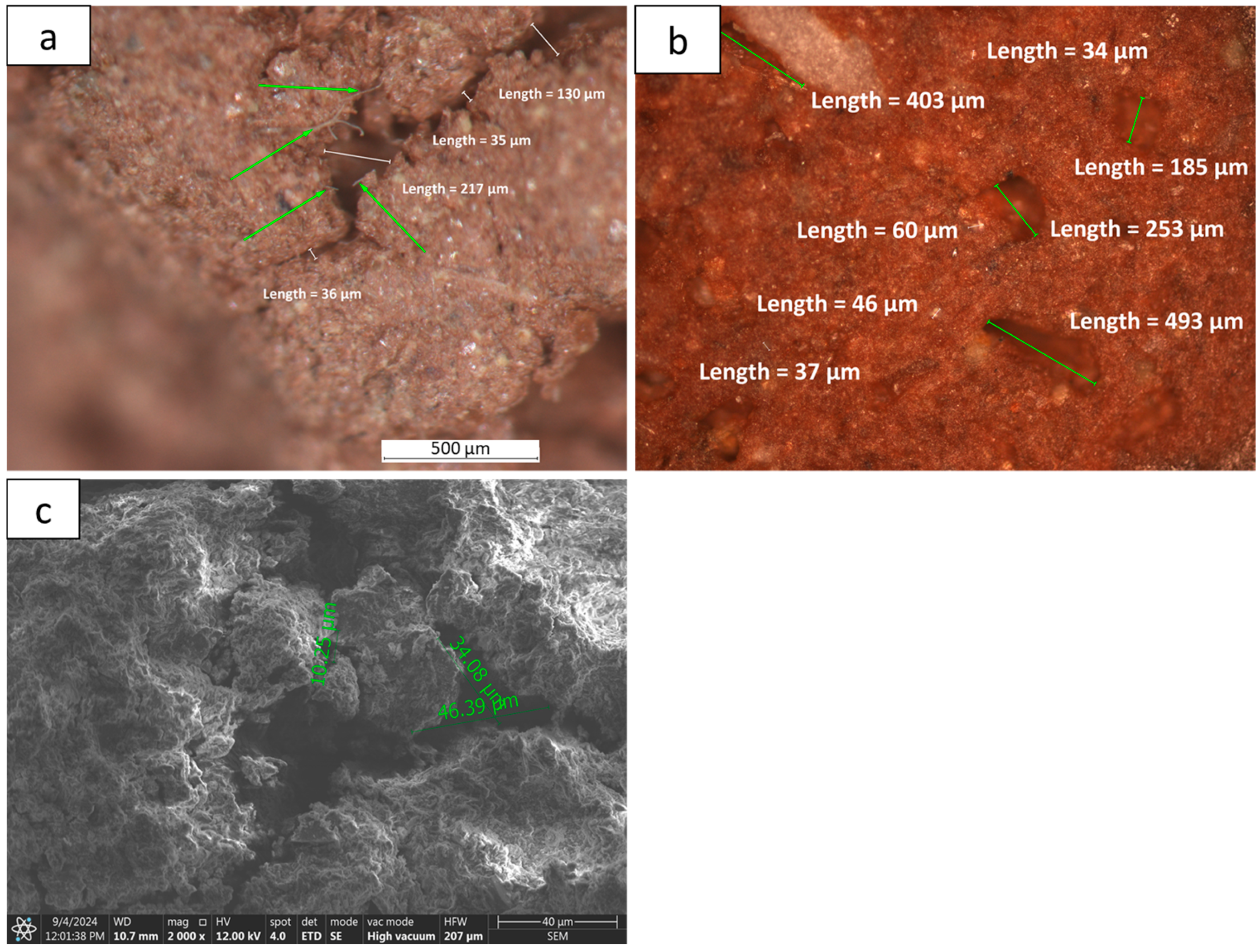

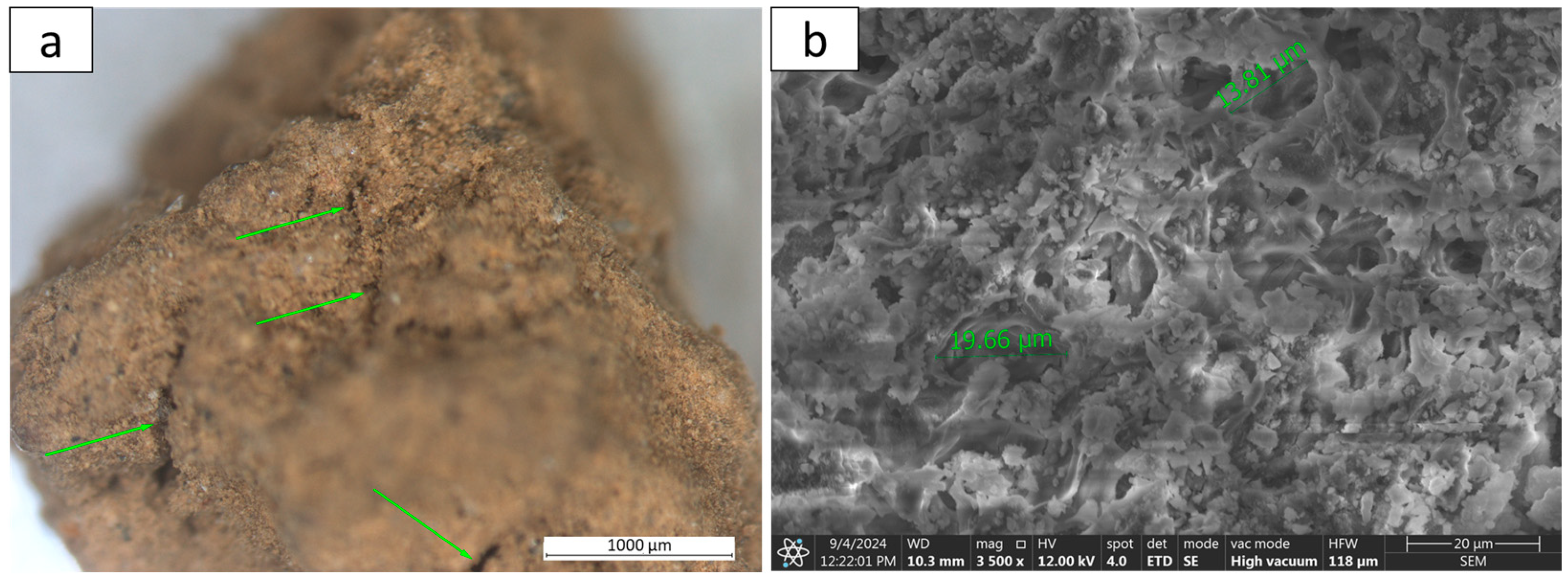

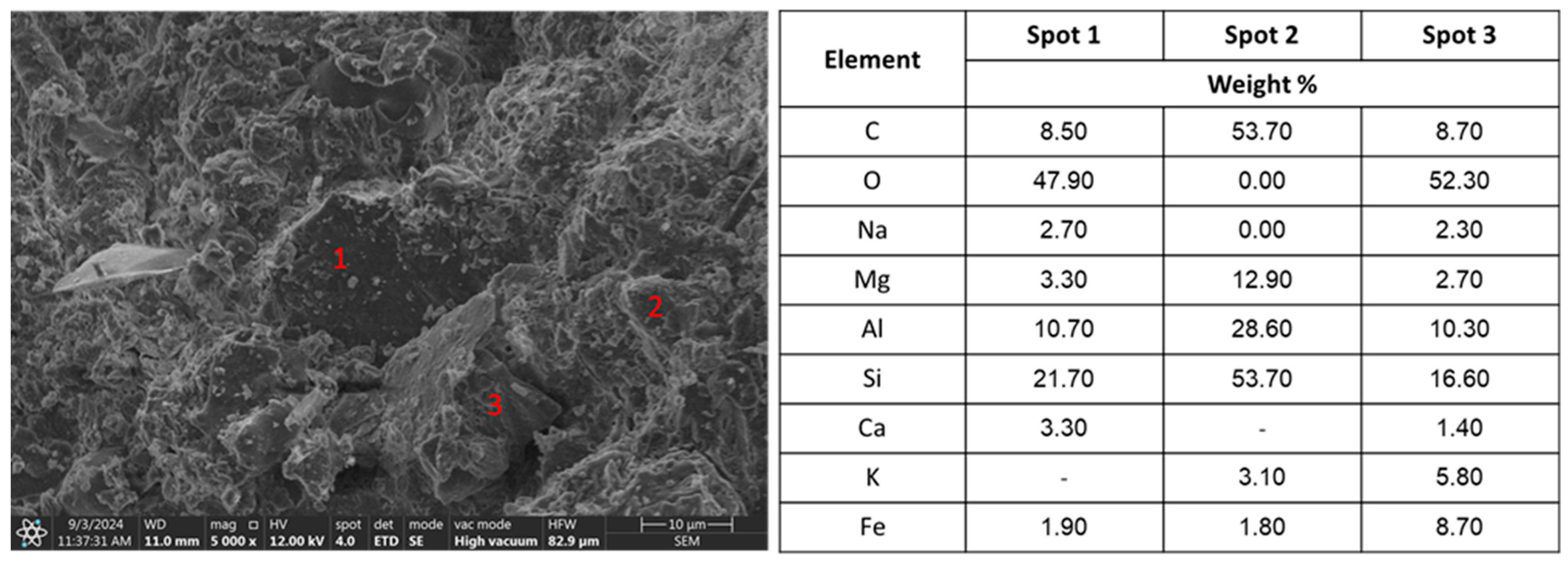

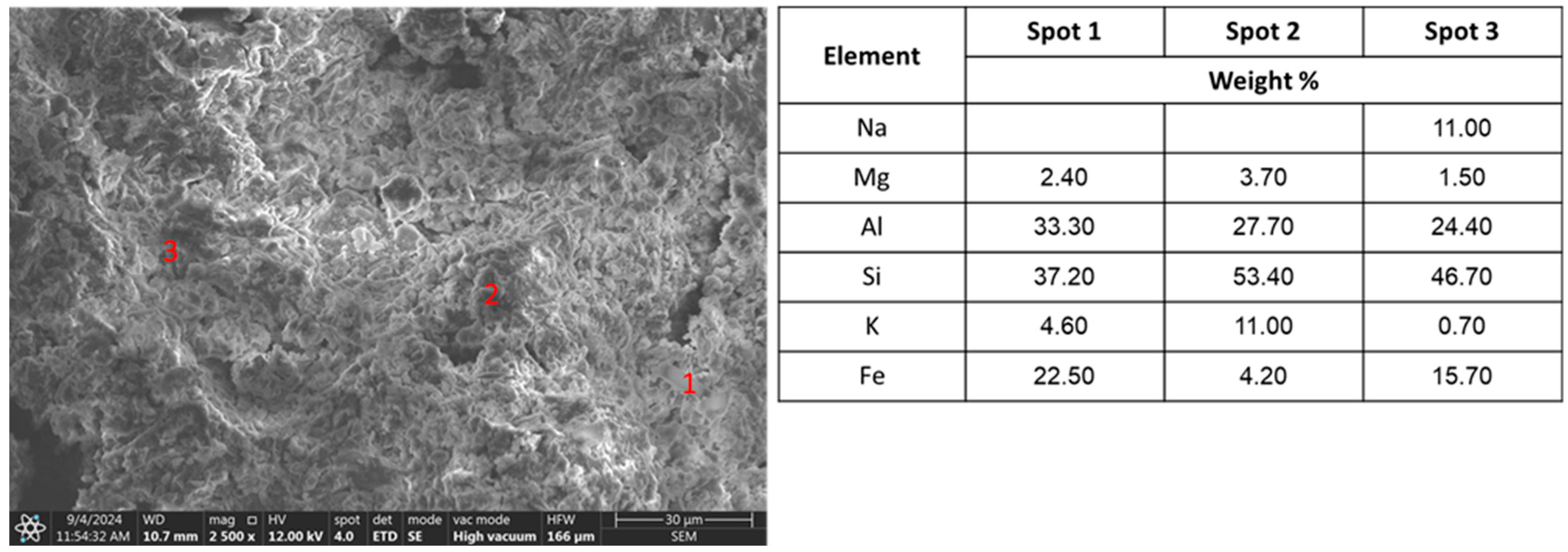

3.2.1. Imaging and Structural Analysis

3.2.2. Apparent and Bulk Density

3.2.3. Resistance to Abrasion, Crushing, and Disintegration Under the Influence of Water

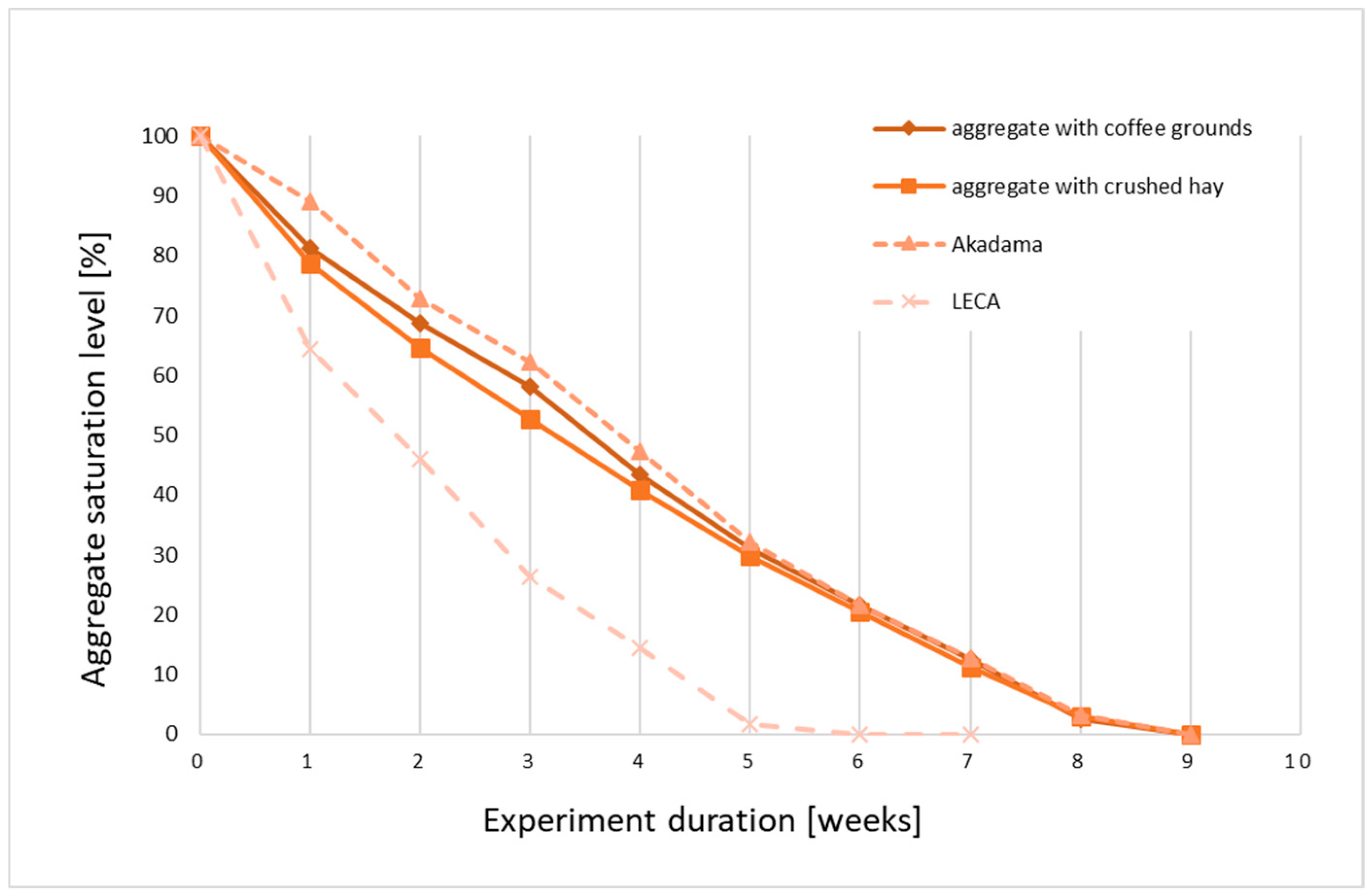

3.2.4. Total Retention and Water Release Process

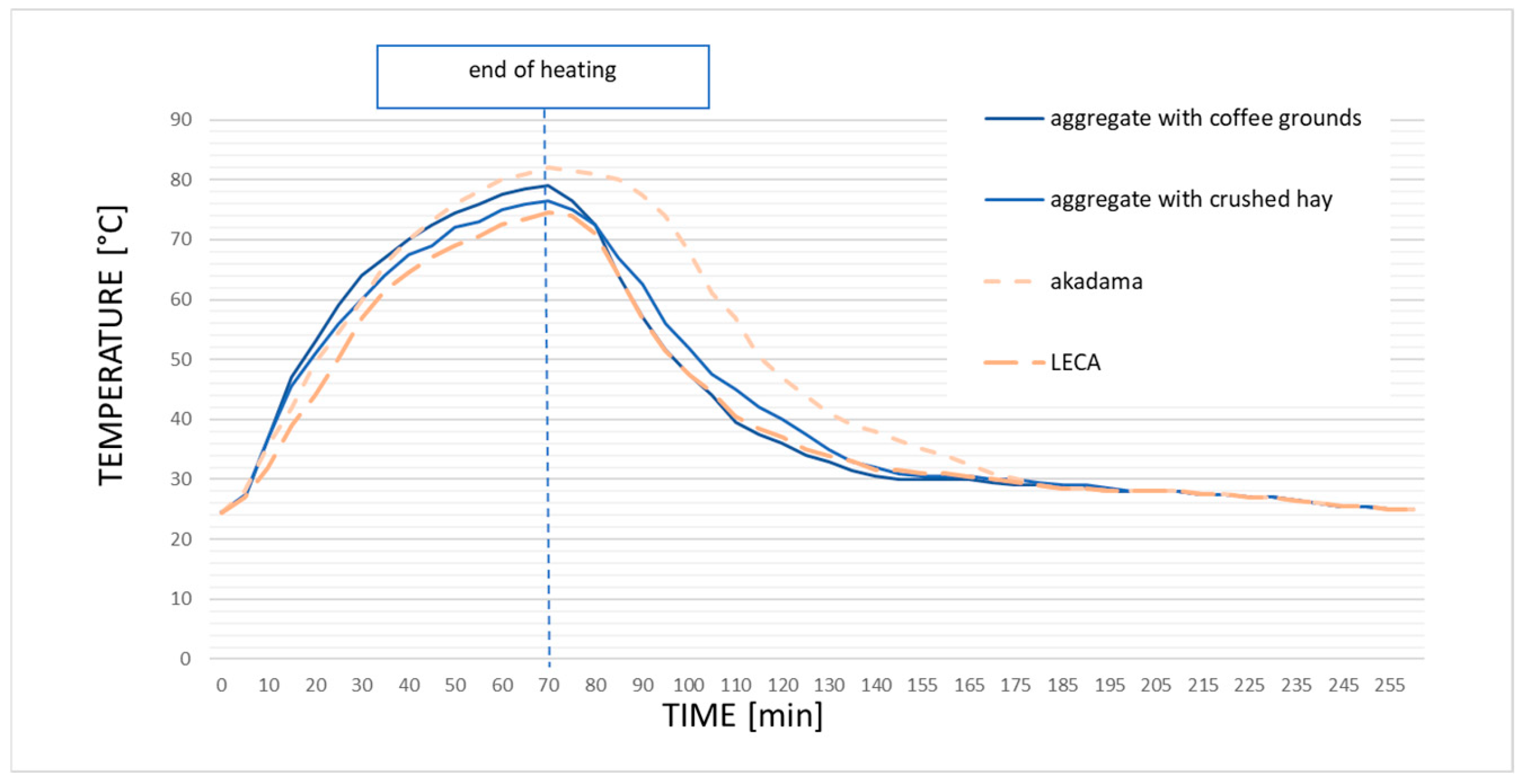

3.2.5. Thermal Properties

3.2.6. Vegetation Test

- (1)

- Supporting the roots and maintaining the plant in space;

- (2)

- Maintaining humidity and the required nutrient contents.

4. Conclusions

- A properly conducted burning process obtained an open porous microstructure with a crater system (aggregate with coffee) or a crevice system (aggregate with crushed hay);

- The aggregate is chemically neutral, does not react with the mineral components of the water medium, and releases useful components (filtrate conductivity greater than 1000 µS);

- The structure of the material ensures permeability and retention for air and water, which was visualized microscopically and analytically tested (water absorption above 40% and retention above 35%);

- The aggregate is not subject to water, cannot change shape, and does not fall apart or crack;

- The mass of the substrate will not affect the statics of the wall or roof structure; the obtained material meets the standards for lightweight aggregate (apparent density of approximately 1.5 g/cm3 and bulk density of approximately 0.7 g/cm3)

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jim, C.Y. Archaeological and historical exploration of the origins of green roofs. Urban For. Urban Green. 2017, 27, 32–42. [Google Scholar] [CrossRef]

- Gutierrez, A.; Bohn, V.J.; Marinangeli, P. Nature-based solutions for sustainable cities: A review of the state of the art of green roof research. J. Sustain. Constr. Mater. Technol. 2025, 10, 93–107. [Google Scholar] [CrossRef]

- Fernandez-Cañero, R.; Emilsson, T.; Fernandez-Barba, C.; Machuca, M.Á.H. Green roof systems: A study of public attitudes and preferences in southern Spain. J. Environ. Manag. 2013, 128, 106–115. [Google Scholar] [CrossRef]

- Magliocco, A.; Perini, K. The perception of green integrated into architecture: Installation of a green facade in Genoa, Italy. AIMS Environ. Sci. 2015, 2, 899–909. [Google Scholar] [CrossRef]

- Molari, M.; Dominici, L.; Manso, M.; Matos Silva, C.; Comino, E. A socio-ecological approach to investigate the perception of green walls in cities: A comparative analysis of case studies in Turin and Lisbon. Nat.-Based Solut. 2024, 6, 100175. [Google Scholar] [CrossRef]

- Nagase, A.; Koyama, S. Attractiveness and preference of extensive green roofs depend on vegetation types and past experience with plants in Japan. Urban Green. 2020, 51, 126658. [Google Scholar] [CrossRef]

- Nagase, A.; Tashiro-Ishii, Y. Habitat template approach for green roofs using a native rocky sea coast plant community in Japan. J. Environ. Manag. 2018, 206, 255–265. [Google Scholar] [CrossRef]

- Nagase, A.; Yamada, Y.; Aoki, T.; Nomura, M. Developing biodiverse green roofs for Japan: Arthropod and colonizer plant diversity on Harappa and Biotope roofs. Urban Nat. 2018, 1, 16–38. [Google Scholar]

- Wong, N.H.; Cheong, D.W.; Yan, H.; Soh, J.; Ong, C.L.; Sia, A. The effects of rooftop garden on energy consumption of a commercial building in Singapore. Energy Build. 2003, 35, 353–364. [Google Scholar] [CrossRef]

- Wong, N.H.; Tan, A.Y.K.; Tan, P.Y.; Sia, A.; Wong, N.C. Perception studies of vertical greenery systems in Singapore. J. Urban Plan. Dev. 2010, 136, 330–338. [Google Scholar] [CrossRef]

- Bureau of Environment. 2021 Rooftop Gardening. Available online: https://www.kankyo.metro.tokyo.lg.jp/nature/green/roof_plant/actual.html (accessed on 31 May 2024).

- Jim, C.Y.; Hui, L.C.; Rupprecht, C.D.D. Public Perceptions of Green Roofs and Green Walls in Tokyo, Japan: A Call to Heighten Awareness. Environ. Manag. 2022, 70, 35–53. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, Z.; Zhao, B.; Sun, R.; Vejre, H. Links between green space and public health: A bibliometric review of global research trends and future prospects from 1901 to 2019. Environ. Res. Lett. 2020, 15, 063001. [Google Scholar] [CrossRef]

- Fei, Y.; Fu, D.; Xu, C.; Singh, R.P. Component design optimization of green roof substrate layer based on the assessment of multifunctional performance. Environ. Res. 2023, 238, 117190. [Google Scholar] [CrossRef] [PubMed]

- Luchkina, V. Application of Green Roofing Technologies as Site Landscaping. IOP Conf. Ser. Mater. Sci. Eng. 2020, 869, 022008. [Google Scholar] [CrossRef]

- Di Miceli, G.; Iacuzzi, N.; Licata, M.; La Bella, S.; Tuttolomondo, T.; Aprile, S. Growth and development of succulent mixtures for extensive green roofs in a Mediterranean climate. PLoS ONE 2022, 17, e0269446. [Google Scholar] [CrossRef] [PubMed]

- Getter, K.L.; Rowe, D.B. The Role of Extensive Green Roofs in Sustainable Development. Hortscience 2006, 41, 1276–1285. [Google Scholar] [CrossRef]

- Pęczkowski, G.; Orzepowski, W.; Pokładek, R.; Kowalczyk, T.; Żmuda, R.; Wójcik, R. Retention properties of the type of extensive green roofs as an example of model tests. Acta Sci. Polonorum. Form. Circumiectus 2016, 15, 113. [Google Scholar] [CrossRef]

- Rosasco, P.; Perini, K. Selection of (Green) Roof Systems: A Sustainability-Based Multi-Criteria Analysis. Buildings 2019, 9, 134. [Google Scholar] [CrossRef]

- Kazemi, M.; Courard, L.; Hubert, J. Coarse recycled materials for the drainage and substrate layers of green roof system in dry condition: Parametric study and thermal heat transfer. J. Build. Eng. 2022, 45, 103487. [Google Scholar] [CrossRef]

- Zhang, Z.; Szota, C.; Fletcher, T.D.; Williams, N.S.; Farrell, C. Green roof storage capacity can be more important than evapotranspiration for retention performance. J. Environ. Manag. 2019, 232, 404–412. [Google Scholar] [CrossRef] [PubMed]

- Santamouris, M. Cooling the cities—A review of reflective and green roof mitigation technologies to fight heat island and improve comfort in urban environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Takakura, T.; Kitade, S.; Goto, E. Cooling effect of greenery cover over a building. Energy Build. 2000, 31, 1–6. [Google Scholar] [CrossRef]

- Köhler, M.; Schmidt, M.; Grimme, F.W.; Laar, M.; Gusmão, F. Urban water retention by greened roofs in temperate and tropical climate. Technol. Resour. Manag. Dev. 2001, 2, 151–162. [Google Scholar]

- Lata, J.-C.; Dusza, Y.; Abbadie, L.; Barot, S.; Carmignac, D.; Gendreau, E.; Kraepiel, Y.; Mériguet, J.; Motard, E.; Raynaud, X. Role of substrate properties in the provision of multifunctional green roof ecosystem services. Appl. Soil Ecol. 2018, 123, 464–468. [Google Scholar] [CrossRef]

- Berardi, U.; GhaffarianHoseini, A.H.; GhaffarianHoseini, A. State-of-the-art analysis of the environmental benefits of green roofs. Appl. Energy 2014, 115, 411–428. [Google Scholar] [CrossRef]

- Sutton, K.R. Green Roof Ecosystems; Ecological Studies; Springer International Publishing: Cham, Switzerland, 2015; Volume 223. [Google Scholar]

- Molineux, C.J.; Gange, A.C.; Connop, S.P.; Newport, D.J. Using recycled aggregates in green roof substrates for plant diversity. Ecol. Eng. 2015, 82, 596–604. [Google Scholar] [CrossRef]

- Rahman, M.S.; MacPherson, S.; Lefsrud, M. Prospects of porous concrete as a plant-growing medium and structural component for green roofs: A review. Renew. Agric. Food Syst. 2020, 37, 536–549. [Google Scholar] [CrossRef]

- Eksi, M.; Sevgi, O.; Akburak, S.; Yurtseven, H.; Esin, İ. Assessment of recycled or locally available materials as green roof substrates. Ecol. Eng. 2020, 156, 105966. [Google Scholar] [CrossRef]

- Mickovski, S.B.; Buss, K.; McKenzie, B.M.; Sökmener, B. Laboratory study on the potential use of recycled inert construction waste material in the substrate mix for extensive green roofs. Ecol. Eng. 2013, 61, 706–714. [Google Scholar] [CrossRef]

- Stempkowska, A.; Gawenda, T. Improved Artificial Aggregates for Use in Green Roof Design. Sustainability 2024, 16, 5512. [Google Scholar] [CrossRef]

- Stempkowska, A.; Gawenda, T. Artificial lightweight aggregate made from alternative and waste raw materials, hardened using the hybrid method. Sci. Rep. 2024, 14, 16880. [Google Scholar] [CrossRef]

- Stempkowska, A.; Gawenda, T.; Staszewska, M. Lightweight alternative aggregate: Characteristics, parameters, application possibilities. In Kruszywa Mineralne; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2024; Volume 7, pp. 187–188. [Google Scholar]

- Bates, A.J.; Sadler, J.; Greswell, R.B.; Mackay, R. Effects of recycled aggregate growth substrate on green roof vegetation development: A six year experiment. Landsc. Urban Plan. 2015, 135, 22–31. [Google Scholar] [CrossRef]

- Shahmohammad, M.; Hosseinzadeh, M.; Dvorak, B. Sustainable green roofs: A comprehensive review of influential factors. Environ. Sci. Pollut. Res. 2022, 29, 78228–78254. [Google Scholar] [CrossRef] [PubMed]

- Vannucchi, F.; Buoncristiano, A.; Scatena, M.; Caudai, C.; Bretzel, F. Low productivity substrateleads to functional diversification of green roof plant assemblage. Ecol. Eng. 2022, 176, 106547. [Google Scholar] [CrossRef]

- Coulibaly, S.F.M.; Aubry, C.; Provent, F.; Rousset-Rouvière, S.; Joimel, S. The role of green roofs as urban habitats for biodiversity modulated by their design: A review. Environ. Res. Lett. 2023, 18, 073003. [Google Scholar] [CrossRef]

- Farrell, C.; Cao, C.T.N.; Ang, X.Q.; Rayner, J.P. Use of water-retention additives to improve performance of green roof substrates. Acta Hortic. 2016, 1108, 271–278. [Google Scholar] [CrossRef]

- Graceson, A.; Hare, M.; Monaghan, J.; Hall, N. The water retention capabilities of growing media for green roofs. Ecol. Eng. 2013, 61, 328–334. [Google Scholar] [CrossRef]

- Mentens, J.; Raes, D.; Hermy, M. Greenroofs as a part of urban water management. Prog. Water Resour. 2003, 8, 35–43. [Google Scholar]

- Latshaw, K.; Fitzgerald, J.; Sutton, R. Analysis of Green Roof Growing Media Porosity. RURALS Rev. Undergrad. Res. Agric. Life Sci. 2009, 4, 2. [Google Scholar]

- Yudina, A.V.; Klyueva, V.V.; Romanenko, K.A.; Fomin, D.S. Micro- within macro: How micro-aggregation shapes the soil pore space and water-stability. Geoderma 2022, 415, 115771. [Google Scholar] [CrossRef]

- Hill, J.; Sleep, B.; Drake, J.; Fryer, M. The effect of intraparticle porosity and interparticle voids on the hydraulic properties of soilless media. Vadose Zone J. 2019, 18, 180176. [Google Scholar] [CrossRef]

- Kazemi, M.; Courard, L.; Attia, S. Water permeability, water retention capacity, and thermal resistance of green roof layers made with recycled and artificial aggregates. Build. Environ. 2023, 227, 109776. [Google Scholar] [CrossRef]

- Pettersson, K.; Maggiolo, D.; Sasic, S.; Johansson, P.; Sasic-Kalagasidis, A. On the impact of porous media microstructure on rainfall infiltration of thin homogeneous green roof growth substrates. J. Hydrol. 2020, 582, 124286. [Google Scholar] [CrossRef]

- Karczmarczyk, A.; Baryła, A.; Kożuchowski, P. Design and Development of Low P-Emission Substrate for the Protection of Urban Water Bodies Collecting Green Roof Runoff. Sustainability 2017, 9, 1795. [Google Scholar] [CrossRef]

- Aggregates Europe. Available online: https://www.aggregates-europe.eu/facts-figures/figures/ (accessed on 7 July 2025).

- Andreola, F.; Borghi, A.; Pedrazzi, S.; Allesina, G.; Tartarini, P.; Lancellotti, I.; Barbieri, L. Spent Coffee Grounds in the Production of Lightweight Clay Ceramic Aggregates in View of Urban and Agricultural Sustainable Development. Materials 2019, 12, 3581. [Google Scholar] [CrossRef] [PubMed]

- Farías, R.D.; Martínez García, C.; Cotes Palomino, T.; Martínez Arellano, M. Effects of Wastes from the Brewing Industry in Lightweight Aggregates Manufactured with Clay for Green Roofs. Materials 2017, 10, 527. [Google Scholar] [CrossRef]

- García, C.M.; Palomino, T.C.; Godino, F.J.I.; Iglesias, F.A.C. Porosity of expanded clay manufactured with addition of sludge from the brewing industry. Int. J. Energy Environ. Eng. 2014, 5, 341–347. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Hamann, B. Review In Situ high-temperature optical microscopy. J. Mater. Sci. 1999, 34, 5419–5436. [Google Scholar] [CrossRef]

- Kang, S.J.L. Sintering, Densification, Grain Growth & Microstructure; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Lucas, M.; Schlüter, S.; Vogel, H.J.; Vetterlein, D. Roots compact the surrounding soil depending on the structures they encounter. Sci. Rep. 2019, 9, 16236. [Google Scholar] [CrossRef]

- Domagała, L. Structural Lightweight Aggregate Concrete/Konstrukcyjne Lekkie Betony Kruszywowe; CUT Publishing House: Cracow, Poland, 2014. (In Polish) [Google Scholar]

- Roces, E.; Muñiz-Menéndez, M.; González-Galindo, J.; Estaire, J. Lightweight expanded clay aggregate properties based on laboratory testing. Constr. Build. Mater. 2021, 313, 125486. [Google Scholar] [CrossRef]

- Rashad Alaa, M. Lightweight expanded clay aggregate as a building material—An overview. Constr. Build. Mater. 2018, 170, 757–775. [Google Scholar] [CrossRef]

- EN 13055:2016; Lightweight Aggregates. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- Al-Busaltan, S.; Amoori Kadhim, M.; Nile, B.K.; Alshama, G.A. Evaluating Porous Pavement for the Mitigation of Stormwater Impacts. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 012052. [Google Scholar] [CrossRef]

- Yang, M.; Dong, W.; Cheng, R.; Wang, H.; Zhao, Z.; Wang, F.; Wang, Y. Effect of highly efficient substrate modifier, super-absorbent polymer, on the performance of the green roof. Sci. Total Environ. 2022, 806, 150638. [Google Scholar] [CrossRef] [PubMed]

- Wong, G.K.L.; Jim, C.Y. Quantitative hydrologic performance of extensive green roof under humid-tropical rainfall regime. Ecol. Eng. 2014, 70, 366–378. [Google Scholar] [CrossRef]

- Ouldboukhitine, S.-E.; Belarbi, R.; Djedjig, R. Characterization of green roof components: Measurements of thermal and hydrological properties. Build. Environ. 2012, 56, 78–85. [Google Scholar] [CrossRef]

- Ouldboukhitine, S.-E.; Belarbi, R. Experimental characterization of green roof components. Energy Proc. 2015, 78, 1183–1188. [Google Scholar] [CrossRef]

- Kim, H.-H.; Kim, C.-S.; Jeon, J.-H.; Lee, S.-K.; Park, C.-G. Performance Evaluation and Field Application of Red Clay Green Roof Vegetation Blocks for Ecological Restoration Projects. Sustainability 2017, 9, 357. [Google Scholar] [CrossRef]

- Schwager, J.; Schaal, L.; Simonnot, M.; Claverie, R.; Ruban, V.; Morel, J.L. Emission of trace elements and retention of Cu and Zn by mineral and organic materials used in green roofs. J. Soils Sediments Prot. Risk Assess. Remediat. 2015, 15, 1789–1801. [Google Scholar] [CrossRef]

- Pęczkowski, G.; Szawernoga, K.; Kowalczyk, T.; Orzepowski, W.; Pokładek, R. Runoff and Water Quality in the Aspect of Environmental Impact Assessment of Experimental Area of Green Roofs in Lower Silesia. Sustainability 2020, 12, 4793. [Google Scholar] [CrossRef]

- Han, X.; Wang, L.; Ling, H.; Ge, Z.; Lin, X.; Dai, X.; Chen, H. Critical review of thermochemical energy storage systems based on cobalt, manganese, and copper oxides. Renew. Sustain. Energy Rev. 2022, 158, 112076. [Google Scholar] [CrossRef]

- Yoshinaga, N.; Aomine, S. Allophane in Some Ando Soils. Soil Sci. Plant Nutr. 1962, 8, 6–13. [Google Scholar] [CrossRef]

- Yoshinaga, N.; Aomine, S. Imogolite in some ando soils. Soil Sci. Plant Nutr. 1962, 8, 22–29. [Google Scholar] [CrossRef]

- Parfitt, R.L. Allophane and imogolite: Role in soil biogeochemical processes. Clay Miner. 2009, 44, 134–155. [Google Scholar] [CrossRef]

| Element [wt.%] | SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | MnO |

| 63.67 | 24.06 | 3.87 | 0.43 | 1.55 | 1.1 | 0.02 | |

| K2O | Na2O | SO3 | P2O5 | Water | LOI | Others | |

| 0.4 | 0.08 | 0.1 | 0.05 | 8.92 | 4.46 | 0.5 |

| Element [wt.%] | SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | MnO |

| 54.74 | 13.92 | 11.88 | 1.12 | 2.78 | 4.42 | 0.22 | |

| K2O | Na2O | SO3 | P2O5 | Water | LOI | Others | |

| 6.32 | 3.53 | 0.06 | 0.91 | 16.59 | 3.78 | 0.1 |

| Aggregate Set | Mass | Mass Share | Bulk Density | Volume Share |

|---|---|---|---|---|

| [g] | [wt.%] | [g/cm3] | [%vol] | |

| Bełchatów clay | 2000 | 57.1 | 1.64 | 39.7 |

| Ground coffee | 650 | 18.6 | 0.65 | 32.6 |

| Water | 850 | 24.3 | 1.00 | 27.7 |

| Dubna Skala clay | 2000 | 64.5 | 1.69 | 38.6 |

| Crushed hay | 150 | 4.8 | 0.16 | 30.3 |

| Water | 950 | 30.7 | 1.00 | 31.1 |

| Sample | Apparent Density [g/cm3] | Bulk Density [g/cm3] |

|---|---|---|

| Aggregate with coffee grounds | 1.47 ± 0.11 | 0.72 ± 0.09 |

| Aggregate with crushed hay | 1.53 ± 0.09 | 0.71 ± 0.11 |

| Akadama (Japan) | 1.93 ± 0.13 | 0.78 ± 0.13 |

| LECA (Poland) | 1.22 ± 0.11 | 0.43 ± 0.08 |

| Sample | Average Weight of the Granule [g] | Average Pressure Force [N] | Max Pressure Force [N] |

|---|---|---|---|

| Aggregate with coffee grounds | 0.122 ± 0.023 | 155.83 ± 25.02 | 203 |

| Aggregate with crushed hay | 0.138 ± 0.010 | 114.60 ± 40.29 | 157 |

| Akadama (Japan) | 0.112 ± 0.034 | 19.94 ± 6.43 | 31 |

| LECA (Poland) | 0.084 ± 0.013 | 154.83 ± 38.09 | 203 |

| Sample | Grain Weight, Size Larger Than 2 mm [g] | Weight Loss [%] | |

|---|---|---|---|

| Before Measurement | After Measurement | ||

| Aggregate with coffee grounds | 1.2899 ± 0.1414 | 1.1932 ± 0.0968 | 1.06 ± 0.56 |

| Aggregate with crushed hay | 1.3531 ± 0.2077 | 1.2463 ± 0.0968 | 0.99 ± 0.35 |

| Akadama | 1.1386 ± 0.1923 | 1.0491 ± 0.1325 | 0.91 ± 0.18 |

| LECA | 0.9584 ± 0.1274 | 0.9489 ± 0.1246 | 0.97 ± 0.28 |

| Sample | Decomposition in Water at 25 °C | ||

|---|---|---|---|

| Time [min] | Result | Description | |

| Aggregate with coffee grounds | 10 | Negative | No disintegration under finger pressure |

| Aggregate with crushed hay | Negative | No disintegration under finger pressure | |

| Akadama (Japan) | Positive | The resulting sediment is at the bottom of the tank; under finger pressure, the grains disintegrate | |

| LECA (Poland) | Negative | No disintegration under finger pressure | |

| Sample | Total Water Absorbability [%] | Retention Capacity [%] | pH of the Filtrate | Filtrate Conductivity [µS] |

|---|---|---|---|---|

| Aggregate with coffee grounds | 42.9 ± 3.1 | 36.7 ± 4.5 | 8.20 | 1325 |

| Aggregate with crushed hay | 46.3 ± 1.5 | 38.1 ± 3.9 | 7.80 | 1260 |

| Akadama (Japan) | ~30 Difficult measurement, suspension | 28.2 ± 7.2 | 7.12 | Measurement not possible, suspension |

| LECA (Poland) | 21.5 ± 0.9 | 19.0 ± 0.5 | 7.06 | 109 |

| Sample | Aggregate Mass [g] | Biomass I Test [g] | Biomass II Test | ||

|---|---|---|---|---|---|

| Leaves [g] | Roots [g] | Total [g] | |||

| Aggregate with coffee grounds | 85 | 0.4810 | 0.1604 | 0.8459 | 1.0063 |

| Aggregate with crushed hay | 85 | 0.5299 | 0.1494 | 0.7611 | 0.9105 |

| Akadama (Japan) | 90 | 0.5354 | 0.1672 | 0.7969 | 0.9641 |

| LECA (Poland) | 40 | 0.4157 | 0.1371 | 0.6459 | 0.7830 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stempkowska, A. Lightweight Aggregates with Special Microstructure for Use in Rooftop Garden Design. Sustainability 2025, 17, 9489. https://doi.org/10.3390/su17219489

Stempkowska A. Lightweight Aggregates with Special Microstructure for Use in Rooftop Garden Design. Sustainability. 2025; 17(21):9489. https://doi.org/10.3390/su17219489

Chicago/Turabian StyleStempkowska, Agata. 2025. "Lightweight Aggregates with Special Microstructure for Use in Rooftop Garden Design" Sustainability 17, no. 21: 9489. https://doi.org/10.3390/su17219489

APA StyleStempkowska, A. (2025). Lightweight Aggregates with Special Microstructure for Use in Rooftop Garden Design. Sustainability, 17(21), 9489. https://doi.org/10.3390/su17219489