Abstract

Modular steel buildings represent a structural system distinguished by rapid construction and environmental sustainability. The modular units and steel components of modular steel structures can be recycled, making this approach an important technology for sustainable development. Glass curtain walls, commonly used as facade systems in modern architecture, have recently appeared in several modular steel buildings. In this study, a seven-story model steel building is designed with a geometric scale factor of 1/9 to investigate its global and local safety in terms of seismic responses. Two glass curtain walls are installed on the seventh story of the model structure. A series of shaking table tests is conducted under varying seismic intensity levels (PGA = 0.035 g, 0.1 g, 0.22 g, 0.31 g). The results show the acceleration responses at the top story are predominantly governed by the fundamental translational modes (first mode and second mode). A slight stiffness degradation of a ratio less than 8.0% appears after the tests. The modular steel structure exhibits a significant acceleration amplification effect under almost all examined load cases. The measured peak structural accelerations (PSAs) notably exceed the limitations specified in current codes. The finite element simulation has validated such amplification. In addition, compared to these global responses, the glass curtain walls exhibit even higher PSAs, making them more vulnerable than the main steel frame. Therefore, the unfavorable seismic performance of modular steel buildings is manifested, and more attention needs to be paid to their design principles.

1. Introduction

At present, the sustainability level of global civil engineering works remains relatively low. The majority of building materials and structural components are difficult to recycle. Instead, construction is one of the leading sources of world carbon emissions.

Modular construction represents a high level of industrialization in the category of prefabricated building technologies. As its distinctive feature, a modular building is divided into container-like modular units, which are then assembled on-site in a “building block” manner. This approach offers several advantages [1], including low carbon emissions, detachable modular units, and the reusability of these units. These advantages play an important role in promoting environmental sustainability for human society.

However, unlike conventional steel structures, modular steel structures are characterized by discrete modular units with multiple beams and columns. Therefore, the force transfer paths between modular units are discontinuous, leading to weaker lateral resistance. Therefore, their seismic performance needs careful evaluation.

The concept of modular construction was proposed in the last century, and numerous modular steel structures have since then been constructed. However, existing research has predominantly focused on the component level, such as joint behaviors under loads [2,3,4,5], performance of multi-beam systems [6,7], and wall-type components [8,9,10,11]. Even in experimental research works, most seismic tests were aimed at low-rise buildings. Annan et al. [12,13,14] investigated the seismic resistance of modular steel frames and found that their internal force redistribution capacity was limited. Inelastic deformations were often concentrated in localized regions. Hong et al. [15] introduced a double-layer thin steel plate wall system into modular structures, revealing that the steel plate walls significantly enhanced the initial lateral stiffness. Fathieh and Mercan [16,17] conducted nonlinear pushover and incremental dynamic analyses on a four-story modular steel structure. Their study revealed that the structure can resist a relatively high base shear force. Landolfo et al. [18] performed full-scale shaking table tests on a two-story modular steel structure. They found that the addition of interior finishes altered the natural period and lateral stiffness of the structure. Jing et al. [19,20] conducted shaking table tests on a three-story modular structure and developed a novel sliding device. Their results demonstrated effective cooperative behavior between the sliding device and the structure. Liu et al. [21] performed full-scale lateral cyclic loading tests on a two-story modular structure. The failure was ductile, with damage primarily concentrated at beam ends and bottom column bases. Sanches et al. [22] conducted numerical simulations to investigate the seismic design and response of multi-story modular structures. The results indicated that modular buildings with different numbers of stories exhibit distinct failure modes. Zhai et al. [23,24] conducted shaking table tests on modular hybrid structures. The results showed that hybrid frame structures exhibited noticeably better seismic performance than pure steel frames. Recognizing the intrinsic lateral resistance of individual modular units, Wang and Chan [25] proposed a distributed seismic design concept. Zhang et al. [26] found that a pure modular steel building was excited into higher-order vibration modes under the long-duration Tohoku earthquake. Recent studies have further advanced the understanding of seismic resilience in modular steel systems. Ye et al. [27] demonstrated that introducing small friction pendulum bearings can effectively enhance the resilience. Mata et al. [28] showed that slender CFT columns with bidirectional moment connections achieve stable ductile behavior under strong earthquakes. Mo et al. [29] proposed an innovative three-dimensional isolation system, significantly improving the seismic resilience of modular steel buildings.

In previous studies, we noticed that experimental investigations on the seismic performance of multi-story modular buildings and their attached glass curtain walls are still lacking. Meanwhile, existing research has indicated that prefabricated steel frames exhibit a significant acceleration amplification effect under seismic excitation [26,30,31,32]. Glass curtain walls are prone to damage when subjected to excessive floor accelerations. This study conducts a series of shaking table tests on a scaled seven-story modular steel building equipped with two glass curtain walls. This study not only presents the seismic response of the main steel frame but also focuses on the acceleration response and dynamic amplification effect of the glass curtain walls. In addition, comparisons with several codes are provided, making the research significant for engineering applications.

2. Experimental Design

2.1. The Prototype

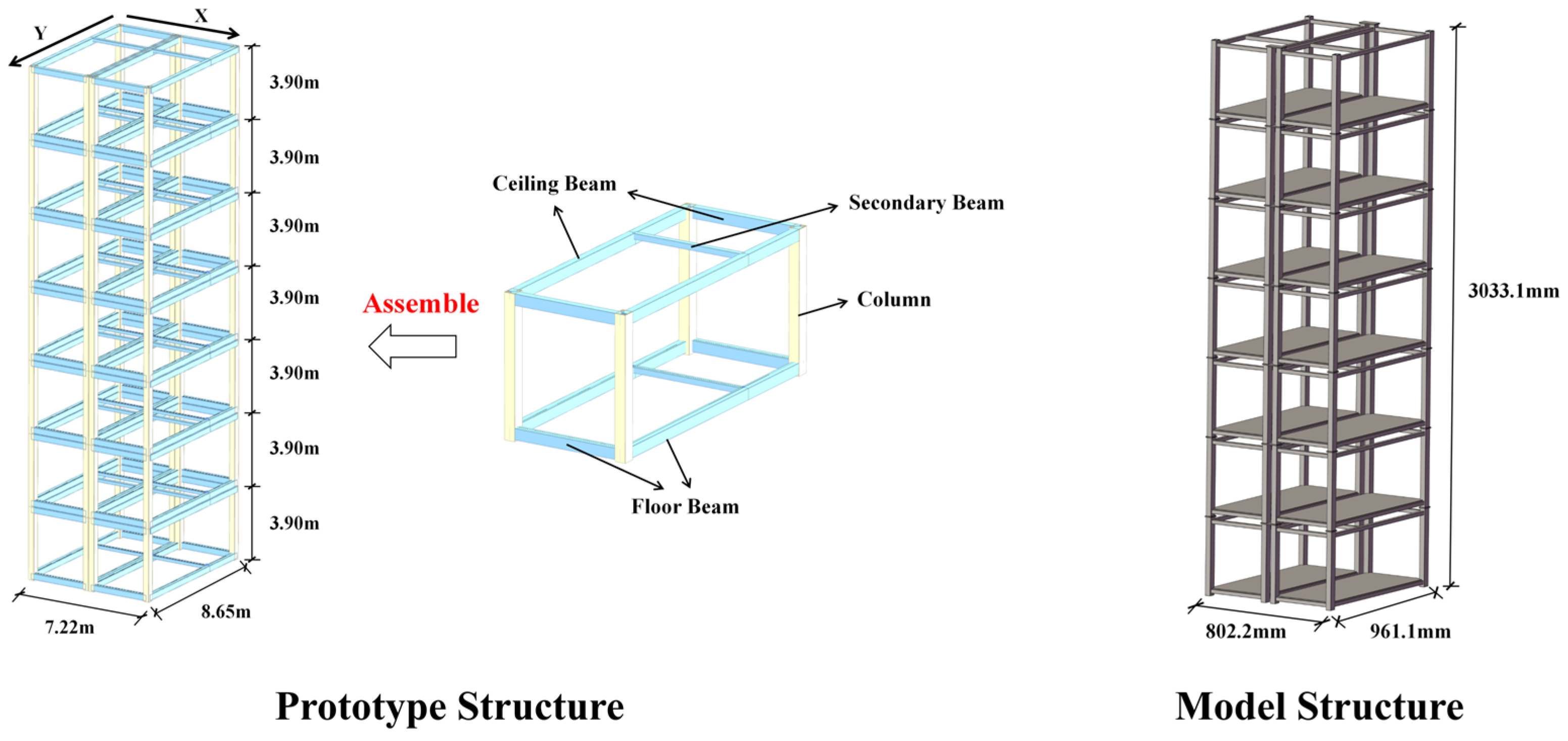

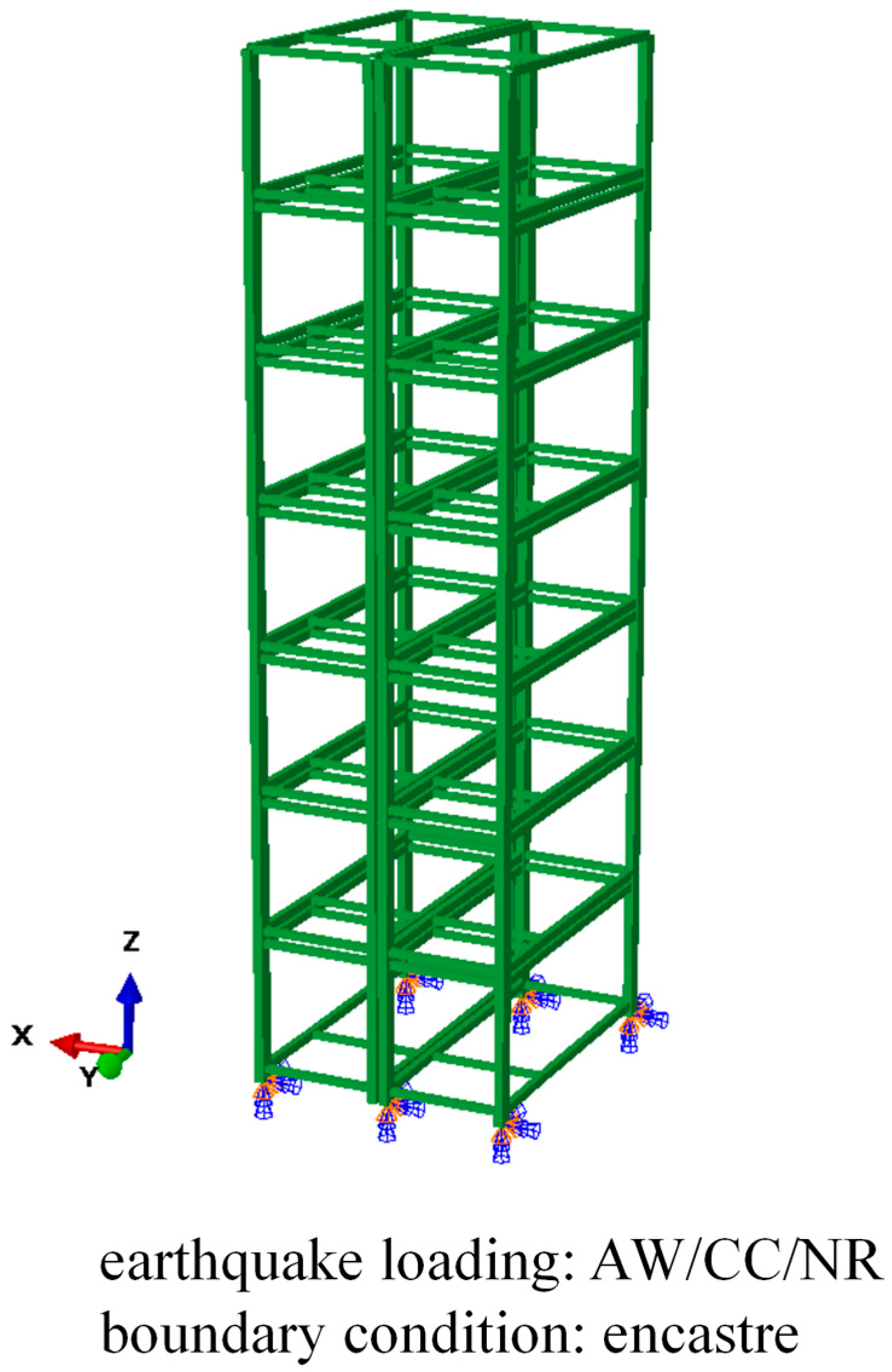

A schematic diagram of the prototype structure is shown in Figure 1. The design is derived from construction drawings of a real industrial building project in Shenzhen, China, undertaken by China Construction Science and Industry Corporation Ltd., (Shenzhen, China). The design complies with the design codes [33,34,35,36,37]. Each story is assembled from two modular units, whose heights are 3.90 m. The total height of this building is 27.30 m. In the transverse direction (X-direction), the length is 7.22 m. In the longitudinal direction (Y-direction), the length is 8.65 m. The total mass of the prototype structure is 2.212 × 105 kg. The beams and columns within each modular unit are box-shaped cross-sections made of Q355B steel. Their dimensions are listed in Table 1.

Figure 1.

Illustration of the prototype and the model.

Table 1.

Cross-sectional dimensions of prototype and model (unit: mm).

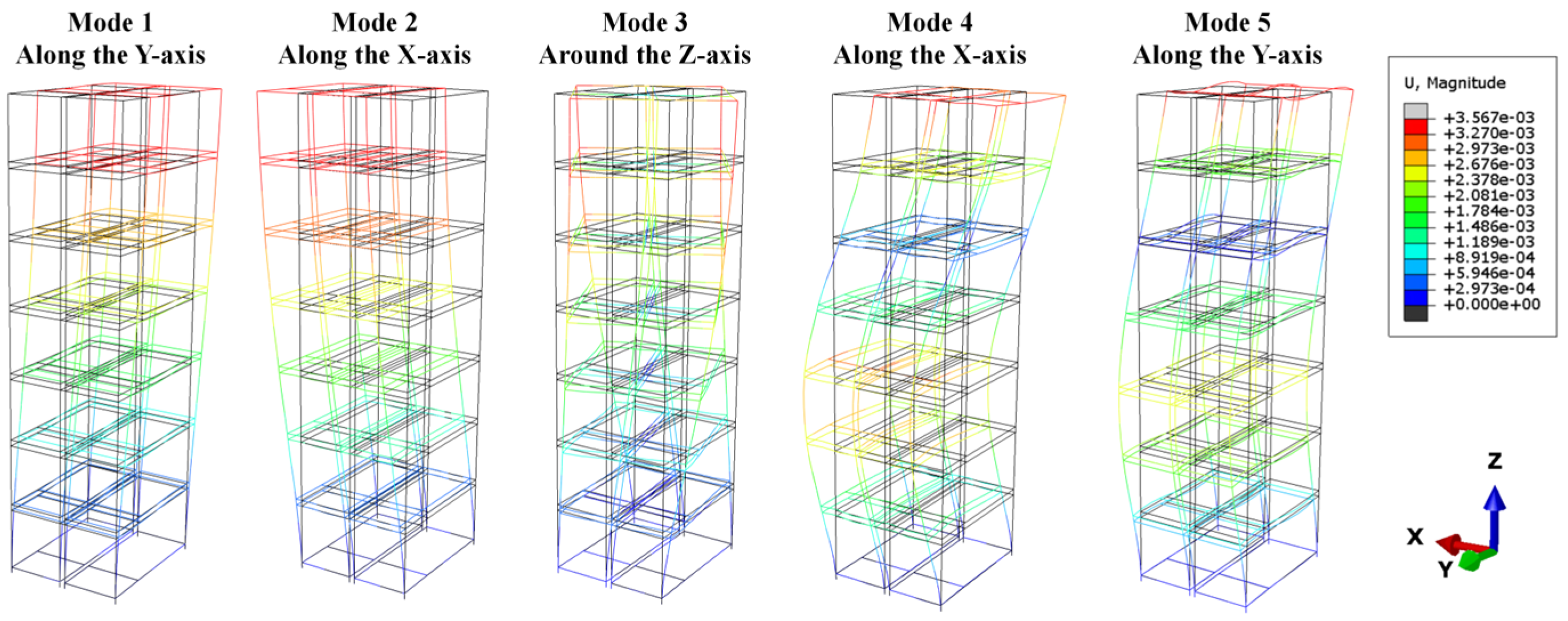

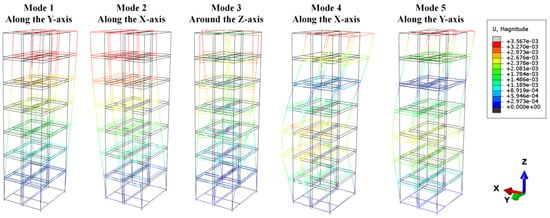

Finite element models (FEMs) of the prototype structure are developed using both YJK 7.0 and ABAQUS 2020 software. Figure 2 and Table 2 respectively illustrate the calculated mode shapes and natural frequencies. Note that the first mode is translational along the Y-direction. The second mode is translational along the X-direction. The third mode involves torsional vibration around the Z-axis, featuring relative rotation between different floor levels. The fourth mode and fifth mode are the higher-order translational modes along the X-direction and the Y-direction, characterized by the presence of inflection points within the mode shapes.

Figure 2.

Diagram of the mode shapes.

Table 2.

FEM analysis of natural frequencies of the prototype structure.

2.2. Similitude Relationship

In structural seismic tests, it is crucial to simultaneously maintain similarity in both elastic restoring forces and inertial forces [38]. Considering the need to satisfy geometric, kinematic, and dynamic similarity conditions, this study adopts the elastic–gravity similarity law.

Following the provisions of the “specification for seismic test of buildings” [39], and considering the experimental capacity, a geometric scale factor of 1/9 is selected for the scaled model. The model is constructed also using the same material, Q355B steel. The similarity factors for various physical parameters are derived [40]. The detailed similarity relationships are presented in Table 3. The parameters of the model and prototype are summarized in Table 4.

Table 3.

Similitude relationships and scale factors.

Table 4.

Parameters converted through similarity relations.

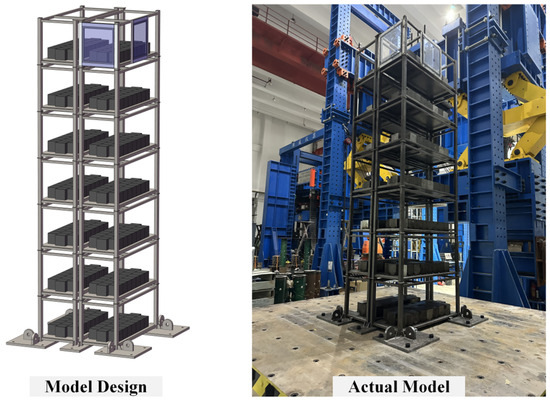

2.3. The Physical Model

2.3.1. Structural Component Design

During the component scaling process, several practical challenges commonly arise. The sections of the components of the prototype are originally thin-walled. If strictly following the geometric factor, the thickness of the scaled sections would present some issues. For instance, excessively thin walls make fabrication and welding technically difficult, and the scaled thicknesses are unable to match the standardized steel sections. Therefore, the scaled sections are designed based on the stiffness equivalence principle [41,42,43]. The dimensions of the scaled components in Table 1 satisfy such stiffness equivalence. Additionally, in the test structure, 5 mm thick Q355B steel plates are used to model the reinforced concrete floor slabs of the prototype structure [41].

2.3.2. Main Frame Design

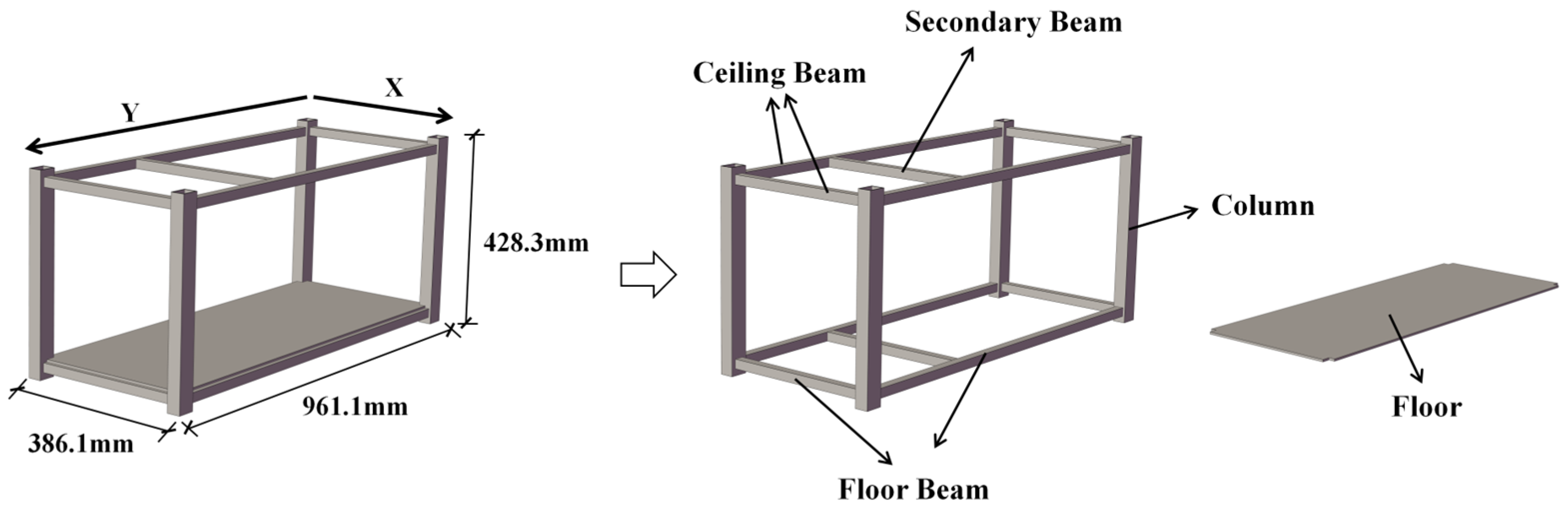

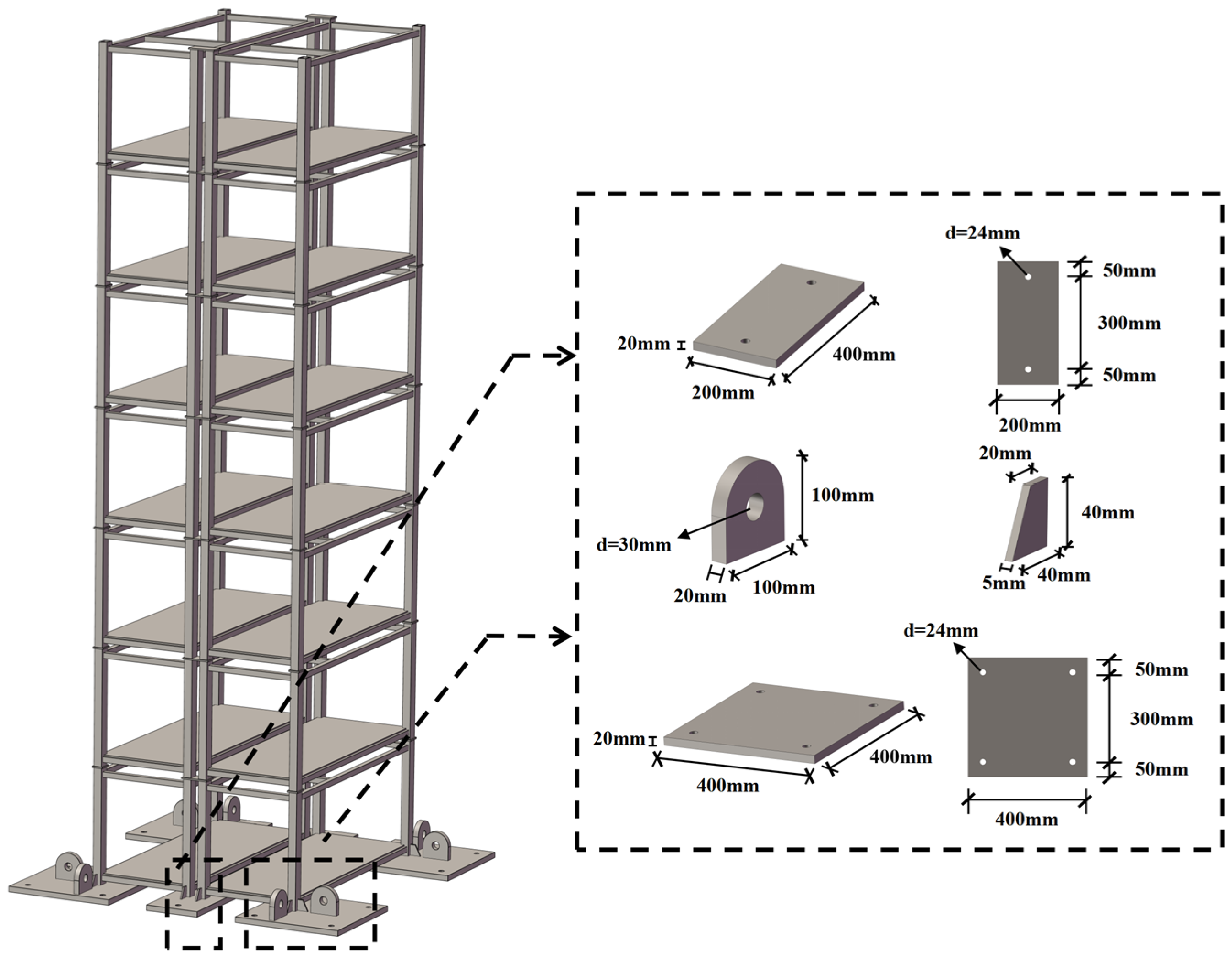

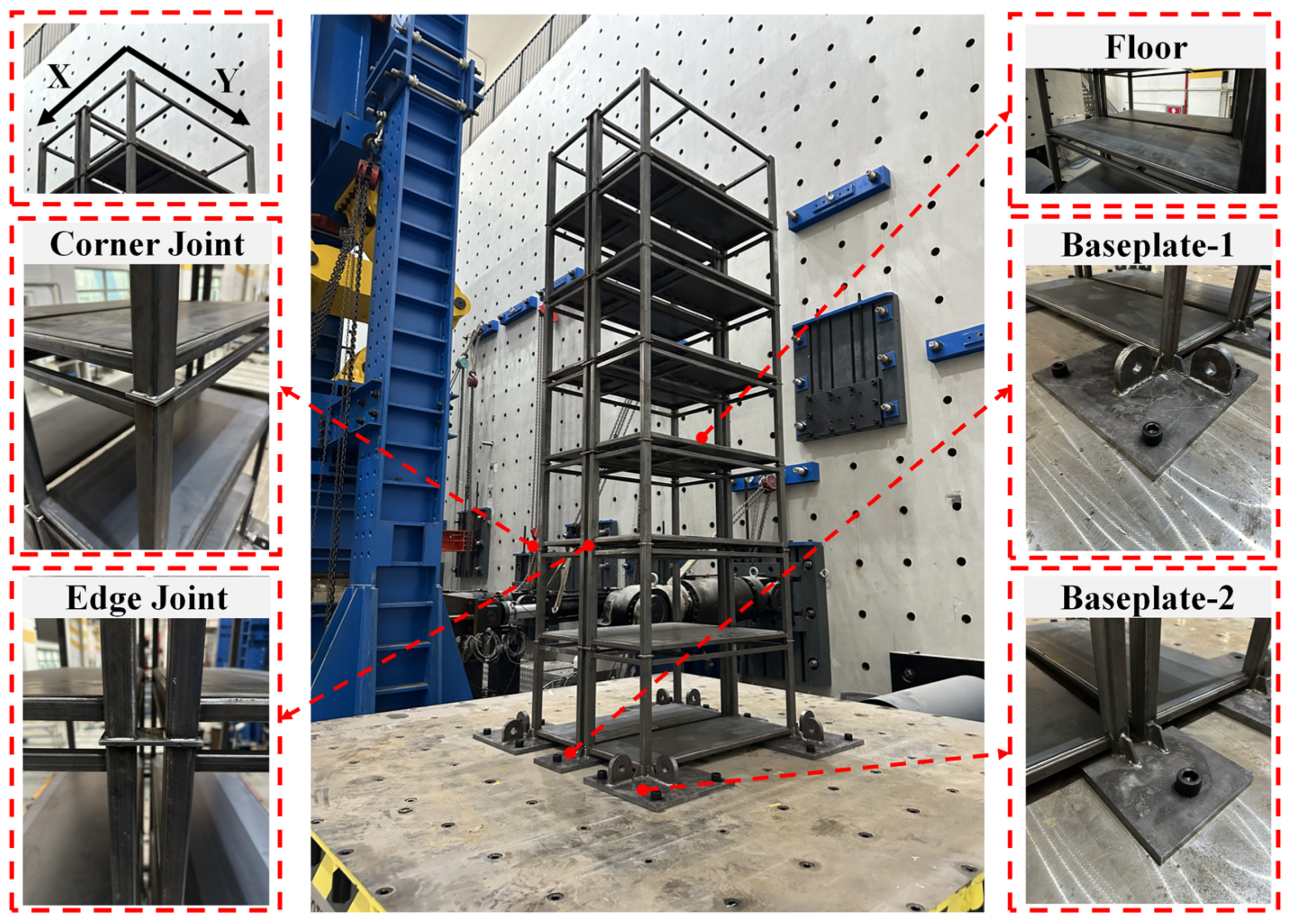

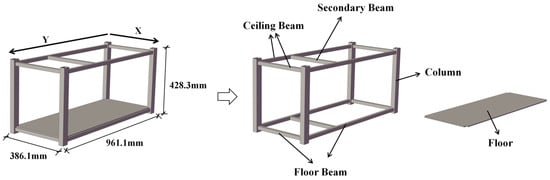

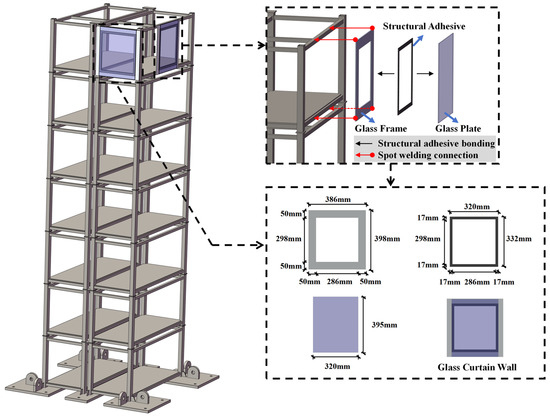

The physical model has an overall height of 3033.1 mm, with plan dimensions of 802.2 mm in the transverse (X) direction and 961.1 mm in the longitudinal (Y) direction. A schematic of the main frame is presented in Figure 1. Each modular unit is composed of multiple structural components, as shown in Figure 3.

Figure 3.

Diagram of a module unit.

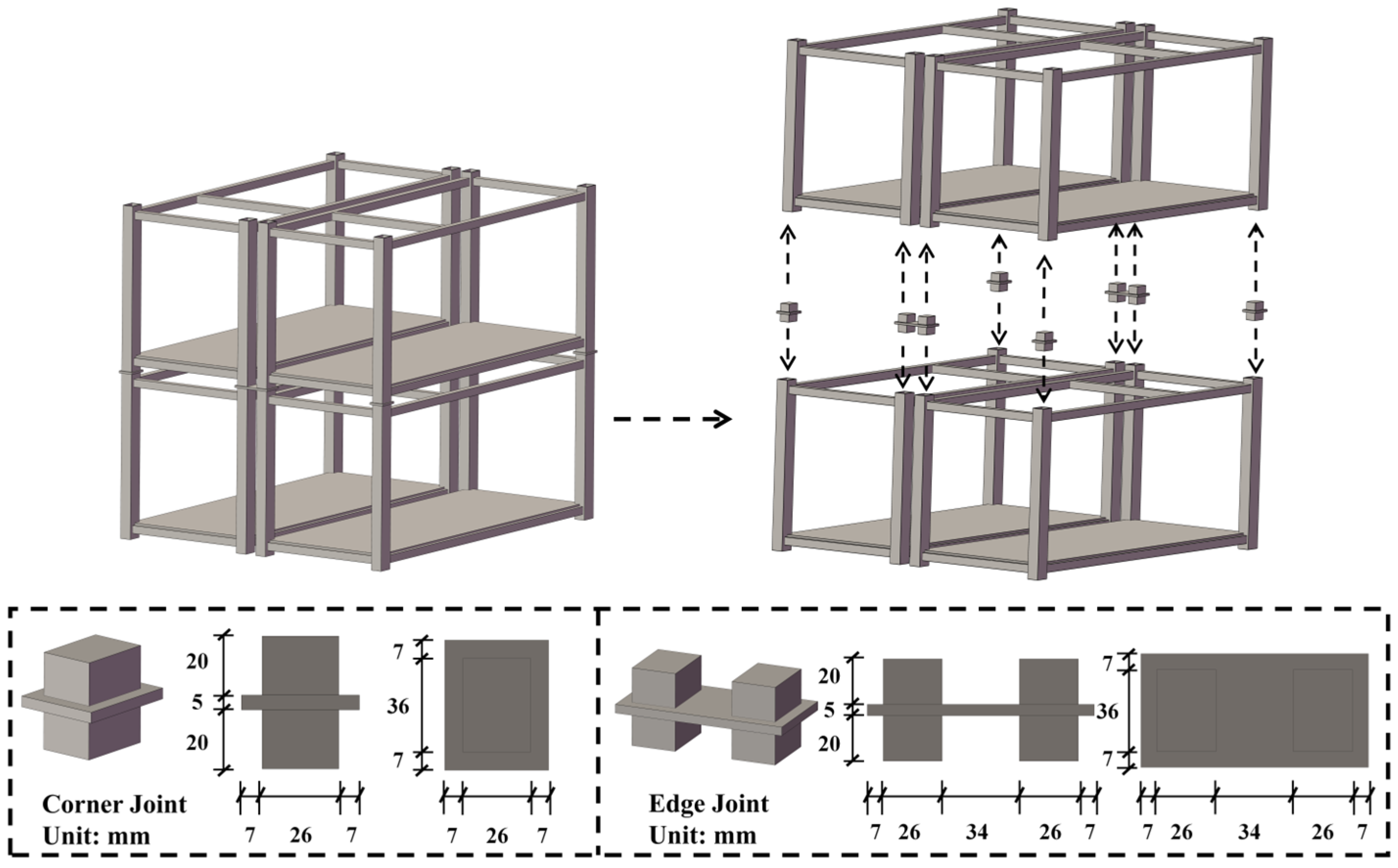

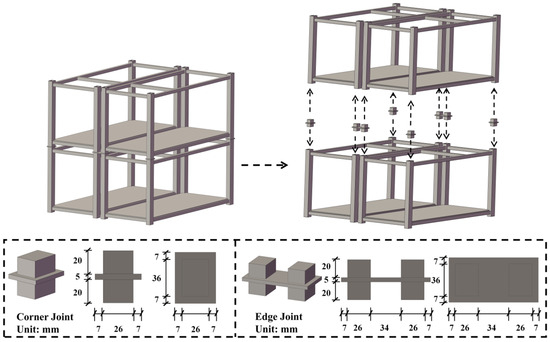

An illustration of the inter-module connections is shown in Figure 4. Adjacent spans are connected through edge joints. Adjacent stories are connected using both edge joints and corner joints. Each inter-story connection has two edge joints and four corner joints. Each joint consists of upper and lower steel casts and a connection plate through precise welding. The steel casts are precisely sized to plug into the interior of the columns. Then, the connection plates are welded to the column ends. In such inter-module connections that are identical to those of the prototype, the force transmission mechanism is concise and clear [44,45].

Figure 4.

Diagram of the inter-module connections.

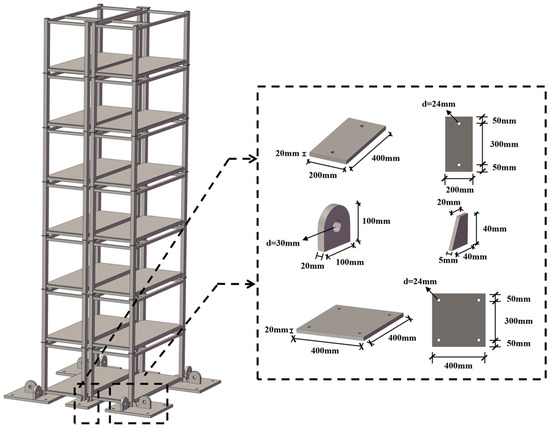

Considering practical test requirements such as crane lifting and anchorage to the shaking table, a specialized model base is designed. This base includes lifting lugs, baseplates, and stiffeners, as shown in Figure 5. During the tests, the model base is firmly connected to the shaking table by fourteen M24 high-strength bolts (100 mm in length). The boundary condition can be considered as fully fixed [41,46].

Figure 5.

Diagram of the model base.

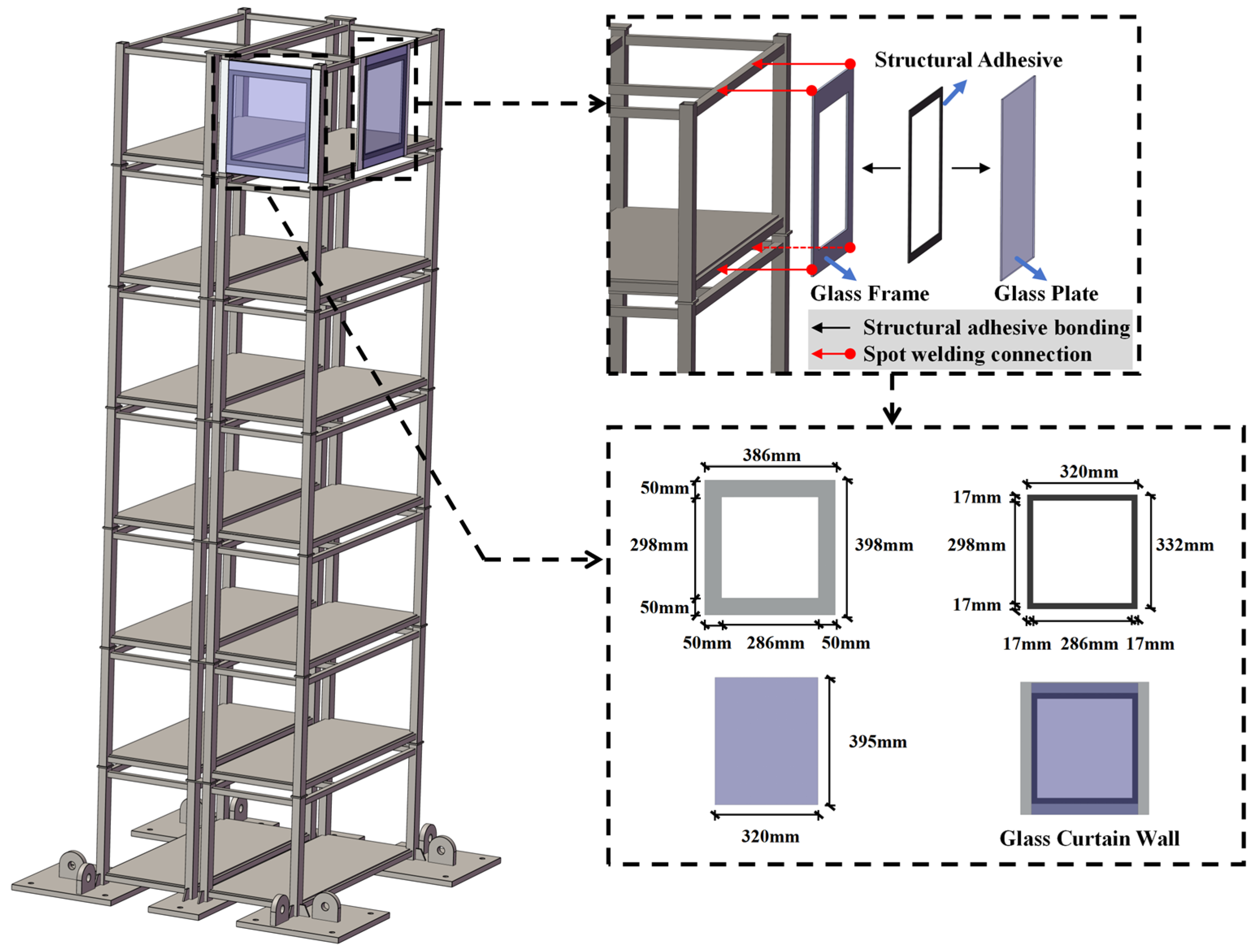

2.3.3. Glass Curtain Wall Design

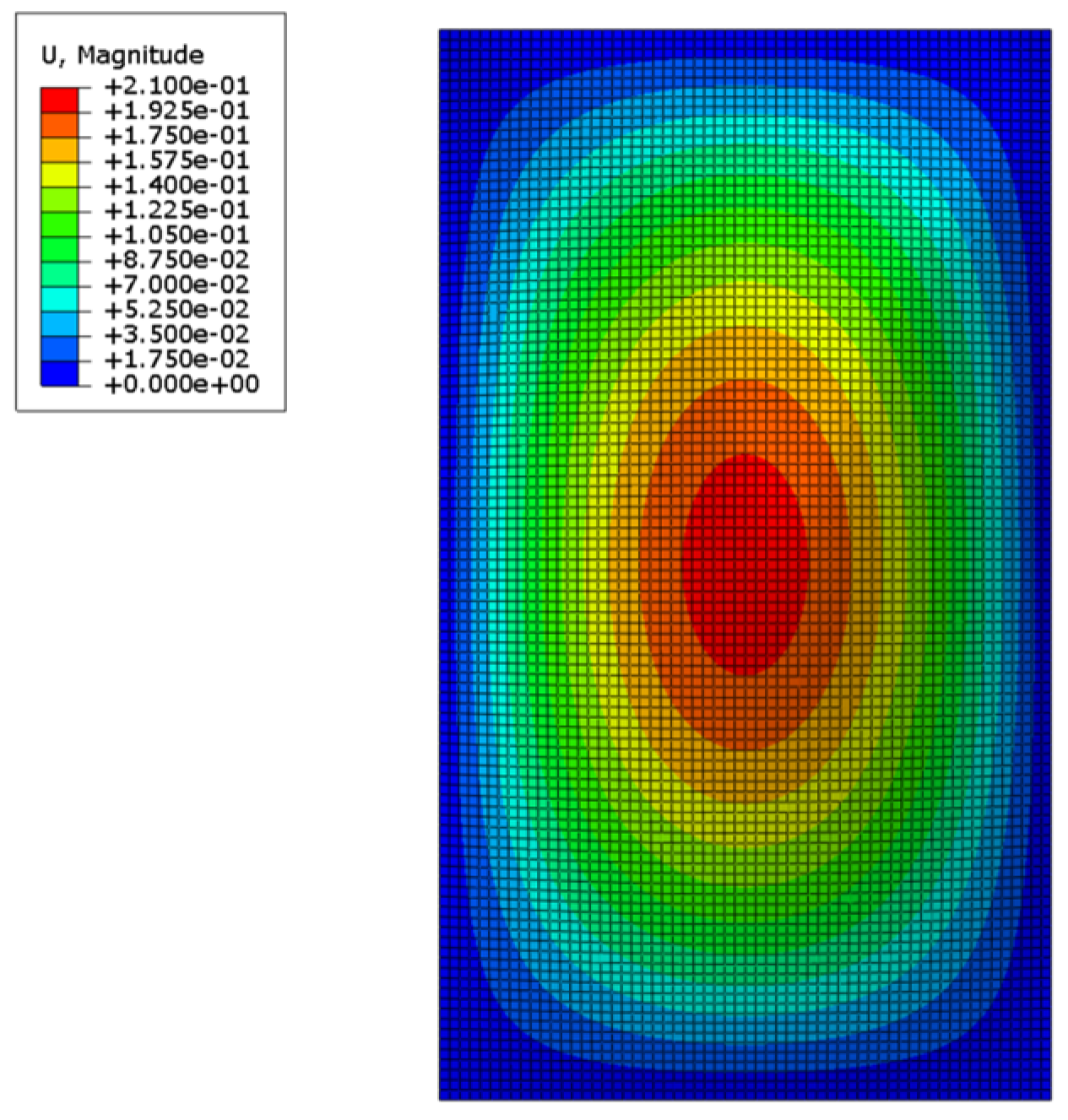

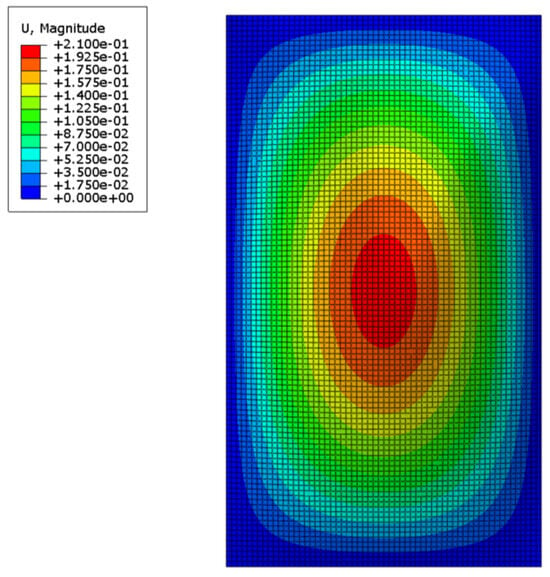

The prototype glass curtain wall is designed with dimensions of 2100 mm × 1200 mm × 15.5 mm, a density of 2500 kg/m3, and a total mass of 97.65 kg. Using ABAQUS 2020, the prototype curtain wall is modeled with S4R shell elements. The assumed elastic modulus is 70 GPa, with a Poisson’s ratio of 0.2. The boundary conditions are defined as simply supported on all four sides. Modal analysis of the prototype indicates that the first-mode natural frequency is 34.85 Hz, with a single-peak deformation centered in the middle of the plate, as shown in Figure 6.

Figure 6.

Mode shape analysis of the prototype glass curtain wall.

The model glass curtain walls are shown in Figure 7 [47]. One consists of a glass plate, structural silicone adhesive, and a frame. The glass plate measures 395 mm × 320 mm × 3.85 mm and is made of tempered glass. The glass frame is fabricated from 3 mm thick Q235 steel plates. The glass plate is bonded to the frame using structural silicone adhesive. The frames of the curtain walls are spot-welded to the top story to complete the installation. The installation positions are selected because the top story of the structure may exhibit a large acceleration amplification factor, and curtain wall damage at higher elevations poses greater hazards. Therefore, the top story can be regarded as the most unfavorable location. To simplify the model, the glass curtain walls at other locations are not physically installed but are considered as additional masses.

Figure 7.

Installation of glass curtain walls.

Assuming material densities of 7800 kg/m3 for the frame, 2500 kg/m3 for the glass, and 1240 kg/m3 for the structural adhesive, their masses are 1.60 kg, 1.22 kg, and 0.04 kg, respectively. The total mass of each assembled curtain wall is 2.86 kg. Both the frame and the adhesive are considered boundary condition elements.

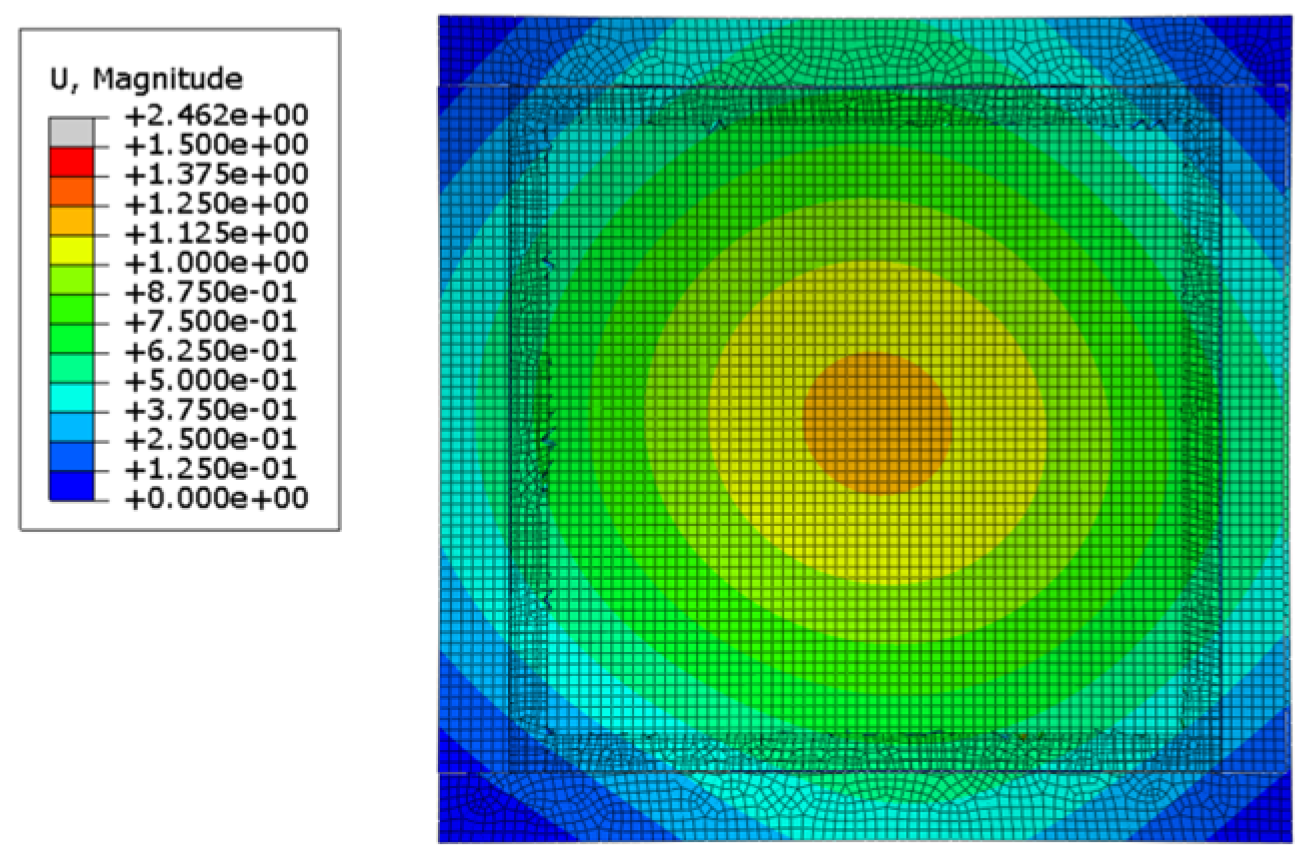

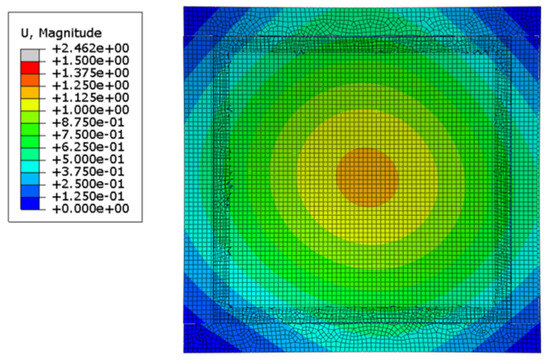

As illustrated in Figure 8, the glass plate is modeled using S4R shell elements, while the frame and structural adhesive are modeled with C3D8R solid elements in ABAQUS. The material properties of the components are summarized in Table 5. The finite element mesh is refined to ensure solution accuracy and convergence, with at least two elements in the thickness direction.

Figure 8.

Mode shape analysis of the model glass curtain wall.

Table 5.

Material settings for glass curtain walls in ABAQUS.

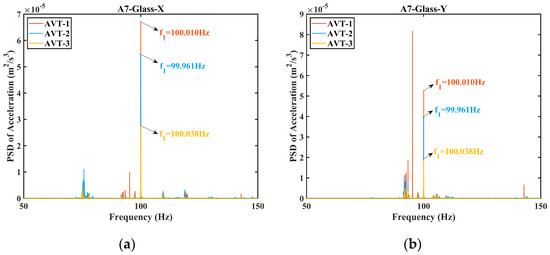

Tie constraints are applied to simulate the bond effect of the adhesive. The four corner nodes of the frame are fixed to simulate the spot-welded connection. The analysis yields the first mode of 107.01 Hz for the scaled glass curtain wall, as shown in Figure 8. As the curtain wall is a thin plate, geometric scaling would result in excessively thin wall thicknesses, posing significant challenges for fabrication. Furthermore, rigorous geometric similarity would compromise the similarity in mass and dynamic properties. Hence, priority is given to achieving similarity in mass and dynamic properties, both of which largely determine the acceleration responses. The similarity relationships for the curtain walls are summarized in Table 6.

Table 6.

Similarity relations of glass curtain walls.

2.3.4. Fabrication of the Model Structure

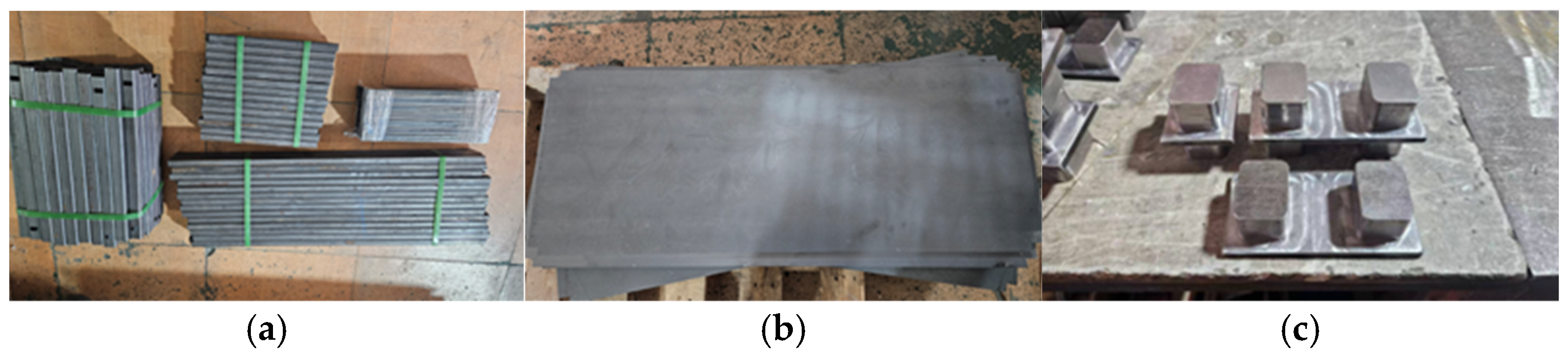

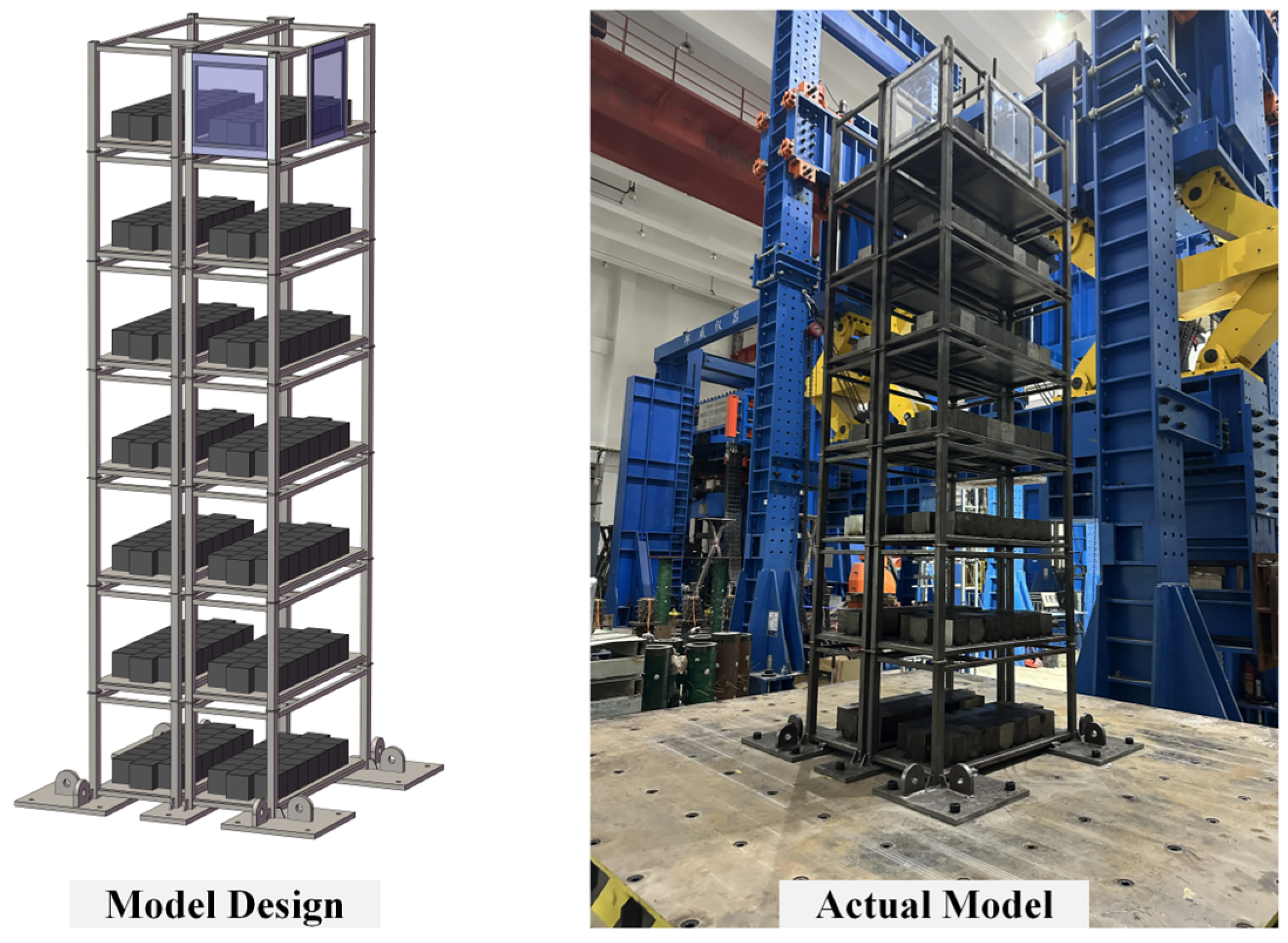

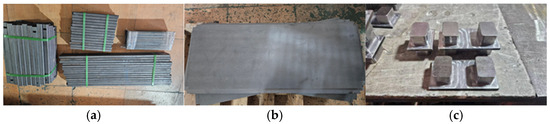

The components are categorized at the fabrication facility, as shown in Figure 9. Then the model frame is fabricated and transported to the laboratory, as shown in Figure 10. For this study, the artificial mass is fabricated using 308 cubes of die steel, each weighing 7.8 kg and of dimensions of 100 mm × 100 mm × 100 mm. All cubes are spot-welded to the floor slabs (Figure 11). The glass plates are bonded to the steel frames using J995 silicone structural sealant [48]. The adhesive is cured under ambient conditions for more than 14 days to ensure complete solidification. The corner regions of the curtain walls are then spot-welded to the beams at the seventh story. After the completion of all assembly procedures, the entire model is secured onto the shaking table, as shown in Figure 11. The verification of mass similarity is shown in Table 7.

Figure 9.

Components: (a) box-shaped cross-section components; (b) floor slab; (c) connection joints.

Figure 10.

The model frame in the laboratory.

Figure 11.

Completed model.

Table 7.

Model mass verification.

2.4. Measurement

2.4.1. Sensors

To acquire the acceleration and strain responses, accelerometers and strain gauges are used, as well as a dynamic signal testing and analysis system. Their specifications are listed in Table 8, Table 9 and Table 10.

Table 8.

IEPE accelerometer specifications.

Table 9.

Strain gauge and strain rosette specifications.

Table 10.

Specifications of the DH5922D dynamic signal testing and analysis system.

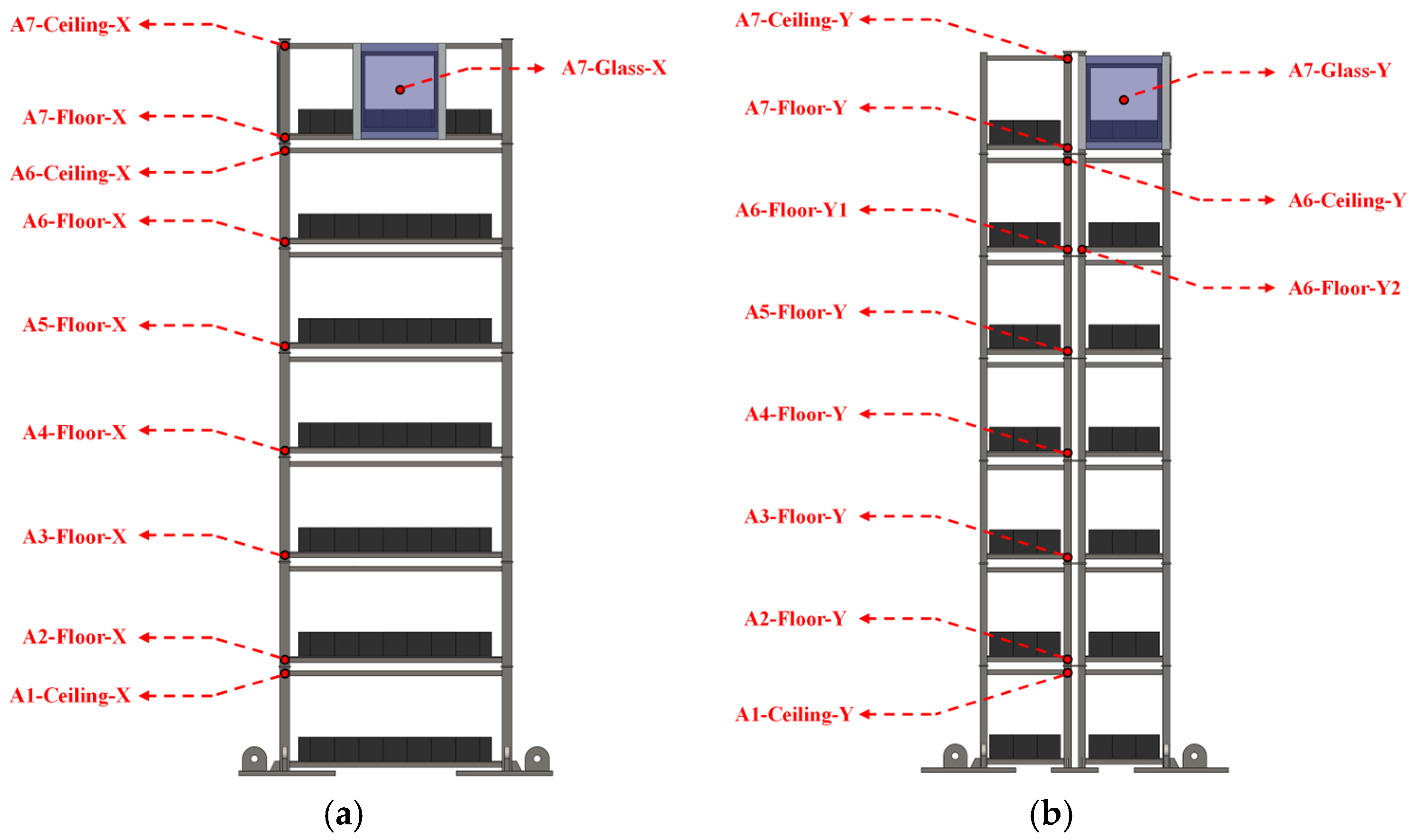

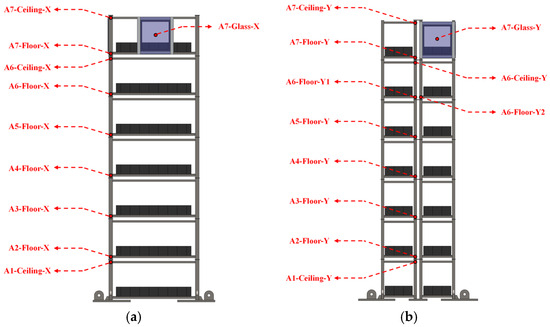

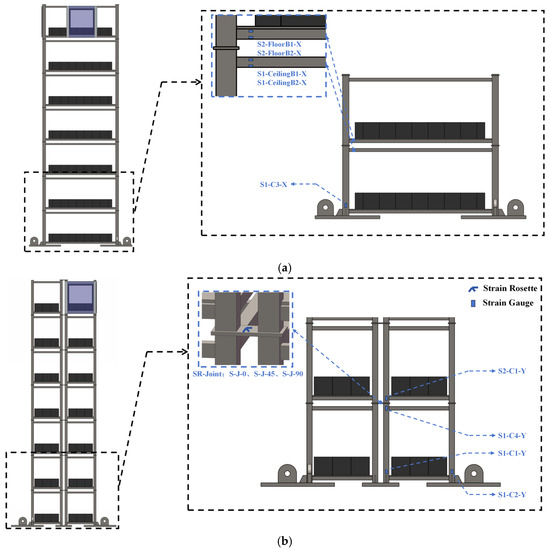

2.4.2. Sensor Arrangement

The arrangement of the accelerometers is shown in Figure 12, where each accelerometer is marked with a red solid dot. The label for each accelerometer follows the format “Ax-xxx-X/Y.” For example, A6-Floor-X is the accelerometer for measuring the acceleration in the X-direction at the floor of the sixth story, while A6-Ceiling-Y is for measuring the acceleration in the Y-direction at the ceiling of the sixth story.

Figure 12.

Accelerometer arrangement diagram: (a) along the X-axis; (b) along the Y-axis.

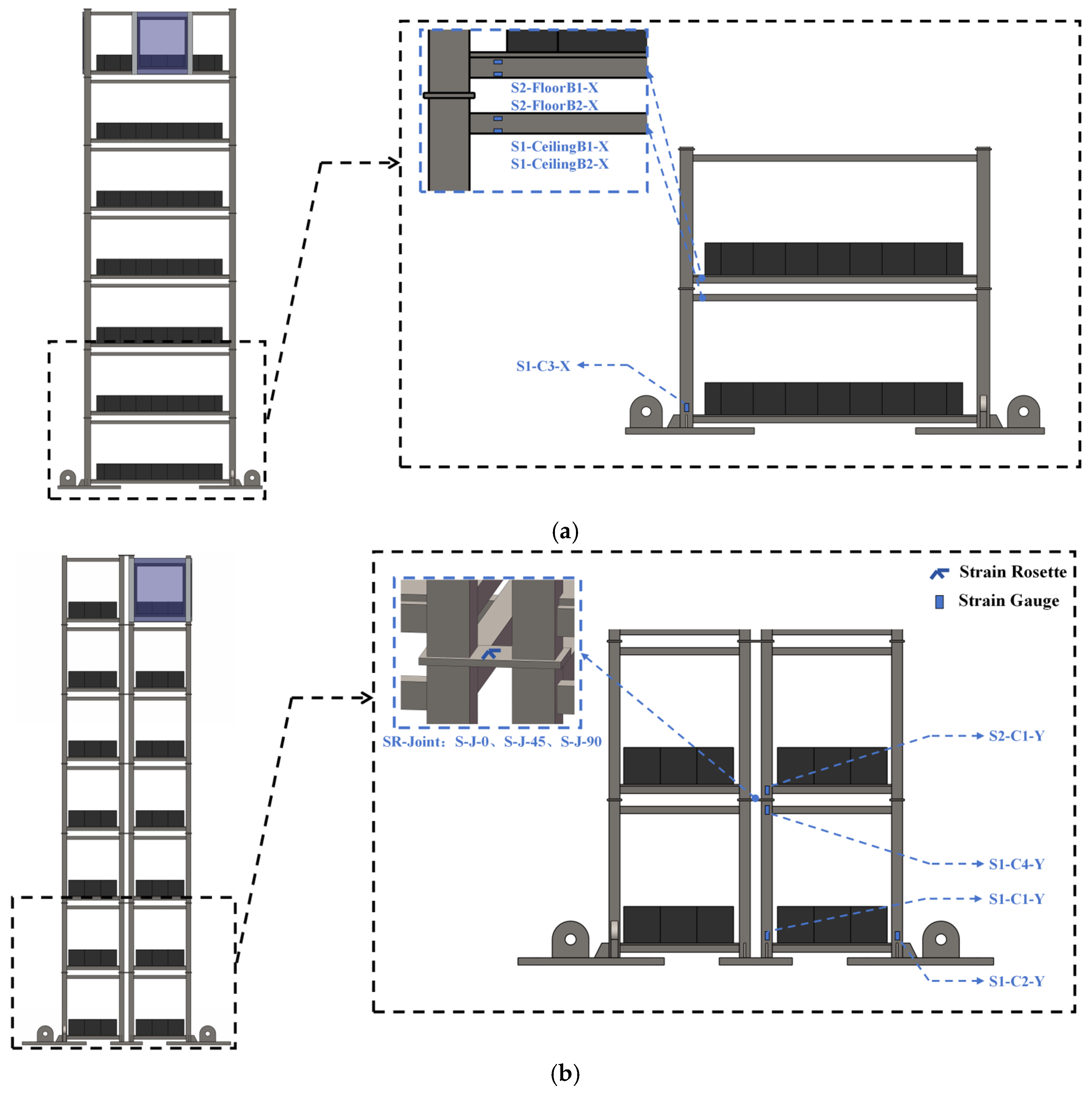

The arrangement of the strain gauges is shown in Figure 13, where each strain gauge is marked with a blue rectangle. There are three types of strain gauges, whose labels include “C”, “B”, and “J”, corresponding to the regions at the column, beam, and joint, respectively. Note that S1-CeilingB1-X stands for strain gauge no.1 on the ceiling beam of the 1st story in the X-direction; S1-C2-Y is for strain gauge no.2 on the column in the Y-direction.

Figure 13.

Strain gauge arrangement diagram: (a) X-direction; (b) Y-direction.

A diagram of the completed model, with all accelerometers and strain gauges arranged, is shown in Figure 14.

Figure 14.

The model structure with sensor set-up accomplished.

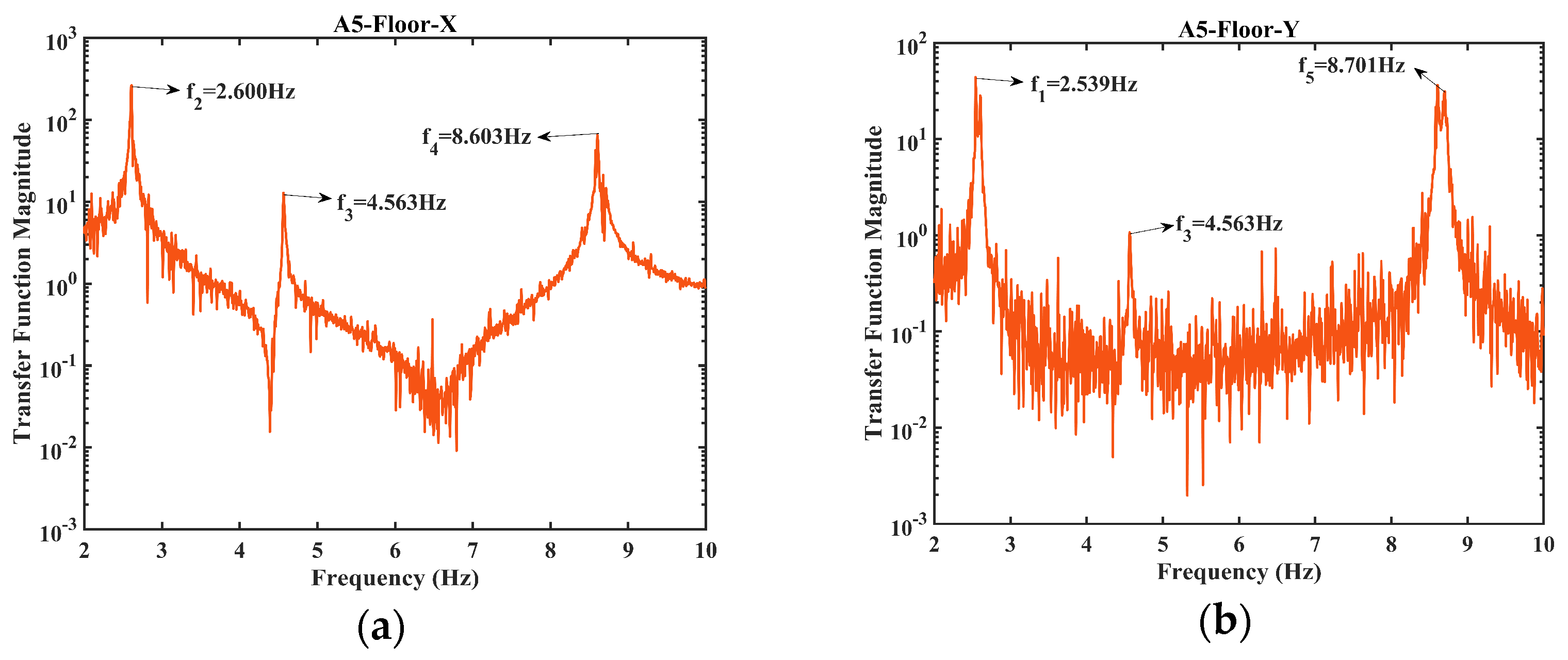

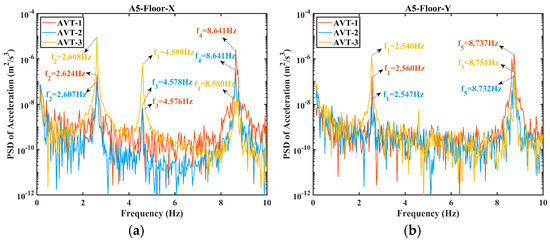

2.5. Dynamic Similarity Verification

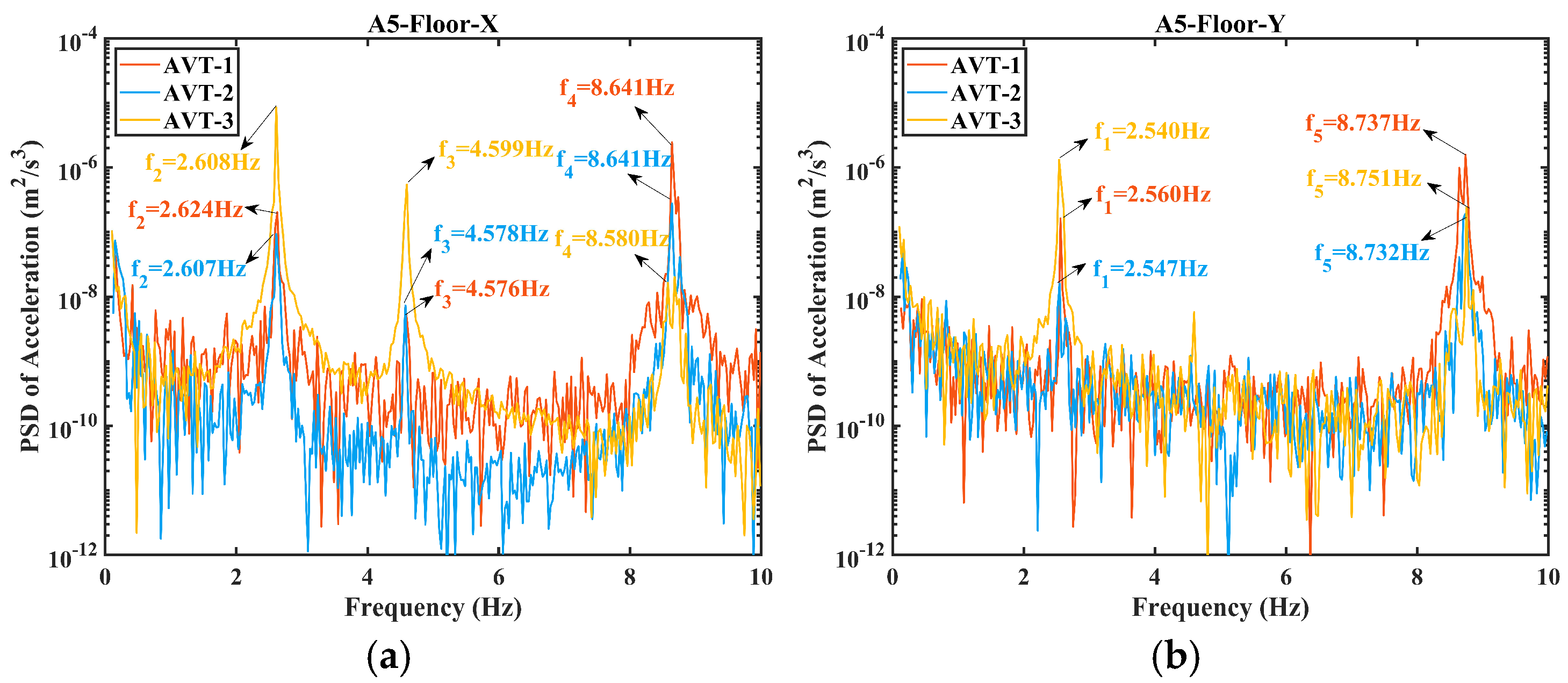

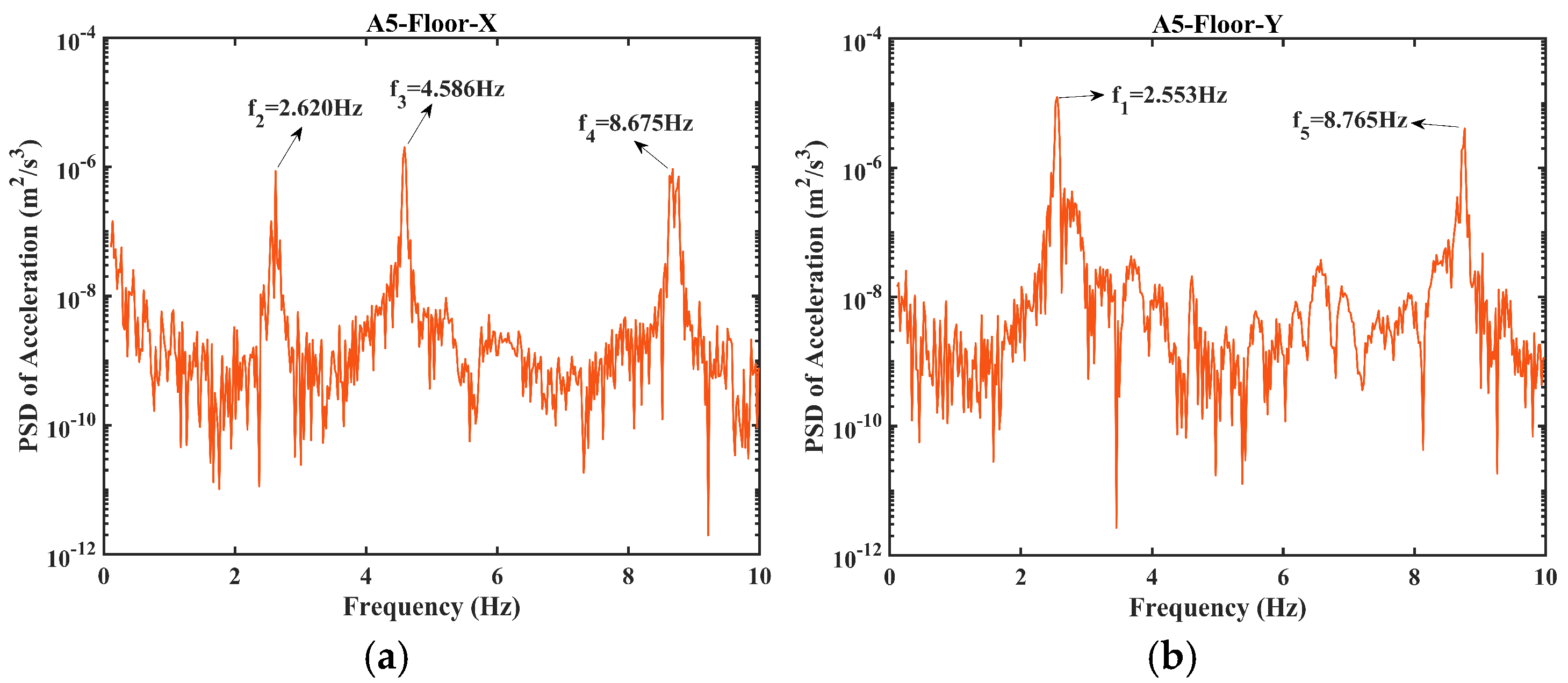

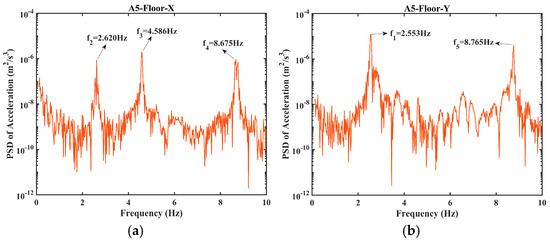

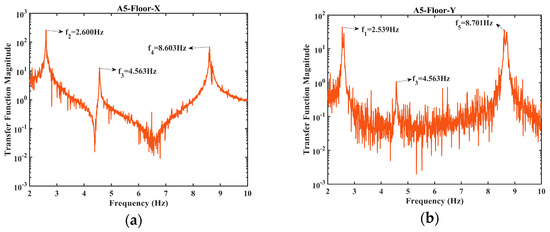

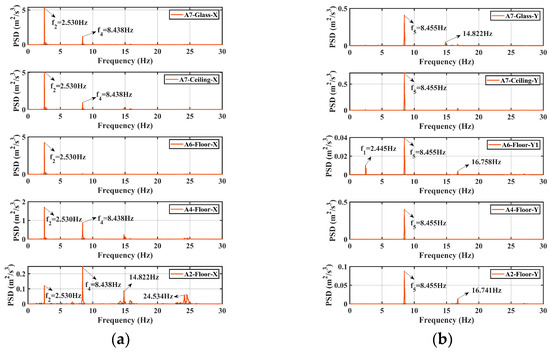

To verify dynamic similarity, ambient vibration tests (AVTs) are conducted. The “A5-Floor-X” and “A5-Floor-Y” records are selected for analysis, as shown in Figure 15. Fourier Transform is applied to analyze the power spectral density (PSD).

Figure 15.

Ambient vibration analysis: (a) PSD of X-direction acceleration; (b) PSD of Y-direction acceleration.

To further verify the accuracy of the natural frequencies identified via AVTs, a hammer test is conducted. The results are shown in Figure 16 and Table 11. They demonstrate that both AVTs and the hammer test successfully identified the natural frequencies with minimal discrepancies. The excitation is applied at the corner column on the sixth floor using a rubber hammer.

Figure 16.

Hammer test analysis: (a) PSD of X-direction acceleration; (b) PSD of Y-direction acceleration.

Table 11.

Comparison of modal identification results of ambient vibration test and hammer test.

The similarity relationships of the model are summarized in Table 12. The differences between the design and measured values of the parameters are minor, except for the third natural frequency (f3). This discrepancy in f3 primarily results from the fabrication process, as mass cubes are welded onto the floor slab (Figure 11), significantly increasing the torsional rigidity of the floors. Nevertheless, considering that the employed shaking table applies unidirectional excitation and the model possesses a rectangular plan with geometric symmetry and even mass distribution, it is difficult for significant torsional motions to be triggered. As a result, the discrepancy in f3 is unlikely to compromise the reliability of the measured translational responses.

Table 12.

Model similarity relationship verification.

In summary, the scaled model meets the essential similarity laws in terms of geometry, mass, and dynamic characteristics.

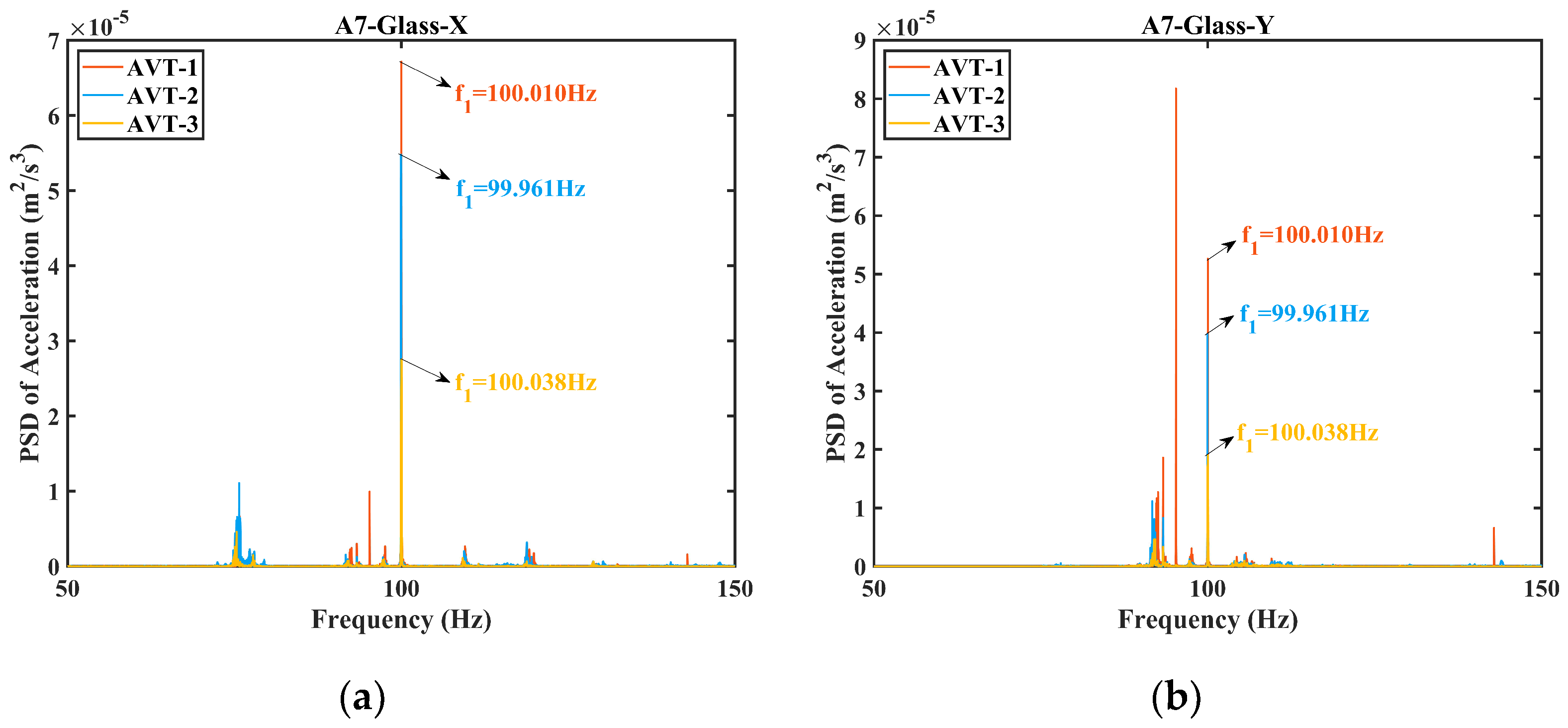

To verify that the model glass curtain walls satisfy dynamic similarity, their modal analysis is also conducted. As shown in Figure 17, distinct peaks are observed at their first natural frequency. The similarity relationships of various parameters of the model curtain walls are shown in Table 13. The model curtain walls satisfy both mass similarity and dynamic similarity.

Figure 17.

Modal analysis of glass curtain walls: (a) PSD of X-direction acceleration; (b) PSD of Y-direction acceleration.

Table 13.

Model glass curtain wall similarity relationship verification.

2.6. Load Scheme

2.6.1. Shaking Table

The seismic tests are conducted using a unidirectional horizontal shaking table at the Harbin Institute of Technology, Shenzhen campus. Its technical specifications are summarized in Table 14.

Table 14.

Specifications of the shaking table.

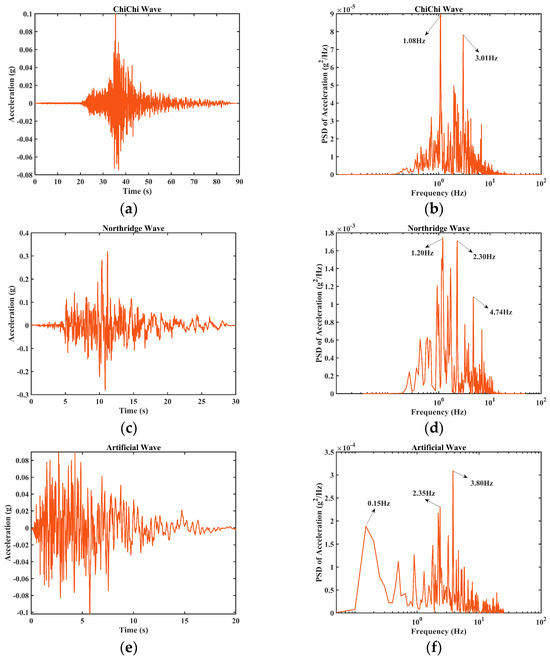

2.6.2. Selection of Seismic Waves

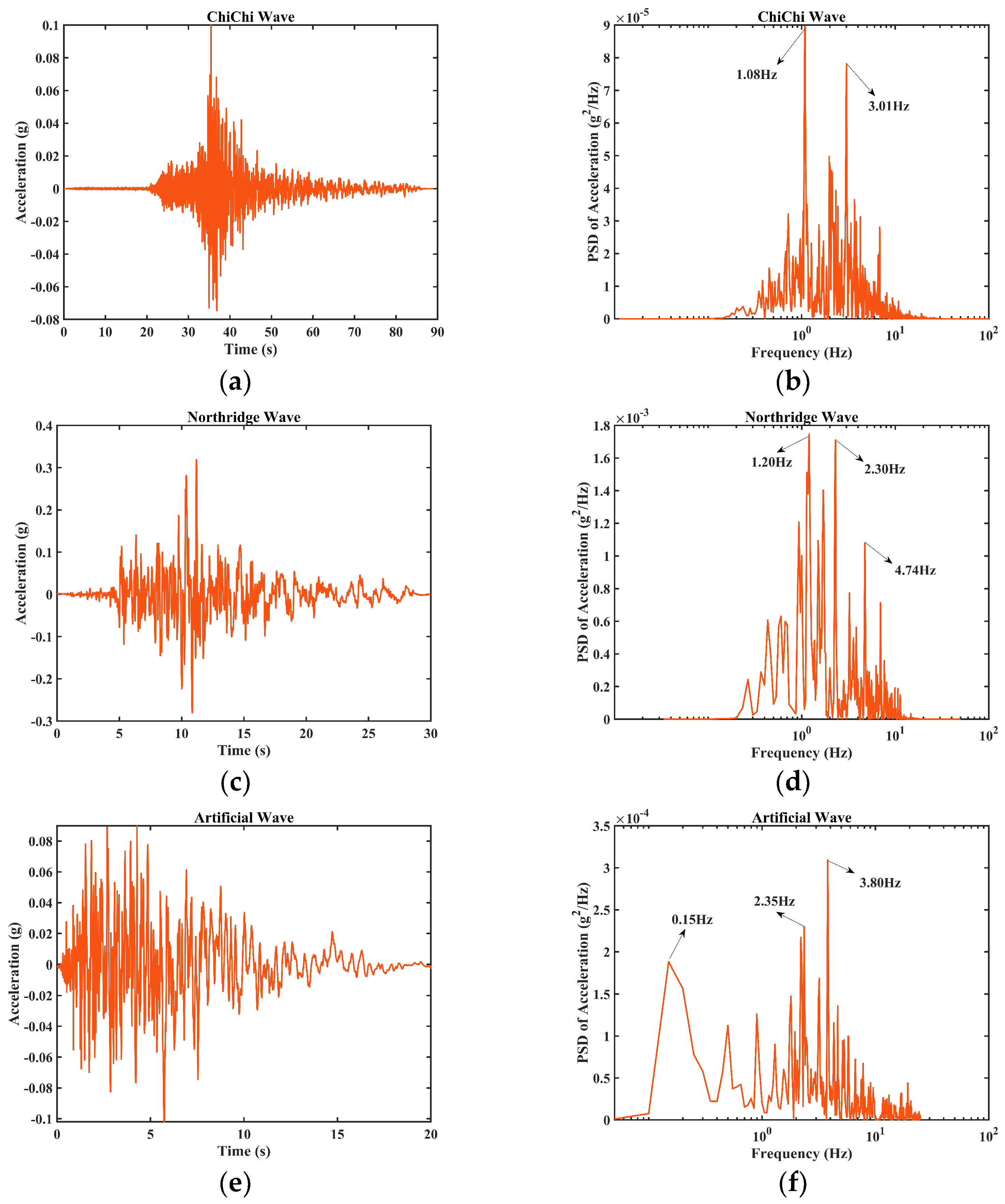

Considering the site conditions, the seismic design intensity, and the structural characteristics of the prototype, two recorded natural earthquake ground motions (ChiChi, 1999, and Northridge, 1994) are selected and one artificial wave is generated as input acceleration time histories for the shaking table tests. These three ground motions all meet the selection requirements specified in the Chinese Code for Seismic Design of Buildings [49]. Table 15 presents the detailed parameters of the selected ground motions, while Figure 18 depicts their acceleration time histories along with the corresponding PSDs.

Table 15.

The selected original seismic waves.

Figure 18.

The time histories and power spectra of the original seismic waves: (a) ChiChi wave time history; (b) ChiChi wave PSD; (c) Northridge wave time history; (d) Northridge wave PSD; (e) artificial wave time history; (f) artificial wave PSD.

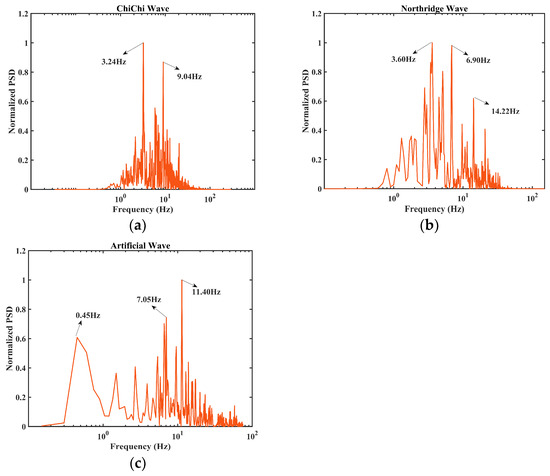

2.6.3. Test Loading Scheme

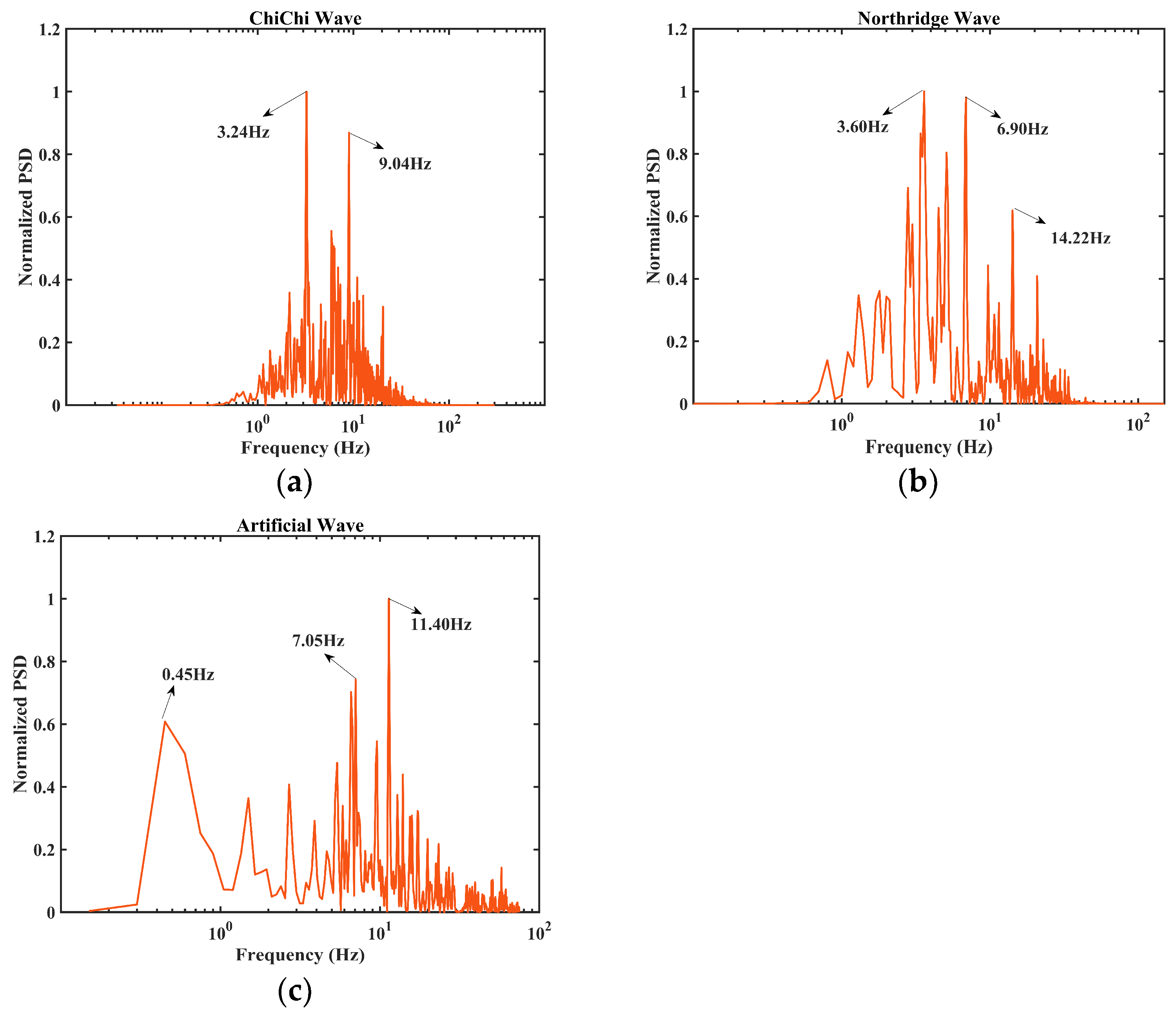

As shown in Table 3, the seismic wave time scale factor is 1/3, and all input motions are resampled at 1000 Hz. For each ground motion listed in Table 16, the entire profile is further scaled by its peak ground acceleration (PGA) to represent four typical intensity levels specified in the seismic code [49]: frequently occurring earthquake at 7-degree intensity (PGA = 0.035 g, FOE7), design basis earthquake at 7-degree intensity (PGA = 0.10 g, DBE7), maximum considered earthquake at 7-degree intensity (PGA = 0.22 g, MCE7), and maximum considered earthquake at 7.5-degree intensity (PGA = 0.31 g, MCE7.5). The input motions adopted in the model tests are summarized in Table 16, while their normalized PSDs are shown in Figure 19. The loading sequence of all 31 cases is provided in Table 17.

Table 16.

Seismic waves in the model test.

Figure 19.

The normalized PSD of the scaled seismic waves: (a) ChiChi wave PSD; (b) Northridge wave PSD; (c) artificial wave PSD.

Table 17.

Loading scheme of the shaking table tests.

3. Test Results and Discussion

3.1. Dynamic Characteristics

According to structural dynamics theory, for a linear time-invariant system, the frequency domain relationship between the input signal x and the output signal y can be expressed by Equation (1). In this equation, represents the PSD of the input signal, is the PSD of the output signal, and denotes the transfer function of the system.

Firstly, the analysis is conducted using the WN1-X scenario (#1). The intact natural frequencies of the model structure are identified by evaluating the transfer functions [30,31], as shown in Figure 20. Compared with the results in Figure 15 and Figure 16, the modal identification using white noise excitation proves to be more effective than that from AVTs and the hammer test. It can be observed that f3 at 4.563 Hz is identified in both directions. In contrast, f3 is difficult to detect in the Y-direction results from the AVTs and hammer test.

Figure 20.

Transfer function under white noise (WN1-X): (a) A5-Floor-X; (b) A5-Floor-Y.

Secondly, a summary of the intact natural frequencies obtained from three methods is presented in Table 18. The discrepancies between the AVTs and the white noise excitation are within 0.50%, while the discrepancies between the hammer tests and the white noise excitation remain within 1.00%. These results indicate that all three methods provide reliable identification. Furthermore, based on the hammer test, the damping ratios of the structure are identified to be 1.88% in the Y-direction and 2.03% in the X-direction.

Table 18.

The natural frequencies tested by different methods.

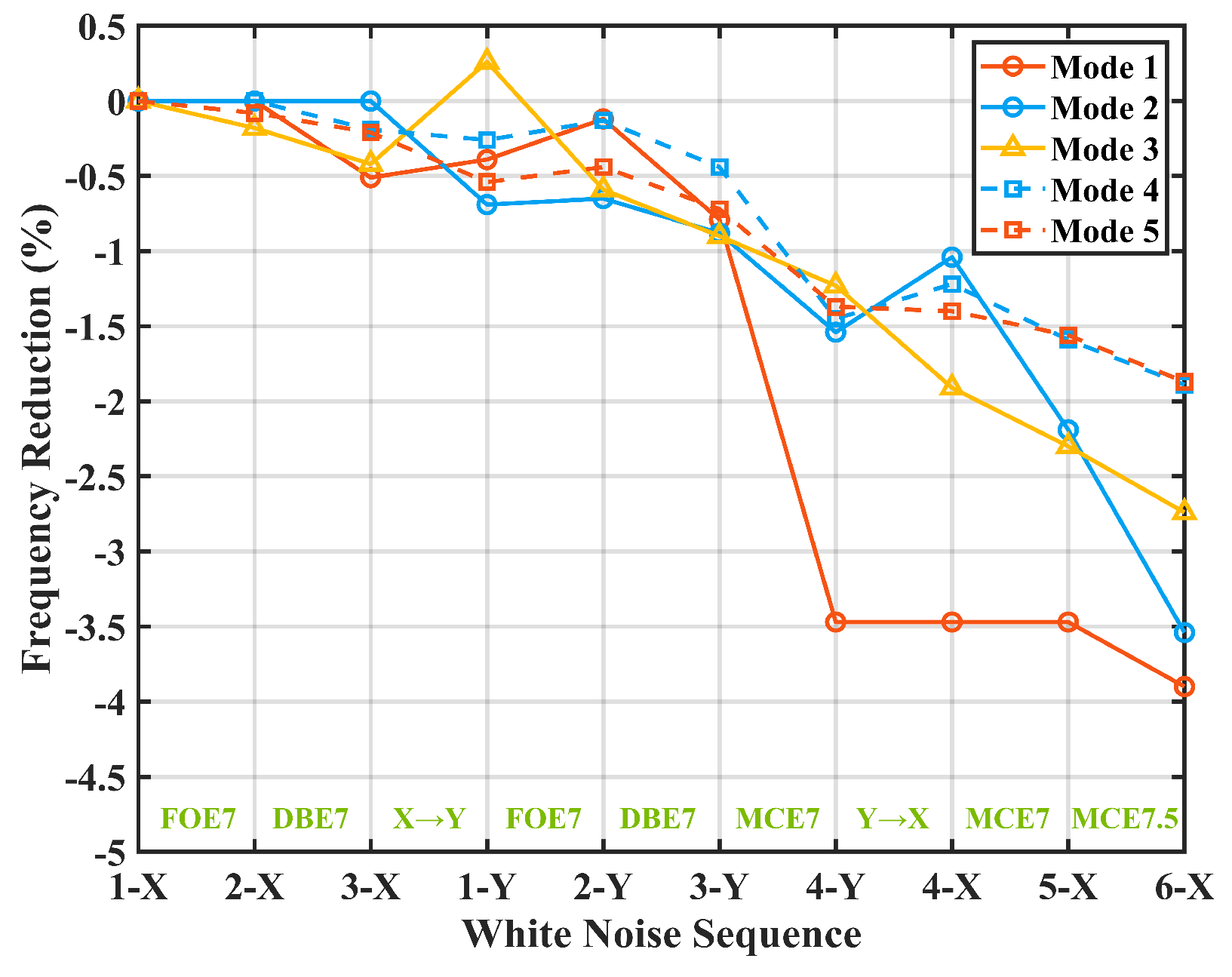

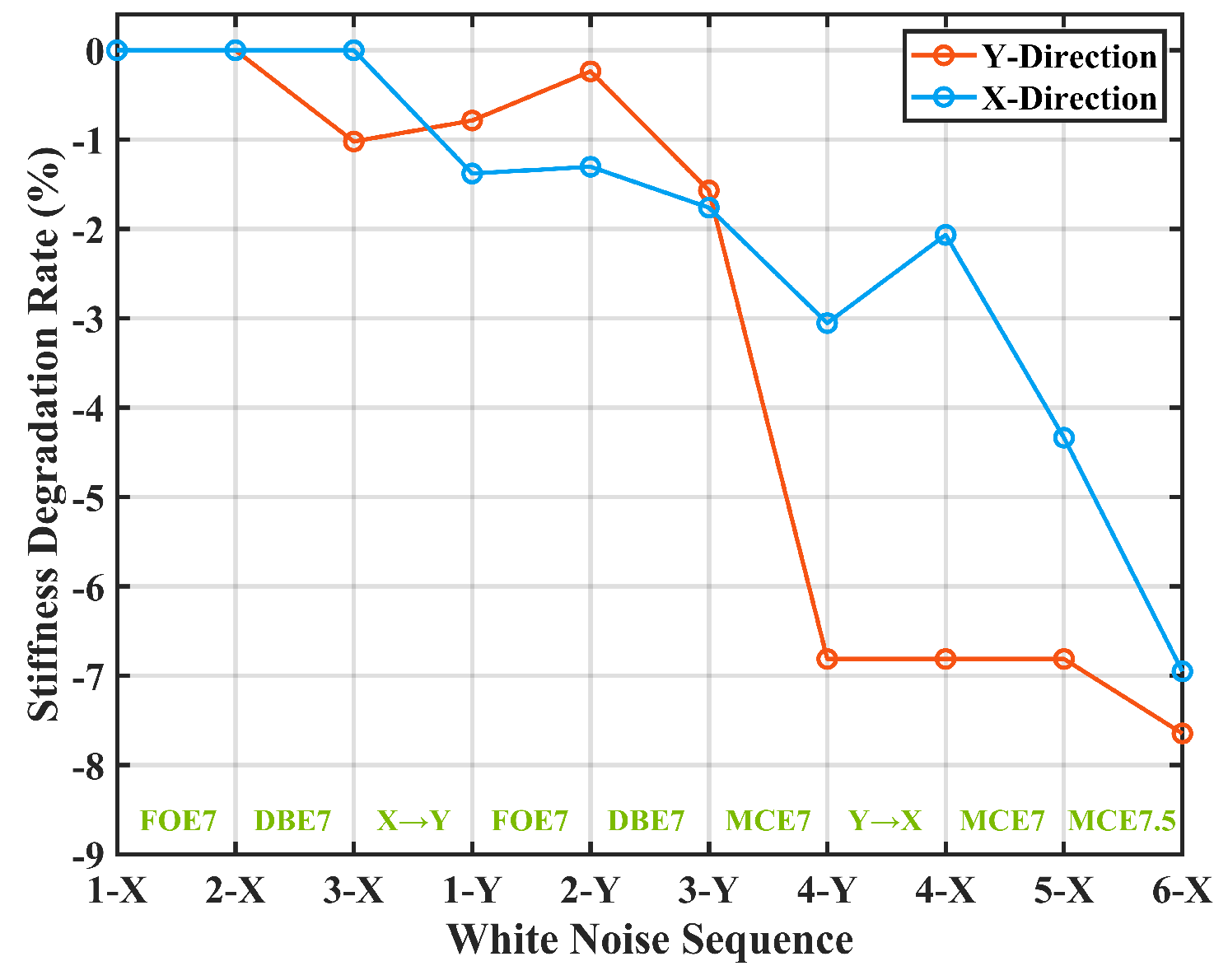

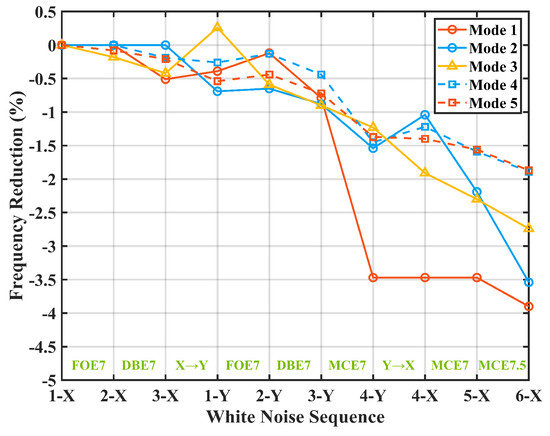

After the completion of each loading group (Table 17) with the same intensity level, white noise tests are conducted to identify the reduction in the natural frequencies. The results are summarized in Table 19, showing the reduction ratios relative to the pre-test intact values.

Table 19.

The natural frequency reductions during the tests.

The reduction ratios of the natural frequencies listed in Table 19 are plotted in Figure 21. This figure presents the frequency reduction during the tests, following the input order of loading scenarios. The analysis reveals the following findings.

Figure 21.

Reductions in natural frequencies during the tests.

As the seismic scenarios progress, an overall trend in the natural frequencies shows a gradual reduction.

According to the white noise result (WN3-Y), by this stage, the model has undergone both FOE7 and DBE7 seismic excitations in both directions. The reductions in f1–f5 remain below 1.0%, indicating that FOE7 and DBE7 earthquakes have a slight impact on the structure.

According to the white noise result (WN6-X), the lower-order modes (f1, f2) exhibit more significant reductions in natural frequencies than the higher-order modes (f4, f5) do. This indicates that when the model is subjected to seismic excitations, the lower-order modes (f1, f2) contribute more significantly to the seismic responses than the higher-order (f4, f5) modes do. As a result, the natural frequencies associated with lower-order modes (f1, f2) are more susceptible to reduction under seismic excitations.

According to the white noise results from WN3-Y to WN6-X, the reductions in f1–f3 are noticeably steeper than in the previous stage. This implies that the higher the seismic intensity, the greater the frequency reduction.

It is also worthwhile to see that during the seismic scenarios, there are instances where the natural frequencies slightly increase instead of decreasing, such as between WN3-X and WN1-Y, and between WN4-Y and WN4-X, but no seismic loading occurred between these white noise tests. Such a small increase is attributed to the fact that the base fixing bolts are retightened after reorientation of the model, restoring the boundary conditions.

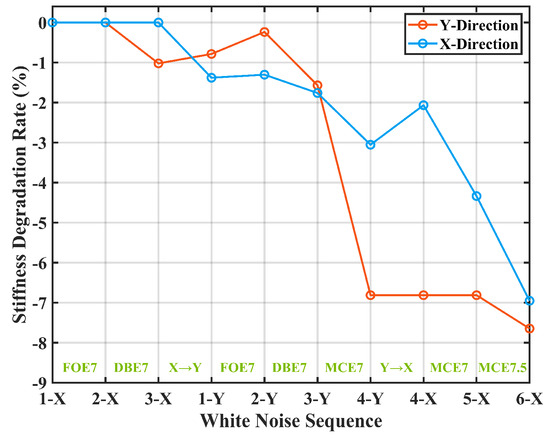

The stiffness degradation ratio is defined in Equation (2) [31], where and represent the intact stiffness and natural frequency of the structure before testing, and and represent the stiffness and natural frequency of the structure after each seismic excitation during the test.

In this study, f1 and f2 are used for the calculation of , as illustrated in Figure 22. The white noise result (WN6-X) indicates that in both directions does not exceed 8.0%.

Figure 22.

The stiffness degradation.

3.2. Acceleration Amplification Coefficient

As defined in Equation (3), the acceleration amplification coefficient provides a direct evaluation of the structural acceleration response [31].

In this equation, represents the peak absolute value of the input ground acceleration from the shaking table, while peak structural acceleration () represents the peak absolute value of the acceleration response recorded at the structure.

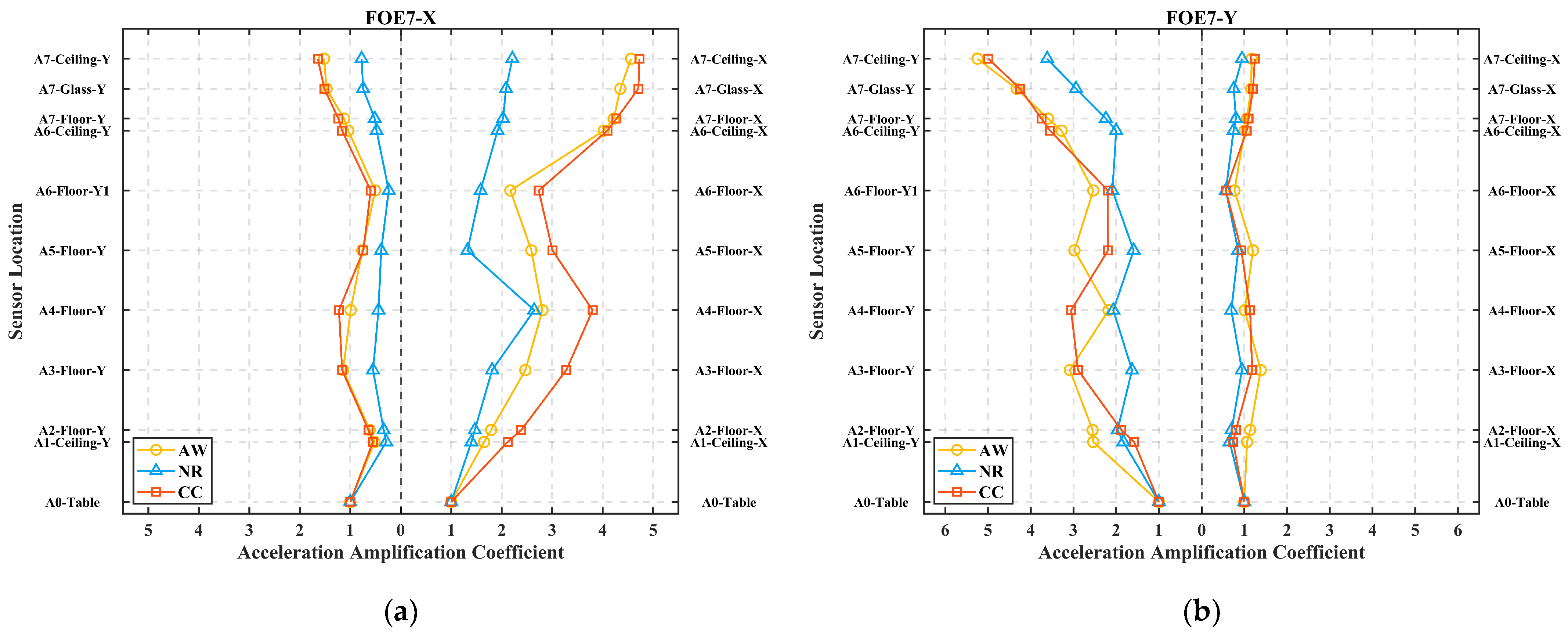

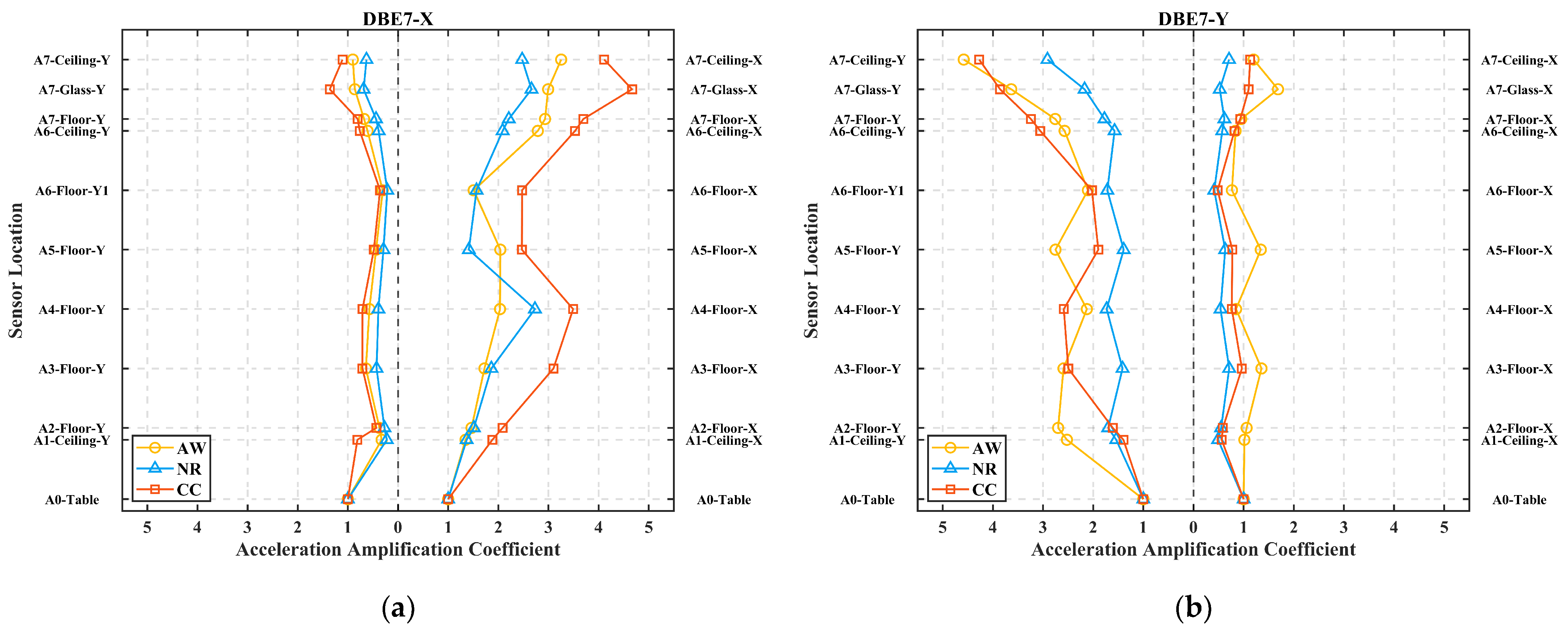

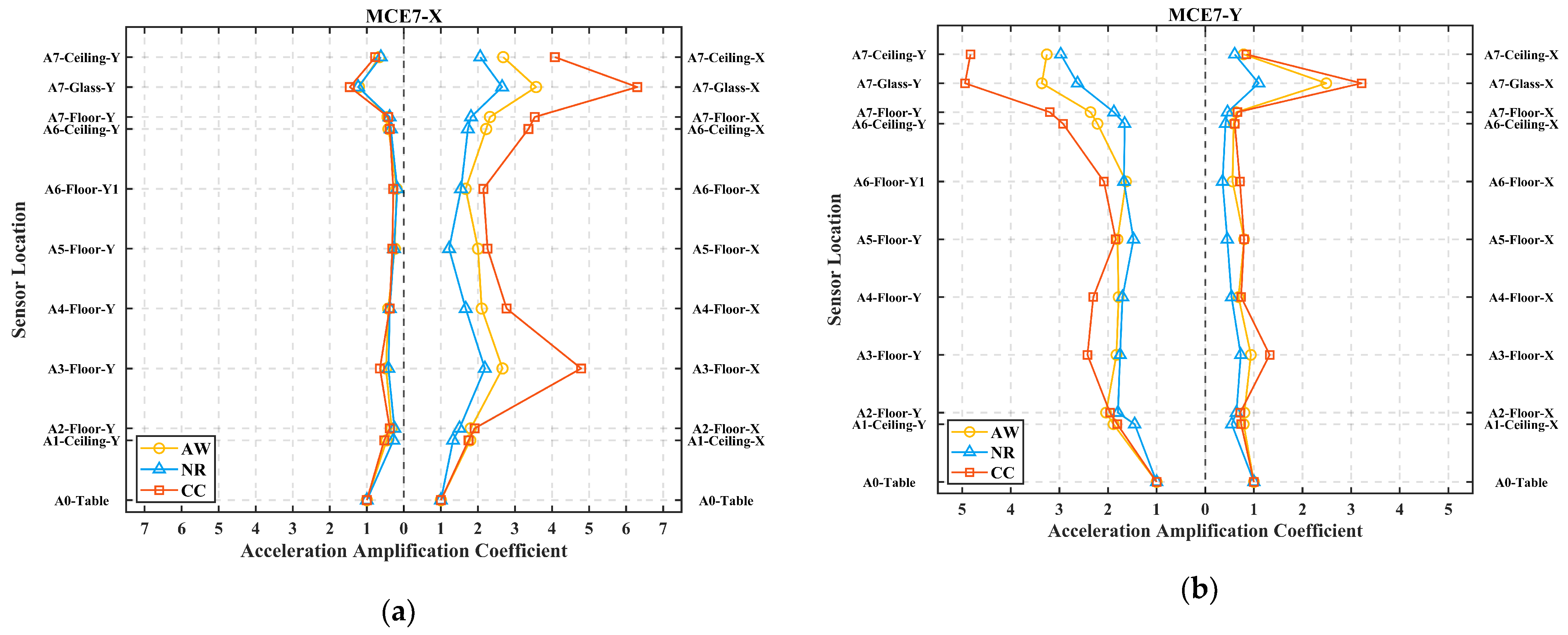

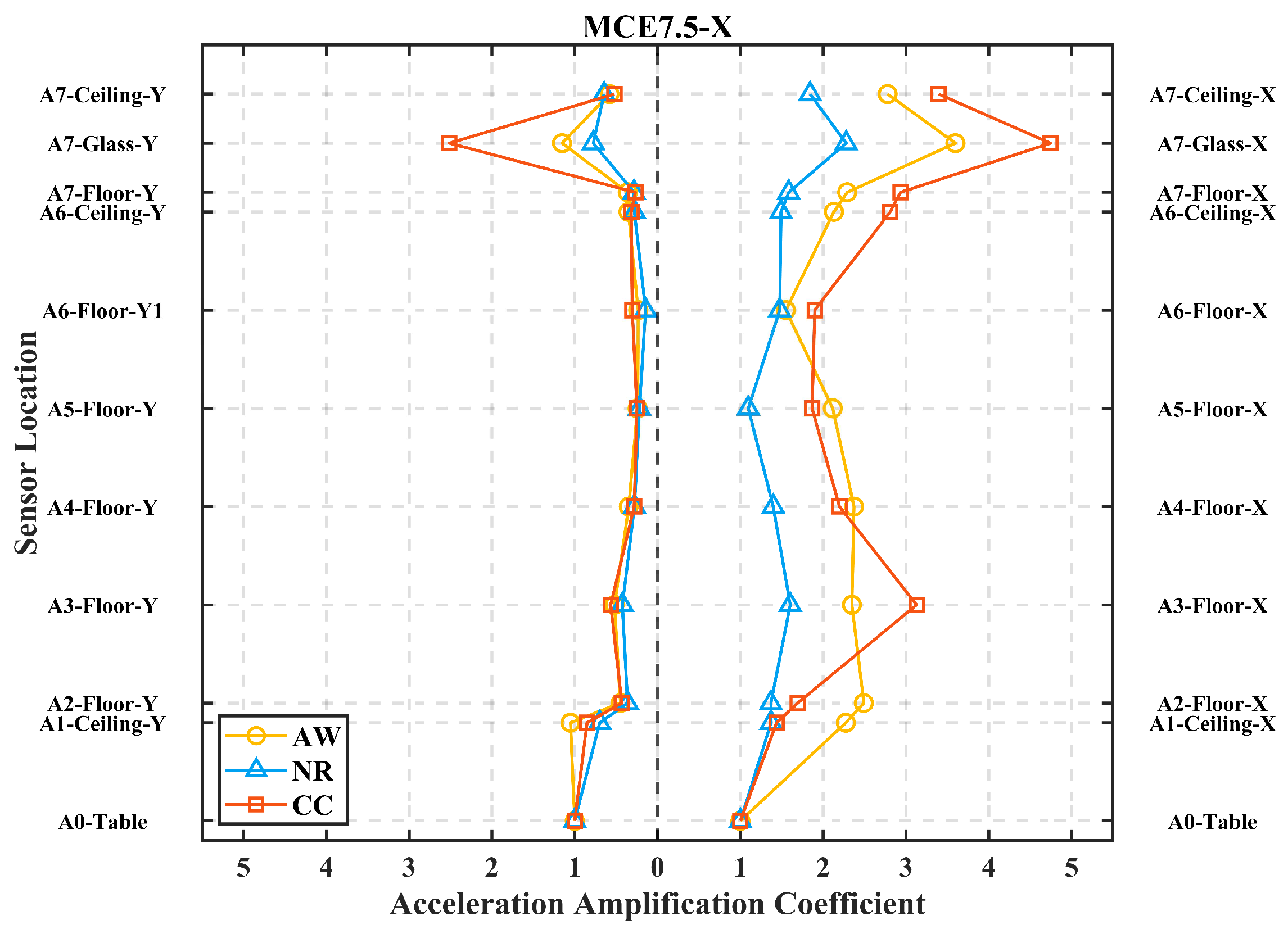

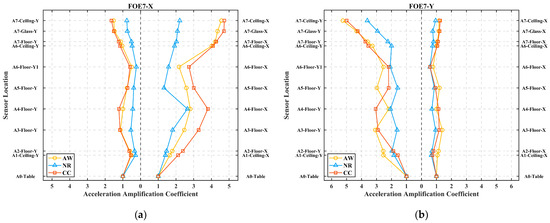

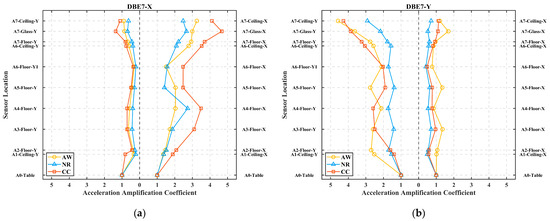

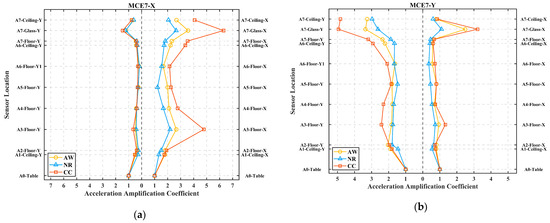

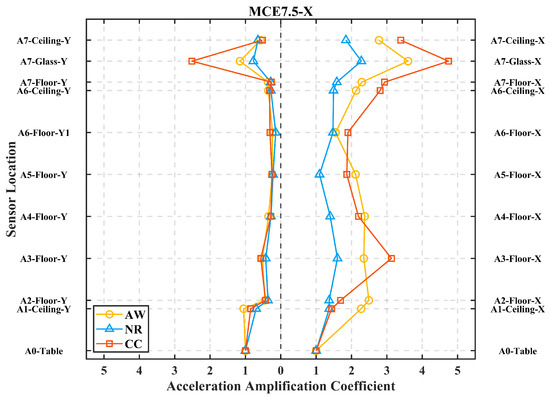

As shown in Figure 23, Figure 24, Figure 25 and Figure 26, the AACs reveal the following findings. In terms of the steel structure, first, as shown in Figure 23, Figure 24, Figure 25 and Figure 26, the AACs exhibit an overall increasing trend with the altitudes of stories. However, this trend is not strictly monotonic, as certain higher locations exhibit lower AAC values than lower locations. Under the ChiChi wave, this phenomenon is more pronounced and exhibits an S-shape amplification curve, which has been reported in [31]. In FOE7 and DBE7 conditions (ChiChi wave), the AAC curves show an increasing trend from sensor A1-Ceiling-X to A4-Floor-X and a decreasing trend from sensor A4-Floor-X to A5-Floor-X; the variation is slight from A5-Floor-X to A6-Floor-X, and the increasing trend reappears above A6-Floor-X. In MCE7 and MCE7.5 conditions (ChiChi wave), a similar trend is observed. However, the turning point occurs at a lower altitude, shifting from A4-Floor-X to A3-Floor-X. The local fluctuations are attributed to the 9.04 Hz frequency component in the ChiChi wave (Figure 19a), which is close to the higher-order natural frequencies of the structure (Figure 20, f4 = 8.603 Hz, f5 = 8.701 Hz). Therefore, higher modes (f4 and f5) in the structural vibration, whose modal shapes exhibit maximum deformation at the third floor and fourth floor, are excited. Second, when seismic waves are applied in the X-direction of the structure, the orthometric acceleration responses are also captured by the Y-direction sensors. The same is true when the input is along the Y-direction. However, the AACs of the orthometric acceleration are small, especially under seismic intensities of MCE7 and above, for which the AACs rarely exceed 1.0. This indicates that under strong ground motion, the out-of-plane and torsional effects are not significant.

Figure 23.

The acceleration amplification coefficient under FOE7: (a) input along the X-axis; (b) input along the Y-axis. (CC: ChiChi; NR: Northridge; AW: artificial wave).

Figure 24.

The acceleration amplification coefficient under DBE7: (a) input along the X-axis; (b) input along the Y-axis. (CC: ChiChi; NR: Northridge; AW: artificial wave).

Figure 25.

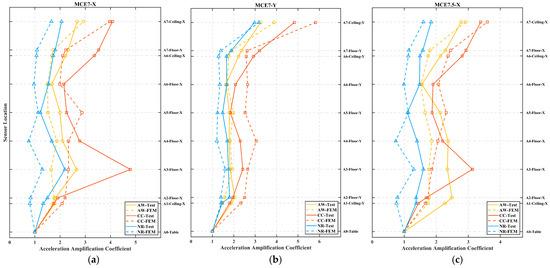

The acceleration amplification coefficient under MCE7: (a) input along the X-axis; (b) input along the Y-axis. (CC: ChiChi; NR: Northridge; AW: artificial wave).

Figure 26.

The acceleration amplification coefficient under MCE7.5. (CC: ChiChi; NR: Northridge; AW: artificial wave).

In terms of the glass curtain wall, as the seismic intensity increases, the acceleration amplification effect of the glass curtain walls becomes more pronounced (A7-Glass-X and A7-Glass-Y in Figure 23, Figure 24, Figure 25 and Figure 26). In FOE7 and DBE7 conditions, the AAC values at the curtain walls exhibit no significant bulge. However, in MCE7 and MCE7.5 conditions, the maximum AAC consistently occurs at the glass curtain walls. This indicates that the higher the seismic intensity, the greater the acceleration amplification effect on the glass curtain walls. In addition, even when the seismic direction (X/Y) is perpendicular to the normal direction of the glass curtain walls, high AAC values are still observed at A7-Glass-Y/X, and the maximum AAC even reaches 3.2. This suggests that, due to the lightweight materials and flexible boundary conditions, the glass curtain walls are more susceptible to intense vibration than the steel structure. Even out-of-plane excitation can induce significant in-plane responses.

To discuss the AACs quantitatively, Table 20 and Table 21 present their measured values in the X- and Y-directions. These AACs are compared with the calculation based on the codes ([49,50,51,52,53,54,55]) in Table 22, where z denotes the altitude from the ground, and h represents the total height of the entire structure.

Table 20.

The acceleration amplification coefficient of the X-direction accelerometers.

Table 21.

The acceleration amplification coefficient of the Y-direction accelerometers.

Table 22.

The code-calculated acceleration amplification coefficients.

First, as shown in Table 22, all code-based formulas represent the AAC as a linear function. However, as discussed earlier, the AACs observed in the tests do not monotonically increase. Therefore, the code formulas fail to accurately represent the actual shape of the AAC curve under seismic excitation. Second, current design codes tend to underestimate the AAC values. For example, under MCE7.5, considering the average of all AAC values, in terms of the steel structure, the Chinese codes ([49,50,51]) underestimate the AAC by 23.2%, the American code [52] by 4.5%, and the European code [53] by 9.3%. In terms of the glass curtain wall, the Chinese codes ([49,50,51]) underestimate the AAC by 45.2%, the American code [52] by 18.6%, and the European code [53] by 31.9%. Therefore, this indicates that the acceleration amplification effect of modular steel buildings can easily exceed the code limits. When developing design guidelines for modular steel structures, the importance of seismic time-history analysis should be emphasized. In addition, it is recommended to incorporate lateral force-resisting systems and energy-dissipating dampers to alleviate the acceleration response.

The AACs obtained in this study (ChiChi wave, PGA = 0.22 g) are compared with the results reported (ChiChi wave, PGA = 0.20 g) in reference [56], as shown in Table 23. The specimen in reference [56] is a seven-story conventional steel frame. The comparison shows that the AACs of the modular steel structure are significantly higher. This indicates that modular steel structures exhibit a stronger dynamic amplification effect under seismic excitation, such that they are subjected to greater seismic forces, and are more likely to experience intense lateral vibrations.

Table 23.

Comparison of the modular steel structure and the conventional steel structure.

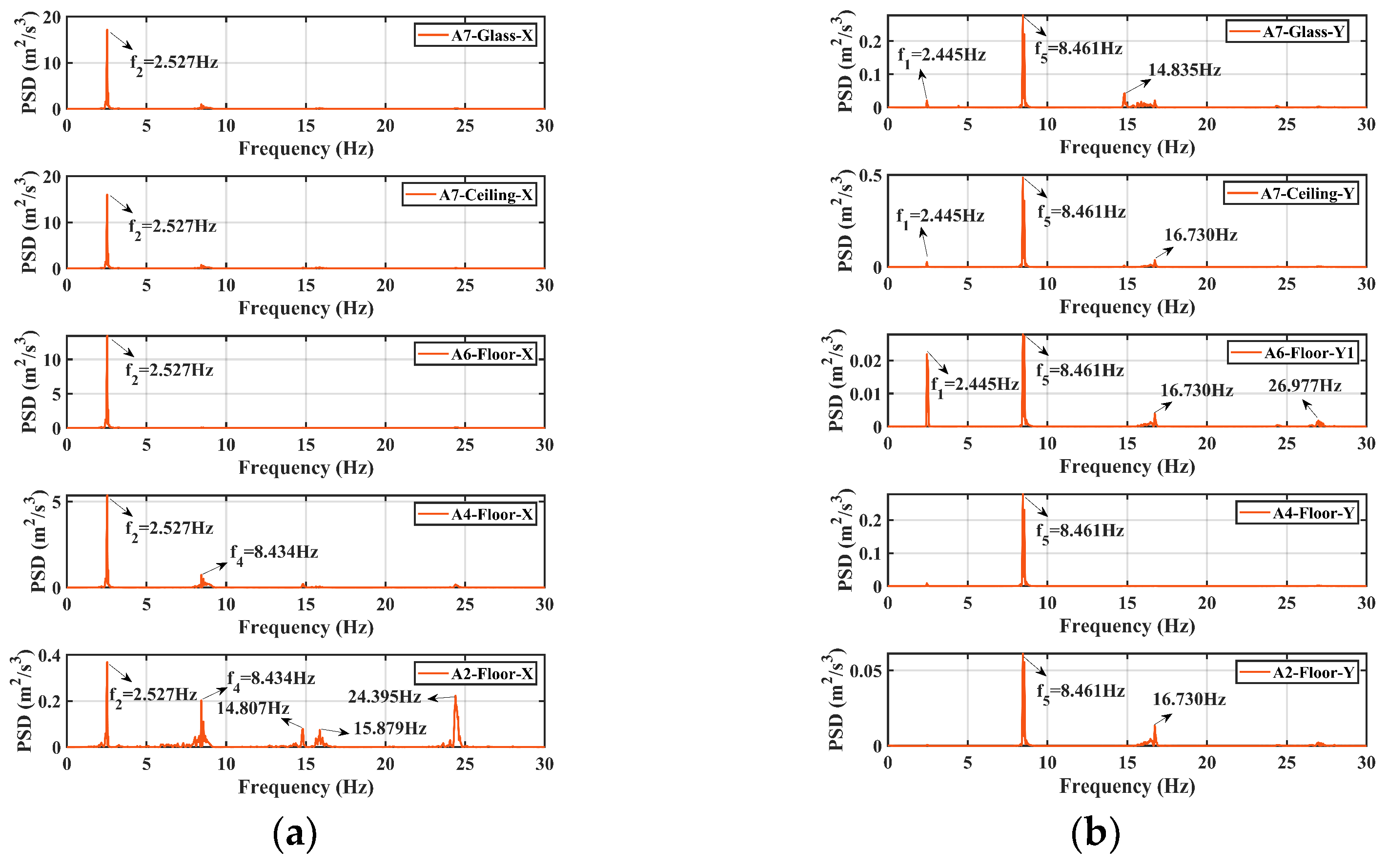

3.3. Acceleration Response Spectrum Analysis

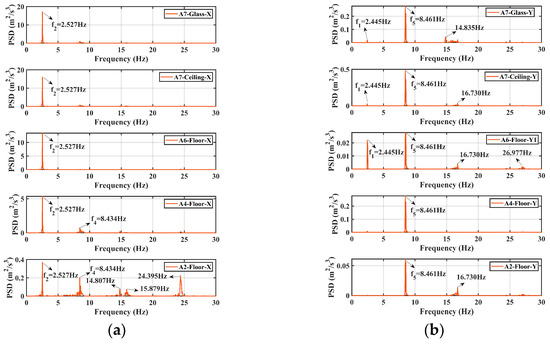

This section discusses representative loading cases and selected accelerometers. Therefore, CC-MCE7.5-X and NR-MCE7.5-X from Table 17 are selected. As shown in Figure 27a, the higher the accelerometer location, the higher the amplitude in the PSD, and the smaller the number of peaks in the PSD. Notably, for the sensors located above A4-Floor-X, only the vibration component at f2 is observed. This suggests that with increasing floor altitude, the second-mode vibration is significantly amplified, whereas the other frequency components are suppressed.

Figure 27.

Spectra of the acceleration response under the X-directional input of the MCE7.5 ChiChi wave: (a) sensors positioned along the X-direction; (b) sensors positioned along the Y-direction.

As shown in Figure 27b, in comparison, the acceleration responses of the sensors are all governed by the higher-order mode (f5). This is because, as shown in Figure 19a, the ChiChi wave contains a 9.04 Hz frequency component, which can excite the higher-order mode (f5) of the model structure. In addition, at A6-Floor-Y1, the PSD shows weaker energy than at both higher and lower locations, likely because this location is near the modal inflection point, which suppresses the energy at 8.455 Hz (f5). In the CC-MCE7.5-X case, the torsional mode frequency (f3) does not appear in the spectra of any measurement points—not just those shown in Figure 27.

As shown in Figure 28a, the vibration in the second story is dominated by the higher-order mode (f4), while those in other stories are primarily governed by the lower-order mode (f2). Furthermore, at f2 (2.530 Hz), the acceleration response energy of the glass curtain wall is somehow greater than that observed at the ceiling of the seventh story right over the curtain. Although the glass curtain walls inherently have high natural frequencies, their spectra are dominated by the much lower natural frequencies of the main structure. Such an effect may compromise the safety of the facade under strong ground motions.

Figure 28.

Spectra of the acceleration response under the X-directional input of the MCE7.5 Northridge wave: (a) sensors positioned along the X-direction; (b) sensors positioned along the Y-direction.

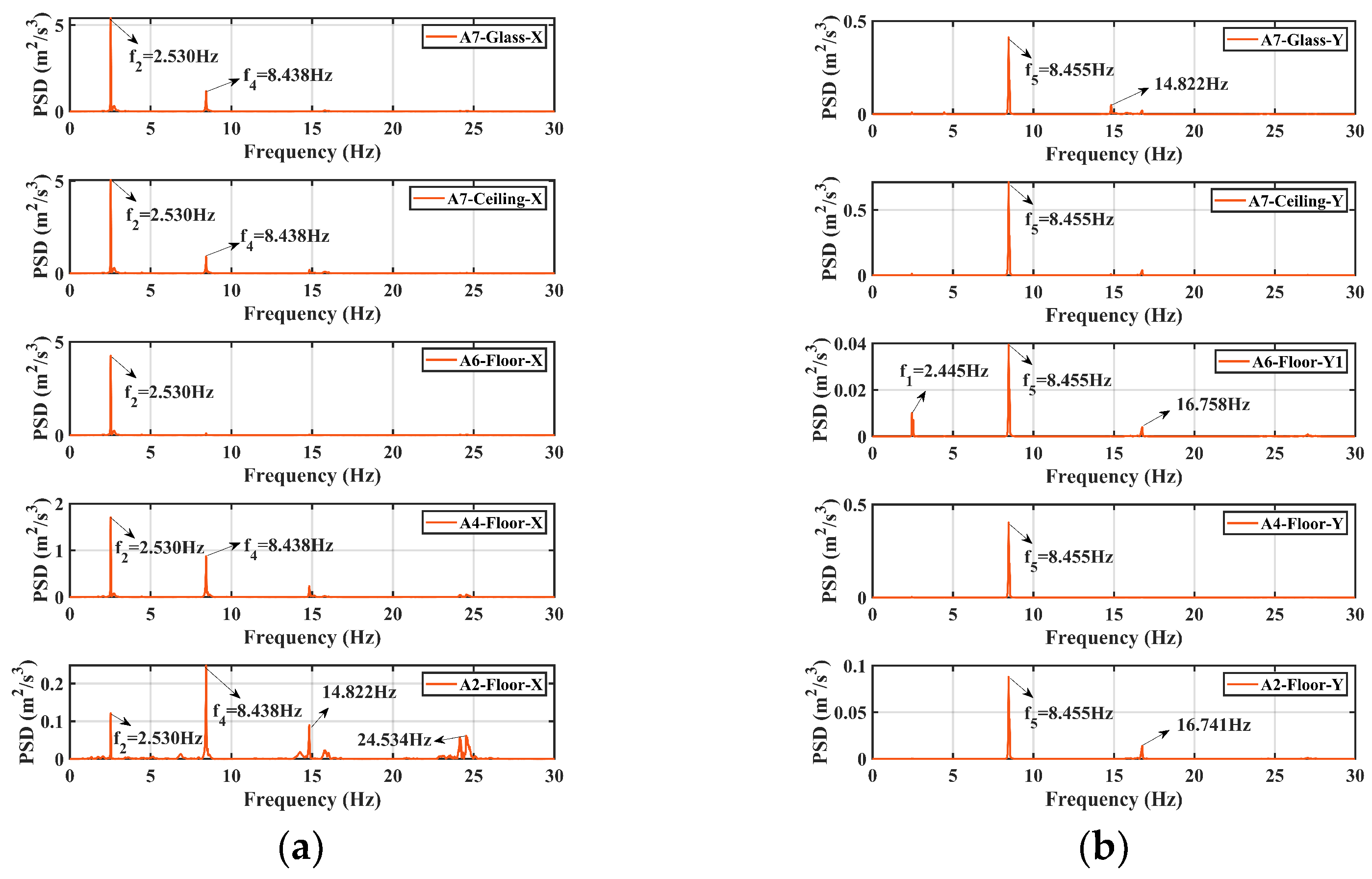

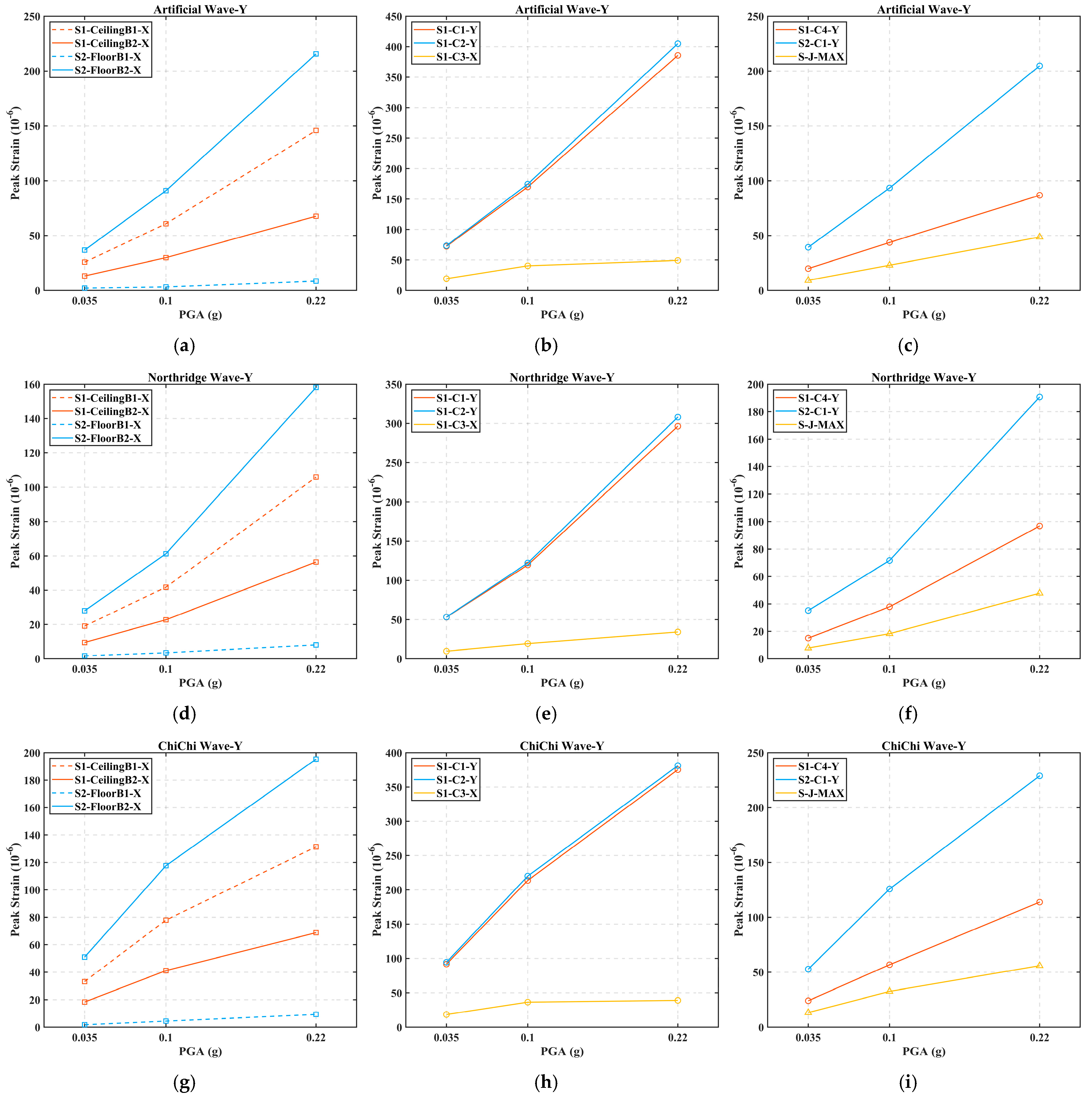

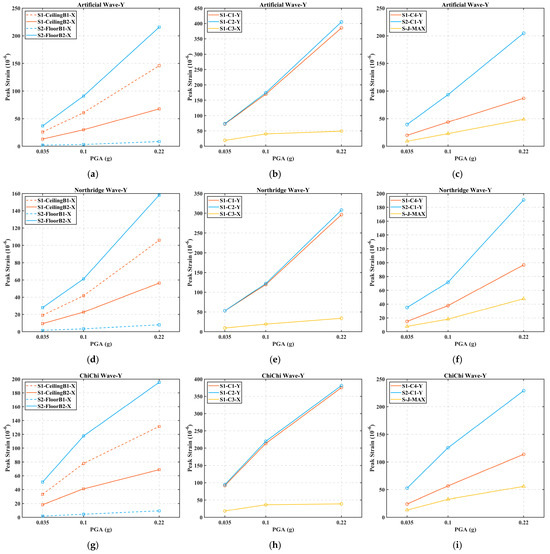

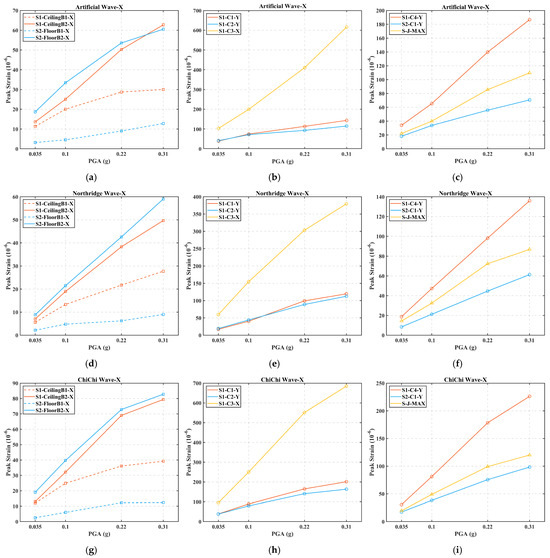

3.4. Strain Response

According to theoretical calculations [57], the yield strain of Q355B steel is 1690 × 10−6. In order to examine the strain responses of the structure under varying levels of seismic intensity, strain gauges are placed at key structural locations. The strain rosette (SR-Joint) in Figure 13b is employed to capture the maximum principal strain of the joint (S-J-MAX). Its formula is given in Equation (4):

where represents the principal strain, while , , and correspond to the strains captured using the strain gauges arranged at 0°, 45°, and 90°, respectively.

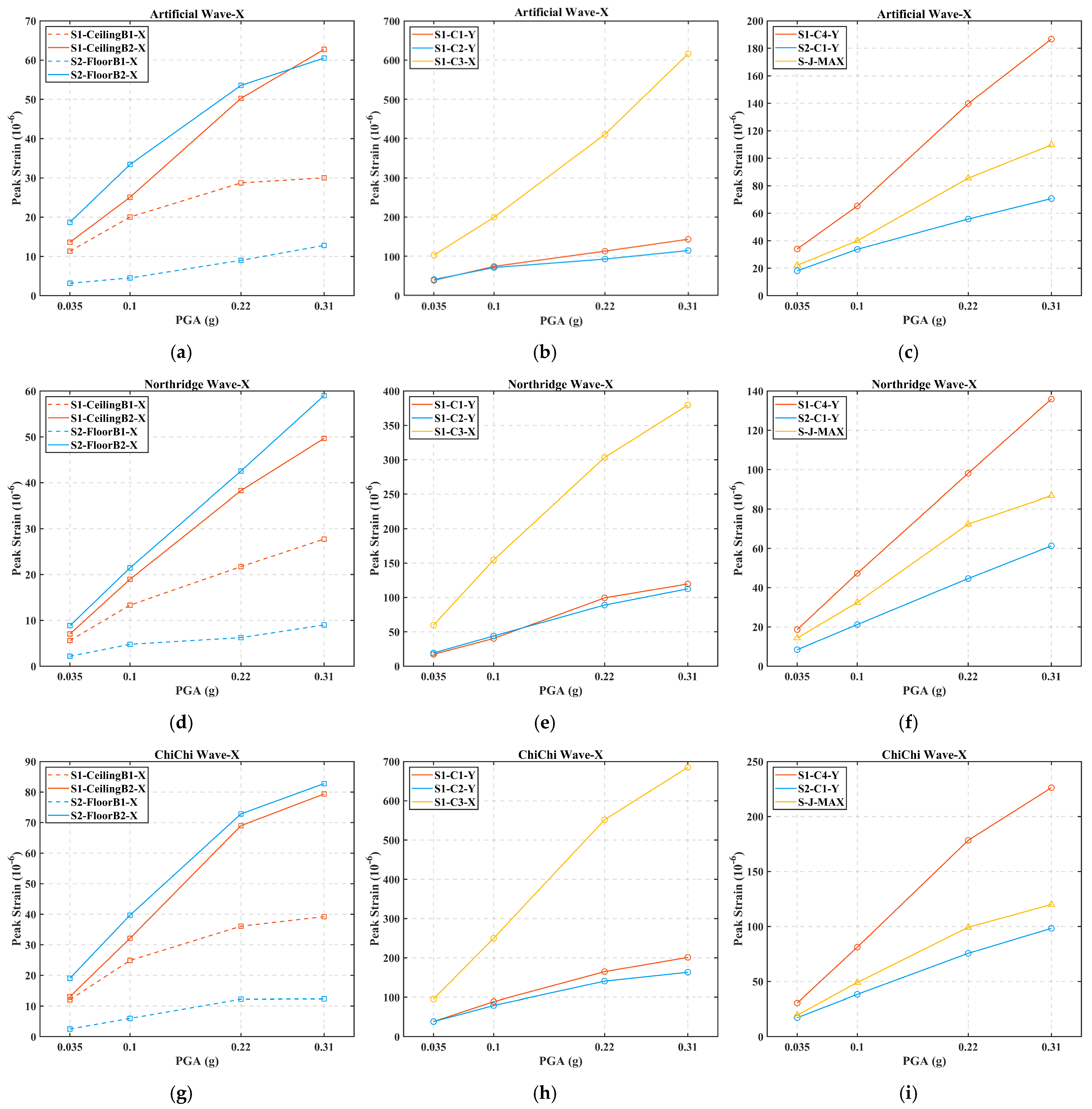

Figure 29 illustrates the peak strain responses under Y-directional seismic input. For the modular beams (Figure 29a,d,g), the strain responses under different seismic waves consistently follow the same pattern, i.e., S2-FloorB2-X > S1-CeilingB1-X > S1-CeilingB2-X > S2-FloorB1-X (see Section 2.4.2 and Figure 13 for the definition), whose arrangements are illustrated in Figure 13. Under the three different types of seismic waves, the peak strain values in the floor beams of the upper unit are all 50% higher than those in the ceiling beams of the lower modular unit. The observed disparity suggests that, in this double-beam system, the floor beam experiences significantly greater seismic loads compared to the ceiling beam right below it.

Figure 29.

Strain responses of the structure under Y-directional seismic inputs: (a) beam region under the artificial wave; (b) column region under the artificial wave; (c) joint region under the artificial wave; (d) beam region under the Northridge wave; (e) column region under the Northridge wave; (f) joint region under the Northridge wave; (g) beam region under the ChiChi wave; (h) column region under the ChiChi wave; (i) joint region under the ChiChi wave. Note that S1-CeilingB1-X stands for strain gauge no.1 on the ceiling beam of the 1st story in the X-direction; S1-C2-Y is for strain gauge no.2 on the column in the Y-direction.

Figure 29b,e,h present a comparison of the strain responses at the base of the edge (S1-C1-Y) and corner (S1-C2-Y) columns on the first story; the diagram of their arrangement is illustrated in Figure 13. Under varying seismic intensities, for S1-C1-Y and S1-C2-Y, the strain amplitudes and their variation trends are nearly consistent, revealing that the corner and edge columns exhibit good structural coordination in load resistance. The strain response at S1-C3-X is significantly smaller because it is oriented in the X-direction, which is perpendicular to the Y-directional seismic input.

Figure 29c,f,i present the strain responses in the connection region, where the strain at the connection plate (Figure 4) is the smallest, demonstrating the safety and reliability of the joint connection.

Figure 30 illustrates the peak strain responses under X-directional seismic input. Figure 29 and Figure 30 indicate that the structural strain response increases with the intensity of the seismic loading. The comparison between these two figures reveals that the input direction of the seismic wave significantly affects the strain responses of the beam and column components. This finding highlights the advantage of using box-shaped sections in modular steel buildings. These sections can resist loads more effectively from all input directions and reduce the risk of damage due to stiffness irregularities.

Figure 30.

Strain responses of the structure under X-directional seismic inputs: (a) beam region under the artificial wave; (b) column region under the artificial wave; (c) joint region under the artificial wave; (d) beam region under the Northridge wave; (e) column region under the Northridge wave; (f) joint region under the Northridge wave; (g) beam region under the ChiChi wave; (h) column region under the ChiChi wave; (i) joint region under the ChiChi wave. Note that S1-CeilingB1-X stands for strain gauge no.1 on the ceiling beam of the 1st story in the X-direction; S1-C2-Y is for strain gauge no.2 on the column in the Y-direction.

Among all tests, the largest strain response in the double-beam region occurred at S2-FloorB2-X is 216 × 10−6 (i.e., 45 MPa), while the largest strain response at the base of the first story column occurred at S1-C3-X is 685 × 10−6 (i.e., 144 MPa) and the largest strain response in the joint region is 229 × 10−6 (i.e., 48 MPa). All measured strain values are lower than the yield strain (1690 × 10−6). Furthermore, the structure is thoroughly inspected after each seismic excitation. No yielding deformation is observed, indicating that it remains in an elastic state.

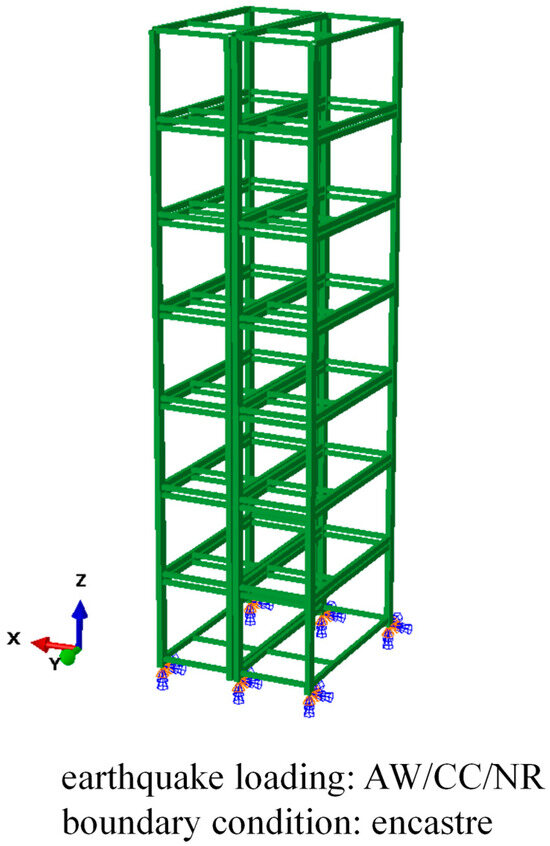

4. Finite Element Model Validation

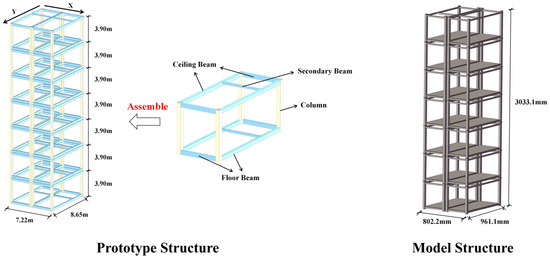

4.1. Finite Element Modeling

The global finite element model of the prototype in ABAQUS is shown in Figure 31. A global seed size is set for the entire model. The number of elements is 1050. Local seeds are applied in the connections to refine the mesh, and it is ensured that there are at least two mesh layers along the thickness direction. The beams and columns are simulated by beam unit B31. A global seed size is set for the entire model. The floor slabs are considered as additional mass. The inter-module connections are modeled using the simplified approach proposed in reference [45]. The elastic modulus of Q355B is defined as 210 GPa, with a Poisson’s ratio of 0.3. Its plastic behavior is defined using a broken line stress–strain constitutive model.

Figure 31.

Finite element model.

All bottom column bases in the finite element model are rigidly connected to the ground. The original seismic waves listed in Table 15 and Figure 18 are selected as the input. Their profiles are scaled with PGAs adjusted to 0.22 g and 0.31 g particularly for examining dynamic responses under MCE7 and MCE7.5 conditions. The time integration scheme is Newton–Raphson iteration in ABAQUS dynamic implicit analysis.

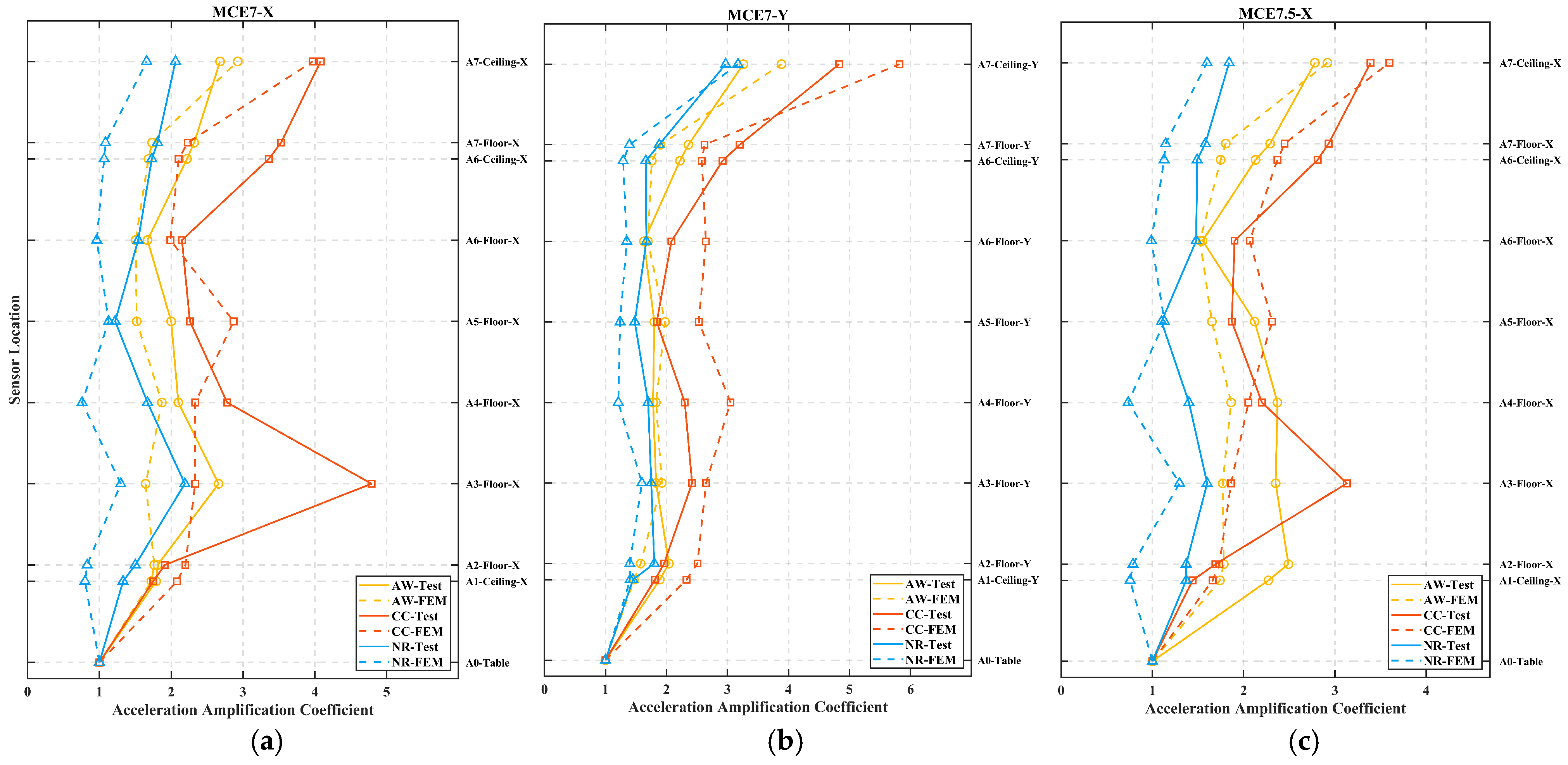

4.2. Comparison of Acceleration Response: Tests vs. FEM

The AAC values (Equation (3)) obtained from both the tests and the FEM simulation are plotted together for comparison, as shown in Figure 32. The FEM results effectively validate the reliability of the test results. On one hand, the AAC curves obtained from the tests closely align with those from the FEM simulations, exhibiting similar increasing trends. On the other hand, the errors at the altitude, A7-Ceiling-X, are as small as about 10%, demonstrating that the experimental study is successful.

Figure 32.

Comparison of the AACs between the tests and the finite element model: (a) MCE7-X; (b) MCE7-Y; (c) MCE7.5-X. (CC: ChiChi; NR: Northridge; AW: artificial wave).

Furthermore, consistent with the findings presented in Section 3.2, neither are the FEM AAC curves strictly monotonic. In certain scenarios, a pronounced acceleration response does exist at the mid-to-lower floors. For example, under the MCE7-X Northridge wave, the lower-level sensor A3-Floor-X records the second highest acceleration. Similarly, under the MCE7.5-X artificial wave, the mid-level sensor A4-Floor-X also exhibits the highest acceleration, only secondary to the top ceiling.

5. Conclusions

This study carries out shaking table tests on a seven-story modular steel building. It examines the dynamic amplification effect of modular steel structures, compares the acceleration responses of the glass curtain wall and the main structure, and analyzes the strain amplitudes and variation trends of the steel components. As these aspects have been insufficiently discussed in previous studies, this research fills that gap. The findings of this study provide valuable references for the engineering design and practical application of modular steel buildings. The main conclusions are as follows.

- (1)

- The ambient vibration test, hammer test, and white noise test are all able to identify the natural frequencies of the structure, with discrepancies of less than 1.0%. The natural frequency decreases progressively with the intensity of seismic waves, especially earthquakes of MCE7 intensity or higher. The lower-order natural frequencies (f1 and f2) decrease by approximately 3.7%, while the higher-order natural frequencies (f4 and f5) decrease by about 1.9%. Thus, the structure has experienced a stiffness degradation, with the degradation rate in both principal directions being approximately 7.3%.

- (2)

- However, the strain values of all types of structural members remain below the yield strain, and the whole building is still in the elastic state. In the double-beam system, the floor beams bear approximately 50% greater seismic loads compared to the ceiling beams below them. The corner and edge columns exhibit good structural coordination in load resistance, because their strain amplitudes and variation trends are nearly consistent.

- (3)

- In the global sense, the AACs exhibit an overall increasing trend with altitudes. However, this trend is not strictly monotonic, as certain upper locations exhibit smaller AAC values than the lower locations. S-shape amplification curves are observed under certain conditions. This phenomenon is also validated in the finite element simulations. In addition, the acceleration responses of the lower stories contain more modal components, while the acceleration responses of the upper stories are primarily governed by lower-order modes (f1 or f2). In the orthogonal direction across all stories, the responses are dominated by higher-order modes (f4 or f5).

- (4)

- In terms of the local response of glass curtain walls, as the seismic intensity increases, the AACs become more pronounced. This suggests that the glass curtain walls are more susceptible to intense vibration than the main structure. Even out-of-plane excitation can induce significant in-plane responses. Although the glass curtain walls inherently have high natural frequencies, their dynamic responses are dominated by the main structure.

The following recommendations for engineering applications of modular steel buildings can also be drawn.

- (a)

- On one hand, modular steel buildings exhibit relatively large PSA values. In design, it is advisable to consider adding lateral force-resisting members [33] or energy dissipation devices [29,43] to reduce the PSA. On the other hand, when applied to modular steel buildings, existing codes tend to underestimate the acceleration amplification effect (Section 3.2, about 9.3–23.2%). Additionally, the acceleration responses in the mid-to-lower stories of the structure also warrant attention.

- (b)

- Compared to the main steel frame, the glass curtain walls exhibit higher PSA values under strong seismic waves, posing a higher safety risk.

- (c)

- The structural seismic response is sensitive to the direction of input. For example, when the structure is excited by MCE7-CC but in different directions (X and Y), the measured strain data at gauge S1-C3-X vary by more than one order of magnitude. Therefore, it is recommended to use box-shaped sections in the design of modular steel structures.

Nevertheless, this study still has certain limitations, and further investigations are needed in the future. It would be highly beneficial to investigate modular buildings with varying numbers of stories and their response to stronger seismic excitations [58]. Inter-story drift angle and roof displacement are also important seismic performance indicators that deserve investigation in future studies.

Author Contributions

Conceptualization, Y.N. and X.Z.; methodology, X.Y.Z. and Y.N.; software, Y.N. and X.Y.Z.; validation, Y.N.; formal analysis, Y.N.; investigation, X.X., K.Q., Y.L. and Z.Z.; resources, X.Y.Z., X.Z., W.X. and Z.Z.; data curation, Y.N. and X.X.; writing—original draft preparation, Y.N.; writing—review and editing, X.Y.Z. and X.Z.; supervision, X.Y.Z. and Y.N.; project administration, Y.N., K.Q. and Y.L.; funding acquisition, X.Y.Z., X.Z., W.X. and Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China Construction Science and Industry Corporation Ltd., Guangzhou Science and Technology Program (Grant No. 2024B03J1389), and the Science and Technology Project of Guangzhou Municipal Construction Co., Ltd. (item No. 2023-KJ033).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge the Engineering Structure Laboratory at Harbin Institute of Technology, Shenzhen, for providing the experimental site and equipment.

Conflicts of Interest

Author Xinxin Zhang was employed by the China Construction Science and Industry Corporation Ltd. Authors Zhan Zhao and Wenjun Xu were employed by the Guangzhou Institute of Building Science Co., Ltd. Author Wenjun Xu was employed by the Guangzhou Testing Center of Construction Quality and Safety Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Dai, X.M. Research on Seismic Behavior and Design Method of Self-Lock Plug-in Joints in Modular Steel Construction. Ph.D. Thesis, Tianjin University, Tianjin, China, 21 May 2019. [Google Scholar]

- Deng, E.F.; Zong, L.; Ding, Y.; Zhang, Z.; Zhang, J.F.; Shi, F.W.; Cai, L.M.; Gao, S.C. Seismic performance of mid-to-high rise modular steel construction—A critical review. Thin-Walled Struct. 2020, 155, 106924. [Google Scholar] [CrossRef]

- Ding, Y.; Deng, E.F.; Zong, L.; Dai, X.M.; Li, Y.M.; Wang, H.P.; Bi, J.X. State-of-the-art on connection in modular steel construction. J. Build. Struct. 2019, 40, 33–40. [Google Scholar]

- Yang, C.; Wang, S.; Wang, X.; Zhao, B.; Wang, Q.; Ou, J. Seismic behavior of full-scale T-shaped joints connected by through-tie rod in MIC. J. Constr. Steel Res. 2022, 197, 107498. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Zhang, Z.; Wu, W. Experimental study on seismic cyclic behavior of an innovative blind bolted connection joint between modules in modular steel frame. Structures 2023, 52, 158–174. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Chang, H.; Ma, R.; Zhang, L. A comprehensive experimental-numerical investigation on the bending response of laminated double channel beams in modular buildings. Eng. Struct. 2019, 200, 109737. [Google Scholar] [CrossRef]

- Xu, B.; Xia, J.; Chang, H.; Ma, R.; Zhang, L. Flexural behaviour of pairs of laminated unequal channel beams with different interfacial connections in corner-supported modular steel buildings. Thin-Walled Struct. 2020, 154, 106792. [Google Scholar] [CrossRef]

- Ding, Y.; Deng, E.F.; Zong, L.; Dai, X.M.; Lou, N.; Chen, Y. Cyclic tests on corrugated steel plate shear walls with openings in modularized constructions. J. Constr. Steel Res. 2017, 138, 675–691. [Google Scholar] [CrossRef]

- Deng, E.F.; Zong, L.; Wang, H.P.; Shi, F.W.; Ding, Y. High efficiency analysis model for corrugated steel plate shear walls in modular steel construction. Thin-Walled Struct. 2020, 156, 106963. [Google Scholar] [CrossRef]

- Hou, J.; Wang, X.; Liu, J.; Chen, Z.; Zhong, X. Study on the stability bearing capacity of multi-column wall in modular steel building. Eng. Struct. 2020, 214, 110648. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, W. A hybrid coupled wall system with replaceable steel coupling beams for high-rise modular buildings. J. Build. Eng. 2020, 31, 101355. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Seismic overstrength in braced frames of modular steel buildings. J. Earthq. Eng. 2008, 13, 1–21. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Experimental evaluation of the seismic performance of modular steel-braced frames. Eng. Struct. 2009, 31, 1435–1446. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Seismic vulnerability assessment of modular steel buildings. J. Earthq. Eng. 2009, 13, 1065–1088. [Google Scholar] [CrossRef]

- Hong, S.G.; Cho, B.H.; Chung, K.S.; Moon, J.H. Behavior of framed modular building system with double skin steel panels. J. Constr. Steel Res. 2011, 67, 936–946. [Google Scholar] [CrossRef]

- Fathieh, A.; Mercan, O. Three-Dimensional, Nonlinear, Dynamic Analysis of Modular Steel Buildings. In Structures Congress; ASCE: Boston, MA, USA, 2014. [Google Scholar]

- Fathieh, A.; Mercan, O. Seismic evaluation of modular steel buildings. Eng. Struct. 2016, 122, 83–92. [Google Scholar] [CrossRef]

- Landolfo, R.; Iuorio, O.; Fiorino, L. Experimental seismic performance evaluation of modular lightweight steel buildings within the ELISSA project. Earthq. Eng. Struct. Dyn. 2018, 47, 2921–2943. [Google Scholar] [CrossRef]

- Jing, J.; Clifton, G.C.; Roy, K.; Lim, J.B. Three-storey modular steel building with a novel slider device: Shake table tests on a scaled down model and numerical investigation. Thin-Walled Struct. 2020, 155, 106932. [Google Scholar] [CrossRef]

- Jing, J.; Clifton, G.C.; Roy, K.; Lim, J.B. Performance of a novel slider device in multi-storey cold-formed steel modular buildings under seismic loading. Structures 2020, 27, 212–246. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Liu, Y.; Bai, Y.; Zhong, X. Full-scale corner-supported modular steel structures with vertical inter-module connections under cyclic loading. J. Build. Eng. 2021, 44, 103269. [Google Scholar] [CrossRef]

- Sanches, R.; Tao, J.; Fathieh, A.; Mercan, O. Investigation of the seismic performance of braced low-, mid- and high-rise modular steel building prototypes. Eng. Struct. 2021, 234, 111986. [Google Scholar] [CrossRef]

- Zhai, X.; Zha, X.; Wang, K.; Wang, K.; Wang, H. Shake table tests of a full-scale two-story plate-type modular composite building with semi-rigid corner connections. Eng. Struct. 2023, 289, 116325. [Google Scholar] [CrossRef]

- Zhai, X.; Zha, X.; Chen, D. Shaking table tests on 0.5-scale multistory models of plate-type modular steel and composite buildings with semi-rigid corner connections. Thin-Walled Struct. 2023, 188, 110833. [Google Scholar] [CrossRef]

- Wang, C.; Chan, T.M. Seismic design and parametric study of steel modular frames with distributed seismic resistance. Thin-Walled Struct. 2023, 182, 110325. [Google Scholar] [CrossRef]

- Zhang, X.; Nie, Y.; Qian, K.; Xie, X.; Zhao, M.; Zhao, Z.; Zheng, X.Y. Experimental investigation of the seismic behavior of a multi-story steel modular building using shaking table tests. Buildings 2025, 15, 2661. [Google Scholar] [CrossRef]

- Ye, Z.; Bu, H.; Liu, Z.; Lu, D.; Min, D.; Shan, H. Seismic resilience design of prefabricated modular pressurized buildings. Resilient Cities Struct. 2025, 4, 53–70. [Google Scholar] [CrossRef]

- Mata, R.; Nuñez, E.; Forcellini, D. Seismic resilience of composite moment frame buildings with slender built-up columns. J. Build. Eng. 2025, 111, 113532. [Google Scholar] [CrossRef]

- Mo, Z.; Lai, B.; Shu, G.; Yang, T.Y.; Ventura, C.E.; Liew, J.R. Enhancing seismic resilience in modular steel buildings through three-dimensional isolation. Eng. Struct. 2025, 323, 119269. [Google Scholar] [CrossRef]

- Zhou, X.; Yao, X.; Xu, L.; Shi, Y.; Ke, K.; Liu, L. Shake table tests on a full-scale six-storey cold-formed thin-walled steel-steel plate shear wall structure. Thin-Walled Struct. 2022, 181, 110009. [Google Scholar] [CrossRef]

- Wu, F.W.; Li, Y.Q. Large-scale shaking table tests of a six-story floor-by-floor assembled CFS frame-framing shear wall structure. Eng. Struct. 2023, 293, 116608. [Google Scholar] [CrossRef]

- Feng, L.Q.; Li, F.; Niu, C.L.; Wei, H.L.; Ji, S.Y.; Yang, P.; Wang, G.J. Design and shaking table test of a ten-storey building with steel plate shear walls partially connected to columns. J. Build. Eng. 2022, 49, 103982. [Google Scholar] [CrossRef]

- SJG 129-2023; Technical Specification for Steel Modular Buildings. Housing and Construction Bureau of Shenzhen Municipality: Shenzhen, China, 2023.

- GB 50017-2017; Standard for Design of Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017.

- GB 50009-2012; Load Code for the Design of Building Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- GB/T 50018-2025; Technical Standard of Cold-Formed Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2025.

- GB 50352-2019; Code for Design of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Chi, S.C.; Lin, S.S. Validation of Similitude Laws for Dynamic Structural Model Test. World Earthq. Eng. 2004, 20, 10. [Google Scholar]

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- Bakarji, J.; Callaham, J.; Brunton, S.L.; Kutz, J.N. Dimensionally consistent learning with Buckingham Pi. Nat. Comput. Sci. 2022, 2, 834–844. [Google Scholar] [CrossRef]

- Li, Z.Y. Shaking Table Test and Finite Element Optimization of Steel Frame Bent Structure with Buckling Restrained Brace. Master’s Thesis, Beijing University of Technology, Beijing, China, 22 June 2022. [Google Scholar]

- He, H.Q. Shaking Table Test and Simulation Analysis of High-Rise Steel Frame-Steel Plate Shear Wall Structure. Master’s Thesis, Chongqing University, Chongqing, China, 24 May 2021. [Google Scholar]

- Liu, L. Research on TMD Vibration Reduction and Vibration Table Test of High-Rise Structure. Master’s Thesis, Guangzhou University, Guangzhou, China, May 2019. [Google Scholar]

- Shi, F.; Wang, H.; Zong, L.; Ding, Y.; Su, J. Seismic behavior of high-rise modular steel constructions with various module layouts. J. Build. Eng. 2020, 31, 101396. [Google Scholar] [CrossRef]

- Yang, C.; Ou, J. Buckling Restrained Brace Steel Frame Modular Assembly Structure and Its Seismic Performance Analysis. J. Disaster Prev. Mitig. 2021, 41, 917–927+953. [Google Scholar]

- Wu, B.; Zhang, Y.; Zhang, A.; Wang, X.; Wang, N. RSF-SIFS limit state study and quantitative parametric analysis of miniature rubber bearings. Structures 2025, 76, 108955. [Google Scholar] [CrossRef]

- JGJ 102-2003; Technical Code for Glass Curtain Wall Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2003.

- GB/T 14683-2017; Silicone and Modified Silicone Sealants for Building. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; China National Standardization Administration: Beijing, China, 2017.

- GB 50011-2010; Code for Seismic Design of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- GB 50981-2014; Code for Seismic Design of Mechanical and Electrical Equipment. Ministry of Housing and Urban-Rural Development of the People’s Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2014.

- JGJ 339-2015; Code for Seismic Design of Non-Structural Components. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- ASCE/SEI 7-16; Minimum Design Loads for Buildings and Other Structures. American Society of Civil Engineers: Reston, VA, USA, 2016.

- Eurocode 8; Design of Structures for Earthquake Resistance–Part 1: General Rules, Seismic Actions and Rules for Buildings. Commission of the European Communities; European Committee for Standardization: Brussels, Belgium, 2004.

- Shang, Q.X.; Zheng, J.Y.; Li, J.C.; Wang, T. Comparative study of relevant specifications on peak floor acceleration in current codes of different countries. Eng. Mech. 2020, 37, 91–96. [Google Scholar]

- Huang, B.; Hua, X.; Lu, W.; Zhang, Q. Floor acceleration amplification factor in the instrumented buildings under historical earth-quake excitations. China. Civ. Eng. J. 2020, 53, 16–27. [Google Scholar]

- Wang, D.; Lu, X.; Liu, Z. Shaking table test and comparison analysis for base-isolated high-rise buildings with different aspect ratios. J. Vib. Shock 2015, 34, 109–118. [Google Scholar]

- Zhang, Y.X.; Wu, B.L.; Zhang, A.L.; Li, Y.L.; Zhang, H.; Xiao, C.Y. Shaking table test and structural dynamic analysis for resilient steel frames with seismically isolated floor under bi-directional seismic action. J. Build. Eng. 2025, 46, 30–50. [Google Scholar]

- Montuori, R.; Nastri, E.; Piluso, V. Theory of plastic mechanism control: A new approach for the optimization of seismic resistant steel frames. Earthquake Eng. Struct. Dyn. 2022, 51, 3598–3619. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).