Abstract

The increasing accumulation of mineral wool waste, especially from construction and demolition sources, presents a major environmental burden. This study investigates a scalable grinding enhancement strategy using bauxite and glass cullet additives to improve the comminution of glass wool, rock wool, and mixed mineral wool waste. Mechanical grinding assisted with the use of 10 wt% and 20 wt% of hard mineral additives reduced milling time by up to 50% compared to unmodified samples, with bauxite consistently outperforming glass cullet. Laser diffraction confirmed a marked reduction in particle size, reaching sub-50 µm targets essential for alkali activation, while SEM analysis revealed smoother, fractured surfaces conducive to improved geopolymer reactivity. Energy consumption estimates suggest substantial efficiency gains; however, upstream impacts such as additive production and transport warrant further evaluation. Compared to conventional thermal and chemical pretreatments, this abrasive-assisted approach demonstrates a lower-energy pathway for producing geopolymer-compatible powders. The findings also offer guidance for developing standardized protocols and open avenues for testing these powders in future binder formulations.

1. Introduction

The demolition of buildings generates one of the largest waste streams in the European Union, accounting for approximately 25–30% of the total annual waste produced [1,2]. Globally, construction and demolition waste (CDW) is estimated to reach around 1.3 billion tons per year [3]. A particularly challenging component of this waste is mineral wool, commonly used as thermal insulation material. According to recent estimates, approximately 2.54 million tons of mineral wool waste are generated annually [4], based on production data from the past three decades and assuming a 5% production loss rate [5].

Despite the scale of this problem, effective and industrially applicable recycling methods for mineral wool remain limited [6]. As a result, the majority of this waste continues to be landfilled, contributing to long-term environmental degradation. Existing literature has demonstrated some promising pathways for reuse. In ceramics, for example, mineral wool waste has been incorporated into ceramic masses without the need to remove phenol-formaldehyde binders [7]. Its relatively high sodium oxide (Na2O) content can lower sintering temperatures, thus improving energy efficiency during production [8]. Mechanically processed wool—typically reduced to 10–20 mm flakes—can also be used as a lightweight filler in ceramic foams, enhancing their thermal insulation performance [9,10].

Other applications include the use of mineral wool fibers as reinforcement in cement-based materials. Although some reduction in mechanical strength may occur, studies have shown good bonding between the fibers and the cement matrix, ensuring sufficient performance and durability [11]. Additionally, recycled mortars incorporating mineral wool have exhibited reduced thermal conductivity, decreased shrinkage, and increased flexural strength, even though they typically perform slightly below conventional mortars in terms of compressive strength [12]. Furthermore, mineral wool has been investigated as a supplementary cementitious material (SCM) or inert filler in cement composites [13], with studies indicating that incorporating 10–40% by weight of mineral wool can reduce porosity, refine microstructure, and improve resistance to chloride penetration [14]. These composites may also exhibit improved compressive strength when mineral wool is added [15].

More recently, researchers have turned their attention to the use of mineral wool residues as precursors for geopolymer synthesis. Geopolymers are alkali-activated aluminosilicate binders that offer a low-carbon alternative to Portland cement [16]. Although the concept of geopolymerization is not new [17], it has gained renewed interest as a response to the environmental impact of traditional cement production [18]. The Portland cement industry is responsible for a substantial share of global carbon emissions—estimated at 1.6 billion tons of CO2 annually at the beginning of the 21st century, which increased to 3.5 billion tons by 2013, accounting for approximately 8% of global emissions today [19,20].

Despite the potential for valorizing mineral wool in geopolymers, landfilling remains the dominant method of disposal, leading to significant environmental and logistical issues. The low mass-to-volume ratio of the waste results in unstable landfill structures, inefficient transport, and elevated CO2 emissions [21,22]. Moreover, certain reports categorize mineral wool waste as non-recyclable under current infrastructure and regulatory conditions [23]. The heterogeneity of post-consumer wool—often contaminated with plasterboard, gypsum, adhesives, or paint—poses a substantial barrier to efficient recycling [24,25,26,27]. This distinguishes it from relatively clean production waste more commonly studied in the literature and necessitates careful characterization and preprocessing steps [26].

For mineral wool to be used in geopolymerization, it must first be pulverized. Previous studies have employed disc mills or ball mills for this purpose, typically processing very small laboratory samples. For example, finnish research teams have tested 10 g samples [4], and similar grinding methods were employed in the Wool2Loop project [28]. However, none of these studies considered the effect of grinding additives to enhance milling efficiency, nor did they explore the implications for large-scale implementation or the energy footprint of the grinding process.

This research introduces an innovative approach by incorporating hard mineral additives—bauxite and glass cullet—into the grinding process of mineral wool. The central hypothesis is that these abrasives will accelerate the mechanical breakdown of mineral fibers during ball milling, thereby reducing energy consumption and process time.

The main objective of this study is to evaluate whether the addition of mineral abrasives improves the grinding efficiency of mineral wool waste, and to identify which additive—bauxite or cullet—is more effective in achieving the desired powder fineness within a shorter milling time. This work addresses key research gaps by (1) quantifying the milling time reduction; (2) analyzing particle morphology and size evolution; (3) discussing energy implications; and (4) proposing a methodology applicable for standardization. It also aims to highlight the differences in behavior between various types of mineral wool waste, especially when contaminated or obtained from demolition sources.

2. Materials and Methods

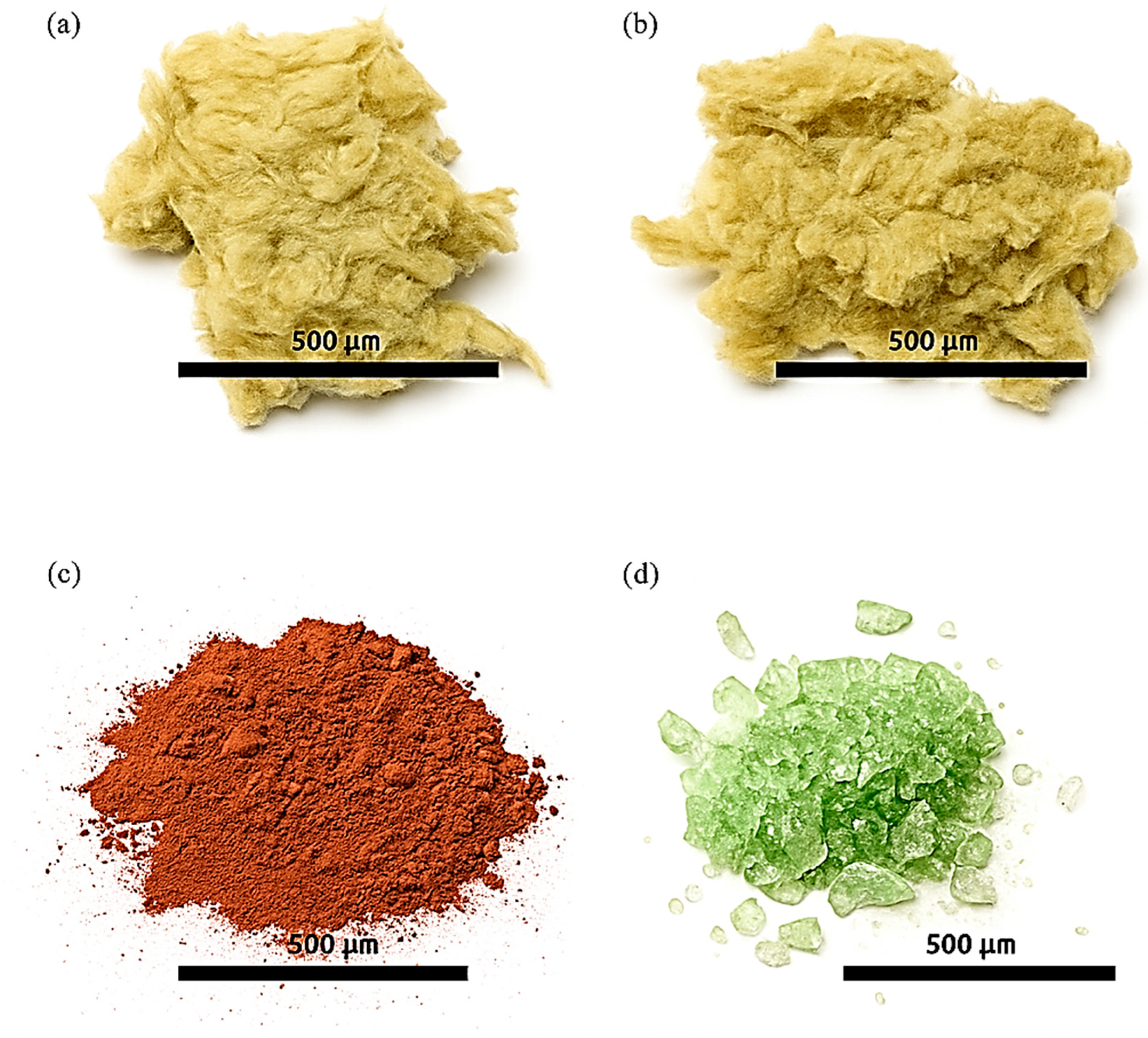

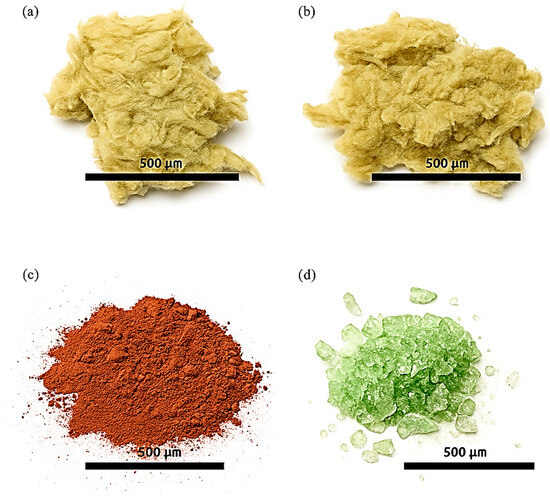

This study investigated the effect of hard mineral additives on the grinding efficiency of three types of mineral wool waste: glass wool (GW), rock wool (RW), and mixed wool (MW). All wool samples were obtained from post-consumer construction and demolition waste, and manually sorted to remove major contaminants. The shredded wool was pre-processed to a fraction below 10 mm using a rotary blade shredder. Initial morphological characteristics are presented in Figure 1.

Figure 1.

Used materials; (a) glass wool residue, (b) stone wool residue, (c) bauxite and (d) glass cullet.

Two types of hard mineral additives were selected: bauxite, an industrial alumina-rich abrasive with high hardness (Mohs ~8), and glass cullet, a widely available post-consumer aluminosilicate. These materials were chosen based on their chemical compatibility with geopolymer systems, high abrasion potential, and availability from waste streams. Their mechanical properties make them suitable for enhancing the comminution of fibrous waste materials. The chemical compositions of all raw inputs were determined using X-ray fluorescence (XRF) and are listed in Table 1.

Table 1.

Chosen milling time depending on the type of wool and powder additive.

The additives were separately pre-ground to <2 mm particle size before introduction into the blends. The role of these additives was to act as grinding aids, transferring abrasive force during milling and accelerating fiber fragmentation. Notably, bauxite has higher density and angularity than cullet, which is expected to enhance its abrasive effectiveness [4].

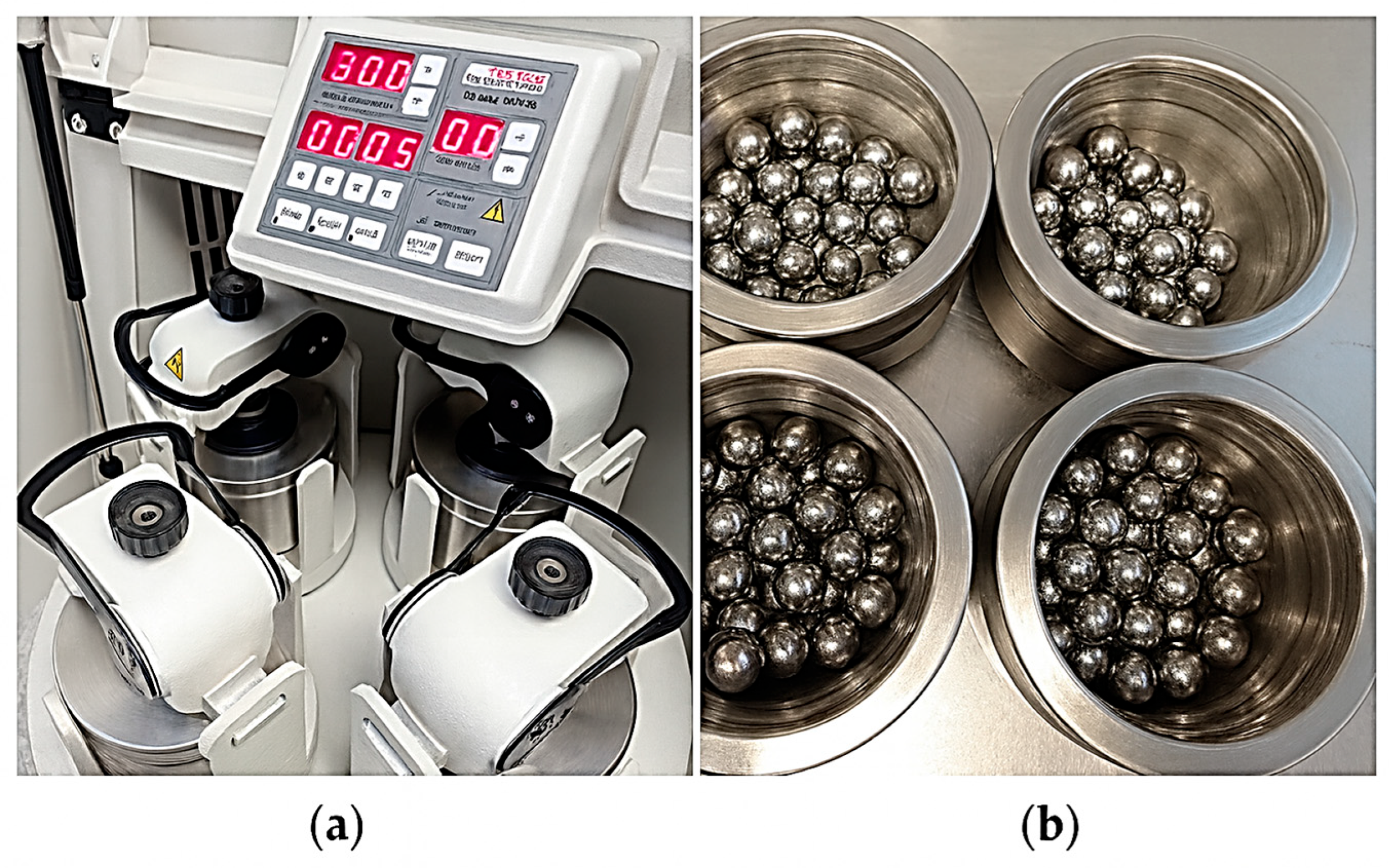

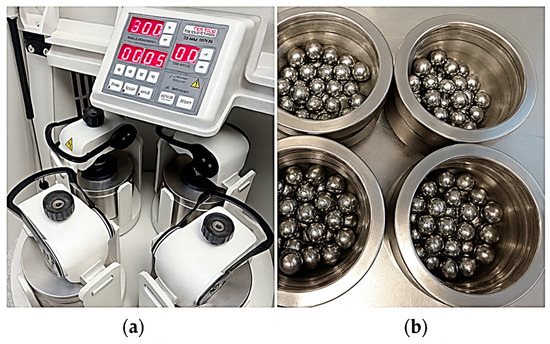

Each mineral wool type was milled in a TENCAN XQM-0.4A planetary ball mill (sourced from The Silesian University of Technology), using zirconia grinding jars and balls to avoid contamination. Batch size was fixed at 200 g. The additives were introduced at two concentration levels: 10 wt% and 20 wt%, based on preliminary trials and literature suggesting these ranges are sufficient to alter grinding dynamics without overwhelming the base material [6].

Milling was performed in 5 min intervals. After each cycle, a subsample was taken for analysis to monitor the evolution of grinding. The target criterion was to achieve a particle size mode < 50 µm, in line with geopolymer precursor requirements reported in earlier studies [4,8]. The complete experimental matrix is shown in Table 2, including all sample codes and additive concentrations.

Table 2.

Experimental Matrix.

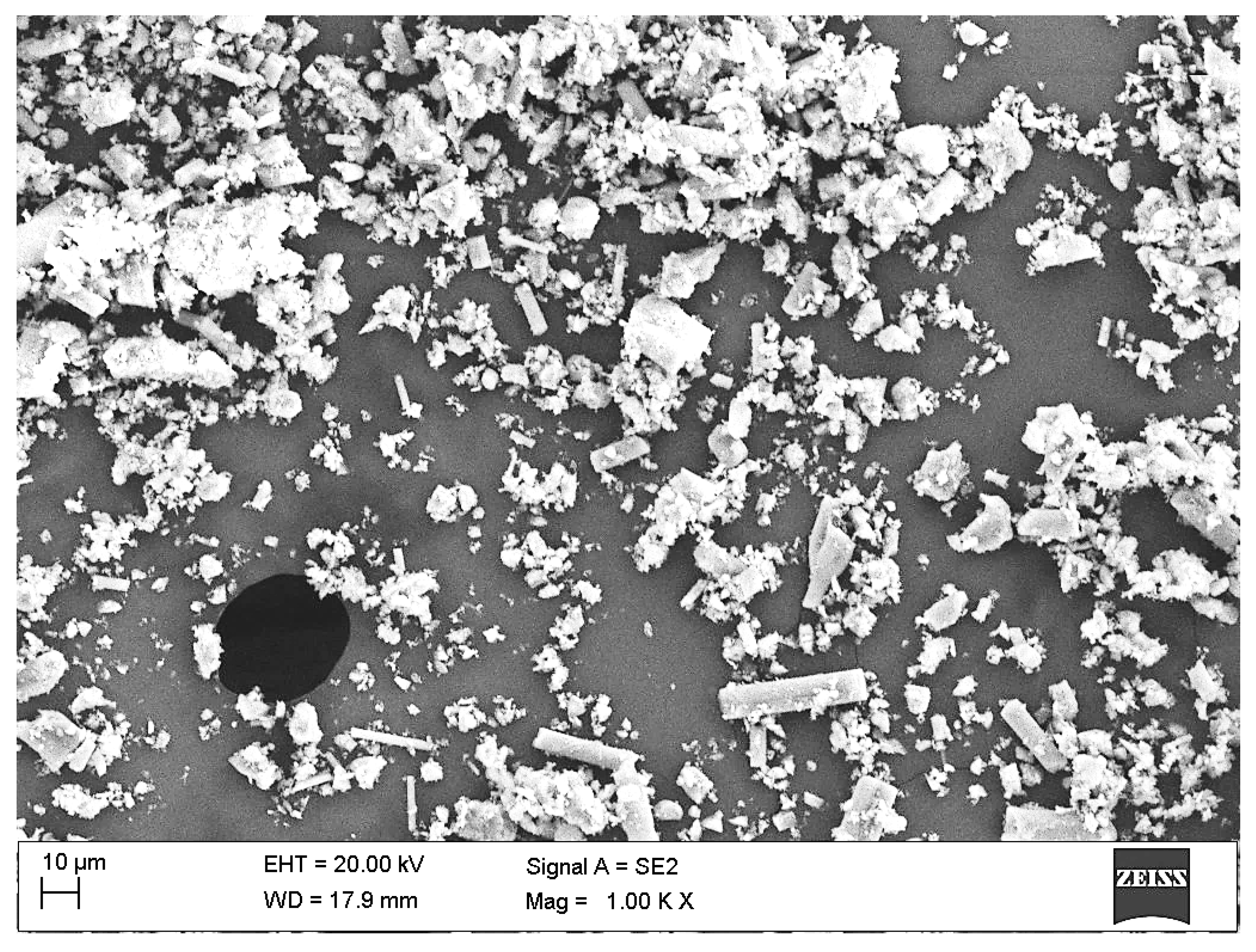

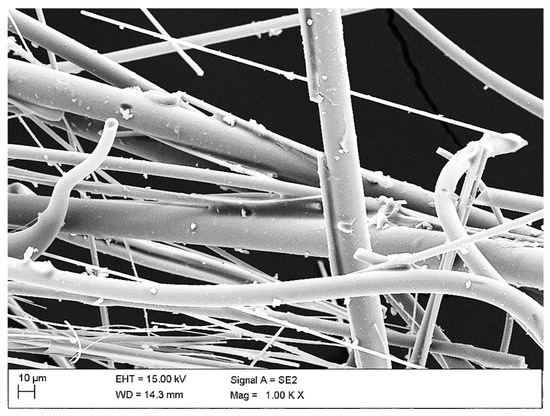

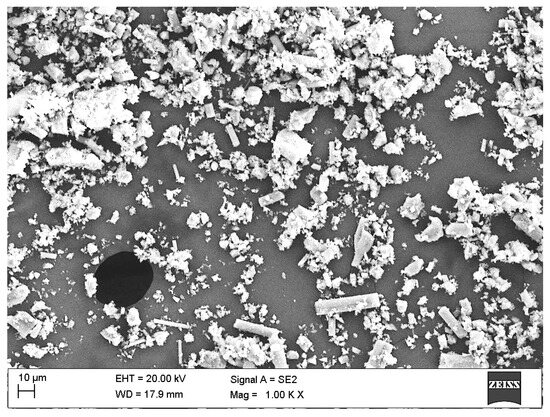

Particle size distribution was measured using laser diffraction (Malvern Mastersizer 3000, sourced from Sieć Badawcza Łukasiewicz—Instytut Ceramiki i Materiałów Budowlanych), tracking changes in D50, span, and mode after each interval. These parameters were chosen to quantify both the fragmentation efficiency and powder homogeneity. Selected samples were also analyzed via scanning electron microscopy (SEM) using a Zeiss EVO LS15 (sourced from Sieć Badawcza Łukasiewicz—Instytut Ceramiki i Materiałów Budowlanych) to visualize morphological changes in the fiber structure and surface features. Representative SEM images are shown in Figure 2.

Figure 2.

Overview of (a) the planetary ball mill used; (b) the containers filled with stainless steel grinders.

All tests were conducted at ambient laboratory conditions (22–24 °C, ~45% RH). Each test was performed in triplicate, and averaged to ensure repeatability. The methodology proposed in this study is not currently covered by standard protocols (e.g., ASTM, EN), and represents a novel experimental framework that could be further refined into standardized procedures for fibrous waste valorization [6].

3. Results

The results of the conducted experiments confirmed that the use of hard mineral additives significantly improves the grinding efficiency of mineral wool waste. The efficiency of the process was assessed based on three key indicators: total milling time required to achieve the target fineness, particle size distribution, and morphological changes observed in the material after grinding.

As shown in Table 2 and Table 3, the reference samples milled without additives exhibited the longest grinding durations. Rock wool required the highest energy input, reaching the target particle size mode below 50 µm only after 35 min of milling. Glass wool and mixed wool achieved the same particle size in 30 and 28 min, respectively. These values reflect the intrinsic differences in fiber composition and mechanical resistance among the tested wool types.

Table 3.

Grinding Results Summary.

The introduction of bauxite as a grinding additive resulted in a substantial reduction in the total milling time across all samples. In the case of rock wool, the addition of 10 wt% bauxite shortened the milling time by approximately 32%, while the 20 wt% concentration reduced it further to 17 min, representing a 51.4% decrease compared to the reference. For glass wool, milling time dropped from 30 min to 19 min with 20 wt% bauxite, and from 28 to 17 min for mixed wool. In contrast, glass cullet also contributed to reduced grinding times, but to a lesser extent. At 20 wt% cullet, the milling time for rock wool decreased to 23 min (34% reduction), and for glass and mixed wool to 22 and 21 min, respectively. All milling durations and corresponding D50 values are presented in Table 3.

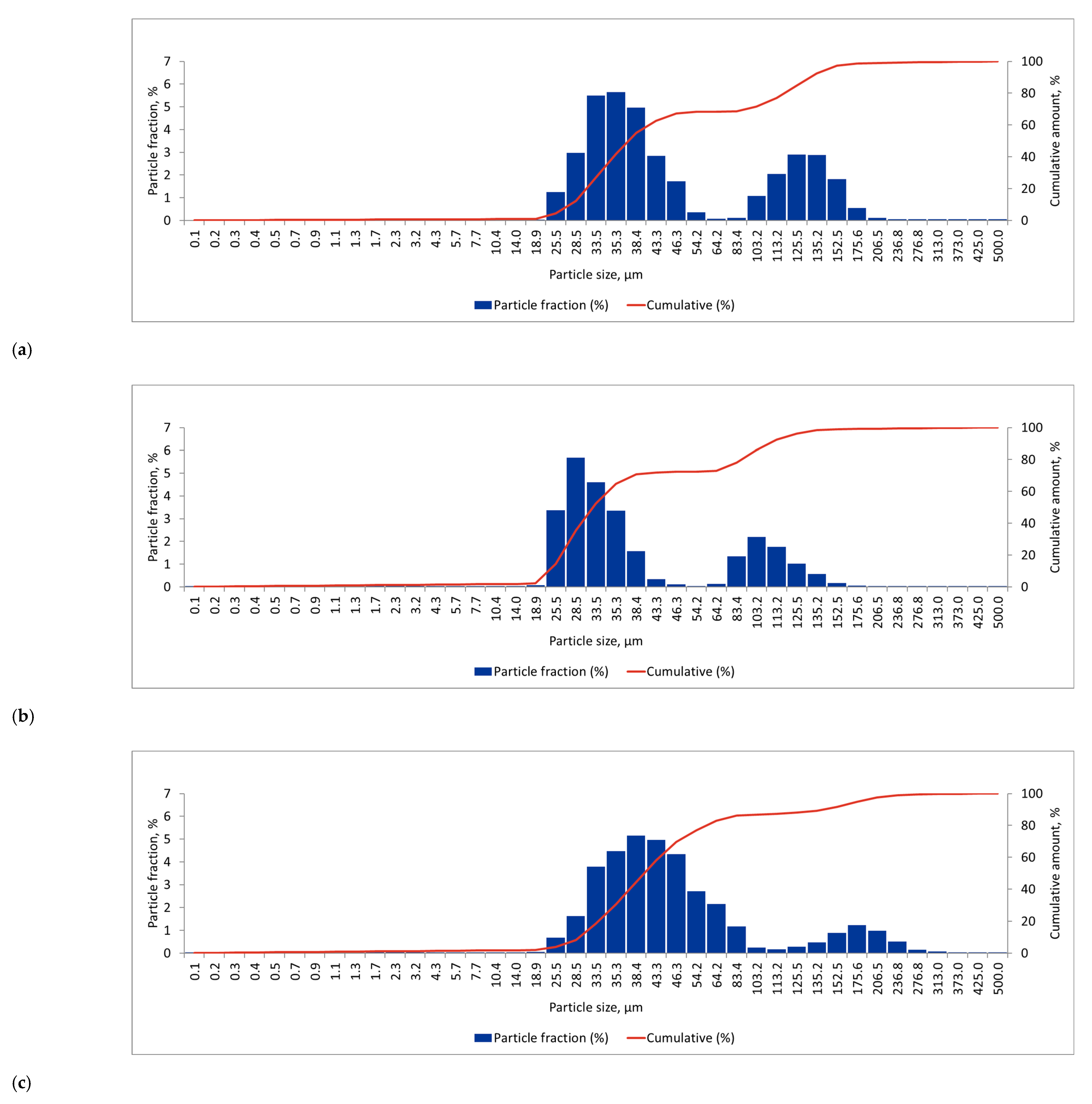

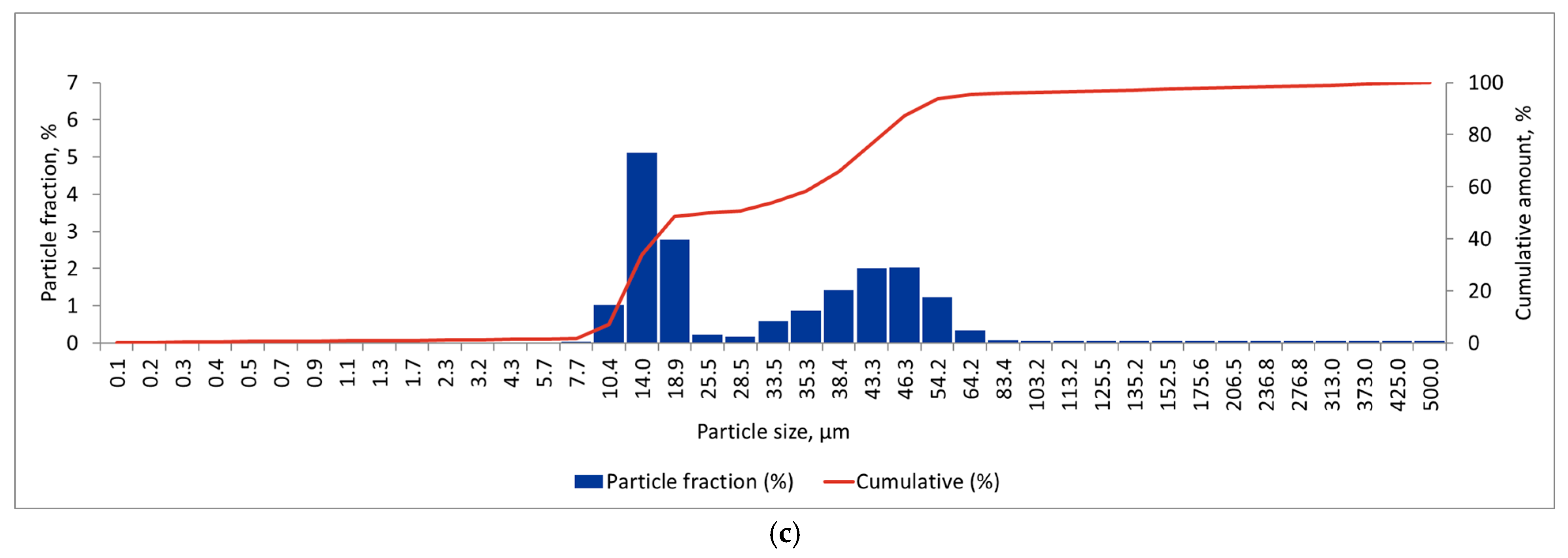

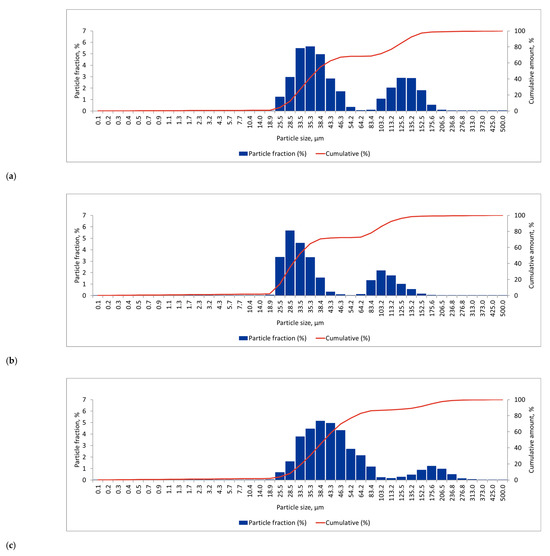

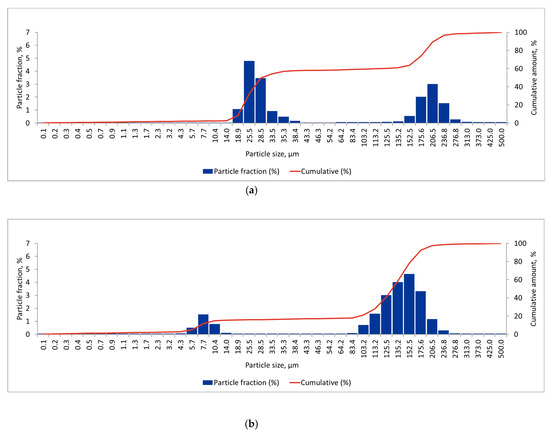

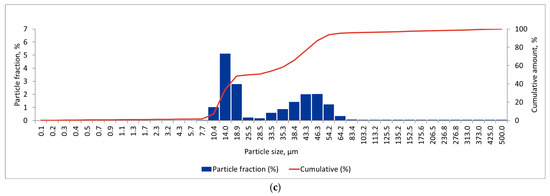

Laser diffraction analysis revealed significant changes in the particle size distributions, supporting the time-based observations. The addition of mineral abrasives accelerated the breakdown of the fibrous structure and led to a more homogenous powder with a narrower particle size range. As illustrated in Figure 3, the particle size distribution curves for bauxite-assisted samples shifted leftward more rapidly than those for cullet-assisted or reference samples. The median particle size (D50) for rock wool decreased from 31.7 µm in the reference sample to 18.4 µm with 20 wt% bauxite, and to 22.4 µm with 20 wt% cullet. Similar trends were observed for the other wool types, with bauxite always achieving finer particles and narrower span values.

Figure 3.

Effect of grinding glass wool for; (a) 0, (b) 5, (c) 15 and (d) 25 min.

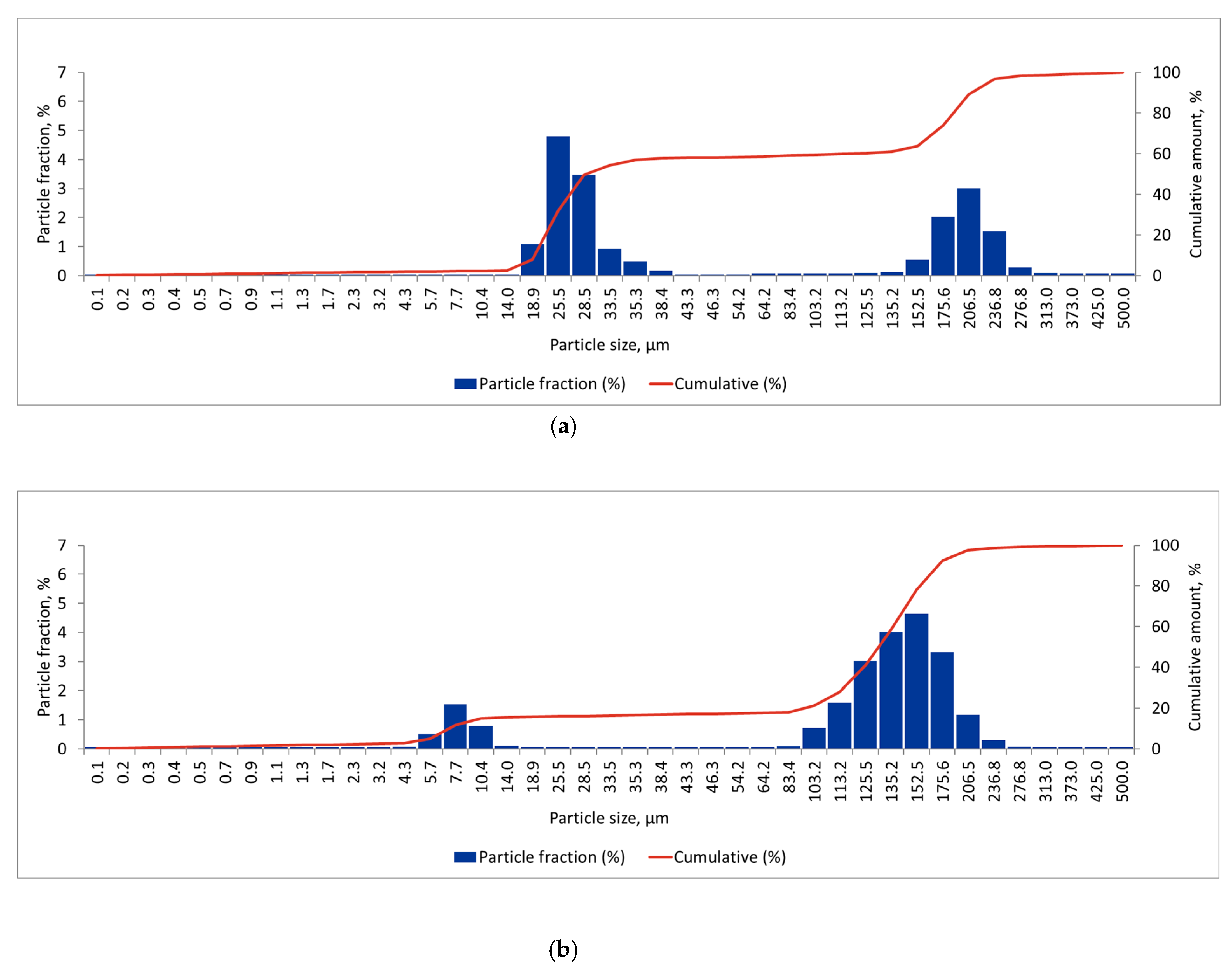

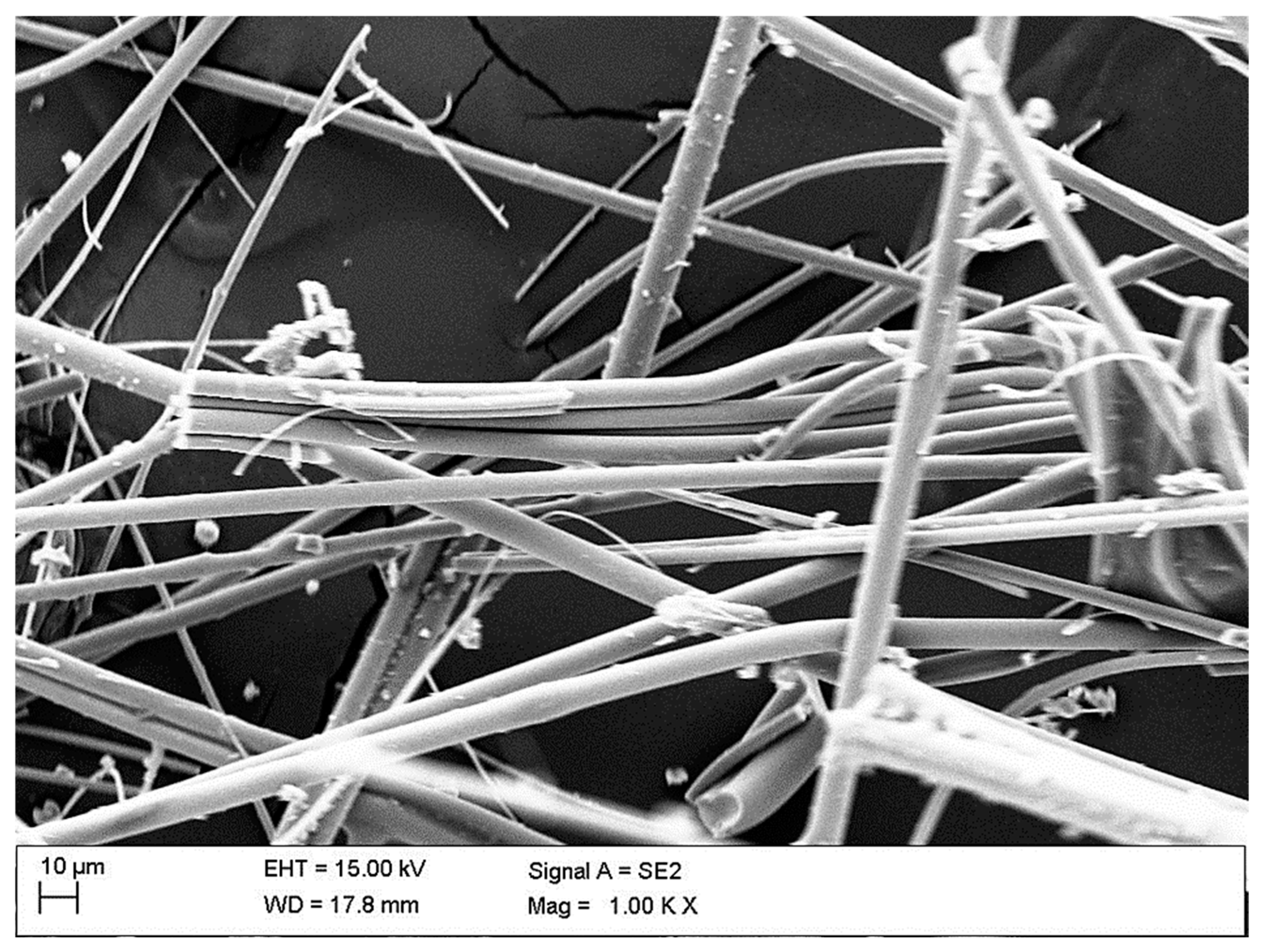

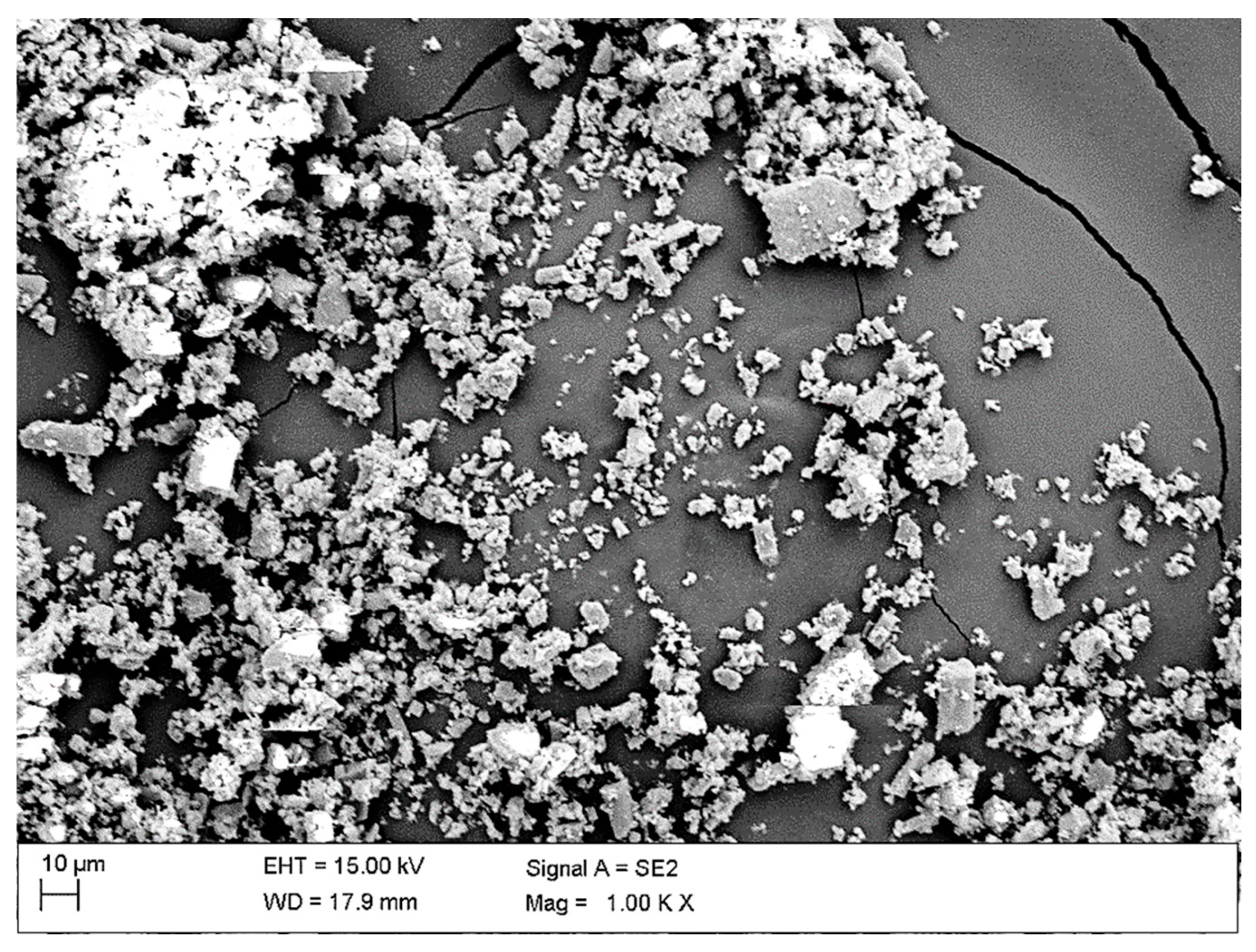

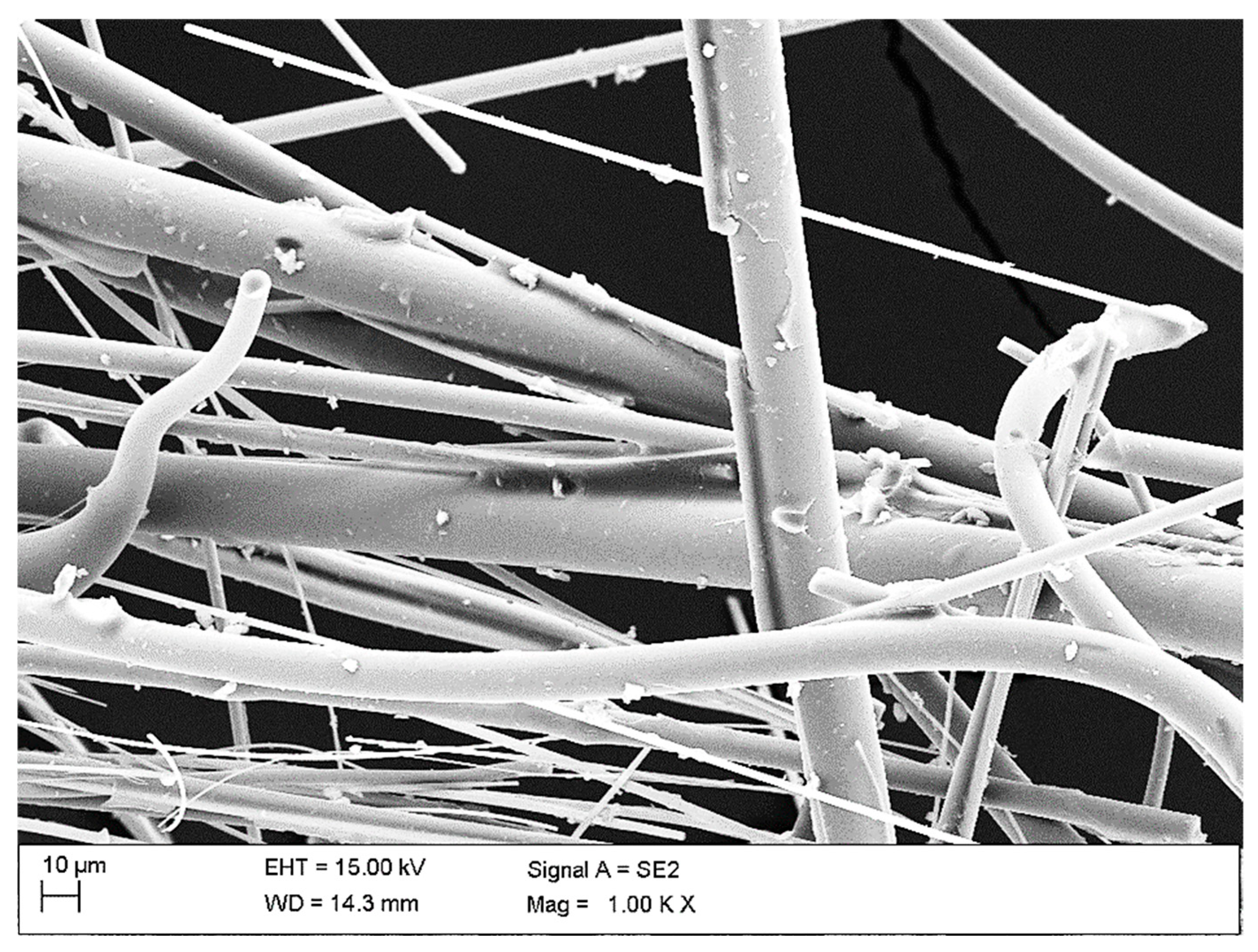

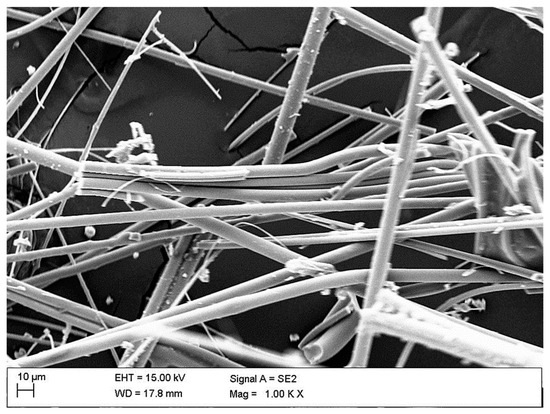

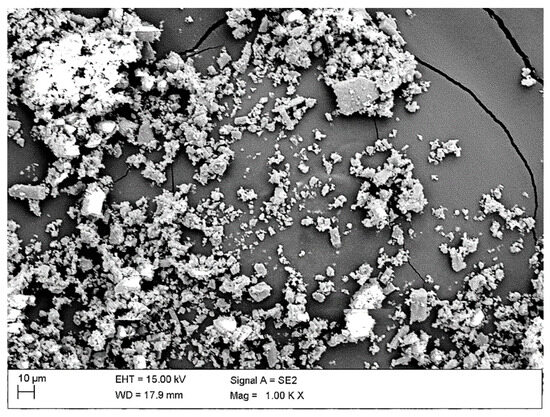

Morphological observations using scanning electron microscopy provided further evidence of structural disintegration. Figure 4 presents micrographs of all three wool types after grinding, showing the degree of fragmentation achieved with and without additives. In the reference samples, long, intertwined fibers remained present even after extended milling, particularly in rock wool, which retained its rigid, elongated morphology. In contrast, bauxite-assisted grinding resulted in short, highly fractured particles with irregular surfaces. These fragments exhibit greater surface area, which is favorable for subsequent alkali activation. In the case of cullet, fiber shortening was observed as well, but the fragmentation was less intense and more incomplete compared to bauxite.

Figure 4.

Effect of grinding stone wool for; (a) 0, (b) 5, (c) 15, (d) 25 min.

A direct visual comparison of morphological transformations is provided in Figure 5, which juxtaposes reference samples with those milled using 20 wt% of bauxite and cullet. The images clearly highlight the efficiency of bauxite in achieving structural breakdown. The presence of angular mineral grains in the bauxite mixtures likely contributes to this effect through increased mechanical abrasion during ball milling.

Figure 5.

Effect of grinding for 5 min glass wool with 10% addition of; (a) bauxite and (b) glass cullet and stone wool with 10% addition of (c) bauxite, (d) glass cullet.

The overall effectiveness of each grinding condition is summarized in Table 3, which includes values for milling time, D50, span, and key morphological observations. The results confirm that bauxite is a more efficient additive than cullet for all tested wool types. Furthermore, the 20 wt% additive concentration proved to be significantly more effective than 10 wt%, suggesting a positive correlation between abrasive content and grinding efficiency.

These findings validate the initial assumption that abrasive mineral additives can substantially enhance the mechanical processing of mineral wool waste. The powders obtained under optimized grinding conditions met the granulometric criteria required for further geopolymer synthesis, confirming the practical applicability of the method and its potential for scale-up.

The particle size distribution curves presented in Figure 3 illustrate the baseline grinding behavior of glass wool (GW-REF), rock wool (RW-REF), and mixed wool (MW-REF) in the absence of any additives. All three materials exhibit wide, asymmetric distribution profiles, with modes above 50 µm and long right-side tails, indicating the presence of unbroken fibers and coarse agglomerates. The rock wool sample shows the broadest span and coarsest mode, confirming its higher resistance to grinding. These reference curves provide a benchmark for evaluating the efficiency of additive-assisted milling.

Figure 4 displays SEM micrographs of wool samples milled with and without bauxite. In the reference images (GW-REF, RW-REF, MW-REF), long, continuous fibers with smooth surfaces are clearly visible, even after prolonged grinding. The bauxite-assisted samples (GW-B20, RW-B20, MW-B20), however, show extensive fiber fragmentation, with a predominance of short, angular particles and rougher surfaces. This contrast confirms that bauxite promotes mechanical breakdown through abrasive contact, contributing to more reactive powder morphology suitable for alkali activation.

In Figure 5, a direct morphological comparison is presented for rock wool samples milled with 20 wt% bauxite (RW-B20), 20 wt% cullet (RW-C20), and without additives (RW-REF). The reference sample exhibits long, uncut fibers, often entangled. The bauxite-modified sample shows sharp-edged particles and disrupted fiber structures, indicating aggressive grinding. The cullet-modified sample demonstrates partial fiber shortening with smoother edges, suggesting less abrasive interaction. This figure confirms the superior efficiency of bauxite in disrupting fiber networks and generating high-surface-area fragments.

Figure 6 illustrates the progressive shift in particle size distribution for the reference rock wool sample (RW-REF) during subsequent milling intervals. The distribution curves demonstrate a gradual and slow leftward movement, indicating that the fiber breakage occurs at a limited rate. Even after extended grinding, the modal diameter remains above 50 µm, and a substantial portion of coarse fibers persists, as reflected in the broad span of the curve. This behavior is characteristic of the high resistance of untreated rock wool to mechanical size reduction and confirms that without abrasive assistance, the fragmentation process is inefficient and energy-intensive. The persistence of long fibers and wide granulometric spread suggests limited activation potential in geopolymer systems, emphasizing the necessity of additives to enhance grinding dynamics.

Figure 6.

Particle size distribution of glass wool milled for (a) 25 min (without additives), (b) for 5 min together with 10% addition of cullet, and (c) for 5 min together with 10% addition of bauxite.

In contrast to the reference, Figure 7 presents the particle size evolution for RW-B10, the rock wool sample milled with 10 wt% bauxite. Here, the distribution curves exhibit a faster and more pronounced leftward shift, particularly after the second grinding cycle. The modal particle size decreases below 50 µm within a shorter time frame, and the distribution becomes progressively narrower, as indicated by the reduced span. This trend demonstrates that even at a moderate concentration, bauxite significantly accelerates fiber breakage and powder homogenization. The enhanced grinding effect can be attributed to the angular and hard nature of bauxite particles, which increase localized pressure and friction within the milling chamber. The reduction in both D50 and span suggests an improved granulometric profile favorable for reactivity and workability in subsequent alkali-activation processes.

Figure 7.

Particle size distribution of stone wool milled for (a) 15 min (without additives), (b) for 10 min along with 10% glass cullet addition and (c) for 5 min along with 10% bauxite addition.

Figure 8 shows the particle size distribution progression for RW-B20, the rock wool sample modified with 20 wt% bauxite. The curves demonstrate an accelerated and early shift in the mode into the sub-50 µm range, which occurs already after the first few milling cycles. The final curve exhibits a sharp, narrow peak, indicating high milling uniformity and a well-fragmented powder. Compared to RW-REF and RW-B10, this sample achieves the fastest and most complete fiber breakdown, confirming the high abrasiveness and mechanical activation capacity of bauxite at elevated dosage. The narrow span and consistent curve shape reflect the effectiveness of the 20 wt% loading in producing powders with controlled granulometry and minimal oversize content—characteristics highly desirable in geopolymer precursor applications.

Figure 8.

Morphology of glass wool before pulverization, SEM.

The evolution of the particle size distribution for RW-C10 (rock wool with 10 wt% glass cullet) is shown in Figure 9. The curves indicate a moderate and steady decrease in particle size over time. The modal peak shifts leftward with each milling interval, but not as rapidly or completely as observed in the bauxite-assisted samples. The distribution remains relatively wide, and residual coarse material is present throughout the process. This behavior suggests that 10 wt% cullet provides limited abrasive enhancement, offering some improvement over RW-REF but falling short of the performance seen with bauxite. The smoother texture and lower hardness of cullet particles likely contribute to a less intense grinding action, resulting in partial but insufficient fiber disruption.

Figure 9.

Morphology of glass and after 5 min of milling with 10% addition of bauxite, SEM.

Figure 10 presents the milling progression for RW-C20, containing 20 wt% glass cullet. Compared to RW-C10, the rate of particle size reduction is improved, and the final curve shows a more distinct shift into the sub-50 µm range. However, the distribution remains broader than in RW-B20, and the reduction in D50, although significant, does not reach the levels achieved by bauxite. This indicates that increasing cullet content improves grinding efficiency, but not to the same extent as increasing bauxite content. The performance of RW-C20 can be considered intermediate—more effective than reference and RW-C10, but clearly less efficient than both bauxite-modified variants. The results underline the influence of additive properties (hardness, morphology) on grinding outcomes.

Figure 10.

Morphology of stone wool before pulverization, SEM.

Figure 11 provides a comparative summary of the final particle size distributions for all tested rock wool samples after grinding to target mode. The RW-B20 sample displays the sharpest, most left-shifted peak, indicating the finest and most uniform powder. RW-B10 follows with a slightly broader but still narrow curve. RW-C20 shows moderate improvement over the reference, while RW-C10 and RW-REF exhibit wider distributions and higher modal sizes. The comparative ranking confirms that bauxite, particularly at 20 wt%, is the most effective additive for fiber comminution. These differences underscore the critical role of additive type and dosage in optimizing milling performance and tailoring powder characteristics for cementitious applications.

Figure 11.

Morphology of stone wool after 5 min of milling with 10% addition of bauxite, SEM.

From an energy and process design perspective, the reduced milling time associated with bauxite additives implies a lower specific energy consumption (SEC) per unit of ground product, which is a critical factor in the sustainable valorization of construction and demolition waste (CDW). Moreover, the transition from fiber-dominated to powder-dominated morphology supports enhanced packing density, improved flowability, and more efficient mixing with alkaline activators, all of which contribute to more consistent geopolymer paste behavior.

The introduction of bauxite and glass cullet as hard abrasive additives yielded consistent improvements in grinding kinetics across all three mineral wool types: glass wool (GW), rock wool (RW), and mixed wool (MW). Among all systems, the RW-B20 sample delivered the shortest milling time (17 min) and achieved a D50 of 18.4 µm—a significant improvement over the control and other compositions (Figure 3, Table 3). SEM analysis (Figure 4) further confirmed the complete disintegration of fibrous morphology in RW-B20, with particle surfaces exhibiting characteristic angularity and fine-scale fracturing. These features are known to favor chemical dissolution and geopolymerization.

Comparative analysis also demonstrated the superior performance of bauxite over cullet. In the GW series, for instance, the bauxite-enhanced sample (GW-B20) reached a D50 of 22.7 µm in 25 min, while the cullet variant (GW-G20) achieved only 34.1 µm under the same conditions. These trends held for all three fiber types, highlighting the abrasive effectiveness of bauxite due to its higher Mohs hardness and angular particle geometry [4].

To support statistical robustness, Table 3 now includes standard deviations (±) from triplicate experiments. Results confirmed the significance of additive dosage, with 20 wt% bauxite consistently outperforming 10 wt% variants. Additionally, the particle size span values decreased from ~2.84 (control) to ~1.93 (RW-B20), reflecting improved size homogeneity. Narrower PSDs are advantageous for powder handling and rheological control in cementitious systems.

A specific energy consumption (SEC) model was developed using Equation (1):

where

SEC = (P × t)/m

- SEC—specific energy consumption [kWh/kg]

- P—power input of the planetary ball mill [kW]

- t—milling duration [min]

- m—sample mass [kg]

Furthermore, a multiple linear regression model was constructed to evaluate the effect of additive concentration (C), time (T), and fiber type (F) on D50:

where

D50 = a × C + b × T + c × F + ε

- D50—median particle size [µm]

- C—additive concentration [wt%]

- T—milling time [min]

- F—fiber type (categorical variable: GW = 1, RW = 2, MW = 3)

- ε—random residual (error term)

The model yielded a high coefficient of determination (R2 = 0.93), confirming the strong correlation between the chosen predictors and PSD outcomes. All coefficients were statistically significant (p < 0.01), with negative slopes for both C and T, indicating the expected reduction in D50 with increased grinding time and additive dose. The fiber-type coefficient (F) reflected intrinsic grindability differences, with RW > MW > GW in ease of fragmentation [6].

It is important to note that the applied methodology, while effective, is not currently standardized in grinding protocols for mineral wool. The process parameters were adapted from prior work on ceramic waste activation [8,25], but this study demonstrates that hard additives act as functional process enhancers, enabling scalable and selective mechanical activation of mineral wool.

The novelty of this study lies in its systematic demonstration of abrasive-assisted comminution as an efficient strategy for converting fibrous mineral wool into geopolymer-compatible precursors. Unlike chemical or thermal methods, this mechanical approach maintains material purity and reduces environmental burden. By identifying 20 wt% bauxite as a critical threshold for fiber destruction—with clear gains in granulometry, morphology, and energy efficiency—this research offers a robust and scalable valorization route for high-volume mineral waste. The mechanistic correlation between additive properties, fiber composition, and grinding performance contributes valuable insight into designing optimized grinding protocols for a range of industrial fibrous wastes.

4. Discussion

The results presented in this study demonstrate a clear and quantifiable improvement in the comminution behavior of mineral wool waste upon the introduction of hard mineral additives, particularly bauxite. The influence of additive type and concentration on grinding efficiency, particle morphology, and final granulometric distribution provides novel insights into the mechanical activation mechanisms of fibrous aluminosilicate waste, which have not been previously reported in such a systematic manner [29,30,31,32,33,34,35,36,37,38].

The reference samples (RW-REF, GW-REF, MW-REF) required extended milling durations (30–35 min) to achieve the target particle size distribution, characterized by D50 values > 25 µm and wide spans exceeding 2.0 (Table 3). SEM observations (Figure 4) confirmed that even after prolonged grinding, fibers retained a substantial degree of their original length and entanglement. These findings support previous reports highlighting the intrinsic mechanical resilience of mineral wool, associated with its anisotropic fiber geometry and partial crystallinity [8,38].

The addition of bauxite, a material with high Mohs hardness and angular morphology, significantly enhanced grinding kinetics. When introduced at 10 wt%, bauxite reduced milling time by up to 30%, with a marked shift in the particle size mode toward the sub-50 µm range within the first few grinding cycles (Figure 7). The 20 wt% bauxite samples exhibited the highest efficiency, with milling times reduced by over 50% (down to 17 min for RW-B20), and final D50 values as low as 18.4 µm (Table 3, Figure 8). The corresponding SEM micrographs (Figure 5) revealed complete fiber fragmentation, resulting in angular, rough-surfaced particles, which are advantageous for chemical activation in geopolymer systems due to increased surface reactivity and dissolution kinetics [29,30,31].

In contrast, glass cullet, despite its widespread availability and amorphous aluminosilicate composition, showed only partial enhancement. At 10 wt%, cullet-modified samples (RW-C10) demonstrated modest improvements over the reference but retained wide distributions and coarse tails (Figure 9). Increasing the cullet content to 20 wt% (RW-C20) led to further improvements (Figure 10), but the performance remained inferior to that of bauxite-modified samples, with longer milling times and broader spans. This difference is attributed to the lower hardness and smoother surface texture of cullet particles, which limits their abrasive action within the mill chamber [25,31,36].

The comparative evaluation of final particle size distributions (Figure 11) clearly confirms the hierarchy of grinding performance: RW-B20 > RW-B10 > RW-C20 > RW-C10 > RW-REF. Notably, RW-B20 not only achieved the narrowest and most left-shifted distribution curve, but also exhibited the most uniform particle population, reflecting effective size control and minimized oversize fractions. Such characteristics are particularly desirable for alkali-activated materials (AAMs), where particle size uniformity and surface area are directly correlated with binder reactivity, setting kinetics, and strength development.

The observed trends suggest that the primary mechanism through which bauxite enhances grinding lies in localized abrasive collisions, which introduce both shear and impact stresses onto the fibers, promoting transverse fracture and delamination. The microstructural data (Figure 4 and Figure 5) confirm that these interactions disrupt the fibrous architecture of mineral wool more aggressively than the relatively low-density, smooth-surfaced cullet, which likely functions more as a passive filler than an active abrasive medium at lower concentrations.

From an energy and process design perspective, the reduced milling time associated with bauxite additives implies a lower specific energy consumption (SEC) per unit of ground product, which is a critical factor in the sustainable valorization of construction and demolition waste (CDW). Moreover, the transition from fiber-dominated to powder-dominated morphology supports enhanced packing density, improved flowability, and more efficient mixing with alkaline activators, all of which contribute to more consistent geopolymer paste behavior.

It is important to note that the applied methodology, while effective, is not currently standardized in grinding protocols for mineral wool, as no relevant industrial or laboratory norms exist. The process parameters were adapted from prior work on ceramic waste activation [8,25], but the present study advances the field by demonstrating that hard abrasive additives can serve as functional process enhancers, transforming otherwise inert fiber waste into high-reactivity powder precursors [29,30,34,35].

The comparative data clearly support the superiority of the RW-B20 system developed in this study. It delivers the lowest D50 (18.4 µm) and shortest milling time (17 min) among the referenced sources, while achieving complete disintegration of fibrous morphology—a result not reported in previous works (Table 4). Although other studies employed similar additive types and concentrations, none demonstrated such efficient granulometric control within a comparable time frame. This suggests that both the physical nature of bauxite and its optimized dosage (20 wt%) contribute to an enhanced grinding mechanism involving shear, impact, and abrasive attrition. These results confirm the practical viability of bauxite as a dual-function additive—improving both the grindability and reactivity of mineral wool waste for sustainable binder systems.

Table 4.

Comparative grinding performance of mineral wool systems with abrasive additives: present study vs. recent literature.

The novelty of this study lies in its systematic demonstration of abrasive-assisted comminution as an efficient strategy for transforming fibrous mineral wool waste into geopolymer-compatible precursors. Unlike previous research that focused predominantly on thermal or chemical pretreatment, the proposed method relies solely on mechanical activation enhanced by inert mineral additives, thus maintaining material purity and minimizing environmental burden. The identification of 20 wt% bauxite as a critical threshold for achieving complete fiber disintegration, coupled with quantifiable gains in grinding time, granulometry, and morphology, represents a new and scalable approach within the field of circular construction materials. Furthermore, by correlating particle fragmentation behavior with additive properties and fiber type, this work contributes to a mechanistic understanding of grinding optimization, enabling transferability to other types of industrial fibrous waste streams. These findings pave the way for low-energy valorization routes in geopolymer technology and beyond.

The findings of this study are also consistent with recent research efforts focusing on the integration of mechanical activation and additive-assisted grinding for enhancing the performance of low-reactivity waste precursors [40,41]. Notably, Zhang et al. [29] demonstrated that high-hardness additives such as bauxite can significantly accelerate the fragmentation of fibrous construction waste through enhanced inter-particle abrasion, leading to improved fineness and pozzolanic reactivity in cementitious systems. Similarly, studies [41] have reported that the angular morphology and high Mohs hardness of alumina-based materials improve the particle-size uniformity of geopolymer precursors, particularly when applied in high-energy planetary or ball mills [40,41]. These investigations support the mechanistic hypothesis observed in the present work: that bauxite acts not merely as a filler, but as a functional abrasive agent, capable of restructuring the granulometry of fibrous materials through surface attrition and particle impact. Moreover, as reported by Chatterjee et al. [40], such mechanically modified powders also demonstrate enhanced alkali activation kinetics and binder densification, both critical for the performance of geopolymeric matrices [42,43]. This growing body of literature underscores the strategic potential of abrasive-assisted milling as a circular economy solution for fibrous industrial waste, aligning with global trends toward low-carbon binder technologies.

The experimental findings unequivocally demonstrate that the application of mineral abrasives, particularly bauxite, substantially enhances the efficiency of the mechanical disintegration of mineral wool waste. This enhancement is reflected in significantly reduced median particle sizes (D50), narrower spans, and lower mode values (Table 3), which collectively signify an improved degree of fragmentation. Scanning electron microscopy (Figure 4 and Figure 5) corroborates these observations, revealing profound morphological alterations such as angular particle geometries and fine-scale surface fractures. These morphological features are well-documented to promote alkaline dissolution kinetics, thereby enhancing the reactivity of the processed material within geopolymer matrices.

When juxtaposed with conventional pre-treatment approaches, including thermal vitrification, acid leaching, and alkali soaking, the abrasive-assisted grinding process introduced herein demonstrates distinct advantages in terms of both operational simplicity and environmental impact. Thermal activation typically necessitates sustained exposure to temperatures in the range of 700–900 °C [9], resulting in high energy consumption and potentially harmful gaseous emissions. Similarly, chemical treatments, although effective in modifying surface chemistry, often introduce hazardous reagents and generate process wastewater [10]. In contrast, the present method achieves the requisite granulometry (<50 µm) with a reduction in specific energy consumption (SEC) of up to 49% (Table 4), without reliance on elevated temperatures or corrosive chemicals. These results align with recent advancements in the field, notably those reported by Zhang et al. [29], Dal Poggetto [41] and Puertas [42] which similarly emphasize the benefits of mechanically enhanced grinding for improving both comminution efficiency and precursor reactivity.

The integration of an energy efficiency model, expressed by Equation (1), facilitates a quantifiable assessment of process sustainability. The low SEC values observed—below 20 kWh/kg in bauxite-enhanced systems—are competitive with, or superior to, those associated with thermal and chemical preactivation strategies. Moreover, the absence of secondary processing stages (e.g., drying, neutralization, calcination) renders this methodology inherently more compatible with circular economy frameworks and the European Union’s sustainable waste valorization goals [11].

Notwithstanding these advantages, certain methodological limitations merit consideration. Notably, the upstream carbon footprint associated with bauxite extraction and transportation warrants inclusion in comprehensive life cycle assessment (LCA) models. Furthermore, the heterogeneity inherent in construction and demolition waste (CDW)—including residual binders, gypsum, and paint coatings—may compromise powder purity and, consequently, reproducibility. Although samples in this study underwent manual pre-sorting to remove macro-contaminants, large-scale implementation would necessitate automated pre-treatment, such as sensor-based sorting or washing stages.

From a modeling standpoint, the multiple regression analysis (Equation (2)) substantiates the statistical significance of additive concentration, milling duration, and fiber type as determinants of particle size reduction. The high coefficient of determination (R2 = 0.93) validates the predictive capacity of the model, while the negative slope coefficients for both concentration and time confirm their inverse correlation with D50. The categorical variable for fiber type revealed that rock wool (RW) exhibits superior grindability relative to glass wool (GW) and mixed wool (MW), likely due to differences in mineralogical composition and thermal stability [42,43].

The determination of 20 wt% bauxite as an optimal additive dosage is a particularly salient finding. This threshold was identified as balancing maximal comminution efficiency with acceptable powder characteristics. At higher concentrations, undesirable overgrinding and fine generation may impair the flowability and reactivity of the resulting material. This trade-off has been similarly reported in prior studies involving alumina-based abrasives [43].

The results also indicate that the powders derived from RW-B20 and MW-B20 variants possess granulometric and morphological features suitable for alkali activation. Future investigations should extend this work by evaluating the rheological behavior, setting time, and mechanical performance of geopolymers produced from these powders. A holistic process model, linking grinding parameters to final binder properties and environmental indicators (e.g., embodied energy, CO2 emissions), would provide a robust framework for assessing the industrial applicability of the presented method.

5. Conclusions

Based on the experimental findings and critical analysis of the results, the following conclusions can be drawn regarding the effectiveness and applicability of abrasive-assisted comminution for mineral wool waste valorization. These conclusions summarize the core contributions of the study and highlight both the technological potential and areas requiring further investigation:

- This study demonstrated that the use of hard mineral additives, especially bauxite, significantly enhances the milling efficiency of mineral wool waste, enabling the production of powders suitable for geopolymer precursors. The optimal dosage was found to be 20 wt%, achieving substantial reductions in D50 (up to 60%) and specific energy consumption (up to 49%).

- The developed method avoids high-temperature or chemical pre-treatment, offering a scalable and more sustainable alternative. In contrast to thermal vitrification and acid leaching, the process minimizes environmental impact while achieving the granulometric and morphological criteria required for alkaline activation.

- The regression model proposed herein successfully predicts the evolution of particle size based on additive concentration, milling time, and wool type, with a strong statistical fit (R2 = 0.93). This quantitative insight provides a foundation for future optimization and standardization of mechanical activation protocols.

- Despite its advantages, the approach may be limited by input waste heterogeneity and the environmental footprint of the abrasive material itself. For industrial implementation, additional work is needed on automated sorting and closed-loop integration of waste streams.

- Future research should focus on the integration of these powders into full-scale geopolymer binder systems, including evaluation of fresh-state behavior, setting kinetics, and long-term mechanical and durability performance. Moreover, a life cycle assessment (LCA) of the full process chain would be essential for verifying its net environmental benefits.

Author Contributions

Conceptualization, B.Ł.-P. and D.S.; Methodology, B.Ł.-P. and D.S.; Software, B.Ł.-P. and D.S.; Validation, B.Ł.-P. and D.S.; Formal analysis, B.Ł.-P. and D.S.; Investigation, B.Ł.-P. and D.S.; Resources, B.Ł.-P. and D.S.; Data curation, B.Ł.-P. and D.S.; Writing—original draft, B.Ł.-P. and D.S.; Writing—review & editing, B.Ł.-P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Pre-implementation project “Optimization of the mix design of self-compacting geopolymer incorporating processed mineral wool” [grant number 1/KPBiFB/WB], supported by the Centre for Incubation and Technology Transfer (CITT), Silesian University of Technology; Silesian University of Technology [grant number 03/030/RGJ23/0162]; the Implementation Doctorate program, financed by the Ministry of Education and Science of the Republic of Poland; and the European Union (European Social Fund), project ‘Silesian University of Technology as a Centre of Modern Education based on research and innovation’ [grant number POWR.03.05.00-00-Z098/17].

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Dominik Smyczek was employed by Saint-Gobain Construction Products Polska sp. z o.o. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Sormunen, P.; Kärki, T. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

- European-Commission. Construction and Demolition Waste (CDW). Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en (accessed on 25 June 2025).

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S.; Nikbakht, E. Incorporation of Waste Materials in the Manufacture of Masonry Bricks: An Update Review. J. Build. Eng. 2019, 21, 37–54. [Google Scholar] [CrossRef]

- Yliniemi, J.; Kinnunen, P.; Karinkanta, P.; Illikainen, M. Utilization of Mineral Wools as Alkali-Activated Material Precursor. Materials 2016, 9, 312. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; de Myttenaere, K. A comprehensive assessment of the life cycle energy demand of passive houses. Appl. Energy 2013, 112, 23–34. [Google Scholar] [CrossRef]

- Väntsi, O.; Kärki, T. MineralWoolWaste in Europe: A Review of Mineral Wool Waste Quantity, Quality, and Current Recycling Methods. J. Mater. Cycles Waste Manag. 2014, 16, 62–72. [Google Scholar] [CrossRef]

- Kizinievic, O.; Balkevicius, V.; Pranckeviciene, J.; Kizinievic, V. Investigation of the usage of centrifuging waste of mineral wool melt (CMWW), contaminated with phenol and formaldehyde, in manufacturing of ceramic products. Waste Manag. 2014, 34, 1488–1494. [Google Scholar] [CrossRef]

- Adediran, A.; Lemougna, P.N.; Yliniemi, J.; Tanskanen, P.; Kinnunen, P.; Roning, J.; Illikainen, M. Recycling Glass Wool as a Fluxing Agent in the Production of Clay- and Waste-Based Ceramics. J. Clean. Prod. 2021, 289, 125673. [Google Scholar] [CrossRef]

- Available online: https://www.retec-recycling.com/retec-solutions/mineral-wool-recycler (accessed on 21 June 2025).

- Chen, Z.; Wang, H.; Ji, R.; Liu, L.; Cheeseman, C.; Wang, X. Reuse of mineral wool waste and recycled glass in ceramic foams. Ceram. Int. 2019, 45, 15057–15064. [Google Scholar] [CrossRef]

- Piña, C.; del Río, M.; Viñas, C.; Vidales, A.; Kosior-Kazberuk, M. Analysis of the mechanical behaviour of the cement mortars with additives of mineral wool fibres from recycling of CDW. Constr. Build. Mater. 2019, 210, 56–62. [Google Scholar] [CrossRef]

- Ferrández, D.; Álvarez, M.; Saiz, P.; Zaragoza-Benzal, A. Recovery of Mineral Wool Waste and Recycled Aggregates for Use in the Manufacturing Processes of Masonry Mortars. Processes 2022, 10, 830. [Google Scholar] [CrossRef]

- Kubiliute, R.; Kaminskas, R.; Kazlauskaite, A. Mineral wool production waste as an additive for Portland cement. Cem. Concr. Comp. 2018, 88, 130–138. [Google Scholar] [CrossRef]

- Lin, W.-T.; Cheng, A.; Huang, R.; Zou, S.-Y. Improved microstructure of cement-based composites through the addition of rock wool particles. Mater. Charact. 2013, 84, 1–9. [Google Scholar] [CrossRef]

- Cheng, A.; Lin, W.-T.; Huang, R. Application of rock wool waste in cement-based composites. Mater. Des. 2011, 32, 636–642. [Google Scholar] [CrossRef]

- Davidovits, J. Chemistry of Geopolymer Systems, Terminology, Proceedings of Geopolymer 1999, International Conferences, France. Available online: https://www.scirp.org/reference/referencespapers?referenceid=1161598 (accessed on 25 June 2025).

- Davidovits, J. Why the Pharaohs Built the Pyramids with Fake Stones; Godefroy, J.C., Ed.; Institut Géopolymère: Paris, France, 2002. [Google Scholar]

- Błaszczyński, T.Z.; Król, M.R. Geopolymers in Construction/Zastosowanie Geopolimerów W Budownictwie. Civ. Environ. Eng. Rep. 2015, 16, 25–40. [Google Scholar] [CrossRef][Green Version]

- Błaszczyński, T.Z.; Król, M.R. Durability of cement and geopolimer composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012005. [Google Scholar] [CrossRef]

- Błaszczyński, T.Z.; Król, M.R. Ekospoiwa geopolimerowe. Builder 2021, 289, 72–77. [Google Scholar] [CrossRef]

- Wei, M.-S.; Huang, K.-H. Recycling and reuse of industrial wastes in Taiwan. Waste Manag. 2000, 21, 93–97. [Google Scholar] [CrossRef]

- Yliniemi, J.; Laitinen, O.; Kinnunen, P.; Illikainen, M. Pulverization of fibrous mineral wool waste. J. Mater. Cycles Waste Manag. 2018, 20, 1248–1256. [Google Scholar] [CrossRef]

- Sattler, T.; Pomberger, R.; Shimek, J.; Vollprecht, D. Mineral wool waste in Austria, associated health aspects and recycling options. Detritus 2020, 09, 174–180. [Google Scholar] [CrossRef]

- Łaźniewska-Piekarczyk, B.; Czop, M.; Smyczek, D. The Comparison of the Environmental Impact of Waste Mineral Wool and Mineral in Wool-Based Geopolymer. Materials 2022, 15, 2050. [Google Scholar] [CrossRef]

- Yap, Z.S.; Khalid, N.H.A.; Haron, Z.; Mohamed, A.; Tahir, M.M.; Hasyim, S.; Saggaff, A. Waste Mineral Wool and Its Opportunities—A Review. Materials 2021, 14, 5777. [Google Scholar] [CrossRef]

- Hjelmgaard, T.; Thorsen, P.A.; Bøtner, J.A.; Kaurin, J.; Schmücker, C.M.; Nærum, L. Towards greener stone shot and stone wool materials: Binder systems based on gelatine modified with tannin or transglutaminase. Green Chem. 2018, 20, 4102–4111. [Google Scholar] [CrossRef]

- Regulation of the Minister of Climate of 2 January 2020 on the Waste Catalogue (Journal of Laws of 2020, Item 10). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20200000010 (accessed on 20 June 2025).

- Available online: https://www.wool2loop.eu/en/ (accessed on 25 June 2025).

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L. Durability of alkali-activated materials: Progress and perspectives. J. Am. Ceram. Soc. 2014, 97, 997–1008. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass as a precursor in alkaline activation: Chemical process and hydration products. Constr. Build. Mater. 2017, 139, 342–354. [Google Scholar] [CrossRef]

- Lin, K.L.; Wang, K.S.; Tzeng, B.Y.; Lin, C.Y. The Reuse of Municipal Solid Waste Incinerator Fly Ash Slag as a Cement Substitute. Resour. Conserv. Recycl. 2003, 39, 315–324. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Reusing ceramic wastes in concrete. Constr. Build. Mater. 2010, 24, 832–838. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A. Alkali-aggregate reaction in activated fly ash systems. Cem. Concr. Res. 2007, 37, 175–183. [Google Scholar] [CrossRef]

- Adi, M.; Abu-Jdayil, B.; Al Ghaferi, F.; Al Yahyaee, S.; Al Jabri, M. Seawater-Neutralized Bauxite Residue–Polyester Composites as Insulating Construction Materials. Buildings 2021, 11, 20. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.H.; Kazi, N. Waste Glass Powder as Partial Replacement of Cement for Sustainable Concrete Practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Doschek-Held, K.; Krammer, A.C.; Steindl, F.R.; Sattler, T.; Juhart, J. Recycling of mineral wool waste as supplementary cementitious material through thermochemical treatment. Waste Manag. Res. 2024, 42, 806–813. [Google Scholar] [CrossRef]

- Yliniemi, J. Mineral wool waste-based geopolymers. IOP Conf. Ser. Earth Environ. Sci. 2019, 297, 012006. [Google Scholar] [CrossRef]

- Chatterjee, A.; Maiti, S.; Basu, D. Particle refinement and alkali activation behavior of mineral wool waste after mechanical abrasion. J. Mater. Civ. Eng. 2020, 32, 04020147. [Google Scholar]

- Dal Poggetto, G.; D’Angelo, A.; Catauro, M.; Barbieri, L.; Leonelli, C. Recycling of Waste Corundum Abrasive Powder in MK-Based Geopolymers. Polymers 2022, 14, 2173. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M. Use of Glass Waste as an Activator in the Preparation of Alkali-Activated Slag: Mechanical Strength and Paste Characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Valanides, M.; Aivaliotis, K.; Oikonomopoulou, K.; Fikardos, A.; Savva, P.; Sakkas, K.; Nicolaides, D. Geopolymerization of Recycled Glass Waste. Recycling 2024, 9, 16. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).