Enhancing the Sustainability of Asphalt Mixtures: A Focus on Operational Factors and Dataset for Environmental Product Declarations

Abstract

1. Introduction

1.1. Background

- The number of EPDs is steadily increasing, making it crucial to establish clear guidelines for more coherent and reliable results, enhancing credibility across sectors. This is mainly due to the current attention to environmental problems.

- Specific Green Public Procurement (GPP) policies can promote the use of EPDs, driving the adoption of environmental performance standards in procurement processes.

- It is important to provide shared tools and guidelines to ensure comparability among EPDs, to ensure consistency and transparency in environmental assessments across different countries.

- Assessing and comparing possible improvements of operational aspects can be beneficial towards more sustainable practices.

- The current comparison of improvements due to the use of recycled materials, lower mixing temperature, and moisture content is usually expressed only in terms of CO2eq.

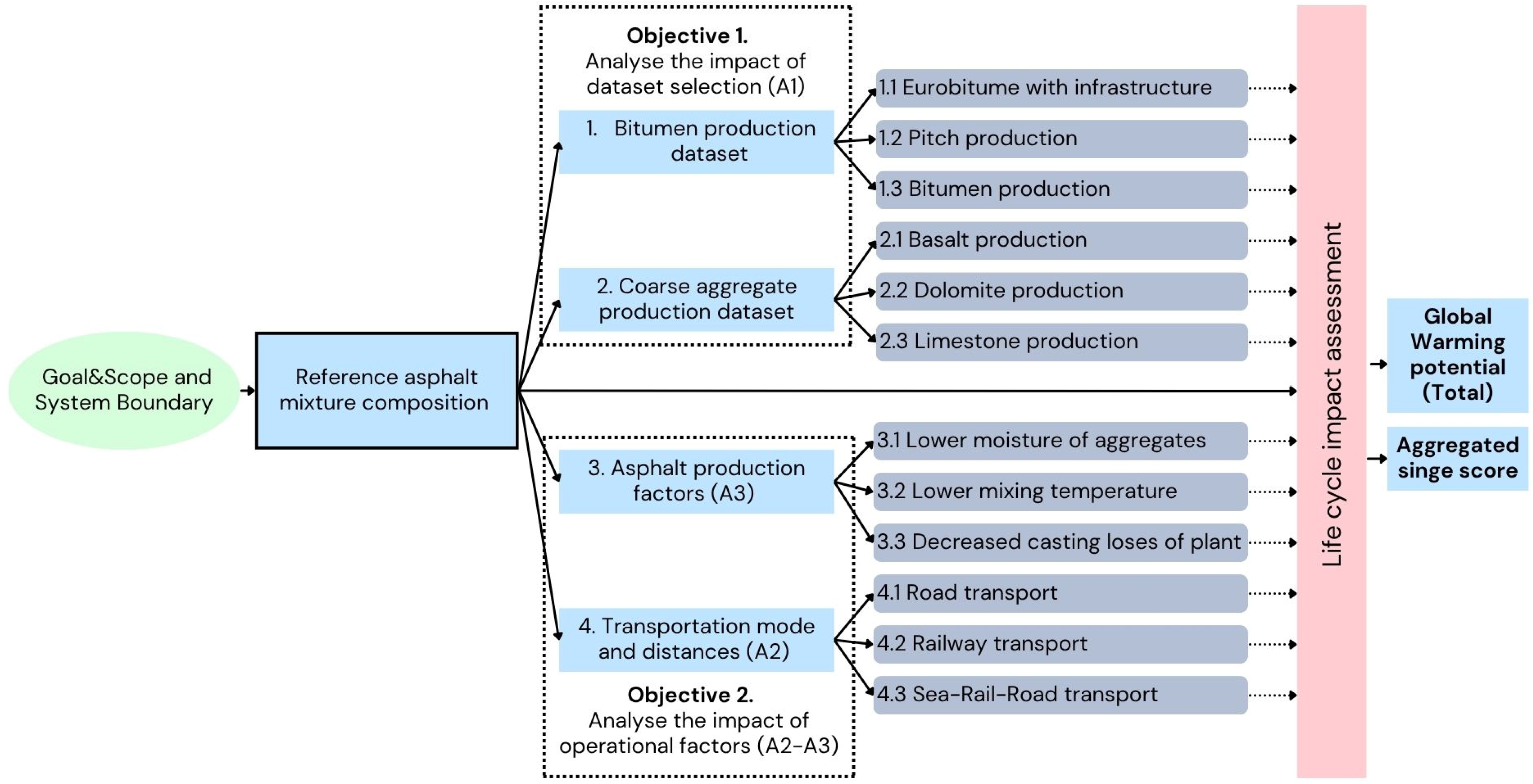

1.2. Goal and Objectives

2. Methods

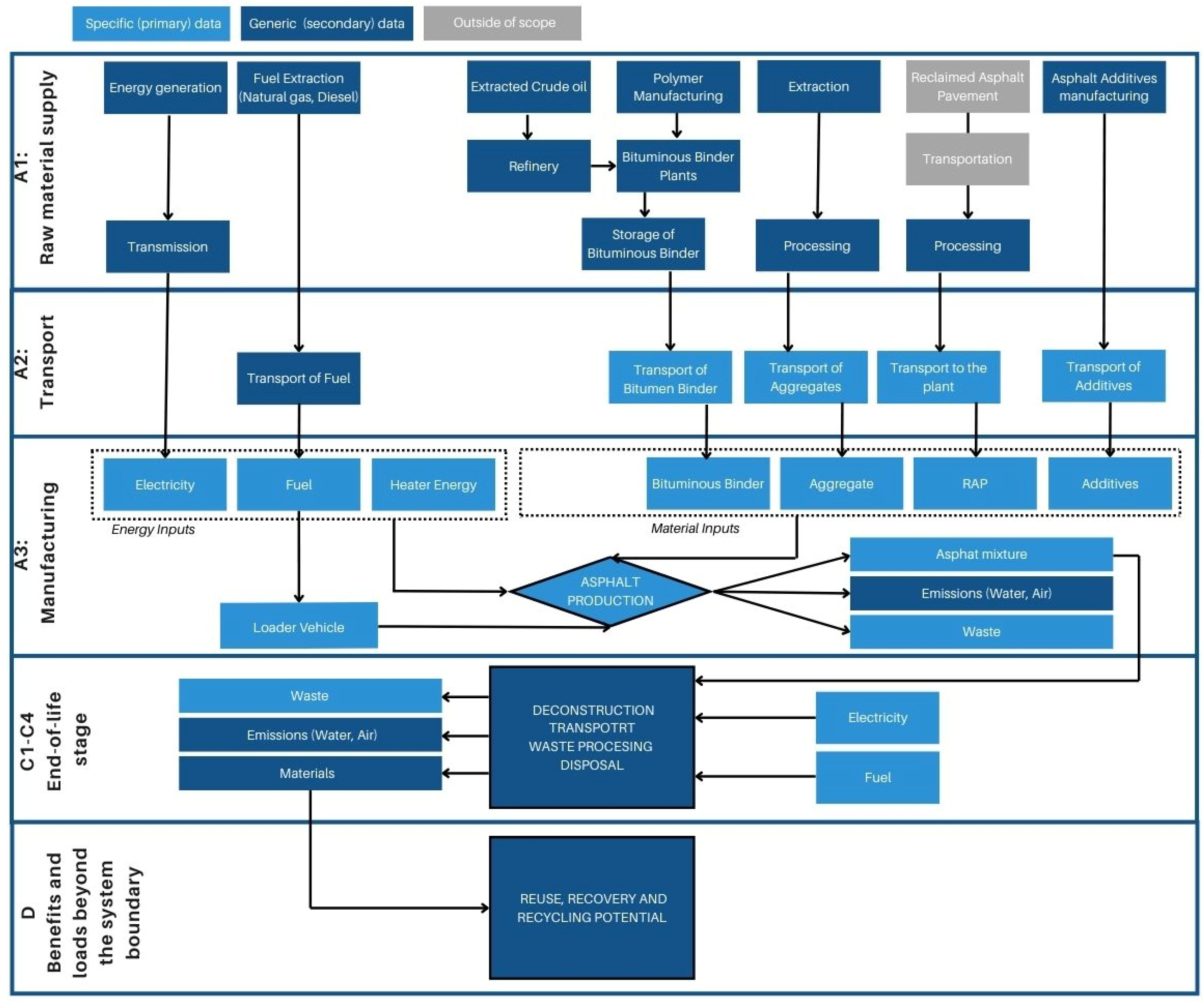

2.1. Goal and Scope of LCA

2.1.1. Declared Unit

2.1.2. System Boundaries

2.1.3. Assumptions and Limitations

2.2. Life Cycle Inventory

2.2.1. Product Stage (A1–A3)

2.2.2. End of Life Stage (C1–C4)

- C1 Deconstruction—Milling and sweeping of asphalt pavement in road section—12.16 MJ/t;

- C2 Transport—average transportation distances from pavement in road section to the site-won asphalt recycling facility at the asphalt plant—87.5 tkm;

- C3 Waste processing—operation of front loader and excavator, crushing and screening machinery—7.51 MJ/t;

- C4 Disposal—it is assumed that no quantity of site-won asphalt is going to be landfilled or incinerated.

2.2.3. Benefits and Loads Beyond the System Boundaries (D)

2.3. Life Cycle Impact Assessment

3. Results

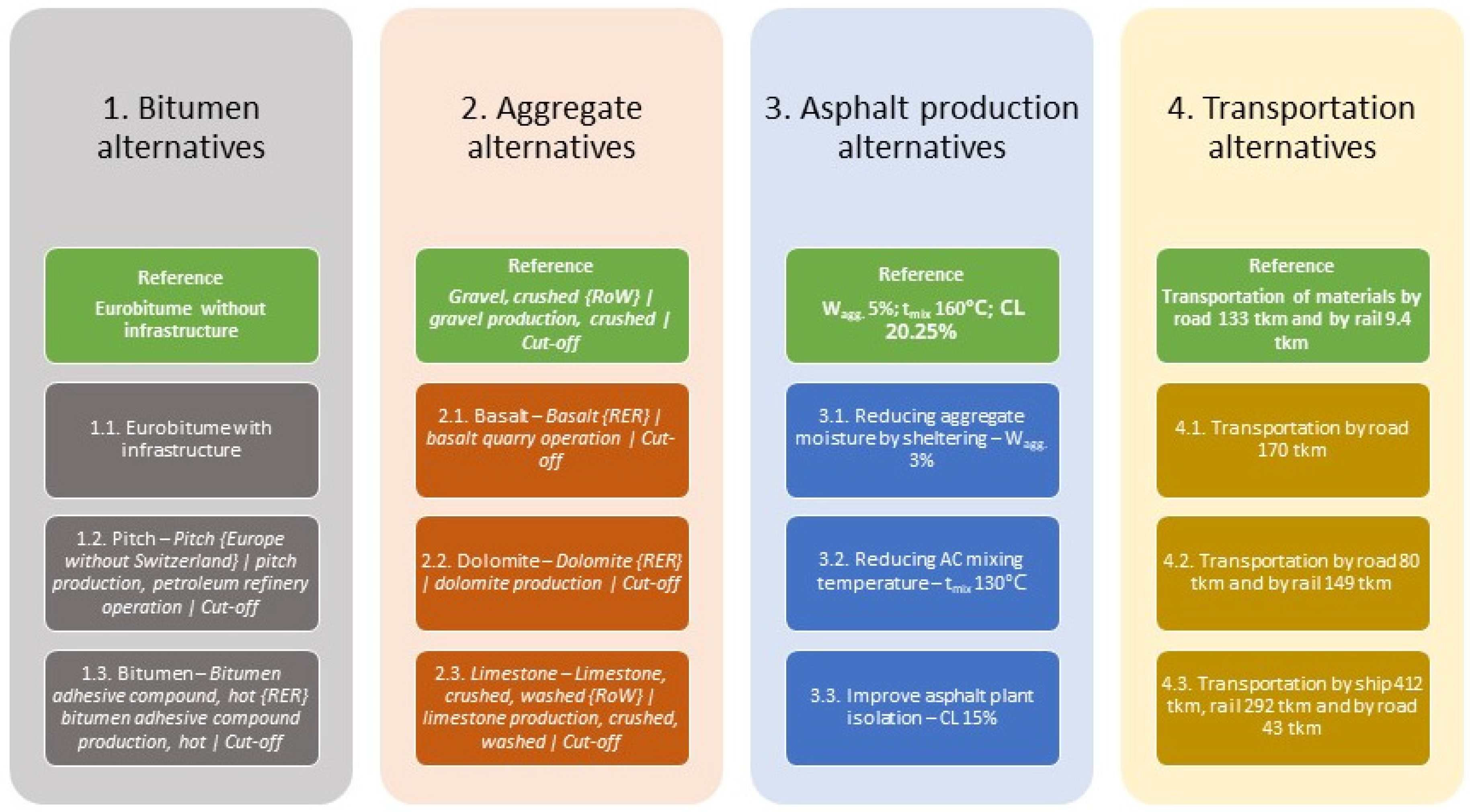

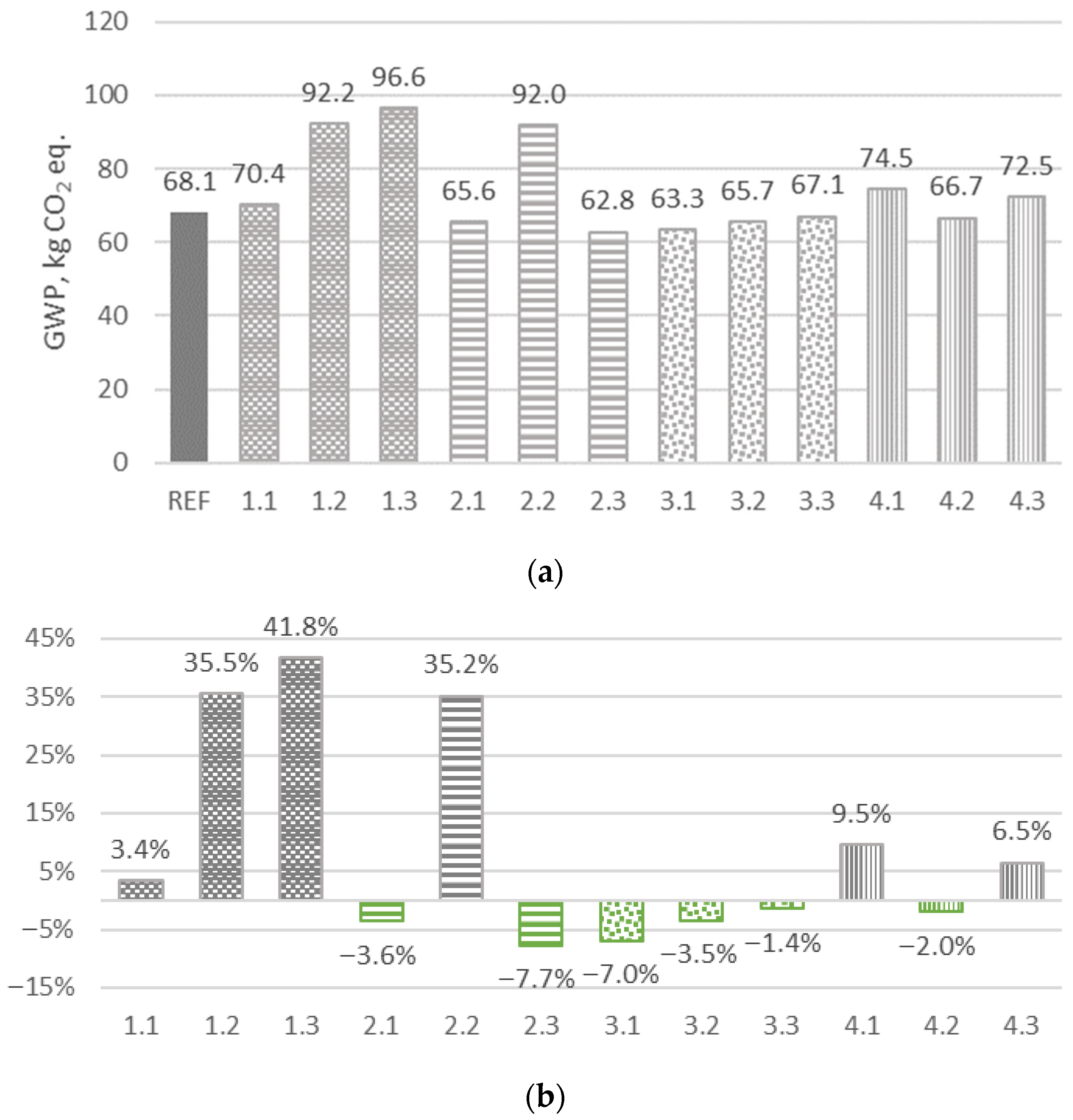

3.1. Discussion of Global Warming Potential Indicator for Modules A1–A3

3.2. Discussion on Holistic Environmental Indicators Comparison for Modules A1–A3

4. Conclusions

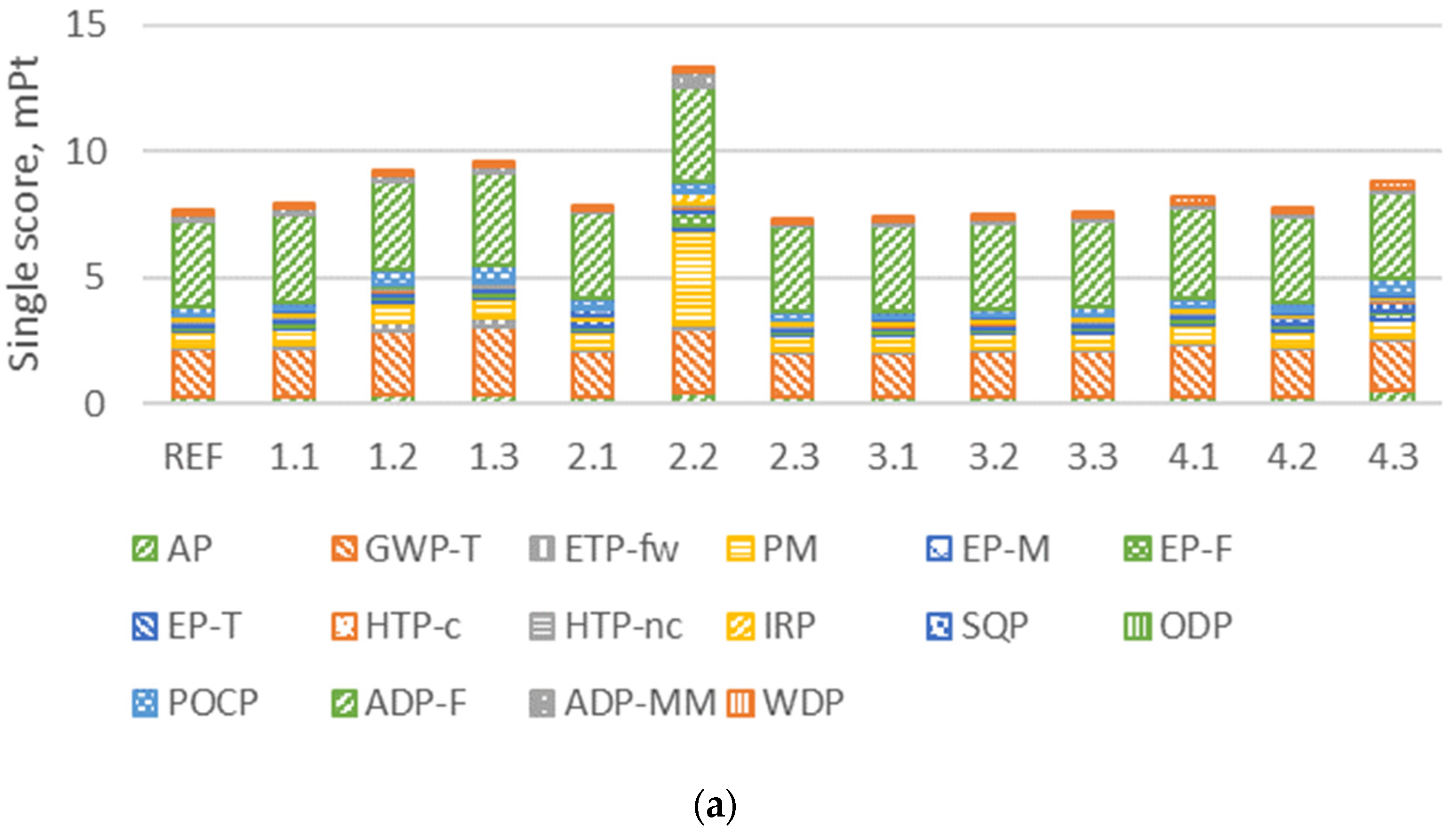

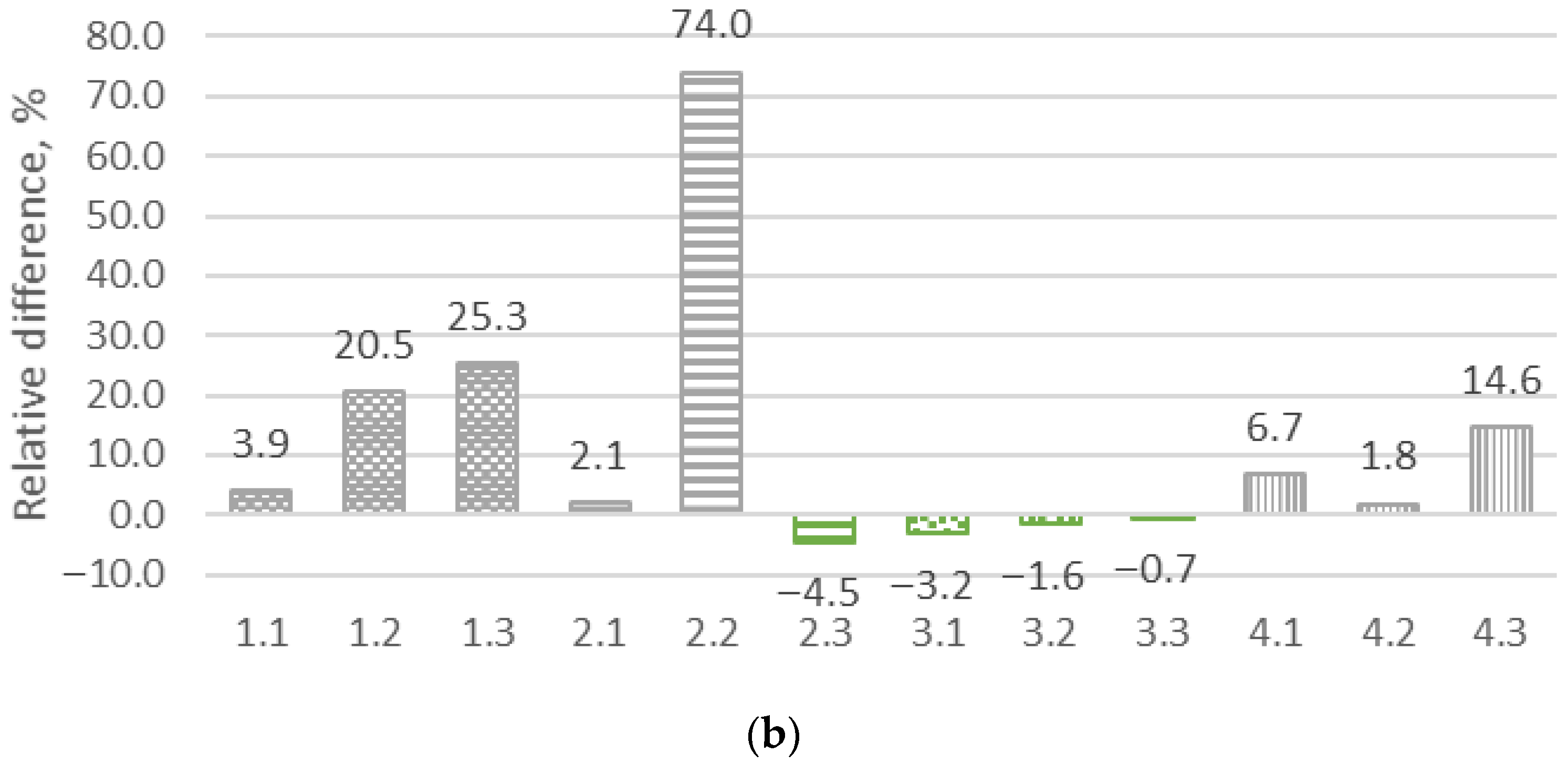

- The sensitivity analysis of the bitumen production dataset showed that the total environmental impact of the life cycle of the asphalt mixture can vary significantly (from 3.4% to 41.8% over GWP-T), according to the choice made by the practitioner when selecting the Life Cycle Inventory input. Considering the high sensitivity of bitumen production, the dataset is crucial to agree on common bitumen binder production inputs on a European level, so that EPDs of asphalt mixtures could be compared internationally for the tendering process. To be on the conservative side, it is recommended to use “bitumen adhesive compound, hot” for the environmental evaluation of bitumen production at LCA Stage A1.

- The sensitivity analysis of the aggregate production dataset showed that LCA practitioners must be careful when evaluating specific aggregate types. The selection of the dolomite production dataset was identified as the factor with the most pronounced influence, leading to a 35.3% increase in GWP-T relative to the baseline scenario. Since dolomite rocks are a dominant local aggregate type for asphalt and concrete production in the Baltic states, and considering that “Dolomite production” in the Ecoinvent database refers to fertilizer production instead of limestone, it is necessary to highlight, revise, and renew the “dolomite production” dataset in the Ecoinvent database. Until then, LCA practitioners are recommended to use EPD data from local dolomite producers.

- During the LCA analysis of asphalt mixtures produced in the specific asphalt plant, the production-related inputs such as moisture of aggregates, mixing temperature, or casting losses are known and fixed. This sensitivity analysis was carried out to demonstrate the potential environmental effects of the procurer’s investments on the plant facility. It was determined that aggregate shedding, followed by a reduction in moisture from 5% to 3%, has the biggest decrease in environmental impact, which can lead to 3.2% lower total emissions under the aggregated single score (ASS). The production of warm mix asphalt, where the temperature is decreased from 160 °C to 130 °C, may result in 1.6% lower total emissions under the ASS. The influence of fuel type was out of the study scope, so this conclusion refers to the natural gas consumption of the batch plant.

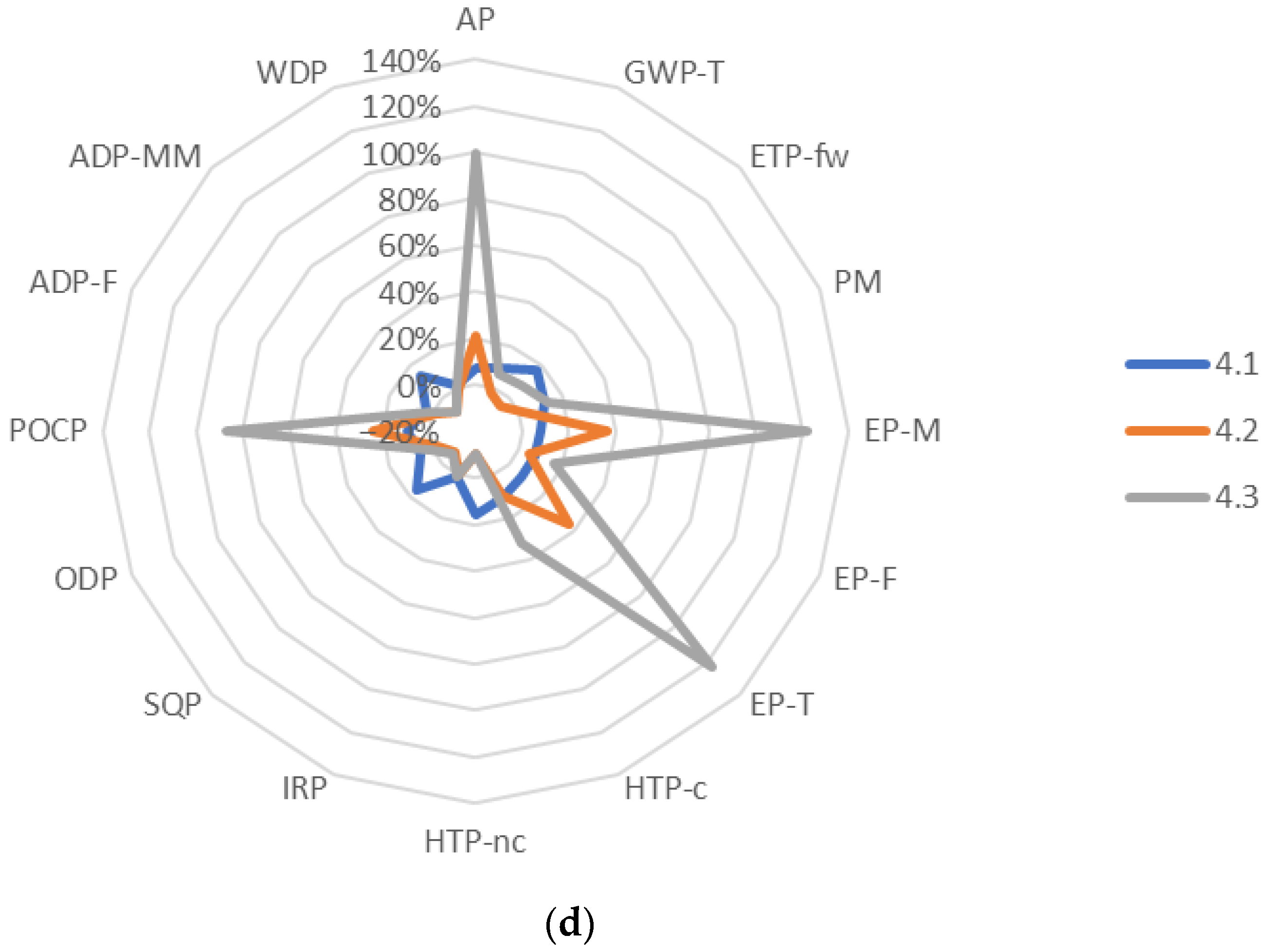

- Sensitivity analysis of transport mode selection may lead to 1.8–6.7% variation in total emissions under the ASS. This indicates that producers may influence the material supply chain by looking for ways for more sustainable transportation. It should be highlighted that transportation mode and distance decisions are equivalent to production facility characteristics.

- In Lithuania and the other Baltic States, granite (basalt) aggregates are not locally available and must be imported from Scandinavia or other countries to meet the performance requirements of asphalt wearing and binder layers. However, this analysis has shown that long-distance transportation may increase the total impacts by 14.6% of ASS. While these imports are unavoidable for high-quality surface layers, environmental performance can still be improved by (i) prioritizing local sourcing of aggregates (dolomite and gravel) in the base and binder layers, (ii) integrating recycled asphalt and aggregates to reduce virgin granite demand, and (iii) optimizing transport logistics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cordella, M.; Sala, S. The European Green Deal in the global sustainability context. In Assessing Progress Towards Sustainability; Elsevier: Amsterdam, The Netherlands, 2022; pp. 73–90. [Google Scholar]

- European Commission. The European Green Deal COM(2019) 640 Final 2019, 24; European Commission: Brussels, Belgium, 2019.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14025; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. International Organization for Standardization: Geneva, Switzerland, 2006.

- Galindro, B.M.; Welling, S.; Bey, N.; Olsen, S.I.; Soares, S.R.; Ryding, S.O. Making use of life cycle assessment and environmental product declarations: A survey with practitioners. J. Ind. Ecol. 2020, 24, 965–975. [Google Scholar] [CrossRef]

- Geber, R.; Kocserha, I.; Gömze, L.A. Influence of Composition and Grain Size Distribution on the Properties of Limestone and Dolomite Asphalt Fillers. Mater. Sci. Forum 2012, 729, 344–349. [Google Scholar] [CrossRef]

- Garbarino, E.; Rodriguez Quintero, R.; Donatello, S.; Wolf, O. Revision of green public procurement criteria for road design, construction and maintenance. In Procurement Practice Guidance Document; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Rangelov, M.; Dylla, H.; Mukherjee, A.; Sivaneswaran, N. Use of environmental product declarations (EPDs) of pavement materials in the United States of America (U.S.A.) to ensure environmental impact reductions. J. Clean. Prod. 2021, 283, 24619. [Google Scholar] [CrossRef]

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. UNE: Brussels, Belgium, 2019.

- EU Regulation 2024/3110; Regulation (EU) No 2024/3110 of the European Parliament and of the Council of 27 November 2024 Laying Down Harmonised Rules for the Marketing of Counstruction Products and Repealing Regulation (EU) No 305/2011. European Parliament and of the Council: Brussels, Belgium, 2024.

- MTE RE 2020; Reglementation Environnementale des Batiments Neufs (Guide RE 2020). Eco-Construire por le Confort de Tous. Ministères Aménagement du Territoire Transition Écologique: Paris, France, 2024.

- Strömberg, L.; Wendel, M.; Lindgren, Å.; Berglund, M. Digitalization of Epds for Asphalt—Experience from Sweden and Input from Norway. In Proceedings of the 7th Eurasphalt and Eurobitume Congress, Virtual, 15–17 June 2021; pp. 1–8. [Google Scholar]

- LEED v4.1, Building Design and Construction. USGBC: Washington, DC, USA, 2025.

- BREEAM. BREEAM Infrastructure: Projects. International; BRE Global: Watford, UK, 2022. [Google Scholar]

- Hasanbeigi, A. Federal Buy Clean Policy Impact on Construction Materials in the US; American Council for an Energy Efficient Economy: Washington, DC, USA, 2021. [Google Scholar]

- Kadefors, A.; Lingegård, S.; Uppenberg, S.; Alkan-Olsson, J.; Balian, D. Designing and implementing procurement requirements for carbon reduction in infrastructure construction–international overview and experiences. J. Environ. Plan. Manag. 2021, 64, 611–634. [Google Scholar] [CrossRef]

- Biswas, W.K.; Alhorr, Y.; Lawania, K.K.; Sarker, P.K.; Elsarrag, E. Life cycle assessment for environmental product declaration of concrete in the Gulf States. Sustain. Cities Soc. 2017, 35, 36–46. [Google Scholar] [CrossRef]

- Dias, A.M.A.; Dias, A.M.P.G.; Silvestre, J.D.; de Brito, J. Comparison of the environmental and structural performance of solid and glued laminated timber products based on EPDs. Structures 2020, 26, 128–138. [Google Scholar] [CrossRef]

- Cruz Juarez, R.I.; Finnegan, S. The environmental impact of cement production in Europe: A holistic review of existing EPDs. Clean. Environ. Syst. 2021, 3, 100053. [Google Scholar] [CrossRef]

- Moins, B.; Hernando, D.; Buyle, M.; Bergh, W.V.D.; Audenaert, A. Reviewing the variability in product category rules for asphalt pavements—A quantitative evaluation of methodological framework differences for environmental product declarations. J. Clean. Prod. 2024, 436, 19. [Google Scholar] [CrossRef]

- Modahl, I.S.; Askham, C.; Lyng, K.A.; Skjerve-Nielssen, C.; Nereng, G. Comparison of two versions of an EPD, using generic and specific data for the foreground system, and some methodological implications. Int. J. Life Cycle Assess. 2013, 18, 241–251. [Google Scholar] [CrossRef]

- Gettu, N.; Buttlar, W.G. Critical Parameters Affecting the Carbon Footprint of Asphalt Mixes. In RILEM Bookseries; Springer Nature: Cham, Switzerland, 2024; Volume 48, pp. 374–383. [Google Scholar]

- Riekstins, A.; Haritonovs, V.; Straupe, V.; Izaks, R.; Merijs-Meri, R.; Zicans, J. Comparative environmental and economic assessment of a road pavement containing multiple sustainable materials and technologies. Constr. Build. Mater. 2024, 432, 136522. [Google Scholar] [CrossRef]

- Covilla-Varela, E.; Turbay, E.; Polo-Mendoza, R.; Martínez-Arguelles, G.; Cantero-Durango, J. Recycled Concrete Aggregates (RCA)-based asphalt mixtures: A performance-related evaluation with sustainability-criteria verification. Constr. Build. Mater. 2023, 403, 133203. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Silva, H.M.R.D.; Oliveira, J.R.M.; Moura, C.F.N.; Loureiro, C.D.A.; Silvestre, J.D.; Rodrigues, M.M.M. Mechanical and Environmental Performance of Asphalt Concrete with High Amounts of Recycled Concrete Aggregates (RCA) for Use in Surface Courses of Pavements. Sustainability 2024, 16, 248. [Google Scholar] [CrossRef]

- Buttitta, G.; Giancontieri, G.; Parry, T.; Lo Presti, D. Modelling the Environmental and Economic Life Cycle Performance of Maximizing Asphalt Recycling on Road Pavement Surfaces in Europe. Sustainability 2023, 15, 14546. [Google Scholar] [CrossRef]

- Androjić, I.; Alduk, Z.D.; Dimter, S.; Rukavina, T. Analysis of impact of aggregate moisture content on energy demand during the production of hot mix asphalt (HMA). J. Clean. Prod. 2020, 244, 118868. [Google Scholar] [CrossRef]

- Thives, L.P.; Ghisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sustain. Energy Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Anderson, R.M.; Baumgardner, G.; May, R.; Reinke, G. Engineering Properties, Emissions, and Field Performance of Warm Mix Asphalt Technologies; Interim Report; Asphalt Institute: Lexington, KY, USA, 2008. [Google Scholar]

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Vidal, R.; Moliner, E.; Martínez, G.; Rubio, M.C. Life cycle assessment of hot mix asphalt and zeolite-based warm mix asphalt with reclaimed asphalt pavement. Resour. Conserv. Recycl. 2013, 74, 101–114. [Google Scholar] [CrossRef]

- Zaumanis, M. Warm Mix Asphalt Investigation; Riga Technical University: Riga, Latvia, 2010. [Google Scholar]

- Middleton, B.; Forfylow, R.W. Evaluation of Warm-Mix Asphalt Produced with the Double Barrel Green Process. Transp. Res. Rec. J. Transp. Res. Board 2009, 2126, 19–26. [Google Scholar] [CrossRef]

- Praticò, F.G.; Perri, G. A Study on Warm Mix Asphalt Sustainability. In Proceedings of the 10th International Conference on Maintenance and Rehabilitation of Pavements (MAIREPAV 2024), Guimarães, Portugal, 24–26 July 2024; pp. 284–292. [Google Scholar]

- Anthonissen, J.; Braet, J.; Bergh, W.V.D. Life cycle assessment of bituminous pavements produced at various temperatures in the Belgium context. Transp. Res. Part D Transp. Environ. 2015, 41, 306–317. [Google Scholar] [CrossRef]

- Eurobitume. The Eurobitume Life-Cycle Inventory for Bitumen Version 3.1; Eurobitume: Brussels, Belgium, 2020. [Google Scholar]

- Jullien, A.; Dauvergne, M.; Cerezo, V. Environmental assessment of road construction and maintenance policies using LCA. Transp. Res. Part D Transp. Environ. 2014, 29, 56–65. [Google Scholar] [CrossRef]

- Santos, J.; Bryce, J.; Flintsch, G.; Ferreira, A.; Diefenderfer, B. A life cycle assessment of in-place recycling and conventional pavement construction and maintenance practices. Struct. Infrastruct. Eng. 2015, 11, 1199–1217. [Google Scholar] [CrossRef]

- Moretti, L.; Mandrone, V.; D’Andrea, A.; Caro, S. Evaluation of the environmental and human health impact of road construction activities. J. Clean. Prod. 2018, 172, 1004–1013. [Google Scholar] [CrossRef]

- Santos, J.; Bressi, S.; Cerezo, V.; Lo Presti, D.; Dauvergne, M. Life cycle assessment of low temperature asphalt mixtures for road pavement surfaces: A comparative analysis. Resour. Conserv. Recycl. 2018, 138, 283–297. [Google Scholar] [CrossRef]

- DN-PAV-03077; Complementary Product Category Rules for Bituminous Mixtures (c-PCR Bituminous Mixtures). Transport Infrastructure Ireland: Dublin, Ireland, 2024.

- Schwarz, A.; Overmars, L.; Bizarro, D.G.; Keijzer, E.; Kuling, L.; van Horssen, A. LCA Achtergrondrapport voor Brancherepresentatieve Nederlandse Asfaltmengsels; TNO 2020 R10987; TNO: Utrecht, The Netherlands, 2020. [Google Scholar]

- de Bortoli, A. Understanding the environmental impacts of virgin aggregates: Critical literature review and primary comprehensive life cycle assessments. J. Clean. Prod. 2023, 415, 137629. [Google Scholar] [CrossRef]

- Haritonovs, V.; Tihonovs, J.; Smirnovs, J. High Modulus Asphalt Concrete with Dolomite Aggregates. Transp. Res. Procedia 2016, 14, 3485–3492. [Google Scholar] [CrossRef]

- Agrawal, Y.; Gupta, T.; Siddique, S.; Sharma, R.K. Potential of dolomite industrial waste as construction material: A review. Innov. Infrastruct. Solut. 2021, 6, 205. [Google Scholar] [CrossRef]

- Šernas, O.; Vorobjovas, V.; Šneideraitiene, L.; Vaitkus, A. Evaluation of Asphalt Mix with Dolomite Aggregates for Wearing Layer. Transp. Res. Procedia 2016, 14, 732–737. [Google Scholar] [CrossRef]

- Vorobjovas, V.; Šernas, O.; Žilionienė, D.; Šneideraitienė, L.; Filotenkovas, V. Evaluation of high-quality dolomite aggregate for asphalt wearing course. In Proceedings of the 10th International Conference on Environmental Engineering, ICEE 2017, Vilnius, Lithuania, 27–28 April 2017; pp. 27–28. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Hajibabaei, M.; Hesarkazzazi, S.; Sitzenfrei, R.; Buttgereit, A.; Queiroz, C.; Tautschnig, A.; Gschösser, F. Environmental potentials of asphalt materials applied to urban roads: Case study of the city of Münster. Sustainability 2020, 12, 6113. [Google Scholar] [CrossRef]

- Siverio Lima, M.S.; Hajibabaei, M.; Hesarkazzazi, S.; Sitzenfrei, R.; Buttgereit, A.; Queiroz, C.; Haritonovs, V.; Gschösser, F. Determining the environmental potentials of urban pavements by applying the cradle-to-cradle lca approach for a road network of a midscale German city. Sustainability 2021, 13, 12487. [Google Scholar] [CrossRef]

- West, R.; Rodezno, C.; Julian, G.; Prowell, B.; Frank, B.; Osborn, L.V.; Kreich, T. Field Performance of Warm Mix Asphalt Technologies; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar]

- EAPA. Asphalt in Figures 2022; European Asphalt Pavement Association: Brussels, Belgium, 2022. [Google Scholar]

| Materials | Amount | Unit | Attribute in the Database |

|---|---|---|---|

| Bitumen binder | 40.38 | kg | Bitumen production final LCI—EUROBITUME 2021 System, without infrastructure |

| Sand | 200.42 | kg | Gravel, round {RoW}|gravel and sand quarry operation|Cut-off, S |

| Coarse aggregates | 749.48 | kg | Gravel, crushed {RoW}|gravel production, crushed|Cut-off, S |

| Filler | 9.6 | kg | Lime {Europe without Switzerland}| lime production, milled, loose |

| Antistripping additive | 0.12 | kg | Chemical, organic {GLO}|production|Cut-off, S |

| Total: | 1000 | kg |

| Materials | Payload Distance | Unit | Attribute in Database |

|---|---|---|---|

| Bitumen binder | 11.8 | tkm | Transport, freight, lorry > 32 metric ton, EURO5 {RER}|transport, freight, lorry > 32 metric ton, EURO5|Cut-off, S |

| Sand | 2.8 | tkm | Transport, freight, lorry 16–32 metric ton, EURO5 {RER}| market for transport, freight, lorry 16–32 metric ton, EURO5|Cut-off, S |

| Coarse aggregates | 127.7 | tkm | Transport, freight, lorry 16–32 metric ton, EURO5 {RER}| market for transport, freight, lorry 16–32 metric ton, EURO5|Cut-off, S |

| 9.4 | tkm | Transport, freight train {Europe without Switzerland}|transport, freight train, diesel | Cut-off, S | |

| Filler | 2.4 | tkm | Transport, freight, lorry 16–32 metric ton, EURO5 {RER}|market for transport, freight, lorry 16–32 metric ton, EURO5|Cut-off, S |

| Antistripping additive | 0.33 | tkm | Transport, freight, lorry 16–32 metric ton, EURO5 {RER}|market for transport, freight, lorry 16–32 metric ton, EURO5|Cut-off, S |

| Production Element | Energy Source | Quantity | Unit | Attribute in Database |

|---|---|---|---|---|

| Production line, mixer, bitumen tanks | Electricity | 3.91 | kWh | Electricity, low voltage {LT}|electricity, low voltage, residual mix|Cut-off, S |

| Burner | Natural gas | 293.76 | MJ | Heat, district or industrial, natural gas {Europe without Switzerland}|heat production, natural gas, at industrial furnace > 100 kW|Cut-off, S |

| Loader | Diesel | 5.78 | MJ | Diesel, burned in building machine {GLO}|diesel, burned in building machine|Cut-off, S |

| Name | Symbol | Value | Unit |

|---|---|---|---|

| Ambient temperature | t0 | 16.5 | °C |

| Mixing temperature | tmix | 160 | °C |

| Specific heat of virgin aggregates | Cagg | 0.74 | KJ/kg/°C |

| Water content of aggregates | Wagg | 5 | % by mass of aggregates |

| Specific heat of water | Cw | 4.1855 | KJ/kg/°C |

| Latent heat of vaporization of water | Lv | 2256 | KJ/kg |

| Specific heat of water vapor | Cvap | 1.83 | KJ/kg/°C |

| Specific heat of bitumen | Cbit | 2.093 | KJ/kg/°C |

| Casing loss factor | CL | 20.25 | % |

| Impact Category | Indicator | Abbreviation | Unit | EF 3.1 Single Score | |

|---|---|---|---|---|---|

| Normalization | Weighting (Pt/Unit) | ||||

| Acidification | Acidification potential, Accumulated Exceedance | AP | Mol H+ eq | 1.799 | 0.062 |

| Climate change | Global Warming Potential total | GWP-T | kg CO2 eq | 1.324 | 0.2106 |

| Ecotoxicity, freshwater | Potential Comitative Toxic Unit for Ecosystems | ETP-fw | CTUe | 1.763 | 0.0192 |

| Particulate matter | Potential incidence of disease due to PM emissions | PM | disease inc. | 1.679 | 0.0896 |

| Eutrophication, marine | Eutrophication potential, fraction of nutrients reaching marine and compartment | EP-M | kg N eq | 5.116 | 0.0296 |

| Eutrophication, freshwater | Eutrophication potential, fraction of nutrients reaching freshwater and compartment | EP-F | kg P eq | 6.223 | 0.028 |

| Eutrophication, terrestrial | Eutrophication potential, Accumulated Exceedance | EP-T | mol N eq | 5.657 | 0.0371 |

| Human toxicity, cancer | Potential Comparative Toxic Unit for Humans | HTP-c | CTUh | 5.796 | 0.0213 |

| Human toxicity, non-cancer | Potential Comparative Toxic Unit for Humans | HTP-nc | CTUh | 7.768 | 0.0184 |

| Ionizing radiation | Potential Human exposure efficiency relative to U235 | IRP | kBq U-235 eq | 2.369 | 0.0501 |

| Land use | Potential soil quality index | SQP | Pt | 1.22 | 0.0794 |

| Ozone depletion | Depletion potential of the stratospheric ozone layer | ODP | kg CFC11 eq | 1.91 | 0.0631 |

| Photochemical ozone formation | Formation potential of tropospheric ozone | POCP | kg NMVOC eq | 2.447 | 0.0478 |

| Resource use, fossils | Abiotic depletion for fossil resources potential | ADP-F | MJ | 1.538 | 0.0832 |

| Resource use, minerals and metals | Abiotic depletion potential for non-fossil resources | ADP-MM | kg Sb eq | 1.572 | 0.0755 |

| Water use | Water (user) deprivation potential, deprivation-weighted water consumption | WDP | m3 depriv. | 8.719 | 0.0851 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kleizienė, R.; Buttitta, G.; Carreño, N.; Presti, D.L. Enhancing the Sustainability of Asphalt Mixtures: A Focus on Operational Factors and Dataset for Environmental Product Declarations. Sustainability 2025, 17, 9349. https://doi.org/10.3390/su17209349

Kleizienė R, Buttitta G, Carreño N, Presti DL. Enhancing the Sustainability of Asphalt Mixtures: A Focus on Operational Factors and Dataset for Environmental Product Declarations. Sustainability. 2025; 17(20):9349. https://doi.org/10.3390/su17209349

Chicago/Turabian StyleKleizienė, Rita, Gabriella Buttitta, Nicolás Carreño, and Davide Lo Presti. 2025. "Enhancing the Sustainability of Asphalt Mixtures: A Focus on Operational Factors and Dataset for Environmental Product Declarations" Sustainability 17, no. 20: 9349. https://doi.org/10.3390/su17209349

APA StyleKleizienė, R., Buttitta, G., Carreño, N., & Presti, D. L. (2025). Enhancing the Sustainability of Asphalt Mixtures: A Focus on Operational Factors and Dataset for Environmental Product Declarations. Sustainability, 17(20), 9349. https://doi.org/10.3390/su17209349