Shear Behavior of Curved Concrete Structures Repaired with Sustainability-Oriented Trenchless Polymer Grouting

Abstract

1. Introduction

2. Shear Tests on Composite Specimens

2.1. Polymer

2.2. Concrete Specimens

2.3. Preparation of Composite Specimens

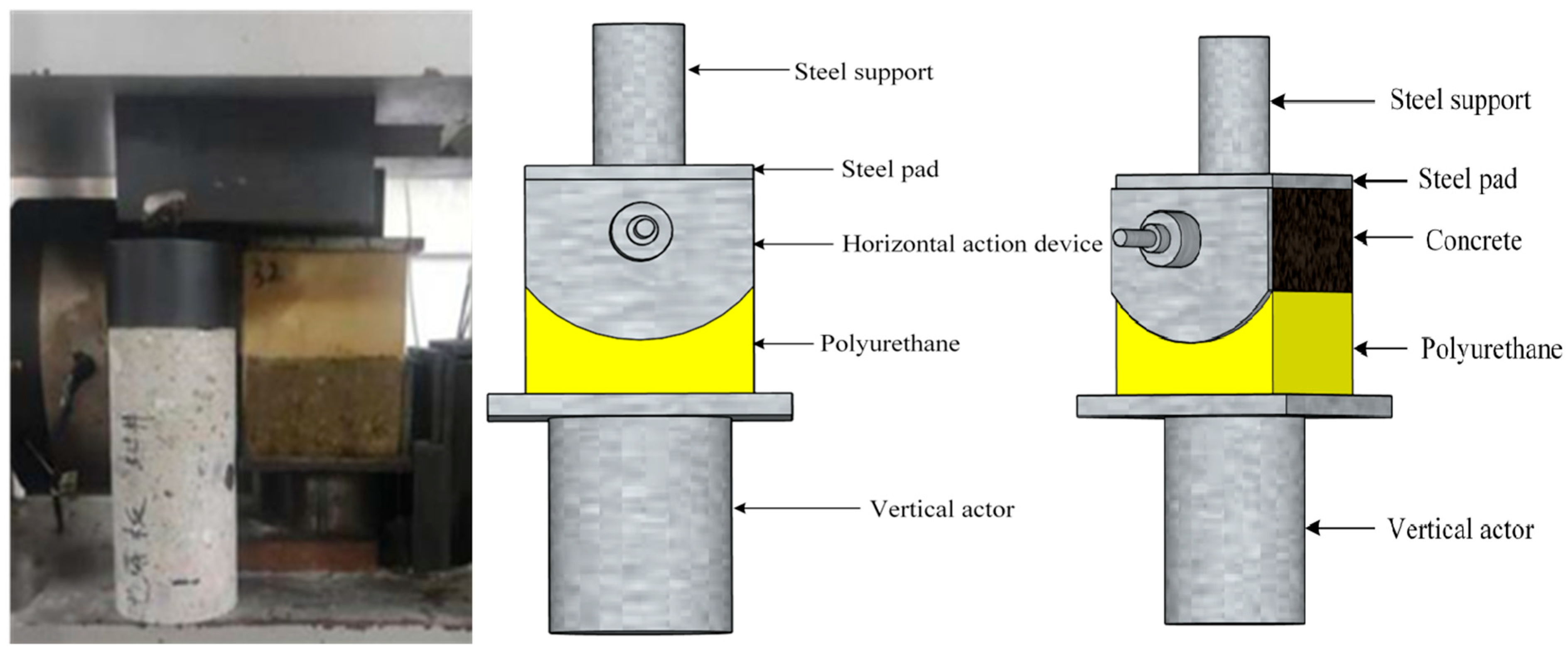

2.4. Experimental Setup

2.5. Experimental Condition Design

3. Results and Discussion

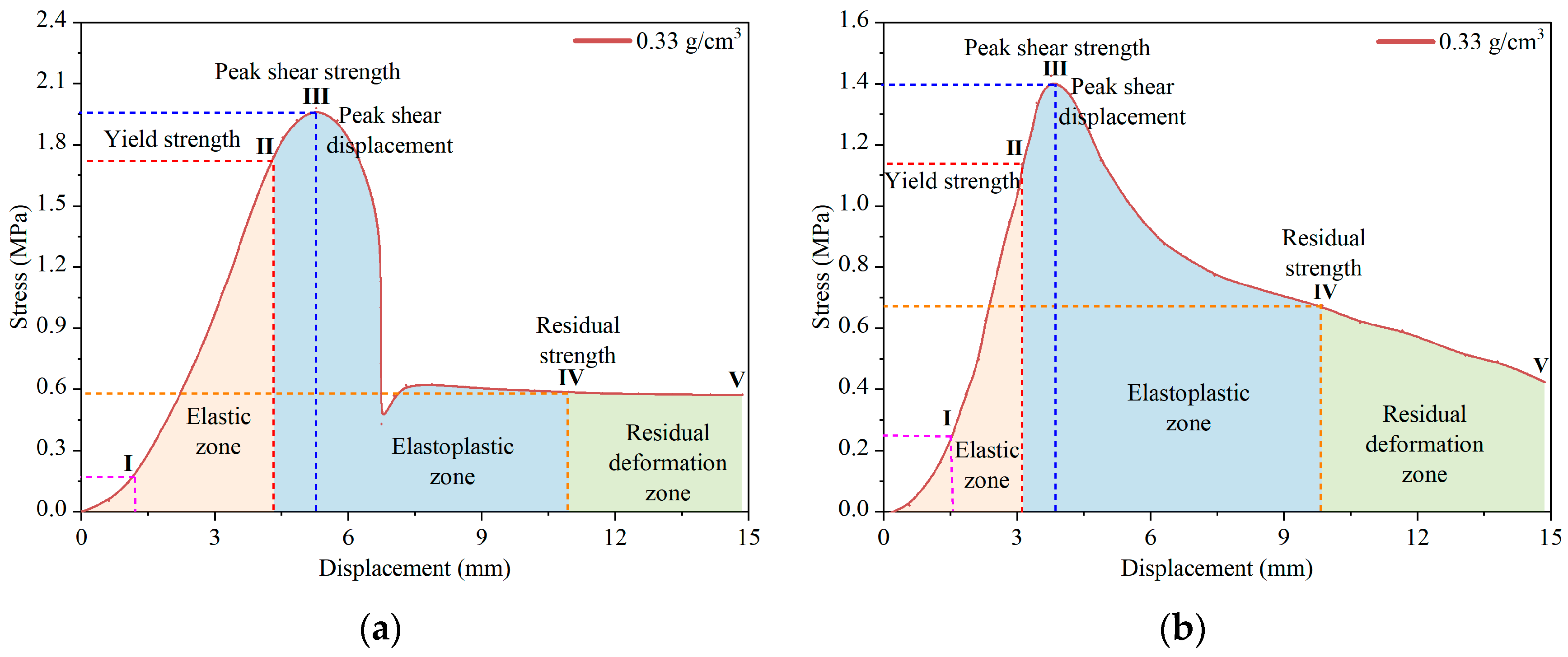

3.1. Typical Shear Stress–Displacement Curves for Curved and Planar Composites

3.2. Experimental Parameter Analysis

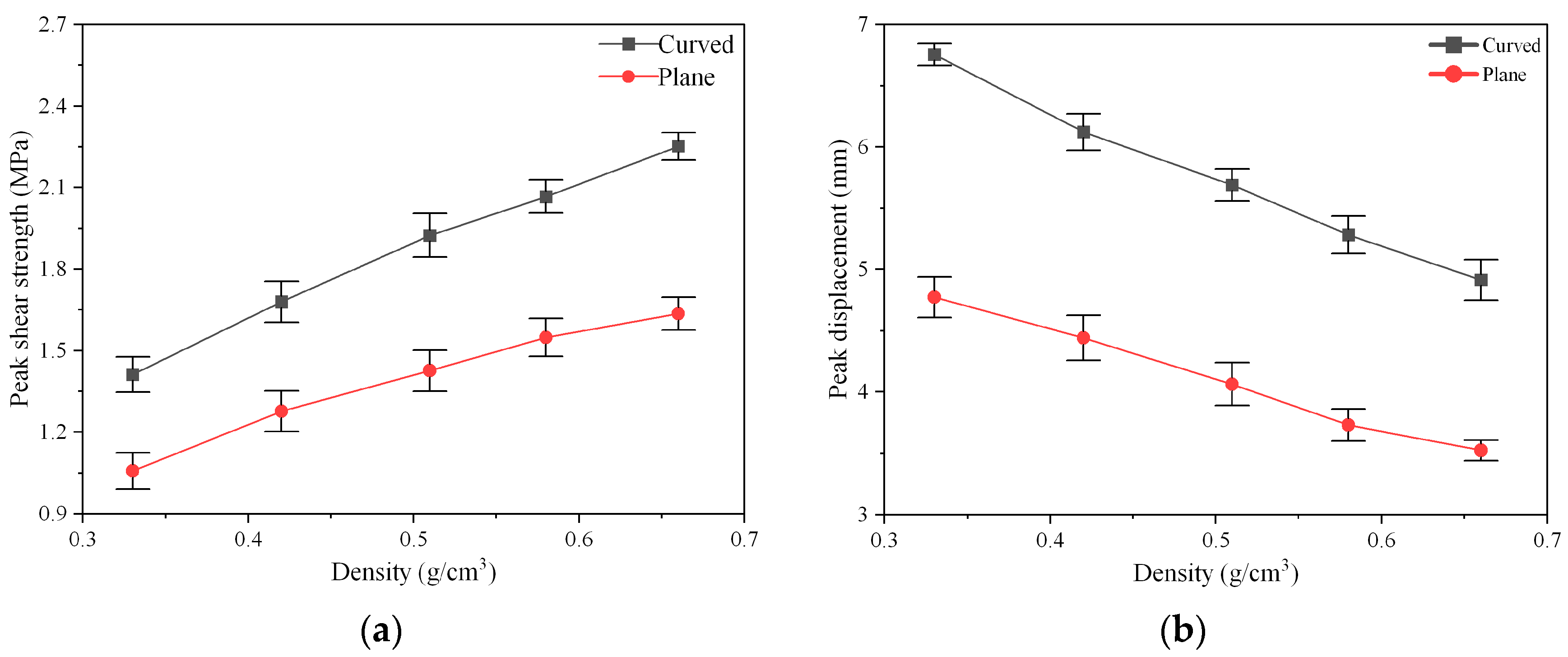

3.2.1. Effect of Polymer Density

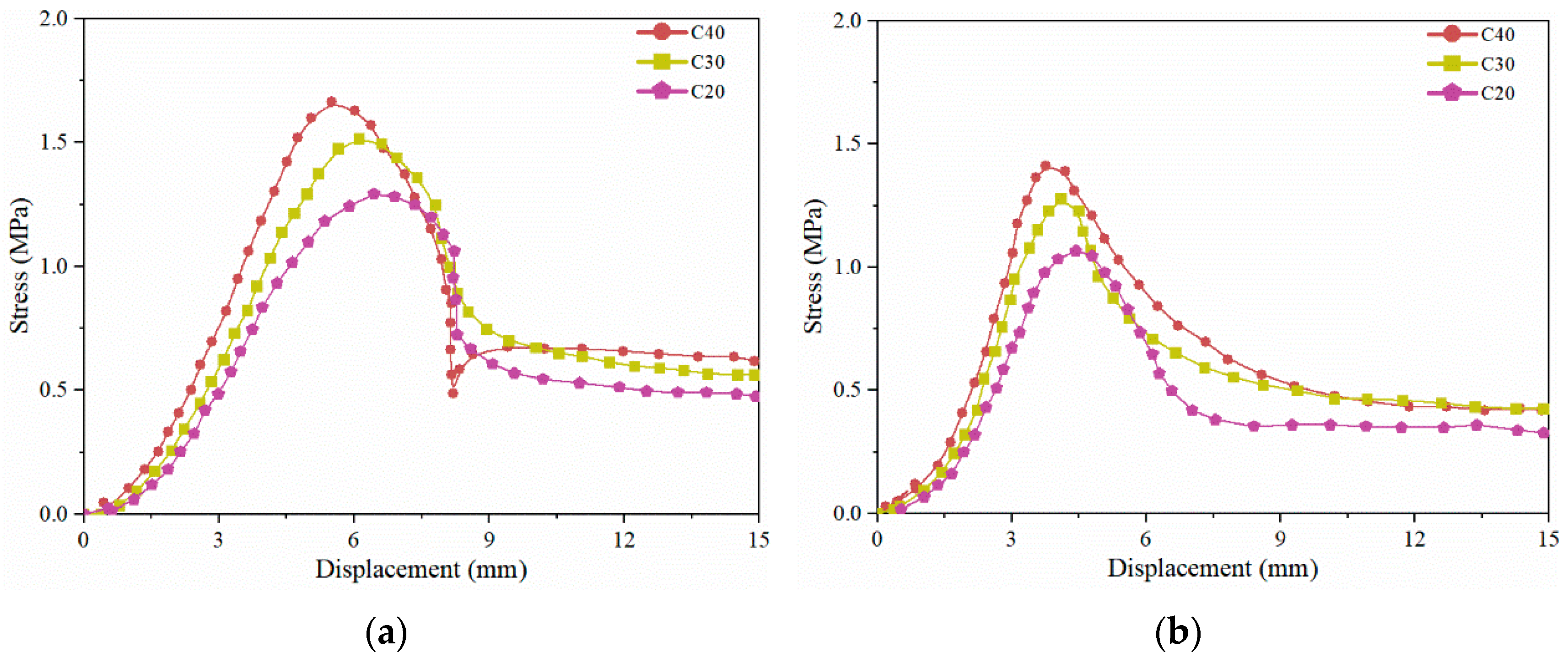

3.2.2. Effect of Concrete Strength

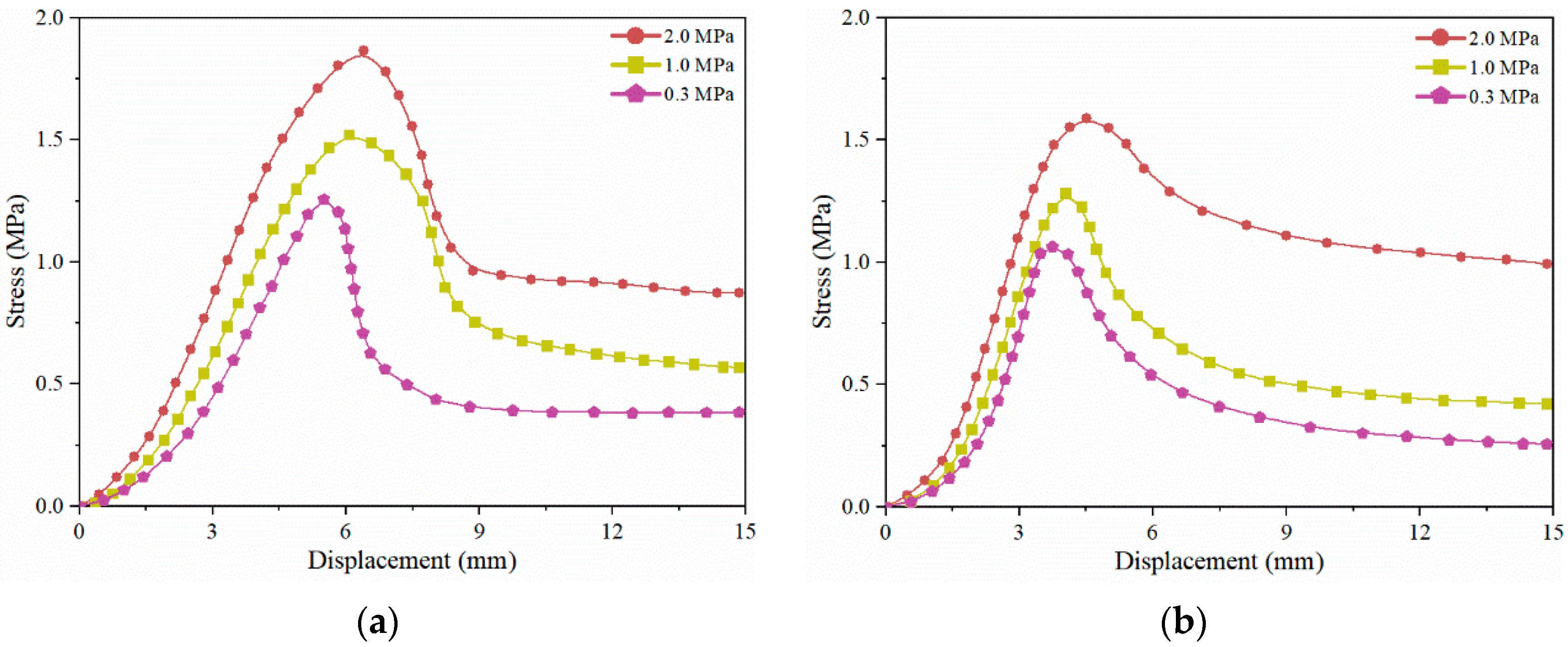

3.2.3. Effect of Normal Stress Level

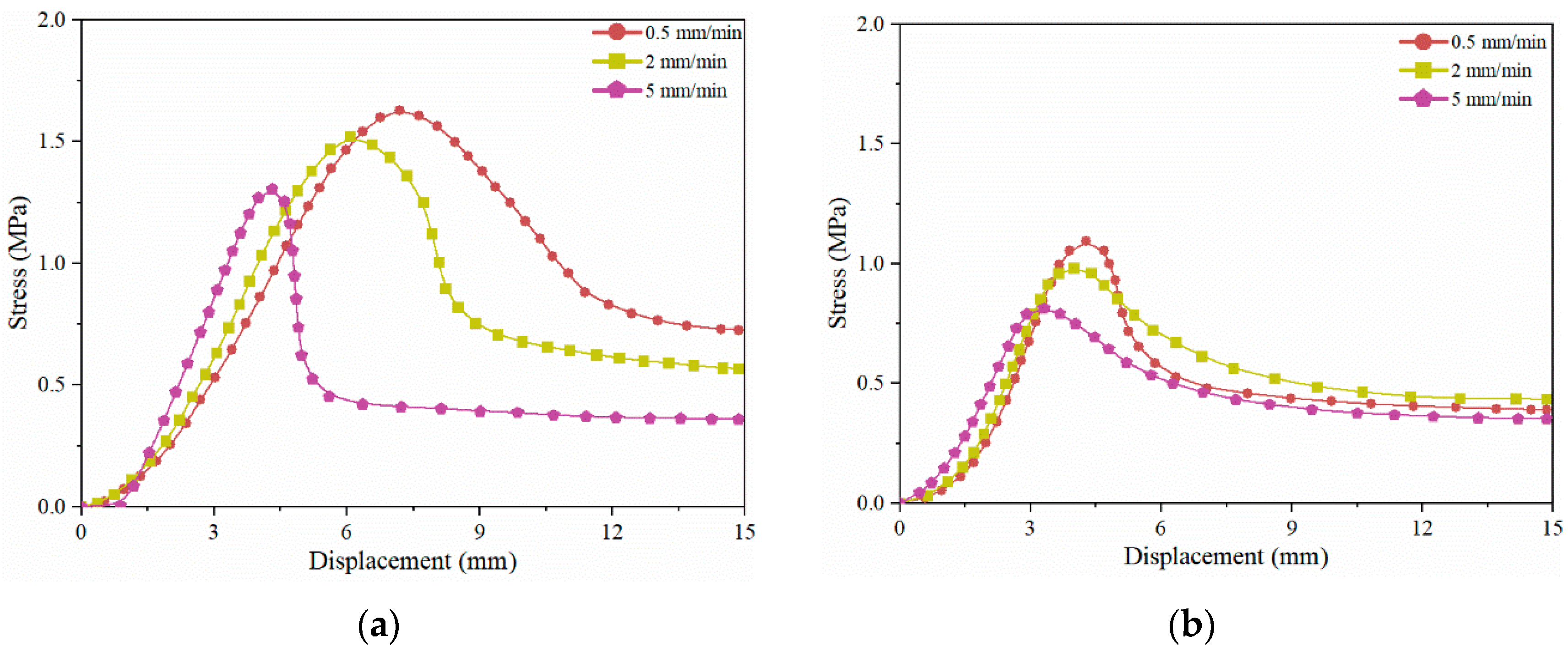

3.2.4. Effect of Shear Rate

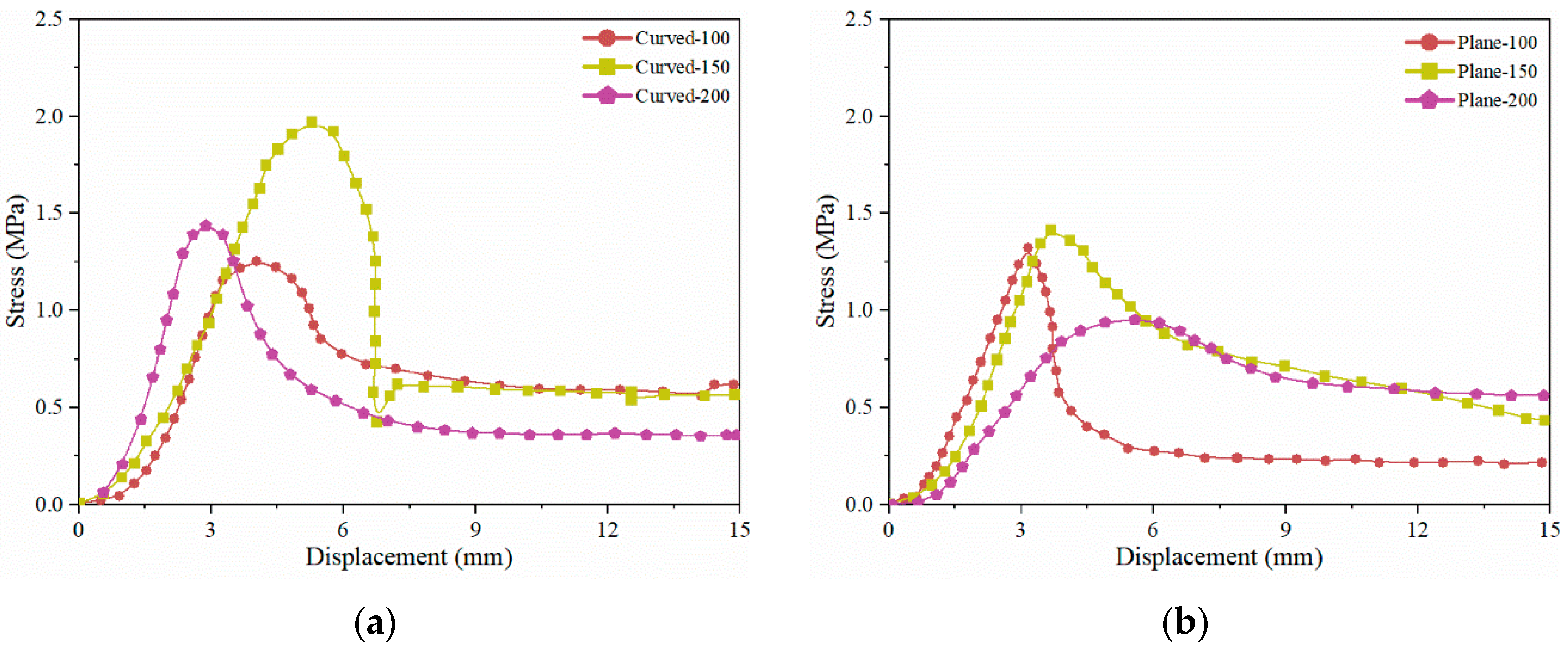

3.2.5. Effect of Size on Shear Behavior

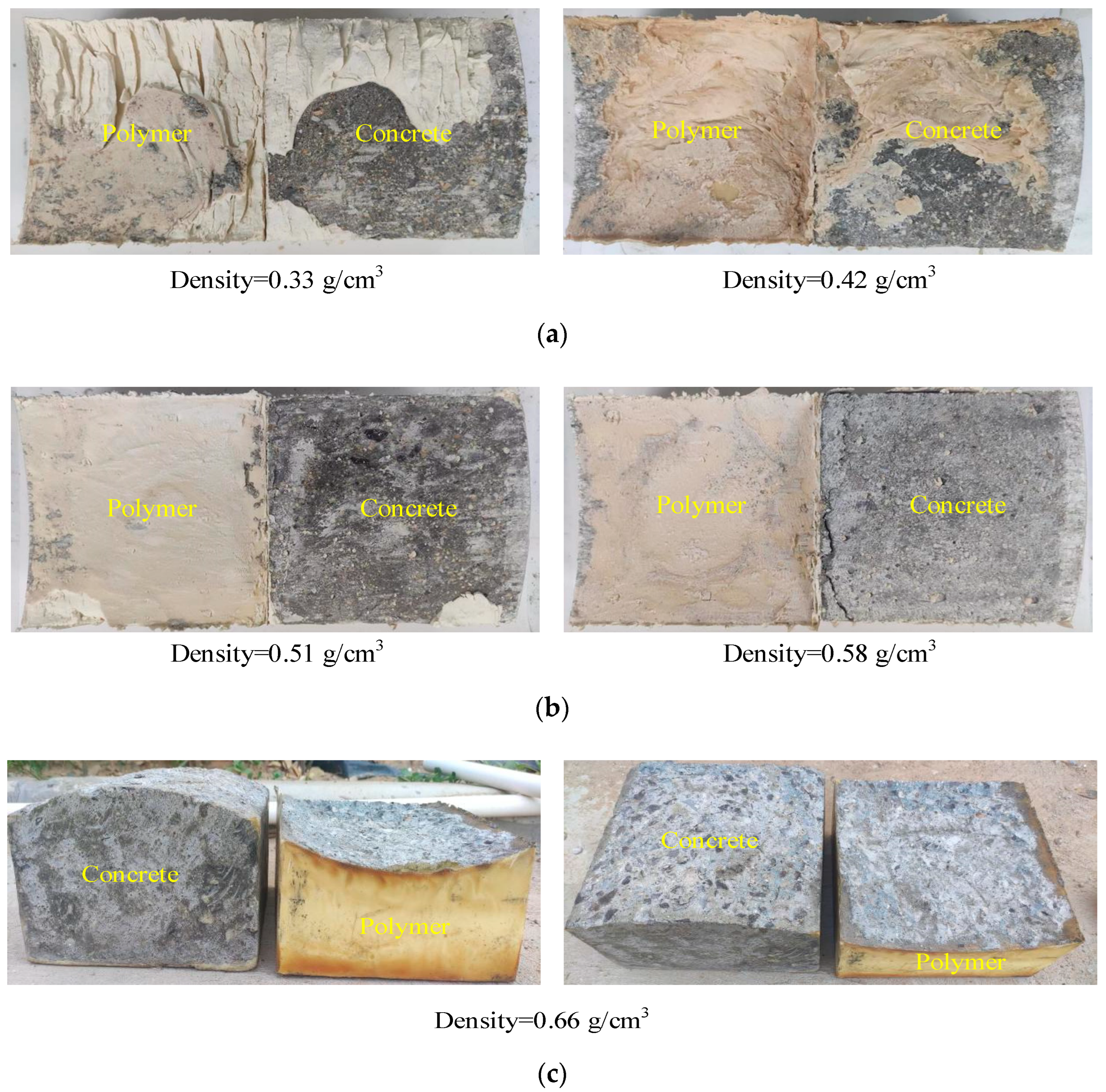

4. Interfacial Failure Characteristics and Failure Mode Analysis

5. Limitations and Future Work

6. Conclusions

- (1)

- Both curved and planar interfaces experience five characteristic shear stages—slow initiation, linear elasticity, yield strengthening, fracture failure, and residual deformation. However, the curved interfaces consistently exhibit higher peak shear strength and larger peak displacement, indicating superior shear performance.

- (2)

- Both polyurethane density and concrete strength enhance peak shear strength but reduce peak displacement. At identical densities, the peak shear strength and displacement of curved specimens are about 1.38 and 1.43 times those of planar specimens. Similarly, under identical concrete strengths, the corresponding ratios are about 1.14 and 1.55, respectively.

- (3)

- Normal stress increases while shear rate reduces peak shear strength and displacement. Under identical normal stress levels, the peak shear strength and displacement of curved specimens are approximately 1.96 and 1.43 times greater than those of planar specimens. Similarly, under identical shear rates, the corresponding ratios are about 1.43 and 1.36, respectively.

- (4)

- Specimen size exerts distinct effects on curved and planar interfaces. For curved specimens, a 150 mm dimension yields optimal shear strength and displacement. In contrast, planar specimens exhibit limited strength improvement but increasing displacement with size.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Liu, G.; Wang, J. Current status, existent problems, and coping strategy of urban drainage pipeline network in China. environ. Sci. Pollut. Res. 2021, 28, 43035–43049. [Google Scholar] [CrossRef]

- Xie, Z.; Jiang, F.; Xu, J.; He, J.; Zheng, D.; Lian, J.; Hou, Z.; Zhao, L.; Wang, Y.; Feng, Y. A narrative of urban underground pipeline system disasters in China in 2021: Spatial and temporal distribution, causal analysis, and response strategies. Sustainability 2023, 15, 10067. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Ti, Y.; Zhang, X.; Yin, T.; Wang, R.; Jiang, X.; Su, Z.; Hao, J. Investigation on shakedown response-behavior of thawed subgrade soils under long-term traffic loading. Front. Earth Sci. 2024, 12, 1361283. [Google Scholar] [CrossRef]

- Chapman, D.N.; Ng, P.C.F.; Karri, R. Research needs for on-line pipeline replacement techniques. Tunn. Undergr. Space Technol. 2007, 22, 503–514. [Google Scholar] [CrossRef]

- Li, B.; Yu, W.; Xie, Y.N.; Fang, H.Y.; Du, X.M.; Wang, N.N.; Zhai, K.J.; Wang, D.C.; Chen, X.M.; Du, M.R. Trenchless rehabilitation of sewage pipelines from the perspective of the whole technology chain: A state-of-the-art review. Tunn. Undergr. Space Technol. 2023, 134, 105022. [Google Scholar] [CrossRef]

- Li, B.; Fang, H.Y.; Zhai, K.J.; Yang, K.J.; Zhang, X.J.; Wang, Y.K. Mechanical behavior of concrete pipes with erosion voids and the effectiveness evaluation of the polymer grouting. Tunn. Undergr. Space Technol. 2022, 129, 104672. [Google Scholar] [CrossRef]

- Wang, F.M.; Shi, M.S.; Li, H.J.; Zhong, Y.H.; Sang, X.M.; Wang, P.C.; Ai, L.; Li, Y.G.; Bu, J.L. Experimental study on the anti-permeability properties of polymer grouting materials. Adv. Mater. Res. 2011, 284, 1952–1955. [Google Scholar]

- Liu, K.; Liang, W.; Ren, F.; Ren, J.; Wang, F.; Ding, H. The study on compressive mechanical properties of rigid polymer grout materials with different densities. Constr. Build. Mater. 2019, 206, 270–278. [Google Scholar] [CrossRef]

- Saleh, S.; Yunus, N.Z.M.; Ahmad, K.; Ali, N. Improving the strength of weak soil using polymer grouts: A review. Constr. Build. Mater. 2019, 202, 738–752. [Google Scholar] [CrossRef]

- Vik, E.A.; Sverdrup, L.; Kelley, A.; Storhaug, R.; Beitnes, A.; Boge, K.; Grepstad, G.K.; Tveiten, V. Experiences from environmental risk management of chemical grouting agents used during construction of the Romeriksporten tunnel. Tunn. Undergr. Space Technol. 2000, 15, 369–378. [Google Scholar] [CrossRef]

- Wu, F.; Ma, Y.; Lei, S.; Liu, S.; He, L.; Liao, J.; Yang, F. Experimental study on the bond behavior of CFRP-grid-reinforced ECC and NC interface. Constr. Build. Mater. 2023, 392, 131947. [Google Scholar] [CrossRef]

- Wang, Y.K.; Wan, Y.S.; Guo, C.C.; Zeng, C.N.; Shao, J.G.; Wang, F.F. Experimental investigation on the monotonic, cyclic and post-cyclic interfacial behavior of non-water reacted polymer and concrete. Constr. Build. Mater. 2021, 292, 123323. [Google Scholar] [CrossRef]

- Qin, L.; Guo, C.C.; Sun, W.; Guan, H.; Yan, W.H.; Wang, F.M. Experimental investigation on the interfacial shear bond performance of non-water reacting polymer and concrete. Constr. Build. Mater. 2022, 331, 127351. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, S.; Feng, J. Frictional behaviour of the interface between concrete and rubber: Laboratory shear test and its elastoplastic model. Eng. Fract. Mech. 2018, 197, 192–205. [Google Scholar] [CrossRef]

- Li, X.X.; Wang, F.M.; Fang, H.Y.; Zheng, D.; Fu, Y.C. Bond behavior between concrete and self-expansion polymer material under normal pressures. Adv. Civ. Eng. 2021, 2021, 6675102. [Google Scholar] [CrossRef]

- Fang, H.; Su, Z.; Li, X.; Wang, F.; Fu, Y. Interfacial bond performance between self-expansion polymer and concrete. Constr. Build. Mater. 2021, 270, 121459. [Google Scholar] [CrossRef]

- Chen, X.B.; Zhang, J.S.; Xiao, Y.J.; Li, J. Effect of roughness on shear behavior of red clay–concrete interface in large-scale direct shear tests. Can. Geotech. J. 2015, 52, 1122–1135. [Google Scholar] [CrossRef]

- Zhang, X.J.; Wang, C.J.; Tian, H.; Shi, M.S. Interface bonding properties between nonwater reaction polyurethane polymer materials and concrete. Adv. Mater. Sci. Eng. 2021, 2021, 1041944. [Google Scholar] [CrossRef]

- Wang, Y.K.; Han, M.S.; Cao, T.C.; Yu, X.; Song, Y.B. Cyclic interface behavior of non-water reactive polymer and concrete during dam restoration. Structures 2021, 34, 748–757. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.L.; Wang, R.J.; Qin, Y.; Cao, Z.L. Experimental investigation of the interfacial bonding properties between polymer mortar and concrete under different influencing factors. Constr. Build. Mater. 2023, 408, 133800. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Z.H.; Ma, G.W.; Zhang, M. Interlayer bonding improvement of 3D printed concrete with polymer modified mortar: Experiments and molecular dynamics studies. Cem. Concr. Compos. 2020, 110, 103571. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Du, M.R.; Fang, H.Y.; Zhang, C.; Li, M.J.; Shi, M.S. Influence of different corrosion environments on mechanical properties of a roadbed rehabilitation polyurethane grouting material under uniaxial compression. Constr. Build. Mater. 2021, 301, 124092. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China; State Administration for Market Regulation of the People’s Republic of China. GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. JG/T 245-2009; Vibrating Table for Concrete Test. Standards Press of China: Beijing, China, 2009.

- Choi, J.S.; Hong, S.H.; Yoo, S.J.; Yang, J.M.; Yoon, Y.S. Effect of internal curing on shrinkage and creep of self-compacting lightweight concrete under different curing conditions. Constr. Build. Mater. 2025, 470, 140612. [Google Scholar] [CrossRef]

- Tian, J.; Zhu, W.; Wu, X.; Sun, C.; Zheng, Y.; Tang, S.W.; Yuan, J.Y.; Zuo, Y.D. Deterioration test and damage model of FRP-ECC-concrete composite interface under sulfate-dry-wet cycles. Constr. Build. Mater. 2025, 471, 140723. [Google Scholar] [CrossRef]

- Wahab, S.; Salami, B.A.; Danish, H.; Nisar, S.; Alateah, A.H.; Alsubeai, A. A hybrid machine learning approach for predicting fiber-reinforced polymer-concrete interface bond strength. Eng. Appl. Artif. Intell. 2025, 148, 110458. [Google Scholar] [CrossRef]

- Xie, F.; Chang, T.; Kuang, G.; Sun, L.G.; Wu, L. Biaxial compression-shear behavior of SAP-PVA enhanced concrete: Experiments and analysis. J. Build. Eng. 2025, 108, 112833. [Google Scholar] [CrossRef]

- Li, B.; Wang, F.M.; Fang, H.Y.; Yang, K.J.; Zhang, X.J.; Ji, Y.T. Experimental and numerical study on polymer grouting pretreatment technology in void and corroded concrete pipes. Tunn. Undergr. Space Technol. 2021, 113, 103842. [Google Scholar] [CrossRef]

- Hao, S.; Liu, Y.; Zhang, Z.; Zhang, J. Experimental investigation of the shear behavior of soft-hard joints under constant normal stress. Bull. Eng. Geol. Environ. 2025, 84, 10. [Google Scholar] [CrossRef]

- Ferrier, E.; Michel, L.; Thiele, M.; Delmas, S. Strain-rate effect on the bond strength of external bonded reinforced carbon fiber-reinforced polymer for concrete structure. Constr. Build. Mater. 2025, 466, 140216. [Google Scholar] [CrossRef]

| Strength | Water–Cement Ratio | Water (kg/m3) | Cement (kg/m3) | Medium Sand (kg/m3) | Coarse Aggregate (kg/m3) | Water-Reducing Agent (kg/m3) |

|---|---|---|---|---|---|---|

| C20 | 0.625 | 175 | 280 | 680 | 1250 | 0.01 |

| C30 | 0.50 | 175 | 350 | 650 | 1200 | 0.01 |

| C40 | 0.40 | 160 | 400 | 600 | 1250 | 0.01 |

| Size (mm) | Concrete strength | Normal stress (MPa) | Shear rate (mm/min) | Density (g/cm3) | ||||

| 150 | C30 | 1.0 | 2.0 | 0.33 | 0.42 | 0.51 | 0.58 | 0.66 |

| Size (mm) | Density (g/cm3) | Normal stress (MPa) | Shear rate (mm/min) | Concrete strength | ||||

| 150 | 0.33 | 1.0 | 2.0 | C20 | C30 | C40 | ||

| Size (mm) | Density (g/cm3) | Concrete strength | Shear rate (mm/min) | Normal stress (MPa) | ||||

| 150 | 0.33 | C30 | 2.0 | 0.3 | 1.0 | 2.0 | ||

| Size (mm) | Density (g/cm3) | Concrete strength | Normal stress (MPa) | Shear rate (mm/min) | ||||

| 150 | 0.33 | C30 | 1.0 | 0.5 | 2.0 | 5.0 | ||

| Density (g/cm3) | Concrete strength | Normal stress (MPa) | Shear rate (mm/min) | Size (mm) | ||||

| 0.33 | C30 | 1.0 | 2.0 | 100 | 150 | 200 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, D.; Sha, Y.; Li, B.; Yao, X.; Li, M.; Du, X.; Zhao, X.; Zhai, K. Shear Behavior of Curved Concrete Structures Repaired with Sustainability-Oriented Trenchless Polymer Grouting. Sustainability 2025, 17, 9340. https://doi.org/10.3390/su17209340

Qi D, Sha Y, Li B, Yao X, Li M, Du X, Zhao X, Zhai K. Shear Behavior of Curved Concrete Structures Repaired with Sustainability-Oriented Trenchless Polymer Grouting. Sustainability. 2025; 17(20):9340. https://doi.org/10.3390/su17209340

Chicago/Turabian StyleQi, Dongyu, Yinan Sha, Bin Li, Xupei Yao, Manjun Li, Xueming Du, Xiaohua Zhao, and Kejie Zhai. 2025. "Shear Behavior of Curved Concrete Structures Repaired with Sustainability-Oriented Trenchless Polymer Grouting" Sustainability 17, no. 20: 9340. https://doi.org/10.3390/su17209340

APA StyleQi, D., Sha, Y., Li, B., Yao, X., Li, M., Du, X., Zhao, X., & Zhai, K. (2025). Shear Behavior of Curved Concrete Structures Repaired with Sustainability-Oriented Trenchless Polymer Grouting. Sustainability, 17(20), 9340. https://doi.org/10.3390/su17209340