Abstract

Sustainable production also involves analyzing greenhouse gas (GHG) emissions throughout the entire cultivation and processing cycle. The emissions balance for different sugar beet varieties is a key element of environmental assessment in sustainable production systems. It is consistent with the objectives of the European Green Deal and aims to decarbonize agri-food technology. This study aims to assess and compare GHG emissions associated with the cultivation of three sugar beet variants (Viola, Jaromir, and Pulitzer) taking into account their technological and quality characteristics. The varieties were selected based on their registration in the National Register and their importance in agricultural practice in Poland, as well as their contrasting technological profiles, which allow for the assessment of the relationship between raw material quality and GHG balance. The study combines life cycle assessment (LCA) with physiological parameters such as CO2 assimilation, sugar content, yield, fuel consumption, and fertilizer use. The aim is to identify the correlation between the technological value of a variety and its environmental impact. It has been shown that genotypic characteristics have a significant impact on both yield and emissions. The Viola and Jaromir varieties showed a favorable balance between photosynthetic efficiency and greenhouse gas emissions, while the Pulitzer variety, despite low emissions per kilogram of product, showed poorer yield performance. The importance of using integrated assessment methods combining production efficiency, environmental efficiency, and crop quality was emphasized. Such an approach is essential for the development of sustainable agricultural practices in line with the EU’s climate neutrality goals. Further research is needed to optimize agrotechnical strategies tailored to the requirements of individual varieties, contributing to climate-resilient and environmentally friendly crop production.

1. Introduction

The analysis of greenhouse gas (GHG) emissions in the context of different sugar beet varieties is an important element of the environmental assessment of sustainable crop production systems, directly contributing to the objectives of the European Green Deal [1,2]. This strategy aims to achieve climate neutrality in the European Union by 2050 and significantly reduce emissions from the agricultural sector, including through the promotion of sustainable agrotechnical practices and efficient resource management. In this context, studying the GHG emissions generated in the production cycle of different sugar beet varieties allows not only for the identification of the most emission-intensive stages of cultivation, but also for the assessment of the impact of genotype and quality characteristics of varieties on the carbon footprint (CF) of a product unit [3,4]. Taking into account the varietal aspect in the environmental analysis allows for the integration of crop selection criteria with the requirements of EU climate policy, which is particularly important in light of the reform of the common agricultural policy (CAP) and the regulation on the sustainable use of natural resources. By analyzing GHG emissions for individual sugar beet varieties, it is possible to identify production variants that combine high technological and biological quality with a low environmental footprint, which facilitates the formulation of practical agrotechnical recommendations in line with the objectives of the European Green Deal [5,6]. This study therefore makes an important contribution to the development of low-carbon agricultural strategies and supports the implementation of environmental assessment tools, such as life cycle analysis (LCA), as a basis for sustainable food production management in European conditions [7,8]. In the context of sustainable sugar beet production, it is not only GHG emissions analysis that is crucial, but also the technological quality of the raw material, which determines the efficiency of the production process in sugar factories.

The good quality of sugar beet is an important prerequisite for the efficient operation of a sugar factory. The selection of methods and a proper understanding of the technological process of sugar production require a thorough knowledge of the mechanical properties and chemical composition of the raw material. The chemical and mechanical properties of sugar beet, which are important for their technological value, are closely related to environmental and agrotechnical factors that affect the quality of the raw material [9].

The implementation of new technologies, both in the field of breeding and cultivation of sugar beets, as well as relatively high mineral fertilization, and the ongoing mechanization and chemicalization, have significantly affected the mutual relationships between the beet components that are important for technological value. The introduction of new instrumental analytical methods has enabled a more accurate and comprehensive examination of the chemical composition of the raw material sent for processing. For this reason, the determination of the composition and mechanical properties affecting the technological value of sugar beet has become the subject of intensive research in many countries. At the same time, progress has been made in the field of sugar technology, taking into account the possibility of adjusting technological parameters to the quality of the raw material. The most important indicator of the technological value of beets is the white sugar yield index, i.e., the difference between the sugar content in beets (polarization) and the sum of all losses. While the amount of loss incurred at extraction and filtration stations, and to a large extent also unmarked loss, depends on the way the technological process is carried out and can be reduced, the loss of sugar in molasses depends primarily on the chemical nature of the non-sugars contained in beets. Even after exemplary purification of juices with lime and saturation gases, and maximum depletion of molasses, losses reach a certain limit, which depends on the amount of important non-sugars introduced from beets into raw juice during the extraction process [10,11]. Factors affecting the quality of sugar beet, such as chemical composition and growing conditions, are also important for the characteristics of foliage, which plays a key role in photosynthesis and biomass accumulation.

The chemical composition of beet has a significant impact on the yield of crystalline sugar in sugar factories. Sodium, potassium, and amino nitrogen are molasses-forming substances that are taken into account when assessing beet quality, testing beet varieties, and in some countries even when calculating payments to producers. The quality of the beet is also influenced by the length of the growing season, weather conditions, and various factors such as variety, root diseases, water stress, nitrogen fertilization, defoliation, and storage [9]. Non-sugars contained in sugar beet also play an important role. The technological value of sugar beet is defined as a set of raw material characteristics that influence the technological process, the type and amount of sucrose losses, and the yield of white sugar. The technological value of beet depends on many factors, including genetics, location, planting density, agrotechnical treatments, fertilization, sowing dates, techniques and timing of beet harvesting, occurrence of diseases, weeds and pests, climatic conditions, and beet storage conditions.

Processing raw materials of reduced technological value, containing large amounts of various non-sugars, causes many difficulties in sugar factories. Among other things, it causes a decrease in the thermostability of sugar juices, which manifests itself in significant changes in the parameters of thin juice, such as increased coloration, increased calcium salt content, loss of alkalinity, reduced purification effect, increased invert content, etc. The composition of non-sugars in raw juice is variable and depends on the technological value of the processed raw material. Non-sugars can be formed during the processing of beets in a sugar factory or during their storage. Beets stored in piles at the edge of a field at a grower’s farm can sometimes be frozen and thawed several times before being sent for processing. Therefore, biochemical changes play a dominant role in the process of changes occurring in sugar beet. Sugar beet tissue contains polysaccharides, i.e., complex sugars that form part of the cell wall structure. They form a complex system of chain molecules of cellulose, hemicellulose, pectin, and proteins, interconnected by hydrogen bonds [12]. The polysaccharides contained in raw juice that have a significant impact on the technological process of obtaining sugar from beets include:

- -

- dextran—a polysaccharide with a very high molecular weight, containing mainly α-1,6 glycosidic bonds of glucose residues,

- -

- levan—a polysaccharide with a high molecular weight [approx. 50 million], containing D-fructose residues linked by β-2,6 bonds,

- -

- raffinose—belonging to the group of carbohydrates, a trisaccharide composed of glucose, fructose, and galactose, interfering with the technological process, mainly during filtration and crystallization of sucrose,

- -

- galactan—a polysaccharide composed of several dozen D-galactose molecules linked by β-1,4-glycosidic bonds,

- -

- araban—a non-reducing pentosan with a low molecular weight, composed of L-arabinose residues linked by α-1,5 glycosidic bonds with an α-1,3 branch [13,14].

Another aspect is the size and length of beet foliage, which varies depending on the season and location and is strongly determined by soil moisture, fertilization, and management skills [15]. High nitrogen uptake stimulates the leaves to grow to very large sizes and causes leaves to grow later [16]. The largest leaves and foliage are produced when growth occurs under ideal growing conditions. The increase in leaf area increases linearly with the increase in nitrogen content in the crop. At the time of maximum leaf development, the weight (dry mass) of foliage is approximately 300–400 g/m2 [16]. The size of the heads together with the leaves is about 50–60 tons per hectare (5–6 t/ha dry weight) and depends on the variety, climatic conditions during the growing season, and the region of cultivation. An important characteristic component of the leaves is chlorophyll. Its content in mature beet leaves is 6.3 mg/g. At the same time, there is a close correlation between high sugar content and high dry matter content. Varieties with high sugar content have the highest dry matter yield. The composition of elements in leaf blades varies depending on their age. The concentration of N, P, K, Zn, and Cu decreases as the leaves mature, while the content of Ca, Mg, Na, Mn, and Mo increases. No correlation was observed in the content of B and Fe, particularly iron [17]. Taking into account the influence of foliage and the chemical composition of sugar beet on the yield and quality of the raw material allows for a better understanding of the relationship between plant characteristics and their environmental footprint, which forms the basis for analyzing GHG emissions in the context of sustainable production.

In recent years, the literature has shown a wide variation in estimates of the carbon footprint of sugar production, with results depending to a large extent on the scope of the analysis (field-gate vs. full field-to-market chain), local production conditions, and the efficiency of technological processes (Table 1).

Table 1.

Comparison of CF values for sugar—literature review (2019–2024).

A review of the latest research indicates that beet sugar production can have both lower and higher GWP values compared to cane sugar, depending on the region and technology: an analysis of global trends has shown that the average unit emissions for beet sugar are often higher than for cane sugar, which is due, among other things, to different systemic assumptions and the intensity of nitrogen fertilizers used. Detailed LCAs of beet sugar production report ranges of several hundred grams of CO2eq per kilogram of sugar (typically 0.24–0.77 kg CO2eq/kg in cross-sectional European compilations), with a significant proportion of emissions occurring at the agricultural stage—primarily N2O emissions associated with nitrogen fertilization and the consumption of energy and machine fuels. Analyses based on plant data show that with high technological efficiency and the use of low-emission energy solutions (e.g., biogas, heat recovery), the total CF of beet sugar can be significantly reduced [19,24]. Empirical studies from European and Scandinavian countries confirm that the carbon footprint (farm to gate) for sugar beet is usually in a relatively low range (0.06–0.12 kg CO2eq/kg), while the full footprint for finished sugar, after taking into account the processing stages, increases significantly. In publications based on plant data in Poland and Europe, the farm-to-gate values for beet sugar often range from 0.14 to 0.60 kg CO2eq/kg, depending on the technology and energy source. A national study published in 2024 estimated the CF values for sugar production in Polish sugar factories, which fall within the middle range of international ranges, confirming the importance of local technological and energy practices [20,25]. The conclusions from the literature review are twofold: firstly, the most effective CF reductions can be achieved by optimizing agronomic practices (precision fertilization, increasing yields while reducing mineral nitrogen, improving machine efficiency) and implementing low-carbon energy sources and heat recovery in processing plants; secondly, comparisons between regions and between LCA studies require standardization of scopes and methodologies (e.g., system boundary selection, by-product allocation, emissions baseline) to make the results comparable and useful for policy and industry. Overall, recent studies emphasize that with effective agricultural practices and modernization of sugar technologies, beet sugar production can achieve a competitive and, in some scenarios, favorable emissions balance compared to alternative sugar sources.

The current approach to sustainable agricultural production increasingly focuses on a thorough analysis of greenhouse gas (GHG) emissions as a key indicator of the environmental impact of crops [26]. These emissions, which are a direct and indirect result of agrotechnical activities (such as fertilization, fuel consumption, crop structure), are one of the main sources of anthropogenic impact of agriculture on the climate. In this context, combining production requirements with environmental aspects in order to optimize the emission balance of the entire cropping system is becoming increasingly important [27]. Despite numerous studies on GHG emissions in the agricultural sector [28,29], there remains a research gap regarding the link between the quality of plant raw materials and the environmental efficiency of their production. In particular, there is a lack of analysis of the impact of the technological value of a product, such as sugar content or root weight in the case of sugar beet on its carbon footprint. Traditional variety assessment is based mainly on yield, ignoring potential differences in emissions related to beet quality and their ability to accumulate biomass in relation to environmental inputs. In light of the need to minimize the environmental impact of agriculture, the integration of GHG emission data with the analysis of the technological quality of sugar beet varieties opens up new opportunities for the development of more sustainable cultivation strategies [30,31].

Although the environmental impact of crop production has been extensively studied, most existing research on sugar beet cultivation focuses primarily on yield and resource inputs without considering the role of product quality in determining environmental efficiency. There is a lack of comprehensive analyses linking the technological value of sugar beet, such as sugar content, root weight, and capacity for biomass accumulation, with the crop’s greenhouse gas (GHG) emissions and carbon footprint. Consequently, the potential trade-offs or synergies between technological quality and environmental performance remain poorly understood. Addressing this gap is crucial for advancing sustainable agricultural strategies that integrate both productivity and quality as drivers of environmental outcomes.

The aim of this study is to compare the level of greenhouse gas emissions associated with the production of three varieties of sugar beet in the context of their technological and quality differences. The analysis will be carried out taking into account key parameters affecting emissions, such as total yield, sugar content in the root, consumption of mineral and organic fertilizers, fuel consumption, and carbon dioxide assimilation by plants. The aim of the work is to determine the relationship between the utility value of a variety and its environmental impact, which may contribute to the development of more sustainable cultivation strategies in which the quality of the plant product becomes an integral part of the environmental assessment. The research focuses on comparing three varieties of sugar beet in terms of quality and technological indicators and the corresponding GHG emissions throughout the crop’s life cycle. The study fills the gap between the assessment of the technological value of raw materials and the assessment of their carbon footprint by proposing an integrated approach (LCA, quality of raw materials sent for processing, physiological parameters). This interdisciplinary approach, integrating production technologies, quality assessment, and life cycle analysis (LCA) in terms of GHG emissions, is in line with current research trends in sustainable agriculture [32,33] and may serve as a basis for formulating new criteria for variety selection in plant breeding with a reduced environmental footprint. The following hypotheses were formulated:

H1:

Sugar beet varieties with higher technological value (e.g., greater sugar content and root weight) demonstrate improved environmental efficiency, reflected in a lower carbon footprint per unit of useful product, despite potentially higher inputs of fertilizers and fuel.

H2:

The integration of technological quality indicators with GHG emission data enables more accurate assessment of the sustainability of sugar beet cultivation compared to yield-based evaluation alone.

H3:

Varietal differences in CO2 assimilation capacity significantly influence the relationship between production inputs and environmental impact, thereby shaping the overall carbon balance of sugar beet cultivation systems.

2. Research Material

Three varieties of sugar beet were analyzed: Viola, Jaromir, and Pulitzer. The selection of the Viola, Jaromir, and Pulitzer varieties was based on their registration and widespread use in Poland (National Register of COBORU—Central Agricultural Plant Variety Testing Center), different technological profiles (sugar content, ash, K/Na), and availability of comparable cultivation sites (Farmer 1 vs. Farmer 2), which allows for the combination of genotype, environment, and agrotechnical practices. These varieties are approved for use by Polish farmers. Field trials were conducted in two locations. Farmer 1 cultivated all three varieties, while Farmer 2 cultivated only the Pulitzer variety, due to the limited amount of agricultural land available for sugar beet cultivation. The entire plant development cycle was monitored from sowing in March until harvest in November, while detailed measurements of physiological parameters were taken in the final phase of vegetation (in June, July, August, September, October, and November). For the purposes of analysis and unambiguous identification of the research material, individual samples were marked according to the variety code and location: V1 refers to the Viola variety, J1 to the Jaromir variety, while P1 and P2 correspond to samples of the Pulitzer variety, originating from the Farmer 1 and Farmer 2 plantations, respectively. The V1 variety was grown on very good soil (Class I, II—soil quality classification of arable land in Poland), under favorable weather conditions and with all the necessary agrotechnical measures in place, hence the very high yield of this variety. In the case of Farmer 2, the crop was grown on poorer quality land (Class IVa—soil quality classification of arable land in Poland), hence the significantly lower yield of the P2 variety.

In a comparative analysis of three sugar beet varieties (Viola, Jaromir, Pulitzer), their environmental and production efficiency was assessed based on two key parameters: carbon dioxide assimilation and greenhouse gas (GHG) emissions (fuel consumption, fertilizer consumption). The assessment was conducted to identify the most effective varieties in terms of photosynthesis and productivity, as well as their impact on the natural environment.

3. Research Methodology

3.1. Experimental Sugar Beet Cultivation System—Agrotechnical Standards, Fertilization Rates, Sowing Parameters

The field designated for sugar beet cultivation was prepared as follows. In the fall, in the year preceding sowing, pre-winter plowing was carried out to a depth of 25–30 cm in order to improve soil structure and increase water retention. In the spring, before sowing, the soil was cultivated and harrowed to obtain a fine and even seedbed, ensuring good growing conditions. Organic fertilization was applied in the year preceding cultivation in the form of manure at a dose of 25–30 t/ha. Mineral fertilization included: nitrogen at a dose of 100–150 kg N/ha (applied in two stages: before and after sowing), phosphorus at a dose of 60–80 kg P2O5/ha, and potassium at a dose of 120–180 kg K2O/ha. In addition, micronutrients (especially boron and magnesium) were applied, which are essential for proper root development and high technological quality of the raw material. Sowing was carried out at the turn of March and April, after the soil temperature reached 5–6 °C. A precision seeder was used to ensure even distribution of the plants. The row spacing was 45–50 cm, and the distance between plants in a row was 18–20 cm, which allowed for a planting density of approx. 100,000 plants/ha. The sowing depth was 2–3 cm on heavier soils and 3–4 cm on lighter soils. The field experiment was planned in a randomized block design, with three replicates. The size of the experimental plots was 20–30 m2. The factors studied were sugar beet variety (Viola, Jaromir, Pulitzer) and location/soil quality (good soils vs. poorer soils). This design made it possible to compare the results of individual genotypes under different conditions and to assess the interaction between variety, soil quality, and the agrotechnical measures applied.

3.2. Measurement of Sugar Beet Photosynthesis Parameters

Measurements of physiological parameters on a sugar beet plantation were performed for the following parameters: normalized difference vegetation index (NDVI), chlorophyll content in leaves, nitrogen content in leaves, photosynthetically active radiation (PAR) absorption, and leaf area index (LAI). The parameters necessary to determine the NDVI were measured using a GreenSeeker device (Trimble, Westminster, CO, USA), and the value was calculated using the formula [34]:

where NIR—reflection in the infrared band; VIS—reflection in the red band

Chlorophyll and nitrogen content in leaves were measured using a Minolta SPAD 502Plus chlorophyll meter (Konica Minolta, Tokyo, Japan). Photosynthetically active radiation (PAR) was measured above the crop (Il) and below the crop (Iu) using an AccuPar probe (Decagon, San Francisco, CA, USA). PAR absorption was calculated according to the formula:

The leaf area index (LAI) was calculated as the ratio of leaf area to soil area. Measurements were taken on 10 representative plants of each sugar beet variety at each time point. The results obtained from the experiment were subjected to statistical analysis using analysis of variance and multiple comparisons using the NIR procedure. A significance level of α = 0.05 was adopted for the comparison of means. The calculations were performed using the R statistical package (Statistica PL v. 13.2) with the agricolae library (aov and LSD.test procedures). The parameters of variability of the assessed traits were also calculated: mean, minimum and maximum values, standard deviation (SD) and coefficient of variation (CV).

Measurements were taken in the VI, VII, VIII, IX, X, and XI months of vegetation, respectively, ~90, ~120, ~150, ~180, ~210, and ~240 DAS (days after sowing; sowing at the end of March/beginning of April). Harvesting was carried out in November (~240 DAS). For each date, NDVI (GreenSeeker, N-Tech Industries, Dalton, GA, USA), SPAD/N in leaves (SPAD 502Plus, Konica Minolta), PAR (AccuPAR, METER Group, Pullman, WA, USA) and LAI were determined; n = 10 plants per variety and date.

3.3. Chemical Characterization of Sugar Beet

The chemical characteristics of sugar beet were determined on the basis of three measurements of each of the analyzed samples, in accordance with the methodology developed at the Institute, described by Butwiłowicz [35]. The analyses were performed under laboratory conditions, which ensured the repeatability of the results obtained. The determinations covered key chemical parameters, and the data obtained form the basis for further comparative analyses between the evaluated sugar beet varieties. In order to determine dry substance content measures of the amount of dry mass in sugar beet have been carried out in accordance with standard PN-EN 12880:2004 [35,36]. High dry substance content usually indicates high sugar yield as most of the dry mass is sucrose. Marc content refers to the amount of insoluble plant components remaining after juice extraction. Lower marc content is desired for more efficient sugar extraction [35]. Sucrose content (amount of sucrose) is directly measured as the main sugar produced from sugar beets. High sucrose content indicates better quality beets for sugar production (method ICUMSA GS6-3, 1994). Berlinski Institute method [35] was used to measure the levels of reducing substances (Invert) such as glucose and fructose, which can affect sugar production quality. Measurements of the mineral content in beet juice have been carried out. Lower ash content is desired as high levels can affect technological processes [35]. Ammonia nitrogen levels were determined as important for assessing the quality of fertilization and its impact on raw material quality, in accordance with standard PN-EN 13342:2002 [37]. In order to indicate the nitrogen content from amino acids, which can affect fermentation processes in sugar production, the α-amino acid nitrogen was determined (method ICUMSA GS6-5, 2007). An important indicator for fermentation processes (like α-amino acid nitrogen), amide nitrogen, has been defined with the use of titration in water steam method [35]. Metallic components such as sodium and potassium can affect the quality of beet juice and production processes; their content has been determined in ASA spectrophotometry [35].

3.4. Technological Value of Sugar Beet

The technological value of sugar beet is determined on the basis of its biological, chemical, and physical characteristics, which directly or indirectly affect the technological process, the type and amount of sucrose losses, and sugar production efficiency. The factors determining the technological value of beets include: sucrose content, α-amino acid nitrogen content, invert sugar content, conductometric ash content, degree of mechanical and microbiological damage to the roots, amount of impurities, content of celery-like roots (so-called rushes), stem and leaf residue content, pulp content, potassium, sodium and magnesium content, raffinose content, and saponin content [38]. Based on three measurements of each sugar beet sample, indicators determining the technological value of the raw material were calculated using the appropriate relationships shown in Table 2.

Table 2.

Indicators determining the technological value of raw materials, together with formulas.

3.5. Assimilation During the Sugar Beet Growing Season

The total amount of carbon dioxide (CO2) assimilated by sugar beets during the growing season can be estimated based on plant physiological parameters and environmental conditions, in accordance with the accepted calculation methodology. This process is based on the use of direct measurements of photosynthesis intensity, leaf area index (LAI), and assumptions regarding the duration of photosynthetic activity. The first stage of the analysis involves direct measurements of CO2 assimilation rates (denoted as A), expressed in units of [µmol CO2 m−2 s−1]. The study used A values obtained at three stages of vegetation for different sugar beet varieties, which form the basis for further calculations. These unit values refer to leaf area and need to be converted to the crop level, i.e., the soil area on which the crop grows. For this purpose, the leaf area index (LAI) is used, which expresses the ratio of the total leaf area to the ground area. Multiplying the A value by the LAI gives the assimilation index for the entire crop (Alan = A × LAI), which reflects the actual CO2 absorption potential of the entire crop. In practice, instead of continuous measurements, average values of A and LAI characteristic for a given month are used, and a constant value of daily photosynthetic activity is assumed. It was assumed that sugar beets carry out active photosynthesis for about 7 h a day during a 170-day growing season, which corresponds to a total exposure time of 4,284,000 s. On this basis, total CO2 assimilation can be calculated using the formula [39]:

where Ac denotes total assimilation [µmol CO2/m2], A denotes the average rate of CO2 assimilation [µmol CO2 m−2 s−1], LAI denotes the leaf area index, and t denotes the duration of photosynthetic activity [s].

Ac = A × LAI × t

The result obtained can then be converted into mass units (e.g., kg CO2/ha) using an appropriate conversion factor that takes into account the molar mass of CO2 (44 g/mol) and Avogadro’s number. This approach allows the total amount of organic carbon stored in plants as a result of photosynthesis to be estimated and enables sugar beet varieties to be compared in terms of their assimilation potential in environmental terms. The combination of physiological and environmental data in this model also allows for a better representation of actual agricultural production conditions and supports the assessment of the sustainability of cultivation.

3.6. GHG Emissions Analysis

The greenhouse gas (GHG) emissions analysis was based on data obtained directly from farmers specializing in sugar beet cultivation. A detailed understanding of the production processes on the farms studied made it possible to formulate general guidelines for assessing GHG emissions in agriculture, including the identification of their main sources. The results of this research can serve as a basis for further optimization of production technologies towards reducing GHG emissions and improving the environmental performance of the agricultural sector. In the long term, the development of consistent methodological principles for assessing greenhouse gas emissions in agricultural production is essential in the context of implementing sustainable development strategies, as well as for adapting to current and future European and international climate regulations. Taking into account the specific nature of individual farms, including the diversity of technologies, cultivation systems, and local agrotechnical conditions, significant differences in GHG emission levels were found. For this reason, it is necessary to develop universal guidelines that take into account technological variability and its environmental consequences. The analysis assessed GHG emissions at each stage of the production cycle. In order to ensure the accuracy of the calculations, a methodology based on fuel conversion factors (2.7 kg CO2 for diesel fuel) was used, in accordance with current databases [40,41], and CO2 conversion factors for the fertilizers used (Table 3) were also applied. This methodology allowed for a quantitative assessment of emissions under real farm conditions. For the purposes of a comprehensive analysis, a dedicated database was developed containing detailed information obtained from farmers for each month of the growing season. Based on the collected data, the total GHG emissions associated with sugar beet cultivation were calculated, taking into account technological conditions and local production practices. The methodology of CF calculation can be found in work [42].

Table 3.

CO2 conversion factors for fertilizers used [43].

The questionnaire covered: the number and type of cultivation operations, diesel consumption [L/ha] per operation, mineral/organic fertilizer doses [kg or L/ha] broken down into N, P, K and form, area [ha] and yield [t/ha]. Direct emissions were calculated from diesel consumption (2.7 kg CO2/l; DEFRA) and emission factors for fertilizers (Table 3; including urea, RSM, Polidap; KOBiZE; DEFRA). Total CF per unit of product:

emissions per hectare:

4. Results and Discussion

4.1. Characteristics of the Chemical Quality Parameters of Sugar Beet

The chemical quality parameters of sugar beet were tested for three beet varieties, using the same method for all samples. The results are presented in Table 4. The dry matter content showed significant differences between the tested varieties. Variety V1 achieved the highest value (24.73%), approaching the level typical for healthy, technologically mature sugar beet, which, according to literature data, averages around 25%. P2 showed a content of 24.19%, P1—24.15%, while J1 achieved the lowest value (22.25%), which may indicate a slightly lower technological maturity of this raw material. The pulp content ranged from 3.8% (J1) to 5.15% (P1). The P1 variety exceeded the upper limit of the optimal range (4–5%), which may result in an increased amount of pulp during processing. P2 (4.15%) and V1 (4.05%) were within the range typical for healthy, technologically mature sugar beet. The pulp content determines the amount of pulp, with an average amount of pulp expected when processing the V1 and P2 varieties. Sugar content was a key parameter differentiating the tested varieties. V1 achieved the highest sucrose concentration (19.16%), remaining in the upper part of the optimal range (14–19%). P2 showed a content of 18.39%, P1- 18.1%, while J1 achieved the lowest value (16.65%). According to literature data, in healthy, technologically mature sugar beet, the sucrose content can vary on average between 14 and 19%. The content of reducing substances (invert) in all varieties was within the optimal range (0.02–0.10%), with the highest value for V1 (0.09%) and identical values for P1 and P2 (0.08%). The invert content at the concentration found will not affect the coloration of the juices or lower their pH during the processing of the tested beets. The analysis of the mineral composition revealed significant differences between the varieties. J1 was characterized by an exceptionally high soluble ash content (0.831%), significantly exceeding the optimal range (0.4–0.6%). P2 showed a content of 0.502%, which is in the upper part of the optimal range, while V1 (0.386%) and P1 (0.341%) reached values below the lower limit of the norm. Soluble ash is inorganic chemical compounds contained in cell sap and weakly bound to sugar beet tissue, which accompany sucrose during the sugar extraction process and end up in the diffusion juice, and then mostly in molasses. The potassium content showed a similar trend, with the highest concentration in the J1 variety (0.272%), while P1 achieved the lowest value (0.126%). P2 (0.210%) and V1 (0.239%) were within the optimal range (0.1–0.3%). The lowest possible potassium content is beneficial for sugar production technology, as in large quantities it can form so-called “molasses formers”. Sodium content was highest in J1 (0.016%) and decreased systematically in subsequent varieties, with the lowest value for V1 (0.006%). Low sodium content, like potassium, is beneficial for sugar production technology. The α-amino acid nitrogen content ranged from 0.007% (P1) to 0.014% (P2), α-amino acid nitrogen is a completely undesirable component of diffusion juice, forming part of the so-called “harmful non-sugars”. The amide nitrogen content ranged from 0.009% (P1) to 0.022% (P2). V1 reached a value of 0.015%, which is considered favorable for technology. Amide nitrogen compounds are undesirable in sugar beet processing because their thermal-chemical degradation causes a decrease in the pH and alkalinity of the thick juice.

Table 4.

Chemical quality parameters of sugar beet.

Polarization values of 16.6–19.2% fall within the ranges for technologically mature beets; elevated K/Na in J1 affects the increase in sugars in molasses (technological loss). In turn, higher LAI and maintenance of photosynthetic activity in V1 (VI–XI) correspond to higher CO2 assimilation efficiency per hectare.

4.2. Assessment of Sugar Beet Technological Value Indicators

An analysis of sugar beet technological value indicators was carried out for three varieties. To ensure the comparability of the results, all measurements were performed according to a uniform analytical methodology, using the same procedures for each sample. The relationships and equations described in detail in Table 2 were applied. The results of the measurements are summarized in Table 5, which allows for a direct comparison of the tested varieties in terms of their technological potential and raw material efficiency.

Table 5.

Indicators of sugar beet technological value.

The indicators taken into account are markers of the technological quality of sugar beet. The optimal values for these indicators are given in the last column. A comparison of the parameters of the analyzed varieties in the context of optimal values was carried out. The predicted purity of thick juice reached the highest values for varieties P1 (96.2) and P2 (94.2%), significantly exceeding the threshold favorable for processing beets into sugar (>92%). V1 showed a purity of 94.1%, while J1 reached the threshold value (92%). The parameter of predicted thick juice purity is favorable for all tested varieties. The purity of the raw material, defined as the ratio of sugar content to dry matter content multiplied by 100, was most favorable for the V1 variety (77%), with identical values for the other varieties (75%). All varieties exceeded the minimum threshold (>70%), indicating that the quality of the tested beets was sufficient in terms of this indicator, which means that the raw material has properties favorable for processing in a sugar factory. The predicted sugar content in molasses, calculated according to Wieninger’s formula taking into account the sodium and potassium content [44], was lowest for varieties P1 (1.2%) and P2 (2.0%). Sugar in molasses is treated as a loss, which is the largest item in the list of sugar losses in the technological process, therefore this indicator is of paramount importance for sugar factories. V1 reached a value of 2.1%, while J1 showed the highest losses (2.7%), exceeding the optimal threshold (<2%). The alkalinity index including invert sugar (WAI) showed significant deviations from the optimal values (1.8–2.3) in all tested varieties. J1 achieved the highest value (5.8), V1—4.4, while P1 and P2 showed similar values (3.1 and 3.5). Values above 2.3 indicate high natural alkalinity and suggest the possibility of an increase in alkalinity during juice concentration, which may indicate a risk of difficulties with adequate alkalinity during the concentration of juice obtained from the tested raw material. The ash index, defined as the ratio of sugar content to soluble ash content in the root, was highest for the P1 (53) and V1 (50) varieties, all exceeding the minimum threshold (>40). P2 (37) deviated slightly from the norm, while J1 showed a value significantly below the norm (20), which means an unfavorable ratio of sugar to ash content. The α-amino acid nitrogen index, which determines the ratio of sugar content to α-amino acid nitrogen content in the root, reached the highest values for varieties P1 (2586), significantly exceeding the minimum threshold (>800). V1 showed a value of 1916, followed by P2 (1314), while J1 reached 1281. It is favorable when the sugar content is at least 800 times higher than the α-amino acid nitrogen content. The amide nitrogen index showed a similar trend, with the highest values for P1 and (2105) exceeding the minimum threshold (>750). V1 reached a value of 1312 and P2 (836), while J1 showed the lowest value (920), but still favorable for processing technology.

The reducing substance index, calculated as the ratio of sugar content to invert content in beet, was highest for the J1 variety (333), with similar values of 226 for P1, 230 for P2, and 213 for V1. All values were higher than the criterion set for this parameter (>100). The non-sugar index, calculated as the ratio of sugar content to soluble non-sugars, showed the highest values for P1 (20), V1 reached a value of 13, followed by P2 (11), while J1 showed a borderline value (9), but still favorable for beet processing into sugar (>10). The potassium and ash alkalinity indices were favorable for all varieties. The potassium alkalinity index was highest for variety V1 (24), followed by J1 (21), while P1 (18) and P2 (15) achieved similar values. The ash alkalinity index was highest for J1 (64), followed by P1 (49) and V1 (39), and lowest for P2 (36). When processing beets with such indices, it will not be necessary to carry out a supplementary treatment consisting of adding aqueous soda solutions to the purified juices.

Summarizing, technological suitability is primarily determined by high sugar content, low ash content (especially K and Na), low N-α and N-amide content, and low “sugar in molasses”. Varieties with increased K/Na and ash (e.g., J1) generate higher molasses losses and may require more intensive juice purification (higher reagent/energy consumption—potentially higher emissions outside the field stage). Higher K/Na and ash in J1 increase sugar in molasses (2.7%), which limits white sugar yield and may require more intensive purification treatments (cost/energy). V1 combines high polarity (19.16%) and favorable alkalinity/ash ratios, which translates into a technologically advantageous profile.

4.3. Assimilation During the Growing Season for Sugar Beet

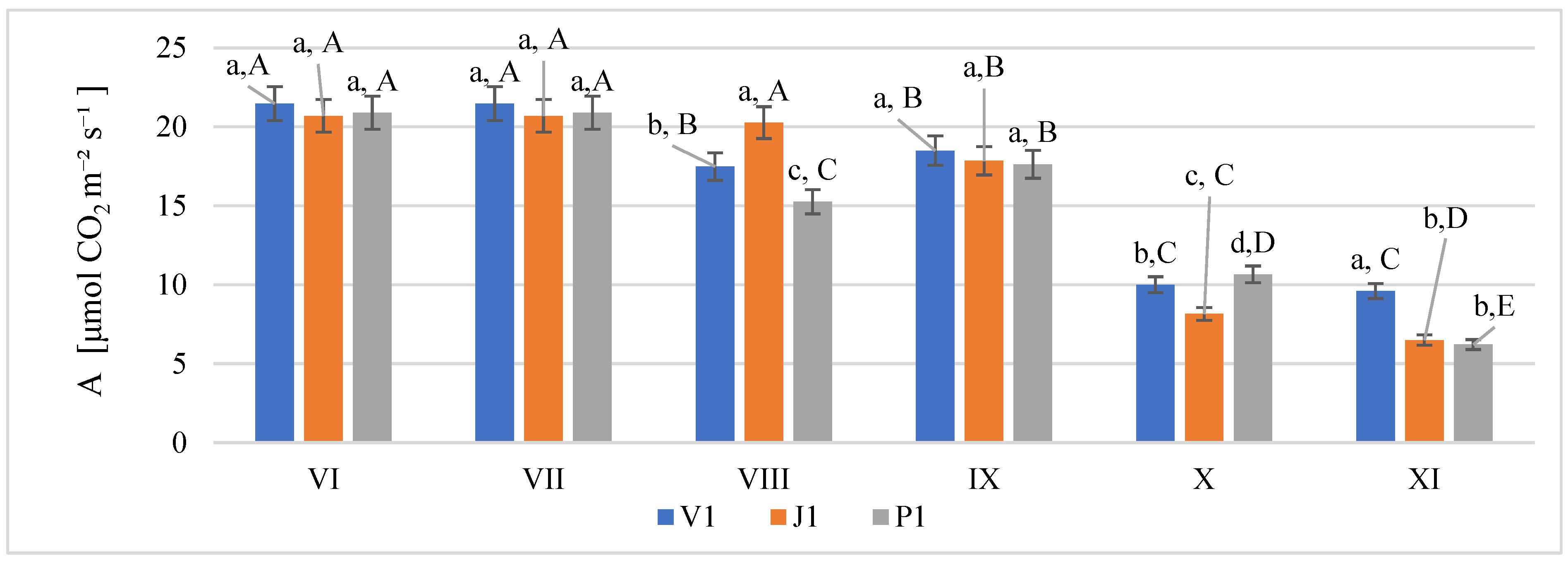

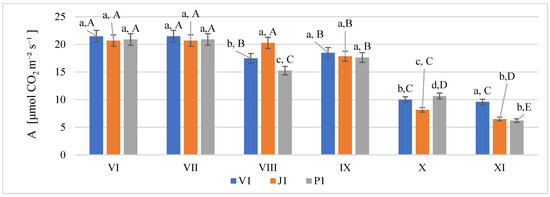

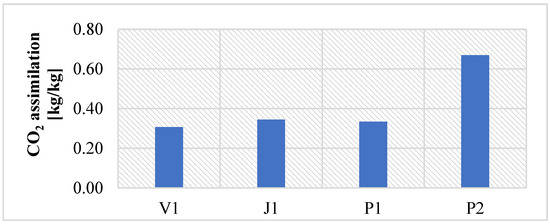

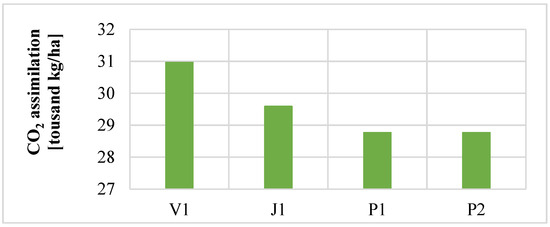

A comparison of sugar beet varieties was made in terms of carbon dioxide assimilation, fuel consumption, fertilizer use, and greenhouse gas (GHG) emissions. CO2 assimilation (net photosynthesis rate, expressed in µmol CO2 m−2 s−1) is a measure of the amount of carbon dioxide bound by a plant per unit of time per unit of leaf area [45]. In terms of CO2 assimilation, the highest value per unit area (kg/ha) was recorded for the V1 variety (30,964.61 kg/ha) (Table 6), while similar, slightly lower values were obtained for varieties J1 (29,587.94 kg/ha) and P1 (28,767.76 kg/ha). When converting CO2 assimilation per unit of yield weight (kg CO2/kg beet), the highest values were obtained for the P2 variety (0.67 kg/kg) (Table 6), which indicates low photosynthetic efficiency in relation to the weight of the raw material produced. The best assimilation index in relation to mass was achieved by the P1 variety (0.3345 kg/kg), which indicates its high photosynthetic efficiency while maintaining favorable yield parameters. The highest rate of carbon dioxide assimilation was measured from June to September for all beet varieties tested (Figure 1), with measurements taken at Farmer 1. In the case of the V1 variety, no significant decrease in the rate of photosynthesis was observed in November compared to October, whereas a significant decrease was observed for J1 and P1.

Table 6.

CO2 assimilation for the analyzed sugar beet varieties.

Figure 1.

Changes in carbon dioxide assimilation rates over a six-month period. n = 3, the same lowercase letters indicate no statistically significant differences between beet varieties in the same month, the same uppercase letters indicate no statistically significant differences between months within a given beet variety (p < 0.05, test NIR/LSD).

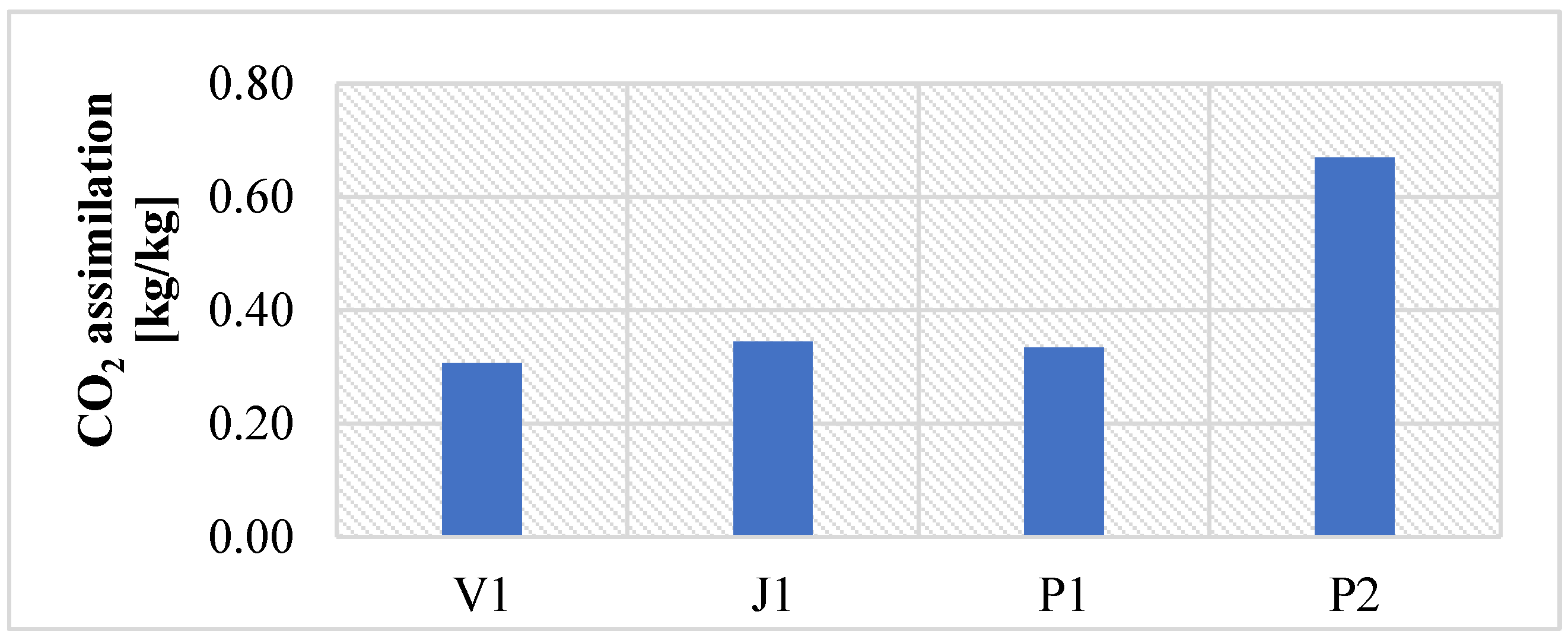

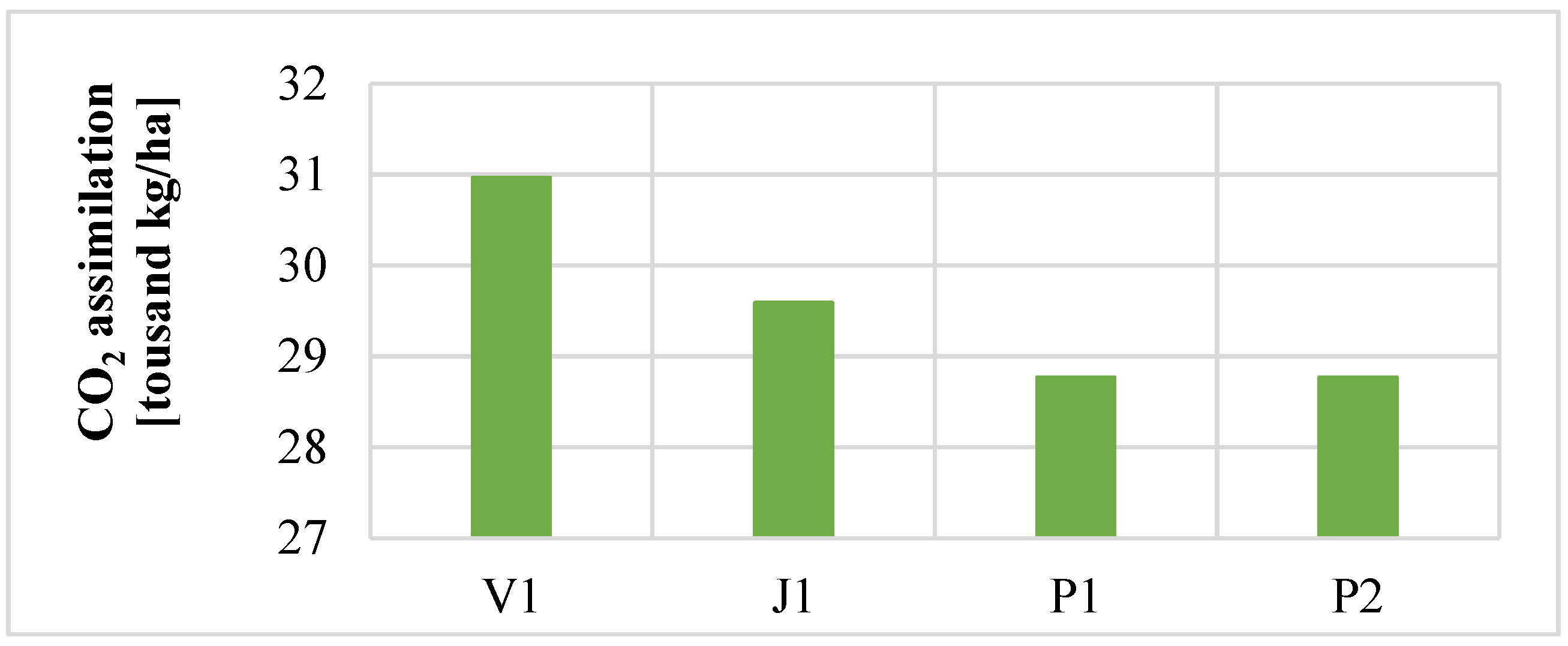

Figure 2 and Figure 3 show a comparison of CO2 assimilation for three sugar beet varieties, in [kg/kg] and [kg/ha], respectively. The results obtained were compared with data from the literature. A summary of CO2 assimilation (annual average values) for different crops and ecosystems according to literature data is presented in Table 7. It is noteworthy that the calculated CO2 assimilation for the analyzed beet crops ranges from 28 to 31 t CO2/ha (Table 6) and exceeds the literature data. This indicates that the treatments applied during beet cultivation increased its ability to accumulate carbon dioxide.

Figure 2.

CO2 assimilation [kg/kg] for the analyzed sugar beet varieties.

Figure 3.

CO2 assimilation [kg/ha] for the analyzed sugar beet varieties.

Table 7.

Summary of CO2 assimilation (annual averages).

Sugar beet achieves very high photosynthetic efficiency, similar to corn, despite being a C3 plant. The increased photosynthetic efficiency results from, among other things, a long period of leaf activity (from May to October), a high LAI (>5), and rapid growth and high biomass yield. According to literature data (Table 7), corn (C4) has the highest CO2 assimilation values among agricultural crops, which results from the C4 photosynthesis mechanism (higher efficiency at high light and temperature). The amount of assimilated CO2 depends on the atmospheric conditions in which it grows [47,48]. Winter wheat (C3) shows significantly lower assimilation, mainly due to lower LAI, earlier end of the growing season (harvest in June or July), lower photosynthesis intensity in colder months [49,50]. Deciduous forests show high total annual assimilation, but part of it is compensated by high respiration (litter decomposition, fungal and root activity), making their net balance comparable or lower than that of intensive crops [51,52]. The assumption that the amount of assimilated CO2 corresponds to the amount of sucrose in the sugar beet is incomplete and simplistic and although it may be useful as a rough estimate, it does not reflect the plant’s overall carbon balance. Carbon dioxide is assimilated by the entire plant and is not only used for sugar production in the sugar beet. Part of the assimilated CO2 is converted into leaf and stem biomass, starch (stored for a short time); proteins, organic acids, lignin; secondary substances (e.g., pectins, cellulose); and is also oxidized in cellular respiration (i.e., it returns to the atmosphere as CO2). Only part of the carbon from CO2 ends up in the sucrose stored in the root. It is estimated that approximately 30–50% of the carbon from assimilated CO2 is stored in the root in the form of sucrose, while the rest remains in the above-ground parts of the plant or is used for its growth processes. The assumption that “all assimilated CO2 corresponds to sucrose in the root” is only true in a simplified sense, if we ignore the contribution of leaves, respiration, and other metabolites. In reality, about 25–40% of the assimilated carbon goes to sugar in the root, and the rest feeds the other structures of the plant or is oxidized. In environmental analyses, the following should be treated separately: total CO2 assimilation, the share of C in the usable product (e.g., sucrose), losses through respiration, and decomposition of residues. It is estimated that approximately 30–50% of the carbon from assimilated CO2 is stored in the root in the form of sucrose, while the rest remains in the above-ground parts of the plant or is used for metabolic purposes during plant growth.

Assuming that approximately 40% of assimilated carbon dioxide is stored in the plant in the form of sucrose, the total amount of assimilated CO2 per unit of sucrose mass was calculated for the tested sugar beet varieties. The values obtained indicate varying efficiency in the conversion of atmospheric carbon into sugar depending on the variety and growing conditions. For sample V1, a value of 0.64 kg CO2/kg sucrose was estimated, which indicates a relatively high efficiency of conversion of assimilated carbon dioxide into a usable form. For sample J1, this value was 0.83 kg CO2/kg sucrose, and for P1 0.74 kg CO2/kg sucrose. The highest value was recorded for sample P2, where 1 kg of sucrose corresponded to as much as 1.46 kg of assimilated CO2, which may result from a lower sugar yield with relatively higher photosynthesis intensity, as well as a higher proportion of assimilated carbon used for other metabolic functions of the plant. These results indicate that varieties differ not only in terms of assimilation capacity, but also in the efficiency of converting assimilated carbon into sugar. Such indicators can be an important criterion for evaluating varieties in terms of carbon efficiency and suitability for sustainable agriculture.

4.4. Greenhouse Gas (GHG) Emissions Analysis

4.4.1. Direct GHG Emissions Related to Fuel Combustion

When analyzing fuel consumption per unit area, significant differences were observed resulting from the size of the cultivated area and the agrotechnical technology used. For varieties V1, J1, and P1 (Table 8), a uniform value of 80 L/ha was adopted, which translated into 1080, 3240, and 2592 kg of CO2 emissions from fuel, respectively. For the P2 variety (Table 8), fuel consumption was divided into individual stages of production, and GHG emissions amounted to 1620 kg CO2. Fuel consumption per unit was more significant for the P2 variety, which, with a lower yield, generated higher GHG emissions per kilogram of product.

Table 8.

GHG emissions from fuel consumption.

4.4.2. Direct GHG Emissions Associated with Fertilizer Use

Differences in fertilizer consumption also correlated with the area and intensity of agrotechnical treatments. The highest emissions related to fertilization were recorded for varieties J1 (30,038.25 kg CO2) and P1 (24,030.60 kg CO2), which was associated with a larger crop area and intensive use of nitrogen fertilizers. Variety P2 showed the lowest fertilizer consumption (1641 kg CO2), but lower fertilizer inputs also translated into lower yields and potentially lower raw material value. Table 9 shows greenhouse gas emissions from the fertilizers used.

Table 9.

GHG emissions from fertilizers used.

4.4.3. Analysis of Total GHG Emissions

A summary analysis of GHG emissions (including emissions from fuel and fertilizers) (Table 10) confirmed that the lowest unit emission rate (0.00948 kg CO2/kg of beet) was achieved by the P2 variety. However, it should be emphasized that the low emission level in this case was primarily due to limited inputs rather than high biological or production efficiency. CF was calculated from “fuel + fertilizer” emissions divided by yield for each variety and location (Table 8, Table 9 and Table 10). The identical CF for J1 and P1 results from the emissions/yield ratio—differences in fuel/fertilizer consumption were offset by differences in yield, resulting in a similar unit value (0.0258 kg CO2eq/kg). The J1 and P1 varieties achieved an identical carbon footprint (0.0258 kg CO2/kg), while V1 achieved a slightly lower value (0.022 kg CO2/kg). When calculated per hectare of cultivated area, the first three varieties showed similar emission levels (approx. 2218.55 kg CO2/ha), while P2 showed a significantly lower level (407.63 kg CO2/ha).

Table 10.

Total GHG emissions and carbon footprint (CF) for the analyzed sugar beet varieties.

The carbon footprints calculated show that beet cultivation is more sustainable compared to the literature (Table 11). The CF data cited for beet cultivation alone (field to farm gate, without processing) usually range from 0.05 to 0.12 kg CO2eq/kg of beet, depending on cultivation intensity, fertilizer use, mechanization technology, and climatic conditions. However, for the final product—beet sugar (which includes the extraction/production stage at the sugar factory)—the values are significantly higher, e.g., in an analysis of Polish plants, 0.14–0.27 kg CO2eq/kg of sugar. Based on aggregate data from the European Union, the average value for beet sugar is higher (0.24–0.77 kg CO2eq/kg of sugar), which results from differences in production technology, energy consumption, drying methods, and local fuel and energy conditions.

Table 11.

Current carbon footprint values for sugar/beet.

4.5. Limitations and Future Work

The present study is subject to several limitations that need to be acknowledged in order to contextualize the findings and define directions for future research. The most significant limitation is the restriction of the life cycle assessment (LCA) to the field stage of sugar beet production. The analysis was deliberately limited to cultivation practices such as fertilization, fuel consumption, and agrotechnical operations, since these are recognized as major contributors to greenhouse gas (GHG) emissions at the agricultural level. However, this scope does not include post-harvest and industrial processes, such as juice extraction, thick juice concentration, and sucrose crystallization, which are known to be highly energy-intensive and may substantially increase the overall carbon footprint of sugar. The omission of these stages means that the results presented here cannot be interpreted as a complete carbon footprint of sugar production, but rather as a field-level environmental assessment.

Another limitation relates to the exclusion of by-product management from the system boundaries. In sugar beet cultivation, significant amounts of biomass are generated in the form of leaves, heads, and stalks. Depending on the management practices applied, such as incorporation into the soil, composting, or conversion into biogas, these residues can either contribute to carbon sequestration and soil fertility improvement or act as sources of GHG emissions through decomposition or burning. The absence of these processes from the current assessment potentially underestimates or misrepresents the overall carbon balance of the cultivation system.

In addition, the study relies on a number of assumptions, particularly regarding CO2 assimilation efficiency and its allocation to plant organs, which inherently introduces uncertainty. For instance, the assumption that a fixed proportion of assimilated carbon is transferred to the root as sucrose simplifies the complexity of carbon partitioning within the plant and does not account for respiration, allocation to proteins, or secondary metabolites. Although these simplifications were necessary to operationalize the calculations, they highlight the need for more advanced models and experimental validation in future studies.

Future work should therefore adopt a more holistic approach by expanding the system boundaries to include both upstream and downstream stages of sugar production. Integrating data from sugar factories would enable a more comprehensive evaluation of energy use and emissions during processing and provide opportunities to analyze synergies between agricultural practices and industrial technologies. Furthermore, research should explicitly address the role of by-product management strategies, assessing their potential to mitigate emissions or enhance carbon sequestration. Developing dynamic models that capture carbon fluxes within the entire production system, including plant physiology, soil interactions, and waste valorization, would provide more accurate and representative assessments of the carbon footprint.

Finally, future investigations should explore the variability introduced by regional and climatic conditions, technological heterogeneity in sugar factories, and alternative agricultural management practices, such as precision fertilization or renewable energy use in mechanization. Such comprehensive analyses would not only refine the environmental assessment of sugar beet production but also contribute to the development of evidence-based strategies for reducing the carbon footprint of the sugar sector. In this way, future research can bridge the gap between field-level sustainability assessments and the full life cycle of sugar production, ultimately supporting the transition towards climate-neutral agricultural and food systems as outlined in the European Green Deal.

5. Summary

Combining life cycle assessment (LCA) with technological quality and environmental parameters enables a comprehensive evaluation of sugar beet varieties in line with the European Green Deal. The study compared three varieties (Viola—V1, Pulitzer—P1, P2, and Jaromir—J1), revealing clear differences in both technological value and environmental performance. V1 exhibited the highest sucrose content (19.16%) and favorable purity (77%), while P1 and P2 achieved high juice purity (96.2%) and low sugar losses in molasses (1.2%), indicating high technological suitability. J1 showed lower sucrose (16.65%), higher ash (0.831%), and greater sugar losses (2.7%), making it less efficient. Beet chemical composition, particularly sucrose, α-amino nitrogen, soluble ash, and potassium, proved decisive for extraction efficiency.

Photosynthetic efficiency was highest in V1 (30,964.61 kg CO2/ha), though P1 achieved the best CO2 assimilation-to-yield ratio (0.344 kg/kg), reflecting optimal resource use. P2, despite high assimilation per kg (0.67), had lower yields, reducing overall efficiency. GHG emissions varied: P2 recorded the lowest per hectare (407.63 kg CO2eq/ha) due to low inputs, while V1, J1, and P1 showed similar levels (2218.55 kg CO2eq/ha). Importantly, CO2 assimilation across all varieties exceeded cultivation-related emissions, confirming sugar beet as a crop with a favorable carbon balance and significant sequestration potential.

The reasons for the variability of the carbon footprint are: the amount and type of fertilizers used (with a dominant share of N2O emissions), the energy efficiency of the sugar factory process (source and intensity of fuel and energy consumption), cultivation practices affecting yield (yield essentially distributes emissions over a larger product mass), and biomass and waste management (the possibility of using by-products as fuel/biomass reduces net emissions). The impact of pesticides and agrochemicals is also non-linear, with some estimates putting their share at over 10% of total agricultural emissions, although nitrogen fertilization is the dominant factor.

From a sustainability perspective, V1, P1, and P2 are recommended for sugar production, balancing high technological performance with moderate environmental impact. J1′s weaker chemical profile reduces efficiency and may require additional processing. The findings highlight the need for further optimization of agrotechnical practices, such as precision fertilization and variety-specific cultivation, to minimize GHG emissions while maintaining high product quality. Future work should also examine environmental and climatic effects on technological traits to guide sustainable breeding and cultivation strategies.

Author Contributions

Conceptualization, M.W.-J., Ł.P. and E.W.; Methodology, M.W.-J., Ł.P., E.W. and A.B.; Validation, M.W.-J., Ł.P. and E.W.; Formal Analysis, M.W.-J., Ł.P., E.W., A.B., A.J., Ł.Ś. and K.S.; Investigation, M.W.-J., Ł.P., E.W., A.B., A.J., Ł.Ś. and K.S.; Resources, M.W.-J. and A.B.; Data Curation, M.W.-J., Ł.P., E.W., A.B., A.J., Ł.Ś. and K.S.; Writing—Original Draft Preparation, M.W.-J., Ł.P., E.W. and A.B.; Writing—Review & Editing, M.W.-J., Ł.P., E.W. and A.B.; Visualization, M.W.-J., Ł.P. and E.W.; Supervision, M.W.-J., and A.B.; Project Administration, M.W.-J. and A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions, A Green Deal Industrial Plan for the Net-Zero Age COM/2023/62. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52023DC0062 (accessed on 5 August 2025).

- Dixon, K.A.; Michelsen, M.K.; Carpenter, C.L. Modern Diets and the Health of Our Planet: An Investigation into the Environmental Impacts of Food Choices. Nutrients 2023, 15, 692. [Google Scholar] [CrossRef]

- Al-Mansour, F.; Jejcic, V. A model calculation of the carbon footprint of agricultural products: The case of Slovenia. Energy 2017, 136, 7–15. [Google Scholar] [CrossRef]

- Guimarães, N.S.; Reis, M.G.; Costa, B.V.d.L.; Zandonadi, R.P.; Carrascosa, C.; Teixeira-Lemos, E.; Costa, C.A.; Alturki, H.A.; Raposo, A. Environmental Footprints in Food Services: A Scoping Review. Nutrients 2024, 16, 2106. [Google Scholar] [CrossRef]

- Atmaca, A. Chapter Twenty-Two—Understanding carbon footprint: Impact, assessment, and greenhouse gas emissions. In Advances and Technology Development in Greenhouse Gases: Emission, Capture and Conversion; Rahimpour, M.R., Makarem, M.A., Meshksar, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 497–516. [Google Scholar] [CrossRef]

- Conti, A.; Opizzi, A.; Binala, J.G.; Cortese, L.; Barone-Adesi, F.; Panella, M. Evaluation of the Climate Impact and Nutritional Quality of Menus in an Italian Long-Term Care Facility. Nutrients 2024, 16, 2815. [Google Scholar] [CrossRef] [PubMed]

- Borsato, E.; Tarolli, P.; Marinello, F. Sustainable patterns of main agricultural products combining different footprint parameters. J. Clean. Prod. 2018, 179, 357–367. [Google Scholar] [CrossRef]

- Pınarlı Falakacılar, Ç.; Yücecan, S. The Impact of Sustainability Courses: Are They Effective in Improving Diet Quality and Anthropometric Indices? Nutrients 2024, 16, 1700. [Google Scholar] [CrossRef]

- Baryga, A.; Ogłaza, I.; Waleriańczyk, E.; Żero, M.; Toboła, A. Development of a Method for Purifying Raw Juice with Sediment Separation After Preliminary Liming. Documentation of Research Work with the Symbol PW-20, Carried out in 2007–2010; IBPRS Institute: Warsaw, Poland, 2010. (In Polish) [Google Scholar]

- Malec, J.; Kositorna, J. Sugar Beet—Cultivation, Protection, Storage, Raw Material Management; SIM Publishing and Printing Center: Warsaw, Poland, 2007. (In Polish) [Google Scholar]

- Sumińska, T.; Sierakowska, M.; Baryga, A.; Kowalska, M.; Sajek, M. Compendium of Knowledge on the Production of White Sugar from Sugar Beet; SGGW Publishing House: Warsaw, Poland, 2019. (In Polish) [Google Scholar]

- Dobrzycki, J. Chemical Foundations of Sugar Technology; Warsaw WNT: Warsaw, Poland, 1984. (In Polish) [Google Scholar]

- Gruska, R.; Baryga, A.; Kunicka-Syczyńska, A.J.; Brzeziński, S.; Rosicka-Kaczmarek, J.; Miśkiewicz, K.; Sumińska, T. Fresh and Stored Sugar Beet Roots as a Source of Various Types of Mono- and Oligosaccharides. Molecules 2022, 27, 5125. [Google Scholar] [CrossRef]

- Jaśkiewicz, A.; Kunicka-Styczyńska, A.; Baryga, A.; Gruska, M.R.; Brzeziński, S.; Świącik, B. Evaluation of the Impact of an Enzymatic Preparation Catalyzing the Decomposition of Raffinose from Poor-Quality Beets During the White Sugar Production Process. Molecules 2024, 29, 3526. [Google Scholar] [CrossRef] [PubMed]

- Goodman, P.J. Physiological analysis of the effects of different soils on sugar beet crops in different years. J. App. Ecol. 1968, 5, 339–357. [Google Scholar] [CrossRef]

- Milford, G.F.J.; Pocock, T.O.; Jaggard, K.W.; Biscoe, P.V.; Armstrong, M.J.; Last, P.J.; Goodman, P.J. An analysis of leaf growth in sugar beet. IV. The expansion of the leaf canopy in relation to temperature and nitrogen. Ann. Appl. Biol. 1985, 107, 335–347. [Google Scholar] [CrossRef]

- Baryga, A.; Rusinowski, S.; Krzyżak, J.; Kunicka-Styczyńska, A.; Świącik, B.; Stec, R.; Smykała, K.; Małkowski, E.; Sitko, K. Sugar management and photosynthesis of sugar beet after infection by Cercospora beticola. Sci. Rep. 2025, 15, 19444. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Zhao, M.; Li, Y.; He, Y.; Han, X.; Ma, X.; Ma, F. Spatiotemporal Trends of the Carbon Footprint of Sugar Production in China. Sustain. Prod. Consum. 2024, 46, 502–511. [Google Scholar] [CrossRef]

- González, M.N.G.; Björnsson, L. Life cycle assessment of the production of beet sugar and its by-products. J. Clean. Prod. 2022, 346, 131211. [Google Scholar] [CrossRef]

- Wróbel-Jędrzejewska, M.; Przybysz, Ł.; Włodarczyk, E. Carbon footprint analysis of sugar production in Poland. Food Bioprod. Process. 2024, 148, 88–94. [Google Scholar] [CrossRef]

- Cech, R.; Leisch, F.; Zaller, J.G. Pesticide Use and Associated Greenhouse Gas Emissions in Sugar Beet, Apples, and Viticulture in Austria from 2000 to 2019. Agriculture 2022, 12, 879. [Google Scholar] [CrossRef]

- García, C.A.; García-Treviño, E.S.; Aguilar-Rivera, N.; Armendáriz, C. Carbon footprint of sugar production in Mexico. J. Clean. Prod. 2016, 112 Pt 4, 263–264. [Google Scholar] [CrossRef]

- Yuttitham, M.; Gheewala, S.H.; Chidthaisong, A. Carbon footprint of sugar produced from sugarcane in eastern Thailand. J. Clean. Prod. 2011, 19, 2119–2127. [Google Scholar] [CrossRef]

- Nordzucker, A.G. Transparency and Measurability—For Results that Count. Available online: https://www.nordzucker.com/en/wp-content/uploads/2024/03/240305-NZ_Nh_Transparency_E.pdf?utm_source=chatgpt.com (accessed on 5 August 2025).

- Martindale, W.; Saeidan, A.; Tahernezhad-Javazm, F.; Hollands, T.; Duong, L.; Jagtap, S. Mapping the path to decarbonised agri-food products: A hybrid geographic information system and life cycle inventory methodology for assessing sustainable agriculture. Int. J. Food Sci. Technol. 2024, 59, 6078–6086. [Google Scholar] [CrossRef]

- Jamei, M.; Hassan, M.; Faroouqe, A.A.; Ali, M.; Karbasi, M.; Randhawa, G.S.; Yaseen, Z.M.; Dwyer, R. Monitoring of greenhouse gas emission drivers in Atlantic Canadian Potato production: A robust explainable intelligent glass-box. Res. Eng. 2024, 24, 103297. [Google Scholar] [CrossRef]

- Palosuo, T.; Heikkinen, J.; Hilasvuori, E.; Kulmala, L.; Launiainen, S.; Lehtilä, A.; Leinonen, I.; Liimatainen, M.; Salminen, M.; Shurpali, N.; et al. Demands and possibilities for field-scale estimation of agricultural greenhouse gas balances. CATENA 2025, 249, 108649. [Google Scholar] [CrossRef]

- Vetter, S.H.; Nayak, D.; McBey, D.; Dondini, M.; Kuhnert, M.; Oyesiku-Blakemore, J. 1.23—Environmental Issues: Greenhouse Gas Emissions. In Sustainable Food Science—A Comprehensive Approach; Ferranti, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 216–248. [Google Scholar] [CrossRef]

- Braun, O.; Coquery, C.; Kieffer, J.; Blondel, F.; Favero, C.; Besset, C.; Mesnager, J.; Voelker, F.; Delorme, C.; Matioszek, D. Spotlight on the Life Cycle of Acrylamide-Based Polymers Supporting Reductions in Environmental Footprint: Review and Recent Advances. Molecules 2022, 27, 42. [Google Scholar] [CrossRef]

- Nazim, M.; Ghafoor, A.; Hussain, A.; Tabassum, M.; Nawaz, A.; Ahmad, M.; Muhammad, M.; Ali, M. Biochar as a Climate-Smart Agricultural Practice: Reducing Greenhouse Gas Emissions and Promoting Sustainable Farming. Phyton-Int. J. Exp. Bot. 2025, 94, 65–99. [Google Scholar] [CrossRef]

- Neale, E.; Balvert, T.; Crinnion, H.; Craddock, J.; Lambert, K.; Charlton, K. Application of Global Warming Potential Star (GWP*) Values to the AUSNUT 2011-13 Food Composition Database: Creation of the GWP*-AUSNUT 2011-13 Database. Nutrients 2025, 17, 464. [Google Scholar] [CrossRef] [PubMed]

- Miranda, A.M.; Hernandez-Tenorio, F.; Ocampo, D.; Vargas, G.J.; Sáez, A.A. Trends on CO2 Capture with Microalgae: A Bibliometric Analysis. Molecules 2022, 27, 4669. [Google Scholar] [CrossRef]

- Carrascal-Hernández, D.C.; Grande-Tovar, C.D.; Mendez-Lopez, M.; Insuasty, D.; García-Freites, S.; Sanjuan, M.; Márquez, E. CO2 Capture: A Comprehensive Review and Bibliometric Analysis of Scalable Materials and Sustainable Solutions. Molecules 2025, 30, 563. [Google Scholar] [CrossRef]

- Rouse, J.W., Jr.; Haas, R.H.; Schell, J.A.; Deering, D.W. Monitoring the Vernal Advancement and Retrogradation (Green Wave Effect) of Natural Vegetation; Report NASA: NASA/GSFC Type III Final Report, Contract NAS5-21867; NASA Goddard Space Flight Center, Texas A&M University: College Station, TX, USA, 1973. [Google Scholar]

- Butwiłowicz, A. Analytical Methods for Production Control in Sugar Factories; Institute of Sugar Industry: Warsaw, Poland, 1997. (In Polish) [Google Scholar]

- PN-EN 12880:2004; Characteristics of Sewage Sludge—Determination of Dry Residue and Water Content. Polish Committee for Standardization: Warsaw, Poland, 2004.

- PN-EN 13342:2002; Characteristics of Sewage Sludge—Determination of Kjeldahl Nitrogen. Polish Committee for Standardization: Warsaw, Poland, 2002.

- Baryga, A.; Kowalska, M.; Sumińska, T.; Sierakowska, M. Development of Effective Methods for Eliminating Microorganisms that form Macromolecular Chemical Compounds in the Sugar Production Process. Report on the Implementation of Work BST 138-01, IBPRS, Sugar Industry Department, Warsaw 2020-2021; IBPRS Institute: Warsaw, Poland. (In Polish)

- Larcher, W. Physiological Plant Ecology: Ecophysiology and Stress Physiology of Functional Groups; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- DEFRA. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2022 (accessed on 5 August 2025).

- KOBiZE, CO2, SO2, NOx, CO, and Total Dust Emission Factors for Electricity Based on Information Contained in the National Database on Greenhouse Gas Emissions and Other Substances for 2022, Warsaw. 2023. Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/wskazniki_emisyjnosci/Wskazniki_emisyjnosci_2022.pdf (accessed on 5 August 2025). (In Polish).

- Wróbel-Jędrzejewska, M.; Klepacka, A.M.; Włodarczyk, E.; Przybysz, Ł. Carbon Footprint of Milk Processing—Case Study of Polish Dairy. Agriculture 2025, 15, 62. [Google Scholar] [CrossRef]

- Jarosz, Z.; Faber, A. Possibilities for reducing greenhouse gas emissions in the life cycle of biofuels. Stud. Rep. IUNG-PIB 2014, 39, 9–27. (In Polish) [Google Scholar] [CrossRef]

- Wieninger, L.; Kubadinow, N. Beziehungen zwischen Rübenanalysen und technischer Bewertung von Zuckerrüben. Comunication presenteé a la 14émé Assemblee Generate de la CITS, 1971. Troncoso, A., Cantos, M. Influence of nitrogen fertilization on sugarbeet (Beta vulgaris) quality in an area of southern Spain. In Plant Nutrition—Physiology and Applications. Developments in Plant and Soil Sciences; van Beusichem, M.L., Ed.; Springer: Dordrecht, The Netherlands, 1990; Volume 41. [Google Scholar] [CrossRef]

- Bowsher, C.; Steer, M.; Tobin, A. Photosynthetic Carbon Assimilation. Plant Biochemistry; Garland Science: New York, NY, USA, 2008; pp. 93–141. [Google Scholar]

- Moureaux, C.; Debacq, A.; Bodson, B.; Heinesch, B.; Aubinet, M. Annual net ecosystem carbon exchange by a sugar beet crop. Agric. For. Meteorol. 2006, 139, 25–39. [Google Scholar] [CrossRef]

- Verma, S.B.; Dobermann, A.; Cassman, K.; Walters, D.T.; Knops, J.; Arkebauer, J.T.; Suyker, E.A.; Burba, G.G.; Amos, B.; Yang, H.; et al. Annual carbon dioxide exchange in irrigated and rainfed maize-based agroecosystems. Agr. For. Meteo. 2005, 131, 77–96. [Google Scholar] [CrossRef]

- Suyker, E.A.; Verma, S.B. Coupling of carbon dioxide and water vapor exchanges of irrigated and rainfed maize–soybean cropping systems and water productivity. Agric. For. Meteorol. 2010, 150, 553–563. [Google Scholar] [CrossRef]

- Anthoni, P.M.; Freibauer, A.; Kolle, O.; Schulze, E.D. Winter wheat carbon exchange in Thuringia, Germany. Agric. For. Meteorol. 2010, 121, 55–67. [Google Scholar] [CrossRef]

- Ammann, C.; Flechard, R.C.; Leifeld, J.; Neftel, A.; Fuhrer, J. The carbon budget of newly established temperate grassland depends on management intensity. Agric. Ecosyst. Environ. 2007, 121, 5–20. [Google Scholar] [CrossRef]

- Baldocchi, D.D.; Finnigan, J.; Wilson, K.; Paw, K.T.U.; Eva Falge, E. On Measuring Net Ecosystem Carbon Exchange over Tall on Measuring Net Ecosystem Carbon Exchange over Tall Vegetation on Complex Terrain Vegetation on Complex Terrain. Bound.-Layer Meteorol. 2000, 96, 257–291. [Google Scholar] [CrossRef]

- Aubinet, M.; Grelle, A.; Ibrom, A.; Rannik, Ü.; Moncrieff, J.; Foken, T.; Kowalski, A.S.; Martin, P.H.; Berbigier, P.; Bernhofer, C.; et al. Estimates of the Annual Net Carbon and Water Exchange of Forests: The EUROFLUX Methodology. Adv. Ecol. Res. 1999, 30, 113–175. [Google Scholar]

- Reichstein, M.; Papale, D. Inter-Annual Variation (IAV) in Global Terrestrial Carbon-Water Balance Derived from Network of Eddy Covariance Flux Sites: Magnitude, Controlling Processes and Climate Factors. 2007. Available online: https://fluxnet.org/data/la-thuile-dataset/lathuile-proposals/reichstein-inter-annual-variation-in-global-terrestrial-carbon-water-balance/ (accessed on 5 August 2025).

- Reichstein, M.; Ciais, P.; Papale, D.; Valentini, R.; Running, S.; Viovy, N.; Cramer, W.; Granier, A.; Ogée, J.; Allard, V.; et al. A combined eddy covariance, remote sensing and modeling view on the 2003 European summer heatwave. Glob. Change Biol. 2007, 13, 634–651. [Google Scholar] [CrossRef]

- Żyłowski, T.; Kozyra, J. Environmental efficiency of root crop cultivation. Ann. Pol. Assoc. Agric. Agribus. Econ. 2020, 22, 208–217. [Google Scholar] [CrossRef]

- Available online: https://apps.carboncloud.com/climatehub/agricultural-reports/benchmarks/334d6dbe-4659-4814-8619-d55793be3b28 (accessed on 24 September 2025).

- Available online: https://apps.carboncloud.com/climatehub/agricultural-reports/benchmarks/4b4fc9d9-5af0-4b5e-9391-e91ae846be0d (accessed on 24 September 2025).

- Klenk, I.; Landquist, B.; Imana, O. The Product Carbon Footprint of EU beet sugar (Part I). Zuckerindustrie 2012, 137, 169–177. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).