Abstract

In this study, construction-related carbon emissions were evaluated across different countries, utilizing 7038 observations from 1990 to 2023. Building and cement production data were combined with economic and demographic indicators to perform descriptive analysis, principal component analysis (PCA), and multiple regression modeling for emission driver identification and the development of the Construction Carbon Sustainability Index (CCSI). The results of this study demonstrate that cement production, combined with building activities, generates the most significant emissions, while population expansion and urban growth patterns create the highest levels of emission intensity. The two main components from the PCA explain more than 80% of national emission patterns through their combination of “Cement and Building Emission Intensity” and “Economic and Urban Development Drivers.” The CCSI shows that OECD and G20 nations achieve the best construction sustainability results, whereas China and India produce the most carbon emissions due to their rapid development, which relies heavily on resource utilization. The findings demonstrate that sustainable construction requires both production efficiency improvements and policy reforms to establish a global standard for construction sector growth that meets net-zero emission targets.

1. Introduction

In the 21st century, climate change represents a pressing global issue as man-made CO2 emissions trigger major environmental changes that also affect economic systems. Global CO2 dynamics are influenced by oceanic processes in addition to land-based construction activities. The warming of the sea surface diminishes the ability of natural carbon sinks to absorb carbon dioxide [1]. Furthermore, methane emissions from South American livestock operations function as a significant greenhouse gas source [2]. The construction sector is a major contributor to climate change because it is responsible for the consumption of substantial amounts of energy while concurrently producing significant carbon emissions [3]. The construction sector forms the physical foundation of urban development, shaping sustainability, resilience, and social equity, in addition to the functional and aesthetic characteristics of cities [4]. The global construction industry generates substantial greenhouse gas emissions, accounting for 30–40% of global energy use and 40% of global CO2 emissions [5]. The cement industry generates between 5% and 8% of all man-made carbon dioxide emissions worldwide [6].

There is an urgent need for decarbonization in the construction industry due to its extensive nature and deep integration with other development sectors. Construction emissions pose challenges because they are distributed across various supply chains, building operations, and on-site processes; in comparison, transportation and energy production emissions tend to concentrate in particular industries.

The environmental significance of construction is widely recognized, yet there is a lack of a comprehensive understanding of CO2 emission dynamics in this field. A systematic bibliometric review revealed that researchers devoted most of their work from 2009 to 2025 to developing life-cycle assessment methods while investigating BIM integration and socio-environmental framework methodologies [7]. The research methods used in these studies provide valuable insights, yet their findings lack the capacity to demonstrate a comprehensive understanding of emission trends because they do not account for global economic, demographic, and technological factors. There is a need for research that combines international studies to evaluate construction sustainability performance across nations and analyze emission-intensity gaps. Research on construction emissions is fragmented, focusing on specific national or regional areas but failing to provide a global framework that connects economic variables with demographic changes and urban development patterns. The absence of a single framework prevents countries from establishing common sustainability benchmarks. Through this study, a knowledge gap was filled through a global assessment, which results in the creation of the Construction Carbon Sustainability Index (CCSI) to measure construction sector emissions and sustainability performance worldwide.

A standardized global dataset was created containing 7038 observations spanning 1990 to 2023. The dataset merges emission statistics from residential and commercial buildings with cement manufacturing data, construction economic output, population statistics, and urban development figures. Principal component analysis (PCA) was employed, and multiple regression modeling was used to develop a CCSI, providing multiple dimensions for understanding sector-specific carbon emissions. This approach enables researchers to determine emission drivers and evaluate sustainability performance among countries and regions through benchmarking.

In this study, a new composite index was established, CCSI, that merges emissions measurements based on population numbers, economic growth, and construction value-added contributions, creating a tool for international policy assessments. The index offers practical guidance to policymakers wanting to meet international climate agreements by revealing the differences between nations deemed successful and unsuccessful in carbon emission mitigation and analyzing the simultaneous effects of economic growth and urbanization.

The findings presented herein enrich the understanding of how construction operations can become sustainable while still advancing economic expansion. The construction sector requires a combination of technological development, policy changes, and international planning coordination to establish a low-carbon future. Multiple countries have established CO2 emission pricing systems through legislation to drive industrial carbon reduction efforts. The European Union Emissions Trading System (EU ETS), launched in 2005, is the world’s first and most developed international carbon market and directly regulates cement and building material producers [8]. The Greenhouse Gas Pollution Pricing Act of Canada, enacted in 2018, establishes fees for industrial CO2 emissions, which include cement production and construction material processing [9]. The existing policies demonstrate how emission fees incorporate environmental costs into business operations while encouraging businesses to adopt cleaner production methods. In the following sections, a review of the existing literature is provided, detailing the methodological approach employed and presenting the results and discussion of this global analysis.

2. Literature Review

2.1. Global Significance of Construction-Related CO2 Emissions

The construction industry stands as a primary sector that produces significant amounts of greenhouse gases while consuming substantial resources globally. The construction sector utilizes the highest proportion of raw materials worldwide, as it consumes 40% of global reserves and accounts for 40% of total CO2 emissions [10,11]. The building sector contributes to emissions primarily through energy consumption for heating, cooling, and electricity generation (57% of building emissions), on-site fuel during construction (24%), and cement and steel production (18%) [12]. Clinker production accounts for approximately half of cement-related CO2 emissions, with the remaining portion derived from carbon fuels and electricity consumption [13]. The present levels of construction-related emissions make it challenging to fulfill international climate targets. The Paris Agreement established emission-reduction targets for the building sector through Nationally Determined Contributions, which serve as vital elements of countries’ mid-term climate action plans [14]. The construction industry is of critical importance to environmental matters because it produces substantial global emissions while simultaneously enabling economic progress and infrastructure development.

2.2. Drivers and Disparities in Construction Carbon Footprints

Numerous researchers have investigated the factors that generate CO2 emissions in construction projects [5,15,16]. Construction emissions rise in direct proportion to expanding economic activities and urban development patterns [17]. The construction sector in developing nations, with expanding infrastructure and real estate development, has experienced rapid growth in CO2 emissions [6].

In developing countries, a direct relationship can be seen between their GDP growth rates and cement use, as rising economic activity drives construction needs that in turn lead to elevated CO2 emissions from cement production [13]. Research findings indicate that high-income nations have begun to decouple economic growth from CO2 emissions, suggesting that rising national income does not automatically lead to increased environmental pollution [18].

The construction of buildings and infrastructure increases as populations grow and urbanization advances, thereby increasing related emissions. The process of new-type urbanization in fast-developing urban areas leads to higher overall carbon emissions and greater per-person carbon emissions [19].

The level of industrialization and the technologies used can significantly affect emission intensity. The majority of OECD nations have achieved decarbonization through energy efficiency improvements and renewable energy adoption, which have brought additional health benefits and cost reductions, yet emerging markets rely on carbon-intensive construction techniques and materials [20,21]. The ongoing extraction of lignite in Germany and hard coal in China, India, and Indonesia generates significant emissions while sustaining construction operations that rely heavily on fossil-fuel-based energy systems [22,23,24]. Research findings demonstrate that higher labor productivity and GDP per capita lead to greater technological progress, resulting in lower carbon-emission intensity and higher carbon productivity in construction activities [25,26,27].

An often-overlooked aspect in this field is the indirect emissions tied to construction supply chains. The results of studies on building lifecycle development reveal that CO2 emissions occur throughout various stages of construction, including material production and transportation, which require building materials to be manufactured in different locations before being moved to construction sites across multiple areas [5]. The level of construction emissions in a nation depends on whether it imports building materials or produces them domestically, since importing leads to the transfer of emissions abroad. Construction-related CO2 emissions increase when building materials and on-site machinery are powered by carbon-intensive energy sources such as diesel fuel [5].

Countries demonstrate significant variations in their ability to reduce construction-related carbon emissions. Construction activities in developed countries produce lower CO2 emissions because these countries have implemented advanced climate policies, including carbon taxes and energy codes, and have adopted low-carbon construction technologies and enforced green building standards [15,28,29]. Rapidly developing economies, such as China and India, produce high CO2 emissions from construction activities because their industrial growth and urban development depend on energy-intensive methods that use carbon-based production systems [30]. The GCC member states, together with other energy-rich Middle Eastern nations, have the highest per capita CO2 emissions globally due to their high economic output [31]. The construction sector’s carbon footprint is a global issue, yet its core sources, combined with its strengths, differ substantially between different settings. Strategic policies require adaptation to national conditions to address overconsumption and inefficiency in high-emitting regions and to prevent carbon-intensive development paths in developing countries undergoing urbanization.

2.3. Strategies for Reducing the Carbon Footprint of the Construction Industry

The construction industry plays an essential role in climate change; as such, multiple mitigation strategies have been implemented in recent years. Research findings demonstrate that supply- and demand-side measures work in synergy as one system and that their combined effects depend on the correct order of policy implementation to achieve maximum emissions reduction [32]. The main approaches employed to achieve carbon footprint reduction consist of the following:

- Decarbonizing Materials and Processes: The high carbon content of cement has led to the development of various strategies aimed at its reduction. Researchers have demonstrated that using fly ash or blast furnace slag as supplementary cementitious materials in cement production reduces the clinker/cement ratio, thereby decreasing both clinker production emissions and energy consumption during manufacturing [13].

- Energy Efficiency in Buildings: The construction sector generates substantial emissions through the operational phase of buildings throughout their operational lifetime. The various building end-uses that produce operational-phase emissions, such as heating, cooling, lighting, cooking, and appliance use, underscore the need for energy-efficient buildings and the implementation of energy codes and green standards to minimize carbon emissions during a building’s operational period [33].

- Market-Based Incentives: The construction industry now relies more frequently on economic instruments for its emission reduction efforts. The implementation of carbon taxes and emissions-trading schemes to monetize energy use and industrial-process emissions has proven effective in lowering CO2 emissions [29]. Furthermore, implementing a carbon tax compels businesses to adopt environmentally friendly technologies because they often lack motivation to change their production methods without such measures [29].

The results of recent studies show that adaptable building design is a vital approach to reducing emissions because it enables space and material reuse, extending building lifespans and minimizing construction waste [34]. The recycling of construction solid waste is an effective method to protect natural resources while lowering carbon emissions, thereby reducing the environmental impacts of material manufacturing processes [35]. Life-cycle assessments demonstrate that using recycled aggregates in concrete production reduces resource extraction and landfill waste disposal and minimizes environmental impacts and construction costs, thereby supporting circular economy development [36]. The circular construction economy has developed into a self-sustaining system that promotes building material and component reuse, refurbishment, and recycling to achieve better resource efficiency through design for disassembly and adaptability [37].

Recent advances in 3D printing technologies have significantly enhanced sustainability within the construction sector. The results of recent studies have demonstrated that 3D-printed concrete can reduce material waste by up to 60% compared to conventional casting methods, while simultaneously enabling the use of eco-friendly binders, such as geopolymer and fly ash, that lower embodied CO2 emissions [38,39,40]. These innovations promote circular economy objectives and align with global decarbonization strategies in the built environment.

The results of numerous studies demonstrate that reducing construction carbon emissions requires an integrated strategy that combines technological breakthroughs with robust regulatory measures to achieve the desired reduction in carbon footprint [41,42]. Evaluations demonstrate that using alternative additives, materials, techniques, and systems throughout the construction and operational phases can decrease CO2 emissions by 90% in specific contexts [15]. The implementation of proven solutions at a global scale has demonstrated substantial potential for mitigation. Multiple barriers impede the construction industry, including high initial costs and inexperienced employees, which slow efforts to reduce carbon emissions [15]. The global transition to low-carbon construction requires solving existing barriers by implementing education programs, providing incentives, and facilitating research and development initiatives.

2.4. Research Gaps and the Need for Integrated Global Analysis

The existing research on construction-related emissions shows increasing growth; however, essential knowledge gaps remain, particularly in macro-level analysis [3,43]. A few studies can be found in the existing literature that involve comprehensive cross-country or global analyses [43,44]. The authors of most studies on construction-related CO2 emissions examine China as a single country; global assessments remain scarce, however, as only one research group has analyzed construction emissions through international trade networks among all macro-level studies, accounting for 6% of total studies [43,45].

The existing knowledge gap in construction research requires holistic macro-level studies, which were successfully addressed in the present study. Herein, a macro-scale analysis is presented by combining an international panel dataset that links construction sector emissions to GDP and population data, in addition to urbanization statistics and sectoral value-added information. The research method enables the examination of wealth–carbon intensity relationships and urbanization effects on building emissions, which cannot be investigated in single-country analyses. This study contributes to the literature through the use of emissions per GDP and construction value-added metrics to address the need for more robust sustainability performance and emission-efficiency benchmarks in construction. In the literature, researchers recommend composite indices and cross-country comparisons to detect sustainable construction leaders and laggards; global benchmarking remains challenging due to data constraints, however.

The findings of this study demonstrate that the global construction industry is producing significantly increasing carbon emissions driven by economic and demographic forces, which technology and policy interventions help reduce. Findings presented in the literature demonstrate that integrated research across nations and over time remains essential to obtain a complete understanding of this issue. In this study, international standardized data were used, combined with PCA, regression methods, and index development techniques, to support recent research on global construction carbon footprint assessment and reduction strategies. An extensive examination is vital for developing effective international policies because it reveals the intricate relationship between development and sustainability in construction that cannot be determined in single-case studies.

3. Methodology

3.1. Data Sources and Compilation

The construction emissions master panel was developed by systematically merging global datasets to ensure consistency, comprehensive coverage, and reliability. The International Energy Agency (IEA) and the Emissions Database for Global Atmospheric Research (EDGAR) databases provided CO2 emissions data following the IPCC 2006 classification, enabling the extraction of cement-related and building-sector emissions in units of gigagrams of CO2. The master panel used IEA/EDGAR data for cement emissions because they provided detailed sectoral breakdowns and broader coverage. Furthermore, Our World in Data (OWID) emissions data were used to validate the IEA/EDGAR data.

The World Bank World Development Indicators (WDI) provided economic and demographic indicators, including GDP_CurrentUSD, Population_Total, Urban_Percent, IndustryInclConstr_CurrentUSD, and IndustryInclConstr_ConstLCU. The WDI “Construction_VA_USD” series enabled us to obtain sector-level comparable data on construction-specific value added.

The final dataset integrated emission data with economic and demographic variables from multiple global sources to create a unified panel that supports thorough research of construction emissions and their macroeconomic connections. The dataset included 7038 observations spanning from 1990 to 2023.

3.2. Data Cleaning and Validation

The research dataset included 7038 country–year observations spanning from 1990 to 2023 after systematic data cleaning and validation procedures. Analysis was focused on the 1990–2023 period because it marked the beginning of global climate reporting and international environmental agreements. The WDI placeholders for missing values were set to null, and years with major data gaps were removed; however, linear interpolation was used to fill small gaps to maintain data continuity. The z-score and interquartile range thresholds were used to detect outliers before verifying these results against database sources to eliminate false entries and maintain authentic extreme values, such as China’s and India’s cement production figures. Unit standardization was performed by converting cement emissions from million tonnes (MtCO2) to gigagrams (Gg CO2), and economic data were standardized to current US dollars, while maintaining industry value-added data in constant local currency units for added reliability. The World Bank population and GDP data served as the basis for gathering three derived indicators: per capita emissions, emissions per GDP, and construction value added.

To control for scale effects, emissions were normalized per capita, GDP, and construction value-added measurements. The normalized indicators enabled comparisons of economies based on their size and development level.

Cross-source verification was performed, which showed that OWID and IEA/EDGAR cement data matched with 95% accuracy during their overlapping periods, and GDP values were verified through multiple WDI data retrievals for precision. The dataset received ISO3 country code alignment through these procedures, resulting in a solid framework for PCA, regression modeling, and CCSI development.

3.3. Statistical Analysis Strategy

The research design involved multiple statistical methods implemented in IBM SPSS, Version 30.0, and followed best practices in empirical social and environmental research.

3.3.1. Descriptive Statistics

All variables were subjected to descriptive statistical analysis, including calculation of mean values and standard deviations, in addition to minimum and maximum values. This initial data analysis procedure helped identify both time-based and country-based variations in emissions and economic indicators and detect unusual patterns [46,47].

3.3.2. PCA

The overall analysis involved PCA of eight direct indicators, which included construction-related CO2 emissions, economic activity, and demographic factors, including CO2_Buildings_1A4_Gg, CO2_Buildings_1A5_Gg, CO2_Cement_2A1_Gg, OWID_Cement_Gg, GDP_CurrentUSD, Construction_VA_USD, Population_Total, and Urban_Percent. The dataset’s adequacy was checked with the KMO statistic and Bartlett’s test of sphericity, as outlined by [46]. The number of factors was set using the Kaiser criterion (eigenvalues above one) and scree plot assessments. Varimax rotation helped clarify the extracted factors, following the method of [47]. Parameter selection for PCA involved statistical criteria and knowledge of construction operations. The variables measuring CO2 emissions from CO2_Buildings_1A4_Gg, CO2_Buildings_1A5_Gg, CO2_Cement_2A1_Gg, and OWID_Cement_Gg identify the main emission sources in the industry; in comparison, Construction_VA_USD, GDP_CurrentUSD, Population_Total, and Urban_Percent rate reflect how development affects emission intensity and market needs. Parameter identification involved the use of both scientific data analysis and construction management expertise. This dual approach aligns statistical analysis with industry realties, allowing PCA to measure production intensity in the global construction sector.

3.3.3. Multiple Linear Regression

Multiple regression analysis was used to identify cement-related CO2 emission factors through the dependent variable CO2_Cement_2A1_Gg. Population_Total, Urban_Percent, GDP_perCapita, and Constr_Share_GDP were used as predictor variables. When using the regression model, the enter method was used to include all predictors simultaneously, as recommended by [46,47]. The model fit assessment significance levels for regression coefficients.

The diagnostic tests identified that the model satisfied all three requirements: linearity, multicollinearity, and residual normality. The VIF values remained under 2, with the included R2 coefficients, ANOVA F-statistic results, and the p < 0.05 condition index, reaching their highest value at 8.166, indicating that the predictors showed no severe intercorrelation. The ANOVA output F-test showed that the regression model was statistically significant, indicating that the selected variables effectively explain variations in cement-related CO2 emissions.

3.3.4. CCSI

The CCSI emerged through the combination of eight direct indicators that measured construction CO2 emissions, economic development, and population distribution. The analysis involved the use of CO2_Buildings_1A4_Gg, CO2_Buildings_1A5_Gg, CO2_Cement_2A1_Gg, OWID_Cement_Gg, Construction_VA_USD, GDP_CurrentUSD, Population_Total, and Urban_Percent as its variables. The indicators underwent standardization through z-score calculations to achieve comparable results between different countries and time periods as follows:

where Xi is the raw value, μi is the mean, and σi is the standard deviation of indicator i.

The principal component analysis (PCA) method was used to reduce data dimensionality while revealing fundamental patterns. The KMO value reached 0.772, and Bartlett’s test produced χ2(28) = 56,490.429 with p < 0.001 to validate sampling adequacy. The analysis produced two factors that together explained 80.7% of the total variance. The first factor, “Cement and Building Emission Intensity”, was measured by combining industrial emission factors from cement production and building activities with population growth. The second factor, “Economic and Urban Development Drivers”, was measured through its analysis of GDP, construction activity, and urbanization rates.

The regression method generated standardized factor scores for each country–year, which were then transformed into a 0–100 scale. The CCSI value for country j combines two standardized factor scores through a weighted sum calculation:

The weights used in this calculation represent the percentage of variance explained by each factor in the rotated solution, as discussed in Section 4.2 PCA. The two components of variance (50.409% and 30.282%) were normalized to unity by dividing their values by the total variance. The resulting weights were 0.625 for the first component and 0.375 for the second component. The CCSI value increases when a nation demonstrates greater sustainability by reducing construction carbon emissions or adopting sustainable development methods to manage growth.

Post hoc Activity Index (AIj) adjustment was used to address the issue of small economies achieving apparent sustainability leadership status due to their minimal absolute emissions. The index serves to assess the scale and significance of construction activities in each country. The calculation of AIj for each nation involved taking the geometric mean of three normalized variables: Construction_VA_USD, GDP_CurrentUSD, and Urban_Percent. The variables were subjected to min–max normalization to create a 0–1 range for each as follows:

where Xij is the raw observed value of indicator i for country j in 2023, min (Xi) is the minimum value of indicator i across all countries in 2023, and max (Xi) is the maximum value of indicator i across all countries in 2023.

The normalized values X’ij were then combined as follows:

The geometric mean was used as the selection method because it penalizes nations that excel in one area but fail in others, thereby requiring balanced development across all three dimensions for high AI values. The adjusted CCSI calculation resulted in the following:

The formula maintained recognition of low-emission countries while giving greater weight to countries with major construction activities.

The qualification criterion was implemented to prevent countries with minimal construction emissions from being mistaken as sustainability leaders. The leadership rankings excluded countries with Construction_VA_USD, GDP_CurrentUSD, and Urban_Percent share values below the bottom decile.

The method allowed the evaluation of both national performance and group performance among the G20, OECD, BRICS, MINT, and GCC countries. The adjusted CCSI* establishes a unified measurement standard that distinguishes countries with advanced sustainability practices from those with limited construction operations, thus enabling better assessment of construction sector sustainability. The PCA method for creating composite indices is a standard approach in sustainability research for combining various indicators into a robust benchmark system [47].

The CCSI yields results different from simple per capita or per GDP ratios, because it shows the relationship between emission intensity and development progress. The CCSI combines four indicators to show whether countries with low emissions have achieved efficiency gains through sustainable construction or whether their construction sectors remain underdeveloped. The CCSI uses PCA weighting to create its multidimensional structure, which enables the identification of countries that sustainably grow their construction sector instead of merely reporting minimal emissions.

3.4. Software and Tools

IBM SPSS Statistics, Version 30.0, was used to perform all statistical tests. For this research protocol, the recommendations of [46,47] were followed to present both statistical precision and practical comprehension in their results.

4. Results and Discussion

4.1. Descriptive Statistics

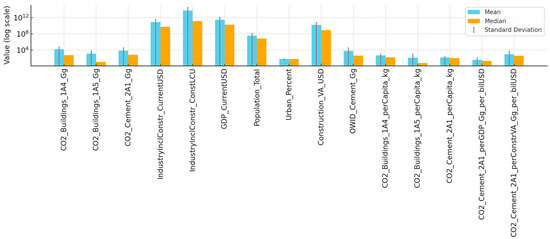

The results presented in the following section provide extensive information about carbon emissions, economic activity levels, construction sector performance, population patterns, and urbanization throughout its worldwide dataset of 7038 observations. The research findings demonstrate substantial differences in CO2 emissions stemming from building and cement production activities. The foundation of the research starts with Table 1 and Figure 1, which present descriptive statistics for all essential variables. The average emissions from residential buildings, CO2_Buildings_1A4_Gg, were 14,807.1 Gg, with a standard deviation of 59,520.7 Gg, indicating substantial differences between countries. Commercial building emissions, CO2_Buildings_1A5_Gg, exhibited a lower average of 1161.1 Gg, yet displayed substantial variability, as indicated by an SD of 6241.2 Gg. Cement production emissions, CO2_Cement_2A1_Gg, reached 6322.3 Gg on average, with a maximum value reaching 820,965 Gg and a standard deviation of 41,279.0 Gg, which demonstrates cement’s essential role in global CO2 emissions. The results confirm the findings of previous studies showing that the cement and building sectors produce the highest carbon emissions across the construction industry [5,6,12,13]. In the current study, the author builds on previous research by using a single global dataset to analyze both production and economic indicators, which measure sectoral emissions. The extensive dataset provides detailed patterns of emission intensity that the authors of earlier country-specific studies failed to detect [43,44,45].

Table 1.

Descriptive statistics.

Figure 1.

Comparison of mean, median, and standard deviation across variables.

The mean per capita emission levels were 458.7 kg for residential buildings, 139.7 kg for cement production, and 118.6 kg for commercial building emissions. The distribution of commercial building emissions shows the greatest variation (SD = 1332.3 kg), indicating that per capita construction emissions differ significantly across nations based on policies, urban density, and technological choices.

Economic indicators enhance our understanding of the patterns in carbon emissions. The economic disparity between developed and developing nations becomes clear from GDP (in current USD) data, which ranges from USD 36.5 million to 27.7 trillion, with a median of USD 298.3 billion and a substantial standard deviation of USD 1.38 trillion. Industrial activity encompassing construction (IndustryInclConstr_CurrentUSD) averaged USD 83.9 billion (SD = USD 363.9 billion); however, construction-specific value added (Construction_VA_USD) reached USD 16.95 billion with significant variability (SD = USD 73.53 billion). The construction sector demonstrates its importance as an economic driver and its direct relationship with carbon emission levels. The OWID_Cement_Gg variable shows significant variation in cement production across countries, with an average of 5634.6 Gg and a standard deviation of 40,067.3 Gg, indicating that some countries generate substantial amounts of cement-related emissions worldwide.

The explanation for the emission trends is further supported by demographic and urbanization patterns. Population size ranged from 11,000 to 1.44 billion, with a median of 34.5 million (SD = 130.8 million), and urbanization levels ranged from 5.4% to 100% with an average of 56.1% (SD = 23.5%). The figures demonstrate substantial differences between urban planning approaches and development intensities. The combination of high population density and insufficient environmental controls in urban areas leads to emission hotspots in developing countries.

In this study, the author evaluated carbon efficiency using two normalized emission indicators. The CO2_Cement_2A1_perGDP_Gg_per_bilUSD variable displayed an average of 34.7 Gg with a standard deviation of 123.7 Gg for cement-related emissions per billion USD of GDP. The CO2_Cement_2A1_perConstrVA_Gg_per_bilUSD variable demonstrated cement emissions per billion USD of construction value with a mean of 853.0 Gg and a significant SD of 5643.4 Gg. The results demonstrate that emission efficiency differs greatly across economies, while showing that increased GDP and construction output do not automatically produce environmentally sustainable development. Some nations demonstrate high emissions per production unit, indicating potential for policy transformation combined with technological improvements and the implementation of sustainable construction practices.

The descriptive analysis demonstrates large variations in construction-related carbon emissions worldwide, both in total and in adjusted measurements. Most variables display wide standard deviations, indicating that emission trends are heavily influenced by a few high-emission countries or regions. These research results demonstrate that sustainability policies need to be designed for specific contexts, and targeted interventions must be implemented in regions with high impact. The construction sector in rapidly developing economies demonstrates major environmental challenges that require immediate attention. The integration of low-carbon materials alongside enhanced regulatory frameworks and cross-country performance benchmarking should be the main focus of future research and policy development to reduce emissions. These findings remain highly significant as international organizations strive to achieve net-zero targets and meet the Paris Agreement’s carbon-neutrality goals.

4.2. PCA

The PCA involved the use of eight direct indicators to measure construction CO2 emissions, economic activity, and population factors. The Kaiser–Meyer–Olkin (KMO) measure reached 0.772, and Bartlett’s test of sphericity produced a highly significant result (χ2(28) = 56,490.429, p < 0.001) to validate the dataset for factor analysis (Table 2).

Table 2.

KMO and Bartlett’s Test of Sphericity.

The variables showed strong communalities ranging from 0.405 to 0.914, with Construction_VA_USD and GDP_CurrentUSD showing the highest communalities (Table 3).

Table 3.

Communalities.

The cement-related variables showed the highest communalities, with that of CO2_Cement_2A1_Gg at 0.887, and cement emissions from OWID_Cement_Gg at 0.894. The factor structure showed strong representation of CO2_Buildings_1A4_Gg (0.835) and CO2_Buildings_1A5_Gg (0.833). The factor structure showed excellent representation of Construction_VA_USD (0.914), GDP_CurrentUSD (0.901), and Population_Total (0.787). The Urban_Percent showed a lower communality value of 0.405, which remained within acceptable limits for the analysis.

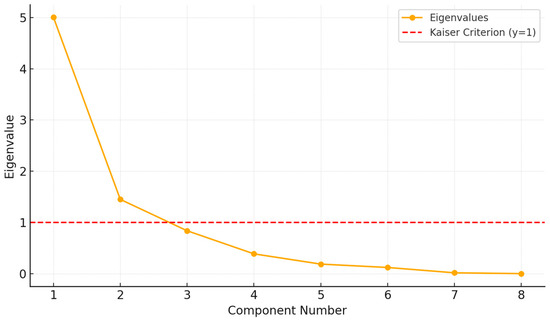

The eigenvalue analysis, supported by the scree plot, indicated that a two-component solution provided the best fit. The first component accounted for 62.57% of the total variance, with an eigenvalue of 5.006; in comparison, the second component accounted for an additional 18.12% with an eigenvalue of 1.450. The two extracted factors together explained 80.69% of the total variance. The rotation sums of squared loadings validated the two-factor structure by showing distinct yet related factors between construction emissions and socioeconomic factors (see Figure 2 and Table 4). The Kaiser criterion selects components with eigenvalues greater than one. The evaluation of borderline components included a tolerance range from 0.95 to 1.05 to address both sampling variations and rounding errors. The method provided stable factor retention while preventing excessive factor extraction.

Figure 2.

Scree plot of eigenvalues.

Table 4.

Variance explained.

The Varimax rotation of the data yielded a two-factor solution that demonstrates both production-based and demand-based factors affecting construction-related emissions (Table 5). The first factor, named “Cement and Building Emission Intensity”, shows strong positive relationships with cement emissions from both CO2_Cement_2A1_Gg (0.911) and OWID_Cement_Gg (0.916), and receives significant contributions from building emissions (CO2_Buildings_1A5_Gg = 0.910 and CO2_Buildings_1A4_Gg = 0.575) and Population_Total (0.875). The factor combines industrial and structural elements of construction emissions through its connection between cement, building outputs, and population growth. Countries with high scores on this dimension exhibit high construction intensity and carbon emissions because they use clinker-rich cement and energy-intensive manufacturing methods and require more materials due to expanding populations. Countries with low scores either operate efficient construction systems with low carbon emissions or have an underdeveloped construction industry. The factor presents a production-based challenge that requires immediate decarbonization solutions through blended cement use, kiln energy optimization, and the implementation of carbon capture technology.

Table 5.

Rotated matrix.

The second component, known as “Economic and Urban Development Drivers”, receives its highest loadings from Construction_VA_USD (0.825), GDP_CurrentUSD (0.879), and Urban_Percent (0.572). The factor demonstrates how construction activities relate to their economic and structural environment through the impact of urban development and economic expansion on emission levels. The countries with high scores on this dimension include fast-developing urban centers and prosperous nations with substantial construction industries, as their rising GDP and construction spending drive higher material and energy requirements. Economies with low construction activity and service-based economies with minimal construction output receive low scores on this factor. The factor highlights a development challenge that requires sustainable urban planning, funding for green infrastructure, and low-carbon construction methods to achieve environmental sustainability during economic development.

The PCA results show that construction emissions result from two separate yet connected elements that include industrial emission intensity and economic and urban development patterns. The first factor shows that cement and building production processes maintain their carbon-intensive nature because of rising population numbers. The second factor demonstrates how economic development, combined with construction industry expansion and urban growth patterns, determines emission patterns. The dual nature of the structure shows that successful emission reduction requires strategies that focus on two areas: improving production efficiency through cement manufacturing decarbonization, building energy optimization, implementing sustainable urban planning, material reduction measures, and building energy efficiency regulations. The two pathways establish a comprehensive analytical framework that helps countries measure their performance and develop targeted reduction strategies. The KMO value of 0.772 showed that the sample size was adequate for analysis, and Bartlett’s test produced a highly significant result (p < 0.001), which confirmed that variable intercorrelations were sufficient. The two-component solution maintained both conceptual value and statistical integrity, which established a reliable foundation for additional analysis.

4.3. Linear Regression Analysis

The multiple linear regression model showed that the selected predictors explained 55% of the CO2 emission variation in cement production (CO2_Cement_2A1_Gg). The F(4,4626) = 1420.82 test proved the overall model significant at p < 0.001 (see Table 6).

Table 6.

Model Fit.

The regression model output is displayed in Table 7. The analysis reveals that Population_Total (β = 0.746, p < 0.001) has the strongest impact on emissions, followed by Urban_Percent (β = 0.072, p < 0.001). The analysis shows that GDP_perCapita (β = –0.007, p = 0.585) and Constr_Share_GDP (β = 0.007, p = 0.501) failed to produce statistically significant effects on emissions.

Table 7.

Regression Coefficients.

The model’s robustness was further evaluated by running collinearity diagnostic tests. The predictors showed acceptable collinearity statistics, as indicated in Table 8, with variance inflation factor (VIF) values remaining under 2 and their tolerances exceeding 0.5. The condition index results presented in Table 9 show that no variable strongly correlated with the others because the highest value was 8.166, which falls below the established threshold of 10. Post hoc diagnostic tests were performed to confirm that the obtained significance results were reliable. The results showed no change when different model configurations were tested.

Table 8.

Collinearity statistics.

Table 9.

Collinearity diagnostics.

Population_Total emerged as the most influential variable because it generated a substantial positive relationship (β = 0.746, p < 0.001) with cement emissions. The main source of cement emissions is population growth, as expanding populations increase demand for housing, infrastructure, and construction materials, which leads to higher cement usage and high carbon emissions. The statistical analysis showed that Urban_Percent has a positive effect (β = 0.072, p < 0.001), as urbanization increases construction activities, which generates additional emissions. The analysis shows that GDP_perCapita (β = –0.007, p = 0.585) and Constr_Share_GDP (β = 0.007, p = 0.501) failed to produce statistically significant results, which indicates that economic structural indicators do not enhance the explanatory power of population growth and urban expansion. The research results demonstrate that population growth and urbanization remain the main factors responsible for cement-related CO2 emissions, which requires policy solutions that combine demand control with sustainable urban development and environmentally friendly construction methods.

The global model shows that GDP per capita and construction share of GDP do not affect emissions because population size and urbanization patterns control emission patterns at the planetary level. The combination of technological progress and efficiency improvements during economic growth periods leads to reduced direct emission increases, which makes these variables insignificant when viewed on a global scale. The direct increase in material usage and cement consumption from population growth and urban development creates emissions that exceed the ability of wealth-driven efficiency to reduce. The low multicollinearity statistics (VIF < 2) show that these variables remain insignificant because population-driven construction needs exceed the efficiency benefits of rising income levels when analyzing countries across the world. The findings indicate that it is necessary for the developers of emission reduction strategies to focus on population growth and urban development patterns rather than simply depending on income-based efficiency enhancements.

These research results validate previous studies demonstrating that fast urban growth, combined with population increase, leads to higher construction emissions [17,18,19]. This research extends previous single-country studies by showing that population growth creates emission increases that affect various economic systems. The study supports the findings of previous studies demonstrating that developing countries need to implement combined urban planning and population control measures to reach emission reduction targets [30,31].

4.4. CCSI Analysis

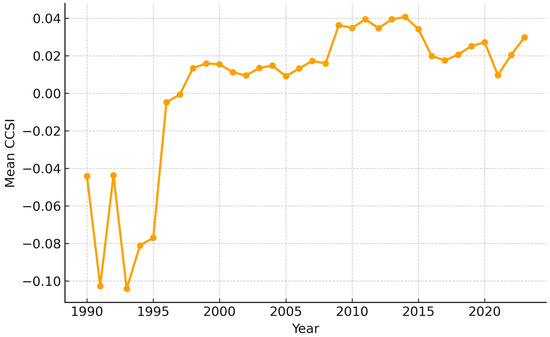

The results presented in Figure 3 show that construction sector sustainability scores displayed negative values during the early 1990s before achieving positive values starting from the late 1990s, indicating slow global advancements. The CCSI results validate previous research findings showing that economic expansion does not automatically result in environmental sustainability [18,20,21]. The study results validate previous findings regarding the restricted ability of developed nations to separate their GDP from construction emissions through time. These research findings demonstrate that technological efficiency and regulatory quality serve as the determining factors for emission reduction during development rather than economic growth [25,26,27].

Figure 3.

Global mean CCSI trend (1990–2023).

The time-based patterns result from technological progress in extracting minerals from the earth. The combination of enhanced cement kiln performance, blended cement usage, and more efficient energy systems technology has led to step-by-step improvements in CCSI values. Several composite indices and evaluation frameworks have been developed to assess sustainability and low-carbon performance in the construction and industrial sectors. For example, the Global Buildings Climate Tracker (GBCT), introduced by the Global Alliance for Buildings and Construction (GlobalABC), serves as a composite “decarbonization index” that integrates multiple normalized and weighted indicators to monitor progress toward building-sector emission targets [48]. Similarly, low-carbon construction performance indices have been proposed at the regional and project levels to evaluate carbon reduction and material efficiency, using structured indicator systems with hierarchical weighting methods such as AHP and CRITIC–TOPSIS [49,50].

The construction supply chain has continued to emit high levels of greenhouse gas emissions because technological advancements in extraction and consumption volumes have failed to keep pace with the rapid growth in these areas. The same emission patterns have been observed in multiple industrial sectors that show rising absolute emissions despite achieving higher operational efficiency [51,52,53,54]. Furthermore, the global mean CCSI shows minimal change during the 33-year period because construction sector decarbonization efforts have resulted in limited overall progress despite technological progress and rising climate awareness. The minimal change in global mean CCSI for 33 years shows that the construction sector has failed to decouple its carbon emissions because local efficiency improvements have not led to a global decrease in construction emissions. The construction sector’s emission reductions in developed countries have been neutralized by developing nations’ fast-paced urban development and construction activities. The equilibrium effect emerges because OECD and G20 countries’ efficiency improvements, material substitutions, and policy-driven progress are matched by rising construction energy and carbon usage in developing economies. The findings of this study demonstrate that worldwide construction sector decarbonization efforts show uneven progress because local initiatives fail to create a global shift in construction material use and process methods.

The 2023 rankings showed significant differences between top-performing nations. The top three countries in 2023, based on the results presented in Table 10, were the United States with (66.6), followed by Japan with (47.6), and Germany with (47.4). The top countries in the ranking included the United Kingdom (46.7), France (45.5), Canada (44.8), Italy (43.8), Australia (43.5), Spain (43.0), and the Netherlands (42.5). The Activity Index adjustment excluded small developing economies from leadership positions because they had minimal construction activity and economic development. The modification shows that sustainable construction leadership demands both emission reduction, operational excellence, and adaptability in major urbanized economies.

Table 10.

Top 10 countries by CCSI* in 2023.

The bottom 10 performing countries in 2023 were split into two separate groups according to their complete dataset. The first group included major high-emitting countries, namely, China with 15.0 and India with 28.3, because their large-scale construction sector activities produced significant carbon emissions. The second group included low-income and least-developed nations, which included Papua New Guinea (36.7), Burundi (36.8), Pakistan (36.8), Niger (36.8), Malawi (36.8), Afghanistan (36.8), Rwanda (36.9), and Turkmenistan (36.9). The above countries achieved low Activity Index scores because their limited construction activities and limited economic and urban development led to poor sustainability results despite their emission levels. The research findings demonstrate that high-emission developing countries and low-activity nations require separate approaches to achieve construction sector sustainability because they present different development challenges (Table 11).

Table 11.

Bottom 10 countries by CCSI* in 2023.

The CCSI* subgroup analyses delivered specific information about sustainability performance across different major economic regions. The results showed distinct performance patterns between different subgroups and within each subgroup, driven by their unique economic, environmental, and structural characteristics in the construction industry. The OECD and G20 high-income groups included top-performing countries such as the United States (66.66), Japan (47.6), and Germany (47.4) because they managed to maintain high construction output with efficient emission management systems. The BRICS and MINT emerging groups showed inconsistent results: Brazil (42.3) and Mexico (43.3) achieved average performance; in comparison, India (28.3) and China (15.0) maintained their position as the lowest performers because of their high total emissions. The GCC countries achieved middle-range scores because their construction industries remained active, but their carbon intensity remained high. These research findings show that construction-related carbon sustainability depends on more than development stage, economic size, and resource wealth because nations need to implement successful strategies for sustainable urban development and emission reduction.

4.4.1. The Group of Twenty (G20)

The G20 subgroup shows how advanced economies control the weighted CCSI* through their strong positions. The United States (66.6), Japan (47.6), and Germany (47.4) held the top spots in the rankings, followed by the United Kingdom (46.7), France (45.5), and Canada (44.8). The results indicate that large economies reach high sustainability levels through the combination of technological efficiency and urban development policies in construction operations. The high construction emissions of China (15.0) and India (28.3) placed them at the bottom of the group, as rapid development without proper emission controls hindered their sustainability achievements.

The G20 leading members achieve strong results because they have established advanced regulatory systems and made significant technological advancements in construction activities. The United States, Japan, and Germany, combined with other G20 nations, have established advanced building energy codes, performed life-cycle carbon assessments, and developed their supply chains with renewable energy and low-carbon materials. Their economic growth has been separated from emissions through these measures, which enables them to sustain high CCSI* values. The large-scale urban development and cement-based infrastructure growth in China and India face limitations because their construction activities still rely on coal-based energy systems. The G20 results demonstrate that environmental governance strength, together with innovation capabilities, plays a greater role in sustainability performance than economic size.

The results align with those of previous studies, which demonstrate that advanced economies reduce their emission intensity through technological progress and climate policy implementation [15,28,29]. The low CCSI* scores of China and India stem from their ongoing use of fossil fuels in construction activities, findings already documented in previous studies [22,23,24,30]. The findings of the current study validate these observed patterns through the use of a broader dataset and an index system that evaluates both environmental impact and operational levels.

4.4.2. The Organization for Economic Co-Operation and Development (OECD)

The OECD subgroup contained numerous countries that achieved top positions in the rankings. The United States (66.6), Japan (47.6), Germany (47.4), the United Kingdom (46.7), and France (45.5) maintained their high positions because of their effective regulatory systems and advanced construction technology capabilities. The sustainability performance of Canada (44.8), Italy (43.8), Spain (43.0), and the Netherlands (42.5) fell in the middle range of the results. The subgroup included nations that struggled with building-related energy consumption because of their heavy dependence on energy-intensive construction activities.

The construction sectors of OECD countries reach high CCSI* scores because they operate under detailed environmental laws, together with binding efficiency rules and carbon pricing systems that function through market mechanisms. The EU Energy Performance of Buildings Directive and ASHRAE standards have led to better building insulation and heating and cooling performance through their long-term implementation, while blended cement and circular economy principles have decreased construction carbon emissions. The nations maintain their urban development pace without increased emissions because their strong institutions both enforce policies and track progress. This finding demonstrates that advanced economies should leverage technological advancement combined with strict policy enforcement to achieve the most successful path to low-carbon construction.

4.4.3. BRICS

The BRICS subgroup demonstrated significant differences between its member countries. Brazil (42.3) achieved a position in the middle range because its construction activities were moderate while its carbon emissions remained relatively low. The cement, steel, and building industries of China (15.0) and India (28.3) produced such high carbon emissions that these countries obtained the lowest positions in global rankings with scores of 14.97 and 28.22, respectively. The results of Russia (40.5) and South Africa (38.6) fell between average and below average because their development progress was inconsistent.

The BRICS results demonstrate the fundamental obstacles that new industrial powers face during their development. The construction activities of China and India achieve the lowest sustainability ratings because their power generation relies on coal, and their cement production uses clinker, while their cities expand faster than green building codes and energy-efficient solutions can spread. The performance of Russia and South Africa falls between average and poor because their industrial base ages while they spend little on renewable energy development; in comparison, Brazil maintains a moderate position because it uses hydropower and has controlled construction growth. The BRICS subgroup demonstrates that uncoordinated environmental regulations during rapid industrial development result in extended high carbon emissions from construction activities.

4.4.4. MINT

The MINT subgroup achieved average results, with some countries performing better than others. The construction growth of Mexico (43.3) and Indonesia (40.8) matched their sustainability progress, which led to their average positions in the rankings. Turkey (39.2) lagged behind other nations because it heavily relies on carbon-intensive construction materials and energy systems. The Activity Index restricted Nigeria (38.3) from achieving better results because the country lacked a sufficient economic and urban development scale.

The MINT countries show diverse sustainability results because their institutional capabilities and material resource needs differ. The two countries of Mexico and Indonesia show progress through their adoption of green building standards and their use of renewable energy at a moderate level, yet Turkey and Nigeria struggle because they lack effective enforcement of efficiency codes and heavily depend on carbon-emitting cement and steel production. The combination of economic instability and unregulated construction activities makes it difficult to control emissions. The findings show that emerging markets need to achieve economic growth and develop strong institutions to successfully implement and track low-carbon construction policies.

4.4.5. The Gulf Cooperation Council (GCC)

The GCC subgroup maintained ongoing sustainability problems in its operations. Saudi Arabia and the United Arab Emirates achieved middle-tier positions with scores of 41.7 and 41.0; in comparison, Qatar (40.3), Kuwait (39.4), Oman (38.7), and Bahrain (38.7) showed weak performance despite their financial strength.

The GCC countries maintain a middle position in global rankings because their construction industry operates at high levels of activity while using significant amounts of energy. The Vision 2030 sustainability initiatives of Saudi Arabia and the United Arab Emirates have led to local green-building codes such as SBC 601 and Estidama, yet most construction projects continue to depend on fossil fuels for power and materials with elevated embodied carbon content. The need for extensive air conditioning and water desalination because of climate conditions leads to higher operational emissions. There is an urgent need for the region to expedite its transition to renewable energy while increasing low-carbon concrete adoption.

The GCC achieved a moderate sustainability rating, confirming previous research that the region faces two main challenges: its dependence on fossil fuels and its energy-intensive construction practices [31]. This study builds on previous findings by establishing a numerical assessment of GCC sustainability performance relative to global standards, which demonstrates that financial resources do not automatically reduce emissions unless accompanied by complete low-carbon policy frameworks.

4.4.6. Cross-Subgroup Insights

The subgroup evaluations demonstrate multiple recurring trends. The G20 and OECD advanced economies lead the way because they unite technological progress with effective regulatory systems. The GCC states face ongoing challenges from fossil fuel usage despite their financial resources, while China and India demonstrate the problems of large-scale construction without sufficient emission controls. The BRICS and MINT groups present diverse sustainability outcomes because some member countries advance while others lag behind because of their high emissions or their limited economic development and urban activities. The findings demonstrate that construction sector sustainability depends on effective emission reduction strategies and growth management systems rather than financial resources or income levels.

5. Conclusions

Through this study, the author aimed to identify which factors have the most significant impact on construction sector carbon emissions and evaluate how sustainability performance varies across different regions worldwide. The author combined 7038 observations spanning 1990 to 2023 to study global construction carbon emissions through economic indicators to demographic factors and emission data. Descriptive statistics, PCA, regression modeling, and CCSI development were used to demonstrate the extensive carbon emission impact of construction activities while showing their various emission sources. The research findings show that cement manufacturing, combined with construction operations, generates the most emissions; in comparison, population expansion and urban development patterns create the greatest increase in cement emissions. In addition, the results indicate that economic growth does not automatically lead to sustainable results because technology advancements, combined with efficient policy implementation, are needed to achieve emission reduction.

The PCA results show that emission reduction requires two connected yet distinct factors to be addressed: production-based emission intensity and development-driven urban expansion. The adjusted CCSI* shows how different nations achieve different sustainability levels because OECD and G20 countries achieve better results through their regulatory systems and efficiency measures; however, China and India struggle with fast development and high-carbon construction techniques. The GCC countries demonstrate intermediate positions in the CCSI*, providing evidence that those in charge of large-scale development projects need to adopt sustainable construction methods.

The authors build upon the results to provide multiple methodological and policy-oriented contributions for the field. This study makes three essential contributions to the field. A common system that enables countries to measure their construction sector emissions and sustainability results was developed. The findings demonstrate that developers of emission reduction plans must focus on specific contexts in order to improve material production efficiency and create sustainable urban development for rapidly growing areas. In addition, the findings show that the CCSI serves as a useful policy tool for tracking climate commitment progress because it combines multiple indicators to assess progress toward meeting the Paris Agreement and global net zero targets.

Through this study, a strong analytical structure was established but has revealed numerous prospects for additional research and practical implementation. Researchers should develop this framework by including life-cycle assessments, construction process renewable energy integration, and real-time emission tracking systems in their future studies. In the construction sector, there is a need for policymakers to support blended cement usage and low-carbon material development, green building standards, and circular economy systems to address both production and market-based challenges. A low-carbon construction future requires international cooperation between economic development and environmental protection initiatives.

Funding

This work was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under grant No. (829-007-D1434). The author, therefore, acknowledges with thanks the DSR’s technical and financial support.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original data presented in the study are openly available in the IEA, EDGAR, Our World in Data, and the World Bank.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mignot, A.; von Schuckmann, K.; Landschützer, P.; Gasparin, F.; van Gennip, S.; Perruche, C.; Lamouroux, J.; Amm, T. Decrease in air-sea CO2 fluxes caused by persistent marine heatwaves. Nat. Commun. 2022, 13, 4300. [Google Scholar] [CrossRef] [PubMed]

- Hancock, S.E.; Jacob, D.J.; Chen, Z.; Nesser, H.; Davitt, A.; Varon, D.J.; Sulprizio, M.P.; Balasus, N.; Estrada, L.A.; Cazorla, M.; et al. Satellite quantification of methane emissions from South American countries: A high-resolution inversion of TROPOMI and GOSAT observations. Atmos. Chem. Phys. 2025, 25, 797–817. [Google Scholar] [CrossRef]

- Zhao, Q.; Wu, Z.; Yu, Y.; Wang, T.; Huang, S. Exploring Carbon Emissions in the Construction Industry: A Review of Accounting Scales, Boundaries, Trends, and Gaps. Buildings 2025, 15, 1900. [Google Scholar] [CrossRef]

- Cheshmehzangi, A. Building Industry Infrastructure: Foundations for Sustainable, Resilient, and Integrated Urban Development. In Advanced City; Springer: Berlin/Heidelberg, Germany, 2025; pp. 393–403. [Google Scholar]

- Wang, G.; Luo, T.; Luo, H.; Liu, R.; Liu, Y.; Liu, Z. A comprehensive review of building lifecycle carbon emissions and reduction approaches. City Built Environ. 2024, 2, 12. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, Y.; Huang, Z.; Chen, D.; Cheng, B.; Wang, D.; Lu, C. Insight from Review Articles of Life Cycle Assessment for Buildings. Appl. Sci. 2025, 15, 7751. [Google Scholar] [CrossRef]

- EC. EU ETS Handbook; European Commission: Luxembourg, 2015. [Google Scholar]

- ECCC. Greenhouse Gas Pollution Pricing Act; Environment and Climate Change Canada: Gatineau, QC, Canada, 2022.

- Ranasinghe, N.; Domingo, N.; Kahandawa, R. Enhancing building material circularity: A systematic review on prerequisites, obstacles and the critical role of data traceability. J. Build. Eng. 2024, 98, 111136. [Google Scholar] [CrossRef]

- Dsilva, J.; Zarmukhambetova, S.; Locke, J. Assessment of building materials in the construction sector: A case study using life cycle assessment approach to achieve the circular economy. Heliyon 2023, 9, e20404. [Google Scholar] [CrossRef]

- IPCC. IPCC Sixth Assessment Report Working Group III: Mitigation of Climate Change, Chapter 9: Buildings; Intergovernmental Panel on Climate Change: Cambridge, UK, 2022. [Google Scholar]

- Ige, O.E.; Von Kallon, D.V.; Desai, D. Carbon emissions mitigation methods for cement industry using a systems dynamics model. Clean Technol. Environ. Policy 2024, 26, 579–597. [Google Scholar] [CrossRef]

- PEEB-AFD. Buildings in the Ndcs: Mapping Targets on Buildings in the Nationally Determined Contributions (NDCs); Programme for Energy Efficiency in Buildings-Agence Francaise de Developpement: Paris, France, 2023. [Google Scholar]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Weigert, M.; Melnyk, O.; Winkler, L.; Raab, J. Carbon Emissions of Construction Processes on Urban Construction Sites. Sustainability 2022, 14, 12947. [Google Scholar] [CrossRef]

- Qian, L.H. An empirical study on the relationship between urbanization, transportation infrastructure, industrialization and environmental degradation in China, India and Indonesia. Environ. Dev. Sustain. 2024. [Google Scholar] [CrossRef]

- Vogel, J.; Hickel, J. Is green growth happening? An empirical analysis of achieved versus Paris-compliant CO2–GDP decoupling in high-income countries. Lancet Planet. Health 2023, 7, e759. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zong, T.; Shuai, C.; Jiao, L. How does new-type urbanization affect total carbon emissions, per capita carbon emissions, and carbon emission intensity? An empirical analysis of the Yangtze River economic belt, China. J. Environ. Manag. 2024, 349, 119441. [Google Scholar] [CrossRef] [PubMed]

- IFC. Building Green: Sustainable Construction in Emerging Markets; International Finance Corporation: Washington, DC, USA, 2023. [Google Scholar]

- OECD. Decarbonising Buildings in Cities and Regions; Organization for Economic Co-operation and Development: Paris, France, 2022. [Google Scholar]

- IEA. Coal 2024: Analysis and Forecast to 2027; International Energy Agency: Paris, France, 2024. [Google Scholar]

- Peng, D.; Liu, H. Measurement and Driving Factors of Carbon Emissions from Coal Consumption in China Based on the Kaya-LMDI Model. Energies 2022, 16, 439. [Google Scholar] [CrossRef]

- Oei, P.-Y.; Herpich, P.J. An Assessment of Germany’s Remaining CO2 Budget: Can Germany Still Afford to Destroy Villages to Burn More Coal? Environ. Sci. Policy Sustain. Dev. 2024, 66, 5–21. [Google Scholar] [CrossRef]

- Hu, X.; Liu, C. Carbon productivity: A case study in the Australian construction industry. J. Clean. Prod. 2016, 112, 2354–2362. [Google Scholar] [CrossRef]

- Yang, X.; Lei, G.; Wang, X. Can the development of digital construction reduce enterprise carbon emission intensity? New evidence from Chinese construction enterprises. Front. Ecol. Evol. 2023, 11, 1250593. [Google Scholar] [CrossRef]

- Yu, Z.; Kanwal, Q.; Wang, M.; Nurdiawati, A.; Al-Ghamdi, S.G. Spatiotemporal dynamics and key drivers of carbon emissions in regional construction sectors: Insights from a Random Forest Model. Clean. Environ. Syst. 2025, 16, 100257. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Jayasinghe, J.A.S.C.; Kulatunga, A.K.; Zhang, G. A comparative life cycle assessment of prefabricated and traditional construction—A case of a developing country. J. Build. Eng. 2023, 72, 106550. [Google Scholar] [CrossRef]

- Kohlscheen, E.; Moessner, R.; Takats, E. Effects of carbon pricing and other climate policies on CO2 emissions. arXiv 2024, arXiv:2402.03800. [Google Scholar] [CrossRef]

- Jiao, Z.; Xing, Z.; Zhang, G.; Ma, X.; Wang, H. Comparing Decoupling and Driving Forces of CO2 Emissions in China and India. Front. Environ. Sci. 2022, 10, 847062. [Google Scholar] [CrossRef]

- Abid, I.; Hechmi, S.; Chaabouni, I. Impact of Energy Intensity and CO2 Emissions on Economic Growth in Gulf Cooperation Council Countries. Sustainability 2024, 16, 10266. [Google Scholar] [CrossRef]

- OECD. Unlocking the Potential of Demand-Side Climate Mitigation Strategies; Organization for Economic Co-operation and Development: Paris, France, 2025. [Google Scholar]

- Yu, Y.; You, K.; Cai, W.; Feng, W.; Li, R.; Liu, Q.; Chen, L.; Liu, Y. City-level building operation and end-use carbon emissions dataset from China for 2015–2020. Sci. Data 2024, 11, 138. [Google Scholar] [CrossRef]

- Mlote, D.S.; Budig, M.; Cheah, L. Adaptability of buildings: A systematic review of current research. Front. Built Environ. 2024, 10, 1376759. [Google Scholar] [CrossRef]

- Wang, Y.; Mu, X.; Hu, G.; Wang, L.; Zhu, X. Life Cycle Assessment-Based Analysis of Environmental and Economic Benefits in Construction Solid Waste Recycling. Sustainability 2025, 17, 3872. [Google Scholar] [CrossRef]

- Dias, A.B.; Pacheco, J.N.; Silvestre, J.D.; Martins, I.M.; de Brito, J. Environmental and Economic Life Cycle Assessment of Recycled Coarse Aggregates: A Portuguese Case Study. Materials 2021, 14, 5452. [Google Scholar] [CrossRef] [PubMed]

- Rao, P.A.; Rahman, M.M.; Duraman, S.B. Adopting circular economy in construction: A review. Front. Built Environ. 2025, 11, 1519219. [Google Scholar] [CrossRef]

- Fonseca, M.; Matos, A.M. 3D Construction Printing Standing for Sustainability and Circularity: Material-Level Opportunities. Materials 2023, 16, 2458. [Google Scholar] [CrossRef]

- Khan, M.A.H.; Ahmed, A.; Ali, T.; Qureshi, M.Z.; Islam, S.; Ahmed, H.; Ajwad, A.; Khan, M.A. Comprehensive review of 3D printed concrete, life cycle assessment, AI and ML models: Materials, engineered properties and techniques for additive manufacturing. Sustain. Mater. Technol. 2025, 43, e01164. [Google Scholar] [CrossRef]

- Motalebi, A.; Khondoker, M.A.H.; Kabir, G. A systematic review of life cycle assessments of 3D concrete printing. Sustain. Oper. Comput. 2024, 5, 41–50. [Google Scholar] [CrossRef]

- Feng, L.; Shi, Y.; Yang, Z.; Lam, J.F.I.; Lin, S.; Zhan, J.; Chen, H. Dynamic correlation of environmental regulation, technological innovation, and corporate carbon emissions: Empirical evidence from China listed companies. Sci. Rep. 2025, 15, 8433. [Google Scholar] [CrossRef]

- Zhang, W.; Hsu, S.-C.; Lee, C.-J.; Wei, H.-H. Responses of Green Innovation to Carbon Emission Policies in China’s Construction Industry. Resour. Conserv. Recycl. 2025, 219, 108326. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M. Carbon footprint of construction industry: A global review and supply chain analysis. Renew. Sustain. Energy Rev. 2020, 124, 109783. [Google Scholar] [CrossRef]

- Mathur, V.S.; Farouq, M.M.; Labaran, Y.H. The carbon footprint of construction industry: A review of direct and indirect emission. J. Sustain. Constr. Mater. Technol. 2021, 6, 101–115. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, B.; Sun, J.; Liu, C.; Xu, Y. Trade decomposition of CO2 emissions of global construction industries. Eng. Constr. Archit. Manag. 2022, 29, 502–522. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using Spss, 3rd ed.; SAGE Publications Ltd.: London, UK, 2009. [Google Scholar]

- Hinton, P.; McMurray, I.; Brownlow, C. SPSS Explained, 2nd ed.; Routledge: New York, NY, USA, 2014. [Google Scholar]

- Kockat, J.; Zuhaib, S.; Rapf, O. A Methodology for Tracking Decarbonisation Action and Impact of the Buildings and Construction Sector Globally; Buildings Performance Institute Europe: Berlin, Germany, 2020. [Google Scholar]

- Wang, H.; Tao, J.; Xu, J.; Zhang, Y. Research on an evaluation index system and evaluation method of green and low-carbon expressway construction. PLoS ONE 2023, 18, e0283559. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Y.; Yu, G.; Sun, J.; Liu, J.; Wang, Y.; Yu, Y. Evaluation of Low-Carbon Development in the Construction Industry and Forecast of Trends: A Case Study of the Yangtze River Delta Region. Sustainability 2025, 17, 5435. [Google Scholar] [CrossRef]

- IPCC. IPCC Sixth Assessment Report Working Group III: Mitigation of Climate Change, Chapter 11: Industry; IPCC: Cambridge, UK; New York, NY, USA, 2022. [Google Scholar]

- IEA; IRENA; UNCCHLC. The Breakthrough Agenda Report 2023: Accelerating Sector Transitions Through Stronger International Collaboration; International Energy Agency: Paris, France, 2023. [Google Scholar]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).