Socio-Environmental Assessment of a Tailings Water Softening Technology for Reuse in Alternative Systems in Central Chile: An Approach to Industrial Ecology

Abstract

1. Introduction

2. Materials and Methods

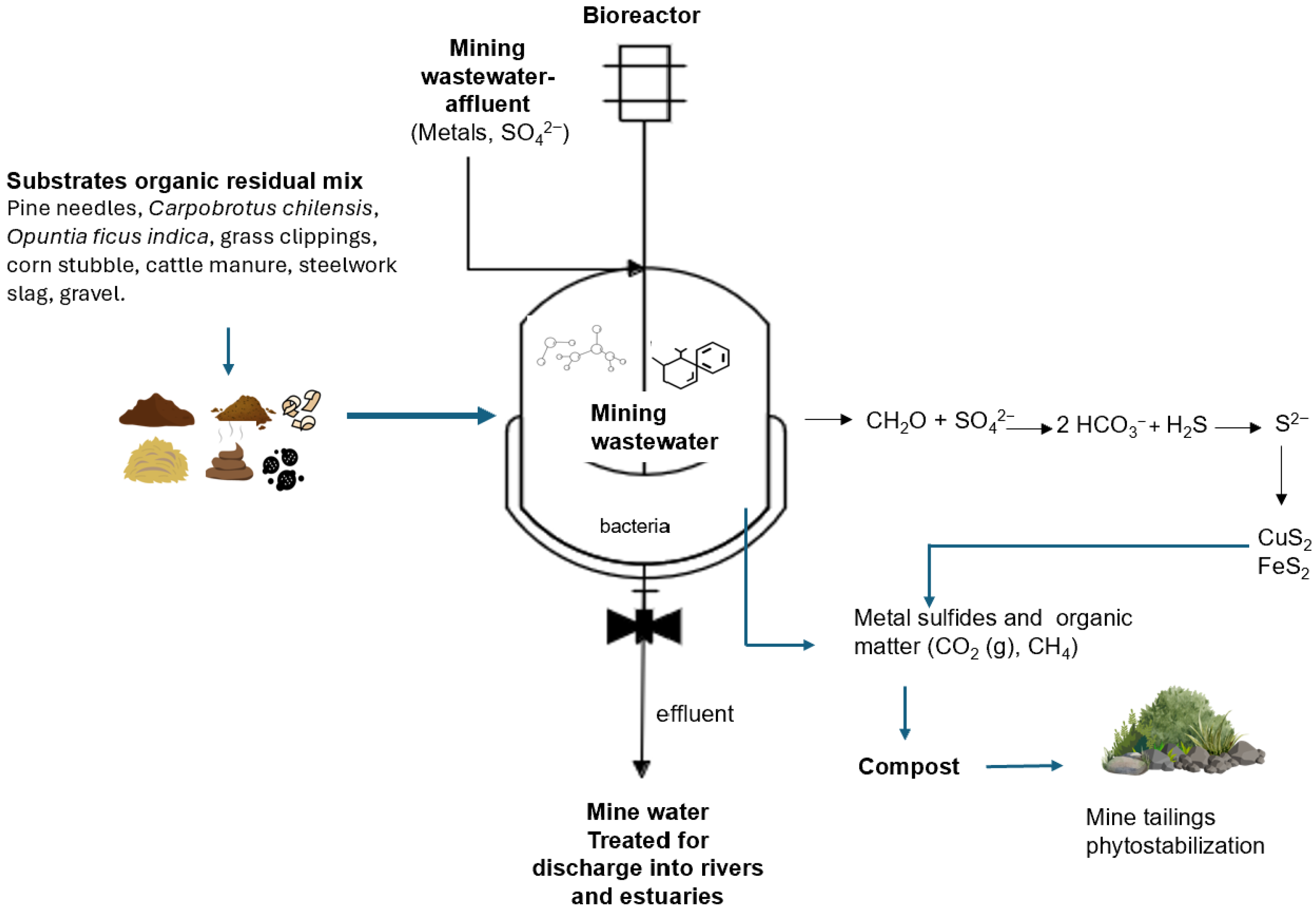

2.1. Bioreactor Technology & Experimental Setup

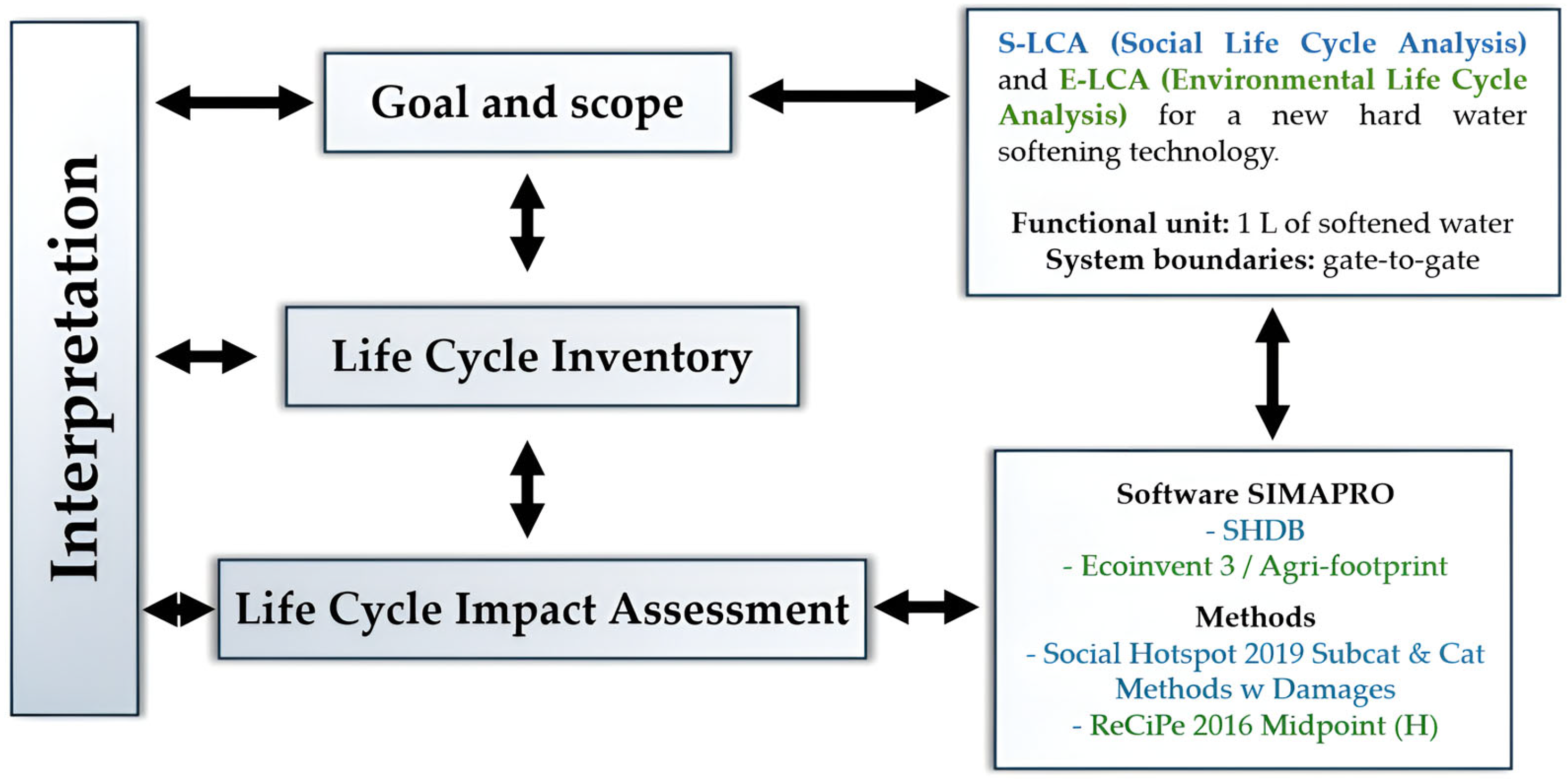

2.2. Life Cycle Assessment Methodology

2.2.1. Goal and Scope Definition

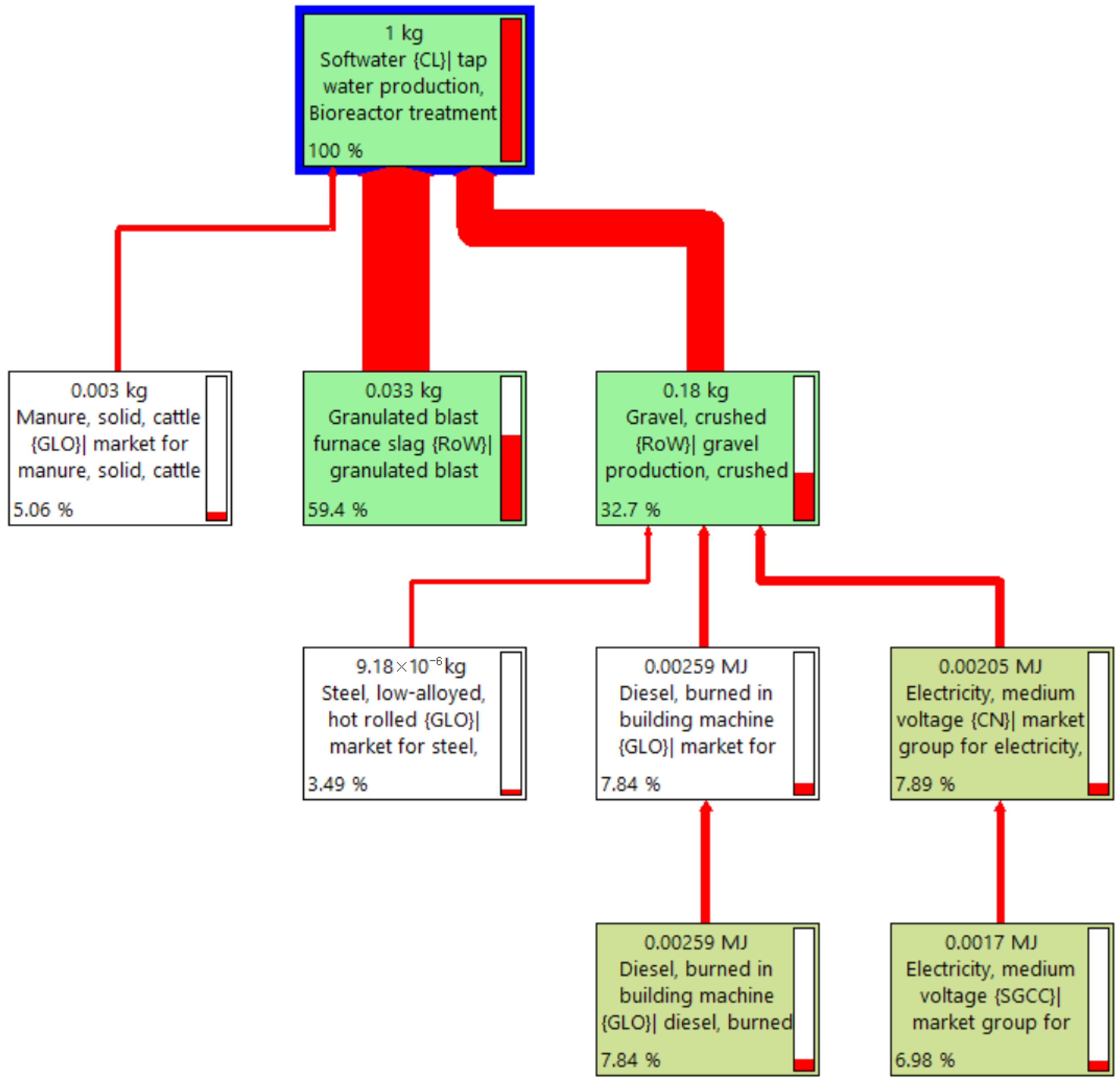

2.2.2. Life Cycle Inventory

2.2.3. Life Cycle Impact Assessment

3. Results

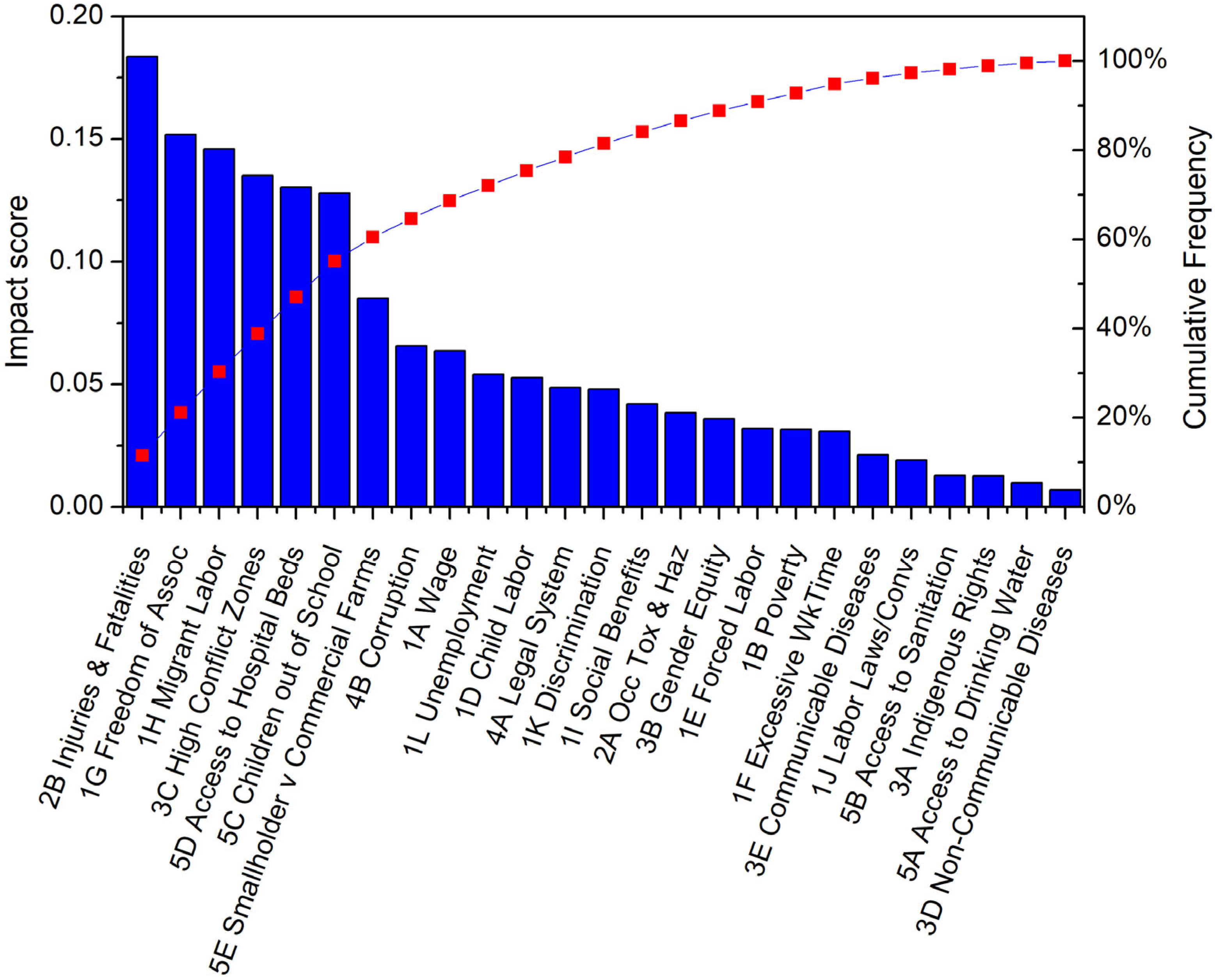

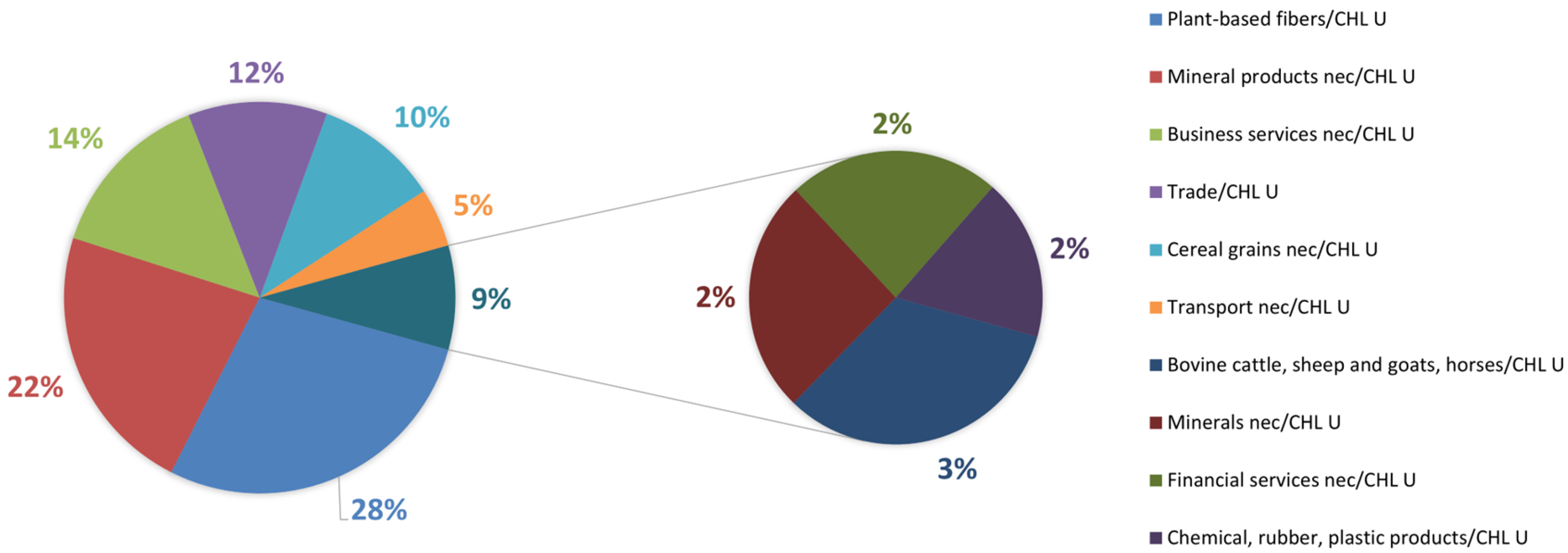

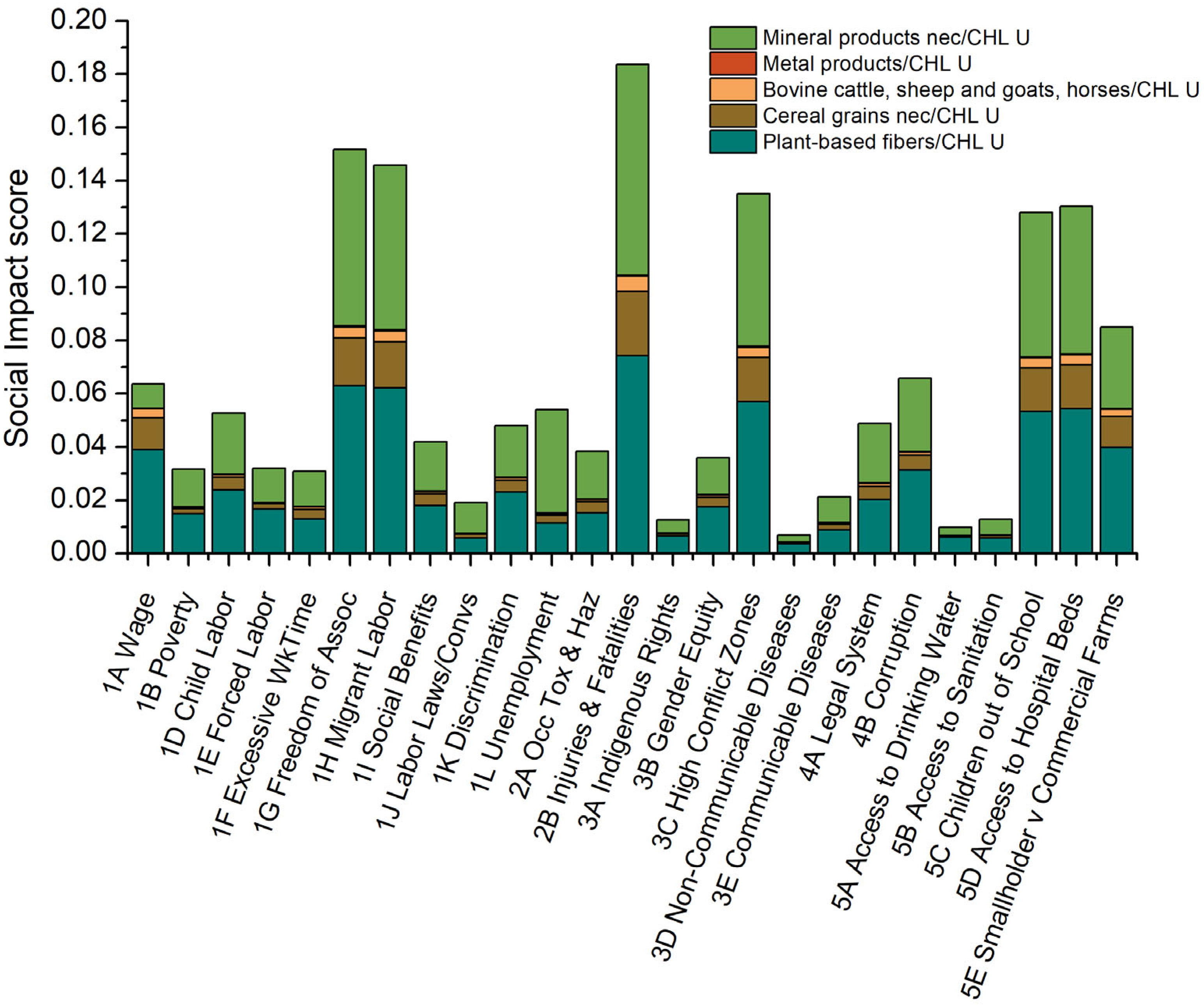

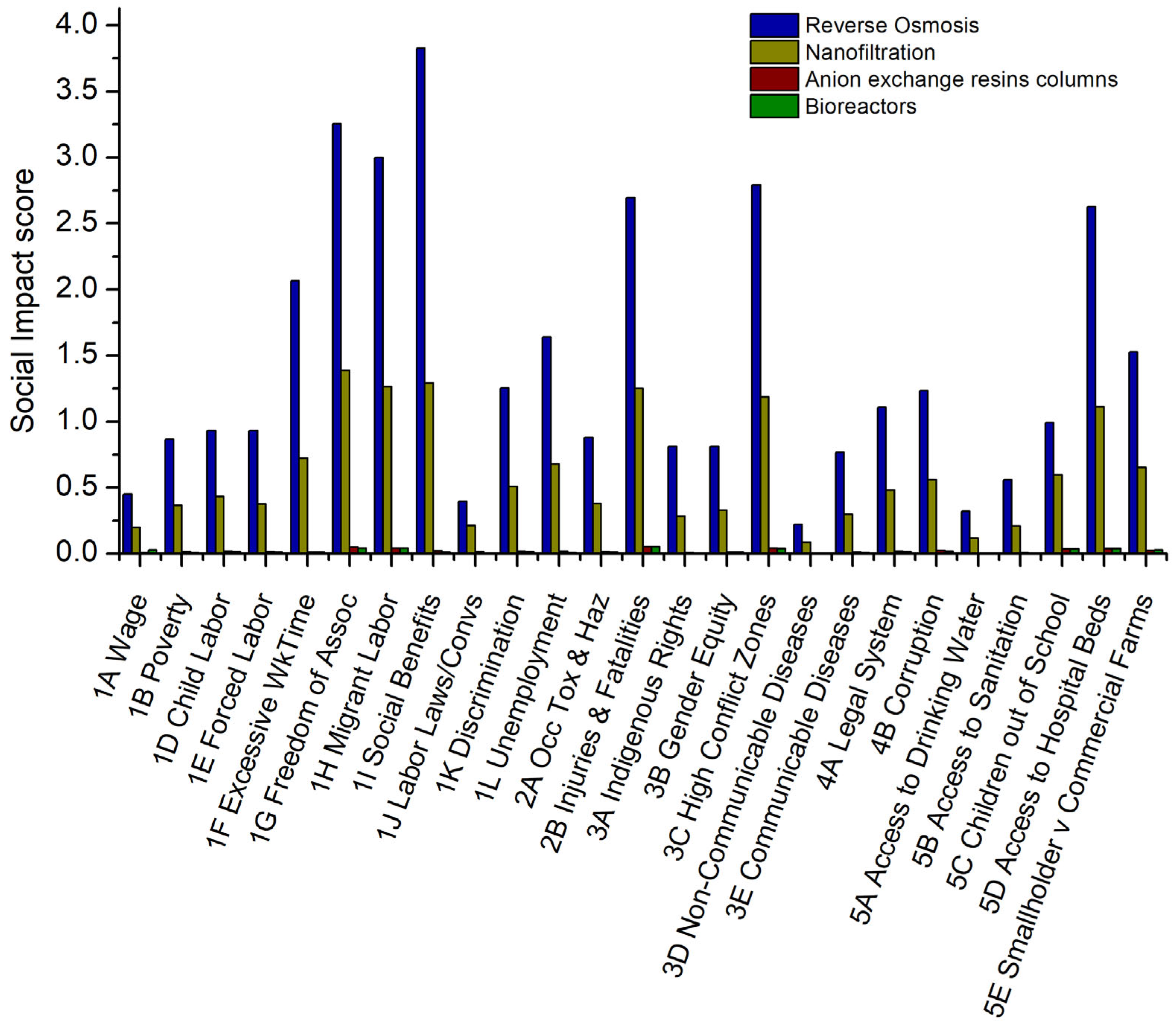

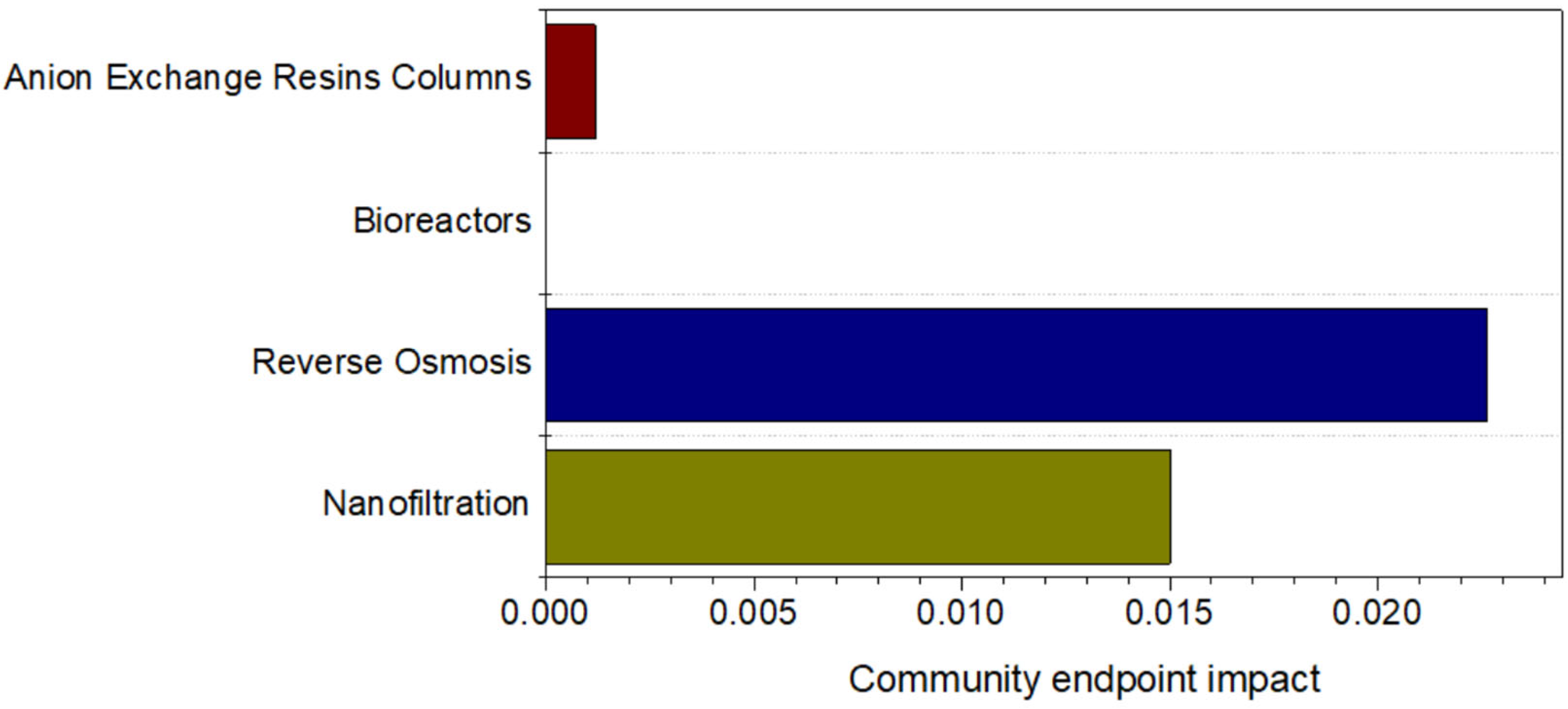

3.1. Social Life Cycle Assessment

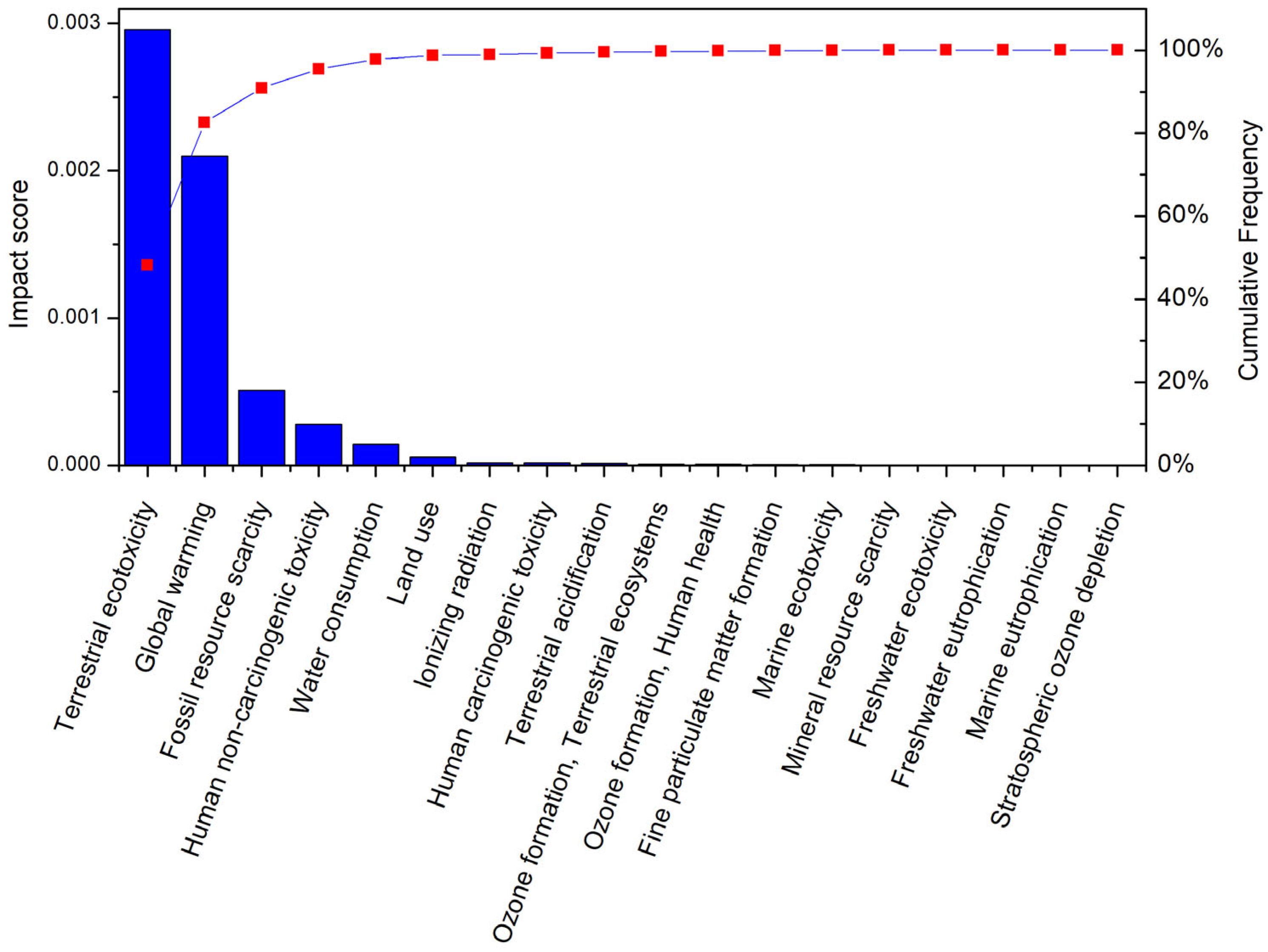

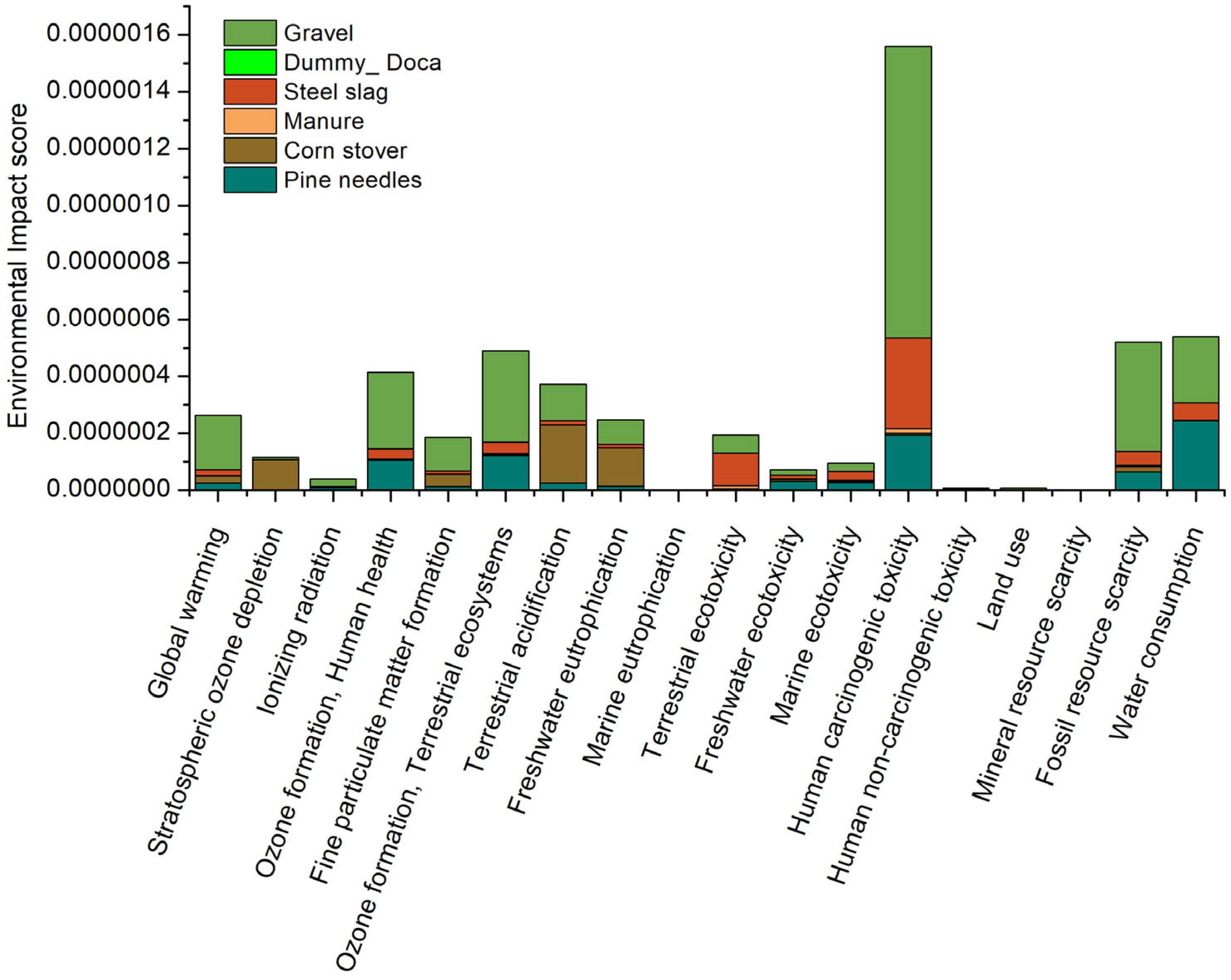

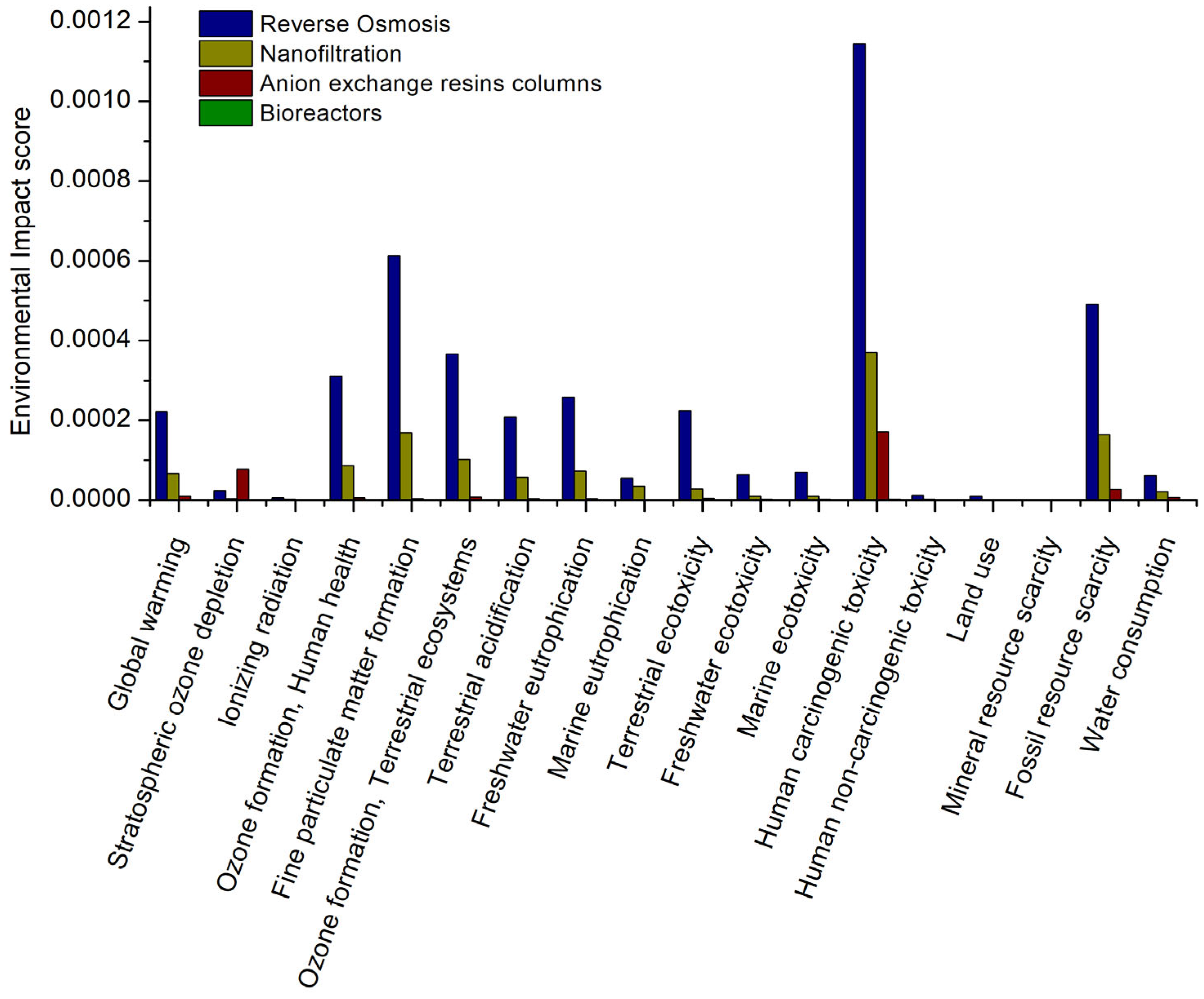

3.2. Environmental Life Cycle Assessment

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| S-LCA | Social Life Cycle Assessment |

| E-LCA | Environmental Life Cycle Assessment |

| SDHB | Social Hotspot Database |

| pbf | Plant-based fiber |

| ocr | Other crops |

| gro | Other grains |

| ctl | Cattle |

| i_s | Iron & Steel |

| nmm | Non-metallic Minerals |

References

- Iberdrola, S. La Contaminación del Agua: Cómo No Poner en Peligro Nuestra Fuente de Vida; 2025. Available online: https://www.iberdrola.com/sostenibilidad/contaminacion-del-agua (accessed on 25 June 2025).

- Herrera-León, S.; Cruz, C.; Negrete, M.; Chacana, J.; Cisternas, L.A.; Kraslawski, A. Impact of seawater desalination and wastewater treatment on water stress levels and greenhouse gas emissions: The case of Chile. Sci. Total Environ. 2022, 818, 151853. [Google Scholar] [CrossRef]

- Garcia-Zavala, C.; Ordens, C.M.; Pagliero, L.; Lèbre, É.; Aitken, D.; Stringer, M. An approach for prioritising environmental, social and governance (ESG) water-related risks for the mining industry: The case of Chile. Extr. Ind. Soc. 2023, 14, 101259. [Google Scholar] [CrossRef]

- Chilean Copper Commission (COCHILCO). Proyección de Demanda de Agua en la Minería del Cobre; 2022, pp. 1–36. Available online: https://www.cochilco.cl/web/informe-proyeccion-de-la-demanda-de-agua-en-la-mineria-del-cobre-2022-2033/ (accessed on 25 June 2025).

- Sairafi Ivan Yarur, C.S. Resiliencia Hídrica Para Santiago de Chile; 2024. Available online: https://www.alliance4water.org/wr4er-cases/water-resilience-for-santiago-de-chile (accessed on 25 June 2025).

- Cisternas, L.A.; Ordóñez, J.I.; Jeldres, R.I.; Serna-Guerrero, R. Toward the Implementation of Circular Economy Strategies: An Overview of the Current Situation in Mineral Processing. Miner. Process. Extr. Metall. Rev. 2022, 43, 775–797. [Google Scholar] [CrossRef]

- Stahel, W.R.; MacArthur, E. The Circular Economy; Routledge: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Vujović, N.; Alivojvodić, V.; Radovanović, D.; Štulović, M.; Sokić, M.; Kokalj, F. Towards Circularity in Serbian Mining: Unlocking the Potential of Flotation Tailings and Fly Ash. Minerals 2025, 15, 254. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Filho, J.J.d.S.; Gaspar, P.D.; do Paço, A.; Marcelino, S.M. Governance-Centred Industrial Symbiosis for Circular Economy Transitions: A Rural Forest Biomass Hub Framework Proposal. Sustainability 2025, 17, 5659. [Google Scholar] [CrossRef]

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; Mccall, D.W.; Patel, C.K.N. Industrial ecology: Concepts and approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef] [PubMed]

- Li, X. Industrial Ecology and Industrial Symbiosis—Definitions and Development Histories. In Industrial Ecology and Industry Symbiosis for Environmental Sustainability; Springer International Publishing: Cham, Switzerland, 2018; pp. 9–38. [Google Scholar] [CrossRef]

- Nordstrom, D.K.; Blowes, D.W.; Ptacek, C.J. Hydrogeochemistry and microbiology of mine drainage: An update. Appl. Geochem. 2015, 57, 3–16. [Google Scholar] [CrossRef]

- Hamraoui, L.; Bergani, A.; Ettoumi, M.; Aboulaich, A.; Taha, Y.; Khalil, A.; Neculita, C.M.; Benzaazoua, M. Towards a Circular Economy in the Mining Industry: Possible Solutions for Water Recovery through Advanced Mineral Tailings Dewatering. Minerals 2024, 14, 319. [Google Scholar] [CrossRef]

- Driussi, C.; Jansz, J. Technological options for waste minimisation in the mining industry. J. Clean. Prod. 2006, 14, 682–688. [Google Scholar] [CrossRef]

- Hatch. Study to Identify BATEA for the Management and Control of Effluent Quality from Mines. MEND NEDEM 2014, 1–723. [Google Scholar] [CrossRef]

- Thomson, M.; Miranda, M.S.; Infield, D. A Small-Scale Seawater Reverse-Osmosis System with Excellent Energy Efficiency over a Wide Operating Range. Desalination 2003, 153, 229–236. [Google Scholar] [CrossRef]

- Shingwenyana, R.; Shabalala, A.N.; Mbhele, R.; Masindi, V. Techno-Economic Analysis of the Reclamation of Drinking Water and Valuable Minerals from Acid Mine Drainage. Minerals 2021, 11, 1352. [Google Scholar] [CrossRef]

- Koyuncu, I.; Sengur, R.; Turken, T.; Guclu, S.; Pasaoglu, M.E. Advances in water treatment by microfiltration, ultrafiltration, and nanofiltration. In Advances in Membrane Technologies for Water Treatment; Woodhead Publishing: Sawston, UK, 2015; Volume 2019. [Google Scholar] [CrossRef]

- Nevárez, M.E. Optimización del Proceso de Regeneración de Resinas de Intercambio Iónico para ser Utilizadas en el Desminerlizador de Agua en Refinería Estatal Esmeraldas. Escuela Superior Politécnica de Chimborazo. Available online: https://dspace.espoch.edu.ec/items/4a1a0ac6-f233-431d-8fce-36c4ae5a4231 (accessed on 26 June 2025).

- Younger, P.L. Mine water pollution from Kernow to Kwazulu-Natal: Geochemical remedial options and their selection in practice. Geosci. South West Engl. 2002, 10, 255–266. [Google Scholar]

- Johnson, D.B.; Hallberg, K.B. Acid mine drainage remediation options: A review. Sci. Total Environ. 2005, 338, 3–14. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, Z.; Lan, J.; Liu, Y.; Du, Y.; Ye, H.; Du, D. Effect of sulfate-reducing bacteria (SRB) and dissimilatory iron-reducing bacteria (DIRB) coexistence on the transport and transformation of arsenic in sediments. Water Res. 2025, 270, 122834. [Google Scholar] [CrossRef]

- Xie, P.; Xu, X.J.; Zhang, Q.; Hou, Y.Y.; Fan, K.L.; Zhang, R.C.; Chen, C.; Wang, A.J.; Lee, D.J.; Ren, N.Q. Potent and Selective Inhibition of Sulfate-Reducing Bacteria by Neutral Red. Environ. Sci. Technol. 2025, 59, 6115–6125. [Google Scholar] [CrossRef]

- Gazea, B.; Adam, K.; Kontopoulos, A. A review of passive systems for the treatment of acid mine drainage. Miner. Eng. 1996, 9, 23–42. [Google Scholar] [CrossRef]

- Kikot, P.; Viera, M.; Mignone, C.; Donati, E. Study of the effect of pH and dissolved heavy metals on the growth of sulfate-reducing bacteria by a fractional factorial design. Hydrometallurgy 2010, 104, 494–500. [Google Scholar] [CrossRef]

- Neculita, C.; Zagury, G.J.; Bussière, B. Passive Treatment of Acid Mine Drainage in Bioreactors using Sulfate-Reducing Bacteria. J. Environ. Qual. 2007, 36, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Gallegos-Garcia, M.; Celis, L.B.; Rangel-Méndez, R.; Razo-Flores, E. Precipitation and recovery of metal sulfides from metal containing acidic wastewater in a sulfidogenic down-flow fluidized bed reactor. Biotechnol. Bioeng. 2009, 102, 91–99. [Google Scholar] [CrossRef]

- European Commission. ILCD Handbook: General guide for Life Cycle Assessment; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar] [CrossRef]

- Hannouf, M.B.; Padilla-Rivera, A.; Assefa, G.; Gates, I. Social life cycle assessment (S-LCA) of technology systems at different stages of development. Int. J. Life Cycle Assess. 2024, 30, 1099–1114. [Google Scholar] [CrossRef]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Lobsiger-Kägi, E.; López, L.; Kuehn, T.; Roth, R.; Carabias, V.; Zipper, C. Social Life Cycle Assessment: Specific Approach and Case Study for Switzerland. Sustainability 2018, 10, 4382. [Google Scholar] [CrossRef]

- UNEP/SETAC. UNEP-SETAC: GUIDELINES FOR SCLA of Product; 2009. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/7912/-Guidelines for Social Life Cycle Assessment of Products-20094102.pdf?sequence=3&%3BisAllowed= (accessed on 26 November 2023).

- Alanis, C.; Ávila-Córdoba, L.; Cruz-Olayo, A.; Natividad, R.; Padilla-Rivera, A. Integrating Environmental and Social Life Cycle Assessment for Sustainable University Mobility Strategies. Sustainability 2025, 17, 7456. [Google Scholar] [CrossRef]

- Orola, A.; Härri, A.; Levänen, J.; Uusitalo, V.; Olsen, S.I. Assessing WELBY Social Life Cycle Assessment Approach through Cobalt Mining Case Study. Sustainability 2022, 14, 11732. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Korevaar, G. Social Life Cycle Assessment of Brine Treatment in the Process Industry: A Consequential Approach Case Study. Sustainability 2019, 11, 5945. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Assessment—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2009.

- Wang, K.; Zhang, Z.; Zhu, L.; Yang, X.; Chen, M.; Yang, C. Comparative Life Cycle Assessment of Conventional and Dry Stack Tailings Disposal Schemes: A Case Study in Northern China. Minerals 2022, 12, 1603. [Google Scholar] [CrossRef]

- Xu, Y.-N.; Chen, Y. Advances in heavy metal removal by sulfate-reducing bacteria. Water Sci. Technol. 2020, 81, 1797–1827. [Google Scholar] [CrossRef]

- Manahan, S. Environmental Chemistry; CRC Press: Boca Raton, FL, USA, 2021; ISBN 9780367558871. [Google Scholar]

- Wang, J.; Li, X.; Guan, F.; Yang, Z.; Zhai, X.; Zhang, Y.; Tang, X.; Duan, J.; Xiao, H. The Isolation of Anaerobic and Facultative Anaerobic Sulfate-Reducing Bacteria (SRB) and a Comparison of Related Enzymes in Their Sulfate Reduction Pathways. Microorganisms 2023, 11, 2019. [Google Scholar] [CrossRef]

- Habe, H.; Sato, Y.; Aoyagi, T.; Inaba, T.; Hori, T.; Hamai, T.; Hayashi, K.; Kobayashi, M.; Sakata, T.; Sato, N. Design, application, and microbiome of sulfate-reducing bioreactors for treatment of mining-influenced water. Appl. Microbiol. Biotechnol. 2020, 104, 6893–6903. [Google Scholar] [CrossRef]

- Garrido, A.L. Evaluation of Humus and Coffee Grounds as Substrates of Bioreactors for Treatment of Mining Waters for Its Potential Reuse in Irrigation. Master's Thesis, Universidad de Chile, Santiago, Chile, 2024. [Google Scholar]

- Tapia, Y.; García, A.; Acuña, E.; Salazar, O.; Casanova, M.; Najera, F.; Kremer, C.; Castillo, B.; Joven, A.; Diaz, O.; et al. Monitoring of Chemical Species in Soils, Waters and Plants Near the Active Copper Mine Tailing Dam Ovejeria (Central Chile). Water Air Soil Pollut. 2024, 235, 176. [Google Scholar] [CrossRef]

- Escobar, S. Evaluation of Carpobrotus Chilensis as a Vegetable Substrate. Available online: https://repositorio.uchile.cl/handle/2250/199116?show=full (accessed on 26 June 2025).

- Ministerio Secretaría General de la Presidencia. Establece Norma de Emisión para la Regulación de Contaminantes Asociados a las Descargas de Residuos Líquidos a Aguas Marinas y Continentales Superficiales. Available online: https://bcn.cl/2k71i (accessed on 26 June 2025).

- Rodríguez-Oroz, D.; Maturana, J.; Malhue, R.; Llona, M. Efecto de la reforestación sobre las propiedades edáficas del tranque de relaves Cauquenes, mina El Teniente, Región del Libertador Bernardo O’higgins-Chile. Agro Sur 2019, 47, 41–49. [Google Scholar] [CrossRef][Green Version]

- New Earth. New Earth Social Hotspot Database; 2022. Available online: http://www.socialhotspot.org/ (accessed on 30 August 2025).[Green Version]

- GTAP. GTAP Data Bases: 57 Detailed Sectoral List; 2025. Available online: https://www.gtap.agecon.purdue.edu/databases/contribute/detailedsector57.asp (accessed on 26 June 2025).[Green Version]

- Bonton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. Desalination 2012, 284, 42–54. [Google Scholar] [CrossRef]

- Vigil, M.; Pedrosa Laza, M.; Moran-Palacios, H.; Alvarez Cabal, J. Optimizing the Environmental Profile of Fresh-Cut Produce: Life Cycle Assessment of Novel Decontamination and Sanitation Techniques. Sustainability 2020, 12, 3674. [Google Scholar] [CrossRef]

- Wang, X.; Peng, J.; Luo, Y.; Qiu, S.; Dong, J.; Zhang, Z.; Vercruysse, K.; Grabowski, R.C.; Meersmans, J. Exploring social-ecological impacts on trade-offs and synergies among ecosystem services. Ecol. Econ. 2022, 197, 107438. [Google Scholar] [CrossRef]

- Zanini, M.T.F.; Migueles, C.P.; Gambirage, C.; Silva, J. Barriers to local community participation in mining projects: The eroding role of power imbalance and information asymmetry. Resour. Policy 2023, 86, 104283. [Google Scholar] [CrossRef]

- Guzmán, J.I.; Karpunina, A.; Araya, C.; Faúndez, P.; Bocchetto, M.; Camacho, R.; Desormeaux, D.; Galaz, J.; Garcés, I.; Kracht, W.; et al. Chile: On the road to global sustainable mining. Resour. Policy 2023, 83, 103686. [Google Scholar] [CrossRef]

| Days | Properties | Control (Only Mining Wastewater) | Substrates with Carpobrotus chilensis | Substrates with Opuntia ficus indica | Chilean Regulation | |

|---|---|---|---|---|---|---|

| NCh 1333 | D90 | |||||

| Initial | pH | 7.9 | 7.9 | 7.9 | 5.5–9.0 | 6.0–8.5 |

| Electrical conductivity (mS/cm) | 2.93 | 2.93 | 2.93 | 0.75–7.5 | - | |

| Mo (mg/L) | 1.37 ± 0.04 | 1.37 ± 0.04 | 1.37 ± 0.04 | 0.01 | 1.00 | |

| SO42− (mg/L) | 2295 ± 285 | 2295 ± 285 | 2295 ± 285 | 250 | 1000 | |

| 75 | pH | 7.2 ± 0.4 | 6.5 ± 0.06 | 5.6 ± 0.4 | 5.5–9.0 | 6.0–8.5 |

| Electrical conductivity (mS/cm) | 2.94 ± 0.04 | 10.8 ± 0.17 | 6.92 ± 0.25 | 0.75–7.5 | - | |

| Mo (mg/L) | 0.93 ± 0.06 | <dl | <dl | 0.01 | 1.00 | |

| SO42− (mg/L) | 1670 ± 60.4 | 308 ± 38.1 | 647 ± 286 | 250 | 1000 | |

| 120 | pH | 7.4 ± 0.23 | 6.9 ± 0.08 | 6.4 ± 0.73 | 5.5–9.0 | 6.0–8.5 |

| Electrical conductivity (mS/cm) | 3.12 ± 0.15 | 10.6 ± 0.65 | 7.93 ± 0.41 | 0.75–7.5 | - | |

| Mo (mg/L) | 0.97 ± 0.05 | <dl | <dl | 0.01 | 1.00 | |

| SO42− (mg/L) | 1702 ± 15.5 | 70.1 ± 30.5 | 70.4 ± 17.7 | 250 | 1000 | |

| Substrate | Density (g/L) | Mg/m3 | Moisture (%) |

|---|---|---|---|

| Pine needles | 79.2 | 0.08 | - |

| Carpobrotus chilensis (Doca) | 554.3 | 0.55 | 92 |

| Corn stover | 26.7 | 0.03 | - |

| Bovine manure | 728.0 | 0.73 | 78 |

| Steel slag | 1822.4 | 1.82 | - |

| Gravel | 1272.0 | 1.27 | - |

| Substrate | Value (kg/L) | Cost USD/kg | Value/USD | SDHB Sector | Source |

|---|---|---|---|---|---|

| Pine needles | 0.007 | 1.83 | 0.01281 | pbf | Chile |

| Carpobrotus chilensis (Doca) | 0.111 | - | - | ocr | Chile |

| Corn stover | 0.003 | 1.81 | 0.00468 | gro | Chile |

| Bovine manure | 0.002 | 0.46 | 0.00085 | ctl | Chile |

| Steel slag | 0.019 | 0.01 | 0.00022 | i_s | Chile |

| Gravel | 0.180 | 0.34 | 0.06048 | nmm | Chile |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas, M.A.; Cisternas, L.A.; Tapia, Y.; Carvalho, A. Socio-Environmental Assessment of a Tailings Water Softening Technology for Reuse in Alternative Systems in Central Chile: An Approach to Industrial Ecology. Sustainability 2025, 17, 9269. https://doi.org/10.3390/su17209269

Vargas MA, Cisternas LA, Tapia Y, Carvalho A. Socio-Environmental Assessment of a Tailings Water Softening Technology for Reuse in Alternative Systems in Central Chile: An Approach to Industrial Ecology. Sustainability. 2025; 17(20):9269. https://doi.org/10.3390/su17209269

Chicago/Turabian StyleVargas, Marco A., Luis A. Cisternas, Yasna Tapia, and Ana Carvalho. 2025. "Socio-Environmental Assessment of a Tailings Water Softening Technology for Reuse in Alternative Systems in Central Chile: An Approach to Industrial Ecology" Sustainability 17, no. 20: 9269. https://doi.org/10.3390/su17209269

APA StyleVargas, M. A., Cisternas, L. A., Tapia, Y., & Carvalho, A. (2025). Socio-Environmental Assessment of a Tailings Water Softening Technology for Reuse in Alternative Systems in Central Chile: An Approach to Industrial Ecology. Sustainability, 17(20), 9269. https://doi.org/10.3390/su17209269