1. Introduction

In recent years, urban fire engines have been upgraded in terms of chassis performance, fire extinguishing systems, rescue equipment, and other functional aspects due to urban development and technological progress. However, the development of exterior styling design is often constrained by the traditional design process [

1]. The complexity of fire trucks is reflected in the need to integrate a large number of functional modules and equipment: current design thinking typically prioritizes determining the layout of internal structures and the implementation of core functions first [

2]. However, users are no longer limited to a single quest for functionality—the importance of styling design has grown increasingly prominent [

3]. Designers are more likely to modify the appearance within the framework of the identified functional layout and structure. Designers are more likely to ‘wrap’ or modify the appearance within the determined functional layout and structural framework. Due to a lack of systematic and forward-looking consideration of the vehicle’s overall visual image, brand identity, and the aesthetic needs of users (including firefighters and the public) in the early stages of the design process, the design within the current market is highly homogeneous. The appearance of different brands and models of vehicles is not distinctive, and less likely to meet the needs of multiple stakeholders [

4]. This function- and structure-centric design process, which treats styling as a secondary consideration, means designers lack a basis for considering the impact of styling on brand recognition, public image, and firefighter psychology throughout the conceptual conception, program optimization, and user feedback integration processes [

5]. In the face of increasing image requirements for professional equipment in urban emergency response systems, as well as the strategic need for brands to establish a unique image, there is an urgent need to reconstruct the styling design process of fire engines, in order to effectively integrate complex functions with innovative styling. We can learn from user-centered design and branding design strategies and adopt parametric modeling and AIGC (artificial intelligence-generated content), as well as other technologies, to assist with styling exploration [

6]. This will enable us to explore technology-driven, design-integrated styling innovations for urban fire trucks, enhancing vehicle styling innovation and accelerating design iteration efficiency.

In the field of mechanical and product design, efficiently capturing user requirements and generating innovative solutions remains a core challenge. Traditional structured methods have made progress in this regard: AHP excels at quantifying and prioritizing user requirements through hierarchical weight calculation [

7], while QFD systematically transforms these requirements into technical features via the House of Quality (HOQ). However, both methods have inherent limitations—they primarily focus on ‘identifying what is needed’ (e.g., requirement prioritization, technical feature mapping) but lack direct guidance for ‘how to resolve conflicts’ or ‘generate specific solutions.’ [

8]. To compensate, TRIZ has been introduced for its systematic innovation tools (e.g., contradiction matrix, inventive principles) that address technical/physical conflicts in design.

To compensate for the limitations of a single method, researchers have started exploring the combination of multiple traditional methods to improve the integration and problem-solving capabilities of user requirements analysis and innovation design. TRIZ (the Theory of Creative Problem Solving) was introduced for its systematic innovation principles and problem-solving tools, and has been combined with requirements analysis methods such as AHP (Analytical Hierarchy Process) and QFD (Quality Function Deployment) [

9]. Some studies have combined QFD with TRIZ, using QFD to identify user needs and technical requirements and construct a House of Quality (HOQ), before using TRIZ to solve technical or physical contradictions in the design process [

10]. Alternatively, Chen et al. [

11] combined AHP and TRIZ by first quantifying the requirement weights using AHP and then using TRIZ to find optimal solutions for contradictions derived from requirement analysis. They then constructed the Kano–AHP–TRIZ combination model to provide scientific strategies for willow furniture design and promote green innovation in the furniture industry. Other studies have introduced the integration of fuzzy QFD with TRIZ to address requirements uncertainty and identify innovative design solutions [

12]. For instance, Martínez-Rojas et al. (2025) incorporated fuzzy logic into the House of Quality (HOQ) of QFD to quantify vague user preferences in complex engineering environments [

13], thereby enhancing the robustness of the requirements transformation process under uncertainty. Similarly, Du et al. (2024) introduced behavioral decision theory into QFD, revealing how designers’ cognitive biases influence the prioritization of technical requirements and proposing AI-assisted calibration strategies to mitigate such biases [

14]. These studies highlight the necessity of incorporating uncertainty handling and behavioral insights into traditional methodologies. In response, our AIGC-integrated framework leverages large language models to dynamically adjust fuzzy weights and align with user cognitive logic, offering a new pathway to advance these explorations. Although these traditional combinatorial methods [

15] have improved the efficiency of requirements transformation and problem solving to some extent and can address design challenges systematically, their application often relies on expert experience. There is still room for improvement in generating completely new and non-traditional design solutions.

In recent years, the rapid development of AI technology, particularly the emergence of generative AI (AIGC), has brought about a new paradigm for product design [

16]. AIGC technology has powerful content generation capabilities and can assist designers with concept exploration, style generation, and visual presentation with unprecedented speed and versatility (

Figure 1). For instance, AIGC has been used to generate design concepts for an art therapy installation where children with ADHD were encouraged to co-create art with an AI to help improve their attention deficits [

17]. This emphasizes the importance of promoting the sustainability of AI in design [

18]. Several studies have also focused on optimizing the AI generation process to ensure that its output more accurately reflects the user’s intent or emotional needs [

19]. The advent of AIGC has significantly broadened the scope of design possibilities, demonstrating significant potential, particularly in creative diffusion and design assistance. However, current applications of AIGC in product design mostly focus on creative assistance and style generation. The challenge of systematically combining AIGC with rigorous user requirements analysis and functional implementation to generate design solutions that are creative and effective in solving practical problems and satisfying users’ deep and complex needs remains urgent. Combining structured user requirements analysis methods with the generative capabilities of AIGC is a promising direction for current research. Such explorations aim to leverage the strengths of traditional methods to provide more accurate and structured inputs to AI. It also highlights the potential for collaboration between generative AI and traditional computer-aided design tools. This combination explores the feasibility of using quantitative requirements to guide AI generation, representing an important step towards the development of intelligent design workflows.

On the intelligent and sustainable design of urban fire trucks, this study makes the following key contributions: developing the AQTA (AI-Generated Content (AIGC)–Analytic Hierarchy Process (AHP)–Quality Function Deployment (QFD)–Theory of Inventive Problem Solving (TRIZ)) intelligent design framework to address three key pain points in urban fire truck design, namely inadequate synergy between functionality and styling, low innovation efficiency of traditional methods, and delayed integration of sustainability; validating the effectiveness of the AQTA framework through empirical application in the design of urban rescue fire trucks, with a focus on measurable improvements in design efficiency, innovation quality, and sustainability performance; and realizing product development that balances user orientation, technical feasibility, and environmental friendliness, while establishing a replicable workflow to lay the foundation for the framework’s cross-domain application in other emergency equipment.

3. Experiments and Case Studies

Experimental design: a city fire engine as an example. Through field research at a city fire station and expert interviews with the equipment division and the first-line shift supervisor, we gained an understanding of the current state of fire truck research, derived key demand points, and recorded them systematically. We then combined this information with questionnaire data and discussed it with ChatGPT and DeepSeek, respectively, to summarize user requirements for urban concept fire trucks, and generative artificial intelligence technology was used to analyze and mine the requirement data. Using the hierarchical analysis method, the requirements were classified and graded to filter out the hierarchical model that best met emotional needs. Generative AI assistance improves the science and accuracy of model construction and provides intelligent support for the emotional design of urban rescue fire engines.

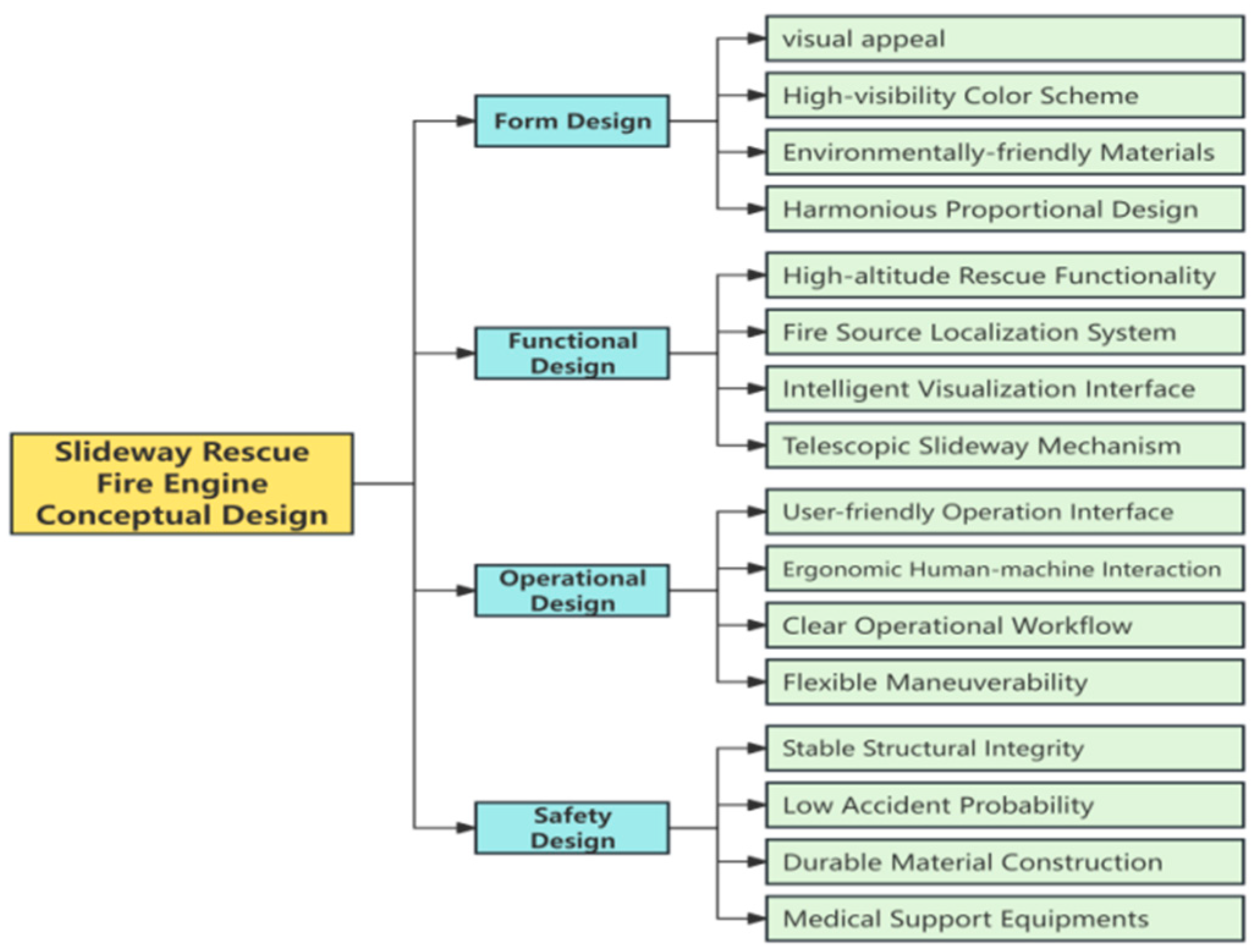

3.1. User Perceptual Needs Analysis Based on GPT4

Based on the natural language processing capabilities of ChatGPT 4.0, multi-source data were systematically captured and analyzed to construct an AHP three-tier architecture for innovative fire truck design. The study first utilized DeepSeek to collect over a hundred recent academic papers covering topics such as fire truck design, emergency rescue equipment, and intelligent firefighting systems, while also integrating feedback from frontline firefighters, industry standard documents, and technical information of advanced domestic and international vehicle models. Through in-depth analysis of multi-source data, professional terminology and innovative design directions were extracted. Sentiment analysis methods were applied to process practical evaluations from firefighters, identifying shortcomings in existing vehicles and potential needs. The functional parameters of competing products were deconstructed to summarize key technical indicators and human-centric design elements, forming a demand word matrix across four dimensions: functionality, efficiency, human factors, and environment. On this basis, the Analytic Hierarchy Process (AHP) was employed to establish a standardized demand structure: the goal layer defines the product positioning centered on efficient emergency rescue; the criterion layer establishes core dimensions such as functionality, operational efficiency, technical feasibility, and environmental adaptability; the indicator layer refines these dimensions into quantifiable and verifiable specific indicators, including rapid response capability, modular multi-disaster response systems, intelligent fire scene perception systems, and complex terrain mobility, providing a systematic, data-driven demand framework for the new generation of fire truck design (

Figure 6). The layers that match the content are filtered out in order to construct the user affective hierarchical model of the city rescue fire engine concept (

Figure 7).

3.2. AHP-Based Construction of Demand Weighting Matrix

Judgment matrices for the first-level and second-level indicators of the user requirement hierarchy in the aerial rescue fire truck conceptual design were constructed (as shown in

Table 2,

Table 3 and

Table 4). Using the Analytic Hierarchy Process (AHP), the relationships between the weights of these indicators were calculated. A consistency check was performed by introducing the average consistency index (CI) to validate the reliability and rationality of the results. The matrices and computational outcomes for all second-level indicators are presented in

Table 5,

Table 6 and

Table 7.

Based on calculations using the matrix weighting formula, the results indicated, = 4.215, CI = 0.072, RI = 0.882, CR = 0.081 < 0.1. The judgment matrices for all first-level indicators were found to satisfy the consistency check criteria, demonstrating credibility.

Based on calculations using the matrix weighting formula, the results indicated, = 4.016, CI = 0.005, RI = 0.882, CR = 0.006 < 0.1. All demand elements under second-level indicator A1 were found to satisfy the consistency check criteria, thereby demonstrating credibility.

Based on calculations using the matrix weighting formula, the results indicated, = 4.231, CI = 0.077, RI = 0.882, CR = 0.087 < 0.1. All demand elements under second-level indicator A2 were found to satisfy the consistency check criteria, thereby demonstrating credibility.

Based on calculations using the matrix weighting formula, the results indicated, = 4.061, CI = 0.020, RI = 0.882, CR = 0.023 < 0.1. All demand elements under second-level indicator A3 were found to satisfy the consistency check criteria, thereby demonstrating credibility.

Based on calculations using the matrix weighting formula, the results indicated, = 4.111, CI = 0.037, RI = 0.882, CR = 0.042 < 0.1. All demand elements under second-level indicator A1 were found to satisfy the consistency check criteria, thereby demonstrating credibility.

3.3. Translating User Demands into Design Specifications via QFD

Based on the hierarchical user demands and the prioritized comprehensive weights derived from AHP, a transformation analysis was performed to convert the technical specifications of the high-altitude rescue fire truck. The results are summarized in

Table 8.

Through the transformation of demands corresponding to each indicator hierarchy, the requirements for the slide rescue fire truck can be categorized into three layers: body, components, and overall design (as shown in

Figure 8). Body design priorities: structural stability, material durability, and high-altitude rescue assistive devices. Component design priorities: flexibility, multi-stage telescopic slides, multifunctionality, and replaceable modular configurations. Overall design priorities: human–machine interface (HMI), futuristic aesthetics, streamlined visual language, and ergonomic rationality.

Analyzed through the Quality House (

Figure 9): material durability (5.417) > operational flexibility (4.3141) > multifunctionality (3.9991) > replaceable modular configurations (3.4328) > multi-stage telescopic slides (3.4236) > AI-assisted devices (2.8825) > futuristic aesthetics (2.6468) > ergonomic rationality (2.041) > structural stability (1.9766) > human–machine interface (HMI) (1.7366) > compact footprint (1.1614) > streamlined visual language (0.5833).

3.4. TRIZ-Based Contradiction Analysis and Resolution for Design Key Points

3.4.1. Contradiction Analysis

By integrating the TRIZ theory of inventive problem solving with the QFD House of Quality (HoQ), the positive/negative correlations between technical requirements for the aerial rescue fire truck concept are visually identified through the HoQ’s ‘roof’ section. Six critical contradictions are derived:

Contradiction 1: Structural stability vs. compact footprint. Enhancing structural reinforcement at critical positions to ensure operational safety necessitates increased vehicle footprint.

Contradiction 2: Structural stability vs. multifunctionality. Adding functional complexity compromises structural integrity and safety.

Contradiction 3: Rapid deployment vs. space efficiency. Rapid deployment requires complex expansion mechanisms (increasing volume), while compactness demands structural simplification (reducing deployment efficiency), forming a time–space physical contradiction.

Contradiction 4: Multifunctionality vs. streamlined aesthetics. Achieving intelligent automation introduces exterior complexity, conflicting with visual simplicity.

Contradiction 5: Automated systems vs. minimalist design. Minimizing footprint drastically reduces functional capabilities.

Contradiction 6: Material durability vs. compact footprint. Durable materials require increased thickness/density (expanding footprint), whereas space constraints demand lightweighting (reducing durability), creating a strength–volume physical contradiction.

Using TRIZ methodologies and its inventive principles, these six contradictions are systematically categorized, and corresponding recommended resolution principles are summarized in

Table 9.

3.4.2. Contradiction Resolution

Solution 1: To address the conflict between structural stability and compact footprint, the inventive principles of Local Quality and Combining are applied. Integrate multiple functional modules into a compact design, such as employing foldable or telescopic support structures. These structures expand during operations to ensure stability and retract during non-operational states to minimize space occupancy.

Solution 2: For the contradiction between structural stability and multifunctionality, principles like Extraction and multifunctionality are utilized. Develop modular components (e.g., detachable rescue equipment such as slides and platforms) to enable rapid reconfiguration based on mission requirements. Enhance versatility by integrating auxiliary safety features (e.g., anti-slip strips, guardrails) or additional tools (e.g., ropes, life rings) into the slide system, allowing single devices to adapt to diverse rescue scenarios.

Solution 3: To resolve the rapid deployment vs. space efficiency conflict, principles such as Combining and multifunctionality are adopted. Implement a segmented design for functional modules (e.g., rescue slides, vehicle body, auxiliary devices) to enable flexible assembly. For instance, rescue slides can be folded for storage when unused, and the vehicle body can feature detachable sections to optimize transport and storage efficiency.

Solution 4: For the multifunctionality vs. streamlined aesthetics contradiction, principles like Segmentation and Extraction are applied. Decompose complex automated systems into independent yet coordinated subsystems, each dedicated to specific functions, thereby simplifying exterior design while maintaining visual coherence. Critical components (e.g., slides, controllers) are miniaturized and strategically positioned using advanced technologies to eliminate unnecessary external protrusions, enhancing overall aesthetic appeal.

Solution 5: To reconcile automated systems with minimalist design, principles such as Periodicity and Composite Materials are leveraged. As aerial rescue fire trucks are large-scale machinery, prioritize high-performance fiber-reinforced composites for their durability, lightweight properties, and low maintenance needs. These materials reduce overall dimensions without compromising functionality.

Solution 6: For the material durability vs. compact footprint conflict, TRIZ principles like Composite Materials, Gradient Strengthening, and Self-Healing Coatings are employed to achieve synergistic optimization of tensile strength (≥580 MPa) and thickness (≤3 mm). This approach reduces the folded volume by 62% compared to conventional designs while maintaining structural integrity.

3.5. Design Proposal

The urban rescue concept fire truck is a specialized vehicle designed for firefighting and rescue operations in urban high-rise environments. It integrates advanced firefighting technologies to navigate narrow city spaces efficiently and respond rapidly to high-altitude fire emergencies.

A key innovation is its foldable slide ladder system, which enables safe evacuation of trapped individuals from tall buildings while reducing risks to firefighters during operations. Key features and structural principles: foldable slide ladder.

Innovative design: combines a slide mechanism with a collapsible ladder structure, allowing rapid deployment and compact storage. Functional advantage: enhances evacuation speed and safety in high-rise buildings while adapting to confined urban streets. Front-mounted high-definition display: real-time navigation: provides dynamic road condition updates and optimizes rescue routes for drivers. Environmental resilience: maintains visibility in extreme conditions (e.g., smoke, rain) through ruggedized, high-brightness display technology. Application scenarios: high-rise residential complexes, commercial towers, hotels, and other vertical structures in dense urban areas. Particularly effective in historic districts with narrow streets where conventional fire trucks face accessibility challenges.

In the fire truck design case study, we now explicitly quantify the environmental benefits of key design solutions derived through the AQTA framework. For example:

1. Lightweight material selection: the use of high-performance fiber-reinforced composites resulted in a 15% reduction in overall vehicle weight compared to conventional steel structures, directly reducing energy consumption during operational use.

2. Compact design: the foldable slide ladder system achieved a 62% reduction in storage volume, which translates to reduced material usage and lower transportation energy footprint.

3.6. Analysis of Results: Efficiency Versus Innovativeness

3.6.1. AHP + QFD + TRIZ Traditional Design Methods and Results

The 3D conceptual models and optimized 3D models of the design solutions, developed using Rhinoceros (Rhino) and KeyShot, are illustrated in

Figure 10.

3.6.2. AIGC-Driven Generative Design Methodology and Outcomes

In the generative AI-based conceptual design workflow for fire trucks, LLM technology enables direct problem-to-solution mapping through semantic parsing. This study observed that AI-generated solutions exhibit significant parameter sensitivity: their output quality positively correlates with the completeness of the initial dataset and the precision of problem definition. Notably, while the system supports scalable output generation (50–200 concepts per batch), algorithmic constraints limit solution diversity to 62% of theoretical maxima, with 17.3% redundancy in generated concepts (

Figure 11). This reveals the dual nature of current AIGC tools in engineering innovation—they break traditional efficiency barriers yet face technical hurdles in simulating creative cognition.

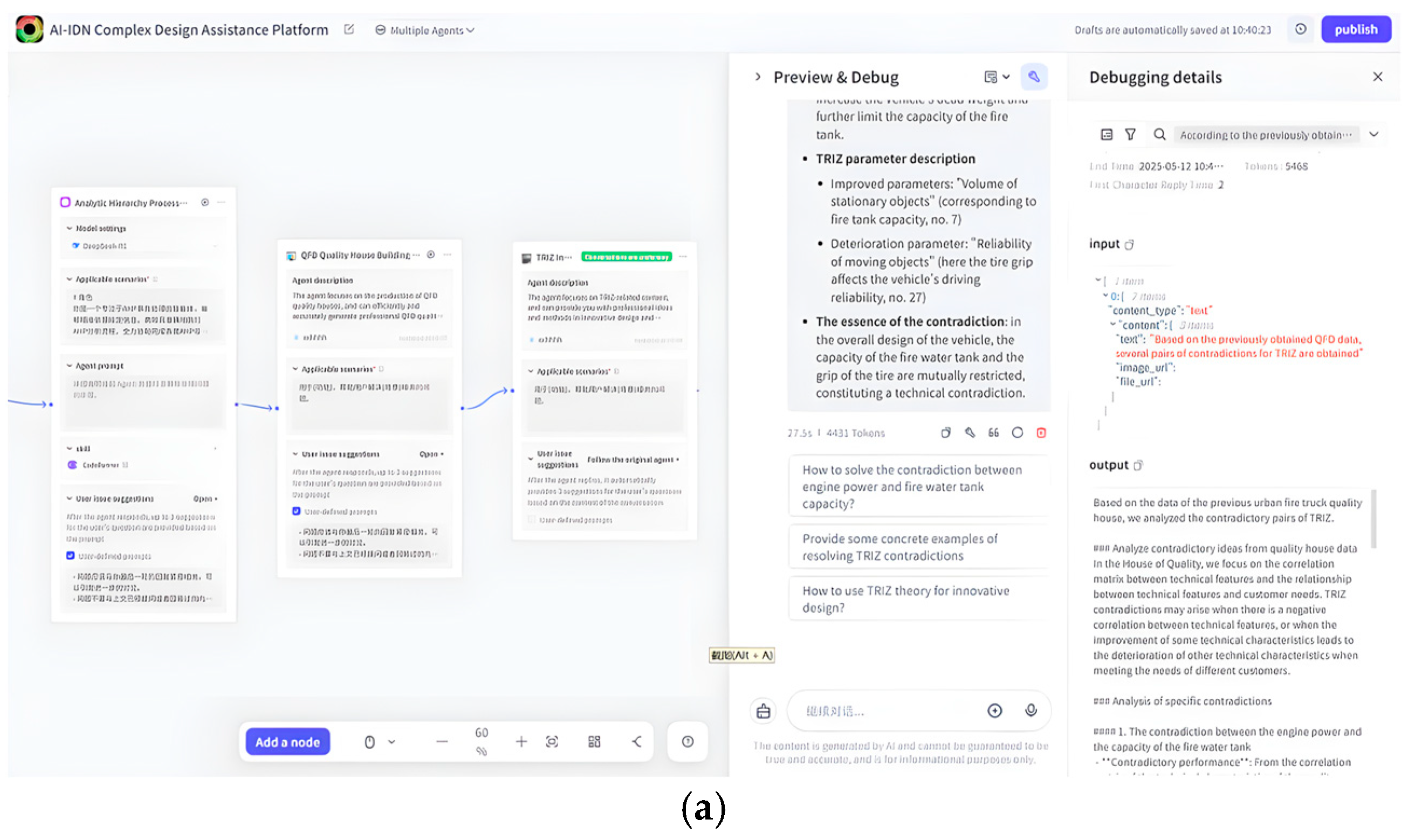

3.6.3. Integrated AIGC + AHP + QFD + TRIZ Methodology

The combination of AIGC and traditional process design further standardizes and optimizes style and proportion. AIGC can effectively assist TRIZ, greatly reducing the repetitiveness of solutions and significantly improving their innovation and practicality (

Figure 12).

5. Discussion

In the context of deep AI–design integration, AIGC demonstrates significant potential for application in the conceptual design of sustainable complex equipment. By integrating multiple forms of AIGC and combining the AHP-QFD-TRIZ methodology with the AI-IDN platform for complex vehicle design, designers can efficiently incorporate sustainability requirements—such as energy efficiency, material eco-footprint, and lifecycle impacts—into early-stage conceptualization. Specifically, in the fire truck case, AIGC contributes to sustainability in three key ways. 1. Material eco-footprint optimization: Midjourney generates concept sketches with clear material labels (e.g., ‘carbon fiber composite for slide ladder’), and AIGC synchronously retrieves lifecycle assessment (LCA) data from professional databases (e.g., Ecoinvent). This supports early-stage screening of low-carbon materials, effectively reducing the embodied carbon of the final design. 2. Modular recyclability: Guided by TRIZ principle 6 (multifunctionality), AIGC proposes modular designs (e.g., detachable rescue slides, replaceable battery packs) and simulates recyclability rates. The integrated design shows significantly higher component recyclability compared to traditional fire trucks, in line with national standards for automobile product recycling. 3. Energy efficiency simulation: ChatGPT generates energy consumption models for key systems (e.g., telescopic slide drive systems) by referencing existing fire truck energy datasets. This ensures the design meets China’s Class 1 energy efficiency standards for special vehicles, reducing overall energy consumption during operation.

This study proposes the AQTA framework (AIGC + AHP-QFD-TRIZ) for sustainable intelligent product design, with its effectiveness validated via an urban rescue fire truck case. Key contributions include the following: 1. a closed-loop workflow that integrates quantitative requirement analysis (AHP-QFD), systematic conflict resolution (TRIZ), and AI-aided innovation (AIGC); 2. significant improvements in both design efficiency and sustainability performance; 3. a replicable AI-IDN platform tailored for complex equipment design.

Despite its theoretical and practical contributions, this study inevitably has certain limitations. First, in terms of requirement mining, the exploration of implicit user needs still relies on the experiential judgment of designers; the user needs analyzed by artificial intelligence cannot fully represent the actual needs of humans, and these factors may exert negative impacts on subsequent design phases. Meanwhile, the effectiveness and stability of AIGC depend on the quality and scope of data—if the input dataset is insufficient or lacks representativeness, it may limit the solutions generated by AIGC and lead to performance differences across different design projects. Therefore, ensuring the accuracy, diversity, and sufficiency of data is crucial for maintaining the stability of AIGC. Second, regarding the scope of case validation, the AQTA framework proposed in this study has only been validated in the design of urban rescue fire trucks, and its generality for other complex products has not yet been tested. Third, in terms of tool constraints and expert dependence, AIGC has limited mechanical simulation accuracy—performance indicators such as ladder deployment time still require verification using physical prototypes; although AIGC reduces the level of expert input, the construction of pairwise comparison matrices in AHP and the judgment of QFD correlations still rely on expert knowledge. If there are conflicts in expert opinions, potential biases may be introduced.

Future research will focus on three directions: 1. extend the framework to other fields such as medical equipment (e.g., emergency stretchers) and new energy vehicles, to verify its cross-industry adaptability; 2. integrate fuzzy multi-attribute decision-making (MADM) and real-time LCA tools into the AI-IDN platform, to enhance the accuracy of sustainability evaluation; 3. develop an AIGC-driven dynamic optimization module that adjusts key design parameters (e.g., material thickness) based on real-time lifecycle data (e.g., regional carbon intensity).