An Optimal Active Power Allocation Method for Wind Farms Considering Unit Fatigue Load

Abstract

1. Introduction

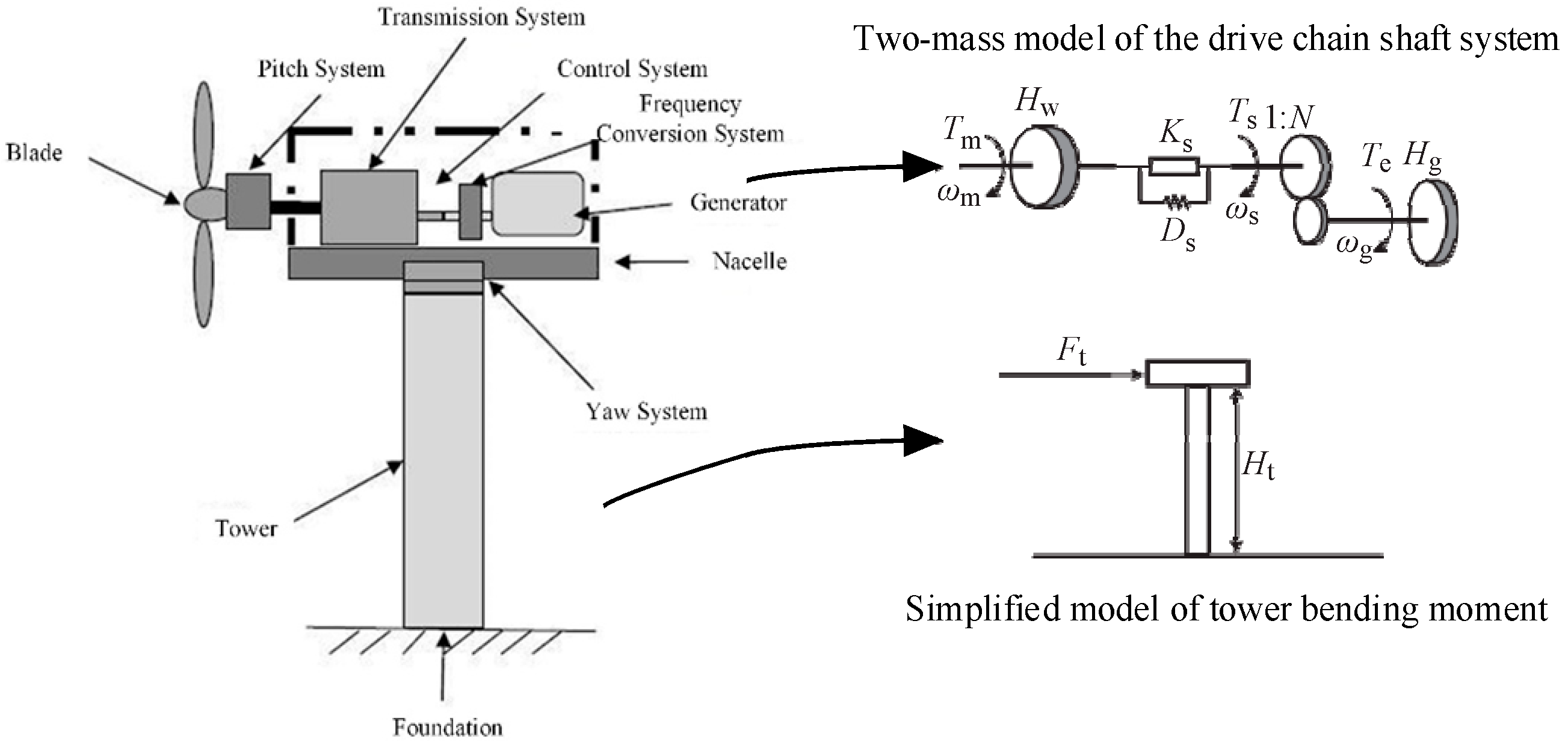

2. Mathematical Model of Fatigue Load in Wind Farms

2.1. Aerodynamic Model

2.2. Drivetrain Model

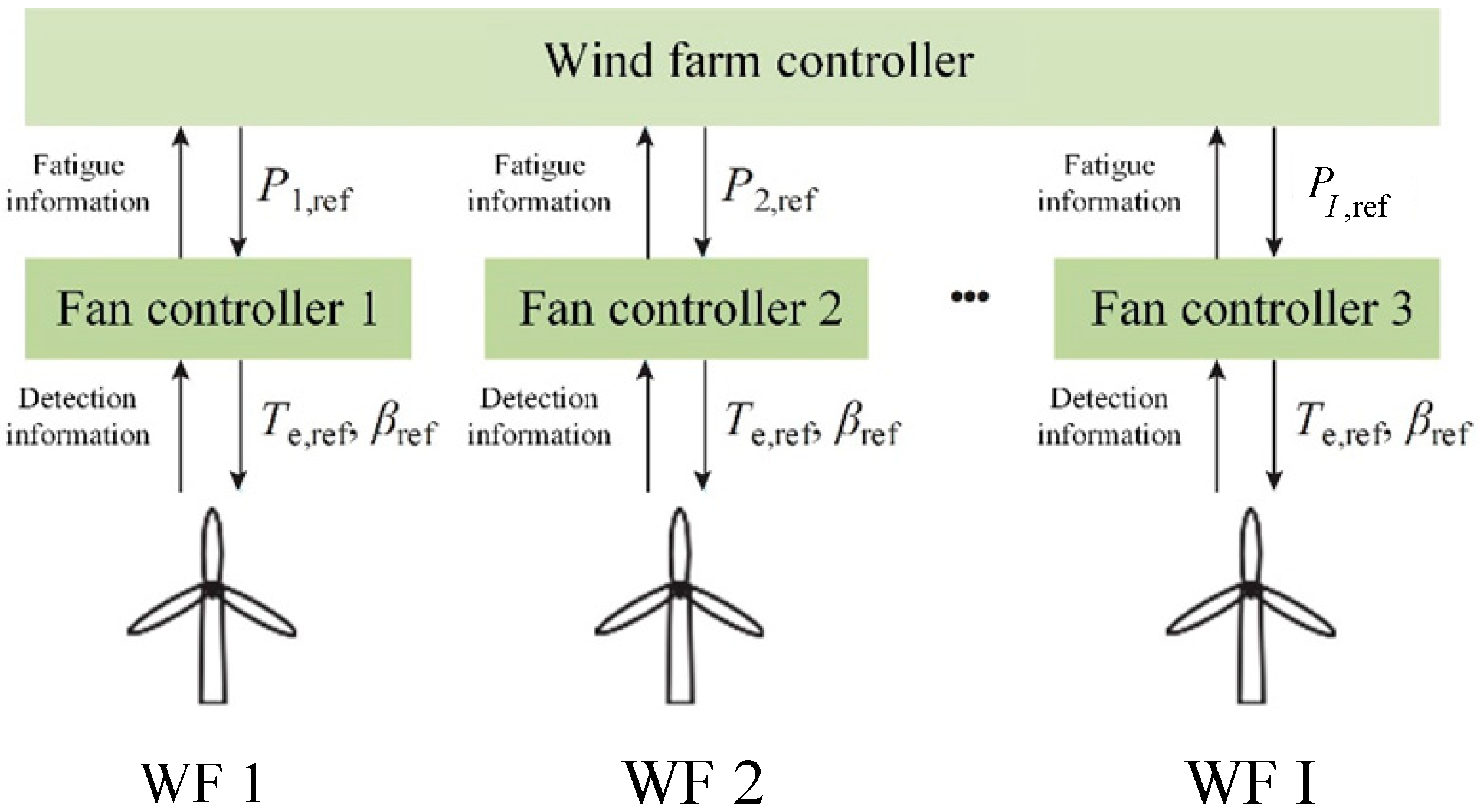

3. Optimal Active Power Scheduling Strategy and Solution for Wind Farms

3.1. Objective Function

3.2. Constraints

3.3. Firefly Algorithm

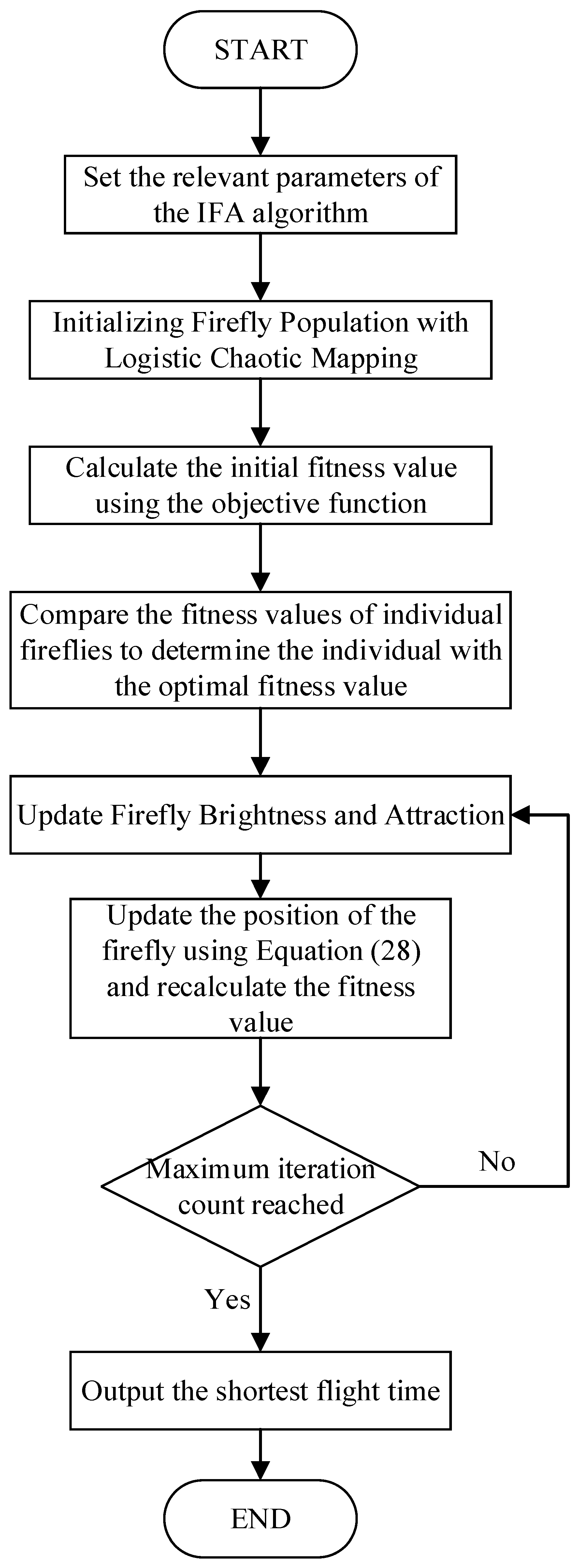

3.3.1. Standard Firefly Algorithm

3.3.2. Improved Firefly Algorithm

- Population Initialization

- 2.

- Adaptive Weight Optimization Based on the Fitness Function

- 3.

- Chaos Optimization

| Algorithm 1: Improved Firefly Algorithm |

| Define the firefly brightness based on the adaptive fitness function and generate the initial firefly population (p = 1, 2, …) Calculate the fitness value of all individuals and select the current best solution. |

| Repeat |

| for p = 1: for q = 1: if () Update the firefly’s position based on Equation (28). end if end for q end for p Sort the fireflies by their brightness and find the best firefly position. |

| Until , output of the optimal result. |

3.4. Execution Process of the Optimized Scheduling Strategy

- The dispatch center issues the total active power adjustment command required for frequency regulation by the wind farm, and the initial active power for each turbine is obtained through a simulation model.

- The initial firefly population is generated using the improved Firefly Algorithm, representing the initial power adjustments for each wind turbine. Data collected from the wind turbine controllers, including pitch angle, rotational speed, wind speed, and current active power, are used to calculate the fatigue load sensitivity for each turbine using Equation (20).

- Based on the fatigue load information for each turbine, the fitness value for all individuals is calculated, and the individual corresponding to the current best solution is selected. The algorithm then checks whether the convergence condition is met. If the algorithm has converged, the optimal power adjustment values for each turbine are output; otherwise, the iteration continues for further optimization.

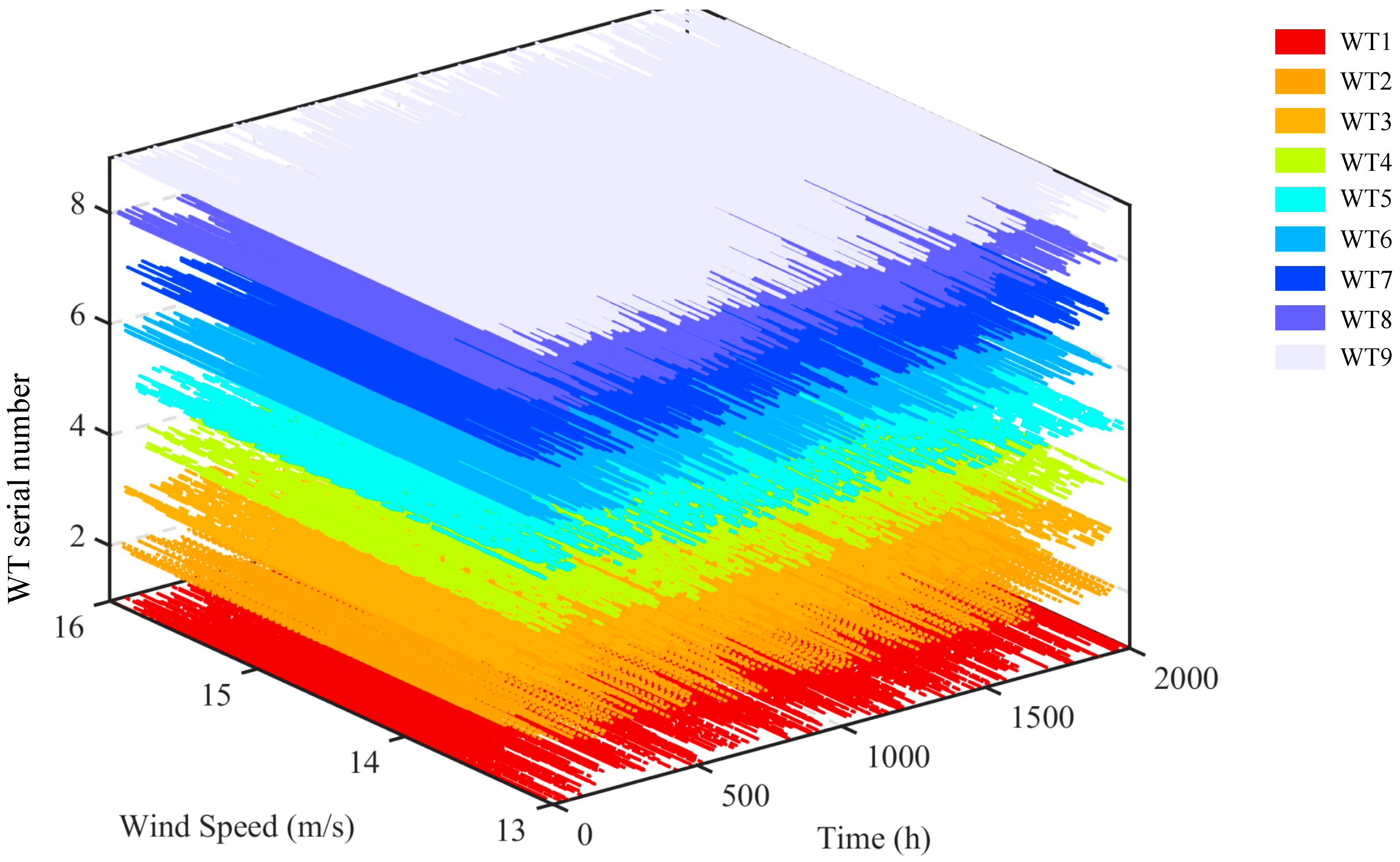

4. Case Study

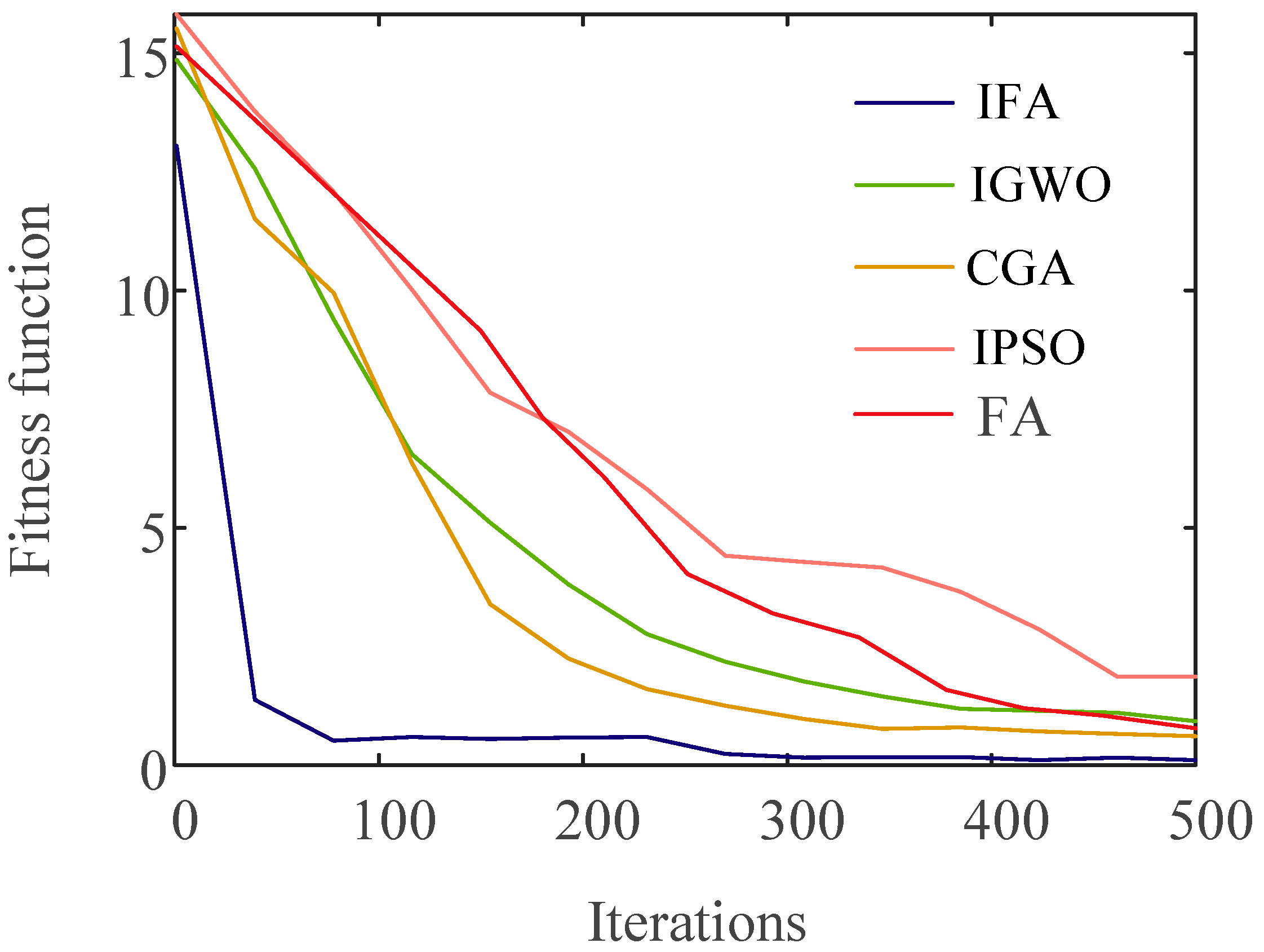

4.1. Iterative Process Analysis

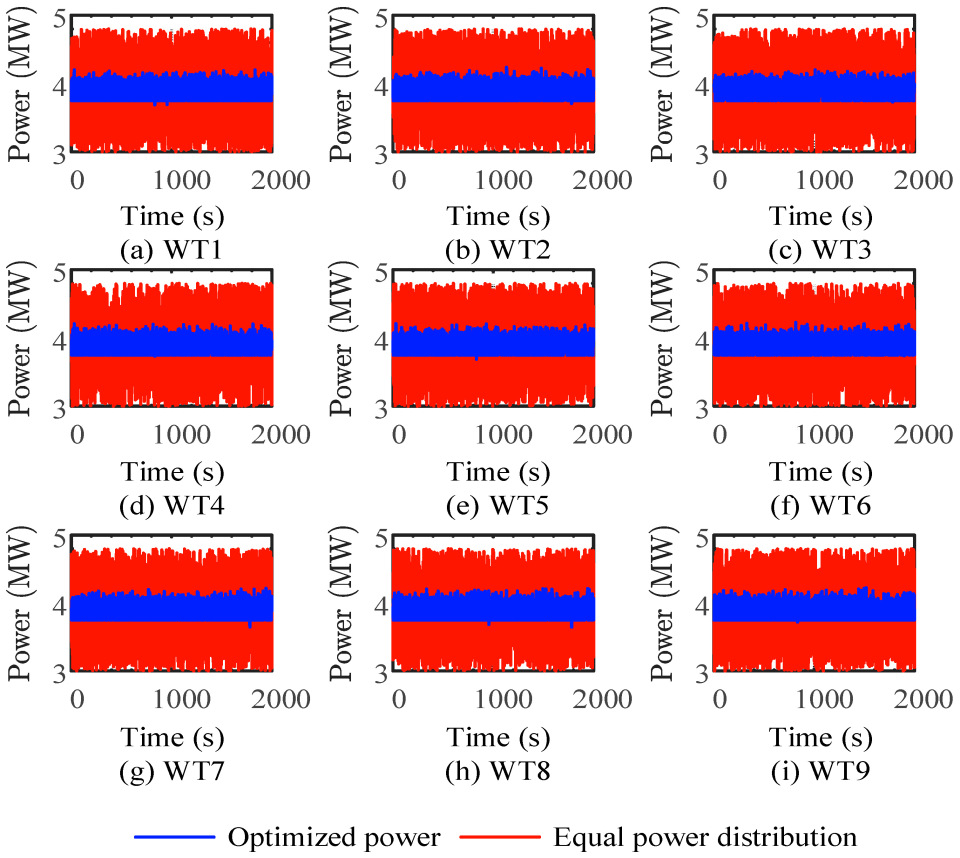

4.2. Comparative Analysis of Wind Farm Optimization Results

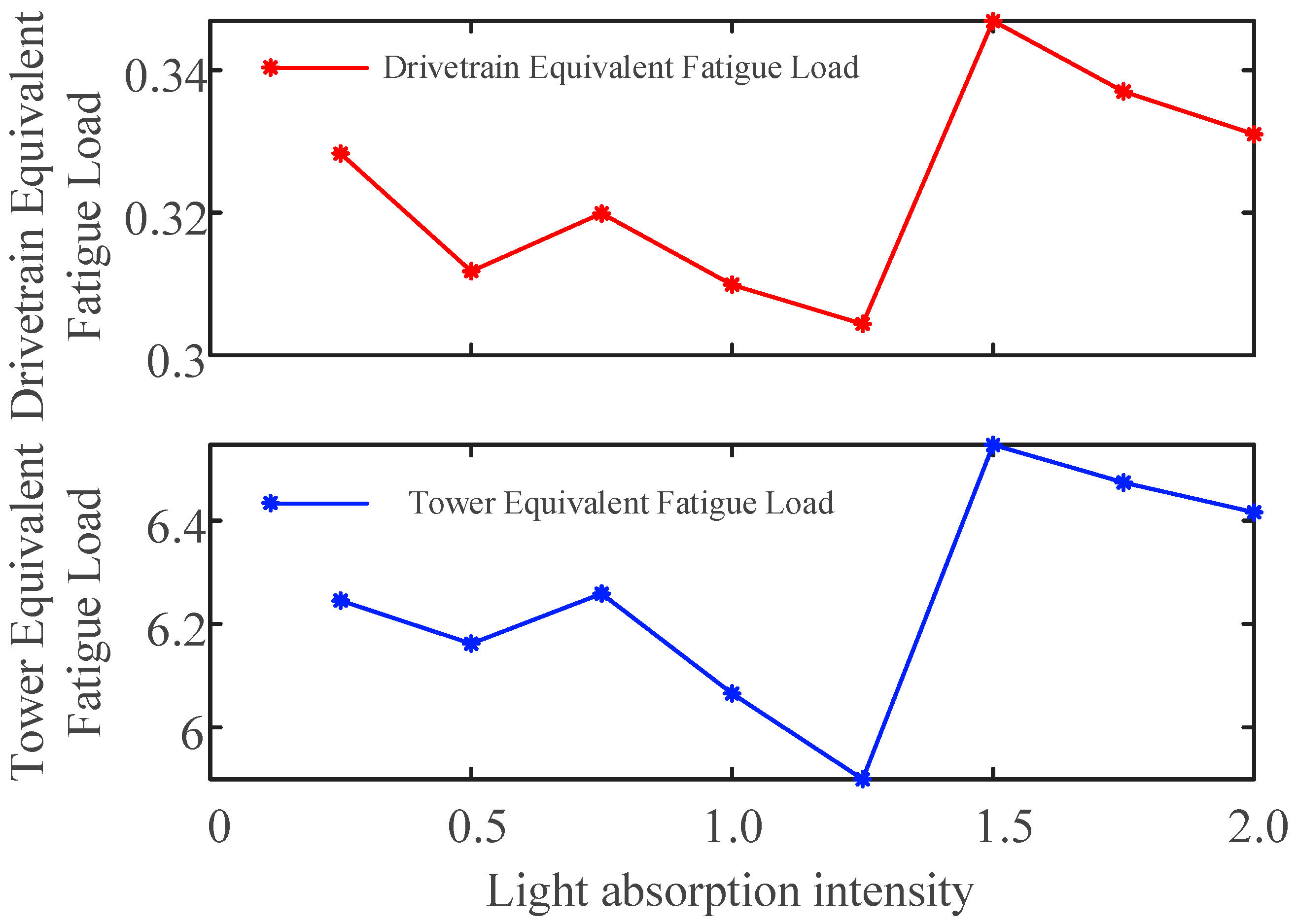

4.3. Sensitivity Analysis

5. Discussion

6. Conclusions

- The torque variation in the turbine drivetrain system and the bending moment fluctuation in the fore-and-aft directions of the tower are the primary factors contributing to the fatigue load of wind turbines. By constructing a fatigue load expression, the quantitative relationship between the fatigue load and the fluctuation of the turbine’s active power output can be clearly established. This expression not only reveals the intrinsic mechanism of fatigue load formation but also provides a theoretical foundation and basis for optimizing the fatigue load suppression during active power control in wind turbines.

- By introducing Logistic mapping and an adaptive weight strategy, the proposed IFA shows significant advantages in convergence performance. Compared to the traditional FA algorithm, IFA achieves optimal values in fewer iterations, demonstrating higher optimization efficiency. Moreover, comparison experiments between IFA, IGWO, CGA, and IPSO show that the proposed IFA outperforms the other algorithms in global convergence and optimization ability, facilitating the development of higher-quality power distribution strategies.

- To enhance the coordination of wind farm operations and the lifespan of turbines, the proposed optimization scheduling strategy fully considers the balance of fatigue levels among turbines in the wind farm. This strategy not only effectively reduces the fatigue differences between turbines but also significantly suppresses fluctuations in the main shaft torque and tower bending moments, thus reducing the fatigue loads on the turbines during operation. After comparing the proposed strategy with the current mainstream proportional distribution algorithm, it is found that our strategy exhibits significant advantages in multiple key metrics: the standard deviation of active power decreases by up to 76.88%, drivetrain fatigue load decreases by up to 43.1%, and tower fatigue load decreases by up to 45.4%. These results fully validate the effectiveness and practical value of the proposed method in optimizing wind farm operational performance and extending turbine lifespan.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lyu, X.; Liu, T. Intelligent learning based active power regulation of wind turbines considering fatigue reduction. IEEE Trans. Ind. Inform. 2022, 18, 405–414. [Google Scholar] [CrossRef]

- Li, B.; Zheng, D.; Li, B.; Ji, L.; Hong, Q.; Meng, Q. Research on low voltage ride-through strategies for doubly-fed wind farms during asymmetric faults. Int. J. Electr. Power Energy Syst. 2024, 160, 110138. [Google Scholar]

- Yao, Q.; Ma, B.; Zhao, T.; Hu, Y.; Fang, F. Optimized active power dispatching of wind farms considering data-driven fatigue load suppression. IEEE Trans. Sustain. Energy 2023, 14, 371–380. [Google Scholar] [CrossRef]

- Yao, Q.; Hu, Y.; Zhao, T.; Guan, Y.; Luo, Z.; Liu, J. Fatigue load suppression during active power control process in wind farm using dynamic-local-reference DMPC. Renew. Energy 2022, 183, 423–434. [Google Scholar] [CrossRef]

- Cai, W.; Hu, Y.; Fang, F.; Yao, L.; Liu, J. Wind farm power production and fatigue load optimization based on dynamic partitioning and wake redirection of wind turbines. Appl. Energy 2023, 339, 121000. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.W.; Wang, X.D.; Miao, Y. Optimal active power dispatch for wind farm based on the improved fatigue load sensitivity. J. Renew. Sustain. Energy 2019, 11, 033306. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Q.; Guo, Q.; Sun, H.; Xue, Y. Distributed model predictive control of a wind farm for optimal active power control Part II: Implementation with clustering-based piece-wise affine wind turbine model. IEEE Trans. Sustain. Energy 2015, 6, 840–849. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, W. Coordinated control method for DFIG-based wind farm to provide primary frequency regulation service. IEEE Trans. Power Syst. 2018, 33, 2644–2659. [Google Scholar] [CrossRef]

- Wang, Y.; Peng, Y.; Sun, J. A review of automatic generation control technology and strategies for wind farms. Power Syst. Technol. 2025, 1–22. Available online: https://www.cnki.com.cn/Article/CJFDTotal-DWJS20250717001.htm (accessed on 2 October 2025).

- Gao, Y.; Tahir, M.; Siano, P.; Bi, Y.; Hu, S.; Yang, J. Optimization of renewable energy-based integrated energy systems: A three-stage stochastic robust model. Appl. Energy 2025, 377, 124635. [Google Scholar] [CrossRef]

- Meng, Q.; Jin, X.; Luo, F.; Wang, Z.; Hussain, S. Distributionally robust scheduling for benefit allocation in regional integrated energy system with multiple stakeholders. J. Mod. Power Syst. Clean Energy 2024, 12, 1631–1642. [Google Scholar] [CrossRef]

- Xu, J.; Yi, X.; Sun, Y.; Lan, T.; Sun, H. Stochastic optimal scheduling based on scenario analysis for wind farms. IEEE Trans. Sustain. Energy 2017, 8, 1548–1559. [Google Scholar] [CrossRef]

- Zhang, B.; Soltani, M.; Hu, W.; Hou, P.; Chen, Z. A wind farm active power dispatch strategy for fatigue load reduction. In Proceedings of the American Control Conference, Boston, MA, USA, 6–8 July 2016; pp. 5879–5884. [Google Scholar]

- Marsh, G.; Wignall, C.; Thies, P.R.; Barltrop, N.; Incecik, A.; Venugopal, V.; Johanning, L. Review and application of Rainflow residue processing techniques for accurate fatigue damage estimation. Int. J. Fatigue 2016, 82, 757–765. [Google Scholar] [CrossRef]

- Tao, T.; Yang, Y.; Yang, T.; Liu, S.; Guo, X.; Wang, H.; Liu, Z.; Chen, W.; Liang, C.; Long, K.; et al. Time-domain fatigue damage assessment for wind turbine tower bolts under yaw optimization control at offshore wind farm. Ocean. Eng. 2024, 303, 117706. [Google Scholar] [CrossRef]

- Yao, Q.; Liu, J.; Hu, Y. Optimized active power dispatching strategy considering fatigue load of wind turbines during de-loading operation. IEEE Access 2019, 7, 17439–17449. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, Y.; Hu, S.; Tahir, M.; Yuan, W.; Yang, J. A three-stage adjustable robust optimization framework for energy base leveraging transfer learning. Energy 2025, 319, 135037. [Google Scholar] [CrossRef]

- Zhang, B.; Soltani, M.; Hu, W.; Hou, P.; Huang, Q.; Chen, Z. Optimized power dispatch in wind farms for power maximizing considering fatigue loads. IEEE Trans. Sustain. Energy 2018, 9, 862–871. [Google Scholar] [CrossRef]

- Zhang, Z.; Kudashev, S.F. Distributed robust cooperative optimization of multi-integrated energy systems based on variational inequality-driven non-cooperative game theory. Appl. Energy 2025, 401, 126696. [Google Scholar] [CrossRef]

- Xie, M.; Wang, Y.; Zhang, K. Development and optimization of a realistic biodiesel-methanol mechanism based on genetic algorithm. Renew. Energy 2025, 250, 123301. [Google Scholar] [CrossRef]

- Meng, Q.; He, Y.; Gao, Y.; Hussain, S.; Lu, J.; Guerrero, J.M. Bi-level four-stage optimization scheduling for Active Distribution Networks with Electric Vehicle integration using multi-mode dynamic pricing. Energy 2025, 327, 136316. [Google Scholar] [CrossRef]

- Yu, Y.-F.; Wang, Z.; Chen, X.; Feng, Q. Particle swarm optimization algorithm based on teaming behavior. Knowl.-Based Syst. 2025, 318, 113555. [Google Scholar] [CrossRef]

- Jin, Z.; Li, X.; Qiu, Z.; Li, F.; Kong, E.; Li, B. A data-driven framework for lithium-ion battery RUL using LSTM and XGBoost with feature selection via Binary Firefly Algorithm. Energy 2025, 314, 134229. [Google Scholar] [CrossRef]

- Wang, L.; Peng, L.; Xiong, X.; Li, Y.; Qi, Y.; Hu, X. Research on high-speed constant tension spinning control strategy based on vibration detection and enhanced firefly algorithm-based FOPID controller. Measurement 2025, 254, 117789. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, Y.; Zhang, D. Optimal ancillary control for frequency regulation of wind turbine generator based on improved fatigue load sensitivity. Int. J. Electr. Power Energy Syst. 2022, 137, 107751. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, J.; Chen, F.; Sun, M. An improved particle swarm optimization for wind resistance performance design of high-rise buildings. Adv. Wind. Eng. 2025, 2, 100053. [Google Scholar] [CrossRef]

- Pourrajabian, A.; Dehghan, M.; Rahgozar, S. Genetic algorithms for the design and optimization of horizontal axis wind turbine (HAWT) blades: A continuous approach or a binary one? Sustain. Energy Technol. Assess. 2021, 44, 101022. [Google Scholar] [CrossRef]

- Luo, K. Enhanced grey wolf optimizer with a model for dynamically estimating the location of the prey. Appl. Soft Comput. 2019, 77, 225–235. [Google Scholar] [CrossRef]

- Shan, J.; Pan, J.-S.; Chang, C.-K.; Chu, S.-C.; Zheng, S.-G. A distributed parallel firefly algorithm with communication strategies and its application for the control of variable pitch wind turbine. ISA Trans. 2021, 115, 79–94. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Cut-in wind speed/Rated wind speed/Cut-out wind speed | 3/11.4/25 (m/s) | Tower height | 90 (m) |

| Rotor diameter | 126 (m) | Rotor inertia | (kg/m2) |

| Rated power | 5 (MW) | Generator inertia | (kg/m2) |

| Start-up speed/Rated speed | 6.9/12.1 (rpm) | Filter time constant | 10 |

| Numbers of Simulation | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Average | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time/s | IGWO | 289.6 | 291.2 | 292.8 | 289.6 | 294.4 | 291.2 | 292.8 | 289.6 | 291.2 | 292.8 | 291.52 |

| CGA | 262.6 | 266.5 | 265.2 | 263.9 | 269.1 | 267.8 | 266.5 | 265.2 | 263.9 | 266.5 | 265.72 | |

| IPSO | 353.6 | 356.2 | 352.3 | 354.9 | 357.5 | 353.6 | 356.2 | 352.3 | 354.9 | 356.2 | 354.77 | |

| FA | 255.39 | 253.27 | 256.18 | 255.22 | 255.90 | 256.73 | 255.32 | 254.28 | 255.04 | 253.98 | 255.13 | |

| IFA | 132.08 | 133.27 | 131.22 | 134.57 | 133.69 | 134.35 | 133.17 | 132.98 | 134.28 | 131.77 | 133.14 | |

| WF | Standard Deviation of Power (Proportional Distribution)/MW | Standard Deviation of Power (Proposed Strategy)/MW | Reduction Proportion/% |

|---|---|---|---|

| 1 | 0.5173 | 0.1192 | 76.96% |

| 2 | 0.5209 | 0.1204 | 76.89% |

| 3 | 0.5197 | 0.1131 | 78.24% |

| 4 | 0.5249 | 0.1171 | 77.69% |

| 5 | 0.5185 | 0.1182 | 77.20% |

| 6 | 0.5191 | 0.1163 | 77.60% |

| 7 | 0.5156 | 0.1186 | 77.00% |

| 8 | 0.5216 | 0.1241 | 76.21% |

| 9 | 0.5196 | 0.1262 | 75.71% |

| WF | Equivalent Fatigue Load (MN·m) | ||

|---|---|---|---|

| Proportional Distribution Strategy | Proposed Strategy | Reduction Proportion/% | |

| 1 | 0.5389 | 0.3281 | 39.12 |

| 2 | 0.4454 | 0.3008 | 32.47 |

| 3 | 0.5661 | 0.3408 | 39.80 |

| 4 | 0.4471 | 0.3123 | 30.15 |

| 5 | 0.3893 | 0.2784 | 28.49 |

| 6 | 0.3825 | 0.2608 | 31.82 |

| 7 | 0.4131 | 0.2883 | 30.21 |

| 8 | 0.3893 | 0.2832 | 27.25 |

| 9 | 0.6154 | 0.3472 | 43.58 |

| WF | Equivalent Fatigue Load (MN·m) | ||

|---|---|---|---|

| Proportional Distribution Strategy | Proposed Strategy | Reduction Proportion/% | |

| 1 | 10.3878 | 6.4797 | 37.62 |

| 2 | 10.0648 | 5.7231 | 43.14 |

| 3 | 10.6394 | 6.7379 | 36.67 |

| 4 | 10.2131 | 5.8298 | 42.92 |

| 5 | 9.4095 | 5.2958 | 43.72 |

| 6 | 9.4076 | 5.1623 | 45.13 |

| 7 | 9.8057 | 5.6714 | 42.16 |

| 8 | 9.5165 | 5.4103 | 43.15 |

| 9 | 10.6864 | 6.7907 | 36.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Yang, X.; Hu, S.; Guo, Y.; Wang, Y.; Liu, X.; Wang, Y.; Liang, W.; Yang, J. An Optimal Active Power Allocation Method for Wind Farms Considering Unit Fatigue Load. Sustainability 2025, 17, 9189. https://doi.org/10.3390/su17209189

Huang Z, Yang X, Hu S, Guo Y, Wang Y, Liu X, Wang Y, Liang W, Yang J. An Optimal Active Power Allocation Method for Wind Farms Considering Unit Fatigue Load. Sustainability. 2025; 17(20):9189. https://doi.org/10.3390/su17209189

Chicago/Turabian StyleHuang, Zhi, Xinyu Yang, Sile Hu, Yu Guo, Yutong Wang, Xianglong Liu, Yuan Wang, Wenjing Liang, and Jiaqiang Yang. 2025. "An Optimal Active Power Allocation Method for Wind Farms Considering Unit Fatigue Load" Sustainability 17, no. 20: 9189. https://doi.org/10.3390/su17209189

APA StyleHuang, Z., Yang, X., Hu, S., Guo, Y., Wang, Y., Liu, X., Wang, Y., Liang, W., & Yang, J. (2025). An Optimal Active Power Allocation Method for Wind Farms Considering Unit Fatigue Load. Sustainability, 17(20), 9189. https://doi.org/10.3390/su17209189