Spatial Spillover Effect of Green Industrial Agglomeration on Carbon Productivity

Abstract

1. Introduction

2. Literature Review

2.1. Carbon Productivity and Industry Agglomeration

2.2. Green Industrial Agglomeration

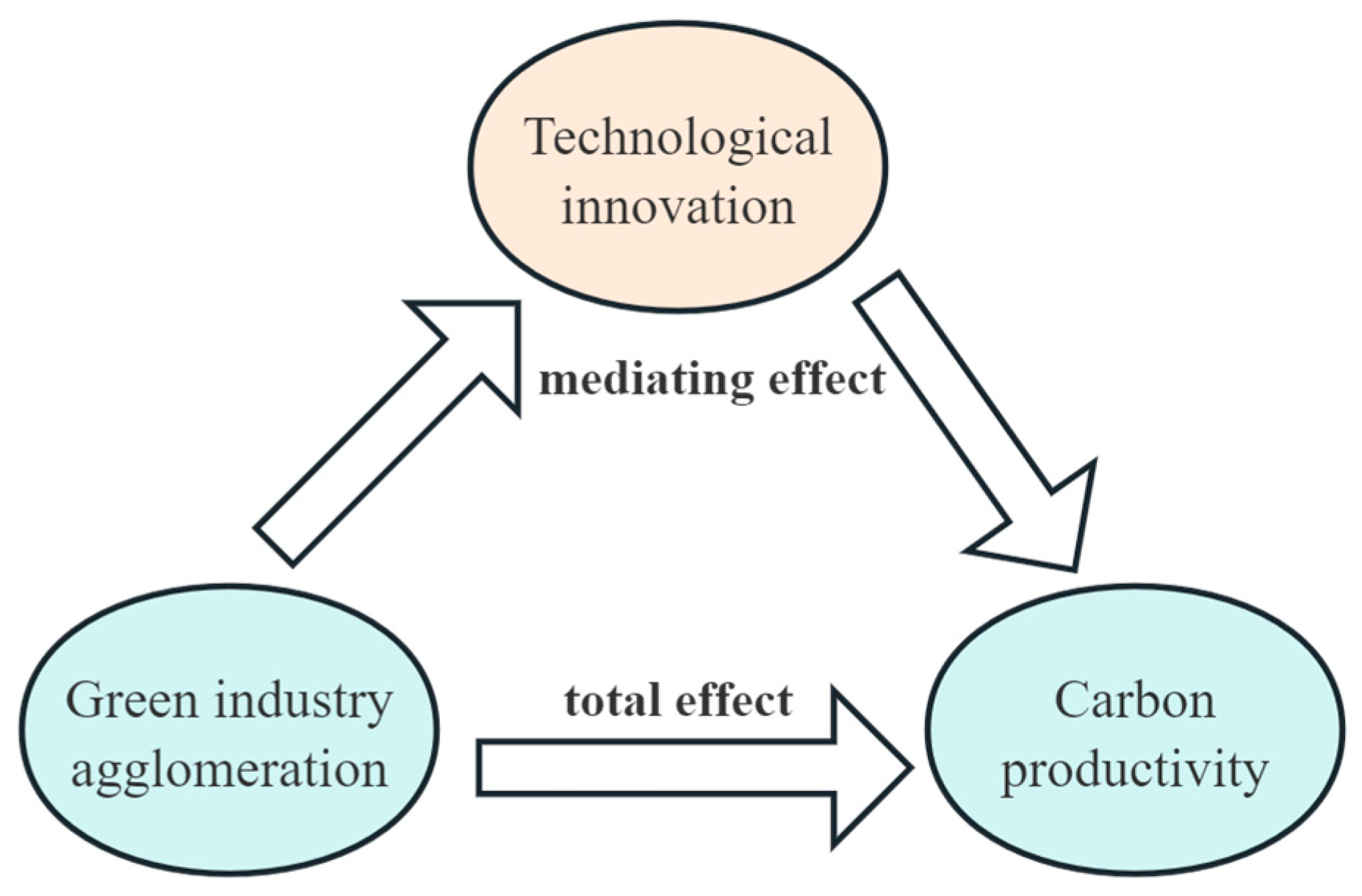

3. Theoretical Analysis and Research Hypotheses

3.1. Direct Effect of Green Industrial Agglomeration on Carbon Productivity

3.2. Indirect Effect of Green Industrial Agglomeration on Carbon Productivity

3.3. Spatial Spillover Effect of Carbon Productivity

4. Methodology and Data

4.1. Basic Regression Model

4.2. Spatial Mediation Effect Model

4.3. Econometric Model

4.4. Variable Definition

4.4.1. Explained Variable: Carbon Productivity (CP)

4.4.2. Key Explanatory Variable: Green Industrial Agglomeration (GIA)

4.4.3. Mediating Variable: Technological Innovation (TEC)

4.4.4. Control Variables

4.5. Data Sources

5. Analysis of Empirical Results

5.1. Results of Spatiotemporal Differentiation

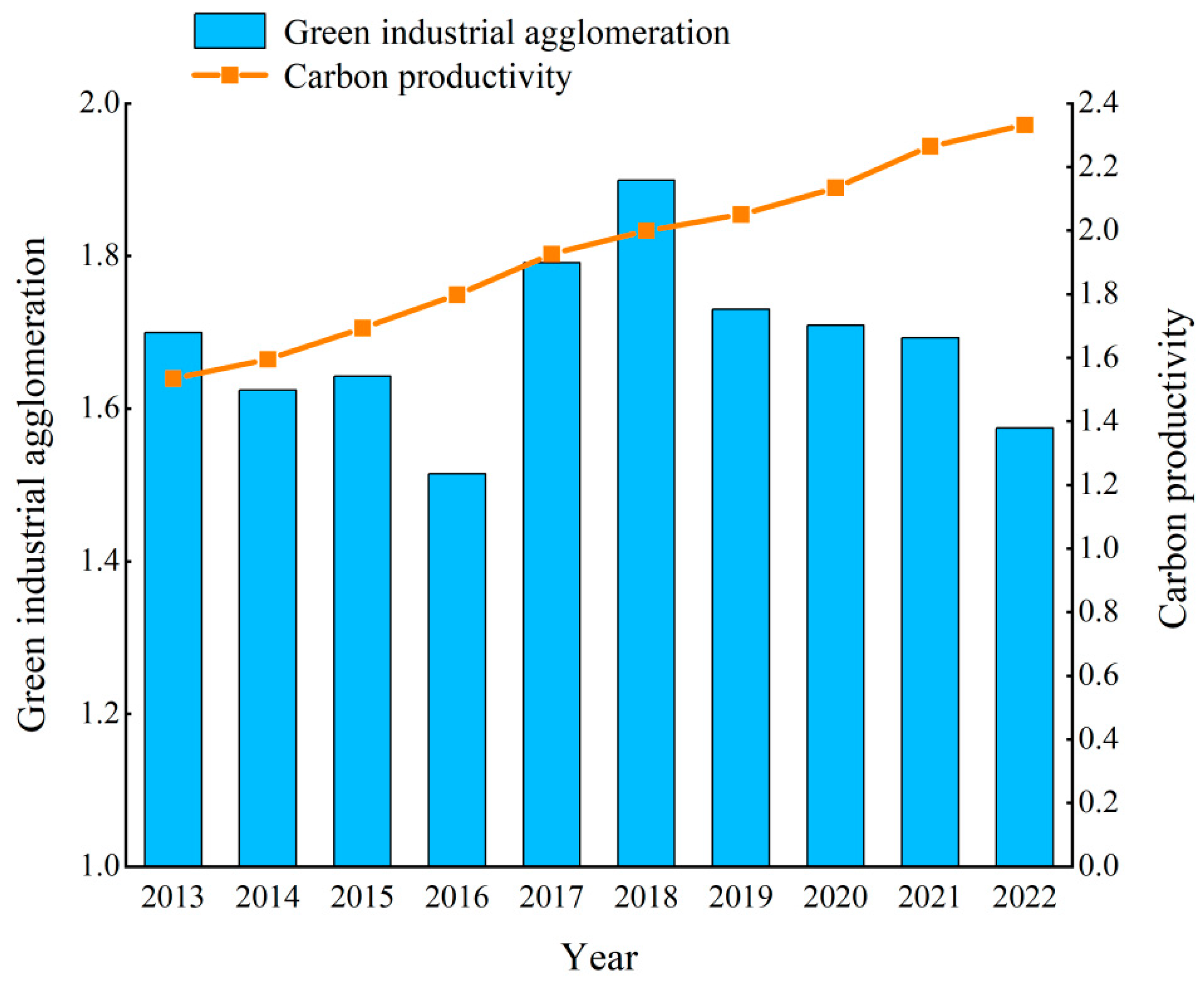

5.1.1. Temporal Variations in Green Industrial Agglomeration and Carbon Productivity

5.1.2. Spatiotemporal Analysis on Carbon Productivity Across China’s Provinces

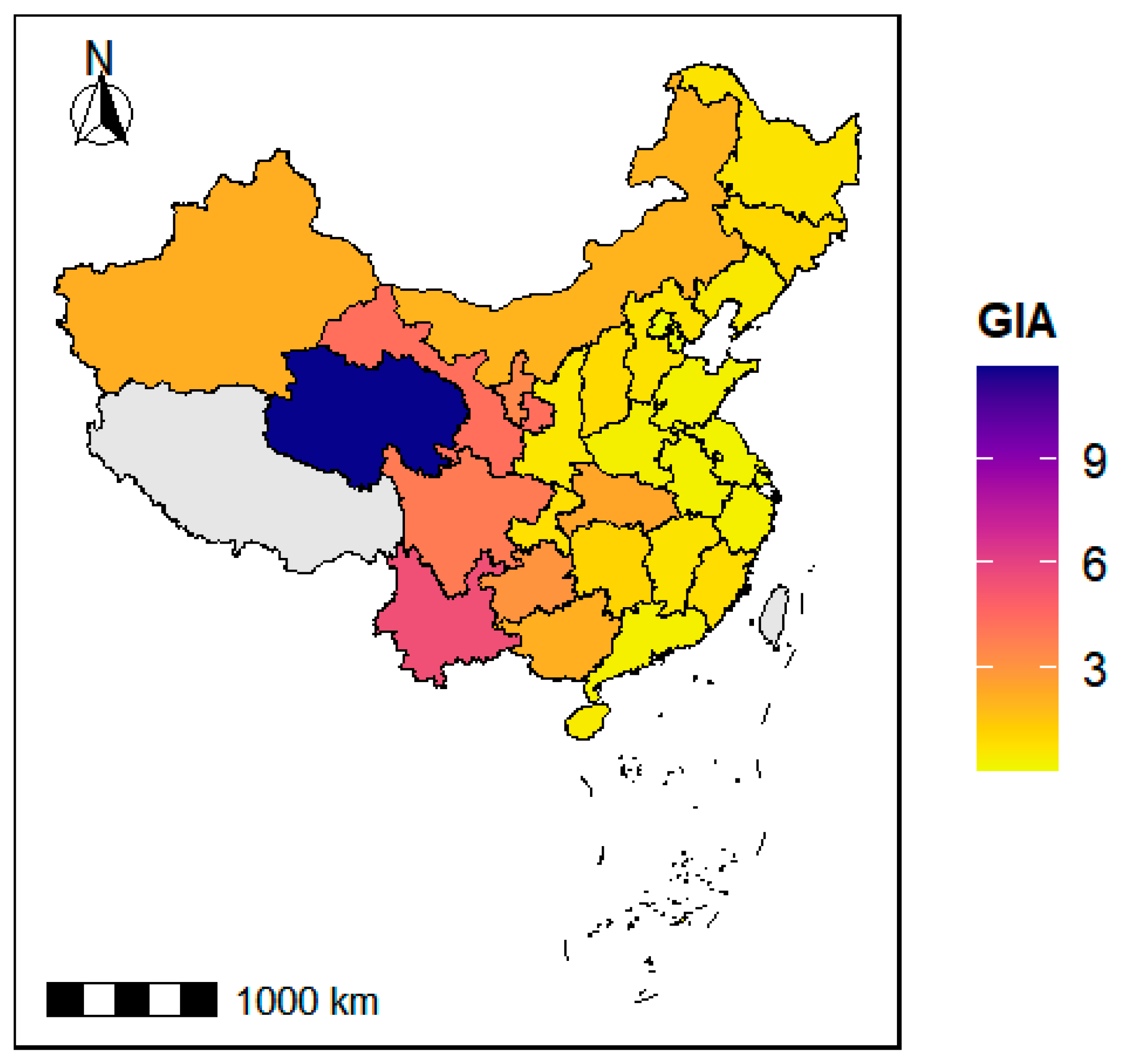

5.1.3. Spatial Distribution Pattern of Green Industrial Agglomeration in China

5.2. Benchmark Regression

5.3. Spatial Mediating Effects Test

5.4. Spatial Durbin Model Analysis

5.5. Robustness Analysis

5.5.1. Shortening the Sampling Period

5.5.2. Replace the Spatial Weight Matrix

5.6. Endogeneity Test

5.7. Regional Heterogeneity Analysis

6. Conclusions and Implications

6.1. Conclusions

6.2. Policy Recommendations

- (1)

- Improve market mechanisms and regional coordination policies. Spatial econometric findings of this study show that green industrial agglomeration not only enhances carbon productivity within the region, but also generates positive spatial spillover effects on neighboring areas. Therefore, it is recommended to further dismantle barriers to factor mobility, facilitating the market-driven flow of capital, talent, technology, and other production factors toward regions and industries with higher green efficiency to enhance factor allocation efficiency. At the same time, establishing regional coordination mechanisms can align green industrial development plans, support shared infrastructure, and promote joint environmental governance. This will better leverage the role of green industrial agglomeration in enhancing carbon productivity locally and in surrounding areas.

- (2)

- Strengthen spatial coordination and diffusion mechanisms for technological innovation. Spatial intermediary effect tests reveal that green industrial clusters not only can boost local technological innovation levels but also stimulate innovation in neighboring regions through spatial spillover channels. Based on these findings, policy design should emphasize the spatial coordination and externalities of technological innovation. Support should be provided for establishing cross-regional green technology cooperation platforms, encouraging the rational flow and sharing of innovation factors across regions, and guiding the formation of interregional innovation collaboration networks. This will amplify the technological spillover benefits generated by green industrial clusters, thereby better leveraging their multi-level driving role in enhancing carbon productivity.

- (3)

- Implement differentiated green industrial agglomeration strategies. The study findings suggest that the effect of green industrial agglomeration on carbon productivity differs among regions with different levels of green productivity. Policy formulation must fully account for this heterogeneity. For regions with moderate green productivity levels, prioritizing support and optimizing the layout of green industrial clusters can effectively enhance carbon productivity. For regions with high green productivity levels, focus should be placed on addressing potential crowding effects from clustering, striving to improve the quality of clustering and innovation efficiency. For regions with high green productivity levels, focus should be placed on addressing potential crowding effects from clustering, striving to improve the quality of clustering and innovation efficiency.

6.3. Research Limitations and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CP | Carbon Productivity |

| GIA | Green Industrial Agglomeration |

References

- Chételat, J.; McKinney, M.A.; Amyot, M.; Dastoor, A.; Douglas, T.A.; Heimbürger-Boavida, L.-E.; Kirk, J.; Kahilainen, K.K.; Outridge, P.M.; Pelletier, N. Climate change and mercury in the Arctic: Abiotic interactions. Sci. Total Environ. 2022, 824, 153715. [Google Scholar] [CrossRef]

- Jacob, T.; Wahr, J.; Pfeffer, W.T.; Swenson, S. Recent contributions of glaciers and ice caps to sea level rise. Nature 2012, 482, 514–518. [Google Scholar] [CrossRef]

- Ang, J.B. CO2 emissions, research and technology transfer in China. Ecol. Econ. 2009, 68, 2658–2665. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Zhao, S.; Tang, T. Does green finance agglomeration improve carbon emission performance in China? A perspective of spatial spillover. Appl. Energy 2024, 358, 122561. [Google Scholar] [CrossRef]

- Zhao, X.; Shang, Y.; Ma, X.; Xia, P.; Shahzad, U. Does carbon trading lead to green technology innovation: Recent evidence from Chinese companies in resource-based industries. IEEE Trans. Eng. Manag. 2022, 71, 2506–2523. [Google Scholar] [CrossRef]

- Hao, Y.; Gai, Z.; Wu, H. How do resource misallocation and government corruption affect green total factor energy efficiency? Evidence from China. Energy Policy 2020, 143, 111562. [Google Scholar] [CrossRef]

- Ling, G.; Razzaq, A.; Guo, Y.; Fatima, T.; Shahzad, F. Asymmetric and time-varying linkages between carbon emissions, globalization, natural resources and financial development in China. Environ. Dev. Sustain. 2022, 24, 6702–6730. [Google Scholar] [CrossRef]

- Li, G.; Lai, S.; Lu, M.; Li, Y. Digitalization, carbon productivity and technological innovation in manufacturing—Evidence from China. Sustainability 2023, 15, 11014. [Google Scholar] [CrossRef]

- Liang, Y.; Hao, X. Can the Agglomeration of New Energy Industries Improve Environmental Efficiency?—Evidence from China. Sustainability 2022, 14, 8961. [Google Scholar] [CrossRef]

- Goldemberg, J. The promise of clean energy. Energy Policy 2006, 34, 2185–2190. [Google Scholar] [CrossRef]

- Lin, B.; Li, Z. Towards world’s low carbon development: The role of clean energy. Appl. Energy 2022, 307, 118160. [Google Scholar] [CrossRef]

- Zhang, F.; Gallagher, K.S.; Myslikova, Z.; Narassimhan, E.; Bhandary, R.R.; Huang, P. From fossil to low carbon: The evolution of global public energy innovation. Wiley Interdiscip. Rev. Clim. Change 2021, 12, e734. [Google Scholar] [CrossRef]

- Diaz-Rainey, I.; Ashton, J.K. Investment inefficiency and the adoption of eco-innovations: The case of household energy efficiency technologies. Energy Policy 2015, 82, 105–117. [Google Scholar] [CrossRef]

- Du, K.; Li, J. Towards a green world: How do green technology innovations affect total-factor carbon productivity. Energy Policy 2019, 131, 240–250. [Google Scholar] [CrossRef]

- Guinot, J.; Barghouti, Z.; Chiva, R. Understanding green innovation: A conceptual framework. Sustainability 2022, 14, 5787. [Google Scholar] [CrossRef]

- Lee, S.-H.; Park, S.; Kim, T. Review on investment direction of green technology R&D in Korea. Renew. Sustain. Energy Rev. 2015, 50, 186–193. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X. Industrial agglomeration, technological innovation and carbon productivity: Evidence from China. Resour. Conserv. Recycl. 2021, 166, 105330. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, F.; He, Y. Exploring the effect of producer services and manufacturing industrial co-agglomeration on the ecological environment pollution control in China. Environ. Dev. Sustain. 2021, 23, 16119–16144. [Google Scholar] [CrossRef]

- Bai, Y.; Qian, Q.; Jiao, J.; Li, L.; Li, F.; Yang, R. Can environmental innovation benefit from outward foreign direct investment to developed countries? Evidence from Chinese manufacturing enterprises. Environ. Sci. Pollut. Res. 2020, 27, 13790–13808. [Google Scholar] [CrossRef]

- Li, W.; Elheddad, M.; Doytch, N. The impact of innovation on environmental quality: Evidence for the non-linear relationship of patents and CO2 emissions in China. J. Environ. Manag. 2021, 292, 112781. [Google Scholar] [CrossRef]

- Hua, Z.; Mengting, H.; Feifei, T. Influence of intelligentization on enterprise green innovation: Evidence from listed companies of new energy industry in China. Resour. Sci. 2022, 44, 984–993. [Google Scholar]

- Yi, H.; Liu, Y. Green economy in China: Regional variations and policy drivers. Glob. Environ. Change 2015, 31, 11–19. [Google Scholar] [CrossRef]

- Carley, S. State renewable energy electricity policies: An empirical evaluation of effectiveness. Energy Policy 2009, 37, 3071–3081. [Google Scholar] [CrossRef]

- Hillebrand, B.; Buttermann, H.G.; Behringer, J.M.; Bleuel, M. The expansion of renewable energies and employment effects in Germany. Energy Policy 2006, 34, 3484–3494. [Google Scholar] [CrossRef]

- Mundaca, L.; Richter, J.L. Assessing ‘green energy economy’stimulus packages: Evidence from the US programs targeting renewable energy. Renew. Sustain. Energy Rev. 2015, 42, 1174–1186. [Google Scholar] [CrossRef]

- Yin, H.; Powers, N. Do state renewable portfolio standards promote in-state renewable generation? Energy Policy 2010, 38, 1140–1149. [Google Scholar] [CrossRef]

- Frondel, M.; Ritter, N.; Schmidt, C.M.; Vance, C. Economic impacts from the promotion of renewable energy technologies: The German experience. Energy Policy 2010, 38, 4048–4056. [Google Scholar] [CrossRef]

- Yi, H. Green businesses in a clean energy economy: Analyzing drivers of green business growth in US states. Energy 2014, 68, 922–929. [Google Scholar] [CrossRef]

- Hu, X.; Liu, C. Carbon productivity: A case study in the Australian construction industry. J. Clean. Prod. 2016, 112, 2354–2362. [Google Scholar] [CrossRef]

- Li, S.; Wang, W.; Diao, H.; Wang, L. Measuring the efficiency of energy and carbon emissions: A review of definitions, models, and input-output variables. Energies 2022, 15, 962. [Google Scholar] [CrossRef]

- Li, S.; Wang, S. Examining the effects of socioeconomic development on China’s carbon productivity: A panel data analysis. Sci. Total Environ. 2019, 659, 681–690. [Google Scholar] [CrossRef] [PubMed]

- Bai, C.; Du, K.; Yu, Y.; Feng, C. Understanding the trend of total factor carbon productivity in the world: Insights from convergence analysis. Energy Econ. 2019, 81, 698–708. [Google Scholar] [CrossRef]

- Zhang, X.; Yao, S.; Zheng, W.; Fang, J. On industrial agglomeration and industrial carbon productivity—Impact mechanism and nonlinear relationship. Energy 2023, 283, 129047. [Google Scholar] [CrossRef]

- Lin, B.; Tan, R. Economic agglomeration and green economy efficiency in China. Econ. Res. J 2019, 54, 119–132. [Google Scholar]

- Steijn, M.P.; Koster, H.R.; Van Oort, F.G. The dynamics of industry agglomeration: Evidence from 44 years of coagglomeration patterns. J. Urban Econ. 2022, 130, 103456. [Google Scholar] [CrossRef]

- Diodato, D.; Neffke, F.; O’Clery, N. Why do industries coagglomerate? How Marshallian externalities differ by industry and have evolved over time. J. Urban Econ. 2018, 106, 1–26. [Google Scholar] [CrossRef]

- Marshall, A.; Guillebaud, C.W. Principles of Economics: An Introductory Volume; Springer: Berlin/Heidelberg, Germany, 1961. [Google Scholar]

- Chen, C.; Jiang, T.; Liu, C. An empirical study on the impact of different industrial agglomeration form on urban technological innovation. Stud. Sci. Sci. 2019, 37, 77–85. [Google Scholar]

- Ciccone, A. Agglomeration effects in Europe. Eur. Econ. Rev. 2002, 46, 213–227. [Google Scholar] [CrossRef]

- Cingano, F.; Schivardi, F. Identifying the sources of local productivity growth. J. Eur. Econ. Assoc. 2004, 2, 720–742. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, D. The interaction and spatial spillover between agglomeration and pollution. China Ind. Econ 2014, 6, 70–82. [Google Scholar]

- Du, Z.; Hao, P. Firm clustering, agglomeration externalities and energy efficiency: Evidence from chinese industrial enterprises. Energy Econ. 2025, 145, 108451. [Google Scholar] [CrossRef]

- Yuan, H.; Zou, L.; Feng, Y.; Huang, L. Does manufacturing agglomeration promote or hinder green development efficiency? Evidence from Yangtze River Economic Belt, China. Environ. Sci. Pollut. Res. 2023, 30, 81801–81822. [Google Scholar] [CrossRef]

- Lu, K.; Qiu, Y.; Zhang, J.; Li, C.; Xie, J. Digital industry agglomeration and inclusive green growth: Synergies and path exploration. Front. Environ. Sci. 2025, 13, 1552159. [Google Scholar] [CrossRef]

- Zhang, R.; Gao, Q.; Gao, K. Impact of marine industrial agglomeration on the high-quality development of the marine economy—A case study of China’s coastal areas. Ecol. Indic. 2024, 158, 111410. [Google Scholar] [CrossRef]

- Shen, N.; Peng, H.; Wang, Q. Spatial dependence, agglomeration externalities and the convergence of carbon productivity. Socio-Econ. Plan. Sci. 2021, 78, 101060. [Google Scholar] [CrossRef]

- Wu, J.; Xu, H.; Tang, K. Industrial agglomeration, CO2 emissions and regional development programs: A decomposition analysis based on 286 Chinese cities. Energy 2021, 225, 120239. [Google Scholar] [CrossRef]

- Kang, W.; Guo, J.; Chen, S. Analysis and validation of energy-conservation and emission-reduction effects of economic agglomeration. Environ. Dev. Sustain. 2025, 27, 14641–14668. [Google Scholar] [CrossRef]

- Wan, J.; Li, C.; Yang, Z.; Wu, L.; Yue, M. Dynamic spatial spillover effects of financial agglomeration on CO2 emissions: The case of China. Humanit. Soc. Sci. Commun. 2025, 12, 178. [Google Scholar] [CrossRef]

- Peng, H.; Shen, N.; Liao, H.; Wang, Q. Multiple network embedding, green knowledge integration and green supply chain performance-Investigation based on agglomeration scenario. J. Clean. Prod. 2020, 259, 120821. [Google Scholar] [CrossRef]

- Li, X.; Xu, H. The Energy-conservation and Emission-reduction Paths of Industrial sectors: Evidence from Chinas 35 industrial sectors. Energy Econ. 2020, 86, 104628. [Google Scholar] [CrossRef]

- Li, H. Environmental Regulation, Technological Progress and Chinese Green Industrial Agglomeration. In Environmental Pollution Governance and Ecological Remediation Technology, Proceedings of the International Conference on Environmental Pollution and Governance, Shanghai, China, 23–25 September 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 817–825. [Google Scholar]

- Zhou, F.; Wen, H. Green industry agglomeration and high quality development of urban industrial sector: Quasi-natural experiment from national Eco-industrial Demonstration Park policy. Comments Sankei Shimbun 2019, 10, 5–19. [Google Scholar]

- Zhao, F.; Luo, L. The Impact of Industrial Agglomeration on Urban Carbon Emissions in the Yangtze River Economic Belt: Heterogeneity and Action Mechanism. Reform 2022, 35, 68–84. [Google Scholar]

- Liu, C.; Zhang, J.; Wang, C.; Ma, Z. How green finance policy catalyzes innovation in industrial clusters: Lessons from China’s new energy vehicle sector. Struct. Change Econ. Dyn. 2025, 75, 20–31. [Google Scholar] [CrossRef]

- Yue, J.; Duan, H. The Influence of New Energy Industry Agglomeration on Regional Green Innovation Performance-Evidence from China. Sustainability 2024, 16, 2029. [Google Scholar] [CrossRef]

- Verhoef, E.T.; Nijkamp, P. Externalities in urban sustainability: Environmental versus localization-type agglomeration externalities in a general spatial equilibrium model of a single-sector monocentric industrial city. Ecol. Econ. 2002, 40, 157–179. [Google Scholar] [CrossRef]

- Peng, H.; Wang, Y.; Hu, Y.; Shen, H. Agglomeration production, industry association and carbon emission performance: Based on spatial analysis. Sustainability 2020, 12, 7234. [Google Scholar] [CrossRef]

- Bosetti, V.; Carraro, C.; Galeotti, M.; Massetti, E.; Tavoni, M. A world induced technical change hybrid model. Energy J. 2006, 27 (Suppl. S2), 13–37. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, P. Have industrial agglomeration aggravated regional environmental pollution-Chinese provincial level empirical evidence. J. Huazhong Univ. Sci. Technol. (Soc. Sci. Ed.) 2013, 27, 97–106. [Google Scholar]

- Dabuo, F.T.; Du, J.; Madzikanda, B.; Coulibaly, P.T. Influence of research and development, environmental regulation, and consumption of energy on CO2 emissions in China—Novel spatial Durbin model perspective. Environ. Sci. Pollut. Res. 2023, 30, 29065–29085. [Google Scholar] [CrossRef]

- Han, B. Research on the influence of technological innovation on carbon productivity and countermeasures in China. Environ. Sci. Pollut. Res. 2021, 28, 16880–16894. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, M.; Xin, X.; Yang, C.; Zhang, Y.; Dai, J. Advancing renewable energy innovation through digital technology and supply chain digitization. Energy Econ. 2025, 147, 108557. [Google Scholar] [CrossRef]

- Yin, X.; Guo, L. Industrial efficiency analysis based on the spatial panel model. EURASIP J. Wirel. Commun. Netw. 2021, 2021, 28. [Google Scholar] [CrossRef]

- Lucas, V.; Gasselin, P.; Van Der Ploeg, J.D. Local inter-farm cooperation: A hidden potential for the agroecological transition in northern agricultures. Agroecol. Sustain. Food Syst. 2019, 43, 145–179. [Google Scholar] [CrossRef]

- Shao, S.; Zhang, K.; Dou, J. Effects of economic agglomeration on energy saving and emission reduction: Theory and empirical evidence from China. Manag. World 2019, 35, 24–42. [Google Scholar]

- Pan, J.; Zhang, L. Research on the regional variation of carbon productivity in China. In Political Economy of China’s Climate Policy; Springer: Berlin/Heidelberg, Germany, 2022; pp. 157–177. [Google Scholar]

- Sun, H.; Chen, T.; Wang, C.N. Spatial impact of digital finance on carbon productivity. Geosci. Front. 2024, 15, 101674. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Yang, X. The impact of collaborative agglomeration of manufacturing and producer services on carbon emission intensity: Influence mechanism and spatial effect. PLoS ONE 2023, 18, e0295948. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Personal. Soc. Psychol. 1986, 51, 1173. [Google Scholar] [CrossRef]

- Jahanger, A.; Usman, M.; Ahmad, P. A step towards sustainable path: The effect of globalization on China’s carbon productivity from panel threshold approach. Environ. Sci. Pollut. Res. 2022, 29, 8353–8368. [Google Scholar] [CrossRef]

| Year | Carbon Productivity | Green Industrial Agglomeration | ||

|---|---|---|---|---|

| Moran’s I | Z Value | Moran’s I | Z Value | |

| 2013 | 0.3593 *** | 3.1505 | 0.2448 *** | 2.9883 |

| 2014 | 0.3671 *** | 3.2146 | 0.3321 *** | 3.5058 |

| 2015 | 0.3211 *** | 2.8465 | 0.3623 *** | 3.9460 |

| 2016 | 0.3455 *** | 3.0337 | 0.5277 *** | 4.9162 |

| 2017 | 0.3465 *** | 3.0553 | 0.4484 *** | 4.5340 |

| 2018 | 0.3737 *** | 3.2596 | 0.3536 *** | 3.9895 |

| 2019 | 0.3633 *** | 3.1786 | 0.3886 *** | 4.7406 |

| 2020 | 0.3414 *** | 3.0105 | 0.4293 *** | 4.5736 |

| 2021 | 0.2841 ** | 2.5493 | 0.3242 *** | 3.6423 |

| 2022 | 0.1972 * | 1.8572 | 0.3634 *** | 3.7539 |

| Year | Carbon Productivity | Green Industrial Agglomeration | ||

|---|---|---|---|---|

| Moran’s I | Z Value | Moran’s I | Z Value | |

| 2013 | 0.0602 *** | 2.8188 | 0.0680 *** | 4.0150 |

| 2014 | 0.0674 *** | 3.0334 | 0.0878 *** | 4.3140 |

| 2015 | 0.0681 *** | 3.0534 | 0.0909 *** | 4.5869 |

| 2016 | 0.0701 *** | 3.1068 | 0.1287 *** | 5.2893 |

| 2017 | 0.0740 *** | 3.2346 | 0.1184 *** | 5.3001 |

| 2018 | 0.0822 *** | 3.4670 | 0.1013 ** | 5.1253 |

| 2019 | 0.0784 *** | 3.3547 | 0.0929 *** | 5.2085 |

| 2020 | 0.0581 *** | 2.7571 | 0.1055 *** | 5.0833 |

| 2021 | 0.0413 ** | 2.2559 | 0.0818 *** | 4.3405 |

| 2022 | 0.0158 * | 1.4992 | 0.0880 *** | 4.2666 |

| LM test | LM-error test | 18.765 *** |

| Robust LM-error test | 0.029 * | |

| LM-lag test | 21.298 *** | |

| Robust LM-lag test | 2.562 * | |

| LR test | LR Test (SAR) | 57.72 *** |

| LR Test (SEM) | 57.72 *** | |

| Wald Test | Wald Test (SAR) | 62.97 *** |

| Wald Test (SEM) | 61.47 *** |

| Variable | Symbol | Name | Measurement |

|---|---|---|---|

| Explained variable | CP | Carbon Productivity | |

| Key explanatory variable | GIA | Green Industrial Agglomeration | |

| Mediating variable | TEC | Technological innovation | The ratio of technology market transaction volume to GDP |

| Control variables | Agdp | Economic development level | The logarithm of per capita GDP (in 10,000 yuan per person) |

| URB | Urbanization level | The logarithm of the urban population size | |

| OP | Openness to the global economy | The ratio of total import and export value to GDP | |

| ER | Environmental regulation | The logarithm of investment in environmental pollution treatment | |

| IND | Industrial structure | The ratio of secondary industry value added to GDP | |

| PDE | Population density | The logarithm of the ratio of resident population to administrative division area |

| Type | Variable | Observation | Mean | Std. Dev | Min | Max |

|---|---|---|---|---|---|---|

| Explained variable | CP | 300 | 1.933 | 0.963 | 0.505 | 4.491 |

| Explanatory variable | GIA | 300 | 1.688 | 2.391 | 0.0176 | 14.29 |

| Mediating variable | TEC | 300 | 0.0196 | 0.0314 | 0.0002 | 0.191 |

| Control variable | Agdp | 300 | 0.754 | 0.188 | 0.344 | 1.279 |

| URB | 300 | 3.348 | 0.321 | 2.449 | 3.976 | |

| OP | 300 | 0.259 | 0.257 | 0.0076 | 1.257 | |

| ER | 300 | 5.226 | 0.890 | 2.302 | 6.859 | |

| IND | 300 | 0.394 | 0.0771 | 0.160 | 0.558 | |

| PDE | 300 | 2.379 | 0.561 | 0.898 | 3.594 |

| CP | ||

|---|---|---|

| Variable | OLS | FE |

| GIA | 0.108 *** | 0.040 * |

| (0.026) | (0.024) | |

| Agdp | 2.284 *** | 6.962 *** |

| (0.331) | (0.982) | |

| URB | 0.808 *** | −7.032 *** |

| (0.244) | (1.511) | |

| OP | −1.842 *** | 0.534 |

| (0.291) | (0.347) | |

| ER | 0.173 ** | 0.107 ** |

| (0.083) | (0.052) | |

| IND | −1.303 ** | −3.896 *** |

| (0.659) | (0.926) | |

| PDE | 0.777 *** | 7.324 *** |

| (0.143) | (2.363) | |

| Constant | −4.442 *** | −4.669 |

| (0.604) | (4.741) | |

| Province Fe | No | Yes |

| Year Fe | No | Yes |

| Observations | 300 | 300 |

| R-squared | 0.3967 | 0.9499 |

| Variables | Model (1) CP | Model (2) TEC | Model (3) CP | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Direct Effect | Indirect Effect | Total Effect | Direct Effect | Indirect Effect | Total Effect | Direct Effect | Indirect Effect | Total Effect | |

| GIA | 0.090 *** | 0.138 *** | 0.228 *** | 0.002 *** | 0.001 * | 0.003 ** | 0.075 *** | 0.144 *** | 0.220 *** |

| (0.026) | (0.056) | (0.066) | (0.001) | (0.001) | (0.002) | (0.026) | (0.056) | (0.067) | |

| Agdp | 2.857 *** | 1.328 *** | 4.186 *** | 0.079 *** | 0.015 * | 0.094 *** | 2.431 *** | 1.466 *** | 3.896 *** |

| (0.559) | (0.445) | (0.896) | (0.016) | (0.008) | (0.020) | (0.575) | (0.508) | (0.978) | |

| URB | 0.760 *** | 0.349 ** | 1.109 *** | −0.026 *** | −0.005 * | −0.031 *** | 0.923 *** | 0.559 ** | 1.482 *** |

| (0.279) | (0.155) | (0.412) | (0.008) | (0.003) | (0.010) | (0.296) | (0.232) | (0.494) | |

| OP | −1.994 *** | −0.920 *** | −2.915 *** | −0.013 | −0.002 | −0.016 | −1.899 *** | −1.142 *** | −3.041 *** |

| (0.401) | (0.293) | (0.607) | (0.011) | (0.003) | (0.013) | (0.382) | (0.354) | (0.644) | |

| ER | 0.183 ** | 0.087 | 0.269 * | 0.015 *** | 0.003 * | 0.018 *** | 0.101 | 0.062 | 0.162 |

| (0.094) | (0.055) | (0.144) | (0.003) | (0.002) | (0.003) | (0.105) | (0.069) | (0.172) | |

| IND | −1.969 *** | −0.923 ** | −2.892 *** | −0.208 *** | −0.040 * | −0.248 *** | −0.793 | −0.475 | −1.268 |

| (0.724) | (0.439) | (1.107) | (0.021) | (0.021) | (0.034) | (0.874) | (0.550) | (1.405) | |

| PDE | 0.650 *** | 0.296 *** | 0.946 *** | 0.012 ** | 0.002 | 0.014 *** | 0.499 *** | 0.292 *** | 0.791 *** |

| (0.179) | (0.100) | (0.252) | (0.005) | (0.001) | (0.006) | (0.178) | (0.111) | (0.271) | |

| TEC | 6.513 *** | 4.073 ** | 10.587 *** | ||||||

| (2.098) | (1.953) | (3.888) | |||||||

| Variables | Direct Effect | Indirect Effect | Total Effect |

|---|---|---|---|

| GIA | 0.090 *** | 0.138 *** | 0.228 *** |

| (0.026) | (0.056) | (0.066) | |

| Agdp | 2.857 *** | 1.328 *** | 4.186 *** |

| (0.559) | (0.445) | (0.896) | |

| URB | 0.760 *** | 0.349 ** | 1.109 *** |

| (0.279) | (0.155) | (0.412) | |

| OP | −1.994 *** | −0.920 *** | −2.915 *** |

| (0.401) | (0.293) | (0.607) | |

| ER | 0.183 ** | 0.087 | 0.269 * |

| (0.094) | (0.055) | (0.144) | |

| IND | −1.969 *** | −0.923 ** | −2.892 *** |

| (0.724) | (0.439) | (1.107) | |

| PDE | 0.650 *** | 0.296 *** | 0.946 *** |

| (0.179) | (0.100) | (0.252) |

| Time Variables | 2013–2022 | 2016–2021 | ||||||

|---|---|---|---|---|---|---|---|---|

| CP | CP | |||||||

| Main | LR_Direct | LR_Indirect | LR_Total | Main | LR_Direct | LR_Indirect | LR_Total | |

| GIA | 0.081 *** | 0.090 *** | 0.138 *** | 0.228 *** | 0.072 ** | 0.084 ** | 0.154 ** | 0.238 *** |

| (0.025) | (0.026) | (0.056) | (0.066) | (0.033) | (0.035) | (0.075) | (0.089) | |

| Agdp | 2.793 *** | 2.857 *** | 1.328 *** | 4.186 *** | 3.846 *** | 3.955 *** | 2.007 *** | 5.962 *** |

| (0.563) | (0.559) | (0.445) | (0.896) | (0.744) | (0.740) | (0.761) | (1.298) | |

| URB | 0.715 *** | 0.760 *** | 0.349 ** | 1.109 *** | 0.826 ** | 0.886 ** | 0.441 * | 1.328 ** |

| (0.286) | (0.279) | (0.155) | (0.412) | (0.377) | (0.370) | (0.230) | (0.563) | |

| OP | −1.944 *** | −1.994 *** | −0.920 *** | −2.915 *** | −3.101 *** | −3.197 *** | −1.609 *** | −4.806 *** |

| (0.402) | (0.401) | (0.293) | (0.607) | (0.611) | (0.607) | (0.580) | (0.995) | |

| ER | 0.181 * | 0.183 ** | 0.087 | 0.269 * | 0.168 | 0.169 | 0.089 | 0.258 |

| (0.097) | (0.094) | (0.055) | (0.144) | (0.124) | (0.120) | (0.077) | (0.191) | |

| IND | −1.926 *** | −1.969 *** | −0.923 ** | −2.892 *** | −2.351 *** | −2.414 *** | −1.239 * | −3.652 ** |

| (0.715) | (0.724) | (0.439) | (1.107) | (0.950) | (0.970) | (0.676) | (1.550) | |

| PDE | 0.632 *** | 0.650 *** | 0.296 *** | 0.946 *** | 0.727 *** | 0.753 *** | 0.370 ** | 1.123 *** |

| (0.168) | (0.179) | (0.100) | (0.252) | (0.227) | (0.242) | (0.154) | (0.355) | |

| N | 300 | 180 | ||||||

| Variables | Direct Effect | Indirect Effect | Total Effect |

|---|---|---|---|

| GIA | 0.094 *** | 1.116 *** | 1.209 *** |

| (0.027) | (0.343) | (0.352) | |

| Agdp | 3.548 *** | 1.439 | 4.987 *** |

| (0.545) | (1.365) | (1.563) | |

| URB | 0.894 *** | 0.348 | 1.242 *** |

| (0.271) | (0.341) | (0.481) | |

| OP | −2.434 *** | −0.976 | −3.411 *** |

| (0.376) | (0.920) | (1.032) | |

| ER | 0.176 ** | 0.076 | 0.252 * |

| (0.090) | (0.104) | (0.168) | |

| IND | −1.766 *** | −0.759 | −2.525 * |

| (0.712) | (0.843) | (1.329) | |

| PDE | 0.961 *** | 0.379 | 1.340 *** |

| (0.150) | (0.358) | (0.389) |

| Variables | IV1: First-Stage GIA | IV1: Second-Stage CP | IV2: First-Stage GIA | IV2: Second-Stage CP |

|---|---|---|---|---|

| IV1 (L.GIA) | 0.859 *** | |||

| (0.040) | ||||

| IV2 (Terrain Und) | 1.612 *** | |||

| (0.119) | ||||

| GIA | 0.169 *** | 0.177 *** | ||

| (0.020) | (0.023) | |||

| Constant | 0.94 * | −5.193 *** | 3.759 *** | −5.253 *** |

| (0.497) | (0.462) | (1.013) | (0.412) | |

| Kleibergen-Paap rk LM statistic | 48.33 *** | 48.329 *** | 63.47 *** | 63.466 *** |

| Kleibergen-Paap rk Wald F statistic | 472.15 | 472.154 | 184.89 | 184.894 |

| Control variables | Yes | Yes | Yes | Yes |

| Obs | 270 | 270 | 300 | 300 |

| Variable | CP | ||

|---|---|---|---|

| High Green Productivity | Medium Green Productivity | Low Green Productivity | |

| GIA | −0.255 *** | 0.382 *** | 0.049 ** |

| (0.070) | (0.099) | (0.022) | |

| Agdp | 2.114 *** | 5.348 *** | 1.476 *** |

| (0.494) | (0.987) | (0.406) | |

| URB | −0.266 | −2.251 ** | 0.883 *** |

| (0.358) | (0.955) | (0.264) | |

| OP | −0.094 | −7.593 *** | −4.118 *** |

| (0.310) | (1.336) | (0.593) | |

| ER | −0.273 ** | 0.290 | 0.125 |

| (0.139) | (0.226) | (0.091) | |

| IND | −2.800 *** | 7.710 *** | −1.732 ** |

| (0.139) | (1.971) | (0.840) | |

| PDE | −1.961 *** | 2.521 *** | 0.472 *** |

| (0.341) | (0.483) | (0.183) | |

| _cons | 9.883 ** | −3.840 *** | −2.969 *** |

| (1.730) | (1.306) | (0.734) | |

| R2 | 0.4708 | 0.4402 | 0.5093 |

| N | 100 | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, J.; Li, Y.; Li, X. Spatial Spillover Effect of Green Industrial Agglomeration on Carbon Productivity. Sustainability 2025, 17, 9175. https://doi.org/10.3390/su17209175

Dai J, Li Y, Li X. Spatial Spillover Effect of Green Industrial Agglomeration on Carbon Productivity. Sustainability. 2025; 17(20):9175. https://doi.org/10.3390/su17209175

Chicago/Turabian StyleDai, Jianglai, Yingying Li, and Xuetao Li. 2025. "Spatial Spillover Effect of Green Industrial Agglomeration on Carbon Productivity" Sustainability 17, no. 20: 9175. https://doi.org/10.3390/su17209175

APA StyleDai, J., Li, Y., & Li, X. (2025). Spatial Spillover Effect of Green Industrial Agglomeration on Carbon Productivity. Sustainability, 17(20), 9175. https://doi.org/10.3390/su17209175