Characteristics and Material Flows of Non-Packaging Plastics in Municipal Solid Waste: A Case Study from Vienna

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Flows of NPW in Vienna

2.1.1. Scope

2.1.2. Material Flow Analysis of NPW

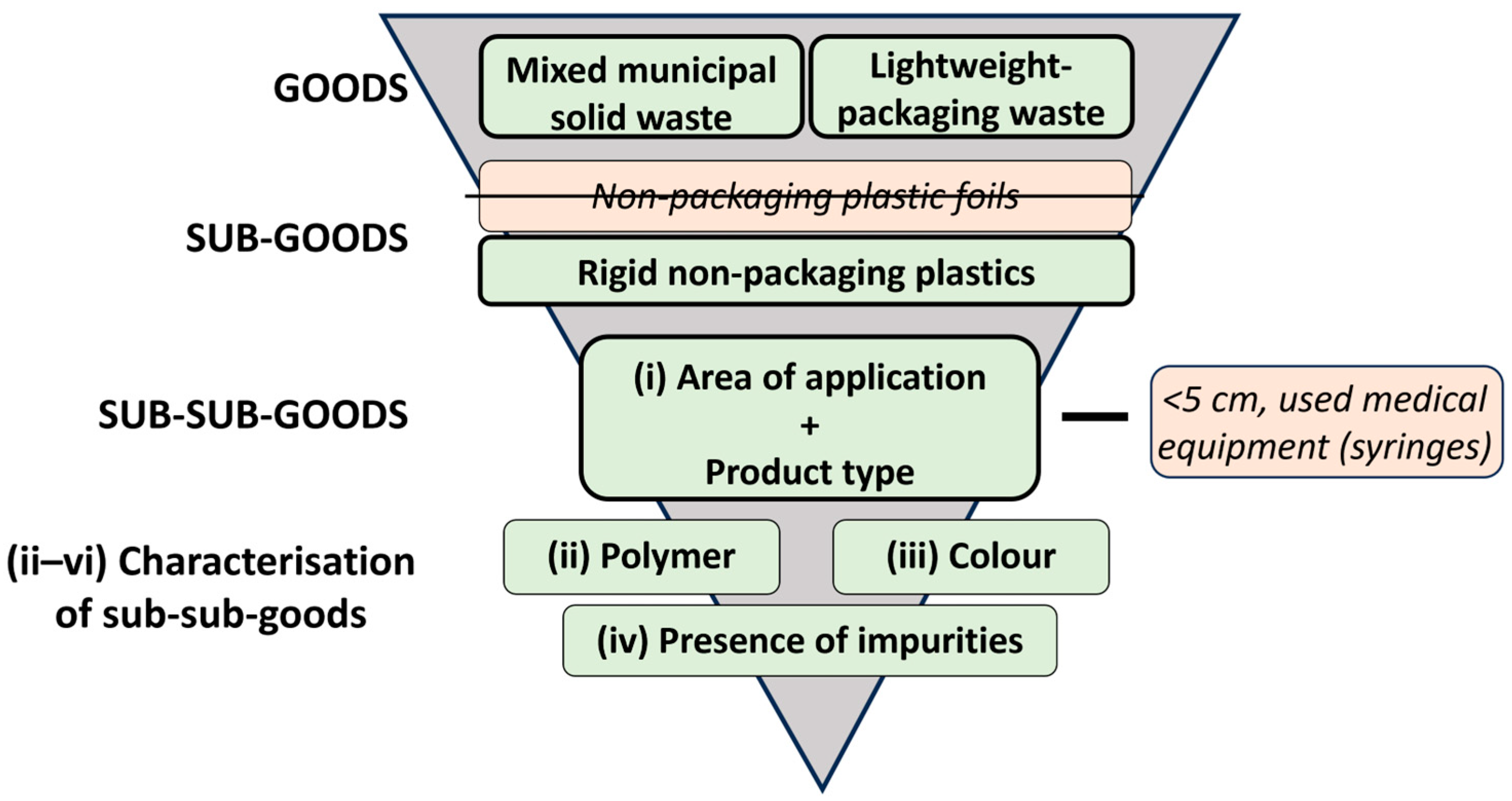

2.2. Sampling and Characterisation of NPW

2.2.1. Waste Sampling and Pre-Sorting

2.2.2. Conducted Characterisation of NPW

2.2.3. Presentation of Results

3. Results and Discussion

3.1. Material Flows of Goods and Subgoods

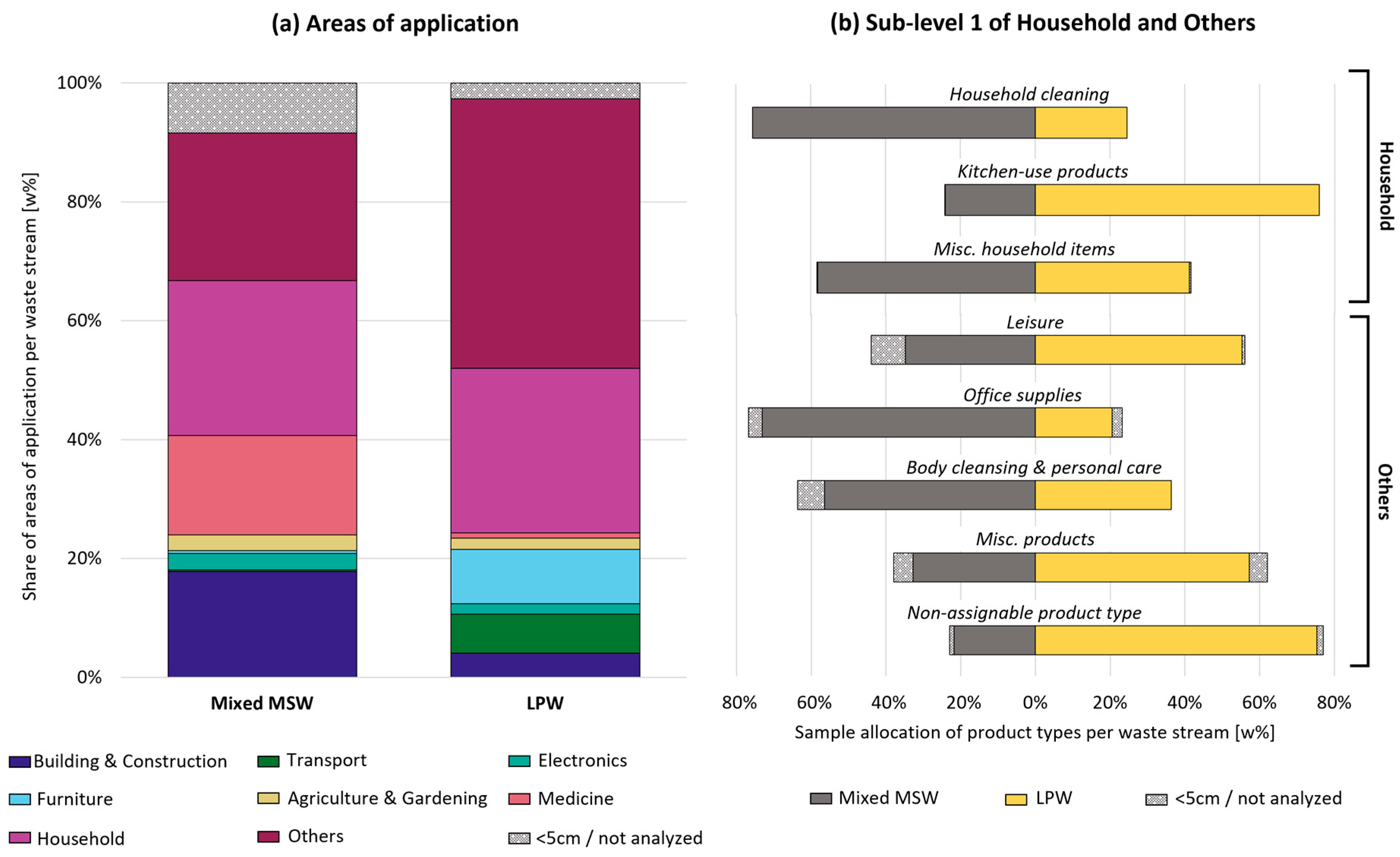

3.2. Areas of Application and Product Types of NPW in Vienna

3.3. Polymer Composition and Material Flows of NPW in Vienna

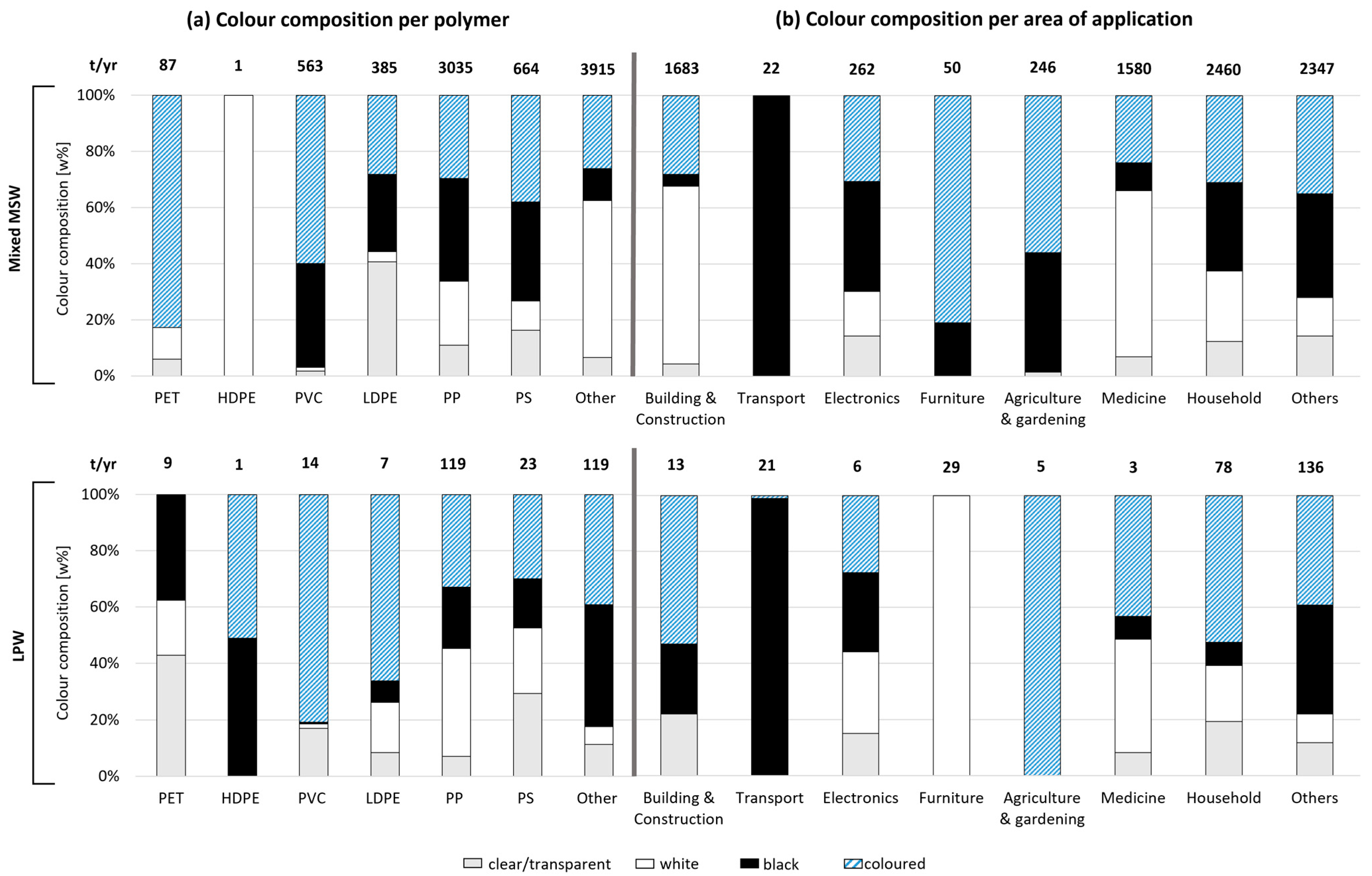

3.4. Colouring and Presence of Impurities in NPW in Vienna

3.5. Research Gaps of NPW and Design for Recycling Recommendations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile butadiene styrene |

| ARA | Altstoff Recycling Austria |

| EPR | Extended producer responsibility |

| FTIR | Fourier-transform infrared spectroscopy |

| HDPE | High-density polyethylene |

| LDPE | Low-density polythethylene |

| LPW | Lightweight packaging waste |

| MA 48 | Magistratsabteilung 48 |

| MFA | Material flow analysis |

| Mixed MSW | Mixed municipal solid waste |

| NIR | Near Infrared |

| NPW | Non-packaging plastic waste |

| PC | Polycarbonate |

| PE | Polyethylene |

| PET | Polyethylene terephtalate |

| PPW | Plastic packaging waste |

| PP | Polypropylene |

| PS | Polystyrene |

| PVC | Polyvinyl chloride |

| RDF | Refuse derived fuel |

| RIC | Resin Identification Code |

| RQ | Research question |

Appendix A

| Area of Application | 1. Building and Construction | 2. Transport | 3. Electronics | 4. Furniture | 5. Agriculture and Gardening | 6. Medicine | 7. Household | 8. Others | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polymer | Waste stream | w% | t/yr | w% | t/yr | w% | t/yr | w% | t/yr | w% | t/yr | w% | t/yr | w% | t/yr | w% | t/yr |

| PET | Mixed MSW | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 79.3% | 69.4 | 0% | 0 | 3.4% | 3 | 17.2% | 15.1 |

| LPW | 0% | 0 | 0% | 0 | 12.9% | 1.1 | 0% | 0 | 0% | 0 | 0% | 0 | 64.1% | 5.7 | 23% | 2 | |

| HDPE | Mixed MSW | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 100% | 1 |

| LPW | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 51.1% | 0.4 | 48.9% | 0.4 | |

| PVC | Mixed MSW | 56.4% | 317.4 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 43.6% | 245.2 |

| LPW | 15.1% | 2.1 | 0% | 0 | 0% | 0 | 0% | 0 | 1% | 0.1 | 0% | 0 | 1.3% | 0.2 | 82.5% | 11.6 | |

| LDPE | Mixed MSW | 5.6% | 21.6 | 0% | 0 | 0% | 0 | 0% | 0 | 21.6% | 83.1 | 3.2% | 12.4 | 0% | 0 | 69.6% | 267.7 |

| LPW | 10.4% | 0.7 | 0% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 0.3% | 0 | 55.5% | 3.9 | 33.8% | 2.4 | |

| PP | Mixed MSW | 12.9% | 392.3 | 0% | 0 | 0.1% | 1.8 | 1.7% | 50.2 | 3.1% | 93.5 | 0% | 0 | 55.6% | 1686.3 | 26.7% | 811.3 |

| LPW | 0.2% | 0.3 | 2.2% | 2.7 | 0.3% | 0.3 | 24.% | 29.4 | 1% | 1.2 | 0% | 0 | 39.1% | 46.5 | 32.4% | 38.4 | |

| PS | Mixed MSW | 13.9% | 92.6 | 0% | 0 | 2% | 13.1 | 0% | 0 | 0% | 0 | 0% | 0 | 8.7% | 57.7 | 75.4% | 500.6 |

| LPW | 0% | 0 | 2.2% | 0.5 | 0.1% | 0 | 0% | 0 | 0% | 0 | 0% | 0 | 28.6% | 6.5 | 69.1% | 15.7 | |

| Other | Mixed MSW | 21.9% | 858.8 | 0.6% | 22.4 | 6.3% | 247.1 | 0% | 0 | 0% | 0 | 40% | 1567.4 | 18.2% | 713.1 | 12.9% | 506.3 |

| LPW | 8% | 9.5 | 15.3% | 18.1 | 3.5% | 4.1 | 0% | 0 | 3.1% | 3.7 | 2.4% | 2.8 | 12.6% | 14.9 | 55.2% | 65.6 | |

| Sum per area in t/yr | Mixed MSW | 1682.7 | 22.4 | 262 | 50.2 | 246 | 1579.8 | 2460.1 | 2347.1 | ||||||||

| LPW | 12.7 | 21.3 | 5.6 | 29.4 | 5 | 2.9 | 78.1 | 136.1 | |||||||||

| Polymer | Waste Stream | Colour Composition | |||

|---|---|---|---|---|---|

| Clear/Transparent | White | Black | Coloured | ||

| PET | Mixed MSW | 6% | 11.2% | - | 82.8% |

| LPW | 42.9% | 19.5% | 37.4% | 0.2% | |

| HDPE | Mixed MSW | - | 100% | - | - |

| LPW | - | - | 48.9% | 51.1% | |

| PVC | Mixed MSW | 1.7% | 1.3% | 36.9% | 60% |

| LPW | 17% | 1.6% | 0.6% | 80.8% | |

| LDPE | Mixed MSW | 40.6% | 3.6% | 27.6% | 28.2% |

| LPW | 8.4% | 17.8% | 7.7% | 66.1% | |

| PP | Mixed MSW | 10.9% | 22.8% | 36.7% | 29.6% |

| LPW | 7% | 38.3% | 21.6% | 33.1% | |

| PS | Mixed MSW | 16.2% | 10.5% | 35.2% | 38% |

| LPW | 29.4% | 23.2% | 17.4% | 30% | |

| Other | Mixed MSW | 6.5% | 55.9% | 11.5% | 26.1% |

| LPW | 11.3% | 6.4% | 43.2% | 39.2% | |

| Area of Application | Waste Stream | Colour Composition | |||

|---|---|---|---|---|---|

| Clear/Transparent | White | Black | Coloured | ||

| 1. Building and Construction | Mixed MSW | 4.3% | 63.4% | 4.3% | 28% |

| LPW | 22% | - | 24.9% | 53.1% | |

| 2. Transport | Mixed MSW | - | - | 100% | - |

| LPW | - | - | 99% | 1% | |

| 3. Electronics | Mixed MSW | 14.3% | 15.9% | 39.2% | 30.6% |

| LPW | 15.1% | 29.1% | 28.2% | 27.6% | |

| 4. Furniture | Mixed MSW | - | - | 19% | 81% |

| LPW | - | 100% | - | - | |

| 5. Agriculture and Gardening | Mixed MSW | 1.5% | - | 42.5% | 56% |

| LPW | - | - | - | 100% | |

| 6. Medicine | Mixed MSW | 6.9% | 59.2% | 10% | 23.9% |

| LPW | 8.3% | 40.3% | 8.2% | 43.2% | |

| 7. Household | Mixed MSW | 12.4% | 25.1% | 31.5% | 31% |

| LPW | 19.4% | 19.9% | 8.2% | 52.5% | |

| 8. Other | Mixed MSW | 14.4% | 13.6% | 37% | 35% |

| LPW | 11.9% | 10.2% | 38.7% | 39.2% | |

| Polymer | Waste Stream | Presence of Impurities | |||

|---|---|---|---|---|---|

| Single-Polymer | Single-Polymer + Metals | Multi-Polymer | Multi-Polymer + Metals | ||

| PET | Mixed MSW | 81.2% | 12.9% | 6% | - |

| LPW | 48.6% | - | 35.9% | 15.6% | |

| HDPE | Mixed MSW | 100% | - | - | - |

| LPW | 48.9% | - | 51.1% | - | |

| PVC | Mixed MSW | 9% | - | 89.3% | 1.7% |

| LPW | 79.2% | 2.6% | 11.9% | 6.3% | |

| LDPE | Mixed MSW | 90.1% | - | 8% | 1.9% |

| LPW | 90.6% | - | 9.4% | - | |

| PP | Mixed MSW | 41.7% | 28.7% | 28.6% | 1.1% |

| LPW | 79.2% | 4.7% | 15.3% | 0.8% | |

| PS | Mixed MSW | 70.2% | 2.6% | 18.3% | 8.9% |

| LPW | 55.6% | 19.3% | 23.5% | 1.6% | |

| Other | Mixed MSW | 65.7% | 2.3% | 31.1% | 0.9% |

| LPW | 58.2% | 9% | 21.7% | 11.1% | |

References

- Dokl, M.; Copot, A.; Krajnc, D.; van Fan, Y.; Vujanović, A.; Aviso, K.B.; Tan, R.R.; Kravanja, Z.; Čuček, L. Global projections of plastic use, end-of-life fate and potential changes in consumption, reduction, recycling and replacement with bioplastics to 2050. Sustain. Prod. Consum. 2024, 51, 498–518. [Google Scholar] [CrossRef]

- OECD. Global Plastics Outlook: Policy Scenarios to 2060: Policy Highlights; OECD Publishing: Paris, France, 2022; Available online: https://www.oecd-ilibrary.org/sites/aa1edf33-en/1/2/1/index.html?itemId=/content/publication/aa1edf33-en&_csp_=ca738cf5d4f327be3b6fec4af9ce5d12&itemIGO=oecd&itemContentType=book (accessed on 16 September 2025).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Beaumont, N.J.; Aanesen, M.; Austen, M.C.; Börger, T.; Clark, J.R.; Cole, M.; Hooper, T.; Lindeque, P.K.; Pascoe, C.; Wyles, K.J. Global ecological, social and economic impacts of marine plastic. Mar. Pollut. Bull. 2019, 142, 189–195. [Google Scholar] [CrossRef] [PubMed]

- Landrigan, P.J.; Stegeman, J.J.; Fleming, L.E.; Allemand, D.; Anderson, D.M.; Backer, L.C.; Brucker-Davis, F.; Chevalier, N.; Corra, L.; Czerucka, D.; et al. Human Health and Ocean Pollution. Ann. Glob. Health 2020, 86, 151. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E. Chapter 31—Plastic recycling. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists, 2nd ed.; Meskers, C., Worrell, E., Reuter, M.A., Eds.; Elsevier: Utrecht, The Netherlands, 2024; pp. 497–510. ISBN 978-0-323-85514-3. [Google Scholar]

- Plastics Europe. Plastics—The Fast Facts 2023. 2023. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2023/ (accessed on 24 January 2025).

- Klevnäs, P.; Peter, F. Europe’s Missing Plastics: Taking Stock of EU Plastics Circularity. 2021. Available online: https://www.agora-industry.org/fileadmin/Partnerpublikationen/2021/Material_Economics_Europes_Missing_Plastics/Material_Economics_Europes_Missing_Plastics.pdf (accessed on 6 October 2025).

- Castell-Rüdenhausen, M.Z.; Almasi, A.; Vanderreydt, I. Non-Packaging Plastics in Europe; ETC-CE Report 2022/7. 2022. Available online: https://www.eionet.europa.eu/etcs/etc-ce/products/etc-ce-products/etc-ce-report-2022-7-non-packaging-plastics-in-europe/@@download/file/ETC%20Report_NPP_CLEAN.pdf (accessed on 8 January 2025).

- Haarman, A.; Magalini, F.; Courtois, J. Study-on-the-Impact-of-Brominated-Flame-Retardants-BFRs-on-WEEE-Plastics-Recycling-by-Sofies-Nov-2020-1. 2020. Available online: https://www.bsef.com/wp-content/uploads/2020/11/Study-on-the-impact-of-Brominated-Flame-Retardants-BFRs-on-WEEE-plastics-recycling-by-Sofies-Nov-2020-1.pdf (accessed on 17 April 2024).

- Plastics Europe. Plastics—The Facts 2021. 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 20 March 2024).

- Plastics Europe. The Circular Economy for Plastics: A European Analysis. 2024. Available online: https://plasticseurope.org/wp-content/uploads/2024/05/Circular_Economy_report_Digital_light_FINAL.pdf (accessed on 24 January 2025).

- Larson, E.R. 4—An Overview of Thermoplastic Materials. In Thermoplastic Material Selection: A Practical Guide; William Andrew: Norwich, UK, 2015; pp. 97–143. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A European Strategy for Plastics in a Circular Economy: COM(2018) 28 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- EC. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A New Circular Economy Action Plan for a Cleaner and More Competitive Europe: COM(2020) 98 Final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Union. Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC: Packaging and Packaging Waste Regulation (PPWR); European Union: Brussels, Belgium, 2024. [Google Scholar]

- European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment: SUP Directive; European Union: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Directive 2008/98/EC of The European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives: Waste Framework Directive; European Union: Brussels, Belgium, 2008. [Google Scholar]

- EC. End-of-Life Vehicles: EU Rules to Make the Automotive Sector Circular, to Maximize the Efficient Use of Resources and to Protect the Environment. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/end-life-vehicles_en (accessed on 16 April 2024).

- European Commission. Regulation (EU) 2024/3110 of the European Parliament and of the Council of 27 November 2024 Laying Down Harmonised Rules for the Marketing of Construction Products and Repealing Regulation (EU) No 305/2011: Construction Products Regulation; European Union: Brussels, Belgium, 2024. [Google Scholar]

- EP. Legislative Train 12.2024 1 A European Green Deal: Circular Electronics Initiative—Q4 2021. 2024. Available online: https://www.europarl.europa.eu/legislative-train/carriage/circular-electronics/report?sid=8701 (accessed on 29 January 2025).

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Gürlich, U.; Kladnik, V.; Pavlovic, K. Circular Packaging Design Guideline: Empfehlung für Recyclinggerechte Verpackung. 2022. Available online: https://digital.obvsg.at/obvfcwacc/download/pdf/8086818?originalFilename=true (accessed on 14 July 2024).

- Neubauer, C.; Stoifl, B.; Tesar, M.; Thaler, P. Sortierung und Recycling von Kunststoffabfällen in Österreich: Status 2019; Report/Umweltbundesamt REP-0744; Medieninhaber und Herausgeber: Vienna, Austria, 2021. [Google Scholar]

- Eriksen, M.K.; Damgaard, A.; Boldrin, A.; Astrup, T.F. Quality Assessment and Circularity Potential of Recovery Systems for Household Plastic Waste. J. Ind. Ecol. 2019, 23, 156–168. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Turner, A. Black plastics: Linear and circular economies, hazardous additives and marine pollution. Environ. Int. 2018, 117, 308–318. [Google Scholar] [CrossRef]

- BPF. A Summary of Recyclability by Design 2024: Core Principles for Plastic Packaging Recyclability. 2024. Available online: https://www.bpf.co.uk/design/recyclability-by-design.aspx (accessed on 8 January 2025).

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Turner, A.; Filella, M. Bromine in plastic consumer products—Evidence for the widespread recycling of electronic waste. Sci. Total Environ. 2017, 601–602, 374–379. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Astrup, T.F. Characterisation of source-separated, rigid plastic waste and evaluation of recycling initiatives: Effects of product design and source-separation system. Waste Manag. 2019, 87, 161–172. [Google Scholar] [CrossRef]

- Blasenbauer, D.; Lipp, A.-M.; Fellner, J.; Tischberger-Aldrian, A.; Stipanović, H.; Lederer, J. Recovery of plastic packaging from mixed municipal solid waste. A case study from Austria. Waste Manag. 2024, 180, 9–22. [Google Scholar] [CrossRef]

- EEA. Managing Non-Packaging Plastics in European Waste Streams: The Missing Part of the Plastic Puzzle. Available online: https://www.eea.europa.eu/publications/managing-non-packaging-plastics (accessed on 13 July 2023).

- Amadei, A.M.; Rigamonti, L.; Sala, S. Exploring the EU plastic value chain: A material flow analysis. Resour. Conserv. Recycl. 2023, 197, 107105. [Google Scholar] [CrossRef]

- Hsu, W.-T.; Domenech, T.; Mcdowall, W. How circular are plastics in the EU?: MFA of plastics in the EU and pathways to circularity. Clean. Environ. Syst. 2021, 2, 100004. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Pivnenko, K.; Faraca, G.; Boldrin, A.; Astrup, T.F. Dynamic Material Flow Analysis of PET, PE, and PP Flows in Europe: Evaluation of the Potential for Circular Economy. Environ. Sci. Technol. 2020, 54, 16166–16175. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the loop for PET, PE and PP waste from households: Influence of material properties and product design for plastic recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef]

- Jacobsen, R.; Willeghems, G.; Gellynck, X.; Buysse, J. Increasing the quantity of separated post-consumer plastics for reducing combustible household waste: The case of rigid plastics in Flanders. Waste Manag. 2018, 78, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Van Eygen, E.; Feketitsch, J.; Laner, D.; Rechberger, H.; Fellner, J. Comprehensive analysis and quantification of national plastic flows: The case of Austria. Resour. Conserv. Recycl. 2017, 117, 183–194. [Google Scholar] [CrossRef]

- Eurostat. Recycling Rate of Municipal Waste. 2023. Available online: https://ec.europa.eu/eurostat/databrowser/view/sdg_11_60/default/table (accessed on 8 January 2025).

- Gritsch, L.; Lederer, J. A historical-technical analysis of packaging waste flows in Vienna. Resour. Conserv. Recycl. 2023, 194, 106975. [Google Scholar] [CrossRef]

- Statistik Austria. Bevölkerung zu Jahres-/Quartalsanfang. Available online: https://www.statistik.at/statistiken/bevoelkerung-und-soziales/bevoelkerung/bevoelkerungsstand/bevoelkerung-zu-jahres-/-quartalsanfang (accessed on 15 February 2025).

- BMK. Bundes-Abfallwirtschaftsplan 2023: Teil 1; Medieninhaber Verleger und Herausgeber: Vienna, Austria, 2023; Available online: https://www.bmluk.gv.at/service/publikationen/klima-und-umwelt/bundes-abfallwirtschaftsplan-2023-teil-1.html (accessed on 16 September 2025).

- Faraca, G.; Martinez-Sanchez, V.; Astrup, T.F. Environmental life cycle cost assessment: Recycling of hard plastic waste collected at Danish recycling centres. Resour. Conserv. Recycl. 2019, 143, 299–309. [Google Scholar] [CrossRef]

- Esguerra, J.L.; Carlsson, A.; Johansson, J.; Anderberg, S. Characterization, recyclability, and significance of plastic packaging in mixed municipal solid waste for achieving recycling targets in a Swedish city. J. Clean. Prod. 2024, 468, 143014. [Google Scholar] [CrossRef]

- Rainer, R.; Blasenbauer, D.; Gritsch, L.; Lipp, A.M.; Lederer, J. Charakterisierung von Kunststofffolien in ausgewählten Abfallströmen. In Proceedings of the 12 Wissenschaftskongress Abfall- und Ressourcenwirtschaft, Hamburg, Germany, 9–10 March 2023; Bockreis, A., Faulstich, M., Flamme, S., Kranert, M., Mocker, M., Nelles, M., Quicker, P., Rettenberger, G., Rotter, V.S., Eds.; Innsbruck University Press: Innsbruck, Austria, 2023; pp. 319–323. [Google Scholar]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management—A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef]

- Hou, P.; Xu, Y.; Taiebat, M.; Lastoskie, C.; Miller, S.A.; Xu, M. Life cycle assessment of end-of-life treatments for plastic film waste. J. Clean. Prod. 2018, 201, 1052–1060. [Google Scholar] [CrossRef]

- Bundesgesetz Über Eine Nachhaltige Abfallwirtschaft (Abfallwirtschaftsgesetz 2002—AWG 2002). Available online: https://erp-recycling.org/de-at/wp-content/uploads/sites/5/2017/11/Abfallwirtschaftsgesetz-2002-i.d.F.-2013.pdf (accessed on 8 January 2025).

- Stadt Wien. Jahresbericht 2019; European Asylum Support Office: Valletta, Malta, 2020. [Google Scholar]

- MA 48 (Magistratsabteilung 48, Vienna, Austria). Personal communication, 2024.

- Stadt Wien. Restmüll—Abfallberatung. Available online: https://abfallberatung.wien.gv.at/restmuell/ (accessed on 8 April 2024).

- Brunner, P.H.; Rechberger, H. Handbook of Material Flow Analysis: For Environmental, Resource, and Waste Engineers; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9781315313443. [Google Scholar]

- TA Sortieranalysen. Leitfaden für die Durchführung von Restmüll-Sortieranalysen; Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie (BMK): Vienna, Austria, 2021; Available online: https://boku.ac.at/fileadmin/data/H03000/H81000/H81300/upload-files/Forschung/Leitfaden_Restmuell-Sortieranalysen_Adaptierung_Okt.2021_1.pdf (accessed on 8 January 2025).

- 13.030.10 (ÖNORM S 2097); Sortieranalyse von Abfällen. Austrian Standards International: Vienna, Austria, 2005. Available online: https://www.austrian-standards.at/de/shop/onorm-s-2097-2-2005-04-01~p1464658 (accessed on 3 December 2024).

- EC. Development of a Methodological Tool to Enhance the Precision & Comparability of Solid Waste Analysis Data (S.W.A.—TOOL). Available online: https://cordis.europa.eu/project/id/EVK4-CT-2000-00030/results (accessed on 3 December 2024).

- Gritsch, L.; Breslmayer, G.; Lederer, J. Quantity and quality of paper-based packaging in mixed MSW and separate paper collection—A case study from Vienna, Austria. Resour. Conserv. Recycl. 2025, 215, 108091. [Google Scholar] [CrossRef]

- Verordnung des Bundesministers für Land- und Forstwirtschaft, Umwelt und Wasserwirtschaft über die Vermeidung und Verwertung von Verpackungsabfällen und bestimmten Warenresten (Verpackungsverordnung 2014). 2024. Available online: https://www.ris.bka.gv.at/NormDokument.wxe?Abfrage=Bundesnormen&Gesetzesnummer=20008902&FassungVom=2024-03-07&Artikel=&Paragraf=0&Anlage=&Uebergangsrecht= (accessed on 8 January 2025).

- MA 48. Wiener Restmüll- und Altstoffanalysen 2022; Enbericht—V.01—24.04.2023; Stadt Wien: Korneuburg, Austria, 2023. [Google Scholar]

- Stadt Wien. Sammlung von Leichtverpackungen im “Gelben Sack”—Plastik-Verpackungen, Getränkekartons (Tetrapacks) und Dosen. Available online: https://www.wien.gv.at/umwelt/ma48/beratung/muelltrennung/plastikflaschen/gelbersack/index.html (accessed on 16 February 2025).

- Neubauer, C.; Stoifl, B.; Tesar, M.; Thaler, P. Sortierung und Recycling von Kunststoffabfällen in Österreich ANHANG: Status 2019; Report/Umweltbundesamt REP-0744; Umweltbundesamt GmbH: Vienna, Austria, 2021; Available online: https://www.umweltbundesamt.at/fileadmin/site/publikationen/rep0744_anhang.pdf (accessed on 2 April 2025).

- Galgani, F.; Hanke, G.; Werner, S.; Oosterbaan, L.; Nilsson, P.; Fleet, D.; Kinsey, S.; Thompson, R.C.; van Franeker, J.; Vlachogianni, T.; et al. Guidance on Monitoring of Marine Litter in European Seas; Publications Office of the European Union: Reims, Luxemburg, 2013; Available online: https://mcc.jrc.ec.europa.eu/documents/201702074014.pdf (accessed on 21 April 2024).

- MA 48. Wiener Altstoff- und Restmüllanalysen 2009; Endbericht vom 13 April 2010; Stadt Wien: Korneuburg, Austria, 2010. [Google Scholar]

- MA 48. Wiener Altstoff- und Restmüllanalysen 2015/16; Endbericht vom April 2016; Stadt Wien: Korneuburg, Austria, 2016. [Google Scholar]

- Gritsch, L.; Breslmayer, G.; Rainer, R.; Stipanovic, H.; Tischberger-Aldrian, A.; Lederer, J. Critical properties of plastic packaging waste for recycling: A case study on non-beverage plastic bottles in an urban MSW system in Austria. Waste Manag. 2024, 185, 10–24. [Google Scholar] [CrossRef]

- Nemat, B.; Razzaghi, M.; Bolton, K.; Rousta, K. The Potential of Food Packaging Attributes to Influence Consumers’ Decisions to Sort Waste. Sustainability 2020, 12, 2234. [Google Scholar] [CrossRef]

- van Velzen, T.; Brouwer, M.T.; Feil, A. Collection behaviour of lightweight packaging waste by individual households and implications for the analysis of collection schemes. Waste Manag. 2019, 89, 284–293. [Google Scholar] [CrossRef]

- Bünemann, A.; Rachut, G.; Christiani, J.; Langen, M.; Wolters, J. Planspiel zur Fortentwicklung der Verpackungsverordnung: Teilvorhaben 1: Bestimmung der Idealzusammensetzung der Wertstofftonne; Im Auftrag des Umweltbundesamtes: Dessau, Germany, 2011; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/461/publikationen/4074.pdf (accessed on 10 April 2024).

- Stadt Wien. Entwicklung der Umweltgerechten Kunststoffsammlung. Available online: https://www.wien.gv.at/umwelt/ma48/beratung/muelltrennung/plastikflaschen/entwicklung.html (accessed on 28 July 2024).

- Jesson, J.K.; Pocock, R.; Stone, I. Barriers to Recycling: A Review of Evidence Since 2008: Final Report. 2014. Available online: https://www.healthandsafetybookstore.co.uk/members/WRAP%20BarrierstoRecycling.pdf (accessed on 30 April 2025).

- Plastic Recyclers Europe. HDPE & PP Market in Europe. State of Play.: Production, Collection and Recycling Data; Plastics Recyclers Europe: Brussels, Belgium, 2020; Available online: https://www.plasticsrecyclers.eu/wp-content/uploads/2022/10/hdpe-pp-market-in-europe.pdf (accessed on 2 June 2025).

- EuRIC-European Recycling Industries’ Confederation. Plastic Recycling Factsheet; EuRIC: Brussels, Belgium, 2020. [Google Scholar]

- Lahl, U.; Zeschmar-Lahl, B. More than 30 Years of PVC Recycling in Europe—A Critical Inventory. Sustainability 2024, 16, 3854. [Google Scholar] [CrossRef]

- Pomberger, R. Entwicklung von Ersatzbrennstoff für das HOTDISC-Verfahren und Analyse der Abfallwirtschaftlichen Relevanz. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Austria, 2008. [Google Scholar]

- REGULATION (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC: EC 1935/2004. 2004. Available online: https://www.legislation.gov.uk/eur/2004/1935 (accessed on 8 January 2025).

- Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mengelers, M.; Mortensen, A.; et al. Scientific Guidance on the criteria for the evaluation and on the preparation of applications for the safety assessment of post-consumer mechanical PET recycling processes intended to be used for manufacture of materials and articles in contact with food. EFSA J. 2024, 22, e8879. [Google Scholar] [CrossRef]

- EFSA. Scientific Opinion on the safety assessment of the processes ‘Biffa Polymers’ and ‘CLRrHDPE’ used to recycle high-density polyethylene bottles for use as food contact material. EFSA J. 2015, 13, 4016. [Google Scholar] [CrossRef]

- Lubello, C.; Fiaschi, S.; Notari, G. Municipal solid waste composition and efficiency of separate collection: A case study in Italy. Clean. Waste Syst. 2025, 11, 100272. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef]

- Borealis. Polyolefin Packaging Design: 10 Codes of Conduct for Design for Recyclability. 2019. Available online: https://www.borealisgroup.com/storage/News/2019/2019-02-26/Polyolefin-Packaging-Design_10-codes-of-conduct_FINAL.pdf (accessed on 27 July 2024).

- Liu, M.; Brandsma, S.H.; Schreder, E. From e-waste to living space: Flame retardants contaminating household items add to concern about plastic recycling. Chemosphere 2024, 365, 143319. [Google Scholar] [CrossRef]

- Kuang, J.; Abdallah, M.A.-E.; Harrad, S. Brominated flame retardants in black plastic kitchen utensils: Concentrations and human exposure implications. Sci. Total Environ. 2018, 610–611, 1138–1146. [Google Scholar] [CrossRef]

- Lipp, A.-M.; Schlossnikl, J.; Gentgen, I.; Koch, T.; Archodoulaki, V.-M.; Lederer, J. Recycling rigid polypropylene from mixed waste: Does the origin affect mechanical recyclate quality? Waste Manag. Res. 2025, 43, 734242X251357137. [Google Scholar] [CrossRef]

- Agilent Technologies, s.a. Series 4300 Handheld FTIR Sepctrometer: Product Introduction. Available online: https://www.agilent.com/en/product/molecular-spectroscopy/ftir-spectroscopy/ftir-compact-portable-systems/4300-handheld-ftir (accessed on 7 March 2025).

- National Library of Medicine. Dioctyl Phthalate. 2025. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Dioctyl-phthalate (accessed on 7 March 2025).

| Polymer | References | Eriksen and Astrup [33] | Faraca and Astrup [31] * | Blasenbauer et al. [34] |

|---|---|---|---|---|

| Sampled Waste Stream | Separately Collected Plastic Waste from Households (Copenhagen) | Plastic Waste from Danish Recycling Centres | Plastic Outputs from Austrian Material Recovery Facilities | |

| PET | - | 3% | 1–2% | |

| PE | 11% | HDPE 22% | HDPE 19–30% | |

| LDPE 0.3% | LDPE 0–4% | |||

| PVC | - | 8% | 1–15% | |

| PP | 61% | 48% | 28–42% | |

| PS | - | 6% | 6–11% | |

| Other | 27% | 12% | 10–26% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Breslmayer, G.; Gritsch, L.; Lederer, J. Characteristics and Material Flows of Non-Packaging Plastics in Municipal Solid Waste: A Case Study from Vienna. Sustainability 2025, 17, 9105. https://doi.org/10.3390/su17209105

Breslmayer G, Gritsch L, Lederer J. Characteristics and Material Flows of Non-Packaging Plastics in Municipal Solid Waste: A Case Study from Vienna. Sustainability. 2025; 17(20):9105. https://doi.org/10.3390/su17209105

Chicago/Turabian StyleBreslmayer, Gisela, Lea Gritsch, and Jakob Lederer. 2025. "Characteristics and Material Flows of Non-Packaging Plastics in Municipal Solid Waste: A Case Study from Vienna" Sustainability 17, no. 20: 9105. https://doi.org/10.3390/su17209105

APA StyleBreslmayer, G., Gritsch, L., & Lederer, J. (2025). Characteristics and Material Flows of Non-Packaging Plastics in Municipal Solid Waste: A Case Study from Vienna. Sustainability, 17(20), 9105. https://doi.org/10.3390/su17209105