Enabling Circular Value Chains via Technology-Driven Scope 3 Cooperation

Abstract

1. Introduction

2. Literature Background

2.1. Sustainable Management of Global Supply Chains and Circular Economy

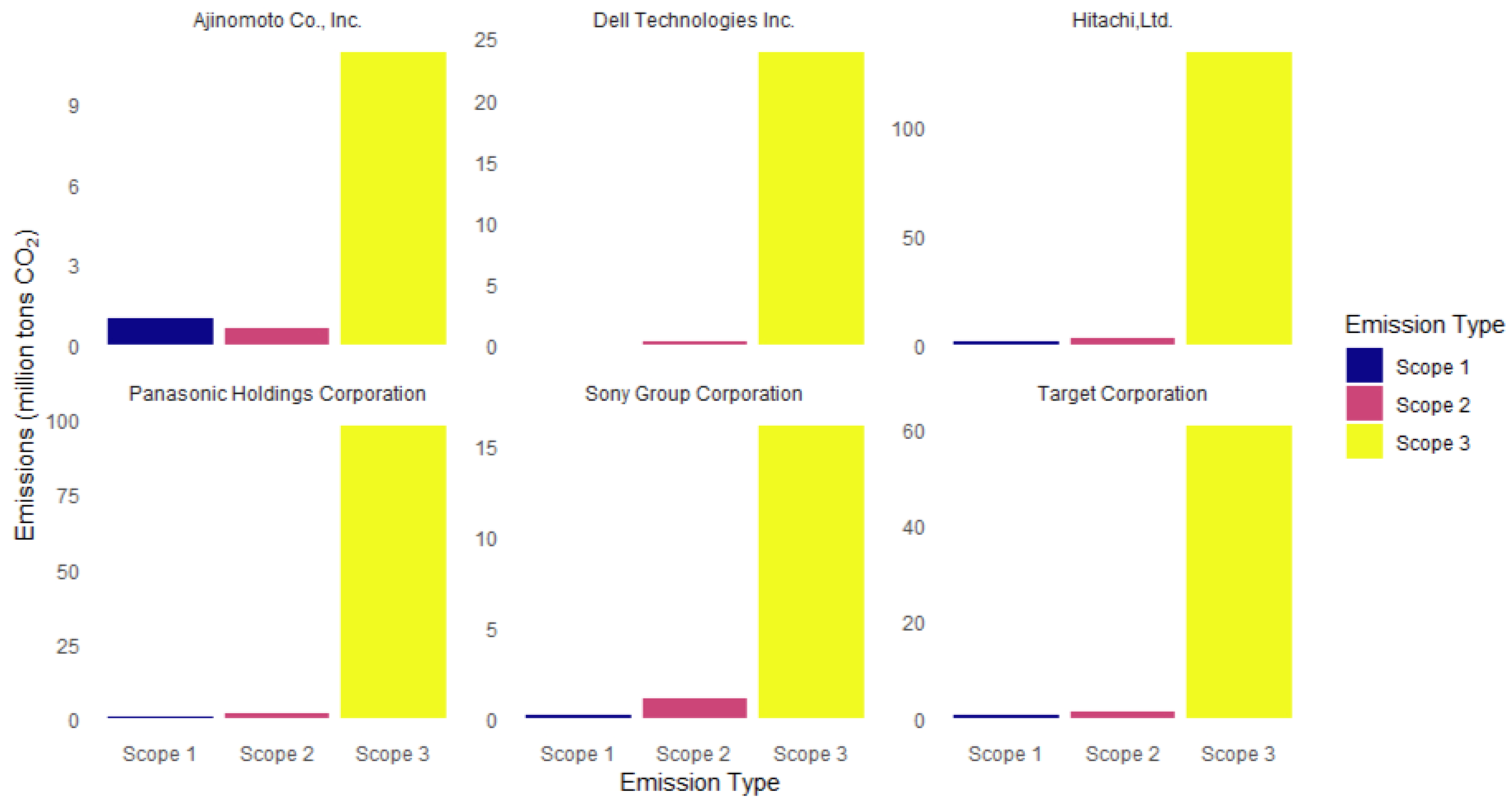

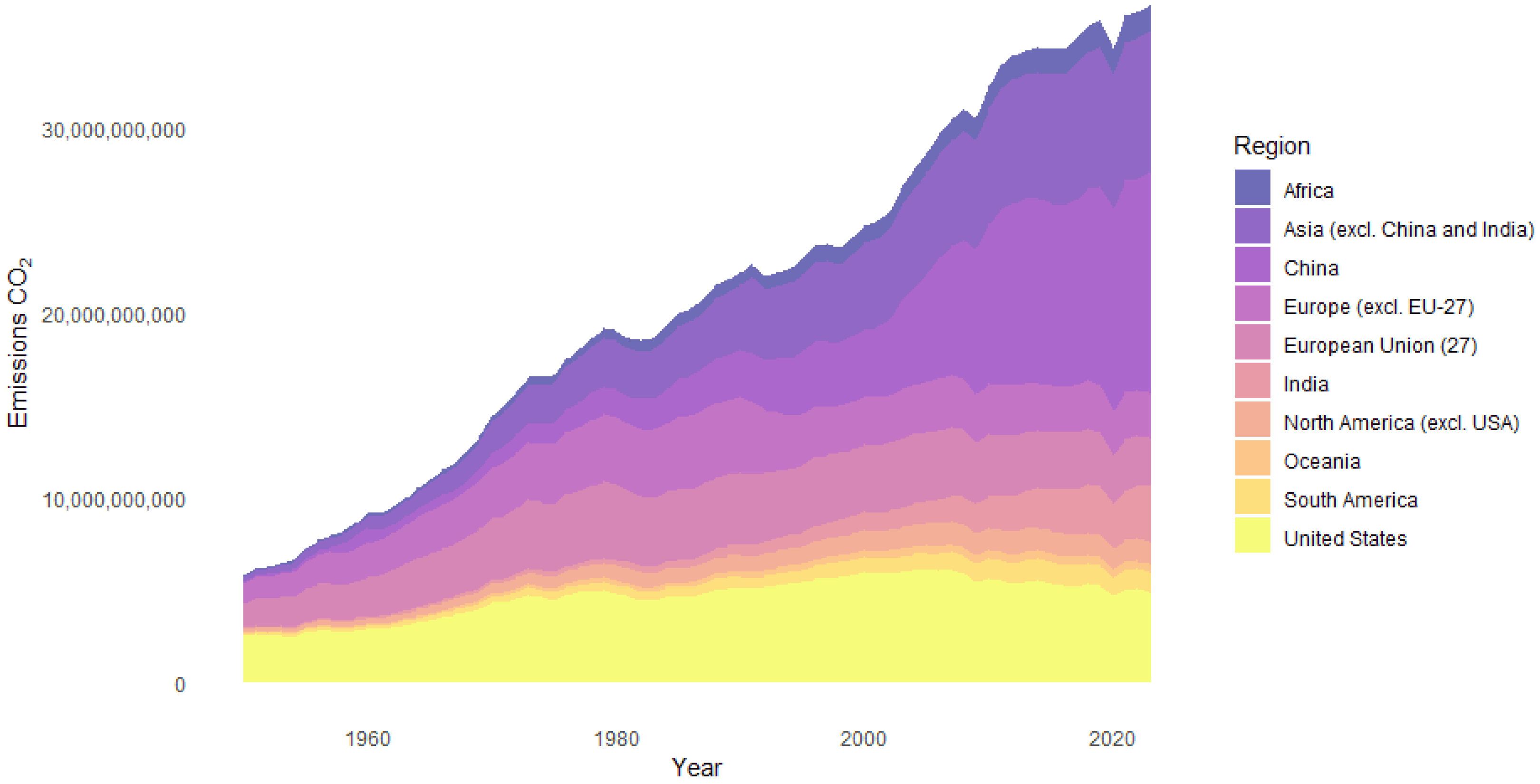

2.2. Circular Economy and Scope 3 Carbon Footprint

2.3. Advanced and Emerging Market Cross-Border Interactions for Circular Global Value and Supply Chains

- What are the existing and proposed types of collaborative SSCM efforts between the principal firm in an advanced economy and its emerging economy supplier?

- Through what technology-driven mechanisms can a collaboration-based SSCM of GSCs enhance CE initiatives, which are largely associated with minimizing environmental damage on a global level?

- How can technology-driven focal firm-emerging market supplier collaboration be effective in fostering long-term sustainability outcomes in the context of cutting down on global emission release?

3. Methodology

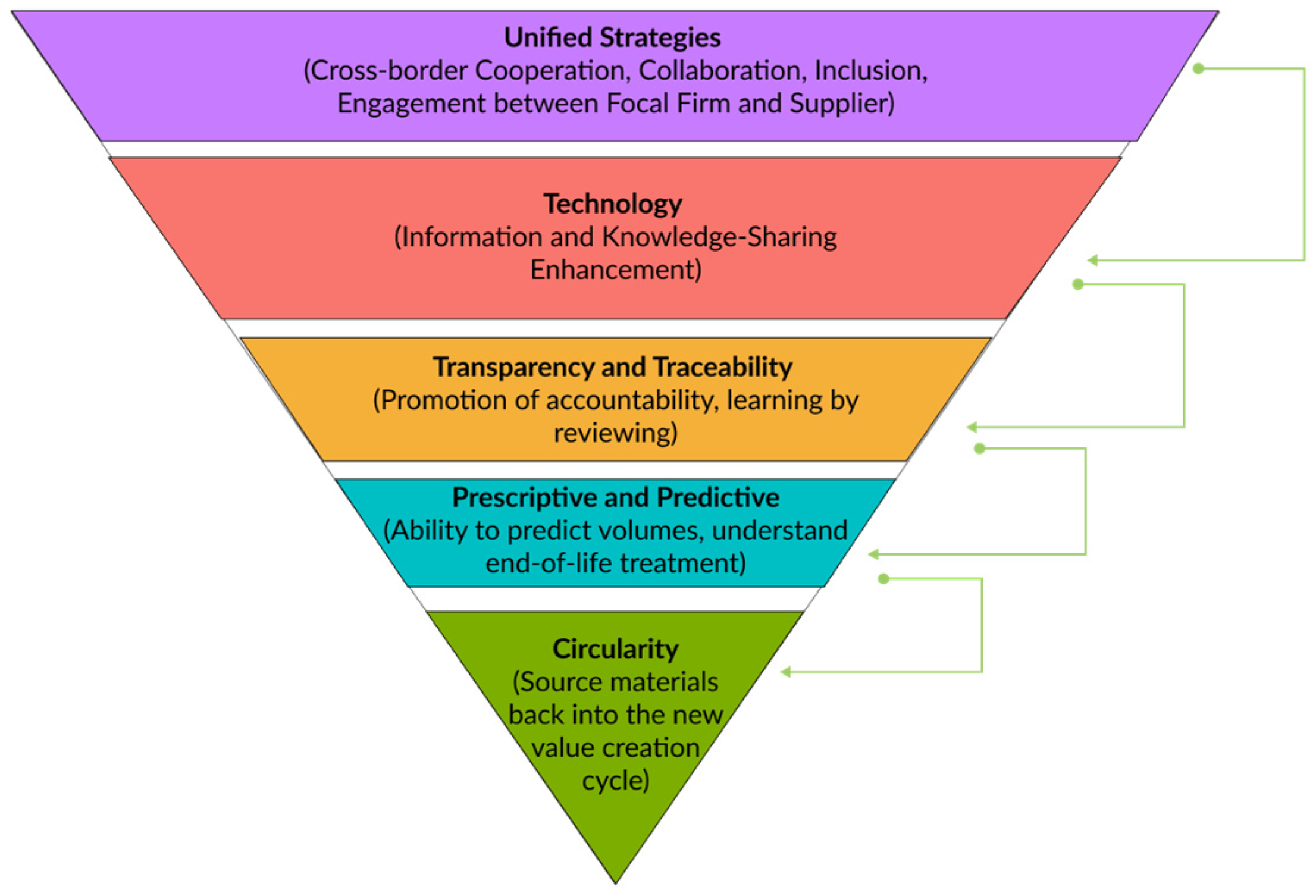

4. Theme-Based Analysis of Current Research and Industry Cases

4.1. Unified Strategies (Cooperation, Collaboration, Inclusion, and Engagement)

4.2. Technology-Driven Cooperation

4.3. Transparency and Traceability: Ensuring Error-Free Objective Information Flow

4.4. Prescriptive and Predictive Capabilities: Gaining Understanding and Improving Decision Making in Circular GVCs

5. Limitations and Future Research Opportunities

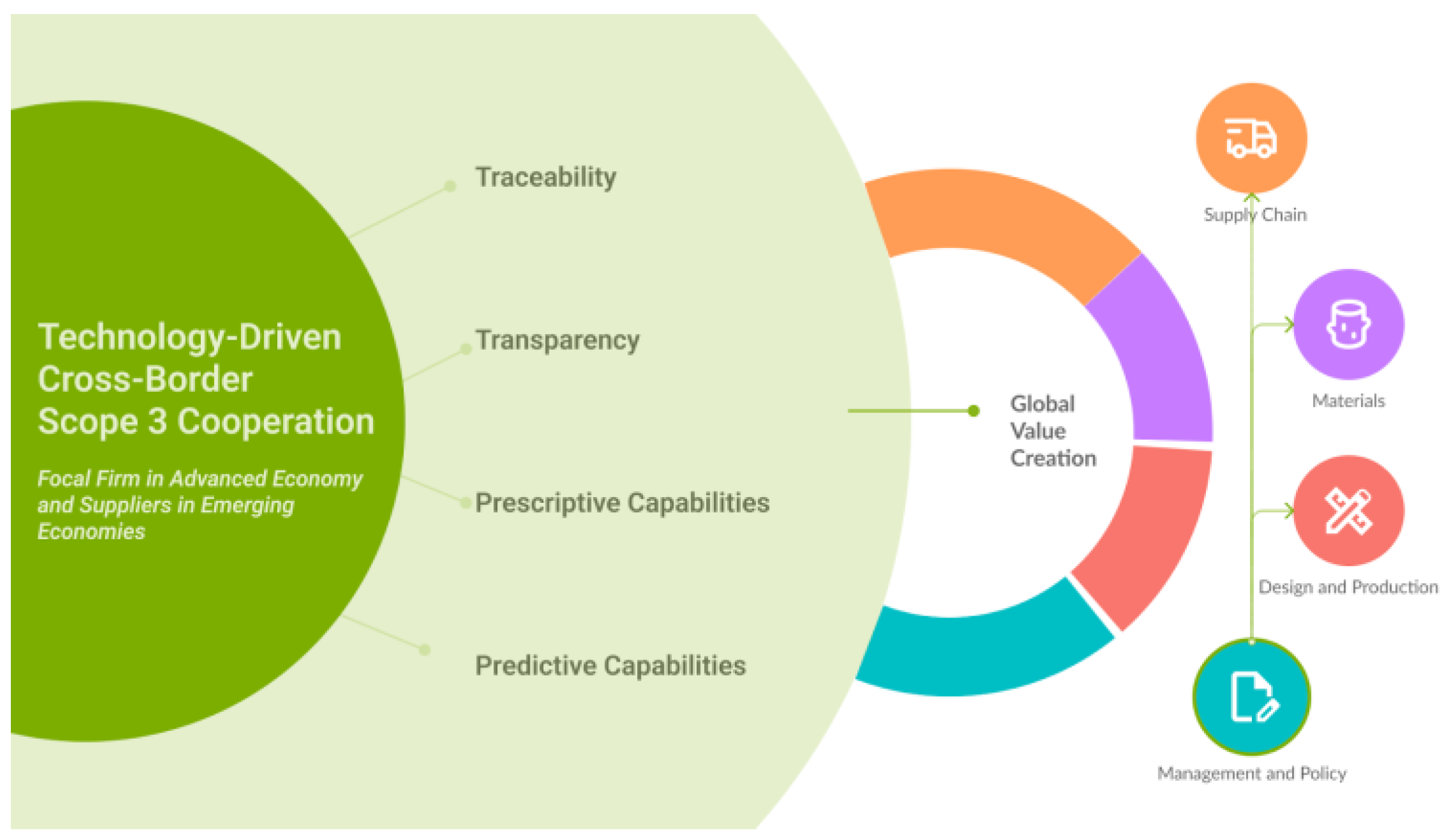

6. Discussion and Framework Extension

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GSC | Global Supply Chain |

| GVC | Global Value Chain |

| SSCM | Sustainable Supply Chain Management |

| CE | Circular Economy |

References

- World Bank. Gross Domestic Product. 2022. Available online: https://databankfiles.worldbank.org/public/ddpext_download/GDP.pdf (accessed on 2 February 2025).

- Watanabe, K.; Ashfaq, U. Which Scope 3 Emissions Will the SEC Deem ‘Material’? MSCI. 2022. Available online: https://www.msci.com/www/blog-posts/which-scope-3-emissions-will/03153333292 (accessed on 30 March 2025).

- NZDPU. Available online: https://nzdpu.com/data-explorer?sics_sector (accessed on 3 February 2025).

- United States Environmental Protection Agency. Scope 3 Inventory Guidance. Available online: https://www.epa.gov/climateleadership/scope-3-inventory-guidance (accessed on 3 February 2025).

- UN Global Impact. Scope 3 Emissions. Available online: https://www.unglobalcompact.org.uk/scope-3-emissions/ (accessed on 24 February 2025).

- Meng, B.; Liu, Y.; Gao, Y.; Li, M.; Wang, Z.; Xue, J.; Andrew, R.; Feng, K.; Qi, Y.; Sun, Y.; et al. Developing countries’ responsibilities for CO2 emissions in value chains are larger and growing faster than those of developed countries. One Earth 2023, 6, 167–181. [Google Scholar] [CrossRef]

- Rooper, H. Emissions Growth in the Developing World. Climate Leadership Council. 2024. Available online: https://clcouncil.org/blog/emissions-growth-in-the-developing-world (accessed on 14 March 2025).

- Mehling, M.; Pirlot, A.; Pradhan, P.; Aisbett, E.; Böhringer, C.; Asane-Otoo, E.; Schneider, J.; Guan, D.; Simas, M.; Wiebe, K.; et al. Close the carbon loophole. One Earth 2021, 4, 587–590. [Google Scholar] [CrossRef]

- Our World in Data. Annual CO2 Emissions by World Region. 2024. Available online: https://ourworldindata.org/grapher/annual-co-emissions-by-region (accessed on 13 March 2025).

- Govindan, K.; Shaw, M.; Majumdar, A. Social sustainability tensions in multi-tier supply chain: A systematic literature review towards conceptual framework development. J. Clean. Prod. 2021, 279, 123075. [Google Scholar] [CrossRef]

- Grimm, J.H.; Hofstetter, J.S.; Sarkis, J. Exploring sub-suppliers’ compliance with corporate sustainability standards. J. Clean. Prod. 2016, 112, 1971–1984. [Google Scholar] [CrossRef]

- Venkatesh, V.G.; Zhang, A.; Deakins, E.; Mani, V. Drivers of sub-supplier social sustainability compliance: An emerging economy perspective. Supply Chain. Manag. Int. J. 2020, 25, 655–677. [Google Scholar] [CrossRef]

- Cloutier, C.; Oktaei, P.; Lehoux, N. Collaborative mechanisms for sustainability-oriented supply chain initiatives: State of the art, role assessment and research opportunities. Int. J. Prod. Res. 2020, 58, 5836–5850. [Google Scholar] [CrossRef]

- Jamalnia, A.; Gong, Y.; Govindan, K. Sub-supplier’s sustainability management in multi-tier supply chains: A systematic literature review on the contingency variables, and a conceptual framework. Int. J. Prod. Econ. 2023, 255, 108671. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V. Sustainable supply chains: Governance mechanisms to greening suppliers. J. Bus. Ethics 2013, 116, 189–203. [Google Scholar] [CrossRef]

- Sancha, C.; Gimenez, C.; Sierra, V. Achieving a socially responsible supply chain through assessment and collaboration. J. Clean. Prod. 2016, 112, 1934–1947. [Google Scholar] [CrossRef]

- Allenbacher, J.; Berg, N. How assessment and cooperation practices influence suppliers’ adoption of sustainable supply chain practices: An inter-organizational learning perspective. J. Clean. Prod. 2023, 403, 136852. [Google Scholar] [CrossRef]

- Chauhan, C.; Kaur, P.; Arrawatia, R.; Ractham, P.; Dhir, A. Supply chain collaboration and sustainable development goals (SDGs). Teamwork makes achieving SDGs dream work. J. Bus. Res. 2022, 147, 290–307. [Google Scholar] [CrossRef]

- Kazakova, E.; Lee, J. Sustainable Manufacturing for a Circular Economy. Sustainability 2022, 14, 17010. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Mishra, A.; Dutta, P.; Jayasankar, S.; Jain, P.; Mathiyazhagan, K. A review of reverse logistics and closed-loop supply chains in the perspective of circular economy. Benchmarking Int. J. 2023, 30, 975–1020. [Google Scholar] [CrossRef]

- Sonar, H.; Sarkar, B.D.; Joshi, P.; Ghag, N.; Choubey, V.; Jagtap, S. Navigating barriers to reverse logistics adoption in circular economy: An integrated approach for sustainable development. Clean. Logist. Supply Chain. 2024, 12, 100165. [Google Scholar] [CrossRef]

- Al Sholi, H.Y.; Wakjira, T.; Kutty, A.A.; Habib, S.; Alfadhli, M.; Aejas, B.; Kucukvar, M.; Onat, N.C.; Kim, D. How circular economy can reduce scope 3 carbon footprints: Lessons learned from FIFA world cup Qatar 2022. Circ. Econ. 2023, 2, 100026. [Google Scholar] [CrossRef]

- De Pascale, A.; Arbolino, R.; Szopik-Depczyńska, K.; Limosani, M.; Ioppolo, G. A systematic review for measuring circular economy: The 61 indicators. J. Clean. Prod. 2021, 281, 124942. [Google Scholar] [CrossRef]

- Liu, Z.; Adams, M.; Cote, R.P.; Chen, Q.; Wu, R.; Wen, Z.; Liu, W.; Dong, L. How does circular economy respond to greenhouse gas emissions reduction: An analysis of Chinese plastic recycling industries. Renew. Sustain. Energy Rev. 2018, 91, 1162–1169. [Google Scholar] [CrossRef]

- Brendzel-Skowera, K. Circular economy business models in the SME sector. Sustainability 2021, 13, 7059. [Google Scholar] [CrossRef]

- Maranesi, C.; De Giovanni, P. Modern circular economy: Corporate strategy, supply chain, and industrial symbiosis. Sustainability 2020, 12, 9383. [Google Scholar] [CrossRef]

- Butt, A.S.; Alghababsheh, M.; Sindhwani, R.; Gwalani, H. Role of supplier engagement to reduce Scope 3 emissions in circular supply chains. Bus. Strateg. Environ. 2025, 34, 598–611. [Google Scholar] [CrossRef]

- Okafor-Yarwood, I.; Adewumi, I.J. Toxic waste dumping in the Global South as a form of environmental racism: Evidence from the Gulf of Guinea. Afr. Stud. 2020, 79, 285–304. [Google Scholar] [CrossRef]

- Abalansa, S.; El Mahrad, B.; Icely, J.; Newton, A. Electronic waste, an environmental problem exported to developing countries: The GOOD, the BAD and the UGLY. Sustainability 2021, 13, 5302. [Google Scholar] [CrossRef]

- Vidal, J. Toxic E-Waste Dumped in Poor Nations, Says United Nations. Our World. 2013. Available online: https://ourworld.unu.edu/en/toxic-e-waste-dumped-in-poor-nations-says-united-nations (accessed on 9 March 2025).

- Jedelhauser, M. The Rich Countries Practice Waste Colonialism. Development and Cooperation. 2023. Available online: https://www.dandc.eu/en/article/industrialised-countries-are-disposing-large-volumes-their-waste-poorer-countries (accessed on 9 March 2025).

- Mirzaei, S.; Shokouhyar, S. Applying a thematic analysis in identifying the role of circular economy in sustainable supply chain practices. Environ. Dev. Sustain. 2023, 25, 4691–4722. [Google Scholar] [CrossRef]

- Burns, H. Thematic analysis: Transformative sustainability education. J. Transform. Educ. 2018, 16, 277–279. [Google Scholar] [CrossRef]

- Clarke, V.; Braun, V. Thematic analysis. J. Posit. Psychol. 2017, 12, 297–298. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Klebert, S. Corporate Climate Action: 3 Essential Steps to Reduce Scope 3 Emissions. World Economic Forum. 2024. Available online: https://www.weforum.org/stories/2024/01/corporate-climate-action-3-essential-steps-to-maximize-impact/ (accessed on 7 March 2025).

- Andersen, M.; Skjoett-Larsen, T. Corporate social responsibility in global supply chains. Supply Chain. Manag. Int. J. 2009, 14, 75–86. [Google Scholar] [CrossRef]

- Mefford, R.N. Sustainable CSR in Global Supply Chains. J. Manag. Sustain. 2020, 9, 1–82. [Google Scholar] [CrossRef]

- LeBaron, G.; Lister, J. Ethical Audits and the Supply Chains of Global Corporations. SPERI Global Political Economy Briefs (1); Sheffield Political Economy Research Institute (SPERI), University of Sheffield: Sheffield, UK, 2016; Available online: https://eprints.whiterose.ac.uk/id/eprint/96303/1/Global-Brief-1-Ethical-Audits-and-the-Supply-Chains-of-Global-Corporations.pdf (accessed on 13 March 2025).

- LG Chem. Audit Report on Huayou Cobalt. Available online: https://www.lgchem.com/sustainability/supply-chain/responsible-supply-chain (accessed on 23 February 2025).

- LG Chem. Audit Report on CDM. Available online: https://www.lgchem.com/upload/file/principle/Audit_Report_CDM_2018.pdf (accessed on 17 September 2025).

- Upadhyay, A.; Mukhuty, S.; Kumar, V.; Kazancoglu, Y. Blockchain technology and the circular economy: Implications for sustainability and social responsibility. J. Clean. Prod. 2021, 293, 126130. [Google Scholar] [CrossRef]

- Gaur, V.; Gaiha, A. Building a Transparent Supply Chain. Harvard Business Review. 2020. Available online: https://hbr.org/2020/05/building-a-transparent-supply-chain (accessed on 21 February 2025).

- Solvay. Solvay Launches Blockchain Platform for Its Guar Sourcing Supply Chain to Empower Indian Farmers. Available online: https://www.solvay.com/en/press-release/blockchain-platform-guar-sourcing-supply-chain-india (accessed on 29 March 2025).

- Solvay. 2021 Annual Integrated Report. 2021. Available online: https://www.solvay.com/en/2021-annual-integrated-report (accessed on 29 March 2025).

- De Beers. TracrTM. Available online: https://www.tracr.com/ (accessed on 31 March 2025).

- Unilever. Palm Oil Story. Available online: https://www.unilever.com/sustainability/nature/deforestation-free-supply-chain/palm-oil-story/ (accessed on 1 March 2025).

- Beyer, R.; Rademacher, T. Species richness and carbon footprints of vegetable oils: Can high yields outweigh palm oil’s environmental impact? Sustainability 2021, 13, 1813. [Google Scholar] [CrossRef]

- Unilever. SAP, Unilever Pilot Blockchain Technology Supporting Deforestation-Free Palm Oil. Available online: https://www.unilever.com/news/press-and-media/press-releases/2022/sap-unilever-pilot-blockchain-technology-supporting-deforestationfree-palm-oil/ (accessed on 3 March 2025).

- Unilever. Sustainability. Available online: https://www.unilever.com/sustainability/ (accessed on 3 March 2025).

- Bekrar, A.; Ait El Cadi, A.; Todosijevic, R.; Sarkis, J. Digitalizing the closing-of-the-loop for supply chains: A transportation and blockchain perspective. Sustainability 2021, 13, 2895. [Google Scholar] [CrossRef]

- Samsung. 3 Ways We Are Reducing E-Waste. Available online: https://www.samsung.com/us/explore/brand/3-ways-we-are-reducing-e-waste/ (accessed on 11 April 2025).

- Samsung. Care for Clean India. Available online: https://www.samsung.com/in/microsite/care-for-clean-india/?srsltid=AfmBOooBFsQzGxUTax6vwheBu_tQ_Hpu1TJ1e2x4OKnPBXkeZtuSiPfH (accessed on 11 April 2025).

- Samsung. Circular Economy. Available online: https://www.samsung.com/global/sustainability/planet/circular-economy/#anchor3 (accessed on 11 April 2025).

- Le, T.T.; Nhu, Q.P.V.; Behl, A. Role of digital supply chain in promoting sustainable supply chain performance: The mediating of supply chain integration and information sharing. Int. J. Logist. Manag. 2024, 36, 1439–1462. [Google Scholar] [CrossRef]

- Roy, M.; Sarker, J. Integration of Circular Economy Principles Within Information Logistics: Case Study of Australia. In Organizational Readiness and Research: Security, Management, and Decision Making; Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 449–490. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective. Int. J. Prod. Econ. 2018, 195, 259–272. [Google Scholar] [CrossRef]

- Razak, G.M.; Hendry, L.C.; Stevenson, M. Supply chain traceability: A review of the benefits and its relationship with supply chain resilience. Prod. Plan. Control. 2023, 34, 1114–1134. [Google Scholar] [CrossRef]

| Themes | Sources |

|---|---|

| Unified Strategies | Sudusinghe, J. I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. [15] Allenbacher, J.; Berg, N. How assessment and cooperation practices influence suppliers’ adoption of sustainable supply chain practices: An inter-organizational learning perspective. [18] Chauhan, C.; Kaur, P.; Arrawatia, R.; Ractham, P.; Dhir, A. Supply chain collaboration and sustainable development goals (SDGs). [19] Klebert, S. Corporate climate action: 3 essential steps to reduce Scope 3 emissions. [38] |

| Technology-driven Cooperation | Kazakova, E.; Lee, J. Sustainable Manufacturing for a Circular Economy. [20] Butt, A. S.; Alghababsheh, M.; Sindhwani, R.; Gwalani, H. Role of supplier engagement to reduce Scope 3 emissions in circular supply chains. [29] Andersen, M.; Skjoett-Larsen, T. Corporate social responsibility in global supply chains. [39] |

| Traceability and Transparency | Mefford, R. N. Sustainable CSR in Global Supply Chains. [40] LeBaron, G.; Lister, J. Ethical audits and the supply chains of global corporations. [41] Audit Report on Huayou Cobalt. LG Chem. [42] Audit Report on CDM. LG Chem. [43] Upadhyay, A.; Mukhuty, S.; Kumar, V.; Kazancoglu, Y. Blockchain technology and the circular economy: Implications for sustainability and social responsibility. [44] Gaur, V.; Gaiha, A. Building a Transparent Supply Chain. [45] Solvay launches blockchain platform for its Guar sourcing supply chain to empower Indian farmers. Solvay. [46] 2021 Annual Integrated Report. Solvay. TracrTM. De Beers. [47] Palm Oil Story. Unilever. [49] Beyer, R.; Rademacher, T. Species richness and carbon footprints of vegetable oils: can high yields outweigh palm oil’s environmental impact? [50] SAP, Unilever pilot blockchain technology supporting deforestation-free palm oil. [51] Sustainability. Unilever. [52] |

| Predictive and Prescriptive Capabilities | Bekrar, A.; Ait El Cadi, A.; Todosijevic, R.; Sarkis, J. Digitalizing the closing-of-the-loop for supply chains: A transportation and blockchain perspective. [53] 3 Ways We Are Reducing E-Waste. Samsung. Care for Clean India. Samsung. [54] Circular Economy. Samsung. [56] Palm Oil Story. Unilever. [49] Abalansa, S.; El Mahrad, B.; Icely, J.; Newton, A. Electronic waste, an environmental problem exported to developing countries: The GOOD, the BAD and the UGLY. [31] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazakova, E.; Lee, J. Enabling Circular Value Chains via Technology-Driven Scope 3 Cooperation. Sustainability 2025, 17, 9099. https://doi.org/10.3390/su17209099

Kazakova E, Lee J. Enabling Circular Value Chains via Technology-Driven Scope 3 Cooperation. Sustainability. 2025; 17(20):9099. https://doi.org/10.3390/su17209099

Chicago/Turabian StyleKazakova, Elena, and Joosung Lee. 2025. "Enabling Circular Value Chains via Technology-Driven Scope 3 Cooperation" Sustainability 17, no. 20: 9099. https://doi.org/10.3390/su17209099

APA StyleKazakova, E., & Lee, J. (2025). Enabling Circular Value Chains via Technology-Driven Scope 3 Cooperation. Sustainability, 17(20), 9099. https://doi.org/10.3390/su17209099