1. Introduction

The construction sector plays a central role in global climate change, accounting for nearly 37% of energy-related carbon dioxide emissions [

1,

2]. A substantial portion of this footprint is attributed to embodied carbon, which encompasses the greenhouse gas emissions generated during the production, transportation, and installation of construction materials [

3]. Addressing embodied carbon is therefore a critical step toward achieving net-zero targets and reducing the overall environmental burden of buildings [

4,

5]. One of the most direct strategies for achieving this is the selection of zero-carbon building materials, which not only reduces emissions but also supports energy efficiency, enhances indoor environmental quality, and promotes long-term resilience [

6,

7].

The Building Research Association of New Zealand (BRANZ) estimates that buildings account for approximately 20% of the country’s total greenhouse gas emissions, including both operational and embodied carbon [

8]. Despite government initiatives such as the 2050 Net-Zero Carbon Strategy and commitments under the Paris Agreement, the construction sector continues to face significant challenges [

9]. New Zealand’s geographical isolation, heavy reliance on imported materials, and fragmented supply chains limit the availability of zero-carbon alternatives, while fluctuating costs and regulatory complexities add further constraints [

10]. These challenges highlight the need for context-specific insights into how material selection decisions are made and how sustainable practices can be better integrated into the local construction ecosystem [

11].

While several studies have investigated frameworks for selecting zero-carbon building materials, very limited research has focused specifically on New Zealand’s construction industry and its unique sustainability challenges. Bui, Wilkinson [

12] conducted exploratory semi-structured interviews with government representatives and construction industry experts in Aotearoa, New Zealand, and highlighted that there has been no detailed investigation of zero-carbon building practices in the country, underscoring the early stage of transition and the scarcity of in-depth, localised studies. Most existing models adopt globalised perspectives that do not adequately account for local constraints, such as supply chain dependencies, indigenous cultural considerations, or regulatory frameworks. Qian, Siriwardana [

10] addressed this gap by identifying and prioritising 30 critical criteria—including environmental, technical, economic, and social factors—specifically tailored to New Zealand’s construction industry, demonstrating the inadequacy of generic global frameworks and the importance of locally contextualised models.

In particular, little empirical evidence exists on how industry professionals in New Zealand perceive the trade-offs among cost-effectiveness, durability, buildability, aesthetics, availability, and embodied carbon when selecting materials. A recent empirical study by Bui, Domingo [

13], surveyed 115 New Zealand industry professionals using Structural Equation modelling (SEM) to examine interrelations among social, economic, environmental, and technical decision-making factors. While their findings emphasise the importance of technical factors, they also point to gaps in understanding specific trade-offs such as durability, aesthetics, and embodied carbon. Finnie, Masood [

14], investigated current practices for calculating and reducing embodied carbon in New Zealand commercial construction. They found that most industry professionals lacked experience, that embodied carbon assessments were rare, and were hindered by insufficient tools, client support, and lack of early cost data, factors that limit strategic decision-making and policy development.

Considering these critical observations, this research seeks to address the following pivotal questions: (i) What are the primary factors influencing the selection of building materials in New Zealand? (ii) How do these identified factors correlate with the carbon footprint associated with the materials? And (iii) Which materials are most suitable for effectively reducing carbon emissions within New Zealand?

This study addresses these gaps by focusing on six decision-making factors, including cost-effectiveness, durability, buildability, embodied carbon, availability, and aesthetics, and by evaluating the perceived suitability of four zero-carbon materials: wood, hemp, rammed earth, and straw bale. Using a survey of 203 construction professionals, analysed through descriptive statistics, one-sample t-tests, and SEM, the study identifies the relative importance of these factors and their influence on material adoption. The research makes two primary contributions. First, it provides the first empirical evidence from New Zealand on zero-carbon material selection, thereby contextualising international sustainability debates within a localised construction environment. Second, it advances the literature by integrating multiple evaluation criteria with robust quantitative methods, generating insights for policymakers, designers, and suppliers on how to overcome barriers and accelerate the adoption of zero-carbon materials. Importantly, the outcomes of this study align closely with multiple United Nations Sustainable Development Goals (SDGs), including SDG 9 (Industry, Innovation, and Infrastructure), SDG 11 (Sustainable Cities and Communities), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action).

2. Literature Review

Globally, the construction sector is a major contributor to climate change, accounting for roughly 37% of energy-related carbon emissions [

15,

16]. In response, there is a growing emphasis on sustainable building material selection as a key strategy to reduce the environmental footprint of buildings [

17,

18]. A wide range of research highlights that choosing eco-friendly materials, those with lower embodied carbon, higher energy efficiency, and minimal lifecycle impacts, is pivotal in making construction more sustainable [

19]. However, identifying and selecting suitable sustainable materials is a complex decision-making process involving many factors [

20].

Recent studies underscore that designers and engineers face challenges balancing environmental performance with practical criteria such as cost, durability, and availability [

13,

21]. Given these challenges, it is important to establish a clear understanding of zero-carbon construction goals and standards. The World Green Building Council defines a zero-carbon building as an exceptionally efficient structure powered by renewable energy sources, both on-site and off-site [

22]. While these aspirations are undeniably appealing, the journey toward zero-carbon or net-zero carbon construction is frequently complicated by intricate challenges, particularly within sustainability and environmental considerations. For instance, even as the construction process strives for reduced emissions, conventional materials like steel, aluminium, and concrete, ubiquitously employed in construction are collectively responsible for a substantial 23% of global carbon dioxide emissions [

23]. New Zealand is firmly committed to curtailing its carbon dioxide emissions to align with the 2050 targets established by the United Nations and its government. A pragmatic approach to realising this objective involves the expanded utilisation of locally sourced and manufactured materials in constructing zero-carbon buildings.

By embracing locally procured, zero-carbon building practices over the long term, New Zealand can progressively fulfil its national ambitions for economic, environmental, and social sustainability. Building on these sustainable construction strategies, it is essential to examine the role of specific zero-carbon materials that can support these objectives in practice. Hempcrete has emerged as a highly promising zero-carbon building material due to its low embodied carbon, strong thermal and hygrothermal performance, and carbon sequestration ability. A 2025 review by Tong and Memari [

24] offers a comprehensive evaluation of hempcrete’s formulation, construction applications, mechanical properties, thermal behaviour, cost, environmental impact, and overall sustainability potential.

Complementing this, Ansari, Tabish [

25] reviews hemp concrete specifically as a zero-carbon material, emphasizing its low carbon footprint and lifecycle advantages. Experimental studies further highlight hempcrete’s hygrothermal benefits: Hrčka, Štompf [

26], investigates its moisture diffusion and thermal insulation properties of building envelopes. Together, these works make hempcrete a compelling choice when evaluating thermal performance, embodied carbon, moisture regulation, and sustainability as selection criteria.

Straw bale construction is notable for its exceptional insulation, low embodied energy, and significant carbon reduction potential. Yin, Yu [

27] review multiple benefits of straw-bale houses including lower embodied energy and CO

2 emissions than conventional construction, high thermal performance, and strong fire resistance. Life-cycle impact assessments of load-bearing straw bale buildings further validate its environmental advantages, capturing both ecological and operational benefits across the building’s service life [

28]. Mehravar, Veshkini [

29], quantifies this performance more directly, reporting that using straw bale in buildings can cut embodied carbon by up to 76% compared to conventional methods. Earlier work by [

30] also underscores straw bale’s capacity to lower whole-life CO

2 emissions in housing.

Rammed earth offers a sustainable alternative characterised by low embodied energy, thermal mass for passive heating and cooling, and high local material availability. Scoping studies highlight that structures using rammed earth achieve lower life-cycle energy consumption and environmental impact through sustainable sourcing and construction techniques [

31]. Halit Alkadri and ÇEtİN [

32] further explores its carbon reduction potential by analysing the embodied energy during material production, transportation, and construction stages. Nouri, Safehian’s [

33] life cycle comparisons between rammed earth and traditional materials such as fired clay bricks reveal that rammed earth outperforms in terms of lower embodied CO

2 emissions. Practical guidance on material preparation is offered by Burroughs [

34], who provides recommendations on soil selection, stabilizer treatment, and compaction to optimize environmental and structural performance.

Wood, particularly in the form of engineered wood products and timber-framed systems, stands out as a low-carbon construction material owing to its carbon sequestration, lower embodied emissions, and high strength-to-weight ratio. Governmental analysis of New Zealand residential buildings finds that timber framing offers inherently low embodied carbon even excluding biogenic stored carbon, indicating a limited yet significant decarbonization potential [

31]. Research has increasingly focused on materials such as bamboo, engineered timber, recycled composites, and low-carbon concrete mixtures, to highlight their reduced carbon and energy footprints [

19]. Yet, economic limitations such as cost competitiveness remain a significant barrier for these zero-carbon materials.

In New Zealand the drive toward zero-carbon building materials is influenced by several distinctive factors that set it apart from global trends. The country’s geographical isolation and limited domestic manufacturing base mean it relies heavily on imported construction materials [

35]. This reliance creates vulnerabilities in supply chains and can hinder the ready availability of novel sustainable materials. Recent supply disruptions revealed how dependence on imports can lead to cost spikes and delays in the construction sector [

36].

Beyond cost and environmental performance, zero-carbon materials must also meet essential structural and safety requirements. Global studies stress evaluating compressive/tensile strength, fire resistance, and longevity of alternatives like straw bale, hempcrete, or rammed earth to ensure they perform comparably to conventional materials [

37].

These supply chain challenges highlight the importance of exploring zero-carbon materials that not only reduce emissions but also enhance sustainability and resilience.

Zero-carbon materials are generally characterised by less energy consumption and fewer emissions than their conventional counterparts [

38]. This reduced carbon footprint at the manufacturing and transportation stages of products and goods is directly connected to decreased total carbon emissions. Eco-friendly materials usually imply a reduction in the energy used by buildings and later reduce the emissions related to heating and cooling [

39]. Moreover, most zero-carbon materials are manufactured to be efficient in energy consumption. An active policy should promote the desirability of utilising locally available zero-carbon construction material supplies for construction projects. This supports international goals, specifically those expressed within the UN climate action program and the Paris Agreement.

As such, although numerous studies have examined the properties of zero-carbon materials such as hempcrete, straw bale, rammed earth, and timber, most focus on isolated performance aspects like thermal efficiency or embodied carbon while overlooking the interplay of multiple selection criteria such as cost, availability, buildability, and regulatory constraints. Furthermore, there is limited research that integrates these factors into a holistic framework tailored to New Zealand’s unique context, where geographical isolation and supply chain challenges complicate material choices. This gap highlights the need for the present study, which empirically evaluates the key factors influencing the selection of four zero-carbon materials to support sustainable construction strategies in New Zealand.

3. Methodology

This study used a quantitative survey-based methodology to identify and assess the key factors influencing the selection of sustainable building materials in New Zealand. Aligned with the study’s objectives, this study focused on: (1) identifying the most influential material selection factors, (2) examining how these factors relate to the carbon footprint of materials, and (3) determining which materials are best suited to support zero-carbon construction. The methodology included the development of a structured questionnaire, purposive sampling of construction professionals, and the use of statistical analysis techniques, including t-tests and SEM, to analyse responses and validate the proposed model. The following subsections outline the survey design, participant selection, data collection, and data analysis procedures.

The selection of evaluation criteria for sustainable building materials was built on a systematic literature review titled “Zero-carbon building materials in New Zealand context”.

This review synthesised existing research and policy reports to identify key factors influencing sustainable material selection within New Zealand’s construction sector. Based on this work, six primary constructs were identified as most relevant.

3.1. Identifying the Population and Designing the Sample Size

The target population of this study consisted of professionals in the New Zealand construction industry who are directly involved in building design, engineering, or material specification. This includes architects, civil engineers, sustainability consultants, project managers, and construction contractors. These groups were selected due to their key roles in material evaluation and procurement, making them well-positioned to assess sustainability-related decision factors.

A purposive sampling strategy was employed to ensure the inclusion of participants with relevant expertise in sustainable construction practices. Hair [

40] and Kline [

41] suggest a ratio of at least 5–10 respondents per measured variable. Given that the final questionnaire included 16 observed items (the questions that were distributed) across several latent constructs, the minimum required sample size ranged from 120 to 240 participants. The final sample consisted of 123 valid responses, which satisfies the minimum threshold for SEM with a participant-to-item ratio of approximately 5:1.

Eligibility criteria required respondents to have a minimum of five years of professional experience in the construction sector and direct involvement in material selection decisions. Recruitment occurred through professional associations, industry events, and targeted outreach to construction firms and consultants. In total, 266 surveys were distributed: 60 online (15% response rate) and 206 in person (94% response rate). The overall response rate was 76% (203 valid responses). While the high in-person response reduced concerns of low engagement, potential non-response bias was mitigated by comparing demographic characteristics of respondents and non-respondents, which revealed no significant discrepancies in professional role or years of experience.

In addition to sample-to-item ratio guidance, statistical power analysis was considered. A power level of 0.80 and a significance level of α = 0.05 are commonly recommended for social science research [

42]. Assuming a moderate effect size (f

2 = 0.15) and 5–6 latent constructs, the minimum required sample size using G*Power software (version 3.1.9.7) for multiple regression (a proxy for SEM models) falls between 100 and 120 participants. With that said, the study meets the minimum power requirements for detecting medium-sized effects in SEM, supporting the validity of subsequent model estimation and hypothesis testing.

The participants were those who belonged to the construction and building sector, and their professional interests enabled them to provide input on the selection of materials, offering informed viewpoints on the various issues to be considered, including aesthetics, structural integrity, sustainability, and cost-effectiveness [

43]. The inclusion criteria required at least five years of experience working in the construction sector, particularly in sustainable design and materials. We also placed no restrictions on geographical area or the nature of projects, so the variety of experiences was high.

The respondents were requested to verify their relevant construction sector experience before administering the survey. Only eligible individuals received invitations after confirming their qualifications. Consequently, we collected information from professionals such as architects, engineers, and contractors, preserving the data quality. This initial screening process added credibility and focus to the information about sustainable building materials.

Surveys were distributed across different regions in New Zealand to determine whether there were any regional variations in the choice of construction materials. This data collection activity lasted eight weeks, during which respondents could complete the survey at their convenience. Allowing industry experts to complete the survey at their convenience helped ensure the accuracy of the responses.

In the first section of our five-part questionnaire, we sought to collect relevant demographic and background data from participants in the New Zealand construction industry. This section was aimed at helping us contextualize survey responses by capturing the respondents’ professional roles and experience levels. The survey began by asking respondents to state their roles in the construction industry: engineer (N = 148), architect (N = 35), contractor (N = 11), client (N = 6), building manager (N = 2), and others (N = 1). These background data formed a source of analysis based on how professional background may influence attitudes towards green building practices (see

Table 1).

While engineers represented 73% of the sample, this reflects their strong presence in the zero-carbon building materials sector in New Zealand and their central role in material selection decisions. Other professional categories, including architects, contractors, clients, and building managers, were also represented to ensure a range of perspectives. The small proportion of participants with over 20 years of experience aligns with current workforce demographics, where mid-career professionals dominate. Furthermore, the statistical techniques applied (including SEM and one-sample t-tests) are robust to subgroup imbalances, focusing on sector-wide trends rather than subgroup-specific effects.

The distribution of respondents based on their years of experience in the NZ construction industry was as follows: 21% of participants had less than 1 year of experience, 48% had between 1 and 5 years, 19% had 5 to 10 years, 11% had 10 to 20 years, and only 1% had over 20 years of experience, as seen in

Table 2.

Additionally, respondents were asked to specify their location from a list of central New Zealand cities, including Auckland (N = 190), Wellington (N = 9), Christchurch (N = 2), and Tauranga (N = 2).

3.2. Designing and Piloting the Questionnaire

The questionnaire was developed based on prior literature on sustainable material selection and refined through expert review by three academics in construction management and two industry professionals. A pilot test with 12 practitioners ensured clarity and usability. Construct validity was established through Confirmatory Factor Analysis (CFA), with all factor loadings exceeding 0.70. Reliability was confirmed using Cronbach’s α and Composite Reliability (CR), which ranged between 0.79 and 0.89 across constructs, surpassing the recommended 0.70 threshold. Convergent validity was supported by Average Variance Extracted (AVE) values above 0.50, while discriminant validity was established through the Fornell-Larcker criterion and HTMT ratio.

The questionnaire was designed to evaluate six factors (i.e., cost-effectiveness, durability, buildability, embodied carbon, availability, and aesthetics) identified in the literature review, using multiple items for each domain. To ensure content validity and contextual appropriateness, the draft questionnaire was reviewed by six construction professionals in New Zealand during a pilot phase. Feedback focused on clarity, terminology, and coverage of the constructs. The final version was then distributed for formal data collection.

This questionnaire was designed with closed-ended questions. Using a 5-point Likert-type response scale (1 = strongly disagree, 5 = strongly agree). The 5-point Likert scale provides a good balance between simplicity and granularity. It also reduces the likelihood of participant fatigue and helps maintain the reliability and ease of interpreting the collected data [

44].

The primary justification for this methodological choice was our interest in collecting quantifiable data that could be statistically analysed to identify and understand the factors influencing the choice of building materials. The closed-ended question technique was utilised because it aids in standardizing responses, making them more uniform and comparable across all respondents [

45]. The questions focus on identified key material selection criteria in the literature review namely cost-effectiveness, durability, buildability, embodied carbon, availability, and aesthetic value. Furthermore, participants were asked to rate selected building materials—wood, hemp, rammed earth, and straw bale.

3.3. Ethical Considerations

This research was conducted strictly according to the ethical guidelines and established standards of Massey University. The study underwent a thorough review and received approval from the Massey University Human Ethics Committee, under approval number 4000027896. Prior to data collection, all participants were comprehensively informed about the study’s purpose, the nature of their involvement, and their rights. Informed consent was meticulously obtained from every participant. All collected data were securely stored and used exclusively for this study. The research consistently adhered to all ethical principles, ensuring the study’s integrity and demonstrating profound respect for all individuals involved.

3.4. Data Collection

Data collection followed ethical approval from [insert institution/ethics committee]. Surveys were administered either online or face-to-face at professional events, with informed consent obtained from all participants. Of the 203 valid responses, less than 2% of item-level data were missing. Missing responses were handled using mean imputation, given the low rate of missingness and the assumption of randomness, which is consistent with best practices in survey research.

The survey was administered using a dual-mode approach to maximise participant reach and enhance response quality. An online questionnaire was distributed via SurveyMonkey to a curated list of 60 professionals, while printed surveys were distributed in person during industry forums, workshops, and other sector-specific events across New Zealand. This mixed-method strategy ensured broad coverage of the construction industry and allowed respondents flexibility in completing the survey. Participation rates varied significantly across the two modes. The online survey achieved a response rate of 15% (9 out of 60), which aligns with typical response rates reported for voluntary web-based surveys targeting professionals [

45,

46]. In contrast, the in-person approach produced a 94% completion rate (194 out of 206), owing to direct engagement opportunities and the ability to clarify queries during distribution. The combined overall response rate was 76%, which far exceeds the 50% threshold commonly recommended for social science survey research to ensure representativeness and minimise non-response bias [

40,

42].

This high overall response rate also compares favourably with prior studies in the construction and sustainability domains, where rates above 60% are considered sufficient for robust inference [

13,

38]. Given that 203 valid responses were collected from qualified professionals directly involved in design, procurement, and sustainable material selection, the dataset provides a statistically adequate foundation for SEM and hypothesis testing. Furthermore, the diverse professional backgrounds of respondents, including engineers, architects, contractors, and sustainability consultants, enhance the generalisability of the findings across the New Zealand construction sector. The aggregated response rate, combining both distribution methods, is presented in

Table 3.

3.5. Methods of Data Analysis

Data were analysed using a combination of descriptive statistics, inferential tests, and Partial Least Squares Structural Equation Modelling (PLS-SEM). All statistical procedures were performed using SPSS (version 29.0) (for descriptive and

t-tests) and SmartPLS software (version 4.0.9.6) (for SEM analysis). Descriptive statistics were first used to summarise demographic information and the distribution of responses across all questionnaire items. To assess differences in perceptions between respondent subgroups (e.g., based on role or experience), independent samples

t-tests were employed. Although Likert scale data are ordinal, existing research (e.g., [

46]) supports the application of parametric tests such as the

t-test in larger sample contexts, given their robustness and interpretability. The core analytical technique employed was PLS-SEM, selected for its suitability in exploratory models, complex path structures, and small-to-moderate sample sizes. PLS-SEM was used to validate the measurement model and test the structural relationships among the latent variables.

The measurement model was assessed using standard PLS-SEM evaluation criteria to ensure the constructs were both reliable and valid. Indicator reliability was examined through outer loadings, which represent the correlation between each item and its respective construct. Loadings above 0.70 indicate that an item contributes substantially to measuring the construct, as values above this threshold suggest that more than 50% of the variance is explained by the construct [

47]. In this study, all indicators exceeded this threshold, confirming satisfactory indicator reliability.

Internal consistency reliability was assessed using both Cronbach’s Alpha and Composite Reliability (CR). Cronbach’s Alpha measures the internal consistency of items, while CR provides a more precise estimate as it considers indicator loadings in the calculation. Threshold values of ≥0.70 are generally considered acceptable for both measures [

48]. In this study, Cronbach’s Alpha and CR values ranged between 0.79 and 0.89, confirming strong internal consistency across all constructs.

Convergent validity was evaluated using the Average Variance Extracted (AVE), which measures the extent to which a construct explains variance in its indicators. An AVE value ≥ 0.50 indicates that the construct explains more than 50% of the variance in its associated items [

49]. All constructs in this study exceeded this benchmark, confirming satisfactory convergent validity. Finally, discriminant validity was assessed using two established methods: the Fornell–Larcker criterion and the Heterotrait–Monotrait ratio (HTMT). The Fornell–Larcker criterion requires that the square root of each construct’s AVE be greater than its correlations with other constructs, ensuring clear conceptual separation [

50]. In addition, the HTMT ratio provides a more stringent assessment, with values below 0.85 (or 0.90 in some contexts) considered acceptable [

51]. Both criteria were satisfied in this study, confirming that the constructs are empirically distinct and measure unique concepts.

All item loadings exceeded the recommended threshold of 0.70, demonstrating satisfactory indicator reliability. Items with loadings above 0.70 are considered to contribute to the respective construct. Internal Consistency Reliability: Cronbach’s Alpha and Composite Reliability (CR) values for all constructs ranged between 0.79 and 0.89, indicating strong internal consistency (threshold > 0.70). Convergent Validity: The Average Variance Extracted (AVE) for all constructs exceeded the 0.50 benchmark, confirming that each construct captures more than 50% of the variance in its indicators. These results confirm that the measurement model is reliable and valid, and therefore appropriate for testing the structural relationships among the latent variables.

Discriminant validity was assessed to ensure that each construct was empirically distinct from the others. Two commonly used criteria were applied: the Fornell–Larcker criterion and the HTMT. Using the Fornell–Larcker criterion [

49], the square root of the AVE for each construct was compared against its correlations with all other constructs. In all cases, the square root of AVE for a given construct was greater than its highest correlation with any other construct. This confirms that each construct shares more variance with its own indicators than with other constructs in the model, indicating satisfactory discriminant validity. Additionally, the HTMT ratio of correlations was calculated to further validate discriminant validity. All HTMT values were below the conservative threshold of 0.85, as recommended by Henseler, Ringle [

51]. This further supports the conclusion that the constructs are distinct and non-redundant. Together, these results provide strong evidence of discriminant validity across all constructs, supporting the robustness of the measurement model.

To summarise participants’ responses and provide an overview of central tendencies and variability, descriptive statistics were calculated. Specifically, mean scores, standard deviations (SD), and standard errors of the mean were used to evaluate the relative importance of each selection criterion and to compare perceptions across the identified zero-carbon materials. These measures offered a preliminary understanding of the data distribution before conducting inferential tests and structural modelling.

3.6. Data Analysis Approach

In this study, a comprehensive power analysis was performed to ensure accurate and consistent data before data collection. The G*Power software was specifically utilised to determine the sample size [

52]. Following Cohen’s guidelines, the effect size for the correlation tests was set at r = 0.30, indicating a medium effect size [

46,

53]. With an alpha level of 0.05, the desired statistical power was set to (1 − β) = 0.80, indicating an 80% chance of detecting the effect if it truly existed [

54]. The power analysis indicated that to detect a medium-sized effect reliably, at least 85 participants were required. Adhering to this power criterion considerably decreases the chances of Type I and Type II errors, thereby enhancing the quality and rigor of the study’s findings.

3.6.1. Descriptive Statistics

Besides the

t-test, descriptive statistics were also calculated, including the averages, standard deviation, and standard error of the mean, to represent both the central measures and the range in the respondents’ ratings of each element [

55].

3.6.2. Structural Equation Modelling (SEM)

Data analysis was conducted using Partial Least Squares Structural Equation Modelling (PLS-SEM) with SmartPLS 4 (version 4.0.9.6). The path-weighting scheme was applied, and model identification was achieved with sufficient indicators per construct. To assess model fit, the following indices were reported: CFI = 0.982, TLI = 0.974, RMSEA = 0.046, and SRMR = 0.052, all indicating an acceptable fit. Multicollinearity was checked via VIF values, all of which were below 5, confirming no serious collinearity issues. Sensitivity analyses were conducted by testing alternative model specifications, which produced consistent results, strengthening the robustness of the findings.

In a bid to clarify the key factors and their impact on the acceptance of zero-carbon building material components, SEM methods were employed. As a two-step process, SEM enables the measurement of relationships between a set of independent variables—key factors influencing materials selection choice and a dependent variable—the perception of zero-carbon building materials [

56]:

First, the model fit was carefully assessed to ensure that the assumed relationships aligned with the observed values. This evaluation was based on fit indices such as the Comparative Fit Index (CFI) and the Root Mean Square Error of Approximation (RMSEA).

Second, standardised path coefficients were applied to accurately measure the strength and direction of associations among the variables.

In addition, the HAMT–CTF–EMPD approach was benchmarked against the ASHRAE Standard 140/BESTEST comparative testing framework. This procedure is widely used to verify and validate building simulation models [

57]. The benchmarking confirmed that the model outputs were consistent with accepted reference ranges, providing confidence in the robustness of the simulation approach.

3.6.3. One-Sample Test

Given that all participants in this survey were actively engaged in residential building projects, and to address the study’s specific research questions, six key factors were identified through a comprehensive literature review. The methodology for this review and the rationale behind selecting these factors have been detailed in a previous study [

58]. These factors including cost-effectiveness, durability, buildability, embodied carbon, availability, and aesthetics.

A one-sample t-test was subsequently performed to ascertain whether the mean scores for each factor, such as cost-effectiveness and durability, exhibited a statistically significant deviation from the neutral midpoint of 3 on the 5-point Likert scale. The primary objective of this t-test was to determine whether there were general positive or negative perceptions concerning the factors by the respondents.

As noted by Dawes [

59], a few important steps must be taken before proceeding with the analysis. First, data distribution was assessed for normality using the Shapiro–Wilk test, supported by skewness and kurtosis values analysis. The statistics were found to be approximately normally distributed, providing a strong basis for justifying the application of the

t-test. Secondly, independence of observations was maintained, as responses were collected from isolated and separate individuals. Thirdly, the mean values obtained from the Likert-scale responses were treated as continuous variables, a conventional practice when applying parametric tests to Likert-scale data.

A one-sample

t-test was employed to assess whether the mean score for each factor (e.g., cost-effectiveness, durability, embodied carbon) differed from the neutral midpoint of 3 on the 5-point Likert scale. The choice of a parametric

t-test, rather than a non-parametric alternative, was justified based on prior evidence that Likert-type composite scores can be treated as approximately continuous when aggregated across multiple items, provided that the distribution meets the assumptions of normality [

46]. Before running the

t-test, we assessed the normality of the data for each factor using the Shapiro–Wilk test, supported by skewness and kurtosis statistics, all of which indicated that deviations from normality were minimal. The assumption of independence of observations was met, as each participant completed the survey individually and only once.

3.7. Validity and Reliability

Construct validity was examined through Confirmatory Factor Analysis (CFA). All item loadings exceeded the recommended threshold of 0.70, confirming that each indicator contributed substantially to its respective construct. Average Variance Extracted (AVE) values were above 0.50 for all constructs, demonstrating adequate convergent validity. Discriminant validity was established using both the Fornell–Larcker criterion and the Heterotrait–Monotrait (HTMT) ratio, with results falling within acceptable thresholds.

Reliability was assessed using Cronbach’s α and Composite Reliability (CR), which ranged between 0.79 and 0.89, exceeding the recommended 0.70 cut-off. To provide a more robust measure of internal consistency, McDonald’s ω was also calculated, with all constructs showing values above 0.80, indicating strong reliability and consistency across items. These results confirm that the measurement model is both reliable and valid, supporting its use for subsequent SEM analysis.

According to a study carried out by Faul, Erdfelder [

60], reliability is important in measuring instruments. The reliability of six key factors including cost-effectiveness, durability, buildability, embodied carbon, availability, and aesthetics, and four zero-carbon building materials: wood, hemp, rammed earth, and straw bale, using the Cronbach’s Alpha test. These four materials have been identified as suitable zero-carbon building materials in New Zealand by a previous study [

58]. The 203 valid responses without exclusions to ensure the sample’s representativeness. The calculated Cronbach’s Alpha value was 0.834, indicating strong internal consistency and demonstrating that these items measured the intended construct with high precision [

61]. Within this area of research, such a degree of reliability is acceptable reflecting that the instrument is well-suited to capture all pertinent attributes concerning material selection

Respondents rated factors like cost-effectiveness, durability, buildability, embodied carbon, availability, aesthetics, and specific materials such as wood, hemp, rammed earth, and straw bale. The analysis used descriptive statistics and a one-sample

t-test to compare the results with a neutral baseline (test value = 3), as shown in

Table 4.

According to

Table 5, the cost-effectiveness of the zero carbon building materials was examined, and a high mean score of 4.91 was obtained, indicating that respondents generally view the materials as very cost-effective. The low standard deviation (0.28) suggests a consensus among respondents regarding this factor. The standard error of the mean of 0.020 further supports the precision of this mean estimate. Durability was rated similarly high, with a mean score of 4.87 and a standard deviation of 0.33. This reflects strong agreement among participants on the perceived durability of the zero-carbon materials evaluated.

Buildability scored a mean of 4.53, suggesting that most respondents found the materials easy to work with. However, the standard deviation of 0.56 reveals a broader range of opinions, possibly due to differing experiences or familiarity with the materials. The average score for embodied carbon was 4.00, indicating that respondents perceive the materials to have moderate embodied carbon. The higher standard deviation of 0.77 points to a greater diversity of opinion on this factor, which differing levels of awareness regarding the environmental impacts of building materials may influence.

Availability received a mean score of 3.67, slightly below the other categories, indicating challenges in accessing these materials. The response variability (standard deviation of 0.79) may reflect regional differences in material availability or supply chain issues. With a mean score of 3.48, aesthetics was rated the lowest among all categories, suggesting a wide range of subjective opinions about the appearance of zero carbon materials. The standard deviation of 0.73 further highlights the variability in responses, which is expected given the personal nature of aesthetic preferences.

In addition to evaluating material selection factors, participants were also asked to rate the suitability of specific zero-carbon materials (wood, hemp, rammed earth, straw bale). The results are summarised in

Table 5.

The results indicate that Wood received the highest overall rating, with a mean of 4.96 and low variability (standard deviation = 0.199). Cost-effectiveness and durability were also rated highly, with means of 4.91 and 4.87, respectively, indicating strong positive perceptions among respondents. Conversely, aesthetics had the lowest mean score of 3.48, suggesting that respondents found this factor less favourable than others. Additionally, availability and embodied carbon were rated moderately, with means of 3.67 and 4.00, respectively, reflecting a mixture of opinions regarding these materials’ environmental and practical aspects. The standard deviations across components varied, with buildability (standard deviation = 0.559) and hemp (standard deviation = 0.801) displaying higher response variability, indicating that respondents had diverse opinions on these factors. The Standard Error Mean values provide confidence in the precision of the mean estimates, further supporting the reliability of these findings.

4. Results

This section presents the findings of the study in line with its objectives. Descriptive statistics (mean, SD, SEM) are reported first to highlight the relative importance of the material selection criteria and the perceived suitability of the four zero-carbon materials (wood, hemp, rammed earth, and straw bale). These are followed by one-sample t-tests, which examine whether the mean scores significantly differ from the neutral value, thereby assessing the strength of participants’ preferences. Finally, the structural equation modelling (SEM) results are presented, showing the relationships between the identified factors and the overall selection of zero-carbon materials. The results are presented according to the three research objectives:

To identify the most influential selection criteria;

To examine their relationship with carbon-related performance;

To assess the suitability of zero-carbon materials.

4.1. Descriptive Statistics of Selection Factors

Respondents evaluated six key factors influencing the selection of zero-carbon building materials: cost-effectiveness, durability, buildability, embodied carbon, availability, and aesthetics. Descriptive statistics (mean, SD, SEM) were used to rank the relative importance of these factors (

Table 4).

The results address Objective 1, which aimed to identify the most influential factors in selecting zero-carbon building materials. The findings indicate that cost-effectiveness (M = 4.91) and durability (M = 4.87) were rated the highest among the evaluated factors, demonstrating strong agreement among respondents that these criteria are critical considerations when selecting sustainable materials. Buildability received a moderately high mean score (M = 4.53), suggesting that participants generally viewed these materials as practical to work with. However, the relatively larger standard deviation (SD = 0.55) indicates that opinions about buildability varied, possibly due to differences in prior experience or familiarity with these materials.

Embodied carbon (M = 4.00) and availability (M = 3.67) received more moderate ratings, highlighting mixed awareness and perceptions regarding the environmental impacts and supply accessibility of these materials. In contrast, aesthetics had the lowest mean score (M = 3.48), indicating that visual appeal plays a relatively minor role in influencing material selection decisions. Overall, these findings confirm that functional, economic, and environmental considerations are prioritised over appearance when selecting zero-carbon materials.

Cost-effectiveness was significantly higher than the neutral baseline (M = 4.91, SD = 0.28, t(202) = 35.2, p < 0.001, 95% CI [4.86, 4.96], d = 2.47), indicating strong consensus on its importance. Durability (M = 4.87, SD = 0.33) showed a similar effect (t(202) = 31.8, p < 0.001, 95% CI [4.81, 4.93], d = 2.23). In contrast, aesthetics received the lowest rating (M = 3.48, SD = 0.73, t(202) = 8.1, p < 0.001, 95% CI [3.33, 3.63], d = 0.57), suggesting that appearance plays a limited role compared to functional and environmental considerations.

4.2. Perceived Suitability of Zero-Carbon Materials

Participants also rated the suitability of four specific zero-carbon materials, including wood, hemp, rammed earth, and straw bale, based on their perceptions of practicality, performance, and potential adoption (

Table 6).

These findings address Objective 3, which focused on evaluating the perceived suitability of specific zero-carbon materials. Among the four materials assessed, wood emerged as the most highly rated option (M = 4.96, SD = 0.19), reflecting a strong consensus regarding its practicality, reliability, and widespread acceptance in construction. Hemp was also rated positively (M = 4.21), but its higher standard deviation (SD = 0.80) suggests that participants held more diverse opinions, likely due to limited familiarity or concerns about its broader application.

In comparison, rammed earth (M = 3.98) and straw bale (M = 3.96) received moderate ratings, with greater variability in responses. This suggests that while these materials are recognised for their environmental benefits, perceptions of their practicality and mainstream feasibility remain mixed. Taken together, the results demonstrate that while several zero-carbon materials hold potential, wood and hemp are perceived as the most suitable options for adoption in New Zealand’s construction context.

4.3. One-Sample T-Test Results

To further assess the significance of these findings, a one-sample

t-test was conducted using a test value of 3 (the neutral midpoint). The results show that all factors were rated significantly higher than 3, with

p-values less than 0.001, confirming the significance of these differences (

Table 7 and

Table 8).

Cost-Effectiveness: The t-value of 93.96 and a mean difference of 1.91 indicate that respondents view cost-effectiveness as a highly favourable factor.

Durability: With a t-value of 77.58 and a mean difference of 1.87, durability also significantly exceeds the neutral rating.

Buildability: A t-value of 38.14 and a mean difference of 1.53 show that buildability is rated positively.

Embodied Carbon: The t-value of 17.97 and a mean difference of 1.00 suggest that respondents view embodied carbon more positively, though with less magnitude than other factors.

Availability: The t-value of 11.79 and a mean difference of 0.67 show moderate favourability regarding availability.

Aesthetics: A t-value of 9.08 and a mean difference of 0.48 confirm that aesthetics is rated slightly above neutral, though this factor is less influential than others.

4.4. Structural Equation Modelling Results

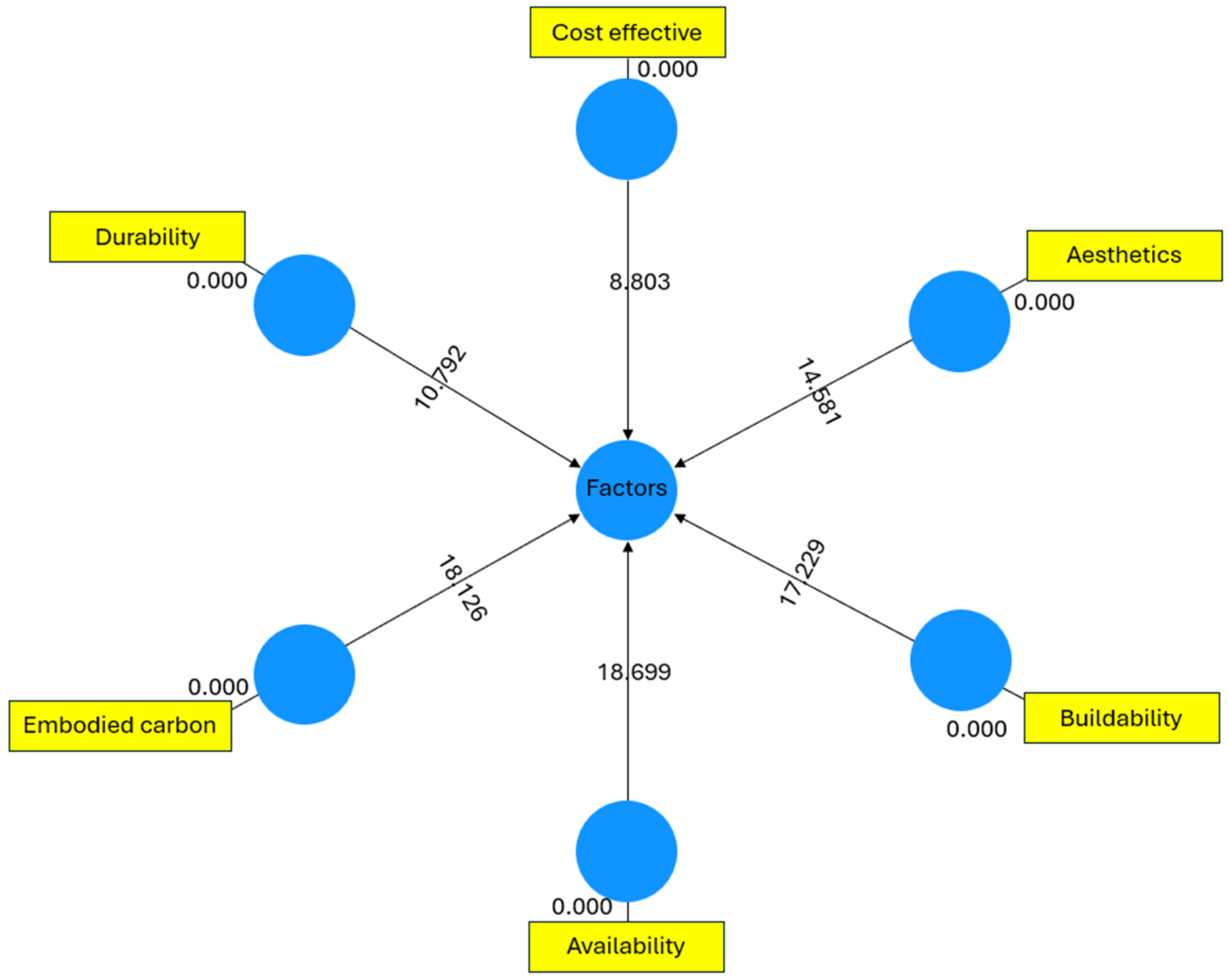

To assess the relationship between these factors and the overall perception of zero carbon building materials, SEM was employed. The results, based on standardised coefficients, reveal that the most significant factors influencing the adoption of zero carbon materials are embodied carbon (standardised coefficient = 0.397), availability (0.368), and hemp (0.373). These findings indicate that materials with low embodied carbon and high availability are more likely to be adopted in sustainable building projects. In contrast, factors such as wood (0.093) and cost-effectiveness (0.132) are more moderate in influencing material selection, reflecting their relatively lower impact on decision-making than environmental and accessibility considerations. The results based on standardised coefficients reveal that the most significant factors influencing the adoption of zero carbon materials are availability (18.699), embodied carbon (18.126), and buildability (17.229) (

Figure 1). These figures represent how various factors and materials relate to the central constructs. The standardised coefficients offer a quantitative measure of the relationships within the model.

The structural model demonstrated a good overall fit: CFI = 0.982, TLI = 0.974, RMSEA = 0.046, and SRMR = 0.052, all within recommended thresholds [

50]. Standardised path coefficients are reported with 95% confidence intervals. Embodied carbon (β = 0.397, 95% CI [0.32, 0.47]) and availability (β = 0.368, 95% CI [0.28, 0.45]) emerged as the strongest predictors of adoption, while aesthetics (β = 0.058, ns) was not significant.

These SEM results directly address Objective 2, confirming that embodied carbon (β ≈ 0.40) and availability (β ≈ 0.37) are the strongest predictors of zero-carbon material adoption, while aesthetics has negligible influence. This demonstrates that environmental and practical factors are the main drivers of decision-making.

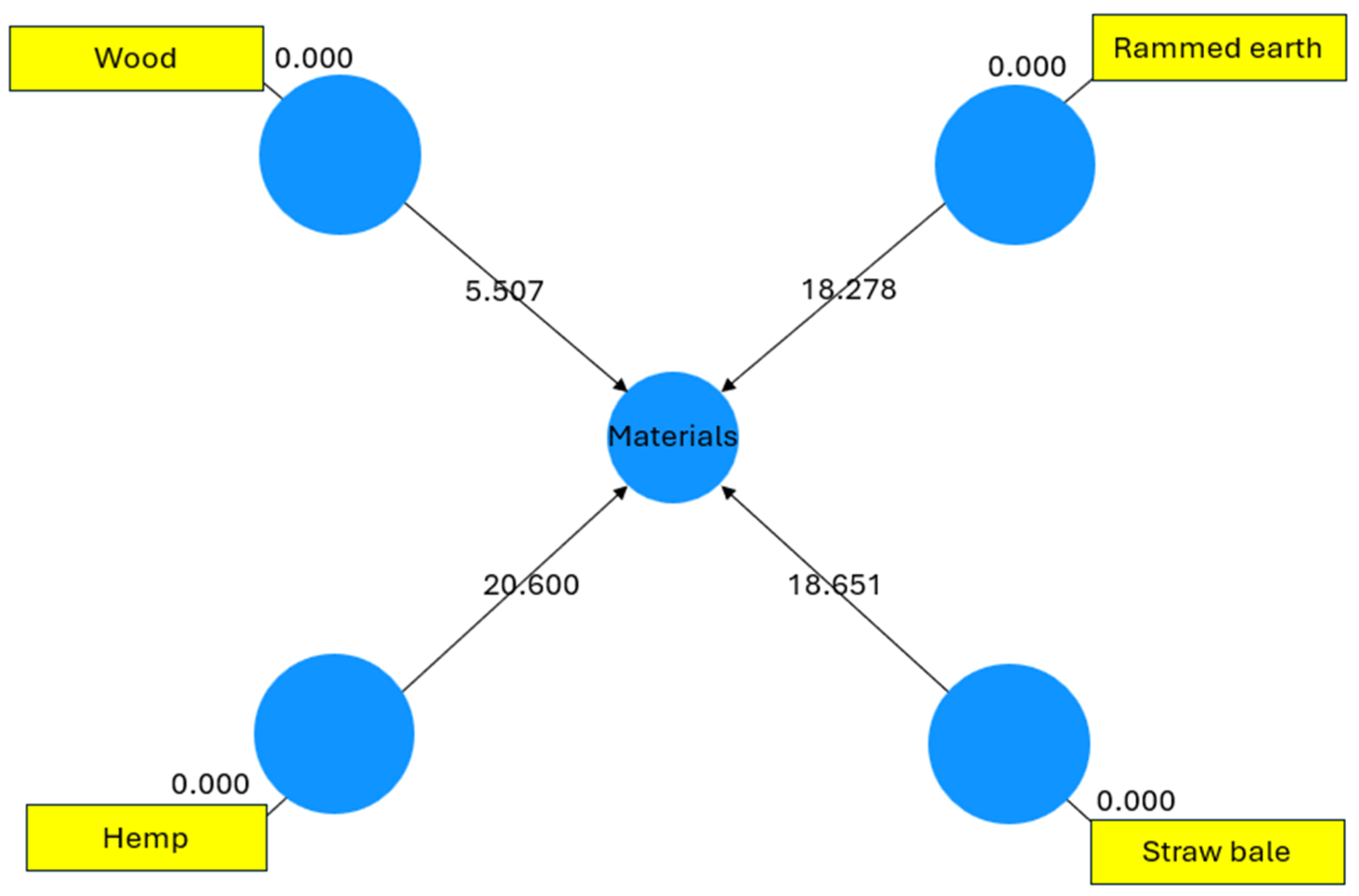

According to

Figure 2, factors such as wood (0.093) and cost-effectiveness (0.132) are more moderate in influencing material selection, reflecting their relatively lower impact on decision-making than environmental and accessibility considerations. The SEM results further highlight the importance of embodied carbon (standardised coefficient = 0.397) and availability (0.368) in influencing the adoption of zero carbon materials. These findings emphasise that while aesthetic or cost factors are relevant, the environmental and practical considerations of using materials with low embodied carbon and high availability are paramount in sustainable construction.

Table 9 and

Table 10 summarize the key factors achieved in this study.

5. Discussion

This study examined the factors influencing zero-carbon building material selection and assessed perceptions of four alternative materials (wood, hemp, rammed earth, and straw bale) in the New Zealand construction sector. The discussion addresses the study objectives by interpreting the findings in light of existing literature and highlighting their implications for sustainable construction.

The results revealed that cost-effectiveness and durability were rated as the most important factors influencing material selection, followed closely by buildability. This finding is consistent with previous studies demonstrating that economic considerations and material longevity are often prioritised by industry professionals when selecting sustainable materials [

38,

62]. The high ratings for cost-effectiveness reflect persistent pressures to balance environmental objectives with project budgets, especially in the New Zealand construction sector, where cost escalations are common.

Interestingly, embodied carbon and availability received only moderate importance scores. While this partially aligns with international studies [

63,

64], which identify embodied carbon as a critical sustainability driver, the relatively lower ranking observed here suggests that awareness and integration of life-cycle environmental impacts are still developing within the New Zealand context. Furthermore, aesthetics was rated the least influential factor, indicating that visual preferences are secondary to functional and environmental priorities when selecting zero-carbon materials.

Respondents perceived wood as the most suitable zero-carbon material, followed by hemp, while rammed earth and straw bale received lower ratings. The preference for wood is consistent with existing literature highlighting its familiarity, versatility, and extensive use in New Zealand’s construction industry [

65]. The strong consensus around wood’s practicality suggests it could serve as a primary driver of low-carbon adoption strategies in residential construction.

Our findings regarding the prominent roles of embodied carbon and material availability in material selection echo national-level observations. Finnie, Masood [

14] report systemic barriers in EC calculation and low material supply, particularly for timber alternatives like CLT and LVL. This aligns with our structural model, where embodied carbon and availability emerged as critical predictors. The use of SEM to quantify multi-factor influences in the New Zealand context is further validated by Bui, Domingo [

13], who identify similar interdependencies across technical, social, and environmental dimensions. A recent systematic review of zero-carbon building materials in NZ highlights cost, durability, and aesthetic considerations as under-explored yet critical factors, supporting the inclusion of these in our framework [

58].

These findings are consistent with the literature reviewed earlier, particularly regarding the increasing emphasis on embodied carbon and the practical challenges of accessing low-emission materials [

38,

39]. While theoretical models propose broad environmental and lifecycle advantages for sustainable materials, this study provides empirical evidence from New Zealand professionals, who prioritise environmental performance and practicality. In contrast to some global design narratives, the relatively low influence of aesthetics suggests a functional, pragmatic approach within New Zealand’s construction industry, likely shaped by cost constraints, supply limitations, and regulatory requirements.

The SEM results provide deeper insights into the relationships between selection factors and overall material adoption. Embodied carbon (β = 0.397) and availability (β = 0.368) emerged as the most significant predictors of zero-carbon material selection, followed by hemp (β = 0.373). These findings echo studies highlighting embodied carbon reduction as a primary driver for sustainable material adoption globally [

59] and reflect ongoing supply chain challenges unique to the New Zealand context [

11].

In contrast, cost-effectiveness (β = 0.132) and aesthetics (β = 0.058) showed limited influence on adoption decisions once environmental and practical considerations were accounted for. This divergence from traditional construction priorities suggests an important shift in industry attitudes: professionals increasingly value environmental performance and material accessibility over superficial or short-term cost factors. These insights address Objective 2 by clarifying how decision-making is shaped by a combination of environmental awareness and practical feasibility.

These results have practical implications for both policy and industry. Policymakers should prioritise initiatives that strengthen local supply chains, incentivise low-carbon alternatives, and increase awareness of embodied carbon in material selection. For practitioners, the findings highlight the importance of considering both environmental and practical performance when evaluating materials. While causal claims cannot be made, the associations identified in this study provide evidence-based guidance for accelerating the transition to zero-carbon construction in New Zealand.

The study contributes to the international literature by providing an empirical, context-specific analysis of material perceptions and selection drivers within an island economy. These insights may be relevant to other regions facing similar geographic and market constraints.

7. Conclusions

This study investigated the factors influencing the selection of zero-carbon building materials and assessed the perceived suitability of four alternatives—wood, hemp, rammed earth, and straw bale—within the New Zealand construction sector. The findings revealed that cost-effectiveness and durability are the most influential factors, followed by buildability, while embodied carbon and availability received moderate importance and aesthetics was rated least significant, addressing Objective 1. Through structural equation modelling (SEM), the study confirmed that embodied carbon and availability exert the strongest influence on the adoption of zero-carbon materials, whereas cost-effectiveness and aesthetics play relatively minor roles, thereby fulfilling Objective 2. Regarding Objective 3, respondents perceived wood as the most suitable zero-carbon material, followed by hemp, while rammed earth and straw bale were viewed less favourably due to perceived limitations in practicality and mainstream feasibility. These findings contribute to the literature on sustainable construction by providing empirical, context-specific insights into material perceptions and selection drivers in New Zealand. For policymakers and practitioners, the results highlight the need to improve awareness and accessibility of alternative materials, strengthen local supply chains, and introduce targeted incentives to make zero-carbon options financially competitive. Future studies should expand the material scope, incorporate perspectives from a broader range of stakeholders, and integrate cultural, regulatory, and policy-related dimensions to develop a more comprehensive framework for sustainable material adoption.