Sustainable Mining of Open-Pit Coal Mines: A Study on Intelligent Strip Division Technology Based on Multi-Source Data Fusion

Abstract

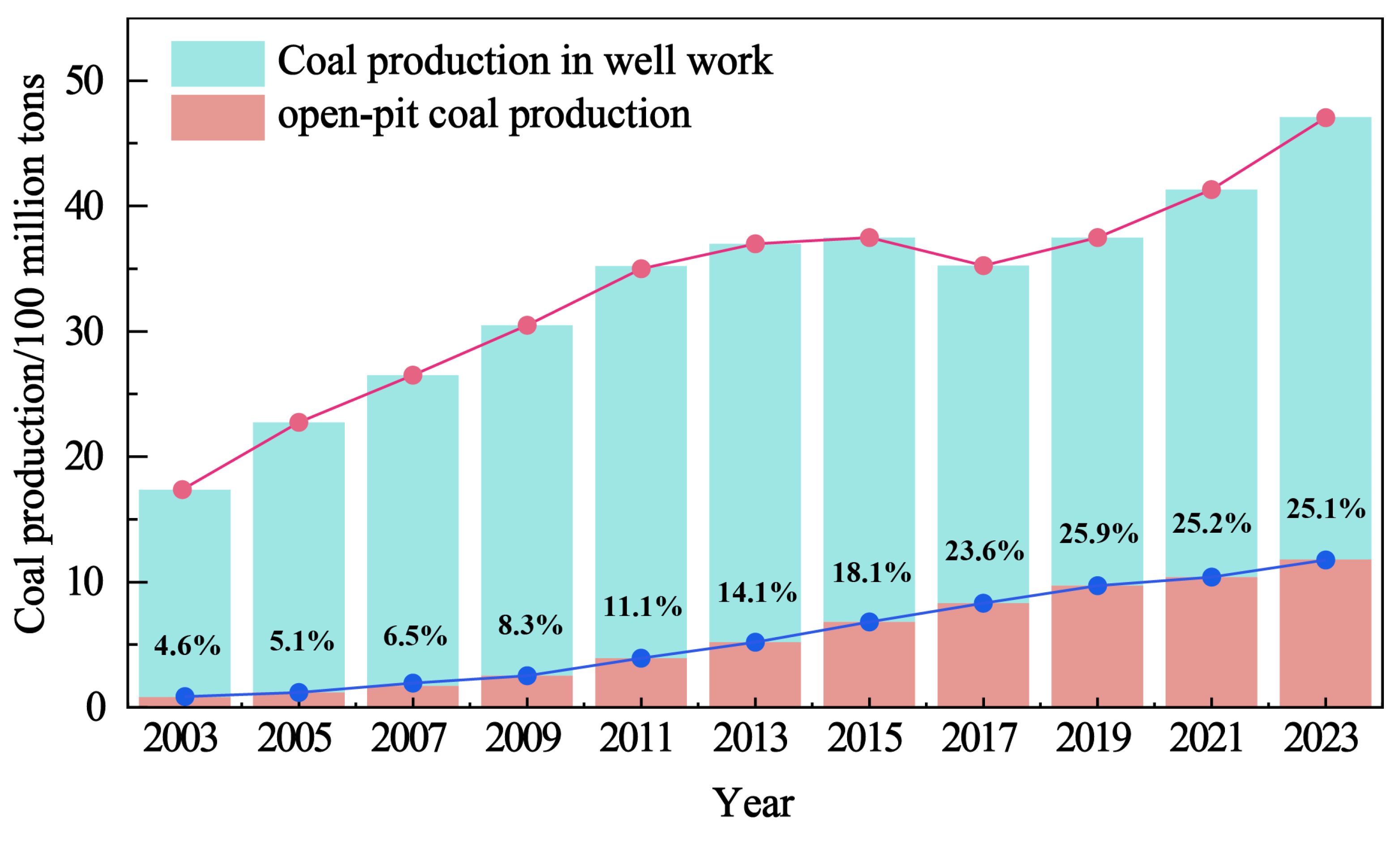

1. Introduction

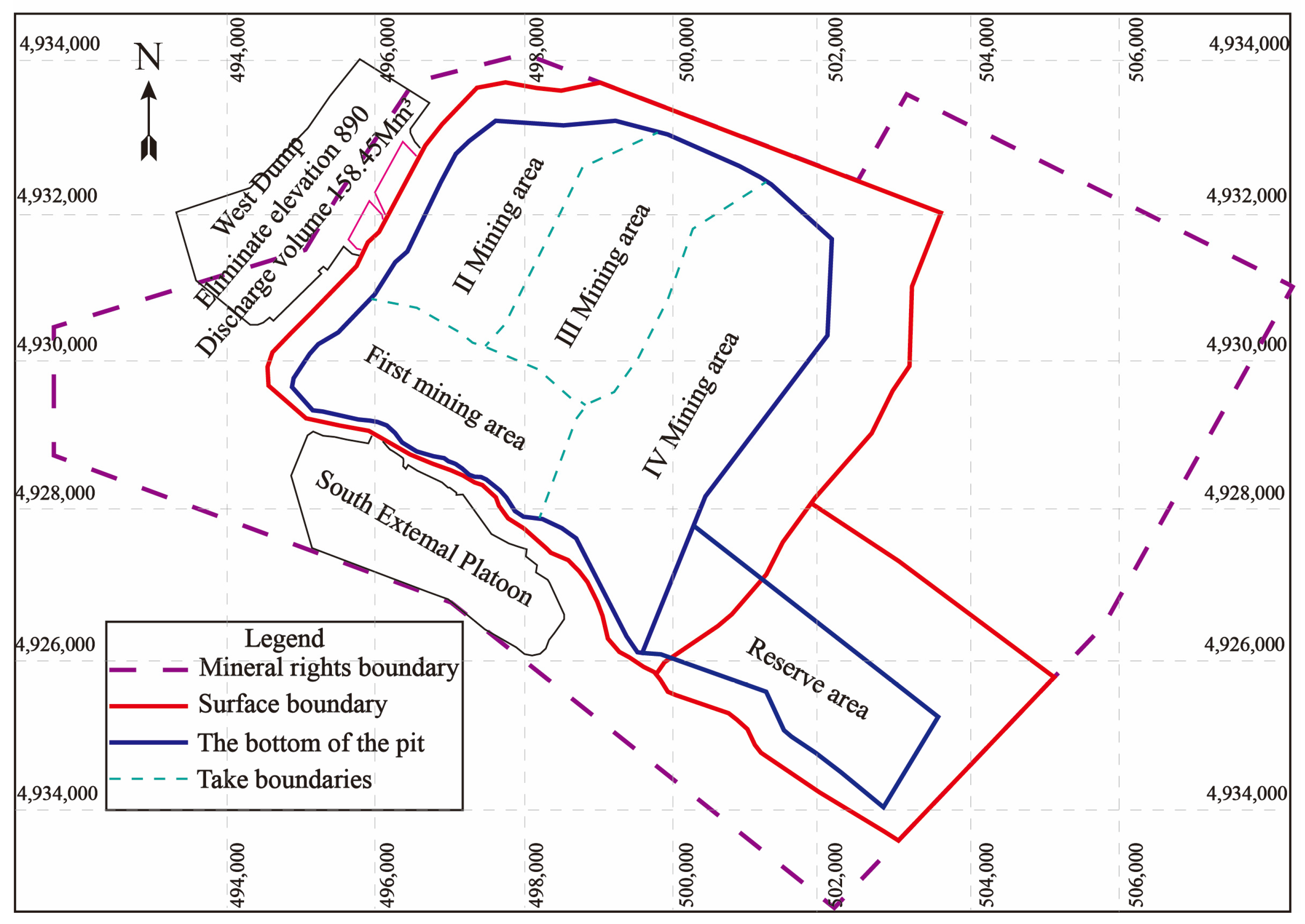

2. Project Background

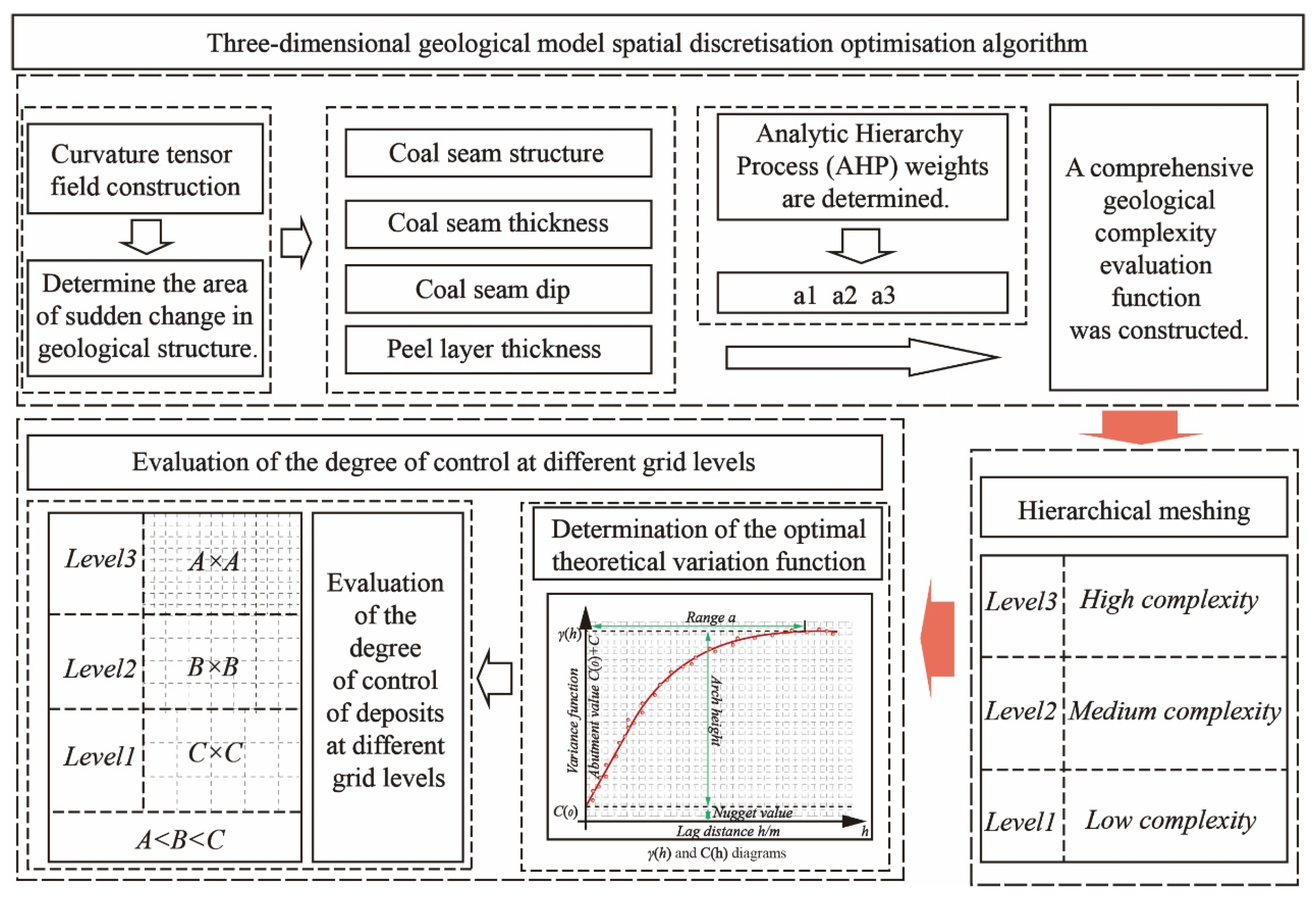

3. Method for Intelligent Mining Area Demarcation in Open-Pit Coal Mines

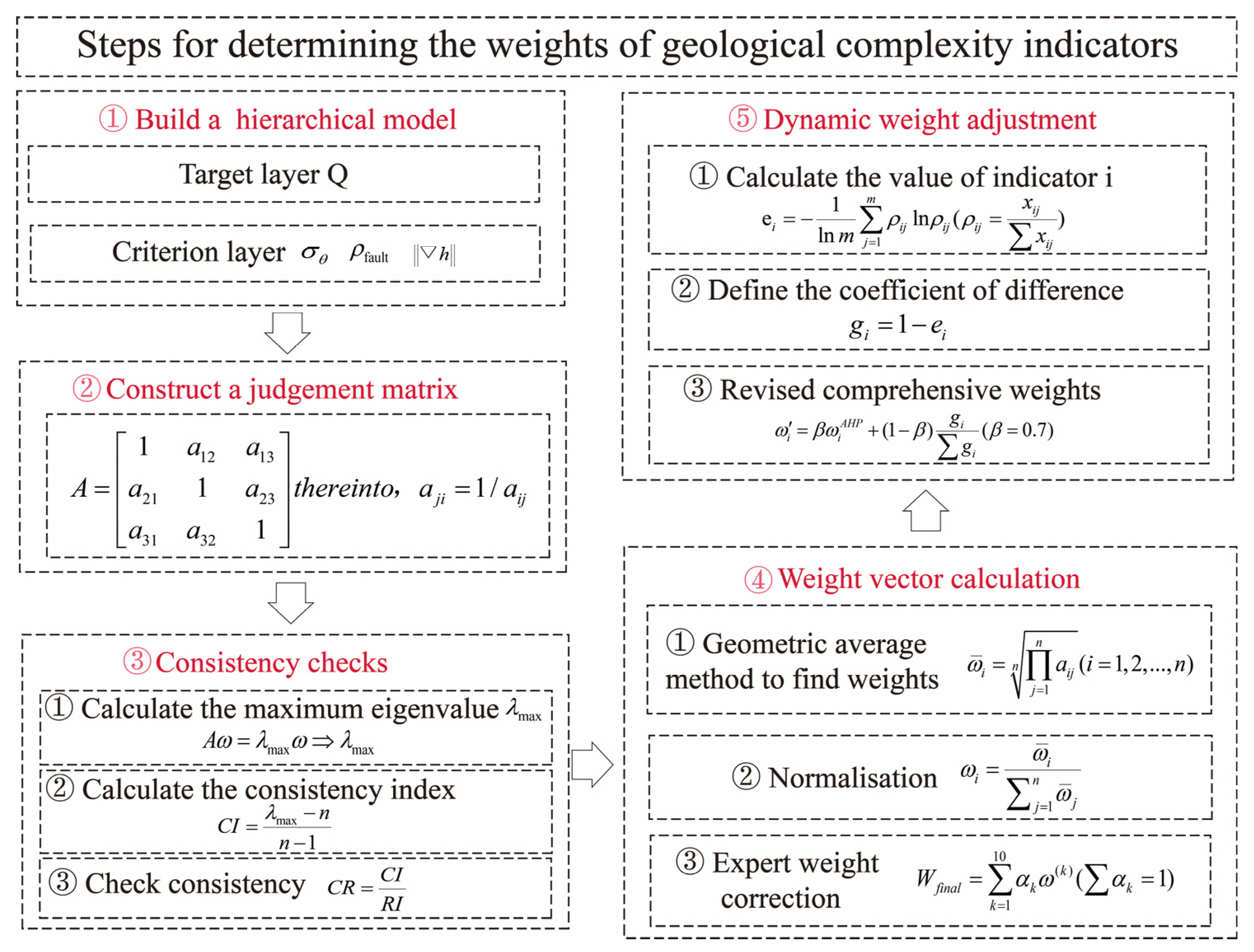

3.1. Construction of the Geological Complexity Quantification Model

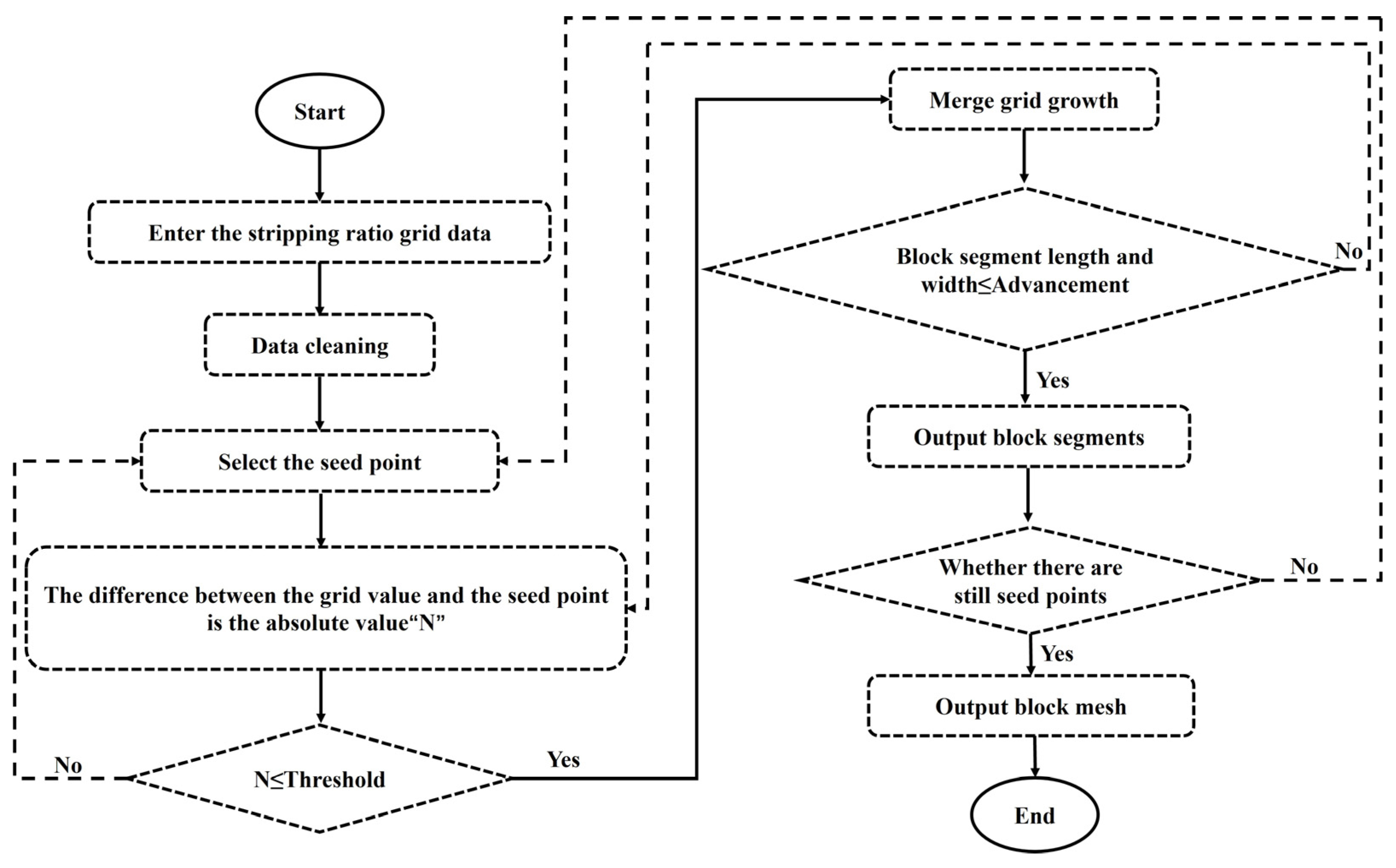

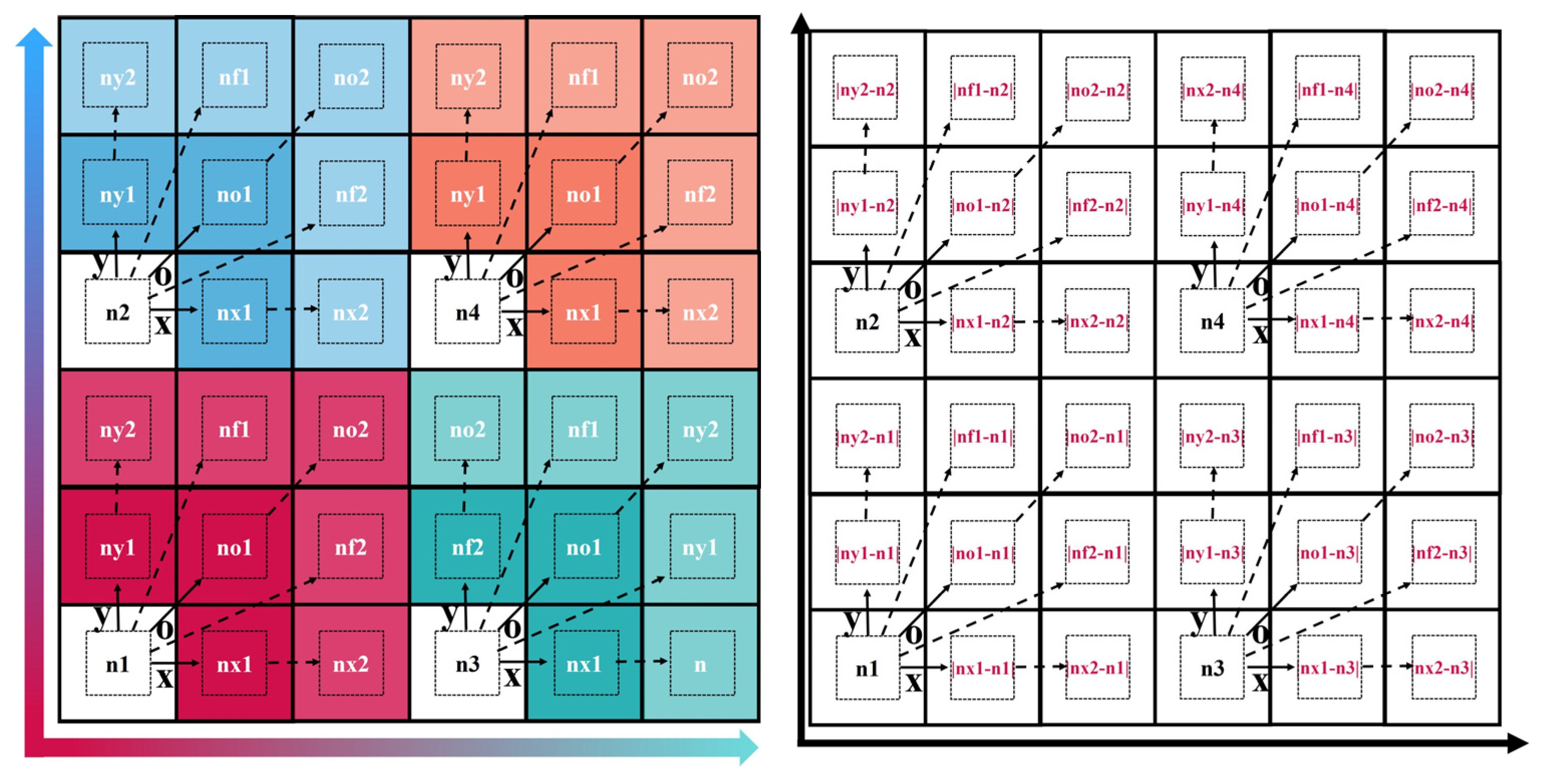

3.2. Block Growth Algorithm Based on Stripping Ratio Grids

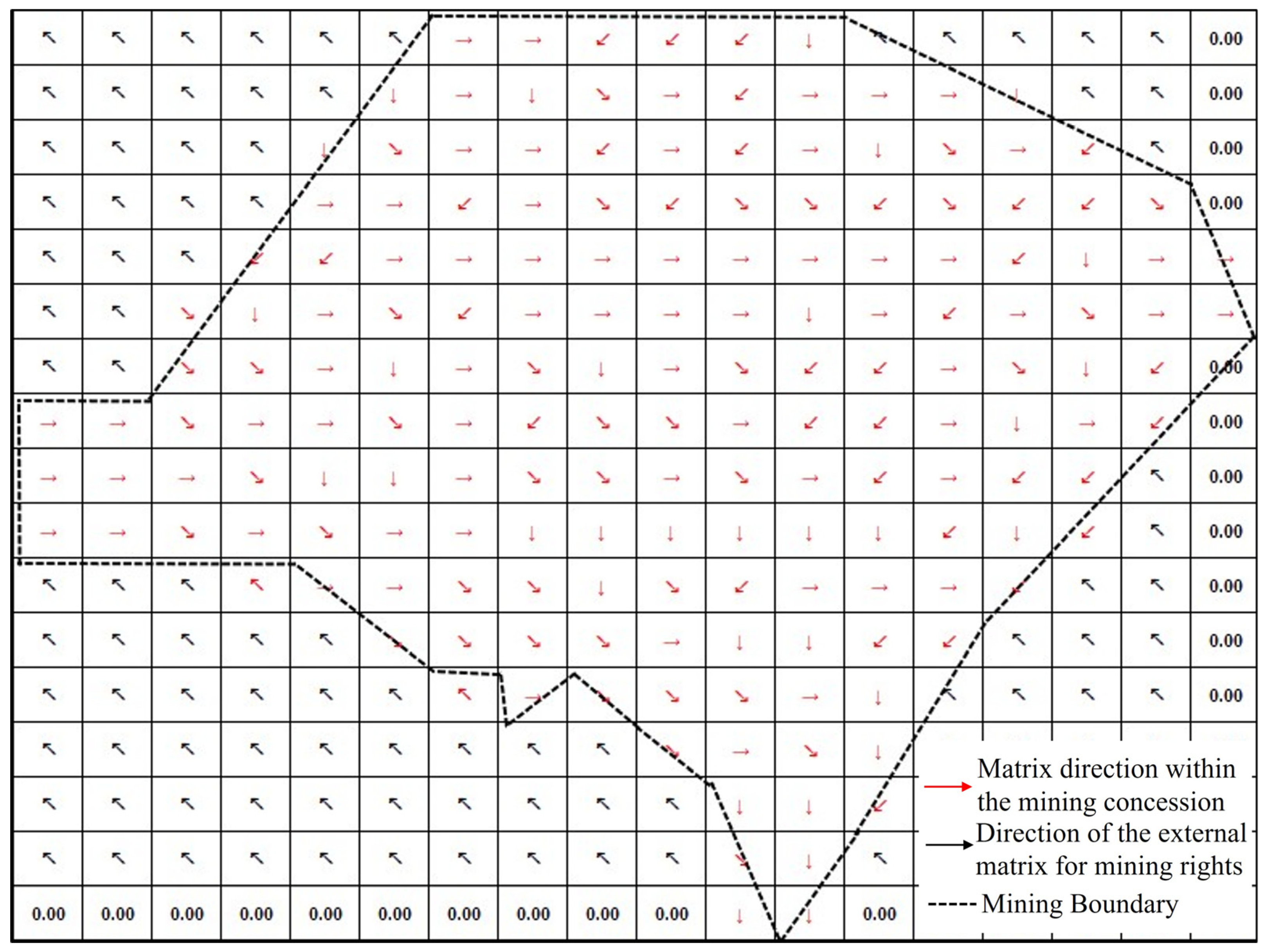

3.3. Construction of the Main Direction Matrix for Changes in the Stripping Ratio in Open-Pit Mines

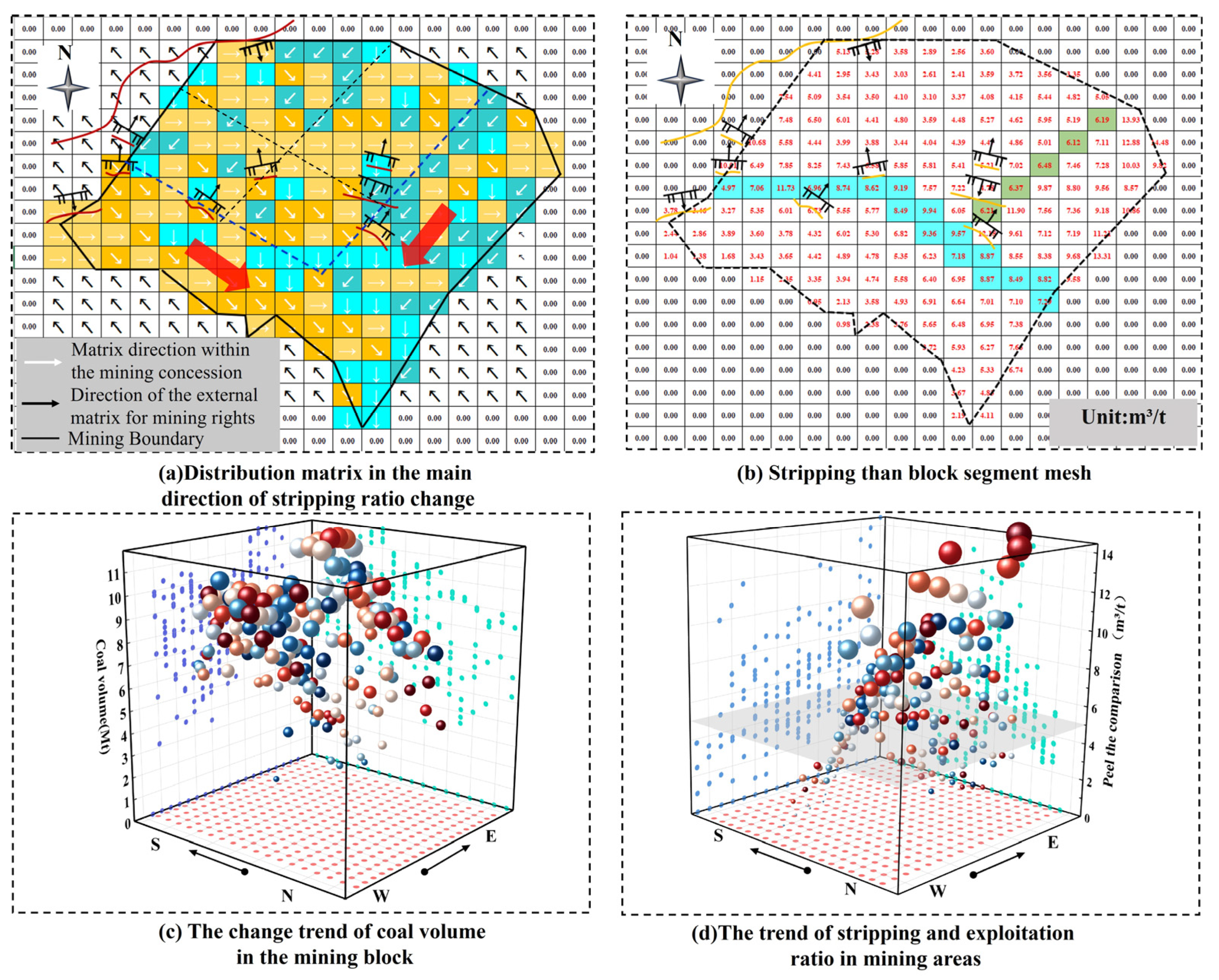

3.4. Mining Area Delineation Based on the Primary Direction of Stripping Ratio Variation

4. Research Findings and Analysis

4.1. Case Study: Shitoumei No. 1 Open-Pit Coal Mine

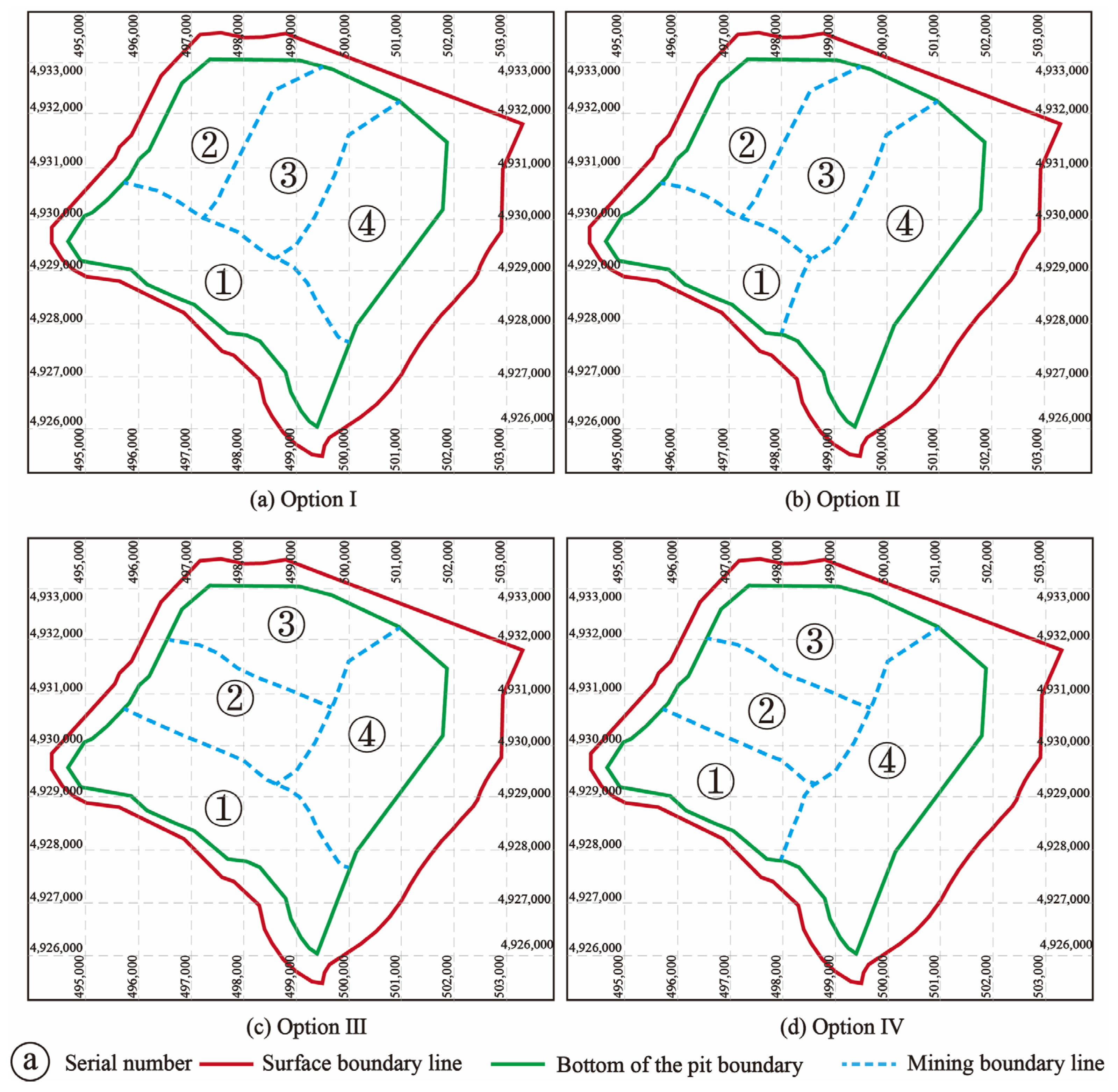

4.2. Comparative Analysis of Optimal Schemes for Shitoumei No. 1 Open-Pit Coal Mine

- (1)

- Analysis of Multi-source Data Indicators and Weighting for Mining Area Demarcation

- (2)

- Results of the Mining Area Division for Shitoumei No. 1 Open-Pit Coal Mine

4.3. Limitations of Previous Research

4.4. Strengths of the Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China Energy Media Research Institute. China Energy Big Data Report; China Energy Media Research Institute: Beijing, China, 2024. [Google Scholar]

- Cai, Q.X.; Chen, Y.L. Review of 70-year achievements of China’s open-pit coal mines and high-quality development framework system. Coal J. 2024, 49, 235–260. [Google Scholar]

- Gu, Q.H.; Li, X.X.; Lu, C.W. Technical path of new mode of intelligent construction of open-pit mine under the background of double carbon. Met. Mine 2023, 5, 1–13. [Google Scholar]

- Zhang, J.W. Intelligent status and development approach of Dananhu No. 2 Open-pit Mine. Ind. Min. Autom. 2022, 48, 47–50. [Google Scholar]

- Noriega, R.; Pourrahimian, Y. A systematic review of artificial intelligence and data-driven approaches in strategic open-pit mine planning. Resour. Policy 2022, 77, 102727. [Google Scholar] [CrossRef]

- Samuel, F.P. Intelligent Modeling: Advances in Open Pit Mine Design and Optimization Research. Int. J. Surf. Min. Reclam. Environ. 2002, 16, 134–143. [Google Scholar]

- Quelopana, A.; Navarra, A. Integration of strategic open-pit mine planning into hierarchical artificial intelligence. J. S. Afr. Inst. Min. Metall. 2021, 121, 643–652. [Google Scholar] [CrossRef]

- Mariz, J.L.V.; Badiozamani, M.M.; Peroni, R.D.L. A critical review of bench aggregation and mining cut clustering techniques based on optimization and artificial intelligence to enhance the open-pit mine planning. Eng. Appl. Artif. Intell. 2024, 133, 108334. [Google Scholar] [CrossRef]

- Mcfarland, J.R.; Herzog, H.J.; Jacoby, H.D. The future of coal consumption in a carbon constrained world. In Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies, Vancouver, BC, Canada, 5 September 2004; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Zhang, J.W. Zhundong open-pit coal mine mining area division demonstration. Small Medium-Sized Enterp. Manag. Sci. Technol. 2009, 6, 243–244. [Google Scholar]

- Ma, J.Y.; Cai, Q.X.; Liu, F.M. Optimization design of stripping engineering during mining area turning in Heidaigou open-pit Mine. Coal Eng. 2014, 46, 1–3. [Google Scholar]

- Yang, L.J.; Shen, W.; Wang, J.D. Study on mining area division and mining scheme of Hesigewula open-pit coal mine. Open-Pit Min. Technol. 2016, 31, 49–52. [Google Scholar]

- Liu, T. Study on the Division and Transition Optimization of Mining Area in Huolinhe No. 1 Open-Pit Mine. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2016. [Google Scholar]

- Ding, X.; Xiao, S.; Ma, L. Optimisation study on coordinated mining model of coal reserves buried between adjacent surface mines. Int. J. Oil Gas Coal Technol. 2017, 16, 283. [Google Scholar] [CrossRef]

- Bai, R.C.; Bai, W.Z.; Liu, G.W. TOPSIS decision-making method and application of open-pit mining area division. J. Liaoning Tech. Univ. Nat. Sci. Ed. 2017, 36, 1240–1245. [Google Scholar]

- Bai, R.C.; Li, H.R.; Liu, G.W. Boundary optimization of adjacent inclined composite coal seam open-pit mine during steering. J. Liaoning Tech. Univ. Nat. Sci. Ed. 2018, 37, 673–679. [Google Scholar]

- Cao, B.; Tao, Y.B.; Bai, R.C. Stage boundary optimization of partition mining in narrow and long open-pit mine with inclined coal seam. J. Chongqing Univ. 2019, 42, 101–110. [Google Scholar]

- Cao, B.; Tao, Y.B.; Han, Y. Open-pit mine partition boundary optimization of inclined coal seam under the condition of burnt rock erosion. Coal Sci. Technol. 2020, 48, 228–235. [Google Scholar]

- Li, H.R. Research on Control Method and Application of Stripping, Mining and Drainage Engineering in Irregular Boundary Open-Pit Mine. Ph.D. Thesis, Liaoning University of Technology, Liaoning, China, 2022. [Google Scholar]

- Si, W.Y. Optimization of production system during the transition period of the third mining area of Antaibao Open-pit Mine. Open-Pit Min. Technol. 2023, 38, 82–85. [Google Scholar]

- Cao, B.; Wang, S.; Bai, R. Boundary optimization of inclined coal seam open-pit mine based on the ISSA–LSSVR coal price prediction method. Sci. Rep. 2023, 13, 7527. [Google Scholar] [CrossRef]

- Wu, J.; Wang, W.; Ni, X. Study on the Application of Real-Time Drone Monitoring in Ordos Open-Pit Coal Mine. Appl. Sci. 2023, 13, 483–495. [Google Scholar] [CrossRef]

- Liu, G.; Guo, W.; Chai, S. Research on production capacity planning method of open-pit coal mine. Sci. Rep. 2023, 13, 8676. [Google Scholar] [CrossRef]

- Ma, L.; Li, R.X.; Liu, F.M. Study on the division of mining area under the influence of nuclear increase of production capacity in open-pit coal mine. Coal Sci. Technol. 2023, 51, 63–70. [Google Scholar]

- Cao, B.; Wang, J.; Guo, X. Research on boundary optimization of adjacent mining areas in open pit coal mine based on calculation of sectional stripping ratio. Sci. Rep. 2023, 13, 21286. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.W.; Liu, W.Q.; Guo, S.L. Research on Production Capacity Planning Method: A case study from the Baorixile Open-pit Coal Mine in Northeast China. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Cheskidov, V.I.; Reznik, A.V. Specifics of Internal Overburden Dumping in Open Pit Mining. J. Min. Sci. 2022, 58, 227–233. [Google Scholar] [CrossRef]

- Che, Z. Optimization of Internal Dumping Development Haulage System in Anjialing Surface Coal Mine. J. Min. Saf. Eng. 2007, 24, 404–407. [Google Scholar]

- Liu, K.; Mei, B.; Li, Q. Collaborative Production Planning Based on an Intelligent Unmanned Mining System for Open-Pit Mines in the Industry 4.0 Era. Machines 2024, 12, 419. [Google Scholar] [CrossRef]

- Liu, G.W.; Tu, J.X.; Guo, W.Q. Transition and continuation scheme of open-pit mining area under complex engineering geological conditions. Coal Sci. Technol. 2025, 53, 450–460. [Google Scholar]

| A | B1 | B2 | B3 | B4 | B5 |

|---|---|---|---|---|---|

| B1 | 1 | 2 | 2 | 1.5 | 4 |

| B2 | 0.5 | 1 | 1.2 | 0.8 | 2.5 |

| B3 | 0.5 | 0.83 | 1 | 0.8 | 2.5 |

| B4 | 0.67 | 1.25 | 1.25 | 1 | 3 |

| B5 | 0.25 | 0.4 | 0.4 | 0.33 | 1 |

| Scheme | Block | Coal Quantity (Mt) | Average Stripping Ratio (m3/t) | Stripping Ratio Variance | Mining Area Continuity Coefficient | Structural Density | Resource Recovery Rate |

|---|---|---|---|---|---|---|---|

| Scheme I | Panel I | 579.98 | 4.9 | 2.6 | 100% | 0.40% | 94% |

| Panel II | 265.6 | 6.21 | 4.08 | 100% | 0.20% | ||

| Panel III | 332.45 | 7.59 | 0.63 | 100% | 0.70% | ||

| Panel IV | 379.64 | 17.08 | 5.37 | 100% | 0.50% | ||

| Scheme II | Panel I | 306.88 | 4.05 | 2.19 | 100% | 0.45% | 94% |

| Panel II | 265.6 | 6.21 | 4.08 | 100% | 0.20% | ||

| Panel III | 332.45 | 7.59 | 0.63 | 100% | 0.70% | ||

| Panel IV | 647.77 | 14.1 | 5.74 | 100% | 0.37% | ||

| Scheme III | Panel I | 579.98 | 4.9 | 2.62 | 100% | 0.40% | 88% |

| Panel II | 191.22 | 7.17 | 2.71 | 100% | 0.57% | ||

| Panel III | 300.11 | 4.32 | 0.73 | 100% | 0.00% | ||

| Panel IV | 379.64 | 17.08 | 5.37 | 100% | 0.50% | ||

| Scheme IV | Panel I | 306.88 | 4.05 | 2.19 | 100% | 0.45% | 87% |

| Panel II | 191.22 | 7.17 | 2.71 | 100% | 0.57% | ||

| Panel III | 300.11 | 4.32 | 0.73 | 100% | 0.00% | ||

| Panel IV | 647.77 | 14.1 | 5.74 | 100% | 0.37% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, S.; Zhang, R.; Tao, Y.; Meng, Z.; Wang, S.; Liu, Z. Sustainable Mining of Open-Pit Coal Mines: A Study on Intelligent Strip Division Technology Based on Multi-Source Data Fusion. Sustainability 2025, 17, 9049. https://doi.org/10.3390/su17209049

Lv S, Zhang R, Tao Y, Meng Z, Wang S, Liu Z. Sustainable Mining of Open-Pit Coal Mines: A Study on Intelligent Strip Division Technology Based on Multi-Source Data Fusion. Sustainability. 2025; 17(20):9049. https://doi.org/10.3390/su17209049

Chicago/Turabian StyleLv, Shuaikang, Ruixin Zhang, Yabin Tao, Zijie Meng, Sibo Wang, and Zhigao Liu. 2025. "Sustainable Mining of Open-Pit Coal Mines: A Study on Intelligent Strip Division Technology Based on Multi-Source Data Fusion" Sustainability 17, no. 20: 9049. https://doi.org/10.3390/su17209049

APA StyleLv, S., Zhang, R., Tao, Y., Meng, Z., Wang, S., & Liu, Z. (2025). Sustainable Mining of Open-Pit Coal Mines: A Study on Intelligent Strip Division Technology Based on Multi-Source Data Fusion. Sustainability, 17(20), 9049. https://doi.org/10.3390/su17209049