Abstract

This study used ceramsite and superphosphate as exogenous additives for composting garden wastes. It investigated the changes in temperature, pH, lignocellulose, enzyme activity, humic substrates, and humification parameters during the composting process. A total of four treatments—T0 (CK), T1 (ceramsite), T2 (superphosphate), and T3 (superphosphate + ceramsite)—were tested in a 50-day composting experiment. It was found that the formation of the compost humic substrate could be increased to 14.69% under the action of ceramsite. In addition, ceramsite promoted lignocellulose degradation, improved enzyme activity, and enhanced the material conversion in the composting process. At the same time, superphosphate also promoted the formation of humic substrates in compost but was less effective than ceramsite. Ceramsite is the best additive in promoting compost maturation.

1. Introduction

The large amount of garden waste generated with the acceleration of urbanization can harm the environment if it is not properly processed. Composting is an effective way to utilize the life activities of microorganisms to convert organic matter into humic substrates (HSs). When applied to the soil, compost can provide rich nutrients for plant growth [1,2]. The potential of compost mainly depends on the quality of compost [1], and the content of HSs is an important indicator for assessing the quality of compost [3,4]. Therefore, improving the synthesis efficiency of HSs in the composting process of garden waste has become a prominent research focus [5].

HSs are macromolecules composed of humic acid (HA) and fulvic acid (FA), where HA is only soluble in alkaline solutions, while FA is soluble in both acidic and alkaline solutions [6]. The degradation and humification of organic matter in the composting process mainly rely on microorganism activity [2]. Lignocellulose in garden waste is an important factor affecting compost decay [7] and is composed of lignin, cellulose, and hemicellulose. Lignin in the lignocellulosic structure is connected and wrapped together with cellulose and hemicellulose through hydrogen bonding, forming an extremely complex and the most stable organic matter during composting [8,9]. This makes it difficult to degrade lignocellulose difficult to be degraded by using microorganisms during the composting process [10]. At the early stage of composting, the concentration of readily available organic matter is high, microbial activity is elevated, and relevant enzymes are secreted, which enhances the efficiency of material conversion. By the middle and late stages of composting, the concentration of readily available organic matter in the compost decreases, and microbial activity is restricted [11], resulting in weakened organic matter degradation during composting, thus reducing composting efficiency. At the same time, the compost enters the period of decomposition, and small molecules begin to synthesize HS in large quantities until the end of composting. Studies have shown that adding exogenous additives to compost is an effective way to promote the composting process, and exogenous additives can improve the microenvironment inside the compost pile through their physical and chemical properties, provide sufficient oxygen and/or nutrients for microbial activities, and then improve the degradation rate of organic matter and the efficiency of HS formation [12,13,14,15]. Therefore, the addition of exogenous additives to compost is important to promote compost humification [16]. In previous studies, it was found that biochar can promote the conversion of humus precursors to humus [17] by strengthening the role of microorganisms in compost, and zeolite can also increase the content of humus in compost [18]. However, these exogenous additives are expensive and cannot be recycled, which increases the cost of composting and is not conducive to large-scale promotion and application, so it is urgent to develop new exogenous additives.

Ceramsite is a spherical material with a high specific surface area and a well-developed microporous structure, which can provide sufficient sites for microorganisms to proliferate [19] and, thus, it is widely used in wastewater purification [20]. The porous nature of ceramsite can increase the permeability of compost and improve the oxygen content and bacterial diversity [21]. It was shown that ceramsite could reduce the migration rate of Cd during sludge composting [22]. In addition, ceramsite has a strong physical structure that is not easily damaged, inexpensive, and can be recycled, further enhancing its utilization value. Li et al. [23] found that applying ceramsite in sludge compost can promote the decomposition and degradation of organic matter. Bai et al. [24] used ceramsite and brewer’s grains as exogenous additives to study the mineralization process of materials in the composting process. However, no research has been conducted on systematically studying the humification effect of composting garden waste using ceramsite as an exogenous additive. Superphosphate is a common and inexpensive acidic chemical. It has been reported that superphosphate accelerates compost humification and promotes the formation of compost HA [25]. Superphosphate can also enhance compost nitrogen fixation and nitrification genes [26], reduce nitrogen loss during composting, improve compost quality [27], inhibit the release of volatile sulfur compounds, and reduce the environmental impact of malodorous gasses produced by composting [28]. Therefore, ceramsite and superphosphate are both cost-effective and ideal compost exogenous additives. However, no studies have compared the effects. Several studies have shown that exogenous additives can be used individually and as combination additives [29]. Moreover, the current research on compound additives mostly focuses on heavy metal passivation [30] and nitrogen conversion [31], and the research on the humification of compost needs to be further explored.

In view of this, ceramsite and superphosphate were selected as exogenous additives for composting in this study to improve the efficiency and product quality of composting of garden wastes, which in turn enhances the degradation rate of lignocellulose and the formation of HS. The specific research objectives include two aspects: (I) to analyze the effects of ceramsite and superphosphate on the key indexes of lignocellulose, HS, FA, and HA in the composting process, and (II) to evaluate the regulatory effects of ceramsite and superphosphate on the humification of composted garden waste and screen out the optimal additives. This study is expected to provide a scientific basis for the efficient composting of garden waste and guidance for selecting composting additives.

2. Materials and Methods

2.1. Preparation of Raw Materials

The compost consisted of four main raw materials: garden waste, air-dried chicken manure, ceramsite, and superphosphate. Garden waste was collected in Xiangshan Park (Beijing, China), consisting of dead branches and fallen leaves produced during the maintenance of greenery in the park. Air-dried chicken manure was purchased from Shijiazhuang Jiaci Trading Co., Ltd. (Shijiazhuang,, China). Ceramsite and superphosphate were purchased from Guangzhou Jiarui Environmental Protection Materials Co., Ltd. (Guangzhou, China) and Chongqing Ruiye Trading Co., Ltd. (Chongqing, China), respectively. Among these raw materials, garden waste was used as the main raw material for composting, air-dried chicken manure was used to adjust the carbon-nitrogen ratio, and ceramsite and superphosphate were used as exogenous additives for composting. Before the beginning of the experiment, the garden waste was naturally air-dried and pulverized to maintain the particle size (approximately 2 cm). The air-dried chicken manure was decontaminated to remove the mixed chicken feathers, stones, and other impurities, and the large pieces of chicken manure were crushed to a particle size of less than 2 cm.

2.2. Experimental Design

The experiment was conducted in the Beilinkeji greenhouse of Beijing Forestry University in Beijing, China. A total of four treatments were set up in the experiment: T0 (no additives), T1 (15% ceramsite), T2 (5% superphosphate), and T3 (15% ceramsite + 5% superphosphate). Before the start of the experiment, the garden waste and air-dried chicken manure were mixed in a ratio of 3:1 (w/w) to make the compost have a carbon-to-nitrogen ratio of 25:1, and then the mixed compost material was evenly divided into four portions. The experiment comprised four treatments: T1 involved the addition of 15% ceramsite (with exogenous additives calculated as the mass fraction of dry matter), T2 incorporated 5% superphosphate, T3 included both 15% ceramsite and 5% superphosphate simultaneously, and T0 served as the control without any exogenous additives. Finally, the water content of the four piles was adjusted to approximately 60% using distilled water, after which the four compost treatments were placed into 100 L polyethylene reaction drums for a 50-day composting test. The compost was turned on the 0th, 8th, 15th, 22nd, 29th, 36th, 43rd, and 50th days of the composting process. Approximately 500 g of samples were collected from the mixed compost using the multi-point sampling method after each turning, followed by the addition of water as needed based on the moisture content of the compost. The collected samples were divided into 2 portions: one was air-dried and pulverized, and the other was stored in a refrigerator at 4 °C to determine test-related indicators. Three copies of each treatment were sampled each time as replicates.

2.3. Methods of Analysis

The temperature of the composting pile was measured by a thermometer every day. The sample was extracted from the compost sample and distilled water at a ratio of 1:10 (w/v), and the supernatant was measured with a pH meter for the pH of the pile. Hemicellulose was determined through hydrochloric acid hydrolysis. Initially, 0.1 g of the sample was weighed into a beaker; then, 10 mL of an 80% mass fraction calcium nitrate solution was added. The mixture was boiled for 5 min, then cooled and centrifuged, with the precipitate rinsed 3 times with hot water. Subsequently, 10 mL of 2 mol/L hydrochloric acid was added to the precipitate, which was then covered with a glass lid and placed into a boiling water bath for 45 min before cooling and centrifugation. The supernatant was transferred into a 100 mL volumetric flask, the precipitate was rinsed 3 times, and the washing solution was incorporated into the volumetric flask; 1 drop of phenolphthalein solution was added to the volumetric flask and neutralized with NaOH solution until it developed a rose color, diluted to the scale, and then filtered into a beaker (the first few drops of filtrate were discarded). Finally, the reduced sugar content in the solution was determined using the DNS method and subsequently multiplied by a coefficient of 0.9, representing the hemicellulose content. The contents of cellulose and lignin were determined using nitric acid–ethanol and concentrated sulfuric acid, respectively [32]. Dehydrogenase, cellulase, and protease were determined using Liu et al.’s method [33]. Humic substances (HSs) and humic acid (HA) were determined using Yu. et al.’s method [34]. Fulvic acid (FA) was calculated as FA = HS−HA. Total organic carbon (TOC) was determined using the potassium dichromate volumetric method, which involves the oxidation of organic carbon in the sample to carbon dioxide through the heat released from the mixing of concentrated sulfuric acid and potassium dichromate solution. The remaining potassium dichromate was then titrated with a standard ferrous sulfate solution. Then, the amount of organic carbon in the sample was calculated according to the method of Yang et al. [35]. Humification parameters were used to assess the humification process and were calculated according to Lei et al.’s method [36]: humification ratio (HR) = (HS/TOC) × 100%; humification index (HI) = (HA/TOC) × 100%; percentage of humic acid (PHA) = (HA/HS) × 100%; H/F = HA/FA.

2.4. Statistical Analysis

All the data were presented as mean and standard deviation. The experimental data were compiled using Microsoft Office Excel 2018 software. SPSS 26 was used for one-way ANOVA with a p-value less than 0.05, which is considered significant; graphical representations were produced using Origin 2021.

3. Results and Analysis

3.1. Changes in Temperature and pH During the Composting Process

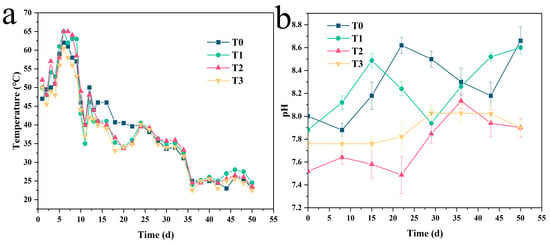

The changes in the composting pile temperature for each treatment in this study are shown in Figure 1a. The temperature changes in each treatment were roughly similar, showing a trend of first rising and then falling. The treatment group reached a high temperature of more than 50 °C on the 1st day, two days earlier than the control group, indicating that ceramsite and superphosphate can promote the heating of the compost of garden waste. All treatments reached maximum temperature on day 6, and then the temperature gradually decreased and remained above 60 °C for 2 (T0), 5 (T1), 3 (T2), and 1 (T3); T1 maintained for the longest number of days, probably because the internal pore structure of the ceramsite is rich in oxygen, the activity of microorganisms in the composting pile is enhanced [21]. On the 36th day, all the treatments entered the mature phase, the temperature gradually stabilized, and composting ended.

Figure 1.

Changes in temperature (a) and pH (b) during composting. The results obtained are the average of the three results with an error of standard deviation. T0: no additives; T1: 15% ceramsite; T2: 5% superphosphate; T3: 15% ceramsite + 5% superphosphate.

Appropriate pH enhances the activity of composting microorganisms [37] and promotes the decomposition of organic matter. As shown in Figure 1b, due to the addition of superphosphate to T2 and T3, the pH values were overall smaller than those of T0 and T1. pH values in the pre-composting stage of each treatment increased to different degrees, which can be attributed to the gradual consumption of acids such as organic acids and nitrogen-containing organic matter such as proteins are mineralized into ammonia [38]; in the late stage of the composting stage, the gradual increase in pH values of T0 and T1 may be attributed to carbonate buffer formation, while the pH values of T2 and T3 decrease significantly, which is speculated to be caused by the generation of organic acids [39]. After composting, the pH values of T2 and T3 were 7.90, which were within the range of mature compost pH values (7~8.5), but the pH values of T0 (8.66) and T1 (8.6) were high.

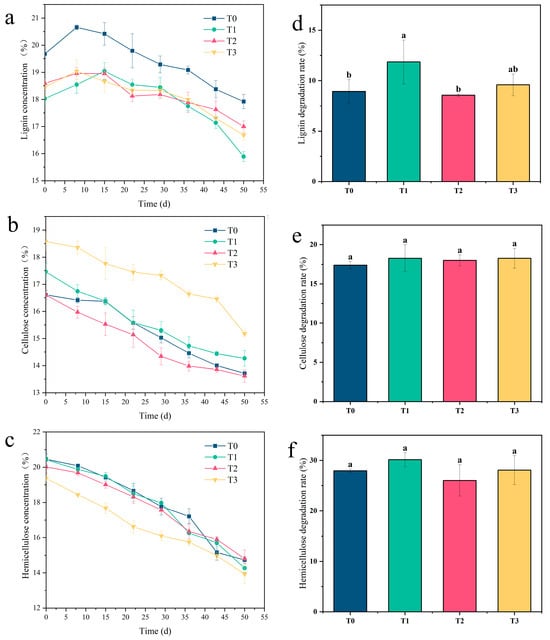

3.2. Changes in Lignocellulose During the Composting Process

Lignocellulose forms the primary structural component of plant cell walls; and the concentration of lignin, cellulose, and hemicellulose in the composting process is depicted in Figure 2. The lignin concentration in the composting process exhibited an initial increase, followed by a subsequent decline (Figure 2a), which may be attributed to the complexity and stability of lignin. In the heating and thermophilic stage of composting, microorganisms mainly consume easily degradable substances such as amino acids to meet the energy required for their rapid growth and metabolism. However, it is difficult to utilize lignin rapidly via microorganisms due to its complex chemical structure, thus leading to an increasing trend in lignin concentration [40,41]. As the composting process progresses, the activity of microorganisms that use simple organic matter as an energy source decreases, and lignin begins to degrade in the presence of bacterial and fungal activity, leading to a reduction in lignin concentration (Figure 2a). At the termination of the composting process, the lignin concentration of T0 decreased by 8.94%, while T1, T2, and T3 decreased by 11.87%, 8.57%, and 9.59%, respectively. The most substantial reduction in lignin concentration was observed in the treatment with ceramsite alone (T1), while a smaller reduction was noted in the treatment with superphosphate alone (T2), which was not significantly different from the control treatment (T0). This suggests that ceramsite promotes lignin degradation. In contrast, the effect of superphosphate on the degradation of lignin was not obvious. The trend in cellulose concentration alterations during composting is presented in Figure 2b, demonstrating an overall decline. At the end of the composting process, the cellulose degradation rates of the treatments were 17.40%, 18.27%, 18.00%, and 18.28%, respectively. The composting process resulted in a rapid decrease in hemicellulose concentration, attributed to microbial activity, which is the most readily degraded component of lignocellulose, consistent with the findings of Wei et al. [42]. The hemicellulose degradation rates of T0–T3 at the end of the composting process were 27.97%, 30.15%, 26.07%, and 28.09%, respectively.

Figure 2.

The changes in lignin (a), cellulose (b), and hemicellulose (c) during the composting process, and the lignin degradation rate (d), cellulose degradation rate (e), and hemicellulose degradation rate (f) of each treatment after composting. The results obtained are the average of the three results with an error of standard deviation. Bars with different letters indicate significant differences between treatments (p < 0.05). T0: no additives; T1: 15% ceramsite; T2: 5% superphosphate; T3: 15% ceramsite + 5% superphosphate.

This study showed that the addition of ceramsite could promote the degradation of lignin in the composting process, while the effect of superphosphate was not obvious. The rich porous structure of ceramsite creates a large oxygen-rich environment for microbial activities [43], which enhances microbial activity and leads to the proliferation of microorganisms that are key to the degradation of lignin [44], thus promoting the decomposition of lignin. Previous studies found that ceramsite has similar effects to biochar in the composting process, which can promote microbial growth and reproduction [23]. At the same time, due to the large number of aromatic clusters on the surface of the ceramsite, the contact area between the cells of the garden waste and the microorganisms was increased [24], which enhanced the microbial degradation of lignin. Studies have shown that the key taxa for lignin degradation are Firmicutes and Actinobacteria [45]. Ceramsite can increase the content of Firmicutes and promote the secretion of a variety of enzymes, which are important for lignin degradation [46]. Actinobacteria are believed to contribute to the degradation of structurally complex organic matter such as lignin [47]. In Li et al.’s study [23], it was found that ceramsite with a porous structure improved the diffusion conditions for oxygen in the compost that significantly increased the abundance of Actinobacteria, with a consequent enhancement of carbohydrate metabolism and more intense degradation of lignin.

pH is an important factor that affects the composting process [48]. Cai et al. [49] found that superphosphate could promote cellulose degradation in a study using dairy manure as composting raw material, which was different from the results of this study (Figure 2e). It is hypothesized that this may be due to the different nature of the composting raw materials, or the amount of superphosphate added [50].

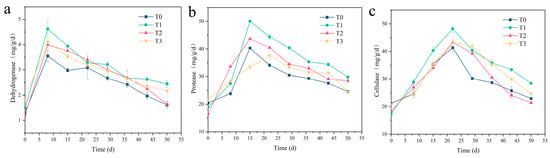

3.3. Changes in Enzyme Activity During the Composting Process

Dehydrogenase can oxidize the organic matter within the compost to produce adenosine triphosphate, an important indicator in responding to microbial degradation [51]. From Figure 3a, it can be seen that the dehydrogenase activity showed an overall trend of increasing and then decreasing. Enzyme activity reached the maximum on day 8, after which the dehydrogenase activity gradually decreased with the decrease in microbial activity, meaning that the compost reached the maturity state [14]. Compared with the control treatment, the enzyme activities of the treatment groups were all in a higher state during the composting process, which indicated that both the ceramsite and superphosphate increased the dehydrogenase activity to some extent. However, at the end of the composting process, the enzyme activity of T1 was higher than the other treatments, which indicated that the ceramsite had a better promotion effect on dehydrogenase activity, which was due to the fact that the biochar provided a larger attachment area for microorganisms to improve the microbial activity [52].

Figure 3.

Changes in dehydrogenase (a), protease (b), and cellulase (c) activities during composting. The results obtained are the average of the three results with an error of standard deviation. T0: no additives; T1: 15% ceramsite; T2: 5% superphosphate; T3: 15% ceramsite + 5% superphosphate.

Proteases act mainly during the active phase of composting [53] and can hydrolyze peptide bonds connecting amino acids. They are the main enzymes for degrading proteins [54]. The changes in protease activity exhibited similar patterns across all treatments in this study, demonstrating an initial increase followed by a decrease (Figure 3b). The peak values were recorded on day 15, measuring 40.30, 50.04, 43.61, and 33.50 mg/g/d, respectively. Notably, T1 and T2 showed increases of 24.17% and 8.21%, respectively, compared to T0. After the start of the composting process, the protease activities of T1 and T2 were always higher than that of T0, with the protease activity of T1 being higher than that of T2, while the protease activities of T3 and T0 were closer to each other. In the pre-composting period, the compost contains a large amount of nitrogenous material that is rich in nutrients; microorganisms can carry out secondary metabolism to synthesize a large number of proteases. During the composting process, the nitrogenous compounds are gradually reduced, microbial activity gradually declines, and the protease activity decreases [33]. Data analysis showed that compared with the control treatment, the group with ceramsite and superphosphate alone promoted higher protease activity during composting, indicating that both additives can enhance the activity of microorganisms’ degrading proteins.

Cellulase can degrade cellulose and other difficult-to-degrade organic matter [55]. The initial cellulase activity was low and reached 41.33, 48.17, 43.31, and 43.34 mg/g/d on day 22, followed by a gradual decrease (Figure 3c). Observations showed that the cellulase activity of T1 surpassed that of the other treatments throughout the later stages of composting, which explains the higher degradation rate of lignocellulose in T1, most likely because the physical structure of the ceramsite facilitates the propagation of cellulase-secreting microorganisms, which maintains their activity during the composting process. Notably, the highest cellulase activity appeared in the mid-composting stage, which may be due to the fact that lignocellulose has a complex structure and is not easily degraded, and the microorganisms need to store enough energy to decompose effectively [52]. When the nutrients are sufficient in the pre-composting stage, the microorganisms store nutrients and energy, the enzyme-producing capacity of the microorganisms increases, and the cellulase activity rises [56]. During the mid-point of the composting process, cellulase activity peaks, which is followed by a decline in compost nutrients and a subsequent reduction in cellulase activity.

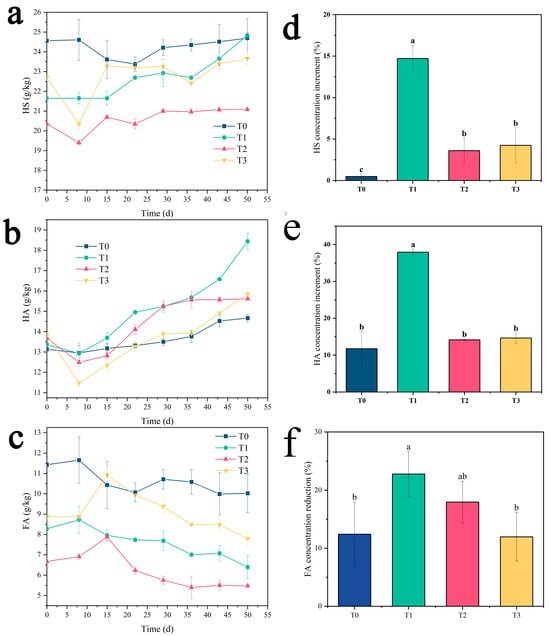

3.4. Changes in HS, HA, FA, and Humification Parameters During the Composting Process

HS is a colloidal organic polymer substance formed by the microbial transformation of organic matter, with HA and FA as its main components. The changes in HS in this study are shown in Figure 4a, showing a decreasing and then increasing trend. At the onset of composting, the structurally unstable compounds in the compost were gradually degraded, and the HS concentration showed a decreasing trend [57]. Thereafter, microorganisms synthesized small molecules, such as soluble sugars, in the compost into HS, causing the HS concentration across all treatments to rise; this suggested that humification in the composting process predominantly occurred in the middle to latter stages. By the end of the composting process, the HS contents for T0, T1, T2, and T3 had increased by 0.48%, 14.69%, 3.57%, and 4.23%, respectively, and the HS concentration of the treatment with added ceramsite (T1) increased the most (Figure 4d). The results potentially indicate that the stronger humification-promoting effect of ceramsite might be attributed to the weak alkaline condition of ceramsite, which fosters a suitable environment for microbial colonization [58], promotes the microorganisms in the compost to release key enzymes required for humification, such as urease, and improves the conversion efficiency of the compost’s organic matter [59]. In contrast, although superphosphate contributed significantly to the formation of HS, it was not as effective as ceramsite.

Figure 4.

The variations in HS (a), HA (b), and FA (c) during composting and increment in HS (d) and HA (e) at the end of the composting process and reduction in FA (f). HS: humic substrate; HA: humic acid; FA: fulvic acid. The results obtained are the average of the three results with an error of standard deviation. Bars with different letters indicate significant differences between treatments (p < 0.05). T0: no additives; T1: 15% ceramsite; T2: 5% superphosphate; T3: 15% ceramsite + 5% superphosphate.

The changes in HA concentration indicate the compost’s degree of humification [4]. Throughout the composting process, the HA concentration continued to increase with a series of condensation reactions of phenols, carbohydrates, and nitrogenous compounds [60]. During the final composting stage, the process transitions into putrefaction, characterized by decreased heap temperature. Concurrently, the activity of thermophilic microorganisms also increases, leading to the decomposition of macromolecular organic matter, including carbohydrates and amide compounds, into simpler small-molecule organic matter. This material can subsequently be polymerized into macromolecules with enhanced adsorption capacity. The HA concentration then increases (Figure 4b) [61,62]. At the end of the composting process, the HA concentration was significantly higher in the T1 treatment than in the other treatments (Figure 4e). It indicates that ceramsite can promote HA formation and strengthen compost humification, which is consistent with findings from a previous study [33].

FA is an important component of HS and plays an important role in the increase in compost nutrient content [63]. During the composting process, small molecules of FA were synthesized into large molecules of HA through a complex humification process under the action of microorganisms. FA provided energy for micro-life activities [63,64], which led to a decreasing trend in FA concentration in all treatments (Figure 4c), similar to results from previous studies [65,66]. At the same time, the decrease in FA concentration also means that the easily accessible organic carbon in the compost gradually decreases, and the stability of the compost gradually increases. It was found that the decrease in FA concentration of T1 was significantly higher than that of other treatments, except for T2 (Figure 4f), which indicated that ceramsite could promote the humification of compost and promote the conversion of small molecule fulvic acid to large molecule humic acid. The addition of ceramsite significantly enhanced the compost’s humification effect, corroborating the HS result. However, the effect of the addition of superphosphate on the conversion of FA was not significant.

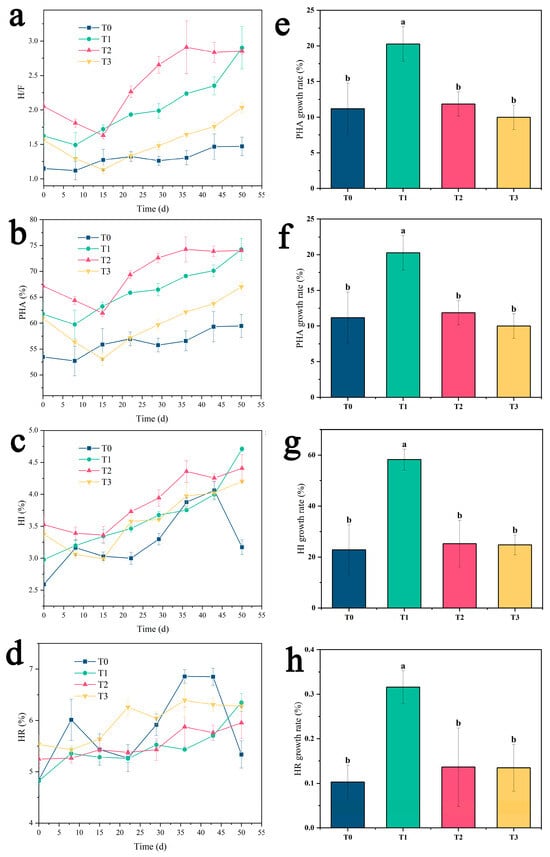

The H/F ratio is an important indicator for assessing the decomposition degree of compost [64], which is positively correlated with compost quality, reflecting the reduction in non-humus components and the formation of macromolecules from simple molecules [67]. As shown in Figure 5a, with the changes in HA and FA concentrations, the H/F ratio showed an overall trend of first increasing and then gradually approaching stability. The H/F values for all treatments exhibited an upward trend throughout the composting process, with the most significant increase observed in the treatment with ceramsite alone (T1) (Figure 5e). Previous studies have concluded that the H/F ratio of mature compost should be higher than 1.6 [68]. In this study, all treatments reached maturity except for the control treatment. The PHA, HR, and HI trends were similar to those of H/F, which showed an increasing trend, indicating an increase in the amount of humus and structural complexity [69,70]. Among these four humification indicators, the treatment with the addition of ceramsite alone (T1) performed the best. The humus content and humification degree of compost is an important basis for judging the maturity of compost [71], and the humification index of ceramsite alone (T1) was significantly higher than that of the other treatments, so it can be observed that ceramsite alone can optimize the physicochemical properties of the compost, and thus, enhance the humification effect and improve the maturity of compost [67].

Figure 5.

The variations in H/F (a), PHA (b), HI (c), and HR (d) during composting and the growth rate of H/F (e), PHA (f), HI (g), and HR (h) at the end of the composting process. H/F: HA/FA; PHA: percentage of humic acid; HI: humification index; HR: humification ratio. The results obtained are the average of the three results with an error of standard deviation. Bars with different letters indicate significant differences between treatments (p < 0.05). T0: no additives; T1: 15% ceramsite; T2: 5% superphosphate; T3: 15% ceramsite + 5% superphosphate.

3.5. Economic Benefit Analysis

This section analyzes the economic costs of commercial composting and composting with ceramsite and superphosphate as exogenous additives. According to previous studies [72], the cost of commercial compost is as follows. (1) Collection of raw materials: approximately USD 20.47 per ton. (2) Pretreatment of raw materials (crushing, removal of impurities, etc.): approximately USD 17 per ton. (3) Utilities consumed in the composting process: USD 20 per day. (4) Manual maintenance during the composting process: USD 13.60 per person per day. (5) Composting that needs to be conducted in the digester and turned over and hydrated weekly and maintenance of the digester (once a month): approximately USD 20.02 per month. (6) Commercial microbial inoculum (added twice): USD 15.80 each time. Compost takes 90–120 days to mature. Therefore, the total cost of commercial composting is USD 1622 to USD 2124 per ton of product.

The addition of exogenous additives, specifically ceramsite and superphosphate, is not required during the composting process within the digester. These additives need to be introduced only once. The cost of adding 15% ceramsite is approximately USD 20.60 per ton, and adding 5% superphosphate is approximately USD 13.74 per ton. In addition, the composting cycle can be shortened to 50 days. Therefore, the cost of composting is calculated as above: adding 15% ceramsite is USD 743, adding 5% superphosphate is USD 736, and adding 15% ceramsite and 5% superphosphate is USD 757. Compared to commercial composting, it can save 53–65% of the cost.

4. Conclusions

In the present study, adding ceramsite increased humic substrates by 14.69% in composting. It also significantly affected the degradation rates of lignin, which were elevated to 11.87%, signifying the promotional role of ceramsite in facilitating the conversion of organic matter and the formation of humic substrates in composting. In addition, adding ceramsite increased the enzyme activity and humification parameters during composting, accelerating the transformation of substances in the composting process. Adding superphosphate alone and combining ceramsite and superphosphate can significantly promote the formation of humus, but the effect is not as good as that of adding ceramsite alone. Therefore, the effect of ceramsite in promoting compost humification was most significant. However, further research is needed on the changes in microbial community structure in compost after adding ceramsite and how to evaluate their effects in long-term composting.

Author Contributions

H.W.: formal analysis, investigation, and writing—original draft. S.L.: conceptualization, visualization, and writing—review and editing. X.S.: supervision. Y.L.: methodology and data Curation. H.D.: resources. D.H.: project administration. D.W.: validation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Research and Demonstration of Key Technologies for the Application of Organic Mulch in Landscape Construction (2019-KJC-02-13).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gao, X.; Tan, W.; Zhao, Y.; Wu, J.; Sun, Q.; Qi, H.; Xie, X.-Y.; Wei, Z. Diversity in the mechanisms of humin formation during composting with different materials. Environ. Sci. Technol. 2019, 53, 3653–3662. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Sun, Y.; Liu, J.; Ren, X.; Zhang, Z.; Wang, Q. Effects of microplastics on humification and fungal community during cow manure composting. Sci. Total Environ. 2022, 803, 150029. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.X.; Liu, H.T.; Wu, S.B. Humic substances developed during organic waste composting: Formation mechanisms, structural properties, and agronomic functions. Sci. Total Environ. 2019, 662, 501–510. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, W.; Strong, P.J.; Zhu, F.; Han, X.; Hong, C.; Wang, W.; Yao, Y. Disentangling the effects of physicochemical, genetic, and microbial properties on phase-driven resistome dynamics during multiple manure composting processes. Environ. Sci. Technol. 2021, 55, 14732–14745. [Google Scholar] [CrossRef] [PubMed]

- Wongsaroj, L.; Chanabun, R.; Tunsakul, N.; Prombutara, P.; Panha, S.; Somboonna, N. First reported quantitative microbiota in different livestock manures used as organic fertilizers in the Northeast of Thailand. Sci. Rep. 2021, 11, 102. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Bi, Z.; Zhang, Y.; Wu, H.; Zhou, L.; Zhang, H. Impact of wine grape pomace on humification performance and microbial dynamics during pig manure composting. Bioresour. Technol. 2022, 358, 127380. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.X.; Chen, Q.J.; Qin, Y.; Yang, Y.R.; Yang, Q.Z.; Wang, Y.X.; Cheng, Z.-A.; Cao, N.; Zhang, G.Q. Succession of the microbial communities and function prediction during short-term peach sawdust-based composting. Bioresour. Technol. 2021, 332, 125079. [Google Scholar] [CrossRef]

- Meng, L.; Xu, C.; Wu, F. Microbial co-occurrence networks driven by low-abundance microbial taxa during composting dominate lignocellulose degradation. Sci. Total Environ. 2022, 845, 157197. [Google Scholar] [CrossRef]

- Zhou, M.; Tian, X. Development of different pretreatments and related technologies for efficient biomass conversion of lignocellulose. Int. J. Biol. Macromol. 2022, 202, 256–268. [Google Scholar] [CrossRef] [PubMed]

- Sajid, S.; Zveushe, O.K.; de Dios, V.R.; Nabi, F.; Lee, Y.K.; Kaleri, A.R.; Ma, L.; Zhou, L.; Zhang, W.; Dong, F.; et al. Pretreatment of rice straw by newly isolated fungal consortium enhanced lignocellulose degradation and humification during composting. Bioresour. Technol. 2022, 354, 127150. [Google Scholar] [CrossRef]

- Shi, M.; Wei, Z.; Wang, L.; Wu, J.; Zhang, D.; Wei, D.; Tang, Y.; Zhao, Y. Response of humic acid formation to elevated nitrate during chicken manure composting. Bioresour. Technol. 2018, 258, 390–394. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; Awasthi, M.K.; Wu, H.; Yang, J.; Li, Z.; Ni, X.; Zhang, J.; Zhang, Z.; Li, H. Biochar regulates bacterial-fungal diversity and associated enzymatic activity during sheep manure composting. Bioresour. Technol. 2022, 346, 126647. [Google Scholar] [CrossRef]

- Ren, X.; Wang, Q.; Li, R.; Chang, C.C.; Pan, J.; Zhang, Z. Effect of clay on greenhouse gas emissions and humification during pig manure composting as supported by spectroscopic evidence. Sci. Total Environ. 2020, 737, 139712. [Google Scholar] [CrossRef]

- Hagemann, N.; Joseph, S.; Schmidt, H.P.; Kammann, C.I.; Harter, J.; Borch, T.; Young, R.B.; Varga, K.; Taherymoosavi, S.; Elliott, K.W.; et al. Organic coating on biochar explains its nutrient retention and stimulation of soil fertility. Nat. Commun. 2017, 8, 1089. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, T.; Tsang, D.C.; Li, G. Effects of external additives: Biochar, bentonite, phosphate, on co-composting for swine manure and corn straw. Chemosphere 2020, 248, 125927. [Google Scholar] [CrossRef]

- Song, C.; Gao, Y.; Sun, Q.; Zhao, Y.; Qi, H.; Chen, Z.; Li, J.; Wang, S.; Wei, Z. Insight into the pathways of biochar/smectite-induced humification during chicken manure composting. Sci. Total Environ. 2023, 905, 167298. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, B.; Zhao, L.; Zhao, C.; Yang, F. Biochar promotes compost humification by regulating bacterial and fungal communities. Front. Microbiol. 2024, 15, 1470930. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ma, R.; Tang, R.; Kong, Y.; Wang, J.; Li, G.; Yuan, J. Effects of phosphate-containing additives and zeolite on maturity and heavy metal passivation during pig manure composting. Sci. Total Environ. 2022, 836, 155727. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Qiu, X.; Zhang, J.; Tao, C. Effects of seaweed fertilizer on enzyme activities, metabolic characteristics, and bacterial communities during maize straw composting. Bioresour. Technol. 2019, 286, 121375. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, Y.; Zuo, J.; Wang, R.; Zhao, J.; Du, Y. Nitrogen removal and N2O accumulation during hydrogenotrophic denitrification: Influence of environmental factors and microbial community characteristics. Environ. Sci. Technol. 2017, 51, 870–879. [Google Scholar] [CrossRef]

- Li, X.; Shi, X.S.; Lu, M.Y.; Zhao, Y.Z.; Li, X.; Peng, H.; Guo, R.B. Succession of the bacterial community and functional characteristics during continuous thermophilic composting of dairy manure amended with recycled ceramsite. Bioresour. Technol. 2019, 294, 122044. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, G.; Chen, T.; Nie, E.; Wang, Y.; Shi, X.; Liu, J. Application of ceramsite and activated alumina balls as recyclable bulking agents for sludge composting. Chemosphere 2019, 218, 42–51. [Google Scholar] [CrossRef]

- Li, X.; Shi, X.S.; Yang, Z.M.; Xu, X.H.; Guo, R.B. Effects of recyclable ceramsite as the porous bulking agent during the continuous thermophilic composting of dairy manure. J. Clean. Prod. 2019, 217, 344–351. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, L.; Yin, Z.; Sun, X. Beer lees and ceramsite amendments enhance the two-stage co-composting of green waste. Bioresour. Technol. 2021, 335, 125288. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Gu, X.; Li, H.; Li, M.; Liu, Z.; Xu, Z.; Li, J.; Luo, Y.; Wang, M.; Wan, X. Effects of phosphorus-containing additives on carbon transformation during pig manure composting. Environ. Technol. Innov. 2023, 32, 103290. [Google Scholar] [CrossRef]

- Zhao, M.; Zhao, Y.; Gao, W.; Xie, L.; Zhang, G.; Song, C.; Wei, Z. Exploring the nitrogen fixing strategy of bacterial communities in nitrogen cycling by adding calcium superphosphate at various periods during composting. Sci. Total Environ. 2023, 901, 166492. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, J.; Shi, L.; Li, Y.; Wang, Y. Role of phosphorous additives on nitrogen conservation and maturity during pig manure composting. Environ. Sci. Pollut. Res. 2021, 28, 17981–17991. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, R.; Li, D.; Qi, C.; Han, L.; Chen, M.; Fu, F.; Yuan, J.; Li, G. Effects of calcium magnesium phosphate fertilizer, biochar and spent mushroom substrate on compost maturity and gaseous emissions during pig manure composting. J. Environ. Manag. 2020, 267, 110649. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Chen, Y.; Li, Y.; Liu, Y.; Jiang, H.; Li, H.; Yuan, Y.; Chen, Y.; Zou, B. Improving the humification by additives during composting: A review. Waste Manag. 2023, 158, 93–106. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Wang, Q.; Huang, H.; Ren, X.; Lahori, A.H.; Mahar, A.; Ali, A.; Shen, F.; Li, R.; Zhang, Z. Influence of zeolite and lime as additives on greenhouse gas emissions and maturity evolution during sewage sludge composting. Bioresour. Technol. 2016, 216, 172–181. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M.K.; Ren, X.; Zhao, J.; Li, R.; Wang, Z.; Chen, H.; Wang, M.; Zhang, Z. Comparison of biochar, zeolite and their mixture amendment for aiding organic matter transformation and nitrogen conservation during pig manure composting. Bioresour. Technol. 2017, 245, 300–308. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Li, S.; Sun, X.; Zhang, L.; Zhang, T.; Wei, L. Maturation of green waste compost as affected by inoculation with the white-rot fungi Trametes versicolor and Phanerochaete chrysosporium. Environ. Technol. 2017, 38, 872–879. [Google Scholar] [CrossRef]

- Liu, H.; Awasthi, M.K.; Zhang, Z.; Syed, A.; Bahkali, A.H. Evaluation of gases emission and enzyme dynamics in sheep manure compost occupying with peach shell biochar. Environ. Pollut. 2024, 351, 124065. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Sun, X.; Li, S.; Cai, L.; Zhang, P.; Kang, Y.; Yu, Z.; Tong, J.; Wang, L. Application of quadratic regression orthogonal design to develop a composite inoculum for promoting lignocellulose degradation during green waste composting. Waste Manag. 2018, 79, 443–453. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yin, Z.; Li, L.; Li, Y.; Liu, Y.; Luo, Y.; Li, G.; Yuan, J. Effects of dicyandiamide, phosphogypsum and superphosphate on greenhouse gas emissions during pig manure composting. Sci. Total Environ. 2022, 846, 157487. [Google Scholar] [CrossRef]

- Lei, L.; Gu, J.; Wang, X.; Song, Z.; Yu, J.; Guo, H.; Xie, J.; Wang, J.; Sun, W. Effects and microbial mechanisms of phosphogypsum and medical stone on organic matter degradation and methane emissions during swine manure composting. J. Environ. Manag. 2022, 315, 115139. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wei, Y.; Zhou, K.; Gao, X.; Chang, Y.; Zhang, K.; Deng, J.; Zhan, Y.; Li, J.; Li, R.; et al. Regulating pH and Phanerochaete chrysosporium inoculation improved the humification and succession of fungal community at the cooling stage of composting. Bioresour. Technol. 2023, 384, 129291. [Google Scholar] [CrossRef]

- Wang, L.; Chang, R.; Ren, Z.; Meng, X.; Li, Y.; Gao, M. Mature compost promotes biodegradable plastic degradation and reduces greenhouse gas emission during food waste composting. Sci. Total Environ. 2024, 926, 172081. [Google Scholar] [CrossRef] [PubMed]

- Shen, C.; Shangguan, H.; Fu, T.; Mi, H.; Lin, H.; Huang, L.; Tang, J. Electric field-assisted aerobic co-composting of chicken manure and kitchen waste: Ammonia mitigation and maturation enhancement. Bioresour. Technol. 2024, 391, 129931. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Wu, Y.; Wang, X.; Zhao, J.; Liu, Y.; Chen, Z.; Jiang, Z.; Tian, W.; Zhang, J. Effects of thermophiles inoculation on the efficiency and maturity of rice straw composting. Bioresour. Technol. 2022, 354, 127195. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Wei, Y.; Kou, J.; Han, Z.; Shi, Q.; Liu, L.; Sun, Z. Improve spent mushroom substrate decomposition, bacterial community and mature compost quality by adding cellulase during composting. J. Clean. Prod. 2021, 299, 126928. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, D.; Wei, D.; Zhao, Y.; Wu, J.; Xie, X.; Zhang, R.; Wei, Z. Improved lignocellulose-degrading performance during straw composting from diverse sources with actinomycetes inoculation by regulating the key enzyme activities. Bioresour. Technol. 2019, 271, 66–74. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Addition of seaweed and bentonite accelerates the two-stage composting of green waste. Bioresour. Technol. 2017, 243, 154–162. [Google Scholar] [CrossRef]

- Ma, C.; Lo, P.K.; Xu, J.; Li, M.; Jiang, Z.; Li, G.; Zhu, Q.; Li, X.; Leong, S.Y.; Li, Q. Molecular mechanisms underlying lignocellulose degradation and antibiotic resistance genes removal revealed via metagenomics analysis during different agricultural wastes composting. Bioresour. Technol. 2020, 314, 123731. [Google Scholar] [CrossRef]

- Wang, H.; Su, Z.; Ren, S.; Zhang, P.; Li, H.; Guo, X.; Liu, L. Combined Use of Biochar and Microbial Agents Can Promote Lignocellulosic Degradation Microbial Community Optimization during Composting of Submerged Plants. Fermentation 2024, 10, 70. [Google Scholar] [CrossRef]

- Zhu, P.; Li, Y.; Gao, Y.; Yin, M.; Wu, Y.; Liu, L.; Du, N.; Liu, J.; Yu, X.; Wang, L.; et al. Insight into the effect of nitrogen-rich substrates on the community structure and the co-occurrence network of thermophiles during lignocellulose-based composting. Bioresour. Technol. 2021, 319, 124111. [Google Scholar] [CrossRef]

- Jia, H.; Chu, D.; You, X.; Li, Y.; Huang, C.; Zhang, J.; Zeng, X.; Yao, H.; Zhou, Z. Biochar improved the composting quality of seaweeds and cow manure mixture and altered the microbial community. Front. Microbiol. 2022, 13, 1064252. [Google Scholar] [CrossRef]

- Liu, X.; Guo, K.; Huang, L.; Ji, Z.; Jiang, H.; Li, H.; Zhang, J. Responses of absolute and specific enzyme activity to consecutive application of composted sewage sludge in a Fluventic Ustochrept. PLoS ONE 2017, 12, e0177796. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; He, Y.; He, K.; Gao, H.; Ren, M.; Qu, G. Degradation mechanism of lignocellulose in dairy cattle manure with the addition of calcium oxide and superphosphate. Environ. Sci. Pollut. Res. 2019, 26, 33683–33693. [Google Scholar] [CrossRef] [PubMed]

- Esteghlalian, A.; Hashimoto, A.G.; Fenske, J.J.; Penner, M.H. Modeling and optimization of the dilute-sulfuric-acid pretreatment of corn stover, poplar and switchgrass. Bioresour. Technol. 1997, 59, 129–136. [Google Scholar] [CrossRef]

- Karak, T.; Kutu, F.R.; Paul, R.K.; Bora, K.; Das, D.K.; Khare, P.; Das, K.; Dutta, A.K.; Boruah, R.K. Co-composting of cow dung, municipal solid waste, roadside pond sediment and tannery sludge: Role of human hair. Int. J. Environ. Sci. Technol. 2017, 14, 577–594. [Google Scholar] [CrossRef]

- Du, J.; Zhang, Y.; Qu, M.; Yin, Y.; Fan, K.; Hu, B.; Zhang, H.; Wei, M.; Ma, C. Effects of biochar on the microbial activity and community structure during sewage sludge composting. Bioresour. Technol. 2019, 272, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Cunha-Queda, A.C.; Ribeiro, H.M.; Ramos, A.; Cabral, F. Study of biochemical and microbiological parameters during composting of pine and eucalyptus bark. Bioresour. Technol. 2007, 98, 3213–3220. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Influence of sugar beet pulp and paper waste as bulking agents on physical, chemical, and microbial properties during green waste composting. Bioresour. Technol. 2018, 267, 182–191. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Peng, Y.; Ye, C.; Zhang, S. Effects of antibiotics on hydrolase activity and structure of microbial community during aerobic co-composting of food waste with sewage sludge. Bioresour. Technol. 2021, 321, 124506. [Google Scholar] [CrossRef]

- Becarelli, S.; Chicca, I.; Siracusa, G.; La China, S.; Gentini, A.; Lorenzi, R.; Munz, G.; Petroni, G.; Levin, D.B.; Di Gregorio, S. Hydrocarbonoclastic Ascomycetes to enhance co-composting of total petroleum hydrocarbon (TPH) contaminated dredged sediments and lignocellulosic matrices. New Biotechnol. 2019, 50, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Barje, F.; El Fels, L.; El Hajjouji, H.; Amir, S.; Winterton, P.; Hafidi, M. Molecular behaviour of humic acid-like substances during co-composting of olive mill waste and the organic part of municipal solid waste. Int. Biodeterior. Biodegrad. 2012, 74, 17–23. [Google Scholar] [CrossRef]

- Ajeng, A.A.; Abdullah, R.; Ling, T.C.; Ismail, S.; Lau, B.F.; Ong, H.C.; Chew, K.W.; Show, P.L.; Chang, J.S. Bioformulation of biochar as a potential inoculant carrier for sustainable agriculture. Environ. Technol. Innov. 2020, 20, 101168. [Google Scholar] [CrossRef]

- Liu, Q.; He, X.; Wang, K.; Li, D. Biochar drives humus formation during composting by regulating the specialized metabolic features of microbiome. Chem. Eng. J. 2023, 458, 141380. [Google Scholar] [CrossRef]

- Zhou, Y.; Selvam, A.; Wong, J.W. Evaluation of humic substances during co-composting of food waste, sawdust and Chinese medicinal herbal residues. Bioresour. Technol. 2014, 168, 229–234. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, Z.; Li, M.; Li, Q. A compost-derived thermophilic microbial consortium enhances the humification process and alters the microbial diversity during composting. J. Environ. Manag. 2019, 243, 240–249. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhao, Y.; Zhang, Z.; Wei, Y.; Wang, H.; Lu, Q.; Li, Y.; Wei, Z. Effect of thermo-tolerant actinomycetes inoculation on cellulose degradation and the formation of humic substances during composting. Waste Manag. 2017, 68, 64–73. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, Y.; Zhao, W.; Yang, T.; Zhang, X.; Xie, X.; Cui, H.; Wei, Z. Effect of precursors combined with bacteria communities on the formation of humic substances during different materials composting. Bioresour. Technol. 2017, 226, 191–199. [Google Scholar] [CrossRef] [PubMed]

- Jindo, K.; Sonoki, T.; Matsumoto, K.; Canellas, L.; Roig, A.; Sanchez-Monedero, M.A. Influence of biochar addition on the humic substances of composting manures. Waste Manag. 2016, 49, 545–552. [Google Scholar] [CrossRef]

- Qi, C.; Yin, R.; Cheng, J.; Xu, Z.; Chen, J.; Gao, X.; Li, G.; Nghiem, L.; Luo, W. Bacterial dynamics for gaseous emission and humification during bio-augmented composting of kitchen waste with lime addition for acidity regulation. Sci. Total Environ. 2022, 848, 157653. [Google Scholar] [CrossRef]

- Yin, Y.; Tao, X.; Du, Y.; Li, M.; Yang, S.; Zhang, W.; Yang, C.; Li, H.; Wang, X.; Chen, R. Biochar improves the humification process during pig manure composting: Insights into roles of the bacterial community and metabolic functions. J. Environ. Manag. 2024, 355, 120463. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag. 2016, 48, 115–126. [Google Scholar] [CrossRef]

- Ren, X.; Wang, Q.; Zhang, Y.; Awasthi, M.K.; He, Y.; Li, R.; Zhang, Z. Improvement of humification and mechanism of nitrogen transformation during pig manure composting with Black Tourmaline. Bioresour. Technol. 2020, 307, 123236. [Google Scholar] [CrossRef]

- Yu, H.; Zhao, Y.; Zhang, C.; Wei, D.; Wu, J.; Zhao, X.; Hao, J.; Wei, Z. Driving effects of minerals on humic acid formation during chicken manure composting: Emphasis on the carrier role of bacterial community. Bioresour. Technol. 2019, 294, 122239. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Yang, T.; Wei, Z.; Li, Y.; Wei, Y.; Chen, X.; Wang, L. Effects of exogenous protein-like precursors on humification process during lignocellulose-like biomass composting: Amino acids as the key linker to promote humification process. Bioresour. Technol. 2019, 291, 121882. [Google Scholar] [CrossRef]

- Iqbal, M.K.; Shafiq, T.; Ahmed, K. Characterization of bulking agents and its effects on physical properties of compost. Bioresour. Technol. 2010, 101, 1913–1919. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhang, L. Addition of mature compost improves the composting of green waste. Bioresour. Technol. 2022, 350, 126927. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).