The Impact of the Convergence of Advanced Manufacturing and Modern Services on Green Innovation Efficiency

Abstract

1. Introduction

2. Literature Review and Hypothesis Development

2.1. Literature Review

2.1.1. Research on CAMMS

2.1.2. Research on CAMMS and Green Innovation Efficiency

2.2. Theoretical Analysis and Research Hypothesis

2.2.1. The Nexus Between CAMMS and Green Innovation Efficiency

2.2.2. The Impact Paths of CAMMS on Green Innovation Efficiency

2.2.3. Spatial Spillover Effect of CAMMS on Green Innovation Efficiency

3. Methodology and Data

3.1. Estimation Methodology

3.1.1. Benchmark Regression Model

3.1.2. Mechanism Testing Model

3.1.3. Spatial Correlation Test Model

3.1.4. Spatial Econometric Model

3.1.5. Spatial Weight Matrix

3.2. Dependent Variable: Green Innovation Efficiency

3.3. Independent Variable: CAMMS

3.4. Mediating Variable

3.4.1. Advanced Industrial Structure

3.4.2. Factor Allocation

3.5. Control Variables

3.6. Sample and Data Sources

4. Empirical Results

4.1. Analysis of the Benchmark Regression Results

4.2. Analysis of Mechanism Test

4.3. Analysis of Spatial Econometric Results

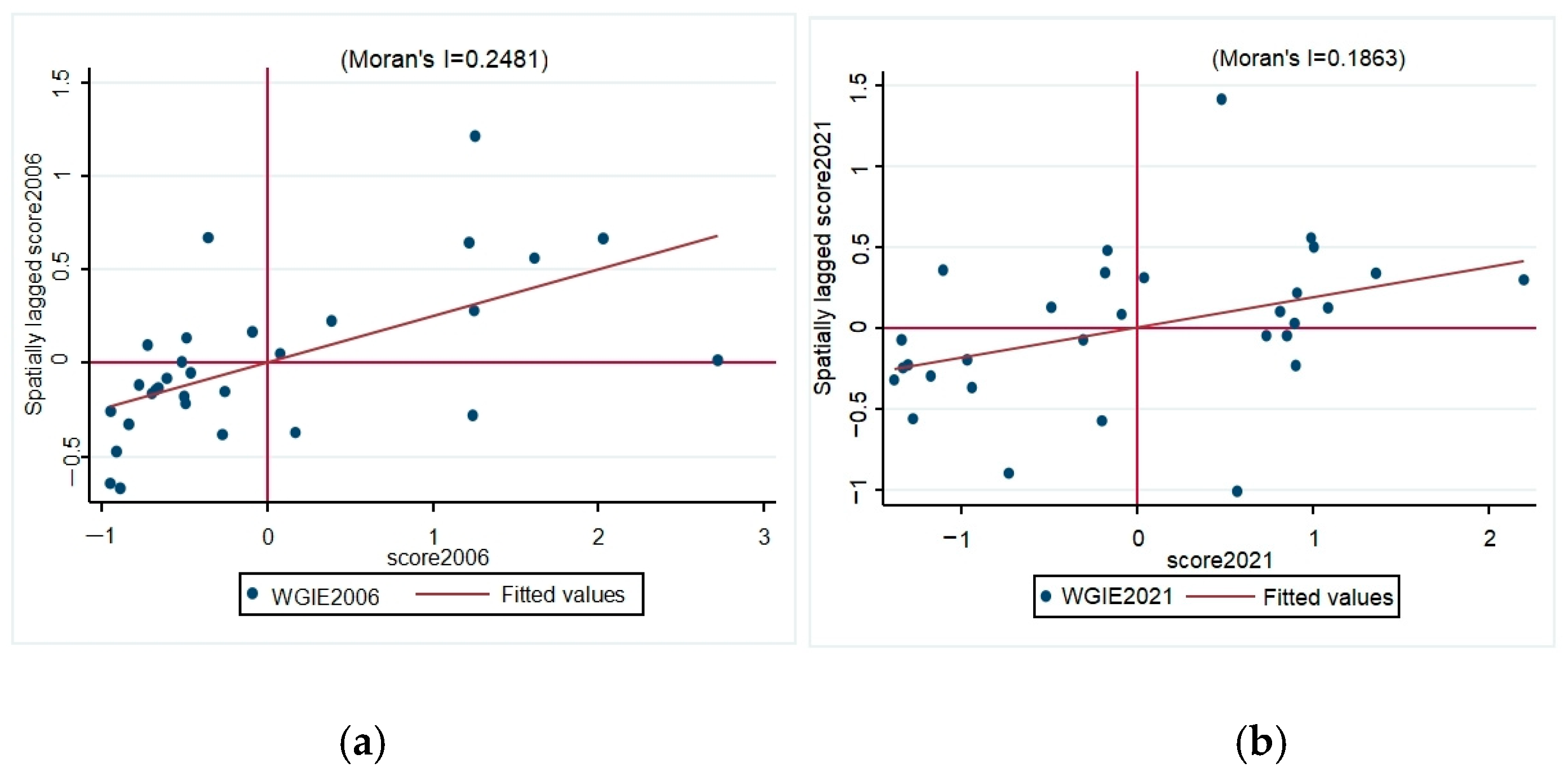

4.3.1. Results of Spatial Correlation Test

4.3.2. Results of the Spatial Spillover Effect

4.3.3. Robustness Test

4.3.4. The Spillover Boundaries of the Spatial Spillover Effect

4.3.5. Heterogeneity Analysis

Heterogeneity Analysis Based on the Region

Heterogeneity Analysis Based on Policy Development

5. Conclusions and Policy Implications

5.1. Conclusions

- (1)

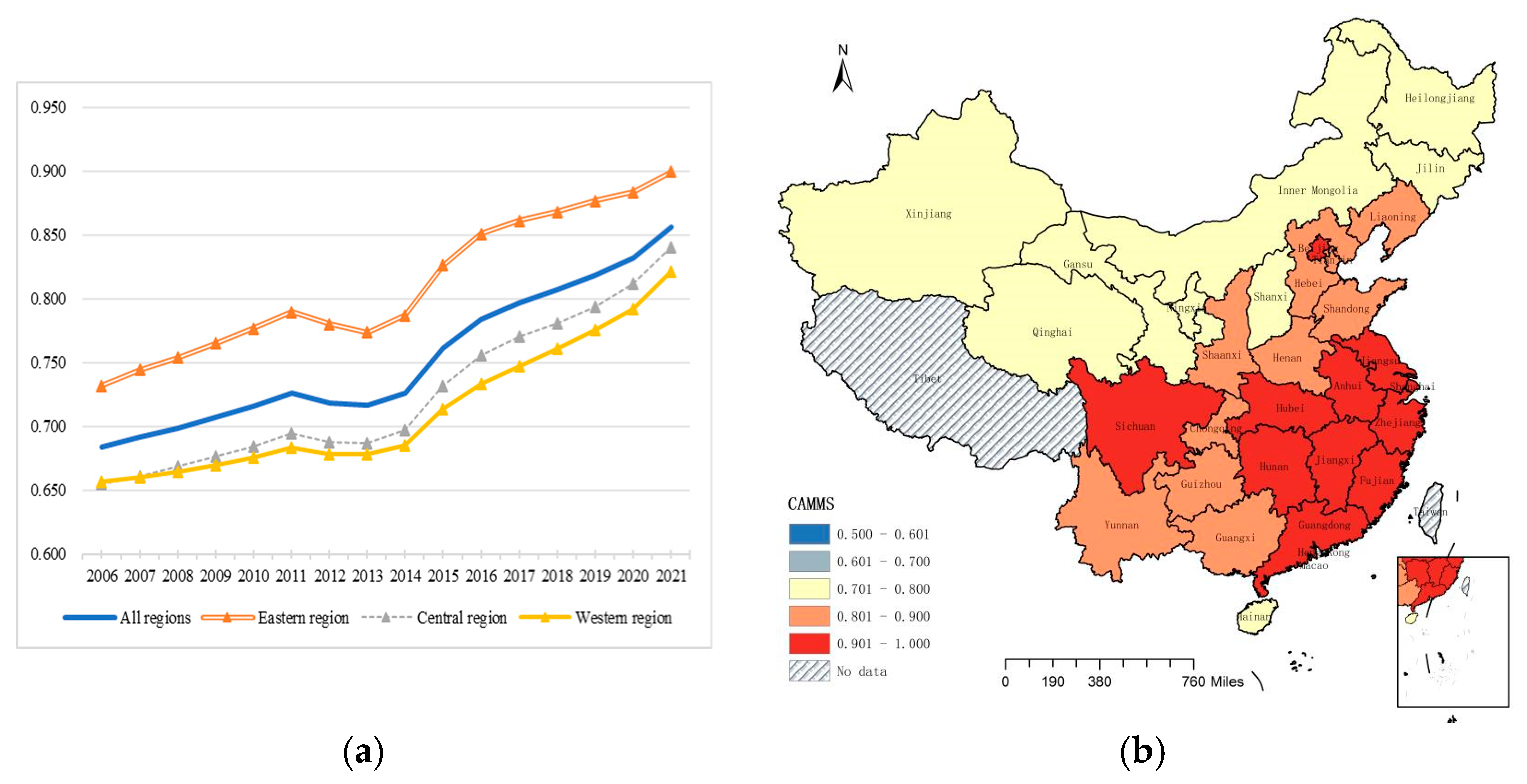

- During the study period, China’s CAMMS demonstrated a notable upward trend, in which its overall integration level advanced from a primary coordination state to a good coordination state. Furthermore, the spatial distribution of CAMMS exhibits a gradual decline from the eastern to western regions.

- (2)

- CAMMS significantly enhances local green innovation efficiency. In particular, the results of the mechanism analysis show that CAMMS optimizes the industrial structure and reduces factor distortion, thus improving green innovation efficiency through advanced industrial frameworks and factor allocation.

- (3)

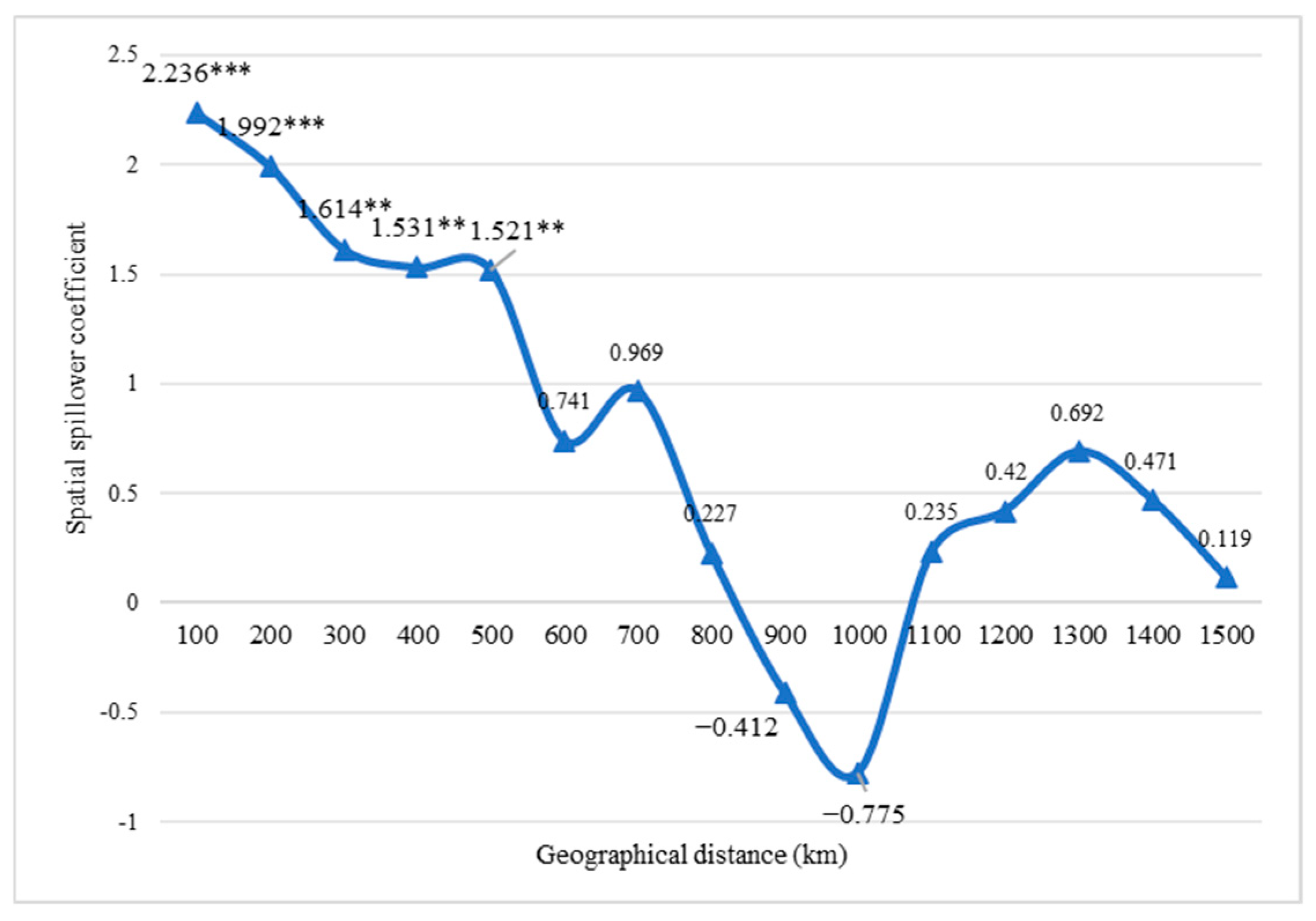

- CAMMS can produce spillover effects on green innovation in neighboring areas; however, such an effect is constrained by regional boundaries, with an effective influence range of 500 km.

- (4)

- The heterogeneity analysis results show that the spillover effects of CAMMS on green innovation are primarily focused in the eastern region, and this effect emerged after the implementation of the comprehensive reform pilot for the modern service industry in 2011.

5.2. Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, X.H.; Xu, H.Y.; Lou, W.G.; Xu, X.; Shi, V. Examining energy eco-efficiency in China’s logistics industry. Int. J. Prod. Econ. 2023, 258, 108797. [Google Scholar] [CrossRef]

- Xie, P.J.; Jamaani, F. Does green innovation, energy productivity and environmental taxes limit carbon emissions in developed economies: Implications for sustainable development. Struct. Chang. Econ. Dyn. 2022, 63, 66–78. [Google Scholar] [CrossRef]

- Miao, C.L.; Duan, M.M.; Zuo, Y.; Wu, X.Y. Spatial heterogeneity and evolution trend of regional green innovation efficiency—An empirical study based on panel data of industrial enterprises in China’s provinces. Energy Policy 2021, 156, 112370. [Google Scholar] [CrossRef]

- Tan, F.F.; Gong, C.Y.; Niu, Z.Y. How does regional integration development affect green innovation? Evidence from China’s major urban agglomerations. J. Clean. Prod. 2022, 379, 134613. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, H.; Wu, J. Impact of industrial structure upgrading on green innovation: Evidence from Chinese cities. Environ. Sci. Pollut. Res. 2023, 30, 3887–3900. [Google Scholar] [CrossRef]

- Zhou, Z. Industrial Convergence: New power of industrial development and economic growth. China Ind. Econ. 2003, 46–52. [Google Scholar]

- Wang, Q.; Geng, C.; E, H.T.; Song, J. Research on capital allocation efficiencies with four-dimensional factor capitals from China’s intelligent manufacturing enterprises. PLoS ONE 2022, 17, e0270588. [Google Scholar] [CrossRef]

- Wang, Y.M.; Zhou, Y.N.; Sun, X.Q. Investigating the dynamics, assessment, and strategies for integrated innovation between advanced manufacturing and modern services in the digital economy: A provincial analysis. Comp. Econ. Soc. Syst. 2024, 1, 61–73. [Google Scholar]

- Dangelico, R.M.; Pujari, D. Mainstreaming green product innovation: Why and how companies integrate environmental sustainability. J. Bus. Ethics 2010, 95, 471–486. [Google Scholar] [CrossRef]

- Wang, D.; Xu, D.Y.; Zhou, N.; Cheng, Y. The asymmetric relationship between sustainable innovation and industrial transformation and upgrading: Evidence from China’s provincial panel data. J. Clean. Prod. 2022, 378, 134453. [Google Scholar] [CrossRef]

- Wang, Y.; Han, P. Digital Transformation, Service-Oriented Manufacturing, and Total Factor Productivity: Evidence from A-Share Listed Companies in China. Sustainability 2023, 15, 9974. [Google Scholar] [CrossRef]

- Dong, F.; Li, Y.F. How does industrial convergence affect regional high-quality development? Evidence from China. J. Asia Pac. Econ. 2024, 29, 1650–1683. [Google Scholar] [CrossRef]

- Yang, J.; Chen, L.M.; Zhang, Y.D. Rural industrial convergence, urbanization development, and farmers’ income growth—Evidence from the Chinese experience. Front. Sustain. Food Syst. 2023, 7, 1237844. [Google Scholar] [CrossRef]

- Soellner, S.; Helm, R.; Klee, P.; Endres, H. Industrial service innovation: Exploring the transformation process to digital servitization in industrial goods companies. Ind. Mark. Manag. 2024, 117, 288–303. [Google Scholar] [CrossRef]

- Dong, F.; Li, Y.; Zhang, X.; Zhu, J.; Zheng, L. How does industrial convergence affect the energy efficiency of manufacturing in newly industrialized countries? Fresh evidence from China. J. Clean. Prod. 2021, 316, 128316. [Google Scholar] [CrossRef]

- Wang, J.D.; Dong, K.Y.; Taghizadeh-Hesary, F.; Dong, X. Does industrial convergence mitigate CO2 emissions in China? A quasi-natural experiment on “Triple Play” Reform. Energy Econ. 2023, 128, 107107. [Google Scholar] [CrossRef]

- Rosenberg, N. Technological change in the machine tool industry, 1840–1910. J. Econ. Hist. 1963, 23, 414–443. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Mc Dermott, O.; Garza-Reyes, J.A. An empirical examination of benefits, challenges, and critical success factors of industry 4.0 in manufacturing and service sector. Technol. Soc. 2021, 67, 101754. [Google Scholar] [CrossRef]

- Geum, Y.; Kim, M.S.; Lee, S. How industrial convergence happens: A taxonomical approach based on empirical evidences. Technol. Forecast. Soc. Chang. 2016, 107, 112–120. [Google Scholar] [CrossRef]

- Kim, N.; Lee, H.; Kim, W.; Lee, H.; Suh, J.H. Dynamic patterns of industry convergence: Evidence from a large amount of unstructured data. Res. Policy 2015, 44, 1734–1748. [Google Scholar] [CrossRef]

- Crozet, M.; Milet, E. Should everybody be in services? The effect of servitization on manufacturing firm performance. J. Econ. Manag. Strategy 2017, 26, 820–841. [Google Scholar] [CrossRef]

- Tian, H.G.; Yang, H.X.; Wang, L.Y. The Integration of “Two Industries” and the Evolution of New Business Forms. Nankai Econ. Res. 2023, 11, 168–185. [Google Scholar]

- Yang, N.; Liu, Q.; Chen, Y. Does industrial agglomeration promote regional innovation convergence in China? Evidence from high-tech industries. IEEE Trans. Eng. Manag. 2021, 70, 1416–1429. [Google Scholar] [CrossRef]

- Di Berardino, C.; Onesti, G. The two-way integration between manufacturing and services. Serv. Ind. J. 2020, 40, 337–357. [Google Scholar] [CrossRef]

- Gambardella, A.; Torrisi, S. Does technological convergence imply convergence in markets? evidence from the electronics industry. Res. Policy 1998, 27, 445–463. [Google Scholar] [CrossRef]

- Tunzelmann, F.N.V. Industry-specific competencies and converging technological systems: Evidence from patents. Struct. Change Econ. Dyn. 2001, 12, 141–170. [Google Scholar]

- Dong, F.; Li, Y.; Qin, C.; Sun, J. How industrial convergence affects regional green development efficiency: A spatial conditional process analysis. J. Environ. Manag. 2021, 300, 113738. [Google Scholar] [CrossRef]

- Cao, L.; Li, L.; Wu, Y.; Zeng, W. Does industrial convergence promote regional metabolism? Evidence from China. J. Clean. Prod. 2020, 273, 123010. [Google Scholar] [CrossRef]

- Xie, K.; Xiao, J.H.; Zhou, X.B.; Wu, J.P. Quality of Convergence between Industrialization and Informatization in China. Econ. Res. J. 2012, 47, 4–30. [Google Scholar]

- Iosifidis, P. Growing pains? The transition to digital television in Europe. Eur. J. Commun. 2011, 26, 3–17. [Google Scholar] [CrossRef]

- Crampes, C.; Hollander, A.J. Triple play time. Commun. Strateg. 2006, 63, 51. [Google Scholar]

- Wang, H.S.; Fang, S.X.; Guo, Q.; Meng, B. Impact of manufacturing servitization on total factor productivity under global trade openness. Rev. Dev. Econ. 2024, 28, 904–928. [Google Scholar] [CrossRef]

- Zhou, D.; Yan, T.T.; Zhao, L.L.; Guo, J. Performance implications of servitization: Does a Manufacturer’s service supply network matter? Int. J. Prod. Econ. 2020, 219, 31–42. [Google Scholar] [CrossRef]

- Eggert, A.; Hogreve, J.; Ulaga, W.; Muenkhoff, E. Industrial services, product innovations, and firm profitability: A multiple-group latent growth curve analysis. Ind. Mark. Manag. 2011, 40, 661–670. [Google Scholar] [CrossRef]

- Xu, J.; Li, L.; Tian, C. Does the manufacturing embedded servitization promote firm innovation? The perspective of quantity and quality. Sci. Technol. Prog. Policy 2022, 39, 95–105. [Google Scholar]

- Zong, Y.; Gu, G.D. The threshold effect of manufacturing servitization on carbon emission: An empirical analysis based on multinational panel data. Struct. Chang. Econ. Dyn. 2022, 60, 353–364. [Google Scholar] [CrossRef]

- Wang, H.S.; Lockett, M.; He, D.N.; Lv, Y. Enhancing green total factor productivity through manufacturing output servitization: A case study in China. Heliyon 2024, 10, e23769. [Google Scholar] [CrossRef]

- Song, Y.W.; Niu, N.; Song, X.Y.; Zhang, B. Decoding the influence of servitization on green transformation in manufacturing firms: The moderating effect of artificial intelligence. Energy Econ. 2024, 139, 107875. [Google Scholar] [CrossRef]

- Byun, G.; Cho, J.Y.; Lee, B.G. Analyzing convergence of IT and energy industry based on social system framework. Int. J. Humanit. Soc. Sciences. 2009, 26, 1256–1261. [Google Scholar]

- Xie, C.; He, X.; Wang, W.; Wang, J. Assessing the impact of manufacturing servitization on the urban green development efficiency in China. Clean Technol. Environ. Policy 2024, 14, 1–25. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, F.; He, Y. Exploring the effect of producer services and manufacturing industrial co-agglomeration on the ecological environment pollution control in China. Environ. Dev. Sustain. 2021, 23, 16119–16144. [Google Scholar] [CrossRef]

- Yang, Z.S.; Song, T.; Chahine, T. Spatial representations and policy implications of industrial co-agglomerations, a case study of Beijing. Habitat Int. 2016, 55, 32–45. [Google Scholar] [CrossRef]

- Cainelli, G.; Mazzanti, M. Environmental innovations in services: Manufacturing–services integration and policy transmissions. Res. Policy 2013, 42, 1595–1604. [Google Scholar] [CrossRef]

- Santos-Vijande, M.L.; López-Sánchez, J.Á.; Pascual-Fernández, P.; Rudd, J.M. Service innovation management in a modern economy: Insights on the interplay between firms’ innovative culture and project-level success factors. Technol. Forecast. Soc. Change 2021, 165, 120562. [Google Scholar] [CrossRef]

- Liu, Y.; Shang, M.; Xu, J.; Zhang, L.; Hua, H. Value chain and the integrated development of manufacturing and modernized services: A case study of Shandong Province, China. Sustainability 2023, 15, 1439. [Google Scholar] [CrossRef]

- Miao, Z. Industry 4.0, technology spillover impact on digital manufacturing industry. J. Enterp. Inf. Manag. 2022, 35, 1251–1266. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Zhang, L.; Nee, A.Y.C. Advanced manufacturing systems: Socialization characteristics and trends. J. Intell. Manuf. 2017, 28, 1079–1094. [Google Scholar] [CrossRef]

- Wang, W.; Lai, K.H.; Shou, Y. The impact of servitization on firm performance: A meta-analysis. Int. J. Oper. Prod. Manag. 2018, 38, 1562–1588. [Google Scholar] [CrossRef]

- Bustinza, O.F.; Bigdeli, A.Z.; Baines, T.; Baines, T.; Elliot, C. Servitization and competitive advantage: The importance of organizational structure and value chain position. Res.-Technol. Manag. 2015, 58, 53–60. [Google Scholar] [CrossRef]

- Qi, G.; Wang, Z.; Wang, Z.; Wei, L. Has industrial upgrading improved air pollution? Evidence from China’s digital economy. Sustainability 2022, 14, 8967. [Google Scholar] [CrossRef]

- Liu, M.; Hua, D. Enhancing resource allocation efficiency: The impact of servitization in China’s manufacturing sector. Ind. Mark. Manag. 2024, 121, 160–178. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Y.; Liu, W. Science and technology resource allocation, spatial association, and regional innovation. Sustainability 2020, 12, 694. [Google Scholar] [CrossRef]

- Che, S.; Tao, M.; Silva, E.; Sheng, M.S.; Zhao, C.; Wang, J. Financial misallocation and green innovation efficiency: China’s firm-level evidence. Energy Econ. 2024, 136, 107697. [Google Scholar] [CrossRef]

- Lesage, J.P.; Pace, R.K. Spatial econometric modeling of origin-destination flows. J. Reg. Sci. 2008, 48, 941–967. [Google Scholar] [CrossRef]

- Hu, C.C. Analyzing dynamic coupling and coordination of modern service and advanced manufacturing industries in Guangdong–Hong Kong–Macao Greater Bay Area. Heliyon 2023, 9, 6. [Google Scholar] [CrossRef]

- Wang, C.; Wang, L.; Xue, Y.; Li, R. Revealing spatial spillover effect in high-tech industry agglomeration from a high-skilled labor flow network perspective. J. Syst. Sci. Complex. 2022, 35, 839–859. [Google Scholar] [CrossRef]

- Ding, J.; Liu, B.; Shao, X. Spatial effects of industrial synergistic agglomeration and regional green development efficiency: Evidence from China. Energy Econ. 2022, 112, 106156. [Google Scholar] [CrossRef]

- Caves, D.W.; Christensen, L.R.; Diewert, W.E. The economic theory of index numbers and the measurement of input, output, and productivity. J. Econom. Soc. 1982, 1, 1393–1414. [Google Scholar] [CrossRef]

- Charnoz, P.; Lelarge, C.; Trevien, C. Communication costs and the internal organisation of multi-plant businesses: Evidence from the impact of the French high-speed rail. Econ. J. 2018, 128, 949–994. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator-mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Personal. Soc. Psychol. 1986, 51, 1173. [Google Scholar] [CrossRef]

- Fan, J.H.; Xiao, Z.H. Analysis of spatial correlation network of China’s green innovation. J. Clean. Prod. 2021, 299, 126815. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, D.; Zhang, F.; Zhao, N.; Wang, L.; Guo, Z.; Zhang, J.; An, B.; Xiao, Y. Spatiotemporal differentiation of carbon emission efficiency and influencing factors: From the perspective of 136 countries. Sci. Total Environ. 2023, 879, 163032. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Lu, Z.; Wu, C. Can internet development accelerate the green innovation efficiency convergence: Evidence from China. Technol. Forecast. Soc. Chang. 2023, 189, 122352. [Google Scholar] [CrossRef]

- Zhai, X.; An, Y. The relationship between technological innovation and green transformation efficiency in China: An empirical analysis using spatial panel data. Technol. Soc. 2021, 64, 101498. [Google Scholar] [CrossRef]

- Fan, F.; Lian, H.; Liu, X.; Wang, X. Can environmental regulation promote urban green innovation Efficiency? An empirical study based on Chinese cities. J. Clean. Prod. 2021, 287, 125060. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, S. What drives technology convergence? Exploring the influence of technological and resource allocation contexts. J. Eng. Technol. Manag. 2015, 36, 78–96. [Google Scholar] [CrossRef]

- Jeong, S.; Kim, J.C.; Choi, J.Y. Technology convergence: What developmental stage are we in? Scientometrics 2015, 104, 841–871. [Google Scholar] [CrossRef]

- Chen, Y.; Shen, L.; Zhang, X.; Chen, Y. Industry convergence and value innovation: A bibliometric analysis and systematic review. Kybernetes 2023, 52, 4576–4610. [Google Scholar] [CrossRef]

- Ye, X.; Wang, J.; Sun, R. The coupling and coordination relationship of the digital economy and tourism industry from the perspective of industrial integration. Eur. J. Innov. Manag. 2024, 27, 1182–1205. [Google Scholar] [CrossRef]

- Lyu, Y.W.; Wang, W.Q.; Wu, Y.; Zhang, J. How does digital economy affect green total factor productivity? Evidence from China. Sci. Total Environ. 2023, 857, 159428. [Google Scholar] [CrossRef]

- Cheng, Y.W.; Hu, W.M. Distortions, misallocation and losses: Theory and application. China Econ. Q. 2011, 10, 1401–1422. [Google Scholar]

- Wang, M.; Zhang, X.; Hu, Y. The green spillover effect of the inward foreign direct investment: Market versus innovation. J. Clean. Prod. 2021, 328, 129501. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, B. The influence of Chinese environmental regulation on corporation innovation and competitiveness. J. Clean. Prod. 2016, 112, 1528–1536. [Google Scholar] [CrossRef]

- Yuan, H.; Feng, Y.; Lee, J.; Liu, H.; Li, R. The spatial threshold effect and its regional boundary of financial agglomeration on green development: A case study in China. J. Clean. Prod. 2020, 244, 118670. [Google Scholar] [CrossRef]

- Xu, Q.; Li, X.; Guo, F. Digital transformation and environmental performance: Evidence from Chinese resource-based enterprises. Corp. Soc. Responsib. Environ. Manag. 2023, 30, 1816–1840. [Google Scholar] [CrossRef]

- You, J.; Zhang, B. The impact and spatial spillover effect of traditional culture on urban green innovation: Empirical evidence from China. J. Environ. Manag. 2024, 369, 122303. [Google Scholar] [CrossRef]

| Primary | Secondary | Advanced Manufacturing | Modern Service |

|---|---|---|---|

| Definition | Definition | ||

| Production factor matching | Labor force | The number of employees in AM | The number of employees in MS |

| Capital investment | Fixed asset investment in AM | Fixed asset investment in MS | |

| Market business matching | Output scale | Output value of AM | The added value of MS |

| Industrial scale | Number of companies in AM | Number of companies in KIBS | |

| Industrial structure | Output value of AM/GDP | The added value of MS/GDP | |

| Workforce structure | Number of AM employees/Number of manufacturing employees | Number of MS employees/Number of service employees | |

| Industrial scale structure | Number of companies in AM/Number of companies in manufacturing | Number of companies in MS/Number of companies in service | |

| Investment structure | Investment in fixed assets of AM/Investment in fixed assets of manufacturing | Investment in fixed assets of MS/Investment in fixed assets of service | |

| Output efficiency | Profit margin in AM | Labor productivity in MS | |

| Investment efficiency | Profit margin in AM/Investment in fixed assets of AM | The added value of MS/Investment in fixed assets of MS | |

| Spatial layout matching | Labor force location entropy | (Regional AM employment/Regional employment)/(National AM employment/National employment) | (Regional MS employment/Regional employment)/(National MS employment/National employment) |

| Capital location entropy | (Regional AM capital/Regional capital)/(National AM capital/National capital) | (Regional MS capital/Regional capital)/(National MS capital/National capital) | |

| R&D labor force location entropy | (Number of R&D personnel in AM/Regional number of R&D personnel)/(National number of R&D personnel in AM/National number of R&D personnel) | (Number of R&D personnel in MS/Regional Number of R&D personnel)/(National number of R&D personnel in MS/National Number of R&D personnel) | |

| R&D capital location entropy | (Internal expenditure on R&D in AM/Regional internal expenditure on R&D)/(Internal expenditure on R&D in AM/National internal expenditure on R&D) | (Internal expenditure on R&D in MS/Regional internal expenditure on R&D)/(Internal expenditure on R&D in MS/National internal expenditure on R&D) | |

| Innovation matching | R&D labor input | Number of R&D personnel in AM | Number of R&D personnel in R&D institutions |

| R&D capital input | Internal expenditure of R&D funds in AM | Internal expenditure of R&D funding in R&D institutions | |

| R&D project input | Investment in R&D projects from AM | Investment in innovative projects from R&D institutions |

| Coupling Coordination Level | Type | Coupling Coordination Level | Type |

|---|---|---|---|

| [0.000, 0.100) | Extremely maladjusted | [0.500, 0.600) | Barely coordinated |

| [0.100, 0.200) | Seriously maladjusted | [0.600, 0.700) | Primary coordination |

| [0.200, 0.300) | Moderately maladjusted | [0.700, 0.800) | Intermediate coordination |

| [0.300, 0.400) | Slightly maladjusted | [0.800, 0.900) | Good coordination |

| [0.400, 0.500) | Nearly maladjusted | [0.900, 1.000] | High-quality coordination |

| Variable | Obs. | Mean | S. D. | Min | Max |

|---|---|---|---|---|---|

| GIE | 480 | 0.761 | 0.347 | 0.080 | 1.761 |

| CAMMS | 480 | 0.742 | 0.087 | 0.620 | 1.000 |

| AIS | 480 | 1.778 | 0.087 | 1.620 | 2.025 |

| FA | 480 | −1.043 | 0.666 | −5.298 | 0.580 |

| OPEN | 480 | 6.264 | 1.924 | 0.539 | 9.615 |

| PGDP | 480 | 9.253 | 0.487 | 8.090 | 10.760 |

| ER | 480 | 2.345 | 0.947 | −2.459 | 4.703 |

| EDU | 480 | 7.796 | 0.321 | 6.876 | 8.817 |

| Variable | VIF | 1/VIF |

|---|---|---|

| PGDP | 2.89 | 0.345 |

| CAMMS | 2.84 | 0.352 |

| EDU | 2.78 | 0.359 |

| OPEN | 1.91 | 0.523 |

| ER | 1.23 | 0.813 |

| Mean VIF | 2.33 |

| Variable | Statistic | p Value |

|---|---|---|

| GIE | 0.669 | 0.969 |

| CAMMS | 0.723 | 0.998 |

| OPEN | 0.748 | 0.999 |

| PGDP | 0.646 | 0.915 |

| ER | 0.645 | 0.909 |

| EDU | 0.702 | 0.995 |

| D_GIE | 0.034 *** | 0.000 |

| D_CAMMS | 0.245 *** | 0.000 |

| D_OPEN | 0.242 *** | 0.000 |

| D_PGDP | −0.013 *** | 0.000 |

| D_ER | 0.252 *** | 0.000 |

| D_EDU | 0.110 *** | 0.000 |

| Variable | GIE | GIE | GIE | GIE | GIE |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | |

| CAMMS | 0.560 *** (5.49) | 0.830 *** (6.79) | 0.463 *** (3.54) | 0.516 *** (3.94) | 0.351 ** (2.21) |

| OPEN | −0.270 *** (−3.88) | −0.897 *** (−7.52) | −0.924 *** (−7.79) | −0.985 *** (−8.01) | |

| PGDP | 0.222 *** (6.35) | 0.212 *** (6.08) | 0.213 *** (6.13) | ||

| ER | −0.099 *** (−2.92) | −0.124 *** (−3.40) | |||

| EDU | 0.086 * (1.83) | ||||

| _Cons | −0.062 (−0.83) | −0.120 (−1.60) | −1.594 *** (−6.55) | −1.608 *** (−6.67) | −1.660 *** (−6.85) |

| Province | Yes | Yes | Yes | Yes | Yes |

| Year | Yes | Yes | Yes | Yes | Yes |

| R2 | 0.548 | 0.561 | 0.595 | 0.602 | 0.604 |

| N | 480 | 480 | 480 | 480 | 480 |

| Variable | GIE (1) | Path I: Advanced Industrial Structure | Path II: Factor Allocation | ||

|---|---|---|---|---|---|

| AIS (2) | GIE (3) | FA (4) | GIE (5) | ||

| CAMMS | 0.351 ** (2.21) | 0.187 *** (5.49) | 0.333 ** (2.09) | −0.088 * (−1.73) | 0.344 ** (2.15) |

| AIS | 0.682 *** (2.90) | ||||

| FA | −0.284 * (−1.88) | ||||

| OPEN | −0.985 *** (−8.01) | 0.246 *** (9.72) | −1.155 *** (−8.45) | 0.447 *** (11.28) | −0.859 *** (−6.07) |

| PGDP | 0.213 *** (6.13) | 0.076 *** (10.71) | 0.159 *** (4.08) | 0.062 *** (5.62) | 0.229 *** (6.33) |

| ER | −0.124 *** (−3.40) | −0.038 *** (−5.05) | −0.088 ** (−2.34) | −0.048 *** (−4.11) | −0.127 *** (−3.40) |

| EDU | 0.086 * (1.83) | 0.014 (1.47) | 0.084 * (1.76) | 0.008 (0.56) | 0.096 ** (2.01) |

| _Cons | −1.660 *** (−6.85) | 0.825 *** (16.66) | −2.225 *** (−7.18) | 1.317 *** (17.01) | −1.287 *** (−4.10) |

| Province | Yes | Yes | Yes | Yes | Yes |

| Year | Yes | Yes | Yes | Yes | Yes |

| R2 | 0.604 | 0.881 | 0.625 | 0.816 | 0.620 |

| N | 480 | 480 | 480 | 480 | 480 |

| Year | Moran’s I | p Value | Year | Moran’s I | p Value |

|---|---|---|---|---|---|

| 2006 | 0.248 | 0.001 | 2014 | 0.263 | 0.001 |

| 2007 | 0.246 | 0.002 | 2015 | 0.237 | 0.003 |

| 2008 | 0.192 | 0.008 | 2016 | 0.198 | 0.007 |

| 2009 | 0.190 | 0.010 | 2017 | 0.144 | 0.033 |

| 2010 | 0.222 | 0.004 | 2018 | −0.008 | 0.382 |

| 2011 | 0.168 | 0.018 | 2019 | 0.023 | 0.273 |

| 2012 | 0.236 | 0.003 | 2020 | 0.242 | 0.002 |

| 2013 | 0.340 | 0.000 | 2021 | 0.186 | 0.011 |

| Variable | SLM | SEM | SDM |

|---|---|---|---|

| (1) | (2) | (3) | |

| CAMMS | 0.469 *** (3.64) | 0.410 *** (2.86) | 0.339 ** (2.54) |

| OPEN | −0.878 *** (−7.73) | −0.834 *** (−7.11) | −0.900 *** (−7.73) |

| PGDP | 0.206 *** (6.19) | 0.208 *** (6.07) | 0.247 *** (7.20) |

| ER | −0.080 ** (−2.47) | −0.058 * (−1.72) | −0.104 *** (−3.12) |

| EDU | 0.202 * (1.69) | 0.198 (1.51) | 0.437 *** (3.01) |

| W*CAMMS | 1.936 *** (5.19) | ||

| W*OPEN | −0.010 (−0.04) | ||

| W*PGDP | −0.241 ** (−2.45) | ||

| W*ER | −0.196 *** (−2.84) | ||

| W*EDU | −0.360 (−1.21) | ||

| rho | 0.325 *** (4.53) | 0.257 *** (2.93) | 0.147 * (1.76) |

| sigma2_e | 0.019 *** (14.86) | 0.020 *** (14.88) | 0.018 *** (14.96) |

| Province | Yes | Yes | Yes |

| Year | Yes | Yes | Yes |

| LR test | 18.00 *** | 22.68 *** | - |

| Wald test | 18.20 *** | 23.20 *** | - |

| Log-likelihood | 242.590 | 237.370 | 263.602 |

| R2 | 0.234 | 0.228 | 0.516 |

| N | 480 | 480 | 480 |

| Variable | Direct Effect | Indirect Effect | Total effect |

|---|---|---|---|

| (1) | (2) | (3) | |

| CAMMS | 0.394 *** (2.89) | 2.299 *** (5.79) | 2.692 *** (6.52) |

| OPEN | −0.910 *** (−7.99) | −0.158 (−0.47) | −1.067 *** (−2.88) |

| PGDP | 0.245 *** (7.31) | −0.242 ** (−2.19) | 0.003 (0.03) |

| ER | −0.110 *** (−3.26) | −0.241 *** (−2.91) | −0.351 *** (−3.74) |

| EDU | 0.431 *** (3.14) | −0.328 (−0.98) | 0.103 (0.35) |

| Variable | Replace the Spatial Weight Matrix | Replace the Explained Variable | Replace the Explanatory Variables | Consider the Lag |

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| L.CAMMS | 0.178 *** (2.99) | |||

| CAMMS | 0.767 *** (5.65) | 0.937 *** (4.40) | 0.241 *** (5.23) | |

| OPEN | −0.943 *** (−7.93) | −0.550 *** (−2.97) | −0.855 *** (−7.43) | −0.915 *** (−6.97) |

| PGDP | 0.227 *** (5.24) | 0.362 *** (6.67) | 0.216 *** (6.55) | 0.205 *** (5.97) |

| ER | −0.096 *** (−2.83) | −0.517 *** (−9.81) | −0.177 *** (−4.92) | −0.138 *** (−3.69) |

| EDU | 0.183 (1.48) | 0.876 *** (3.81) | 0.455 *** (3.20) | 0.097 ** (2.08) |

| W*CAMMS | 1.234 *** (3.42) | 5.342 *** (8.78) | 0.910 *** (6.42) | |

| W*OPEN | −0.894 *** (−2.69) | 2.000 *** (4.41) | 0.256 (0.86) | |

| W*PGDP | −0.029 (−0.28) | −0.970 *** (−6.22) | −0.204 ** (−2.36) | |

| W*ER | −0.264 ** (−2.14) | 0.070 (0.62) | −0.372 *** (−4.98) | |

| W*EDU | 0.399 (0.56) | −0.626 (−1.32) | −0.040 (−0.14) | |

| rho/lambda | 0.171 ** (1.98) | 0.126 * (1.65) | 0.091 (1.08) | |

| sigma2_e | 0.019 *** (14.94) | 0.045 *** (14.97) | 0.017 *** (14.99) | |

| Province | Yes | Yes | Yes | |

| Year | Yes | Yes | Yes | |

| Loglikelihood | 246.855 | 57.036 | 273.128 | |

| R2 | 0.309 | 0.360 | 0.577 | 0.640 |

| N | 480 | 480 | 480 | 450 |

| Variable | Eastern Region | Central and Western Regions | ||||

|---|---|---|---|---|---|---|

| Direct Effect | Indirect Effect | Total Effect | Direct Effect | Indirect Effect | Total Effect | |

| (1) | (2) | (3) | (4) | (5) | (6) | |

| CAMMS | 1.454 *** (6.80) | 3.066 *** (7.39) | 4.520 *** (7.96) | 0.560 ** (2.08) | 0.418 (0.78) | 0.979 (1.50) |

| OPEN | −0.514 *** (−2.79) | −4.027 *** (−9.64) | −4.541 *** (−9.76) | −1.014 *** (−5.96) | 0.348 (0.89) | −0.666 (−1.45) |

| PGDP | 0.412 *** (5.30) | 0.736 *** (4.44) | 1.148 *** (6.93) | 0.193 *** (3.08) | −0.171 (−1.22) | 0.021 (0.16) |

| ER | −0.066 (−1.50) | −0.014 (−0.23) | −0.080 (−0.94) | −0.120 * (−1.66) | 0.140 (0.77) | 0.020 (0.10) |

| EDU | −0.125 *** (−5.95) | −0.238 *** (−6.39) | −0.363 *** (−7.15) | 0.138 (1.01) | 0.218 (0.31) | 0.356 (0.47) |

| Variable | 2006–2010 | 2011–2018 | 2019–2021 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Direct Effect | Indirect Effect | Total Effect | Direct Effect | Indirect Effect | Total Effect | Direct Effect | Indirect Effect | Total Effect | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | |

| CAMMS | 0.201 (0.56) | −1.535 (−1.37) | −1.334 (−1.07) | 1.157 *** (6.76) | 2.298 *** (5.74) | 3.454 *** (7.58) | 0.720 *** (2.76) | 2.470 ** (2.35) | 3.190 *** (2.63) |

| OPEN | −1.089 *** (−3.25) | −2.896 ** (−2.13) | −3.984 ** (−2.55) | −1.084 *** (−7.04) | −0.626 (−1.52) | −1.711 *** (−3.95) | −0.830 *** (−3.86) | 0.435 (0.43) | −0.394 (−0.36) |

| PGDP | 0.333 *** (3.12) | 0.785 ** (2.05) | 1.117 *** (2.76) | 0.305 *** (4.88) | −0.370 *** (−3.08) | −0.065 (−0.66) | 0.177 *** (2.66) | −0.303 (−1.24) | −0.126 (−0.52) |

| ER | −0.226 *** (−2.83) | −0.134 (−0.34) | −0.360 (−0.84) | −0.018 (−0.42) | −0.161 (−1.19) | −0.180 (−1.32) | −0.156 ** (−2.29) | −0.951 ** (−2.47) | −1.107 *** (−2.68) |

| EDU | 2.520 (0.66) | 5.666 (0.38) | 8.187 (0.58) | -0.017 (−0.09) | 2.418 *** (2.90) | 2.401 *** (2.91) | 0.153 (0.88) | −1.150 (−0.83) | −0.998 (−0.66) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Nie, S.; Wan, L. The Impact of the Convergence of Advanced Manufacturing and Modern Services on Green Innovation Efficiency. Sustainability 2025, 17, 492. https://doi.org/10.3390/su17020492

Zhang H, Nie S, Wan L. The Impact of the Convergence of Advanced Manufacturing and Modern Services on Green Innovation Efficiency. Sustainability. 2025; 17(2):492. https://doi.org/10.3390/su17020492

Chicago/Turabian StyleZhang, Hongying, Song Nie, and Liyang Wan. 2025. "The Impact of the Convergence of Advanced Manufacturing and Modern Services on Green Innovation Efficiency" Sustainability 17, no. 2: 492. https://doi.org/10.3390/su17020492

APA StyleZhang, H., Nie, S., & Wan, L. (2025). The Impact of the Convergence of Advanced Manufacturing and Modern Services on Green Innovation Efficiency. Sustainability, 17(2), 492. https://doi.org/10.3390/su17020492