Sustainability of Key Proteins in Plant-Based Meat Analogs Production: A Worldwide Perspective

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Main Protein Ingredients Used in the Production of Commercial Plant-Based Meat Analogues

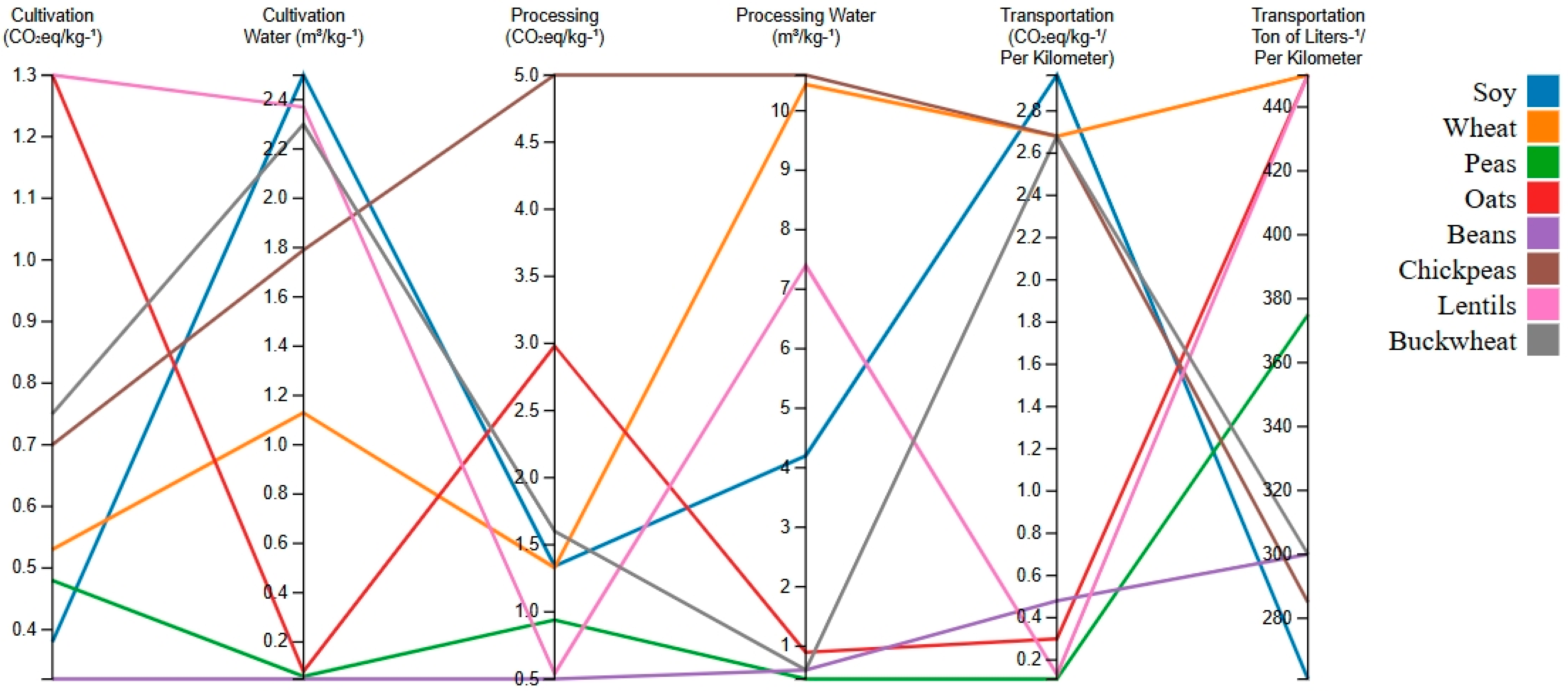

3.2. Use of Resources During the Cultivation, Processing, and Transportation Phases of the Primary Protein Sources Used in Plant-Based Meat Analogs

3.3. Production Context of the Main Protein Ingredients Used

3.3.1. Soy

3.3.2. Wheat

3.3.3. Peas

3.3.4. Chickpeas

3.3.5. Beans

4. Limitations of the Study and Further Research Suggestions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hirabayashi, Y.; Mahendran, R.; Koirala, S.; Konoshima, L.; Yamazaki, D.; Watanabe, S.; Kim, H.; Kanae, S. Global Flood Risk under Climate Change. Nat. Clim. Chang. 2013, 3, 816–821. [Google Scholar] [CrossRef]

- Zhao, Q.; Yu, P.; Mahendran, R.; Huang, W.; Gao, Y.; Yang, Z.; Ye, T.; Wen, B.; Wu, Y.; Li, S.; et al. Global Climate Change and Human Health: Pathways and Possible Solutions. Eco-Environ. Health 2022, 1, 53–62. [Google Scholar] [CrossRef]

- Romanello, M.; McGushin, A.; Di Napoli, C.; Drummond, P.; Hughes, N.; Jamart, L.; Kennard, H.; Lampard, P.; Solano Rodriguez, B.; Arnell, N.; et al. The 2021 Report of the Lancet Countdown on Health and Climate Change: Code Red for a Healthy Future. Lancet 2021, 398, 1619–1662. [Google Scholar] [CrossRef] [PubMed]

- Perera, A.T.D.; Nik, V.M.; Chen, D.; Scartezzini, J.L.; Hong, T. Quantifying the Impacts of Climate Change and Extreme Climate Events on Energy Systems. Nat. Energy 2020, 5, 150–159. [Google Scholar] [CrossRef]

- Matthews, H.D.; Zickfeld, K. Climate Response to Zeroed Emissions of Greenhouse Gases and Aerosols. Nat. Clim. Chang. 2012, 2, 338–341. [Google Scholar] [CrossRef]

- Zhang, P.; Wiens, K.; Wang, R.; Luong, L.; Ansara, D.; Gower, S.; Bassil, K.; Hwang, S.W. Cold Weather Conditions and Risk of Hypothermia among People Experiencing Homelessness: Implications for Prevention Strategies. Int. J. Environ. Res. Public Health 2019, 16, 3259. [Google Scholar] [CrossRef] [PubMed]

- Ebi, K.L.; Capon, A.; Berry, P.; Broderick, C.; de Dear, R.; Havenith, G.; Honda, Y.; Kovats, R.S.; Ma, W.; Malik, A.; et al. Hot Weather and Heat Extremes: Health Risks. Lancet 2021, 398, 698–708. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhou, T.; Zhang, L.; Chen, X.; Zhang, W.; Jiang, J. Global Land Monsoon Precipitation Changes in CMIP6 Projections. Geophys. Res. Lett. 2020, 47, e2019GL086902. [Google Scholar] [CrossRef]

- Zeng, J.; Bao, R.; McFarland, M. Clean Energy Substitution: The Effect of Transitioning from Coal to Gas on Air Pollution. Energy Econ. 2022, 107, 105816. [Google Scholar] [CrossRef]

- Food Agriculture Organization (FAO). Greenhouse Gas Emissions from Agrifood Systems Global, Regional and Country Trends, 2000–2020; Food Agriculture Organization (FAO): Rome, Italy, 2022. [Google Scholar]

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Monforti-Ferrario, F.; Tubiello, F.N.; Leip, A. Food Systems Are Responsible for a Third of Global Anthropogenic GHG Emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef]

- Tubiello, F.N.; Karl, K.; Flammini, A.; Gütschow, J.; Obli-Laryea, G.; Conchedda, G.; Pan, X.; Qi, S.Y.; Halldórudóttir Heiðarsdóttir, H.; Wanner, N.; et al. Pre- and Post-Production Processes Increasingly Dominate Greenhouse Gas Emissions from Agri-Food Systems. Earth Syst. Sci. Data 2022, 14, 1795–1809. [Google Scholar] [CrossRef]

- Hoekstra, A.Y. The Hidden Water Resource Use behind Meat and Dairy. Anim. Front. 2012, 2, 3–8. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; Teixeira De Mattos, M.J. Environmental Impacts of Cultured Meat Production. Environ. Sci. Technol. 2011, 45, 6117–6123. [Google Scholar] [CrossRef] [PubMed]

- Tziva, M.; Negro, S.O.; Kalfagianni, A.; Hekkert, M.P. Understanding the Protein Transition: The Rise of Plant-Based Meat Substitutes. Environ. Innov. Soc. Transit. 2019, 35, 217–231. [Google Scholar] [CrossRef]

- Hargreaves, S.M.; Rosenfeld, D.L.; Moreira, A.V.B.; Zandonadi, R.P. Plant-Based and Vegetarian Diets: An Overview and Definition of These Dietary Patterns. Eur. J. Nutr. 2023, 62, 1109–1121. [Google Scholar] [CrossRef] [PubMed]

- Najjar, R.S.; Feresin, R.G. Plant-Based Diets in the Reduction of Body Fat: Physiological Effects and Biochemical Insights. Nutrients 2019, 11, 2712. [Google Scholar] [CrossRef] [PubMed]

- Aydar, E.F.; Tutuncu, S.; Ozcelik, B. Plant-Based Milk Substitutes: Bioactive Compounds, Conventional and Novel Processes, Bioavailability Studies, and Health Effects. J. Funct. Foods 2020, 70, 103975. [Google Scholar] [CrossRef]

- Veniranda, V.; Surya, R. Consumer Analysis of Commercial Plant-Based Jerky. IOP Conf. Ser. Earth Environ. Sci. 2022, 998, 012059. [Google Scholar] [CrossRef]

- Romão, B.; Botelho, R.B.A.; Torres, M.L.; Maynard, D.d.C.; de Holanda, M.E.M.; Borges, V.R.P.; Raposo, A.; Zandonadi, R.P. Nutritional Profile of Commercialized Plant-Based Meat: An Integrative Review with a Systematic Approach. Foods 2023, 12, 448. [Google Scholar] [CrossRef]

- Peters, G.P. Carbon Footprints and Embodied Carbon at Multiple Scales. Curr. Opin. Environ. Sustain. 2010, 2, 245–250. [Google Scholar] [CrossRef]

- Wakeland, W.; Cholette, S.; Venkat, K. Food Transportation Issues and Reducing Carbon Footprint. In Green Technologies in Food Production and Processing; Food Engineering Series; Springer: Boston, MA, USA, 2012; pp. 211–236. [Google Scholar] [CrossRef]

- United Nations Objetivos de Desenvolvimento Sustentável|As Nações Unidas No Brasil. Available online: https://brasil.un.org/pt-br/sdgs (accessed on 19 December 2022).

- Demiris, G.; Oliver, D.P.; Washington, K.T. Defining and Analyzing the Problem. In Behavioral Intervention Research in Hospice and Palliative Care: Building an Evidence Base; Elsevier: Amsterdam, The Netherlands, 2019; pp. 27–39. [Google Scholar] [CrossRef]

- Ferrari, R. Writing Narrative Style Literature Reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

- Grand View Research. Plant-Based Meat Market Size, Share & Trends Analysis Report by Source (Soy, Pea, Wheat), by Product, by Type (Chicken, Pork, Beef, Fish, Others), by End-Use, by Storage, by Region, and Segment Forecasts, 2024–2030; Grand View Research: San Francisco, CA, USA, 2024. [Google Scholar]

- Araújo, W.M.C.; Montebello, N.d.P.; Botelho, R.B.A.; Borgo, L.A. Alquimia Dos Alimentos, 2nd ed.; Senac: Brasília, Brazil, 2011. [Google Scholar]

- Mariseva, A.; Beitane, I. Assessment of Ingredients and Nutritional Value of Vegan Products in Latvian Market. Res. Rural. Dev. 2020, 35, 118–124. [Google Scholar]

- Curtain, F.; Grafenauer, S. Plant-Based Meat Substitutes in the Flexitarian Age: An Audit of Products on Supermarket Shelves. Nutrients 2019, 11, 2603. [Google Scholar] [CrossRef] [PubMed]

- D’Alessandro, C.; Pezzica, J.; Bolli, C.; Di Nicola, A.; Falai, A.; Giannese, D.; Cupisti, A. Processed Plant-Based Foods for CKD Patients: Good Choice, but Be Aware. Int. J. Environ. Res. Public Health 2022, 19, 6653. [Google Scholar] [CrossRef] [PubMed]

- Romão, B.; Botelho, R.B.A.; Nakano, E.Y.; Raposo, A.; Han, H.; Vega-Muñoz, A.; Ariza-Montes, A.; Zandonadi, R.P. Are Vegan Alternatives to Meat Products Healthy? A Study on Nutrients and Main Ingredients of Products Commercialized in Brazil. Front. Public Health 2022, 10, 1565. [Google Scholar] [CrossRef] [PubMed]

- Costa-Catala, J.; Toro-Funes, N.; Comas-Basté, O.; Hernández-Macias, S.; Sánchez-Pérez, S.; Latorre-Moratalla, M.L.; Veciana-Nogués, M.T.; Castell-Garralda, V.; Vidal-Carou, M.C. Comparative Assessment of the Nutritional Profile of Meat Products and Their Plant-Based Analogues. Nutrients 2023, 15, 2807. [Google Scholar] [CrossRef]

- Falkenberg, C.; Trexler, A.; Garaus, C.; Pöchtrager, S. Meat Substitute Markets: A Comparative Analysis of Meat Analogs in Austria. Foods 2023, 12, 2211. [Google Scholar] [CrossRef]

- Escobar, N.; Tizado, E.J.; zu Ermgassen, E.K.H.J.; Löfgren, P.; Börner, J.; Godar, J. Spatially-Explicit Footprints of Agricultural Commodities: Mapping Carbon Emissions Embodied in Brazil’s Soy Exports. Glob. Environ. Chang. 2020, 62, 102067. [Google Scholar] [CrossRef]

- Chaudhary, A.; Marinangeli, C.P.F.; Tremorin, D.; Mathys, A. Nutritional Combined Greenhouse Gas Life Cycle Analysis for Incorporating Canadian Yellow Pea into Cereal-Based Food Products. Nutrients 2018, 10, 490. [Google Scholar] [CrossRef]

- de Sousa Carvalho, V.L.; de Sousa, E.V.; de Oliveira, L.L.; Júnior, U.J.R.; Nagata, K.M.R. Virtual Water and Soy Water Footprint: Increasing Exports in Brazilian Amazon Ports versus Environmental and Water Risks. Res. Soc. Dev. 2023, 12, e15312238189. [Google Scholar] [CrossRef]

- do Carmo, H.F.; Madari, B.E.; Wander, A.E.; Moreira, F.R.B.; Gonzaga, A.C.d.O.; da Silveira, P.M.; Silva, A.G.; da Silva, J.G.; de Almeida, P.L.O.M. Balanço Energético e Pegada de Carbono Nos Sistemas de Produção Integrada e Convencional de Feijão-Comum Irrigado. Pesqui. Agropecu. Bras. 2016, 51, 1069–1077. [Google Scholar] [CrossRef][Green Version]

- Barbier, C.; Couturier, C.; Pourouchottamin, P.; Cayla, J.-M.; Silvestre, M.; Pharabod, I. Energy and Carbon Footprint of Food in France from Production to Consumption; Centre International de Recherche sur l’Environnement et le Développement: Nogent-sur-Marne, France, 2019; Volume 1. [Google Scholar]

- Browne, D.; O’Regan, B.; Moles, R. Use of Carbon Footprinting to Explore Alternative Household Waste Policy Scenarios in an Irish City-Region. Resour. Conserv. Recycl. 2009, 54, 113–122. [Google Scholar] [CrossRef]

- Bleninger, T.; Kotsuka, L.K. Conceitos de Água Virtual e Pegada Hídrica: Estudo de Caso Da Soja e Óleo de Soja No Brasil. Rev. Recur. Hídricos 2015, 36, 15–24. [Google Scholar] [CrossRef][Green Version]

- Bielski, S.; Marks-Bielska, R.; Wiśniewski, P. Investigation of Energy and Economic Balance and GHG Emissions in the Production of Different Cultivars of Buckwheat (Fagopyrum Esculentum Moench): A Case Study in Northeastern Poland. Energies 2022, 16, 17. [Google Scholar] [CrossRef]

- Nategh, N.A.; Banaeian, N.; Gholamshahi, A.; Nosrati, M. Sustainability Assessment and Optimization of Legumes Production Systems: Energy, Greenhouse Gas Emission and Ecological Footprint Analysis. Renew. Agric. Food Syst. 2021, 36, 576–586. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. The Green, Blue and Grey Water Footprint of Crops The Green, Blue and Grey Water Footprint of Crops and Derived Crop Products The Green, Blue and Grey Water Footprint of Crops. Hydrol. Earth Syst. Sci. Discuss. 2011, 8, 763–809. [Google Scholar] [CrossRef]

- Heusala, H.; Sinkko, T.; Sözer, N.; Hytönen, E.; Mogensen, L.; Knudsen, M.T. Carbon Footprint and Land Use of Oat and Faba Bean Protein Concentrates Using a Life Cycle Assessment Approach. J. Clean. Prod. 2020, 242, 118376. [Google Scholar] [CrossRef]

- Beebe, S.E.; Rao, I.M.; Blair, M.W.; Acosta-Gallegos, J.A. Phenotyping Common Beans for Adaptation to Drought. Front. Physiol. 2013, 4, 35. [Google Scholar] [CrossRef] [PubMed]

- Lopez, L.I.F.; Bautista-Capetillo, C. Green and Blue Water Footprint Accounting for Dry Beans (Phaseolus Vulgaris) in Primary Region of Mexico. Sustainability 2015, 7, 3001–3016. [Google Scholar] [CrossRef]

- Drury, C.F.; Yang, X.M.; Reynolds, W.D.; McLaughlin, N.B. Nitrous Oxide and Carbon Dioxide Emissions from Monoculture and Rotational Cropping of Corn, Soybean and Winter Wheat. Can. J. Soil Sci. 2011, 88, 163–174. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bacenetti, J.; Fiala, M. Water Footprint of Crop Productions: A Review. Sci. Total Environ. 2016, 548–549, 236–251. [Google Scholar] [CrossRef] [PubMed]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon Footprint: Current Methods of Estimation. Environ. Monit. Assess. 2010, 178, 135–160. [Google Scholar] [CrossRef] [PubMed]

- Jia, F.; Peng, S.; Green, J.; Koh, L.; Chen, X. Soybean Supply Chain Management and Sustainability: A Systematic Literature Review. J. Clean. Prod. 2020, 255, 120254. [Google Scholar] [CrossRef]

- Döll, P.; Siebert, S. Global Modeling of Irrigation Water Requirements. Water Resour. Res. 2002, 38, 8-1–8-10. [Google Scholar] [CrossRef]

- Augustin, M.A.; Chen, J.; Ye, J. Processing to Improve the Sustainability of Chickpea as a Functional Food Ingredient. J. Sci. Food Agric. 2024, 104, 8397–8413. [Google Scholar] [CrossRef]

- Tukker, A. Life Cycle Assessment as a Tool in Environmental Impact Assessment. Environ. Impact Assess. Rev. 2000, 20, 435–456. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Braun, M.; Muñoz, I.; Schmidt, J.H.; Thrane, M. Sustainability of Soy Protein from Life Cycle Assessment. FASEB J. 2016, 30, 894.5. [Google Scholar] [CrossRef]

- Kazlauskas, M.; Bručienė, I.; Savickas, D.; Naujokienė, V.; Buragienė, S.; Steponavičius, D.; Romaneckas, K.; Šarauskis, E. Life Cycle Assessment of Winter Wheat Production Using Precision and Conventional Seeding Technologies. Sustainability 2023, 15, 14376. [Google Scholar] [CrossRef]

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A Review of Life Cycle Assessment (LCA) on Some Food Products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Perrin, A.; Basset-Mens, C.; Gabrielle, B. Life Cycle Assessment of Vegetable Products: A Review Focusing on Cropping Systems Diversity and the Estimation of Field Emissions. Int. J. Life Cycle Assess. 2014, 19, 1247–1263. [Google Scholar] [CrossRef]

- Voora, V.; Larrea, C.; Bermudez, S. Global Market Report: Soybeans; IISD: Winnipeg, MB, Canada, 2020. [Google Scholar]

- USDA (United States Department of Agriculture) Soybeans|USDA Foreign Agricultural Service. Available online: https://fas.usda.gov/data/production/commodity/2222000 (accessed on 17 March 2024).

- Cuiabano, S.M. Principais Fatores Responsáveis Pela Expansão Da Soja No Brasil. Braz. J. Int. Relat. 2020, 8, 460–487. [Google Scholar] [CrossRef]

- Lima, M.; da Silva Junior, C.A.; Rausch, L.; Gibbs, H.K.; Johann, J.A. Demystifying Sustainable Soy in Brazil. Land Use Policy 2019, 82, 349–352. [Google Scholar] [CrossRef]

- Cavalett, O.; Ortega, E. Emergy, Nutrients Balance, and Economic Assessment of Soybean Production and Industrialization in Brazil. J. Clean. Prod. 2009, 17, 762–771. [Google Scholar] [CrossRef]

- Goldsmith, P.D. Soybean Production and Processing in Brazil. In Soybeans: Chemistry, Production, Processing, and Utilization; Elsevier Inc.: Amsterdam, The Netherlands, 2008; pp. 773–798. [Google Scholar] [CrossRef]

- Ortega, E.; Cavalett, O.; Bonifácio, R.; Watanabe, M. Brazilian Soybean Production: Emergy Analysis with an Expanded Scope. Bull. Sci. Technol. Soc. 2005, 25, 323–334. [Google Scholar] [CrossRef]

- Ercin, A.E.; Aldaya, M.M.; Hoekstra, A.Y. The Water Footprint of Soy Milk and Soy Burger and Equivalent Animal Products. Ecol. Indic. 2012, 18, 392–402. [Google Scholar] [CrossRef]

- Li, M.; Zhu, K.-X.; Guo, X.-N.; Brijs, K.; Zhou, H.-M. Natural Additives in Wheat-Based Pasta and Noodle Products: Opportunities for Enhanced Nutritional and Functional Properties. Compr. Rev. Food Sci. Food Saf. 2014, 13, 347–357. [Google Scholar] [CrossRef] [PubMed]

- Ceresini, P.C.; Castroagudín, V.L.; Rodrigues, F.Á.; Rios, J.A.; Eduardo Aucique-Pérez, C.; Moreira, S.I.; Alves, E.; Croll, D.; Maciel, J.L.N. Wheat Blast: Past, Present, and Future. Annu. Rev. Phytopathol. 2018, 56, 427–456. [Google Scholar] [CrossRef]

- Australia Foreign Agricultural Service Global Market Analysis; International Production Assessment Division. Australia Wheat Production Second Highest on Record. Commodity Intelligence Report. 2022. Available online: https://ipad.fas.usda.gov/highlights/2022/10/Australia/index.pdf (accessed on 5 December 2024).

- Magrin, G.O.; Travasso, M.I.; Rodriguez, G.R.; Solman, S.; Nuñez, M. Climate Change and Wheat Production in Argentina. Int. J. Glob. Warm. 2009, 1, 214–226. [Google Scholar] [CrossRef]

- Veeck, G.P.; Dalmago, G.A.; Bremm, T.; Buligon, L.; Jacques, R.J.S.; Fernandes, J.M.; Santi, A.; Vargas, P.R.; Roberti, D.R. CO2 Flux in a Wheat-Soybean Succession in Subtropical Brazil: A Carbon Sink. J. Environ. Qual. 2022, 51, 899–915. [Google Scholar] [CrossRef]

- Fioreze, S.L.; Drun, R.P.; Wuaden, A.F.; Mazzuco, V.; de Oliveira, J.C. Source-Sink Relationships of Wheat Plants Obtained by the Application of Systemic Herbicides. Pesqui. Agropecu. Bras. 2021, 56, e01600. [Google Scholar] [CrossRef]

- Ortolan, F.; Steel, C.J. Protein Characteristics That Affect the Quality of Vital Wheat Gluten to Be Used in Baking: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 369–381. [Google Scholar] [CrossRef] [PubMed]

- Siddique, K.H.M.; Johansen, C.; Turner, N.C.; Jeuffroy, M.H.; Hashem, A.; Sakar, D.; Gan, Y.; Alghamdi, S.S. Innovations in Agronomy for Food Legumes. A Review. Agron. Sustain. Dev. 2012, 32, 45–64. [Google Scholar] [CrossRef]

- Nette, A.; Wolf, P.; Schlüter, O.; Meyer-Aurich, A. A Comparison of Carbon Footprint and Production Cost of Different Pasta Products Based on Whole Egg and Pea Flour. Foods 2016, 5, 17. [Google Scholar] [CrossRef]

- Kahramanoğlu, İ.; Usanmaz, S.; Alas, T. Water Footprint and Irrigation Use Efficiency of Important Crops in Northern Cyprus from an Environmental, Economic and Dietary Perspective. Saudi J. Biol. Sci. 2020, 27, 134–141. [Google Scholar] [CrossRef] [PubMed]

- CNA/SENAR Ervilha: Cultivo e Comercialização. Available online: https://cnabrasil.org.br/cna-pulses/page4.html (accessed on 18 January 2024).

- de Lima Tartaglia, F.; Lúcio, A.D.C.; Diel, M.I.; Tischler, A.L.; Krysczun, D.K.; Zemolin, J.A.; Marques, L.E. Experimental Plan for Tests with Pea. Agron. J. 2021, 113, 1394–1406. [Google Scholar] [CrossRef]

- Ariffin, N.I.B.; Hannan, M.A. Wingsail Technology as a Sustainable Alternative to Fossil Fuel. IOP Conf. Ser. Mater. Sci. Eng. 2020, 788, 012062. [Google Scholar] [CrossRef]

- Püschl, W. High-Speed Sailing. Eur. J. Phys. 2018, 39, 044002. [Google Scholar] [CrossRef]

- Abas, N.; Kalair, A.; Khan, N. Review of Fossil Fuels and Future Energy Technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Lam, A.C.Y.; Can Karaca, A.; Tyler, R.T.; Nickerson, M.T. Pea Protein Isolates: Structure, Extraction, and Functionality. Food Rev. Int. 2018, 34, 126–147. [Google Scholar] [CrossRef]

- Maningat, C.C.; Jeradechachai, T.; Buttshaw, M.R. Textured Wheat and Pea Proteins for Meat Alternative Applications. Cereal Chem. 2022, 99, 37–66. [Google Scholar] [CrossRef]

- Saget, S.; Costa, M.; Santos, C.S.; Vasconcelos, M.W.; Gibbons, J.; Styles, D.; Williams, M. Substitution of Beef with Pea Protein Reduces the Environmental Footprint of Meat Balls Whilst Supporting Health and Climate Stabilisation Goals. J. Clean. Prod. 2021, 297, 126447. [Google Scholar] [CrossRef]

- Messina, M.; Messina, V.L. Exploring the Soyfood Controversy. Nutr. Today 2013, 48, 68–75. [Google Scholar] [CrossRef]

- Ferraz, L.C.C.B.; Araújo, A.C.M.; Rossi, C.E. Preliminary Evaluation of Meloidogyne Incognita Race 3 Reproduction on Garden Pea Cultivars in Brazil. Semin. Cienc. Agrar. 2000, 21, 97. [Google Scholar]

- Oliveira, E.C.; Carvalho, J.d.A.; Rezende, F.C.; de Freitas, W.A. Viabilidade Técnica e Econômica Da Produção de Ervilha (Pisum sativum L.) Cultivada Sob Diferentes Lâminas de Irrigação. Eng. Agrícola 2011, 31, 324–333. [Google Scholar] [CrossRef]

- Çelik, Ş. Modelling and Estimation of Chickpea Production in Turkey Using Artificial Neural Networks and Time Series Analysis. J. Eng. Sci. 2020, 10, 2319–6483. [Google Scholar]

- Merga, B.; Haji, J. Economic Importance of Chickpea: Production, Value, and World Trade. Cogent Food Agric. 2019, 5, 1615718. [Google Scholar] [CrossRef]

- Güngörmüşler, M.; Başınhan, İ.; Üçtuğ, F.G. Optimum Formulation Determination and Carbon Footprint Analysis of a Novel Gluten-Free Pasta Recipe Using Buckwheat, Teff, and Chickpea Flours. J. Food Process Preserv. 2020, 44, e14701. [Google Scholar] [CrossRef]

- Shim, Y.Y.; Mustafa, R.; Shen, J.; Ratanapariyanuch, K.; Reaney, M.J.T. Composition and Properties of Aquafaba: Water Recovered from Commercially Canned Chickpeas. J. Vis. Exp. 2018, 2018, e56305. [Google Scholar] [CrossRef]

- Aslan, M.; Ertas, N. Possibility of Using “chickpea Aquafaba” as Egg Replacer in Traditional Cake Formulation. Harran Tarım Ve Gıda Bilim. Derg. 2020, 24, 1–8. [Google Scholar] [CrossRef]

- He, Y.; Shim, Y.Y.; Mustafa, R.; Meda, V.; Reaney, M.J.T. Chickpea Cultivar Selection to Produce Aquafaba with Superior Emulsion Properties. Foods 2019, 8, 685. [Google Scholar] [CrossRef] [PubMed]

- Buhl, T.F.; Christensen, C.H.; Hammershøj, M. Aquafaba as an Egg White Substitute in Food Foams and Emulsions: Protein Composition and Functional Behavior. Food Hydrocoll. 2019, 96, 354–364. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Herranz, B.; Fuentes, R.; Cuesta, F.J.; Canet, W. Replacement of Wheat Flour by Chickpea Flour in Muffin Batter: Effect on Rheological Properties. J. Food Process Eng. 2017, 40, e12372. [Google Scholar] [CrossRef]

- Gómez, M.; Oliete, B.; Rosell, C.M.; Pando, V.; Fernández, E. Studies on Cake Quality Made of Wheat-Chickpea Flour Blends. LWT-Food Sci. Technol. 2008, 41, 1701–1709. [Google Scholar] [CrossRef]

- Instituto Brasileiro de Geografia e Estatística Produção de Feijão No Brasil|IBGE. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/feijao/br (accessed on 20 January 2024).

- Brazil Ministério da Saúde. Vigilância de Fatores de Risco e Proteção Para Doenças Por Inquérito Telefônico—VIGITEL; Centrais de Conteúdo: Brasília, Brazil, 2020. [Google Scholar]

- Uebersax, M.A.; Cichy, K.A.; Gomez, F.E.; Porch, T.G.; Heitholt, J.; Osorno, J.M.; Kamfwa, K.; Snapp, S.S.; Bales, S. Dry Beans (Phaseolus vulgaris L.) as a Vital Component of Sustainable Agriculture and Food Security—A Review. Legume Sci. 2023, 5, e155. [Google Scholar] [CrossRef]

- Arrieta, E.M.; González, A.D. Energy and Carbon Footprints of Food: Investigating the Effect of Cooking. Sustain. Prod. Consum. 2019, 19, 44–52. [Google Scholar] [CrossRef]

- Coltro, L.; Mourad, A.L.; Kletecke, R.M.; Mendonça, T.A.; Germer, S.P.M. Assessing the Environmental Profile of Orange Production in Brazil. Int. J. Life Cycle Assess. 2009, 14, 656–664. [Google Scholar] [CrossRef]

- Good Food Institute Muito Além Da Soja e Da Ervilha: O Potencial Do Feijão Para a Indústria de Proteínas Alternativas Vegetais e Para o Brasil—GFI Brasil. Available online: https://gfi.org.br/muito-alem-da-soja-e-da-ervilha-o-potencial-do-feijao-para-a-industria-de-proteinas-alternativas-vegetais-e-para-o-brasil/ (accessed on 20 January 2024).

- Ramos-Diaz, J.M.; Kantanen, K.; Edelmann, J.M.; Jouppila, K.; Sontag-Strohm, T.; Piironen, V. Functionality of Oat Fiber Concentrate and Faba Bean Protein Concentrate in Plant-Based Substitutes for Minced Meat. Curr. Res. Food Sci. 2022, 5, 858–867. [Google Scholar] [CrossRef] [PubMed]

- Nepa. Tabela Brasileira de Composição de Alimentos: TACO; Núcleo de Estudos e Pesquisas em alimentação, Ed.; Unicamp: Campinas, Brazil, 2011; Volume 4, p. 161. [Google Scholar]

- de Paiva Gouvêa, L.; Caldeira, R.; de Lima Azevedo, T.; Galdeano, M.C.; Felberg, I.; Lima, J.R.; Grassi Mellinger, C. Physical and Techno-Functional Properties of a Common Bean Protein Concentrate Compared to Commercial Legume Ingredients for the Plant-Based Market. Food Hydrocoll. 2023, 137, 108351. [Google Scholar] [CrossRef]

- De Angelis, D.; Latrofa, V.; Caponio, F.; Pasqualone, A.; Summo, C. Techno-Functional Properties of Dry-Fractionated Plant-Based Proteins and Application in Food Product Development: A Review. J. Sci. Food Agric. 2023, 104, 1884–1896. [Google Scholar] [CrossRef] [PubMed]

- Rother, E.T. Revisão Sistemática X Revisão Narrativa. Acta Paul. Enferm. 2007, 20, v–vi. [Google Scholar] [CrossRef]

- Green, B.N.; Johnson, C.D.; Adams, A. Writing Narrative Literature Reviews for Peer-Reviewed Journals: Secrets of the Trade. J. Chiropr. Med. 2006, 5, 101–117. [Google Scholar] [CrossRef] [PubMed]

| Reference | Country | Produced Plant-Based Analog | Main Protein Sources | Protein Source Forms of Presentation |

|---|---|---|---|---|

| Mariseva et al. (2020) [28] | Latvia | Various meat analogs without discrimination | Soy, | Soy protein, isolated soy protein, soy flour |

| Wheat, | Flour, gluten | |||

| Non-specified, Pulses, | NA * | |||

| Oats. | Rolled flakes, flour | |||

| Curtain et al. (2019) [29] | Australia | Burgers, sausages, minced meat, chicken, cutlets and seafood | Soy, | Soy protein, isolated soy protein, soy flour, textured vegetable protein (TVP) |

| Pea, | Pea protein, pea isolated protein | |||

| Mycoprotein. | Isolated mycoprotein | |||

| D’Alessandro et al. (2022) [30] | Italy | Burgers, cold cuts, cutlets and meatballs | Soy, | Soy protein, isolated soy protein, soy flour |

| Oats, | Whole flakes | |||

| Buckwheat. | Flour | |||

| Romão et al. (2022) [31] | Brazil | Burgers, minced meat, chicken nuggets, chicken cutlets, seafood, sausages and cold cuts | Soy, | Soy protein, isolated soy protein, soy flour, textured vegetable protein (TVP) |

| Wheat, | Flour, gluten | |||

| Pea, | Pea protein, pea isolated protein | |||

| Beans, | Whole grains, flour | |||

| Chickpeas. | Whole grains, flour | |||

| Costa-Catala et al. (2023) [32] | Spain | Burgers, sausages, meatballs and chicken nuggets | Soy, | Soy protein, isolated soy protein, soy flour, textured vegetable protein (TVP) |

| Peas, | Pea protein, pea isolated protein | |||

| Chickpeas, | Whole grains, flour | |||

| Lentils. | Whole grains | |||

| Falkenberg et al. (2023) [33] | Austria and Australia | Minced meat and sausages | Peas, | Pea protein, pea isolated protein |

| Soy, | Soy protein, isolated soy protein, soy flour, textured vegetable protein (TVP) | |||

| Wheat, | Gluten | |||

| Lentils, | Whole grains | |||

| Sunflower Protein. | Isolated sunflower protein |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romão, B.; Sommo, M.; Zandonadi, R.P.; de Holanda, M.E.M.; Borges, V.R.P.; Saraiva, A.; Raposo, A. Sustainability of Key Proteins in Plant-Based Meat Analogs Production: A Worldwide Perspective. Sustainability 2025, 17, 382. https://doi.org/10.3390/su17020382

Romão B, Sommo M, Zandonadi RP, de Holanda MEM, Borges VRP, Saraiva A, Raposo A. Sustainability of Key Proteins in Plant-Based Meat Analogs Production: A Worldwide Perspective. Sustainability. 2025; 17(2):382. https://doi.org/10.3390/su17020382

Chicago/Turabian StyleRomão, Bernardo, Maximiliano Sommo, Renata Puppin Zandonadi, Maria Eduarda Machado de Holanda, Vinicius Ruela Pereira Borges, Ariana Saraiva, and António Raposo. 2025. "Sustainability of Key Proteins in Plant-Based Meat Analogs Production: A Worldwide Perspective" Sustainability 17, no. 2: 382. https://doi.org/10.3390/su17020382

APA StyleRomão, B., Sommo, M., Zandonadi, R. P., de Holanda, M. E. M., Borges, V. R. P., Saraiva, A., & Raposo, A. (2025). Sustainability of Key Proteins in Plant-Based Meat Analogs Production: A Worldwide Perspective. Sustainability, 17(2), 382. https://doi.org/10.3390/su17020382