2. Materials and Methods

2.1. Material and Storage Methods

Plant material was obtained from the producer’s farm in Kujawsko-Pomorskie Province, Poland. The zucchini ‘Lanka F1’ was harvested on 23 July 2024 (first experiment) and 26 August 2024 (second experiment). The fruit was harvested at a relatively early growth stage (15–25 cm in length and 3–4.5 cm in diameter). Immediately after harvest, the zucchini was transported to the laboratory, which took approximately 4 h. In the laboratory, the fruit was stored at 10 °C overnight. The following day, the fruit was removed from the cold room and washed in water that was 5 °C warmer than the fruit flesh, i.e., 17 °C. After washing, the fruit was disinfected in a 0.01% sodium hypochlorite solution (2 min) and rinsed in tap water. The fruit was placed on flat screens for surface drying. Storage experiments were set up in a two-factor system: A and B. Factor A was the zucchini storage method: 1. CA with 5.0 kPa CO2 + 2.0 kPa O2; 2. DCA with 0.5 kPa CO2; 3. DCA with 2.0 kPa CO2; 4. normal atmosphere (NA) with 0.0 kPa CO2 + 21.0 kPa O2; and 5. control—storage outside the container in crates lined with polyethylene (PE) film. Factor B was the storage temperature: 8 and 5 °C.

Fruit of excellent quality, i.e., without any defects, was used for the storage study. The experiment was set up with 20 replicates of 1 fruit each, which were arranged in 2 plastic crates. Twenty batches of 10 fruits of uniform size were selected, and individual fruits from each batch were placed separately in boxes assigned to specific experimental objects. The weight of each fruit was determined before being placed into storage. In addition, samples were prepared for chemical analysis and measurement of the respiration intensity. The zucchini fruit (except control samples) was stored in gas-tight containers of 70 cm × 100 cm × 64 cm (W × D × H). Oxygen and carbon dioxide levels in containers with CA and DCA was monitored by using Fruit System A&B Instruments 2022 (Van Amerongen CA Technology, Tiel, The Netherlands). DCA containers used HarvestWatch™ technology to monitor chlorophyll fluorescence (DCA-CF) to detect low oxygen stress. Chlorophyll fluorescence sensors (Satlantic, NS, Canada; distributed by Isolcell S.p.A., Laives, Italy) were placed over a sample of 4 fruits in each batch. In containers with DCA, the signal from sensors based on chlorophyll fluorescence measurements indicated a threshold for anaerobic respiration at an oxygen level of 0.4 kPa (Fα = 0.4 kPa). The oxygen concentration for further storage was set at 0.3 kPa higher than Fα, which was 0.7 kPa. The cold storage period was 20 d. The control combination was introduced into the study in order to compare storage in CA and DCA with standard zucchini storage. Additionally, this allows access to the stored material during storage, because in the case of CA and DCA, the material is sealed throughout the entire period of cold storage. After cold storage, zucchini fruit from all experimental treatments were moved to 15 °C for further storage under retail conditions for 8 d.

2.2. Quality Assessment

Weight loss measurements and morphological observations were performed immediately after cold storage and after 4 and 8 d of shelf life at 15 °C. Weight loss was calculated as the percentage decrease in weight measured during storage compared to the weight measured on the day the storage experiment began, i.e., the day the zucchini were placed in cold storage. As part of the morphological observations, the development of cold damage and fruit and stalk rot were assessed. The marketable value of the zucchini was determined based on these observations. The individual traits were evaluated using 9-point scales, with 1 indicating no signs of change in a given trait and 9 indicating the maximum intensity of a given change, i.e., very strong development of cold damage or fruit or stalk rot. The commercial value was also assessed on a 9-point scale as follows: 1–no commercial value, 3–bad, 5–sufficient (market value threshold), 7–good, 9–excellent. On four dates, namely on the day the storage experiment was set up, immediately after cold storage, and after 1 and 4 d of storage at 15 °C, the respiration intensity was measured. These measurements were made in 3 replicates for each experimental combination. A single fruit was sealed in a 3.3 L glass jar for 2 h, after which the released CO2 content was measured using a Check Mate 3 O2(Zr) CO2-100% analyzer (MOCON Europe A/S, Ringsted, Denmark). On the day the experiment was set up and after 20 d of cold storage, CIE L*C*h* (color space defined by International Commission on Illumination) measurements were recorded on 10 fruits from each treatment using a Minolta CM—700 d spectrophotometer (Konica Minolta Optiks INC., Sakai, Japan).

2.3. Chemical Analysis

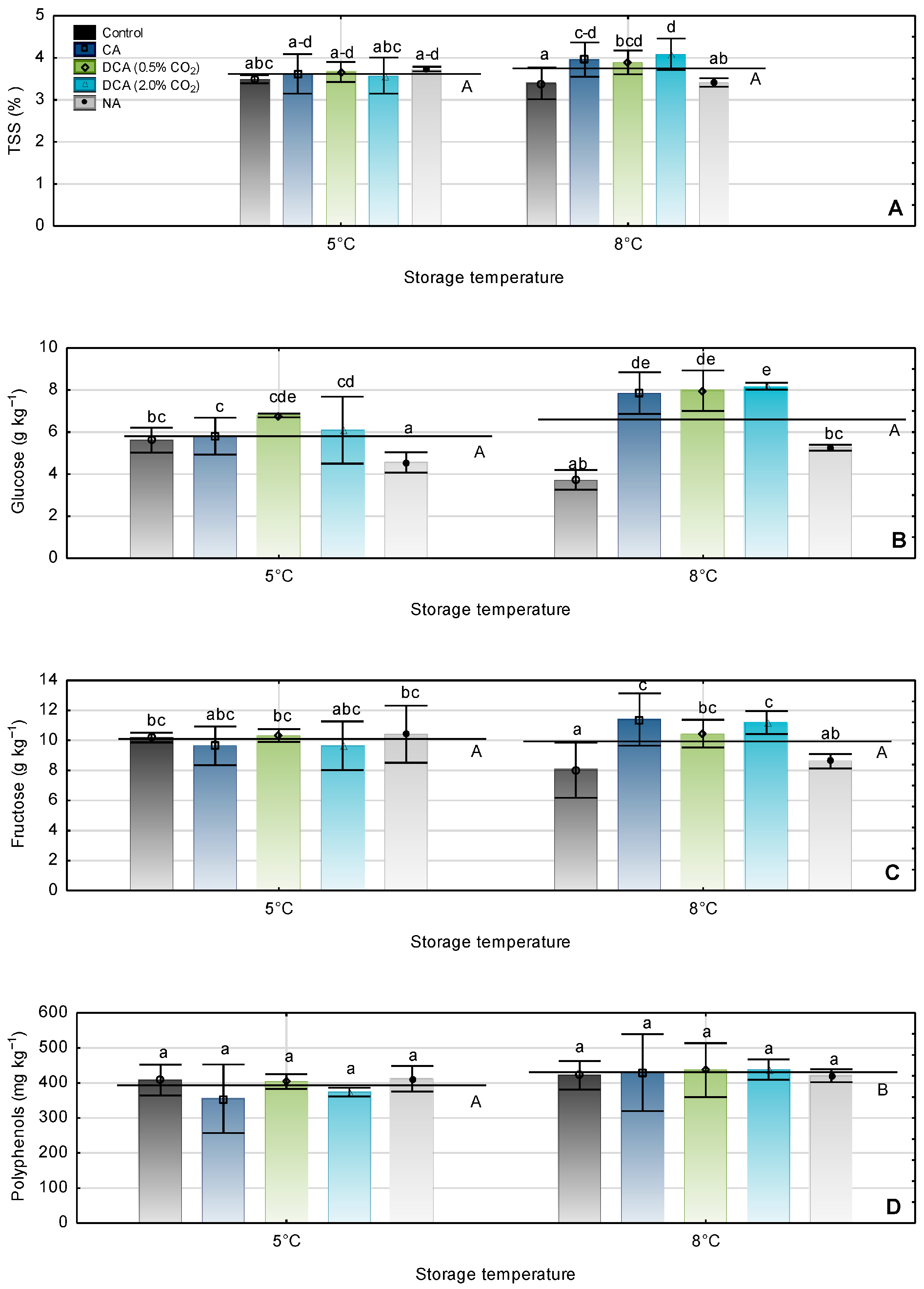

Chemical analyses were performed after 20 d of refrigerated storage. The contents of the following components were determined: total soluble solids (TSSs), glucose, fructose, and polyphenols. The TSS content was measured using a refractometer (Mettler Toledo, RE50, Greifensee, Switzerland) and expressed as a percentage of fresh weight (FW).

The analysis of glucose and fructose in zucchini ware determined by high-performance liquid chromatography Agilent 1200 HPLC system (Agilent Technologies, Morges, Switzerland), equipped with a differential refractometric detector. The separation of sugars was carried out using a column (Aminex HPX-87C, 300 mm × 7.5 mm) (Bio-Rad Laboratories, Hercules, CA, USA) with a precolumn. The isocratic flow was 0.6 mL min−1, column temperature was 80 °C, and the mobile phase was 0.1 mM edetate calcium disodium (Ca-EDTA). The redistilled water, was added to zucchini and next the samples were homogenized and purified on a Waters SepPak PLUS C18 filter (Waters, MA, USA). Quantitative determinations were made using a calibration curve for glucose and fructose, and the results were expressed in g kg−1 FW.

The total polyphenol content (TPC) was measured using a spectrophotometric method with Folin–Ciocalteu reagent [

31]. The 5 g sample of zucchini fruit was homogenized with 80% ethanol, and the homogenate was centrifuged for 10 min at 15,680 relative centrifugal force (RCF). The prepared solution was filtered under reduced pressure through a Büchner funnel filter. Then, 0.75 mL of the extract was transferred to a 25 mL volumetric flask, and 10 mL of distilled water, 1.25 mL of Folin–Ciocalteu reagent, and 2.5 mL of 20% NaCO

3 solution were added and mixed. The volume was topped up to 25 mL with distilled water. The samples were incubated in the dark for 1 h at room temperature. The absorbance was then measured using a UviLine 9400 spectrophotometer (SI Analytics, Hofheim am Taunus, Germany) at a wavelength of 750 nm and compared to the blank sample. The TPC was expressed as mg of catechin equivalents in mg kg

−1 FW of the analyzed zucchini sample.

2.4. Statistical Analysis

Statistical analysis was carried out by two-factor and one-factor analysis of variance using StatSoft STATISTICA version 13. Two-factor analysis was used to calculate the zucchini storage results as a function of temperature and storage method. One-factor analysis was used to compare means between storage temperatures (5 and 8 °C). The significance of differences between the averages was determined using the Tukey test at a significance level of p < 0.05.

4. Discussion

Zucchini is a non-climacteric vegetable harvested for the European market, most often at the immature stage when the fruit reaches about 20 cm in length. Such fruit is highly susceptible to wilting, rotting, and senescence during storage. New developments in improving the storage ability of zucchini are essential for unloading the supply at harvest time and for enabling transport over longer distances. CA and DCA are methods that positively influence the durability of zucchini ‘Lanka F1‘ but in appropriate temperature regimes. In the current study, CA and DCA improved the storage life of zucchini at 8 °C, but no significant improvement was found at 5 °C. This is in contrast to the results of Mencerelli [

19], who found that a carbon dioxide concentration of 5 kPa was useful for zucchini storage at 5 °C. This reaction may have been caused by specific characteristics of the Romanesco cv., which also responded to reduced CO

2 concentrations by lowering its respiration rate. Wang and Ji [

20] found that a low oxygen atmosphere (1.0 kPa) increases the level of polyamines in the skin of ‘Ambassador’ zucchini, which reduces the extent of surface pitting during exposure to low temperatures (2.5 °C). In the present study, minimal CI occurred even after zucchini was stored for 20 d at 8 °C, but the severity was much lower than at 5 °C. Also, Palma et al. [

2] and Zuo et al. [

14] found that refrigeration damage occurred when the fruit was stored at temperatures lower than 7–10 °C. Whereas Gualanduzzi et al. [

12] reported that the pits on the fruit skin were visible after 20 d at 10 °C. According to Carvajal et al. [

11] and Palma et al. [

2], each variety can vary in its cold sensitivity depending on its biochemical and morphological characteristics. However, Balandran-Quintena et al. [

32] showed that 12 °C does not cause cold damage in zucchini. When the zucchini was moved to 15 °C after 20 d of refrigerated storage, the chilling-damaged tissue quickly rotted, reducing symptoms, such as pitting on the skin. It follows that rotting is also an indicator of the susceptibility of zucchini to CI. Carvajal et al. [

11] found that even at 4 °C, the index of chilling damage, when based on pitting intensity, decreased with increasing storage period in some varieties. The results of rotting were not given, but it can be assumed that they developed, and therefore, the pits became less visible.

There were no statistically significant differences when storing zucchini under CA and DCA, but there was a slight tendency for zucchini to retain better quality after storage under DCA at 0.5 kPa CO

2. Zucchini under this treatment showed the lowest respiration intensity immediately after cold storage. This confirms previous reports by Prange et al. [

23] and Zanella et al. [

24] that DCA reduces vital processes, including respiratory intensity, during storage to a greater degree than CA. In general, the use of CA and DCA has made it possible to significantly extend the storage period of zucchini (20 d at 8 °C + 8 d at 15 °C), since according to Jacobi et al. [

33], it can be stored for only 1–2 weeks at 7–10 °C. Zucchini, as a non-climacteric vegetable, showed stable oxygen demand during 20 d of refrigerated storage. After the first LOL indication and setting the oxygen level above the threshold by 0.3 kPa, FC sensors did not indicate any more stress in zucchini metabolism until the end of the storage period. In non-climacteric vegetables and fruit, HarvestWatch technology is most needed to determine the threshold for anaerobic respiration, which according to Thewes et al. [

29], can vary even within the same species. However, operating at very low O

2 levels, chlorophyll chromatography status control should be maintained throughout the storage period.

Weight loss was very low in the current study compared with data from the literature. After 20 d at 5 or 8 °C, weight loss was much lower than that after 7 d at 4 or 20 °C in the study by Palma et al. [

2] and after 14 d at 4 or 12 °C in the study by Carvajal et al. [

11]. Similar weight losses were obtained by Megias et al. [

34] but after short-term storage of fruit wrapped in shrink film. Control fruit was protected with PE film, which maintained a higher air humidity, contributing to lower weight losses than under NA storage.

This study showed a trend toward higher reducing soluble carbohydrate (fructose and glucose) contents in CA- and DCA-treated samples than in NA-treated samples. Zucchini under CA and DCA showed greater resistance to cold damage than those under NA, which is consistent with the results of Palma et al. [

2], who found that reducing sugars may be involved in the adaptation of zucchini fruit to cold storage. Acting as osmoprotectants, they help stabilize proteins and cell membranes, protecting them from damage caused by stressful conditions. Lower glucose and fructose levels and greater CI in NA zucchini than in CA and DCA may also be related to higher respiration rates and the use of these carbohydrates for respiration, rather than for increasing cold tolerance. The glucose and fructose contents after 20 d at 8 °C under CA and DCA were only slightly lower than those in organic fruit immediately after harvest in the study by Kopczynska et al. [

35].

At 8 °C, zucchini retained a higher TPC than at 5 °C. This may have been influenced by the higher respiration rate of zucchini stored at 5 °C. Higher sugar consumption during more intense respiration reduces oxidative stability, leading to degradation and loss of polyphenols, while low respiration helps to maintain polyphenol content at a higher level., The TPC level in current study was high, exceeding the content of 264–324 mg kg

−1 FM reported by Ninfali et al. [

36] and 380 mg kg

−1 reported by Cieslik et al. [

37]. In contrast, it was similar to the results obtained by Kopczynska et al. [

35] for organic zucchini immediately after harvest. Plant material collected for the study was at an early maturity stage. According to Seleim et al. [

38], the younger the fruit, the more phenols they contain, but this content decreases with ripening. In general, an earlier harvest date results in higher nutritional and taste values for zucchini fruit.

Cold storage of zucchini at 8 °C under CA and DCA conditions allowed it to retain a higher market value for a longer period of time under commercial conditions. The risk of product losses due to CI and rotting was reduced. For producers and traders, this should translate into a better market position and greater profitability. However, it should be remembered that the implementation of CA and DCA systems involves technological investments in specialized equipment and new technologies.

The current studies examined the reactions of zucchini to storage in CA and DCA conditions only on one cultivar, Lanka F1. Therefore it would be advisable to test other cultivars in future studies. The impact of CA and DCA on the sensory properties of zucchini, especially its taste and smell, also needs to be determined. Other new solutions, including CA and DCA with other combinations of O2 and CO2, should also be tested in future studies.

5. Conclusions

CA and DCA have a beneficial effect on the storage life of zucchini, but temperature regimes must be maintained during cold storage. Of the two temperatures tested, 5 and 8 °C, the better response of zucchini to reduced O2 levels and increased CO2 levels was found at 8 °C. The application of CA and DCA at 8 °C reduced cold damage, which became evident during the subsequent storage period at 15 °C, as rotting was reduced, thus maintaining a higher marketable value. CA and DCA also contributed to maintaining higher levels of the tested chemical compounds (glucose, fructose, polyphenols) than NA and the control conditions. It is worth noting that treatment with DCA at 0.5 kPa CO2 for 20 d of cold storage resulted in a good to excellent marketable value after another 4 d at 15 °C. Zucchini under these conditions showed the lowest respiration intensity immediately after cold storage.

Both CA and DCA are chemical-free technologies that will allow an extended time for the commodity to be managed when the harvest is abundant and there are many deliveries to the market. Storing zucchini at 8 °C is more beneficial to the environment than storing it at 5 °C, because zucchini is harvested from open fields in the summer. During this time, cooling the chamber and maintaining a temperature of 8 °C uses less energy than maintaining a temperature of 5 °C.

The use of Ca or DCA at a temperature of 8 °C for storing zucchini should help to reduce losses and improve economic results for both producers of this vegetable and traders. This is in line with the United Nations’ “Responsible Consumption and Production” goal, which aims to reduce resource use, improve prosperity and support a sustainable global economy.