Abstract

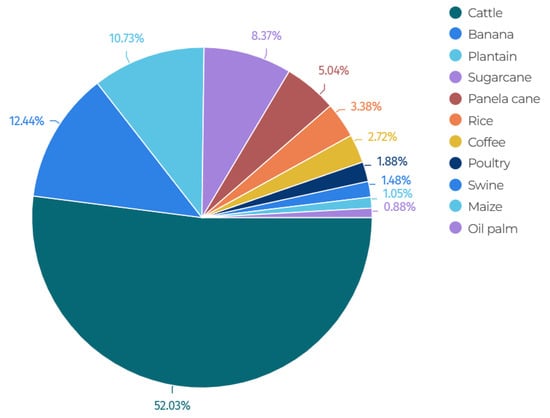

Colombia, due to its agricultural and livestock diversity, has significant potential for electricity generation from residual biomass. This study proposes a methodological framework to evaluate the most appropriate conversion technologies for the Colombian context, considering both technical and territorial factors. Through a review of thermochemical, biochemical, and physical methods, the available technologies and their respective energy products were identified. A national inventory of homogeneous residues by department was then developed, revealing that livestock waste accounts for 52.03% of the total, followed by banana residues (12.44%) and plantain residues (10.73%). These data were incorporated into a decision matrix linking regional residue availability with technological compatibility. The results emphasize the high feasibility of anaerobic digesters, ethanol bioreactors, gasifiers, and pyrolysis reactors, depending on the type and volume of residues. Furthermore, electricity generation remains largely concentrated in sugarcane bagasse from sugar mills in the southwest, highlighting the need to diversify applications in other regions. The proposed decision matrix provides a practical tool to prioritize technologies at the territorial level, positioning anaerobic digestion, bioethanol production, gasification, and pyrolysis as the most promising options to diversify Colombia’s energy matrix and strengthen regional energy resilience.

1. Introduction

In the past century, humans have exploited nonrenewable energy sources in an uncontrolled manner. These resources consist of elements that accumulated underground throughout geological history. A defining characteristic of nonrenewable energy sources is that they cannot be replenished as rapidly as renewable ones; in other words, their regeneration capacity is far lower than the rate at which they are consumed. This situation has raised serious concerns about climate change and sustainability, prompting many countries to explore cleaner energy alternatives. In the case of Colombia, its rich biodiversity provides a wide range of biomass resources, including agricultural and forestry residues. Nevertheless, it is essential to analyze the technological advancements required to implement the treatments that enable energy production from biomass. Such an approach is critical to diversifying the country’s energy matrix and fostering long-term environmental sustainability.

As the world advances toward Net Zero Emissions targets for 2050, biomass stands out as a viable alternative to replace fossil fuels [1]. In Colombia, biomass represents more than 9% of the primary energy supply, with sugarcane bagasse and firewood playing a particularly important role in electricity generation [2]. This underscores the relevance of biomass in the country’s energy transition, reducing dependence on nonrenewable sources and contributing to a cleaner and more diversified energy matrix.

This article aims to evaluate biomass energy utilization technologies for electricity generation in Colombia, assessing its potential as a renewable source and the range of available conversion methods. The main contributions of this study are as follows:

- A structured overview of biomass to electricity pathways, covering residue identification, biofuel conversion, and power generation.

- A departmental decision matrix that links biomass residues with the most suitable conversion technologies for each region.

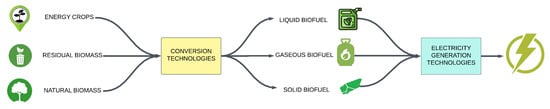

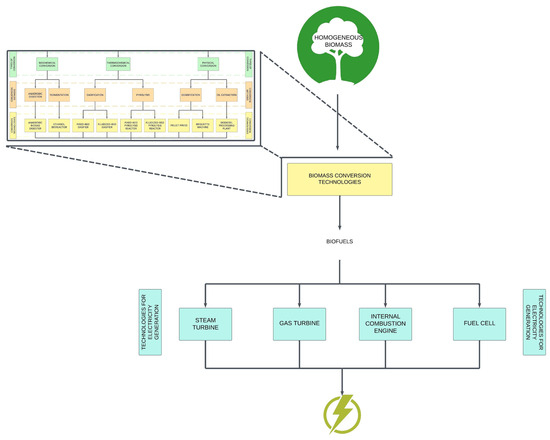

A structured overview is presented on the application of technologies for utilizing residual biomass in electricity generation. First, the type of biomass is identified and processed through a conversion technology that transforms it into a solid, liquid, or gaseous biofuel. This biofuel subsequently supplies electricity generation systems, whose ultimate objective is to produce electrical energy.

To support the selection of appropriate processes, we propose a departmental decision matrix that links the primary and secondary residues of each region with the most compatible conversion technologies. This tool identifies, at the departmental level, the most promising conversion methods according to the volume and characteristics of the available residues.

Despite progress made by previous studies in assessing biomass potential and analyzing specific conversion technologies in Colombia, there is still a lack of integrated approaches that systematically connect regional residue availability with technology selection. This gap constrains the design of territorialized strategies for biomass utilization. To address this limitation, the present work develops and applies a methodological framework based on a departmental inventory of homogeneous residues and a decision matrix linking these residues with appropriate conversion technologies. This applied framework constitutes the main novelty of the study, as it provides a practical tool to guide regional implementation and support Colombia’s transition toward a more diversified and sustainable energy matrix.

The document is structured as follows: Section 2 presents the study methodology, including theoretical concepts on biomass and its classifications; Section 3 outlines the technological pathway from biomass to electricity generation; Section 4 provides a detailed examination of the various conversion technologies; Section 5 discusses their application in electricity generation; Section 6 presents an inventory of residual biomass in Colombia and analyzes its current use for electricity generation; and finally, Section 7 summarizes the main conclusions.

2. Methodology

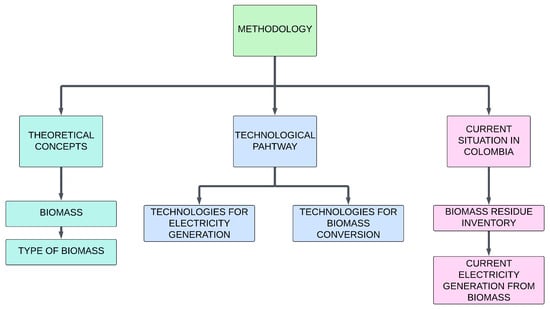

The analysis of technologies for electricity generation from biomass in Colombia is structured into three stages. First, the theoretical concepts of biomass and its classifications are presented, together with a technological pathway outlining the main methods for converting biomass into electrical energy. Second, the specific technologies employed at each stage of the value chain are examined in detail. Finally, a national diagnostic is conducted: an inventory of available residual biomass is compiled by department, and this information is integrated into a decision matrix that cross-references each type of residue with the analyzed conversion technologies (Figure 1).

Figure 1.

Methodology diagram.

The decision matrix was designed as a qualitative tool to relate regional biomass residues with compatible conversion technologies. Compatibility was assessed based on technical criteria reported in the literature, such as feedstock composition, conversion efficiency, and pretreatment requirements, as well as on the regional availability of each residue type. The objective of this matrix is not to establish weighted scores or perform a full multi-criteria decision-making (MCDM) analysis, but rather to provide a transparent and structured framework for guiding the identification of feasible technological options by region. More advanced approaches, including the incorporation of weighted criteria, uncertainty analysis, or hybrid MCDM methods, are recognized as valuable extensions for future research.

2.1. Theoretical Concepts of Biomass

Biomass is a renewable energy source derived from organic materials such as plant residues, agricultural waste, wood, and other biodegradable matter resulting from human and natural activities. It is regarded as a sustainable energy alternative because its use does not increase net carbon dioxide emissions to the atmosphere, provided that collection and regeneration are managed sustainably [3].

Historically, biomass has been primarily utilized through direct combustion, a method classified by the International Energy Agency as conventional biomass [4]. This process involves burning the material in stoves or open fires to convert it directly into heat [3]. However, technological advancements have enabled the development of far more efficient processes, allowing biomass to be converted into significantly cleaner forms of energy. These include thermochemical, biochemical, and physical methods, which are categorized by the International Energy Agency under the term modern biomass [4].

Types of Biomass

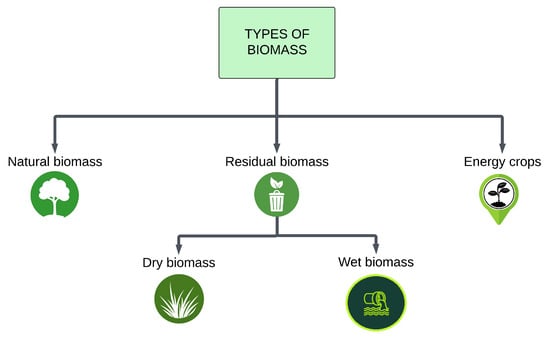

According to Fernández [4], biomass can generally be classified into three main categories for energy applications: natural biomass, residual biomass, and bioenergy crops (Figure 2).

Figure 2.

Types of biomass.

Natural biomass is obtained directly from nature without significant human intervention in its growth or collection. It includes natural vegetation and organisms found in ecosystems such as forests, wetlands, and grasslands. This type of biomass is used locally and typically consists of wood from fallen trees, natural pruning residues, and decaying aquatic vegetation.

On the other hand, residual biomass originates from agricultural, forestry, industrial, and urban activities. It includes crop residues, forestry by products, wood industry wastes, and urban organic matter such as food scraps. Beyond its energy potential, residual biomass plays an important role in waste management by reducing the environmental burden of landfills.

Finally, energy crops are plants specifically cultivated for use as energy sources. These crops are harvested in a controlled manner to maximize the biomass that can be converted into renewable fuels such as biogas, biodiesel, or bioethanol. Common examples include corn, sugarcane, and oil palm.

Technologies for biomass utilization in electricity generation are a crucial aspect of classifying this renewable energy source. These technologies are closely linked to the type of biomass used as input; in other words, each biomass type, whether agricultural, forestry, industrial residues, or energy crops, requires specific technologies that enable its efficient conversion for energy production. In this study, particular emphasis is placed on the utilization processes of homogeneous residues, that is, those composed of uniform waste streams [5].

3. Technological Pathway from Biomass to Electricity Generation

The process of converting biomass into electricity is not homogeneous; rather, it varies according to the physicochemical characteristics of the biomass source. For instance, agricultural residues, which are rich in organic matter and have a low energy density, are particularly suitable for anaerobic digestion processes that produce biogas. Anaerobic digestion enables the efficient utilization of these residues, transforming them into useful energy while mitigating the environmental impacts of their disposal. This is especially relevant in regions where agricultural production generates large volumes of organic waste, which can be converted into biogas for use as a renewable energy source [6].

In contrast, forestry residues or woody biomass, due to their higher calorific value, are more commonly employed in gasification and direct combustion technologies for energy generation. These technologies facilitate the efficient use of forest resources, particularly in areas with high biomass density, where calorific capacity is harnessed to optimize the conversion processes [7].

It is important to note that, in addition to technologies designed to convert biomass into solid, liquid, or gaseous biofuels, there are also specialized technologies dedicated to generating electricity directly from these resources (Figure 3). These technologies are essential for the efficient integration of biomass into the energy matrix, as they enable the effective and sustainable conversion of biofuels into electrical energy.

Figure 3.

Technological pathway from biomass to electricity generation, highlighting how different types of biomass can feed conversion processes and subsequently be utilized through specific technologies for electricity production.

The main electricity generation technologies include internal combustion engines, gas turbines, and steam turbines, as well as an emerging alternative: fuel cells, which convert biogas directly into electricity through electrochemical processes without the need for combustion.

The selection of the most appropriate technology depends not only on the type of biofuel available but also on factors such as project scale, operating costs, existing infrastructure, and the specific needs of each region. A strategic combination of these technologies can significantly enhance energy system efficiency and contribute to the transition toward cleaner and more sustainable energy sources.

4. Review of Biomass Conversion Technologies

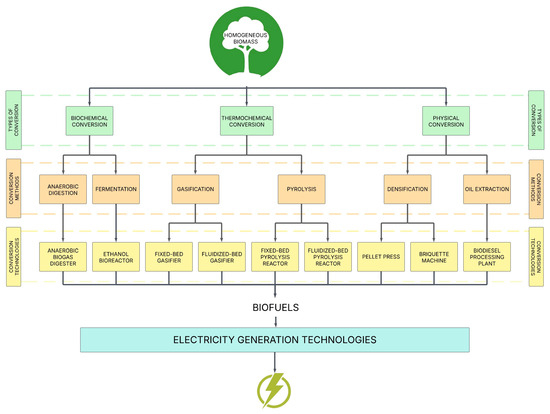

This section reviews the main technologies for biomass conversion, organized according to the methods used to transform organic matter into usable energy carriers. It is important to distinguish between method and technology: the method refers to the general process by which the conversion occurs (e.g., anaerobic digestion or gasification), while the technology corresponds to the specific infrastructure or equipment that enables its practical application, such as an anaerobic digester or a gasifier.

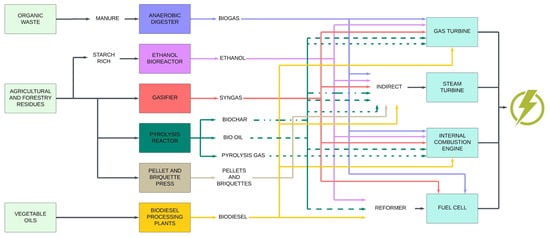

Biomass conversion can be approached from different perspectives, depending on the physical, chemical, or biological properties of the feedstock. For analytical purposes, these approaches are grouped into three main categories: biochemical, thermochemical, and physical or mechanical (Figure 4). The following subsections present the most widely applied technologies within each category, highlighting their principles of operation, energy products, and relevance for electricity generation.

Figure 4.

Biomass conversion technologies. Schematic representation of the main biomass conversion pathways: biochemical, thermochemical, and physical, each with specific methods that lead to the production of biofuels subsequently used for electricity generation.

- Biochemical Conversion:

- Method: Anaerobic DigestionTechnology: Biogas Anaerobic Digester

- Method: FermentationTechnology: Ethanol Bioreactor

- Thermochemical Conversion:

- Method: Direct CombustionTechnology: Biomass Boilers

- Method: GasificationTechnologies: Fixed-Bed Gasifier, Fluidized-Bed Gasifier

- Method: PyrolysisTechnologies: Pyrolysis Reactor, Continuous Pyrolyzers

- Physical or Mechanical Conversion:

- Method: DensificationTechnologies: Pellet Press, Briquetting Machine

- Method: Oil ExtractionTechnology: Biodiesel Processing Plant

Each of these technologies plays a fundamental role in the bioenergy value chain, enabling the conversion of diverse biomass sources such as agricultural, forestry, urban residues, and energy crops into energy carriers including biogas, biodiesel, bioethanol, and electricity. The following sections provide a detailed analysis of each technology, addressing their operating principles, potential applications, and relevance within the broader context of renewable energy production.

4.1. Biogas Anaerobic Digester

Anaerobic digestion is a biological process in which consortia of microorganisms decompose organic matter in the absence of oxygen, producing a combustible gas known as biogas [8]. A major advantage of this pathway is its feedstock flexibility, as biogas can be generated from a wide range of organic residues including food waste, wastewater biosolids, and animal manure without being limited to specific geographical conditions. To optimize gas yields according to substrate characteristics, anaerobic digesters are engineered in different sizes and configurations. This versatility enables their deployment across multiple scales, from small household systems to large industrial facilities [8].

4.2. Ethanol Bioreactor

Ethanol is one of the most widely produced and studied biofuels, playing a central role as a renewable substitute for conventional liquid fuels. It is obtained through the fermentation of glucose by yeasts of the genus Saccharomyces under controlled conditions [9]. This process is carried out in bioreactors, where reactor configuration and operating parameters are critical factors in optimizing both the yield and quality of ethanol production [9].

4.3. Fixed-Bed and Fluidized-Bed Gasifiers

Two main types of gasifiers are employed for the thermochemical conversion of biomass into gaseous biofuels: fixed-bed gasifiers and fluidized-bed gasifiers.

The fixed-bed gasifier operates by oxidizing biomass with agents such as air, oxygen, or steam. This technology is widely applied due to its efficiency in converting low-cost feedstocks into electricity, particularly within the power range of 10–100 kW [10,11]. Fixed-bed systems are further classified into updraft and downdraft configurations, in which the feedstock is introduced from the top and descends through the reactor, passing through successive reaction zones. This process results in a producer gas with relatively low tar content [12], an otherwise undesirable by product formed during pyrolysis. In dual-stage designs, gas quality and calorific value can be further enhanced.

On the other hand, the fluidized-bed gasifier introduces the gasifying agent from the bottom of the reactor, creating a fluidized state in which biomass particles are suspended, thereby enhancing the gasification process. Although the producer gas obtained typically exhibits a lower calorific value than biogas and contains ash and other impurities, this technology offers the advantage of operating at relatively low temperatures (750–900 °C), which mitigates tar formation and reduces the presence of unburned material [10].

Both gasifier types are effective in converting biomass into gaseous biofuels, but each presents distinct characteristics and advantages depending on feedstock type and system requirements (Table 1).

Table 1.

Comparison between fixed-bed and fluidized-bed gasifiers: Characteristics and applications, including operating temperatures, power generation ranges, and typical applications.

4.4. Fixed-Bed and Fluidized-Bed Pyrolysis Reactors

Fixed-bed pyrolysis reactors are primarily applied in slow pyrolysis processes, where the low heating rate favors the production of biochar (Table 2). In these systems, biomass is thermally decomposed in an inert atmosphere or under very limited oxygen conditions to prevent combustion. Experimental studies have demonstrated that larger reactors operating at lower heating rates yield greater amounts of biochar due to the more complete conversion of the feedstock into the carbonized fraction [13].

By contrast, fluidized-bed pyrolysis reactors are mainly employed in fast pyrolysis processes, which favor the production of bio oils or liquid biofuels. These reactors typically operate at temperatures between 400 and 500 °C in low-oxygen environments, promoting the formation of condensable vapors that are subsequently converted into bio oil (Table 2). Their relatively simple design and high heat transfer efficiency make them one of the most widely used pyrolysis technologies [14]. During operation, biomass is dried and pretreated to a particle size of approximately 2–4 mm to facilitate fluidization. The inert gas or carrier medium introduced from the bottom promotes rapid thermal decomposition, while solid residues and condensable vapors are recovered for further processing.

Table 2.

Different operating modes of pyrolysis, summarizing the operating conditions of slow and fast pyrolysis processes and highlighting the influence of temperature on the distribution of products such as char, bio-oil, and gases. Adapted from the Colombian technological catalog for energy generation and storage technologies.

Table 2.

Different operating modes of pyrolysis, summarizing the operating conditions of slow and fast pyrolysis processes and highlighting the influence of temperature on the distribution of products such as char, bio-oil, and gases. Adapted from the Colombian technological catalog for energy generation and storage technologies.

| Mode | Conditions | Composition | ||

|---|---|---|---|---|

| Liquid | Char | Gas | ||

| Fast pyrolysis | Moderate temperature, short residence time | 75% | 12% | 13% |

| Carbonization | Low temperature, very long residence time | 30% | 35% | 35% |

| Gasification | High temperature, long residence time | 5% | 10% | 85% |

Source: Based on [15].

4.5. Pellet Press and Briquetting Machine

Pellet presses and briquetting machines are widely employed for the densification of biomass, particularly from forestry and agricultural residues. Densification, together with calorific value, represents a fundamental aspect in the production of solid biofuels. The calorific values of different raw materials typically range between 10 and 19 MJ/kg (Table 3). In comparison, pellets generally exhibit slightly higher values, exceeding 20 MJ/kg [16]. Additionally, density must be taken into account, as greater density combined with a higher calorific value results in a higher energy content per unit volume [16].

Table 3.

Higher heating value (HHV) for various biomass sources.

4.6. Biodiesel Processing Plants

Biodiesel is a liquid biofuel primarily derived from vegetable oils, animal fats, and alternative sources such as algae or used cooking oils [17]. The most commonly employed vegetable oils include soybean, palm, and coconut oil, while animal fats also represent a viable feedstock. A major advantage of biodiesel lies in its chemical composition, which is sufficiently similar to that of conventional diesel, enabling its direct use in compression ignition (diesel) engines without requiring significant modifications [17].

The predominant technology for biodiesel production is transesterification, also referred to as alcoholysis [17]. This process employs the aforementioned feedstocks and involves a chemical reaction that separates the compounds into two main products: biodiesel and glycerin. Methanol is most commonly used as the alcohol, together with suitable catalysts to accelerate the transesterification reaction. During the process, the oils or fats are mixed with methanol, leading to the separation of biodiesel as the primary product and glycerin as a by product.

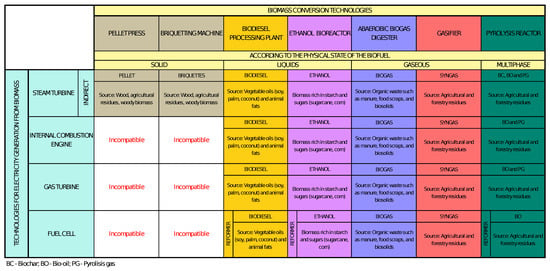

4.7. Summary of Biomass Conversion Technologies

This section outlines the principal technologies employed to transform biomass into combustible products suitable for subsequent energy generation. Each technology is adapted to the specific characteristics of the feedstock, enabling the production of gaseous, liquid, or solid fuels with improved calorific value and energy usability (Table 4).

Table 4.

Summary of biomass conversion technologies, showing different biomass sources alongside the conversion methods that process them into usable energy carriers.

In some cases, these processes not only enable energy utilization but also enhance the calorific value of the raw material. This synthesis provides a structured overview of the relationship between feedstock type, conversion method, and resulting energy product, serving as a reference framework for analyzing the subsequent technological pathways toward electricity generation.

5. Use of Biomass Conversion Technologies for Electricity Generation

Building upon the technological pathway described in Section 3, the generation of electricity from biofuels derived from biomass emerges as a viable alternative to diversify the energy matrix and reduce reliance on fossil fuels. This approach leverages the transformation of heterogeneous organic residues into standardized energy carriers, which can then be efficiently converted into electricity.

This section presents the main technologies employed for this purpose, emphasizing both their operational principles and the mechanisms by which the chemical energy contained in biofuels is transformed into electrical energy. Each technology exhibits distinct advantages and limitations in terms of efficiency, cost, and scalability, with the choice of system depending largely on the available resources and the specific energy requirements of each region.

These technologies are powered by biofuels obtained from biomass conversion processes. In the case of turbines and internal combustion engines, the biofuel first generates mechanical energy, which is subsequently coupled to an electric generator, thus completing the technological pathway toward electricity production from biomass (Figure 5).

Figure 5.

Electricity generation technologies using biofuels. The diagram details the technologies that were initially grouped as a single block in Figure 4. Turbines and internal combustion engines first transform the biofuel into mechanical energy, which is then coupled to an electric generator, completing the pathway toward electricity production from biomass.

5.1. Steam Turbine

Steam turbines are devices that convert the thermal energy of pressurized steam into mechanical energy, which is subsequently transformed into electricity. They are widely used in thermal power plants and industrial facilities due to their versatility, since the steam can be produced from different fuels such as natural gas, diesel, and biomass [18].

According to Méndez Quezada [18], steam turbines are frequently integrated into cogeneration systems, where the recovery of residual heat increases overall process efficiency. Additional advantages include their high dispatch capacity, the possibility of operating in island mode or isolated networks, and the ability to restart power generation after an outage without requiring an external energy source.

From an environmental perspective, steam turbines powered by biomass are associated with relatively low sulfur dioxide (SO2) and nitrogen oxide (NOx) emissions, which represents an advantage compared to fossil fuel alternatives. However, in some cases carbon monoxide (CO) emissions can be higher and must be properly managed. Overall, this is a mature and consolidated technology for biomass-based electricity generation, characterized by efficient performance and relatively low operating costs [18].

5.2. Gas Turbine

Gas turbines convert the thermal energy of high-temperature combustion gases into mechanical energy, which is then transformed into electricity through a generator coupled to the turbine shaft. This technology is widely applied in cogeneration systems, where the simultaneous production of heat increases overall energy efficiency and reduces thermal losses in line with the Carnot principle [18]. In addition, gas turbines can operate in grid isolated systems, such as island networks, and are capable of rapid load adjustments owing to their relatively low inertia. Similar to steam turbines, they do not present problems related to harmonics or flicker, which facilitates their integration into the electrical grid [18].

When fueled with syngas derived from biomass gasification, gas turbines require specialized equipment capable of withstanding high operating temperatures and efficient gas cleaning systems to remove suspended particles before combustion [19]. Their efficiency strongly depends on operating conditions: it decreases significantly at partial loads, with reductions of up to 75% when operating at 50% of nominal capacity. Furthermore, environmental factors such as pressure, humidity, and ambient temperature influence power output; higher pressure increases generation capacity, whereas elevated temperatures reduce it [18].

Overall, gas turbines represent a mature and reliable technology for electricity generation from biomass-derived syngas, offering operational flexibility and cogeneration benefits, though their performance is highly sensitive to load and environmental conditions.

5.3. Reciprocating Internal Combustion Engines

Reciprocating internal combustion engines convert the chemical energy of a fuel into mechanical energy through combustion within closed cylinders. The thermal energy generated drives pistons in a reciprocating motion, which is then transformed into rotational motion by a crankshaft, enabling the engine to power an electric generator for electricity production [18,20].

These engines are widely applied in backup generation systems due to their fast start up capability and ability to operate in island mode, which allows them to function independently of the grid. Their black start capability is particularly valuable in situations where no external power supply is available. In addition, reciprocating engines provide a rapid response to fluctuations in energy demand, dynamically adjusting output as required. With proper technical coordination, they can also inject power into the electrical grid, contributing to system stability and reliability [18].

Overall, reciprocating internal combustion engines represent a flexible and well-established technology for biomass-based electricity generation, offering operational resilience and adaptability, though their efficiency and emissions performance depend on fuel quality and engine design.

5.4. Fuel Cells

Fuel cells, also referred to in the literature as fuel batteries, are electrochemical devices that convert the chemical energy of a hydrogen rich fuel directly into electricity through electrochemical reactions [21]. This technology holds significant promise as a green energy source due to its numerous advantages. A key feature is that fuel cells are not constrained by the Carnot cycle, enabling high conversion efficiency. In addition, they produce minimal, often negligible, pollutant emissions and feature a modular, flexible design, making them adaptable to a wide range of applications [22].

Structurally, fuel cells are composed of two electrodes and an electrolyte, similar to conventional batteries. However, unlike batteries, they can generate electricity continuously as long as a constant flow of fuel and oxidant is supplied, ensuring stable power output. Moreover, their isothermal operation prevents large temperature fluctuations, thereby reducing potential environmental impacts on air and water. Unlike other conversion methods that involve multiple stages with associated thermal losses, fuel cells operate in a single step, minimizing energy losses and enhancing overall efficiency [23].

Overall, fuel cells represent an emerging but highly efficient option for electricity generation from biomass-derived fuels such as syngas or biogas, although challenges related to cost, durability, and large scale deployment remain key barriers to widespread adoption.

5.5. Process Flow Diagram and Technological Compatibility

The processes involved in electricity generation from biomass utilization are outlined in a flow diagram (Figure 6).

Figure 6.

Flowchart of electricity production from biomass, outlining the processes involved in electricity generation from biomass utilization.

- Biogas: Produced through anaerobic digestion of organic waste, primarily animal manure. Biogas can be used in gas turbines, where it is combusted to generate high-temperature, high-pressure gases that drive the turbine. In this configuration, residual heat can be recovered for cogeneration, thereby improving overall system efficiency [24]. It can also be utilized in Otto cycle internal combustion engines specifically designed for this biofuel [24] or in solid oxide fuel cells capable of operating directly with biogas [25]. Finally, in steam turbines, biogas like other biofuels is burned in a boiler to produce high-pressure steam that powers the turbine.

- Ethanol: Although its use in gas turbines is not common, it is technically feasible with adaptations to the combustion chamber. A notable case is the Juiz de Fora power plant in Brazil, where ethanol derived from sugarcane is used for power generation [26]. Ethanol is more widely applied as a fuel in internal combustion engines, either in pure form or blended with gasoline (e.g., E10 or E20). However, engine modifications are required due to its higher octane rating and lower calorific value compared to gasoline [27]. For use in fuel cells, ethanol must first be reformed into hydrogen, which serves as the feed gas for the cell [28].

- Syngas: Before utilization, syngas must be purified to remove impurities. Similar to natural gas, its combustion generates high-temperature, high-pressure gases that can drive a turbine [29]. It can also fuel reciprocating internal combustion engines, where it is mixed with air, compressed, and ignited to produce mechanical energy [30]. Furthermore, syngas can be used in solid oxide fuel cells, which take advantage of its compatibility with high operating temperatures [25].

- Pellets and briquettes: These solid biofuels are primarily used in steam turbines. They are combusted in boilers to generate high-pressure steam that drives the turbine, a process commonly applied in cogeneration systems [31].

- Biodiesel: This biofuel can be used either partially blended or as a full substitute for conventional diesel in gas turbines, particularly in combined cycle configurations that couple gas and steam turbines to enhance efficiency [32]. It is also suitable for internal combustion engines, where it provides greater safety in storage and transport compared to petroleum diesel [33]. Like ethanol, biodiesel can be reformed to produce hydrogen for fuel cell applications [34].

- Pyrolysis products: Biochar can be utilized in combustion processes similar to those for pellets and briquettes [35]. Pyrolysis gas, with properties comparable to syngas, can be applied in similar electricity generation technologies. Bio oil, despite having different characteristics from biodiesel or ethanol, can also be used in energy applications, provided that the processes are adapted accordingly [35].

The compatibility between biomass conversion processes and electricity generation technologies is represented diagrammatically, showing how biofuels obtained from conversion processes can be utilized either directly or after additional conditioning to power various generation systems (Figure 7).

Figure 7.

Compatibility between biomass conversion technologies and electricity generation technologies. The diagram shows the interconnections, highlighting how biofuels obtained from conversion processes can be used either directly or after additional conditioning to power different electricity generation systems.

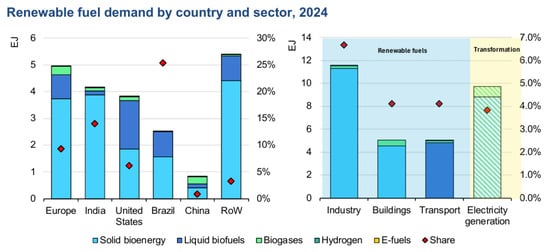

5.6. Biofuel Trends

Biofuels, derived from various biomass conversion technologies, are generally classified into liquid, gaseous, and solid forms, each with specific applications. According to the International Energy Agency’s Renewables 2024 report [36], liquid biofuels such as ethanol and biodiesel are predominantly used in the transportation sector due to their compatibility with existing combustion engines and their fuel properties similar to those of fossil fuels. Their capacity to reduce greenhouse gas emissions has reinforced their growing adoption.

In contrast, gaseous biofuels (biogas and biomethane) are mainly applied in electricity generation, representing more than 50% of their current use. However, a strong increase in their role within the transport sector is projected between 2024 and 2030, supported by favorable policies in regions such as India, the European Union, and the United States. Despite this, the requirement for large volumes of organic waste to sustain production remains a technical and logistical challenge [36] (Figure 8).

Figure 8.

Renewable fuel demand by country and sector in 2024, illustrating the global outlook on biofuel consumption. Renewable hydrogen and e-fuels are currently used only in the transport sector, and in very small quantities. For this reason, they are not visibly represented in the figure; however, they are included by the International Energy Agency due to their projected future utilization [36].

Solid biofuels, including pellets and briquettes, are key for electricity generation, particularly in countries like India, where the expansion of sugarcane production has accelerated their use. These fuels are primarily combusted in biomass boilers coupled with steam turbines to produce both electricity and process heat in cogeneration systems. Moreover, solid biofuels account for over 70% of the projected growth in renewable fuel production, with sustained demand in regions such as Europe, India, the United States, and Brazil [36].

Regarding liquid biofuels, although their use in transportation continues to grow, their contribution to electricity generation remains limited. This is mainly due to the relatively low efficiency of combustion engines operating with biodiesel or biomethane at high power levels, which restricts their application in large-scale energy generation systems [18].

Pyrolysis, a technology capable of converting biomass into solid, liquid, and gaseous products, also holds significant potential for waste valorization. Nevertheless, its large-scale implementation faces challenges derived from the heterogeneity of biomass feedstocks, particularly in the case of urban waste. Despite these limitations, pyrolysis is still considered a promising pathway for the utilization of the vast amounts of waste generated in cities.

In summary, global trends indicate a steady increase in the demand for renewable biofuels, supported by public policies and the development of new applications in both the electricity and transportation sectors. This highlights the strategic role of biofuels as an integral component of the ongoing energy transition toward sustainable sources.

6. Analysis of the Current Situation in Colombia

After presenting the main biomass conversion technologies and global biofuel trends, the next step is to assess their potential applicability in the Colombian context. Given the country’s rich biodiversity and diverse natural conditions, this requires a detailed understanding of the national resource base. Accordingly, this section provides an overview of residual biomass availability in Colombia, offering a foundation to evaluate the feasibility of integrating biomass conversion technologies into the national energy system.

6.1. Inventory of Residual Biomass in Colombia

The inventory of residual biomass considered in this study is based on the Atlas of the Energy Potential of Residual Biomass in Colombia [37], which compiles data on the availability of agricultural, livestock, and urban organic solid waste. To ensure homogeneity in the analysis, only agricultural and livestock residues were included, excluding urban waste. The data compiled in the Atlas correspond to the statistical reference year 2019, which is explicitly stated in order to clarify the temporal scope of the study.

In the agricultural sector, the crops analyzed were banana, coffee, sugarcane, panela cane, oil palm, plantain, rice, and corn. In the livestock sector, the subsectors considered were poultry, cattle, and pigs.

The quantities of waste for each subsector were obtained from Annex E of the Atlas [37], which reports the data by department and by crop or livestock activity. For this study, the information was aggregated to provide a national-level overview (Table 5).

Table 5.

Quantities by type of residue, showing the annual production of agricultural and livestock residues in Colombia (tons).

The relative contribution of agricultural and livestock residues to Colombia’s annual biomass availability highlights the predominance of specific categories within the national total (Figure 9).

Figure 9.

Relative contribution of the main agricultural and livestock residues to Colombia’s annual biomass availability. Cattle manure represents the largest share (52.03%), followed by banana residues (12.44%) and plantain residues (10.73%). Together, these three categories account for more than 75% of the total residual biomass considered in this study.

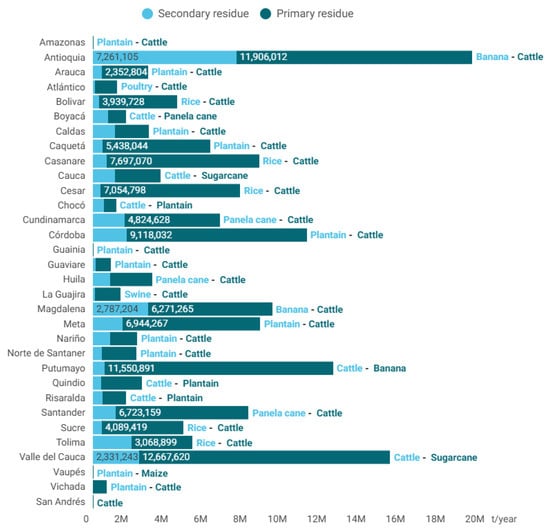

After consolidating the national inventory, the data were further disaggregated by department to provide a geographical perspective on the concentration of biomass resources and their potential for regional energy projects (Figure 10).

Figure 10.

Distribution of agricultural and livestock residues across Colombia’s 32 departments. For each department, the predominant residue type and the secondary residue type are identified, providing a geographical overview of the main biomass resources and highlighting their potential for regional energy projects.

Once the national inventory was completed, providing a clear overview of waste production, a decision matrix was developed (Table 6). This matrix lists the 32 departments of Colombia on one side and, on the other, first identifies the primary and secondary resources for each department. Next, the technologies studied in this work are presented, with some grouped together (for instance, fixed-bed and fluidized-bed pyrolysis reactors are considered as a single category, as is the case for gasification technologies). For each technology, its feasibility is evaluated according to the type of waste available in each department. Three possible outcomes are considered:

| ✓ | The residue is highly compatible with the technology. |

| ✓ | The residue requires pretreatment to be compatible with the technology. |

| × | The residue is poorly compatible with the technology. |

Table 6.

Decision matrix for biomass conversion technologies. Provides a comprehensive view of the possible synergies between the residues available in each department and the biomass conversion technologies, facilitating the identification of opportunities for the development of bioenergy projects at the regional level.

First, anaerobic biogas digesters are identified as viable technologies in all departments. This is due to the livestock sector, particularly the cattle subsector, having a significant share in the generation of organic waste nationwide, which favors the use of digesters owing to the constant availability of manure.

It is also important to highlight that this technology can be applied to the treatment of agricultural residues. Although the use of biodigesters has traditionally been associated with livestock waste, various scientific sources [38] and international organizations [39] recognize their potential for agro industrial residues. Therefore, these should also be considered in the analysis, although in most cases their use may require pretreatment steps to optimize anaerobic digestion.

Next, ethanol bioreactors are frequently used for the utilization of agricultural residues rich in starch [9], such as those generated from plantain, banana, rice, corn, and sugarcane. Compared to anaerobic digester technology, ethanol bioreactors present greater direct applicability to these resources, since biodigesters often require pretreatment, whereas bioreactors can use them more efficiently and without demanding preliminary conditions (Table 6).

At this stage of the analysis, gasifiers and pyrolysis reactors emerge as highly versatile technologies, with a broad range of applicability across the different departments. Their high adaptability stems from their capacity to process a wide variety of residues, including dry agricultural waste, forestry residues, and even by-products from other thermochemical or biological processes (Table 6).

However, gasifiers present an important distinction: the residue to be treated must have a low moisture content. Therefore, wet organic residues such as manure or fresh agro industrial waste must undergo drying pretreatments for proper gasification. This condition is not as restrictive for pyrolysis reactors, which can tolerate slightly higher levels of moisture, although they also benefit from the use of dry residues.

It is worth mentioning that recent studies have even proposed the use of anaerobic digestion by products (such as dried digestate) as input for gasifiers or pyrolysis reactors [35], which would enable the integration of cascade technologies and optimize the energy utilization of residual biomass.

Pellet presses and briquetting machines have traditionally been used for the processing of forestry residues. However, these technologies have also proven effective in the densification of residues from the agro industrial sector, which has expanded their deployment in various regions (Table 6).

Their wide territorial applicability is explained by the broad availability of dry and fibrous residues in many departments. Nevertheless, it is important to highlight that, due to the nature of this technology, these machines require specific pretreatment steps, such as drying and grinding, to ensure efficient densification. This aspect is already discussed in Section 4.5.

Finally, biodiesel processing plants do not initially appear to be a technology with high application potential (Table 6). Although, as discussed in Section 4.6, animal fats can be used as feedstock for biodiesel production, the matrix’s reference to the livestock sector is limited to residues such as animal excreta, which are not suitable for this technology. This distinction explains the limited presence of biodiesel plants in the departmental-level analysis.

Nevertheless, their relevance could gradually increase with the expansion of energy crops in Colombia, particularly oil palm, which does provide suitable raw materials for transesterification and regional scale biodiesel production.

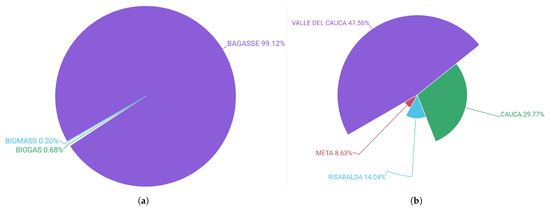

6.2. Current Electricity Generation from Residual Biomass in Colombia

To conclude, the current state of electricity generation from biomass in Colombia was analyzed using a report from the system operator XM, corresponding to May 2025 [40] (Table 7). Although three types of fuels were identified (bagasse, biogas, and biomass), electricity production is overwhelmingly dominated by bagasse, which accounts for more than 99% of total generation. This predominance, as well as the regional distribution of generation across departments, reflects the central role of the sugar industry in biomass-based electricity production (Figure 11).

Table 7.

Generation resources from biomass in Colombia, including resource name, electricity generation (GWh), type of fuel, department, and representative agent.

Figure 11.

Participation and regional distribution of electricity generation from biomass in Colombia. (a) Share of biomass resources in electricity generation, showing that bagasse accounts for 99.12% of the total, while biogas and rice industry residues represent marginal shares. (b) Departmental distribution of bagasse-based electricity generation, highlighting Valle del Cauca with 47.56% of national production, followed by Cauca, consistent with the location of the country’s main sugar mills.

7. Conclusions

This study developed and applied a methodological framework for the selection and regional implementation of biomass to electricity technologies in Colombia. By integrating a national inventory of homogeneous residues with a departmental decision matrix, the analysis demonstrated the compatibility between regional feedstocks and specific conversion pathways.

The results show that livestock residues, particularly from cattle, account for 52.03% of the total biomass potential, followed by banana residues (12.44%) and plantain residues (10.73%). Based on these resources, anaerobic digesters present the highest territorial applicability, while ethanol bioreactors show strong potential for starch- and sugar-rich residues. Gasifiers and pyrolysis reactors stand out for their versatility but require pretreatment steps such as drying and grinding. Pellet presses and briquetting machines, although energy-efficient, face limitations due to feedstock preparation requirements and high initial investment costs. Biodiesel production, while currently less aligned with predominant residues, could gain importance with the expansion of energy crops.

Currently, electricity generation from biomass in Colombia remains highly concentrated in sugarcane bagasse at sugar mills in the southwest. This pattern reflects both the maturity of the technology and the regional availability of resources. Expanding this model to other agricultural regions, along with the integration of hybrid systems that utilize by products from multiple processes, could significantly increase the contribution of biomass to the national energy mix.

The findings indicate clear policy and research priorities. Public policies must provide targeted incentives, financing mechanisms, and infrastructure investment to support technology deployment, particularly in rural areas. Research should advance techno-economic analyses, supply chain optimization, and environmental risk assessments (e.g., methane leakage, pyrolysis emissions, and waste treatment). In addition, attention must be given to social dimensions such as farmer acceptance, workforce training, and overcoming cultural barriers to adoption.

Ultimately, biomass is not only a renewable energy source with significant untapped potential but also a strategic pathway to diversify Colombia’s energy matrix, strengthen regional energy security, and promote sustainable development. The methodological framework developed in this study provides a replicable tool for guiding technology selection and regional implementation. Future research should expand this framework by integrating economic, logistical, environmental, and social dimensions, thereby building a more holistic foundation for decision-making in bioenergy planning.

Author Contributions

Conceptualization, methodology, R.E.-S. and E.G.-L.; validation, R.E.-S., E.G.-L. and R.F.-M.; investigation, R.E.-S.; writing—original draft preparation, R.E.-S.; writing—review and editing, R.E.-S., E.G.-L., R.F.-M. and J.C.V.; supervision, E.G.-L., R.F.-M. and J.C.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The first and second authors thank the GRALTA research group of the Universidad del Valle, Colombia, for their contributions during the development of this paper.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- International Energy Agency. Net Zero by 2050 Data Explorer. International Energy Agency. 2023. Available online: https://www.iea.org/data-and-statistics/data-tools/net-zero-by-2050-data-explorer (accessed on 5 May 2024).

- Unidad de Planeación Minero Energética (UPME). Balance Energético Colombiano 2022–2023; Ministerio de Minas y Energía: Bogotá, Colombia, 2025; pp. 1–29. [Google Scholar]

- Fernández Salgado, J. Guía Completa de la Biomasa y los Biocombustibles; Madrid Vicente, Ediciones: Madrid, Spain, 2010. [Google Scholar]

- International Energy Agency. Clean Energy Demonstration Projects Database: Biofuels. Available online: https://www.iea.org/data-and-statistics/data-tools/clean-energy-demonstration-projects-database?subsector=Biofuels (accessed on 5 May 2024).

- Gazzotti, S.; De Felice, B.; Ortenzi, M.A.; Parolini, M. Approaches for Management and Valorization of Non-Homogeneous, Non-Recyclable Plastic Waste. Int. J. Environ. Res. Public Health 2022, 19, 10088. [Google Scholar] [CrossRef] [PubMed]

- Glavaš, H.; Ivanović, M.; Mandić, N. Resources and possibilities of agro biomass usage for energy purposes in Slavonia region (Croatia). In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), Dubrovnik, Croatia, 13–16 May 2014; pp. 1150–1155. [Google Scholar]

- Santi, E.; Paloscia, S.; Pettinato, S.; Fontanelli, G.; Clarizia, M.P.; Guerriero, L.; Pierdicca, N. Forest Biomass Estimate on Local and Global Scales Through GNSS Reflectometry Techniques. In Proceedings of the 2019 IEEE International Geoscience and Remote Sensing Symposium (IGARSS), Yokohama, Japan, 28 July–2 August 2019; pp. 8680–8683. [Google Scholar]

- Ganesh, Y.N.V.; Resmi, R. Hardware Implementation of Anaerobic Biogas Digester for Household and Community Purposes. In Proceedings of the 2023 Innovations in Power and Advanced Computing Technologies (i-PACT), Kuala Lumpur, Malaysia, 8–10 December 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Imtiaz, U.; Jamuar, S.S.; Sahu, J.N. Bioreactor Profile Design and Optimization for Ethanol Production. In Proceedings of the 2024 International Conference on Biotechnology and Bioengineering Applications, Barcelona, Spain, 25–27 August 2024; IEEE: Kuala Lumpur, Malaysia, 2024. [Google Scholar]

- Yepes Maya, D.M.; Chejne Janna, F. Gasification of waste biomass in the flower industry, case: Eastern Antioquia. Rev. ION 2012, 25, 49–55. [Google Scholar]

- Damartzis, T.; Zabaniotou, A. Thermochemical Conversion of Biomass to Second Generation Biofuels Through Integrated Process Design: A Review. Renew. Sustainable Energy Rev. 2011, 15, 366–378. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Y.; Zhang, Q.; Zhou, J.; Wang, H.; Tong, P. Design and Experimental Study of a Two-Stage Pilot Scale Biomass Fixed Bed Gasifier. In Proceedings of the 2013 IEEE Conference on Emerging Technologies and Factory Automation (ETFA), Cagliari, Italy, 10–13 September 2013; IEEE: Nanjing, China, 2013; pp. 1–6. [Google Scholar]

- Flórez Ramos, D.F.; Barco Burgos, J.; Rincón Prat, S.L. Análisis comparativo de la carbonización de cuesco de palma de aceite en reactores de lecho fijo. Rev. Tecnura 2016, 20, 45–58. [Google Scholar] [CrossRef]

- Faxas Esaclona, R.; Suárez Rodríguez, J.A.; Beatón, P.A. Reactores en lecho fluidizado. Tecnol. Quím. 2009, XXIX, 205–212. Available online: http://www.redalyc.org/articulo.oa?id=445543761025 (accessed on 6 February 2025).

- Ministerio de Minas y Energía (MME), Unidad de Planeación Minero Energética (UPME), Agencia Danesa de Energía (DEA), Emergente. Catálogo Tecnológico Colombiano para Tecnologías de Generación y Almacenamiento de Energía 2025; UPME: Bogotá, Colombia, 2025. Available online: https://www.upme.gov.co/ (accessed on 12 February 2025).

- Forero Núñez, C.A.; Guerrero Fajardo, C.A.; Sierra Vargas, F.E. Producción y uso de pellets de biomasa para la generación de energía térmica: Una revisión a los modelos del proceso de gasificación. ITECKNE 2012, 9, 21–30. [Google Scholar] [CrossRef]

- Mayasari, F.; Dalimi, R. Vegetable Oil Based Biodiesel Feedstock Potential in Indonesia. In Proceedings of the 2014 Makassar International Conference on Electrical Engineering and Informatics (MICEEI), Makassar, Indonesia, 26–30 November 2014; IEEE: Makassar, Indonesia, 2014; pp. 37–41. [Google Scholar]

- Méndez Quezada, V.H. Generación Distribuida: Aspectos Técnicos y su Tratamiento Regulatorio; Tesis para la Obtención del grado de Doctor, Universidad Pontificia Comillas de Madrid: Madrid, Spain, 2005; Directed by Prof. Dr. Juan Rivier Abbad; Available online: https://www.comillas.edu/ (accessed on 18 February 2025).

- Carlos Augusto. Gasificación de Biomasa para Producción de Combustibles de Bajo Poder Calorífico y su Utilización en Generación de Potencia y Calor; Informe Técnico; Bogotá, Colombia, 2024. [Google Scholar]

- García Jaime, R. Estudio del Hidrógeno como Combustible Libre de Carbono en Motores de Combustión Interna Alternativos; Trabajo de Fin de Grado en Ingeniería Mecánica, Universitat Politècnica de Catalunya: Barcelona, Spain, 2024; Directed by Carlos Ruiz Moya; Available online: https://upc.edu/ (accessed on 20 February 2025).

- Huang, Y. MEMS-Based Electrochemical Power Sources for Extended Operational Duration of Micro Unmanned Vehicles; Ph.D. Dissertation, Chemical and Biomolecular Engineering, University of Pennsylvania: Philadelphia, PA, USA, 2024; Supervised by Dr. Sue Ann Bidstrup Allen and Dr. Mark G. Allen; Available online: https://repository.upenn.edu/ (accessed on 21 February 2025).

- Wang, C.; Nehrir, M.H. Power Management of a Stand-Alone Wind/Photovoltaic/Fuel Cell Energy System. IEEE Trans. Energy Convers. 2008, 23, 957–967. [Google Scholar] [CrossRef]

- Acuña Garrido, F.; Muñoz Yi, V. Celdas de combustible: Una alternativa amigable con el medio ambiente para la generación de potencia y su impacto en el desarrollo sostenible de Colombia en el siglo XXI. Ing. Desarro. 2010, 10, 94–104. [Google Scholar]

- Castro Reyes, J.A. Evaluación del uso de Residuos Agrícolas para la Producción de Energía Renovable por Medio de un Proceso de Gasificación; Trabajo de grado para optar al título de Magíster en Ingeniería—Ingeniería Química, Universidad Nacional de Colombia, Facultad de Ingeniería, Sede Bogotá: Bogotá, Colombia, 2023; Director: Ana María Castillo Moreno. [Google Scholar]

- Castro, L.; Gómez, J.; Gutiérrez, C.; Orjuela, P. Cogeneración a través de uso de celdas de combustible. Tecnura 2019, 23, 51–61. [Google Scholar]

- General Electric (GE). Brasil se Convierte en el Primer país en Producir Electricidad en Base a Etanol. Available online: https://n9.cl/6ciqg (accessed on 28 May 2025).

- Bradley, C.; Runnion, K. Understanding El Etanol Combustible: Producción and Uso; Paper Technical #3, Volunteers in Technical Assistance (VITA): Arlington, VA, USA, 1984; ISBN 0-86619-203-4. [Google Scholar]

- Bahamonde, R.; Sánchez, J.; Muñoz, M. Evaluación energética y ambiental de la gasificación de biomasa residual en Chile. Rev. Ing. Recursos Nat. Ambient. 2023, 22, e003. [Google Scholar]

- Martínez Reina, J. Estudio del Aprovechamiento Energético de Residuos Agrícolas Mediante Digestión Anaerobia para su Aplicación en el Sector Primario; Proyecto Fin de Carrera para optar al título de Grado en Ingeniería Mecánica, Universidad de Córdoba, Escuela Politécnica Superior: Córdoba, Spain, 2020; Director: Rafael Martín Ramos. [Google Scholar]

- García Linares, J.D.; Hurtado Pérez, J.E.; Zafra Meza, F.A. Gasificación de biomasa residual para generación distribuida de energía eléctrica: Análisis del potencial técnico en Colombia. Tecnol. Ciencia-TECNOLÓGICAS 2022, 25, e206. [Google Scholar]

- Comisión Nacional de Energía (CNE). Tecnologías de Generación de Energía a Partir de Biomasa Forestal; Documento técnico de apoyo a la Estrategia de Biomasa Forestal, Gobierno de Chile, Ministerio de Energía: Santiago, Chile, 2015; Available online: https://energia.gob.cl/ (accessed on 20 May 2025).

- Energía Estratégica. Informe Técnico de la UTN Muestra Importantes Avances en el uso de Biodiesel para la Generación Eléctrica en Turbinas de ciclo Combinado. Available online: https://www.energiaestrategica.com/informe-tecnico-de-la-utn-muestra-importantes-avances-en-el-uso-de-biodiesel-para-la-generacion-electrica-en-turbinas-de-ciclo-combinado/ (accessed on 28 May 2025).

- Alfonso Álvarez, J.A. Análisis del Aprovechamiento Energético de Residuos Agroindustriales Mediante Gasificación para su Aplicación en Zonas Rurales Aisladas; Trabajo Fin de Máster para optar al título de Máster en Ingeniería Industrial, Universidad de Sevilla, Escuela Técnica Superior de Ingeniería: Sevilla, Spain, 2022; Tutor: Juan Manuel Rodríguez Hidalgo. [Google Scholar]

- Tomás Pardillos, V. Estudio del Potencial Energético de Residuos Agrícolas y Forestales de Aragón: Aplicación en Sistemas de Trigeneración Mediante Gasificación; Trabajo Fin de Máster en Ingeniería Industrial, Universidad de Zaragoza, Escuela de Ingeniería y Arquitectura: Zaragoza, Spain, 2023; Director: Julio Martínez Gracia; Available online: https://zaguan.unizar.es/record/149461 (accessed on 22 May 2025).

- Segovia Espinoza, I.J. Evaluación Técnica y Económica de un Proceso de Gasificación para la Valorización Energética de Digestato Proveniente de lodos Sanitarios; Memoria para optar al título de Ingeniera Civil Química e Ingeniera Civil en Biotecnología, Universidad de Chile, Facultad de Ciencias Físicas y Matemáticas, Departamento de Ingeniería Química, Biotecnología y Materiales: Santiago, Chile, 2024; Profesor guía: Felipe Díaz Alvarado. [Google Scholar]

- International Energy Agency. Renewables 2024: Analysis and Forecast to 2030, Revised version; International Energy Agency: Paris, France, October 2024; Available online: https://www.iea.org/ (accessed on 27 May 2025).

- Unidad de Planeación Minero Energética (UPME). Atlas del Potencial Energético de la Biomasa Residual en Colombia; Publicación técnica desarrollada para evaluar el potencial energético de la biomasa residual en los sectores agrícola, pecuario y de residuos sólidos urbanos, Instituto de Hidrología, Meteorología y Estudios Ambientales (IDEAM), Departamento Administrativo de Ciencia, Tecnología e Innovación (Colciencias), Universidad Industrial de Santander (UIS): Santander, Colombia, 2010. Available online: https://www.minenergia.gov.co/ (accessed on 8 May 2025).

- Montenegro Orozco, K.T.; Rojas Carpio, A.S.; Cabeza Rojas, I.; Hernández Pardo, M.A. Potencial de biogás de los residuos agroindustriales generados en el departamento de Cundinamarca. Rev. ION 2016, 29, 23–37. [Google Scholar] [CrossRef]

- Genia Bioenergy. Funciones del Digestor. Available online: https://geniabioenergy.com/funciones-del-digestor/ (accessed on 17 May 2025).

- Operador del Sistema Interconectado Nacional (XM). Generación del Sistema Interconectado Nacional (SIN). Available online: https://sinergox.xm.com.co/oferta/Paginas/Informes/GeneracionSIN.aspx (accessed on 2 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).