Abstract

Recently, there has been a surge in the popularity of renewable energy systems due to their lucrative and sustainable attributes. Among these, photovoltaic (PV) systems stand out as prominent examples. Nevertheless, it is imperative to ascertain the management of waste produced by these systems in order to mitigate environmental pollution and harness their economic potential. This study aims to assess the present status and forecast the accumulation of waste generated by PV power plants in Chile. Utilizing openly available public data, a database is constructed to track the accumulation of waste. Two scenarios, namely, early-loss and regular-loss scenarios are employed to estimate the projected accumulation of PV waste. The findings indicate that by the years 2035 and 2043, the accumulation of waste is estimated to reach 100,000 tons under the early-loss scenario and regular-loss scenario. The total anticipated waste from solar PV modules is projected to be 284,906 tons, with c-Si PV modules contributing 175,595 tons to this total in Chile. Remarkably, it is determined that more than 235,000 tons of materials from this waste is recoverable, amounting to nearly USD 781 million in economic value. Silver is projected to bring the most economic value, with nearly USD 379 million, while lead, tin, cadmium, and zinc are each valued at less than USD 1 million. This study highlights the importance of promoting the sustainable development of PV systems, particularly in alignment with Sustainable Development Goals 7 (Affordable and Clean Energy) and 13 (Climate Action). Future research is expected to place greater emphasis on eco-design approaches in PV module production.

1. Introduction

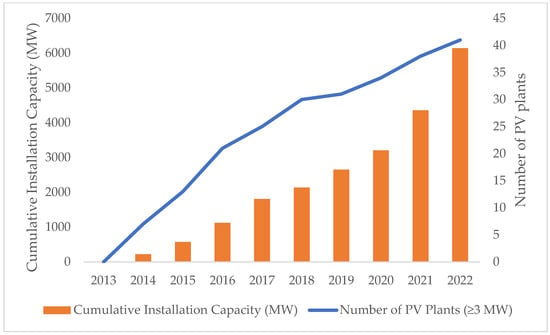

Photovoltaic systems represent a cost-effective means of generating renewable energy without emitting greenhouse gases. As of 2021, the capacity of global solar photovoltaic (PV) installations amounted to 942 GW, a dramatic contrast to the approximately 100 GW installed in 2012 [1,2], indicating a significant surge in the global deployment of PV systems. Chile, renowned for its high level of irradiation, stands out as one of the countries with immense potential for PV installation. Solar PV accounted for 18% of the country’s electricity production by 2022 [3]. Figure 1 illustrates a nearly six-fold increase in the number of PV plants in Chile, with an installation capacity greater than 3 MW, which rose from 7 to 41 between 2014 and 2022. Furthermore, the total installed capacity of PV power plants in the country reached 6142 MW by 2022 [4,5,6].

Figure 1.

Number of PV power plants in Chile and installation capacity by year [4,5,6].

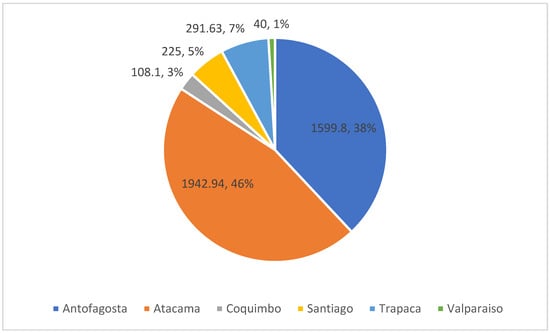

Solar PV power plants are positioned across diverse regions of Chile, encompassing Antofagosta, Atacama, Coquimbo, Santiago, Trapaca, and Valparaiso. As illustrated in Figure 2, the deployment of solar PV plants is notably concentrated in two principal regions, namely, Anofagosta and Atacama, whose installations jointly constitute 74% of the total installations. Subsequently, the Trapaca region contributed 7% of the overall installations. It should be noted that the power plants which are represented in Figure 2 have a minimum capacity of 3 MW.

Figure 2.

Solar PV installations in Chile by region (MW) [5,6].

Solar PV power plants consist of several integral components, including PV modules, support structures, inverters, transformers, and cables [7]. The types of photovoltaic modules vary, encompassing diverse technologies such as crystalline silicon (c-Si) and thin-film PV modules. Within crystalline PV modules, two predominant types exist: mono c-Si and poly c-Si PV. Additionally, thin-film PV modules exhibit variation in certain factors, including amorphous silicon (a-Si), Cadmium Telluride (CdTe), and Copper Indium Gallium Selenide (CIGS). Mono c-si PV modules are produced by sizing silicon ingots into wafers [8]. On a global scale, crystalline silicon PV modules command a significant market share, constituting 95% as of 2021 [9]. However, the utilization of PV module types fluctuates depending on factors such as regional PV module production, transportation considerations, and accumulated experience. Polycrystalline silicon PV modules are produced using silicon with different crystal structures, whereas thin-film modules are fabricated by depositing semiconductor materials onto backing substrates [8,10]. Among these technologies, mono c-Si modules exhibit the highest cell efficiency, followed by poly c-Si and thin-film modules [8,10]. In terms of cost, poly c-Si modules are the most economical, followed by mono c-Si and thin-film technologies [8,10]. Despite their lower efficiency, thin-film modules are widely utilized due to their flexibility, which allows their integration into a variety of structural applications [10]. Table 1 illustrates the cumulative installation of solar PV plants with a capacity greater than 3 MW categorized by module type in Chile.

Table 1.

Cumulative PV installations considered in this study by module type in Chile.

Despite the numerous advantages of renewable energy systems, there remains a notable gap in the assessment of and management projections for their waste, particularly PV system wastes. However, several studies in the literature have endeavored to estimate waste values for PV power plants. Chowdhury et al. [11] project a global accumulation of approximately 78 million tons of PV waste by 2050. Similarly, Kastanaki and Giannis [12] forecast that between 14.3 and 18.5 million tons of PV waste will have accumulated in 27 EU countries by 2050. Furthermore, several studies examined the waste amounts of PV systems on a country-specific basis. For instance, Paiano [13] assessed PV waste in Italy, estimating that more than 6 million tons of glass and 617 thousand tons of aluminum could be recovered by 2050. Likewise, Kim and Park [14] suggested that over 1 million tons of metals from PV systems could be recycled in Korea by 2080. Additionally, there are studies focusing on various regions worldwide, including Australia, Mexico, Spain, the USA, and China [7,15,16,17,18,19]. Table 2 provides a summary of the studies in the literature along with their respective methodologies and key findings.

Table 2.

Studies in the literature with their corresponding methods and findings.

The literature documents numerous efforts to recycle waste materials across diverse sectors, including construction, electronics, and renewable energy technologies, such as wind turbines, largely motivated by environmental and economic benefits [20,21,22,23]. Similarly, the recycling of PV module waste can generate environmental and economic benefits for societies on multiple fronts. Firstly, recycling PV modules can substantially reduce both CO2 emissions and mineral extraction requirements [24,25]. Faircloth et al. [26] demonstrated that, compared to landfilling, recycling one ton of PV modules can prevent up to 23 tons of CO2 emissions. Moreover, Mazzi et al. [27] reported that recycling processes can recover approximately 90% of the raw materials used in crystalline silicon PV modules, corresponding to nearly 95% of their economic value. Furthermore, PV waste recycling contributes to a reduction in other environmental impacts in various ways. PV modules contain toxic elements such as cadmium, tellurium, and amorphous silicon, which pose health risks to both humans and animals [28]. Therefore, preventing the disposal of these materials into the environment is of vital importance. Furthermore, the disposal of PV module waste can lead to substantial land occupation in landfills due to their significant volume. Chowdhury et al. [11] estimate that over 78 million PV modules will reach their end-of-life by 2050, indicating a substantial land use impact. Additionally, the utilization of rare elements like indium, gallium, and ruthenium in PV modules raises concerns about potential depletion in the near future [29]. Given the projected growth of PV module waste, recycling emerges as a critical necessity, offering substantial environmental benefits for the future. Secondly, recycling PV modules holds monetary value, as they include precious metals, glass, and aluminum. Markert et al. [30] estimated the economic worth of recycled materials from crystalline silicon PV modules to be USD 13.6/m2, while Weckend et al. [31] projected that the economic value of PV waste will reach USD 15 billion by 2050. Thirdly, recent studies suggest that PV recycling creates new job opportunities within society [32]. Lastly, PV recycling can yield indirect economic impacts by reducing the costs incurred by governments and municipalities for establishing new waste management areas [33]. Considering these factors, the recycling of PV modules emerges as a matter of significant importance.

Several studies in the literature have focused on electronic waste (e-waste) estimation, management, and recycling in Chile. Forti et al. [34] estimated that Chile generates 8.9 kg of e-waste per capita, making it the second-largest producer of e-waste in Latin America after Brazil. In Chile, e-waste management involves the separation of printed circuit boards (PCBs) from other materials, with the former processed domestically and the latter sent overseas for processing [35]. Additionally, it is noted in the literature that Chile has the potential to recover valuable materials from e-waste due to its extensive experience in pyro metallurgical processes, stemming from its developed mining sector [36,37]. However, despite advancements in the e-waste management sector, there remains a lack of development in the PV module recycling sector in the country. In this regard, this paper presents the first PV waste assessment for Chile. The novelty of this study lies in its pioneering application of PV waste projection for Chile with a forecasting methodology, namely, Weibull distribution modeling. Moreover, this study undertakes economic analyses concerning the recoverable waste of photovoltaic (PV) modules, an area that has received limited attention in the existing literature.

2. Materials and Methods

In this study, a thorough analysis of PV waste assessment for Chile is undertaken, using a database developed by the author through the compilation of open public data considering power plants with a capacity of at least 3 MW [5,6]. The Chilean PV waste database was meticulously curated based on information extracted from journal articles, PV power plant operator websites, PV module manufacturer websites, and relevant factsheets. It is important to note that this study relies on existing data regarding PV installations and the corresponding estimates of PV waste. As future installation trends remain uncertain and represent a potential avenue for further research, the present analysis focuses exclusively on the current potential of PV waste, consistent with approaches adopted in the literature [16]. Furthermore, future installations are expected to have an insignificant effect on PV waste accumulation within the time horizon considered, as only limited contributions are projected before 2052, in line with previous findings [18].

The methodology employed in this study entails several key steps. Firstly, a PV waste assessment is conducted utilizing historical PV installation data alongside Weibull distribution modeling. Secondly, anticipated waste materials until 2052 are estimated based on the classification of PV module types. Lastly, the economic value of potentially recoverable materials is assessed. Traditionally, some studies in the literature have employed fixed lifetimes of 25 or 30 years for the assessment of waste from PV modules [11,13]. However, considering the possibility of failures, accidents, or external factors affecting PV modules before the end of their designated lifespans, this study adopts a more realistic approach. Here, waste assessment projection is performed using the Weibull distribution function, commonly utilized for predicting the remaining useful life or lifetime of a system [14,16].

In this study, the lifetime of a PV module is not assumed to be fixed. Instead, the failure time of PV modules, denoting the point at which a PV module becomes waste, is modeled using the Weibull distribution, as given in Equation (1).

where t represents the current life of the PV module in years, τ denotes the scale parameter which signifies the average lifetime of a PV module, and β is the shape factor. The Weibull distribution incorporates the shape factor (β), responsible for shaping the Weibull curve in two distinct scenarios in this research: early-loss and regular-loss scenarios. The average lifetime of a PV module (τ) is taken as 30 years in this study [16]. The early-loss scenario encompasses stages of infant, mid-life, and wear-out failures occurring prior to the anticipated lifetime of a PV module, typically regarded as 30 years in the existing literature [16]. Conversely, the regular-loss scenario posited in this study assumes a lifespan devoid of initial and early failures, drawing upon the findings of a statistical lifetime prediction study outlined in the literature [38]. In delineating the early-loss scenario, various analyses from scholarly sources are amalgamated with expert insights. Within this framework, certain assumptions are made, including that 0.5% of PV panels sustain damage prior to arrival at construction sites, while 0.5% of panels become obsolete within two years, 2% become obsolete after ten years, and 4% become obsolete after 15 years, to establish the shape factor for the Weibull distribution [31]. This shape factor is derived through a regression analysis conducted between data points extracted from the literature and early failure indicators generated by the aforementioned assumptions. Consequently, the shape factor for the early-loss scenario is determined as 2.4928 [31]. For the regular-loss scenario, a time-to-failure analysis is employed, entailing a correlation assessment between field data and accelerated test data. The outcome of this analysis yields a beta value of 5.3759 for the regular-loss scenario [38]. It is important to acknowledge that the predetermined shape factors were estimated within specific studies, taking into account certain PV models. Consequently, this study is constrained by the assumption of shape factors derived from prior research. Nevertheless, the shape factors applied to regular-loss and early-loss scenarios are considered suitable for Chilean conditions, as previous studies focusing on countries such as Australia and Spain with comparable climatic and environmental characteristics employed the same parameters [16,17]. Moreover, these shape factors are among the most commonly utilized in the literature for PV waste projections.

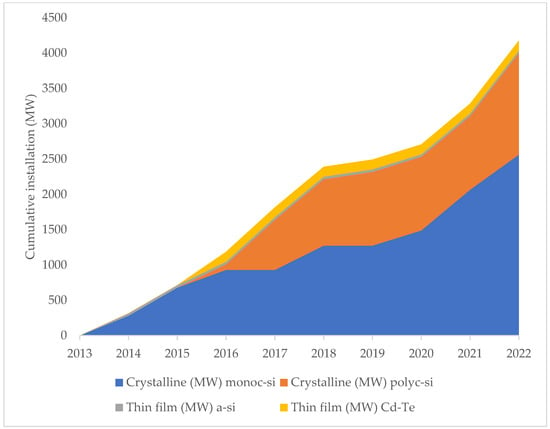

Furthermore, the type of PV module plays a crucial role in accurately estimating the amounts of extracted materials. Hence, it is essential to estimate expected waste flow according to the module types over the years. Figure 3 depicts the historical installations of solar PV plants in Chile categorized by PV module type. In this study, for each year, the ratio of PV waste is determined utilizing the Weibull distribution. Subsequently, the weight of the waste is calculated by multiplying the weight of each module type. Consequently, the waste flow is estimated for each year according to the module type.

Figure 3.

Cumulative PV power plant installation in Chile by PV module type.

Additionally, this paper calculates the flow of waste materials from each type of PV module based on the material compositions reported in the literature [13,39,40]. The calculation involves multiplying the total waste amount per year by the proportion of each material in the specific PV module type. Table 3 presents the average material composition of four PV module types commonly used in Chile.

Table 3.

Average material composition of PV module types.

Finally, the total amount of estimated recovered material from PV waste is determined by utilizing recovery rates. Recovery rates for various materials vary across different studies. For example, Duflou et al. [41] reported a glass recovery rate of 98% through thermal and chemical treatment, while Strachala et al. [39] found a glass recovery rate of 95% for c-Si PV modules using chemical, mechanical, and thermal methods. The existing literature presents considerable variability in reported glass recovery rates, reflecting differences in methodologies and study contexts. In this study, the average values reported in the reviewed literature are employed in order to ensure a conservative and reliable approach [42]. Similar variations exist for other materials, such as aluminum, silicon, copper, lead, silver, zinc, cadmium, indium, tellurium, and germanium. Additionally, some studies suggest a recovery rate of 100% for materials such as aluminum, silicon, and copper [11,15]. However, achieving a 100% recovery rate for materials used in PV modules is challenging, and from a scientific standpoint, some argue that it may not be accurate. Therefore, this study adopts average recovery rates for materials from the literature [11,43,44,45]. Table 4 outlines the recovery rates for each material utilized in this study.

Table 4.

Material recovery rates [11,43,44,45].

While PV module recycling has been explored in the literature, much of the research remains theoretical or limited to laboratory-scale studies. However, there have been significant developments in the industry regarding PV recycling. For instance, in 2018, the first recycling plant for solar PV modules commenced operations in France with a capacity of 4.000 tons per year [46]. Subsequently, in the USA, one of the largest PV recycling plants globally was inaugurated a year later, boasting a capacity of 35.000 tons per year [47]. Remarkably, this plant is equipped to recycle any type or make of PV panels [47]. However, it is worth noting that, to the author’s knowledge, there is no dedicated PV module recycling plant in Chile. Nevertheless, it is noteworthy that the recycling sector in Chile primarily addresses municipal solid waste. Annually, the nation generates a total of 17 million tons of waste, with approximately 10% being subjected to recycling initiatives [48]. Predominantly, the materials recycled encompass paper/cardboard, glass, plastic bottles, and aluminum cans. Conversely, items such as electronics, batteries, plastics, and metals pose accessibility challenges for Chileans, thereby hindering their effective integration into recycling practices.

3. Results and Discussion

This study has produced results across three primary categories. Firstly, the amount of PV module waste per year has been estimated based on early- and regular-loss scenarios. Secondly, the total quantity of waste materials originating from PV modules has been projected by aggregating the expected PV module waste over time. Lastly, an assessment has been conducted to determine the anticipated recoverable materials and their corresponding economic value.

3.1. PV Module Waste Flow

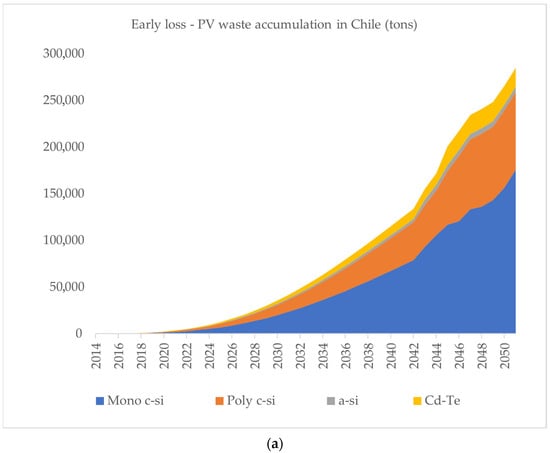

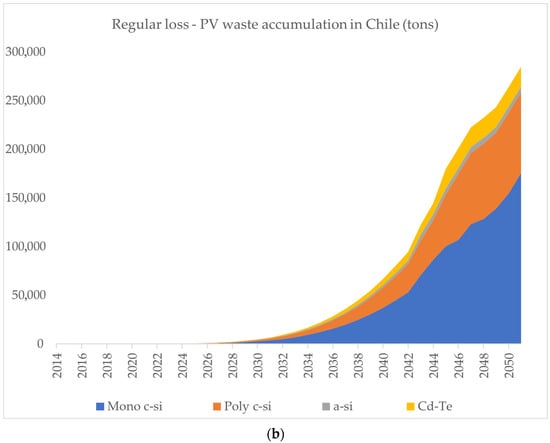

The results indicate that the total expected solar PV module waste amounts to 284,906 tons, with 175,595 tons attributed to mono c-Si PV modules in Chile. The flow of photovoltaic module waste was derived using Weibull distribution modeling based on two scenarios: early-loss and regular-loss scenarios. In the early-loss scenario (Figure 4a), waste amounts are projected to reach 35,000 tons by 2030 and 100,000 tons by 2035. By 2040, approximately 40% of the installations, equivalent to 115,159 tons of PV module waste, are anticipated to reach the end of their lifespan. Notably, more than 55% of the waste is expected to be composed of mono c-Si PV module types by 2030 in this scenario. Conversely, in the regular-loss scenario (Figure 4b), waste amounts are estimated to reach 35,000 tons by 2037 and 100,000 tons by 2043. By 2040, nearly 24% of the installations, corresponding to 66,896 tons of PV module waste, are projected to phase out. Similar to the early-loss scenario, more than 55% of the PV module waste is projected to come from mono c-Si PV modules by 2040 in this scenario as well.

Figure 4.

Amount of waste production by year based on early-loss (a) and regular-loss (b) projections.

3.2. Expected Waste Material Amounts

Table 5 provides a detailed breakdown of the anticipated amounts of waste materials from various PV module types in Chile until 2052. The highest expected mass of waste material comes from glass, totaling 129,940 tons, while the lowest expected mass comes from lead, amounting to 105 tons for mono c-Si PV modules. Aluminum frames, essential components of mono c-Si PV modules, are projected to constitute 18,086 tons of waste, followed by polymers with 11,501 tons. The material with the least amount of waste from mono c-Si PV modules is lead, corresponding to 105 tons. For poly-Si PV modules, glass waste is estimated to reach 56,058 tons, followed by aluminum waste at 14,974 tons. Silver and tin are expected to produce the least amount of waste materials, totaling 44 tons from poly c-Si PV modules. In the case of a-Si PV modules, glass is projected to account for the highest amount of waste material at 5031 tons, followed by copper with 53 tons. Silicon will contribute the least amount of waste, totaling 374 kg, while plastics and adhesives, aluminum, and tin are also expected to generate relatively low amounts of waste, ranging from 1 to 3 tons. CdTe PV modules are estimated to generate 19,392 tons of glass waste, along with 14 tons of cadmium and 14 tons of tellurium. Other materials such as polymers and copper are anticipated to contribute higher amounts of waste, totaling 714 tons and 204 tons, respectively, compared to aluminum waste, which is projected to be 71 tons. The least amount of waste material from CdTe PV modules is zinc at 2 tons.

Table 5.

Amount of waste generated from PV modules by type until 2052.

3.3. Expected Recoverable Material Amounts and Their Economic Value and CO2 Reduction

Table 6 presents the estimated recoverable materials and their economic values from total cumulative PV module waste in Chile until 2052. The recoverable amount of waste materials is determined by multiplying the total waste volume by the recovery rate specific to each material. The economic value of recovered materials from PV modules is estimated by multiplying the commodity price of each material by its respective recoverable amount. Commodity prices are based on North American values as of September 2025. While commodity prices are subject to temporal fluctuations and are difficult to forecast due to volatile global market conditions, this study employed current commodity prices in conjunction with present monetary values to ensure consistency. The total recoverable amount from PV modules in Chile is estimated to be 235,786 tons, nearly 195,000 tons of this being glass. The second-largest recoverable amount comes from aluminum, totaling 31,278 tons, while the least amount of recoverable material comes from zinc, with only 2 tons. In terms of the economic value from recoverable waste, the total amount is almost USD 781 million from solar PV module waste until 2052 with the 2025 prices. Silver is projected to bring the most economic value, with nearly USD 379 million, followed by glass with more than USD 204 million. Aluminum waste is estimated to have a value of USD 84 million, while germanium waste has an economic value of USD 51 million. Based on current market valuations, copper, tin, tellurium, and indium are projected to exceed USD 1 million in value each. Conversely, lead, tin, cadmium, and zinc are each valued at less than USD 1 million. On the other hand, the residues of PV recycling are mostly disposed of in landfills [49]. Therefore, the weight of residues (49,120 tons), which is calculated by subtracting recoverable PV waste from total expected PV waste, is multiplied by the disposing fee (18 USD/ton) to estimate the cost of handling residues in Chile [50]. The total cost for residue management is estimated to be USD 884,160.

Table 6.

Expected recoverable materials and their economic values until 2052.

Furthermore, based on the carbon emission reduction values reported by Faircloth et al. [26], recycling PV module waste in Chile could prevent approximately 6.6 million tons of CO2 emissions by 2052. This finding is particularly significant in the context of the global net-zero emissions target set for 2050. It is important to note that, for Chile, the reduction in carbon emissions through PV recycling is valued at approximately USD 204.9 million, based on the OECD’s 2023 carbon pricing rate [51].

3.4. Discussion

Table 7 provides a comparative analysis of the findings from this study with the findings from previous studies in the literature regarding PV waste estimation for various regions worldwide. Several studies in the literature have examined PV estimation with varying time horizons, ranging from 2030 to 2080. Methodologically, differences exist among studies, with some employing fixed failure times for PV modules, while others categorize the end-of-life of PV modules as early and regular, considering different lifetimes for projecting PV waste [13,14]. Most of the studies reviewed in the literature adopted Weibull failure modeling for PV module waste projections [7,15,16,17]. The Weibull distribution is commonly utilized to project PV module waste in two scenarios: early loss and regular loss.

Table 7.

Yearly cumulative PV waste accumulation and its economic value by country.

The primary disparity between the results of this study and those of other studies lies in the projected solar PV module waste accumulation by the 2050s in Chile. One contributing factor to this difference is the relatively late onset of solar PV in Chile compared to other countries. For instance, solar PV installations commenced in 1987 in Italy, in 2000 in the USA, in 2001 in Australia, and in 2005 in Mexico, whereas installations in Chile began in 2014 [7,11,15,16]. Additionally, the populations of these countries significantly exceed that of Chile, resulting in lower energy demands and consequently less extensive deployment of solar PV systems (populations: Italy: 60 M; USA: 338 M; Australia: 26 M; Mexico: 128 M; Chile: 19 M) [52]. Nevertheless, Chile’s exceptional irradiance makes it an attractive location for solar PV installation, with projections indicating a quadrupling of installations in just five years [53].

Another notable distinction between this study and others in the literature is the composition of expected recoverable waste materials. For instance, in this study, it was found that 83% of the recoverable material consists of glass, whereas this proportion differs in other countries: 96% for Italy’s solar PV waste accumulation and 68% for Australia’s. These variations can be attributed to differences in solar PV module types used across countries. In Chile, mono c-Si, poly c-Si, a-Si, and CdTe PV modules were utilized, whereas in Italy, poly c-Si, a-Si, CdTe, and CIGS module technologies were employed. CdTe and CIGS modules contain a higher percentage of glass in their composition: 95% and 84%, respectively. Consequently, the usage of CdTe and CIGS modules has a greater impact on glass yields in Italy compared to Chile.

Subsequently, this investigation compared the economic valuation of retrievable materials from anticipated photovoltaic (PV) module waste across various global regions with the findings elucidated herein. Mahmoudi et al. [16] ascertained the economic worth of PV waste in Australia to be USD 1.2 billion per 797,965 tons of PV waste material, equivalent to USD 1.5 million per ton of PV waste. Conversely, Domínguez and Geyer [7] reported the economic value of PV waste in the USA as USD 22 billion per 6,610,391 tons of PV waste material, corresponding to USD 3.3 million per ton of PV waste [7]. Moreover, Kastanaki and Giannis [12] estimated the economic worth of PV waste in European Union (EU) countries to be a minimum of USD 22 billion per 14,300,000 tons of PV waste, equating to USD 1.5 million per ton of PV waste. The current investigation forecasts an accumulation of 284,906 tons of PV waste in Chile, valued at USD 781 million, which corresponds to USD 3,3 million per ton of PV waste. Notably, the economic value per ton of PV waste aligns closely with the aforementioned studies documented in the extant literature. Furthermore, the economic value based on the power installed is estimated at USD 191,147 per MW installation with 2025 prices.

Policies for PV end-of-life management vary based on countries’ internal dynamics. In the USA, there is state-based regulation. For instance, PV waste is considered hazardous waste and treated as such in California, while in Washington state, according to the Stewardship and Takeback program, end-of-life responsibility for PV systems is given to the manufacturers of solar panels [54]. On the other hand, PV waste management in the EU is unified under the Waste Electrical and Electronic Equipment Directive [55]. In Australia, PV waste has been added to the list of waste materials which the federal government’s Product Stewardship Act holds PV module producers responsible for processing [56]. In Chile, the Extended Producer Responsibility legislation was enacted in 2016 and came into effect in 2023. Under this framework, producers are responsible for the end-of-life management of their products. However, specific regulatory provisions for PV modules have not yet been established [57]. It would be preferable for future revisions of the directive to explicitly address PV waste, potentially accompanied by incentives to encourage early recycling efforts. Based on the findings of this study, the Chilean government should develop a roadmap for PV module waste management strategies by 2030, given that the volume of PV waste is expected to increase substantially thereafter.

Moreover, there is still room for improvement in PV module recycling and waste management. In the literature, mechanical and chemical recovery methods have been utilized extensively for PV recycling, while thermal treatment has been overlooked [57]. In addition, bulk recycling, which combines different types of PV modules for recycling, is the most common approach in the industry. However, it decreases the quality of recovered metals [58]. Therefore, this technique must be avoided in the future. Furthermore, future research is expected to place greater emphasis on eco-design approaches in PV module production [59].

4. Conclusions

This paper presents an analysis of the current and projected waste accumulation of solar PV modules in Chile. The study utilizes the Weibull distribution to model waste flow, considering early- and regular-loss scenarios for the country. The significance of this study lies in its status as the first comprehensive analysis of solar PV module waste in Chile, a country with promising potential for solar PV installations. The following conclusions can be drawn from this study.

- By the year 2052, the total expected solar PV module waste is estimated to reach 284,906 tons, with a substantial portion of 175,595 tons attributed to mono c-Si PV modules in Chile.

- Glass constitutes the largest share of material in PV waste, amounting to 210,421 tons, whereas silver represents the most economically valuable component, with an estimated recoverable value of approximately USD 379 million.

- The study estimates the recoverable amount of materials from each type of PV module, revealing that more than 235,000 tons of materials is deemed recoverable. This corresponds to nearly USD 781 million in terms of economic value.

- The economic valuation of PV waste in Chile corresponds harmoniously with findings in the extant literature.

- The economic advantage extends beyond mere monetary dividends, encompassing significant implications across multiple dimensions. Specifically, it contributes to diminishing reliance on raw materials, particularly those of a rare nature, while concurrently fostering employment opportunities within the recycling sectors.

- Given the anticipated rapid growth of PV waste generation in Chile in the near future, the development of targeted policies for PV waste management is essential.

Although, the amount of recoverable material and the economic value of solar PV module waste may appear low compared to other countries within the same time horizon, the recycling of PV modules remains a valuable endeavor due to Chile’s potential and its increasing exposure to solar PV installations in the future.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The author declares no conflicts of interest.

References

- IEA. Snapshot of Global PV Markets 2022. Available online: https://iea-pvps.org/wp-content/uploads/2022/04/IEA_PVPS_Snapshot_2022-vF.pdf (accessed on 28 August 2025).

- IEA. Snapshot of Global PV 1992–2013. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/PVPS_report_-_A_Snapshot_of_Global_PV_-_1992-2013_-_final_3.pdf (accessed on 15 September 2025).

- Energy Monitor. The World’s Top Ten Solar Power Superpowers. Available online: https://www.energymonitor.ai/tech/renewables/the-worlds-top-ten-solar-power-superpowers (accessed on 28 August 2025).

- IRENA. Renewable Capacity Statistics 2023. Available online: https://www.irena.org/Publications/2023/Mar/Renewable-capacity-statistics-2023 (accessed on 15 September 2025).

- ListSolar. Largest Solar Power Stations in Chile. Available online: https://list.solar/plants/largest-plants/chile/ (accessed on 15 September 2025).

- Open Infrastructure Map. All 942 Power Plants in Chile. Available online: https://openinframap.org/stats/area/Chile/plants (accessed on 15 September 2025).

- Domínguez, A.; Geyer, R. Photovoltaic Waste Assessment of Major Photovoltaic Installations in the United States of America. Renew. Energy 2019, 133, 1188–1200. [Google Scholar] [CrossRef]

- Kumar, N.M.; Chopra, S.S.; Oliveira, A.K.V.; Ahmed, H.; Vaezi, S.; Madukanya, U.E.; Castañón, J.M. Chapter 3—Solar PV module technologies. In Photovoltaic Solar Energy Conversion; Gorjian, S., Shukla, A., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 51–78. [Google Scholar] [CrossRef]

- IEA. Solar PV. Available online: https://www.iea.org/reports/solar-pv (accessed on 28 August 2025).

- Slaoui, A.; Collins, R.T. Photovoltaics: Advanced Inorganic Materials. In Encyclopedia of Materials: Technical Ceramics and Glasses; Pomeroy, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 5–16. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Kastanaki, E.; Giannis, A. Energy decarbonisation in the European Union: Assessment of photovoltaic waste recycling potential. Renew. Energy 2022, 192, 1–13. [Google Scholar] [CrossRef]

- Paiano, A. Photovoltaic waste assessment in Italy. Renew. Sustain. Energy Rev. 2015, 41, 99–112. [Google Scholar] [CrossRef]

- Kim, H.; Park, H. PV waste management at the crossroads of circular economy and energy transition: The case of South Korea. Sustainability 2018, 10, 3565. [Google Scholar] [CrossRef]

- Domínguez, A.; Geyer, R. Photovoltaic waste assessment in Mexico. Resour. Conserv. Recycl. 2017, 127, 29–41. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Behnia, M. Photovoltaic waste assessment: Forecasting and screening of emerging waste in Australia. Resour. Conserv. Recycl. 2019, 146, 192–205. [Google Scholar] [CrossRef]

- Santos, J.D.; Alonso-García, M.C. Projection of the photovoltaic waste in Spain until 2050. J. Clean. Prod. 2018, 196, 1613–1628. [Google Scholar] [CrossRef]

- Zhang, L.; Chang, S.; Wang, Q.; Zhou, D. Projection of Waste Photovoltaic Modules in China Considering Multiple Scenarios. Sustain. Prod. Consum. 2022, 33, 412–424. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. Environmental emissions influencing solar photovoltaic waste management in Australia: An optimised system network of waste collection facilities. J. Environ. Manag. 2022, 314, 115007. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Y.; Fang, K.; Zhang, Y.; Wang, C. Developing fully recycled alkali-activated mortar made with waste concrete fines as a substitute for both binder and sand: Multi-properties evaluation. Constr. Build. Mater. 2025, 477, 141323. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Y.; Dai, Y.; Wu, H.; Ma, Z. In-situ 4D CT analysis of microcrack evolution in carbonated fiber-reinforced recycled aggregate concrete. Cem. Concr. Compos. 2025, 163, 106161. [Google Scholar] [CrossRef]

- Erkmen, A.N.; Ulber, R.; Jüstel, T.; Altendorfner, M. Towards sustainable recycling of critical metals from e-waste: Bioleaching and phytomining. Resour. Conserv. Recycl. 2025, 215, 108057. [Google Scholar] [CrossRef]

- Jasińska, D.; Dutkiewicz, M. Waste management of wind turbine blades—A review of recycling methods and applications in cementitious composites. Sustainability 2025, 17, 805. [Google Scholar] [CrossRef]

- Mao, D.; Yang, S.; Ma, L.; Ma, W.; Yu, Z.; Xi, F.; Yu, J. Overview of life cycle assessment of recycling end-of-life photovoltaic panels: A case study of crystalline silicon photovoltaic panels. J. Clean. Prod. 2024, 434, 140320. [Google Scholar] [CrossRef]

- Ma, L.; Mao, D.; Yu, Z.; Yu, J.; Ma, W.; Xu, P.; Wang, Y. Energy efficiency analysis and life cycle assessment of a recovery process from end-of-life photovoltaic panels. Sol. Energy Mater. Sol. Cells 2026, 294, 113931. [Google Scholar] [CrossRef]

- Faircloth, C.C.; Wagner, K.H.; Woodward, K.E.; Rakkwamsuk, P.; Gheewala, S.H. The environmental and economic impacts of photovoltaic waste management in Thailand. Resour. Conserv. Recycl. 2019, 143, 260–272. [Google Scholar] [CrossRef]

- Mazzi, A.; Barbiero, C.; Miserocchi, F.; Nisato, F.; Tassinato, G.; Cerchier, P. Life cycle assessment of Al-Cu-Ag-Si recycling process from photovoltaic waste. Resour. Conserv. Recycl. 2024, 211, 107885. [Google Scholar] [CrossRef]

- Nkuissi, H.J.T.; Konan, F.K.; Hartiti, B.; Ndjaka, J.M. Toxic materials used in thin film photovoltaics and their impacts on environment. In Reliability and Ecological Aspects of Photovoltaic Modules; IntechOpen: London, UK, 2020. [Google Scholar]

- Grandell, L.; Höök, M. Assessing rare metal availability challenges for solar energy technologies. Sustainability 2015, 7, 11818–11837. [Google Scholar] [CrossRef]

- Markert, E.; Celik, I.; Apul, D. Private and externality costs and benefits of recycling crystalline silicon (c-Si) photovoltaic panels. Energies 2020, 13, 3650. [Google Scholar] [CrossRef]

- Weckend, S.; Wade, A.; Heath, G.A. End of Life Management: Solar Photovoltaic Panels; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2016; NREL/TP-6A20-73852.

- Curtis, T.L.; Buchanan, H.; Heath, G.; Smith, L.; Shaw, S. Solar Photovoltaic Module Recycling: A Survey of US Policies and Initiatives; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2021; NREL/TP-6A20-74124.

- Majewski, P.; Al-shammari, W.; Dudley, M.; Jit, J.; Lee, S.H.; Myoung-Kug, K.; Sung-Jim, K. Recycling of solar PV panels—Product stewardship and regulatory approaches. Energy Policy 2021, 149, 112062. [Google Scholar] [CrossRef]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University: Bonn, Germany, 2020. [Google Scholar]

- Cayumil, R.; Khanna, R.; Ikram-Ul-Haq, M.; Rajarao, R.; Hill, A.; Sahajwalla, V. Generation of copper-rich metallic phases from waste printed circuit boards. Waste Manag. 2014, 34, 1783–1792. [Google Scholar] [CrossRef] [PubMed]

- Ulloa, G.; Cayumil, R.; Sánchez, M. Urban Mining in Chile: State of the Art. In Proceedings of the Fourth Symposium of Urban Mining and Circular Economy, Bergamo, Italy, 21–22 May 2018. [Google Scholar]

- Cayumil, R.; Khanna, R.; Konyukhov, Y.; Burmistrov, I.; Kargin, J.B.; Mukherjee, P.S. An overview on solid waste generation and management: Current status in Chile. Sustainability 2021, 13, 11644. [Google Scholar] [CrossRef]

- Kuitche, J.M. Statistical Lifetime Predictions for PV Modules. Presentation. Available online: https://www1.eere.energy.gov/solar/pdfs/pvrw2010_kuitche.pdf (accessed on 26 October 2023).

- Strachala, D.; Hylský, J.; Vaněk, J.; Fafilek, G.; Jandová, K. Methods for recycling photovoltaic modules and their impact on environment and raw material extraction. Acta Mont. Slovaca 2017, 22, 257–266. [Google Scholar]

- Corcelli, F.; Ripa, M.; Leccisi, E.; Cigolotti, V.; Fiandra, V.; Tammaro, M.; Sannino, L.; Graditi, G.; Ulgiati, S. Material recovery and energy savings from c-Si PV panels end-of-life. Life Cycle Assessment of PV panels thermal treatment. In Proceedings of the Global Cleaner Production & Sustainable Consumption Conference, Barcelona, Spain, 1–4 November 2015. [Google Scholar]

- Duflou, J.R.; Peeters, J.R.; Altamirano, D.; Bracquene, E.; Dewulf, W. Demanufacturing photovoltaic panels: Comparison of end-of-life treatment strategies for improved resource recovery. CIRP Ann. 2018, 67, 29–32. [Google Scholar] [CrossRef]

- Divya, A.; Adish, T.; Kaustubh, P.; Zade, P.S. Review on recycling of solar modules/panels. Sol. Energy Mater. Sol. Cells 2023, 253, 112151. [Google Scholar] [CrossRef]

- Mulazzani, A.; Eleftheriadis, P.; Leva, S. Recycling c-Si PV modules: A review, a proposed energy model and a manufacturing comparison. Energies 2022, 15, 8419. [Google Scholar] [CrossRef]

- Xanthopoulos, P.; Bevandić, S.; Spooren, J.; Binnemans, K.; Kukurugya, F. Recovery of copper, zinc and lead from photovoltaic panel residue. RSC Adv. 2022, 12, 2351–2360. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, W.; Wang, S.; Liu, D.; Deng, P.; Deng, J.; Jiang, W. Research status of recovery of tellurium from cadmium telluride photovoltaic modules. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 022024. [Google Scholar] [CrossRef]

- World Economic Forum. France Has Opened Europe’s First Solar Panel Recycling Plant. Available online: https://www.weforum.org/agenda/2018/06/france-has-opened-europes-first-solar-panel-recycling-plant (accessed on 28 August 2025).

- Solar Power World. We Recycle Solar: Largest PV Recycling Plant in the Nation. Available online: https://www.solarpowerworldonline.com/2023/05/we-recycle-solar-largest-pv-recycling-plant-nation/ (accessed on 28 August 2025).

- International Trade Administration. Chile Waste Management and Recycling. Available online: https://www.trade.gov/market-intelligence/chile-waste-management-and-recycling (accessed on 28 August 2025).

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H. Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules. Waste Manag. 2017, 60, 716–722. [Google Scholar] [CrossRef]

- Calixto, S. Pre-Feasibility Study of a Waste-to-Energy Plant in Santiago, Chile. Master’s Thesis, Columbia University, New York, NY, USA, 2017. [Google Scholar]

- OECD. Pricing Greenhouse Gas Emissions. Available online: https://www.oecd.org/content/dam/oecd/en/topics/policy-sub-issues/carbon-pricing-and-energy-taxes/carbon-pricing-chile.pdf (accessed on 25 September 2025).

- Worldometer. Countries in the World by Population. Available online: https://www.worldometers.info/world-population/population-by-country/ (accessed on 14 August 2023).

- Global Data. Chile Solar Photovoltaic (PV) Analysis: Market Outlook to 2035 Report. 2023. Available online: https://www.globaldata.com/store/report/chile-solar-pv-market-analysis/ (accessed on 28 August 2025).

- EPA. End-of-Life Solar Panels: Regulations and Management. Available online: https://www.epa.gov/hw/end-life-solar-panels-regulations-and-management (accessed on 15 September 2025).

- Nieto Morone, M.B.; García Rosillo, F.; Muñoz-García, M.Á.; Alonso-García, M.D.C. Photovoltaic waste generation in the context of sustainable energy transition in EU member States. Resources 2025, 14, 37. [Google Scholar] [CrossRef]

- Sustainable Victoria. National Approach to Manage Solar Panel, Inverter and Battery Life Cycles. Available online: https://www.sustainability.vic.gov.au/circular-economy/product-stewardship/national-approach-to-manage-solar-panel-inverter-and-battery-lifecycles (accessed on 15 September 2025).

- IEA. Law 20920. Establishment of a Framework for Waste Management, Extended Producer Responsibility and Recycling. Available online: https://www.iea.org/policies/16005-law-20920-establishment-of-a-framework-for-waste-management-extended-producer-responsibility-and-recycling (accessed on 15 September 2025).

- Maghraby, Y.R.; Ibrahim, A.H.; Tayel, A.; Azzazy, H.M.E.S.; Shoeib, T. Towards sustainability via recycling solar photovoltaic Panels, A review. Sol. Energy 2025, 285, 113085. [Google Scholar] [CrossRef]

- Luu, L.Q.; Cellura, M.; Guarino, F.; Longo, S. Eco-design of emerging BIPV modules based on LCA and LCC. Energy 2025, 333, 137500. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).