Areal Assessment in the Design of a Try-Out Grid-Tied Solar PV-Green Hydrogen-Battery Storage Microgrid System for Industrial Application in South Africa

Abstract

1. Introduction

2. Overview of Green Hydrogen Initiatives in Africa

3. Green Hydrogen Microgrids Using Solar Photovoltaic Systems

4. Site Evaluation for the Green Hydrogen Microgrid

4.1. Site Energy Consumption Assessment

4.1.1. Electricity Price

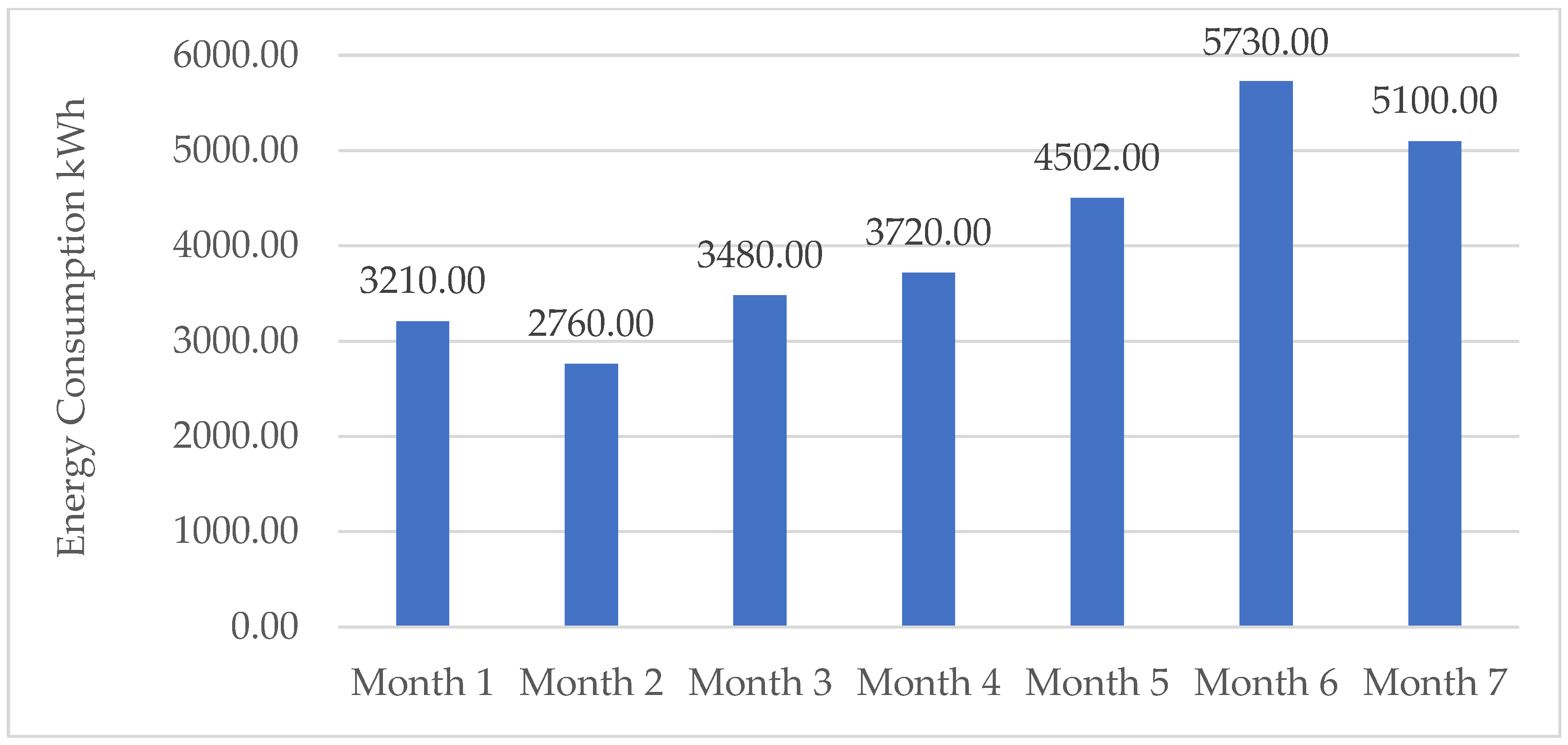

4.1.2. Monthly Energy Consumption

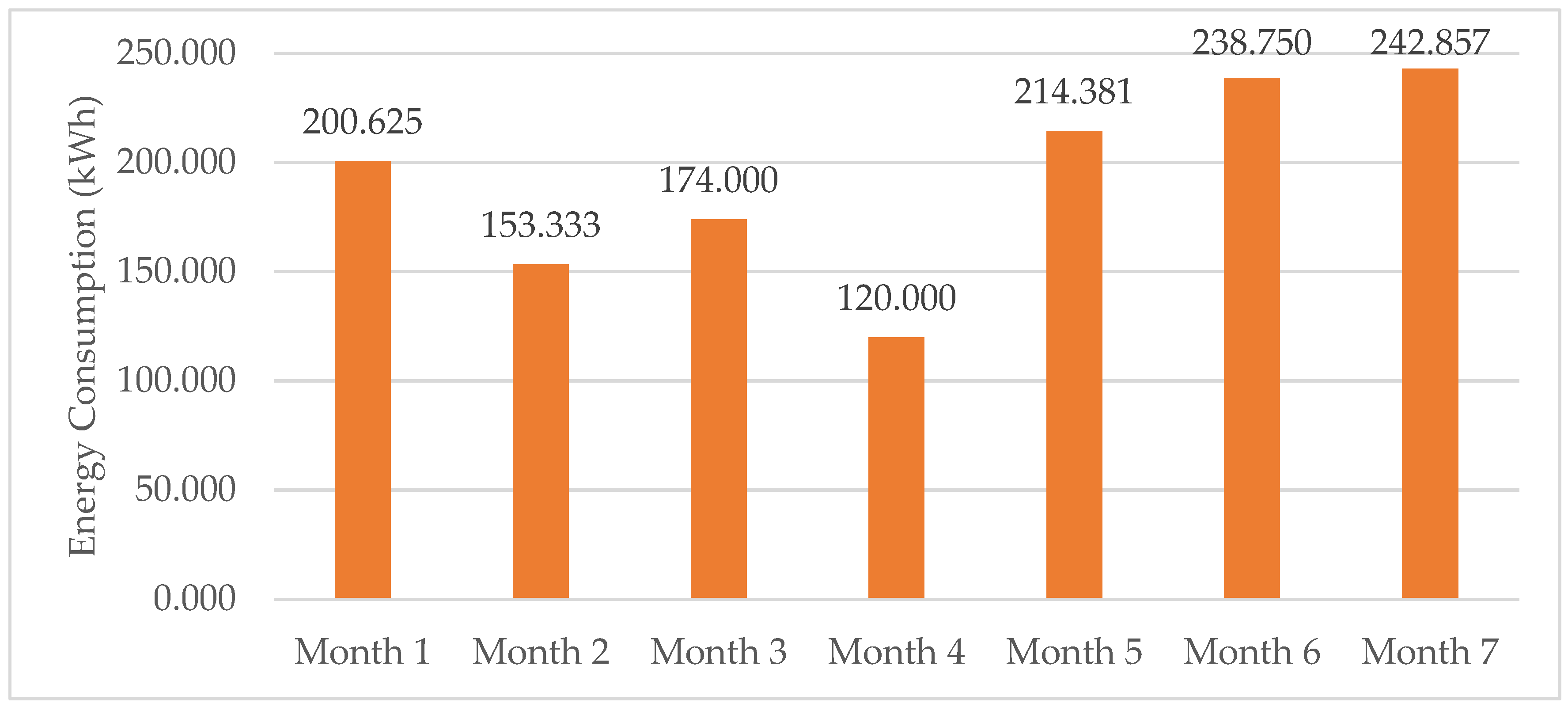

4.1.3. Average Daily Energy Consumption

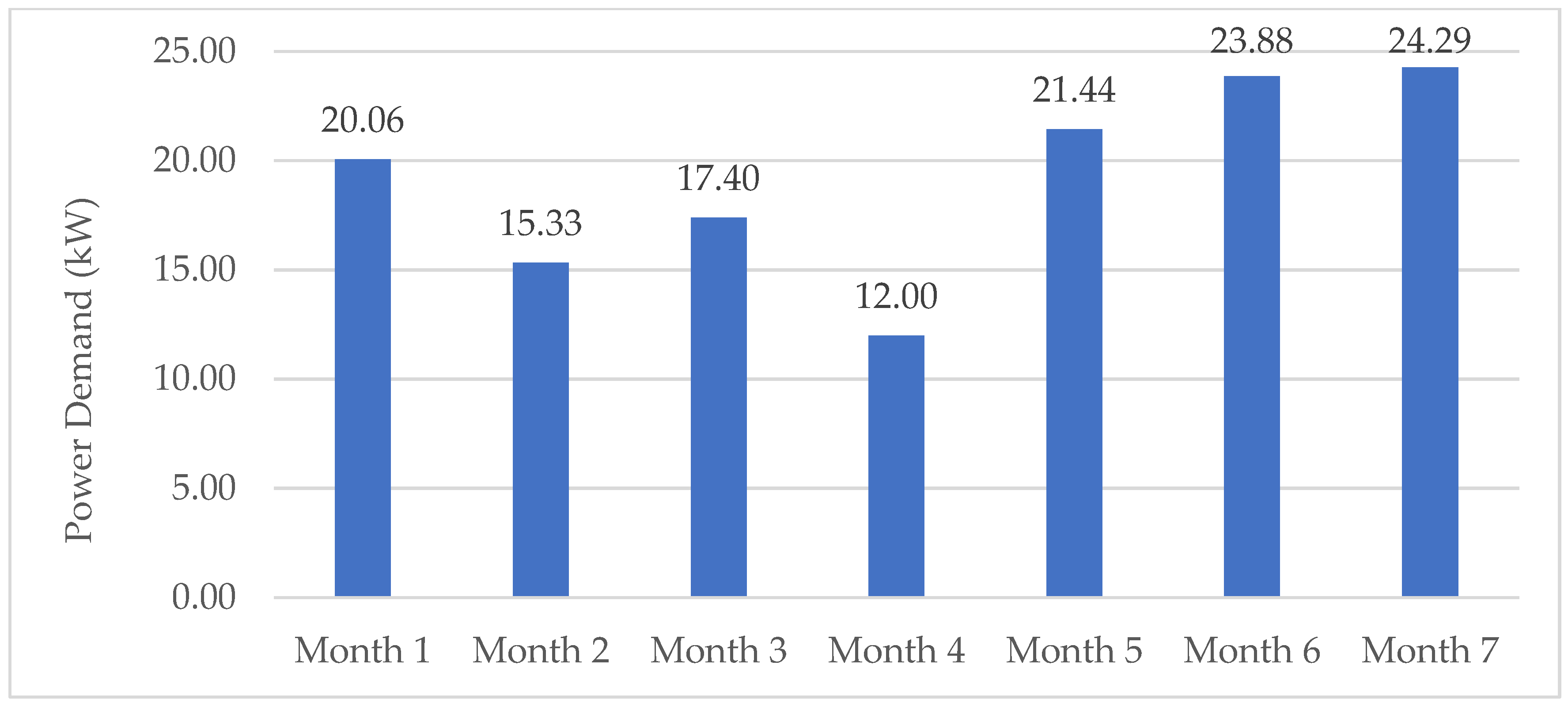

4.1.4. Load Estimation Using Monthly Energy Consumption

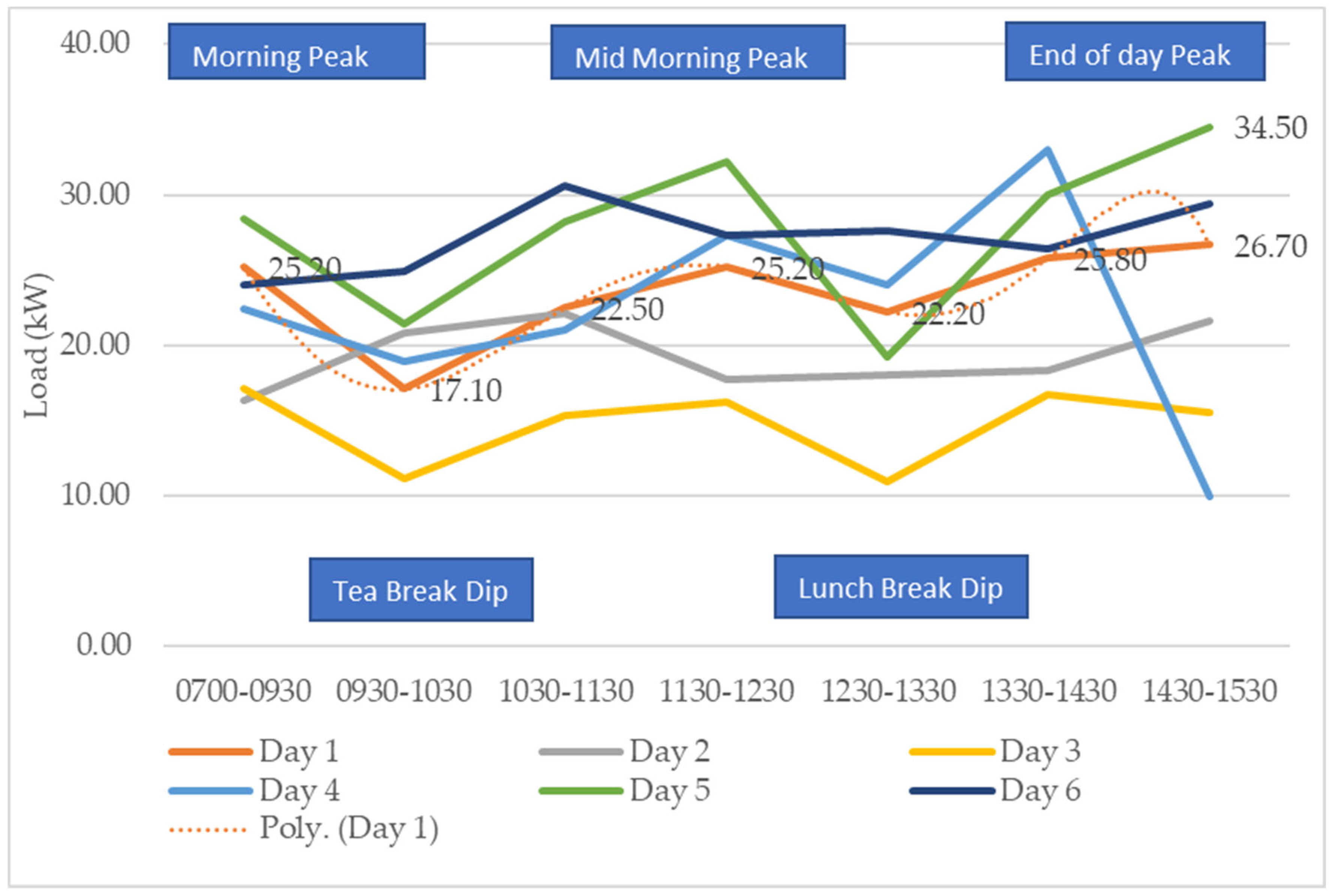

4.1.5. Site Load Profile-Monitoring

4.1.6. Site Idle Load Consumption

4.1.7. Walk-Through Energy Audit-Equipment List

4.1.8. Back-Up Generator

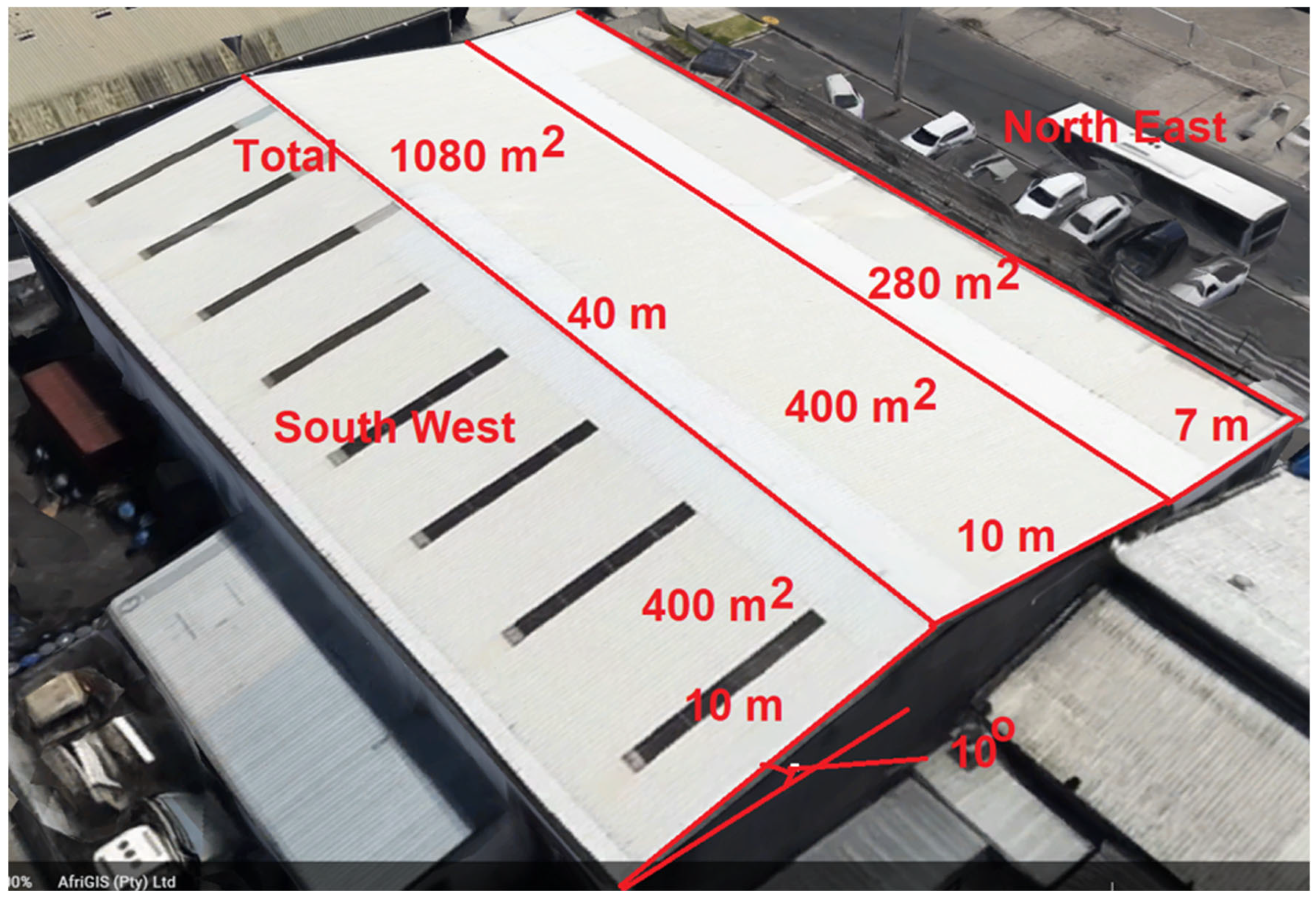

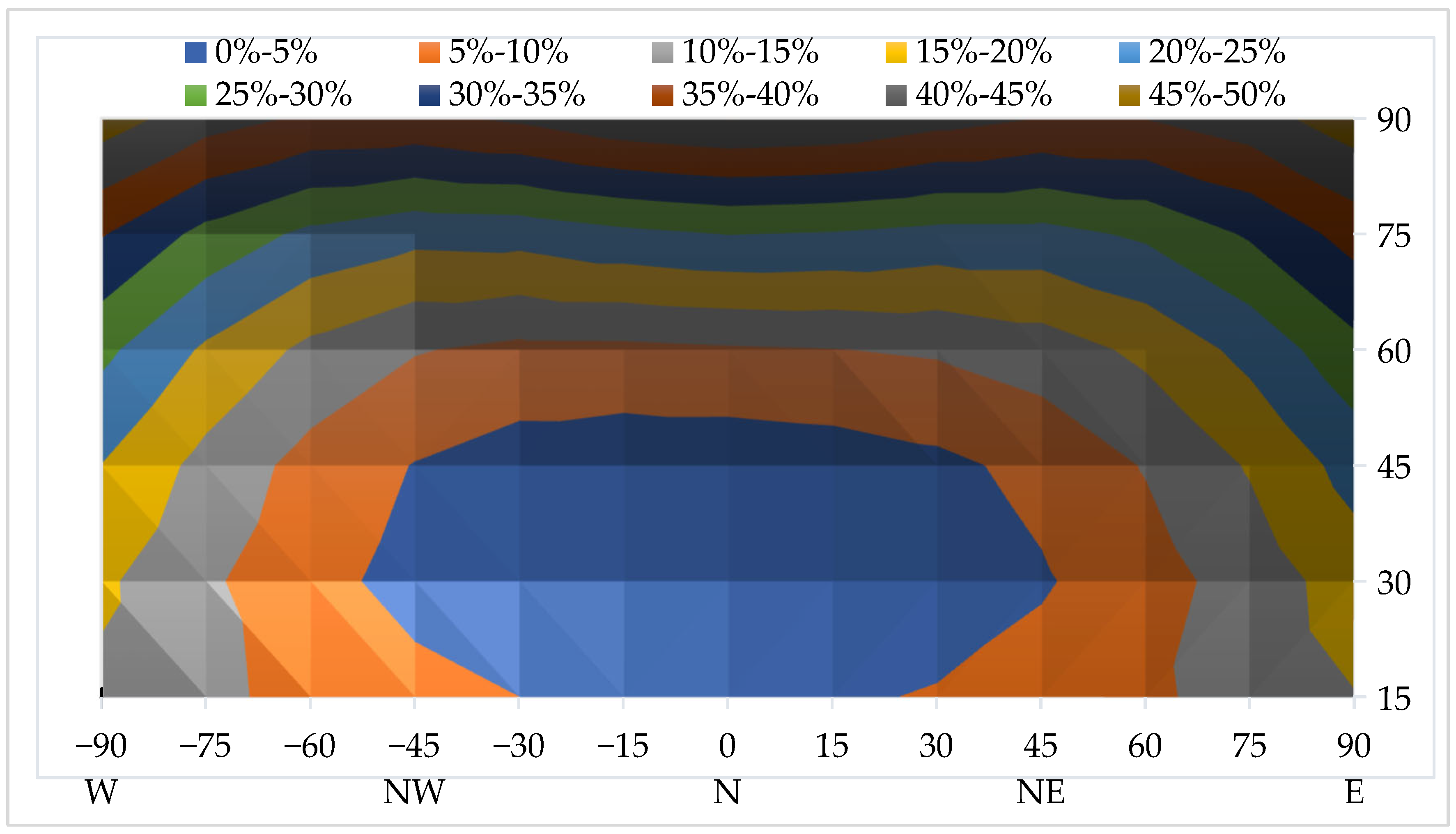

4.2. Site Roof Space Assessment for Solar Photovoltaic Installation

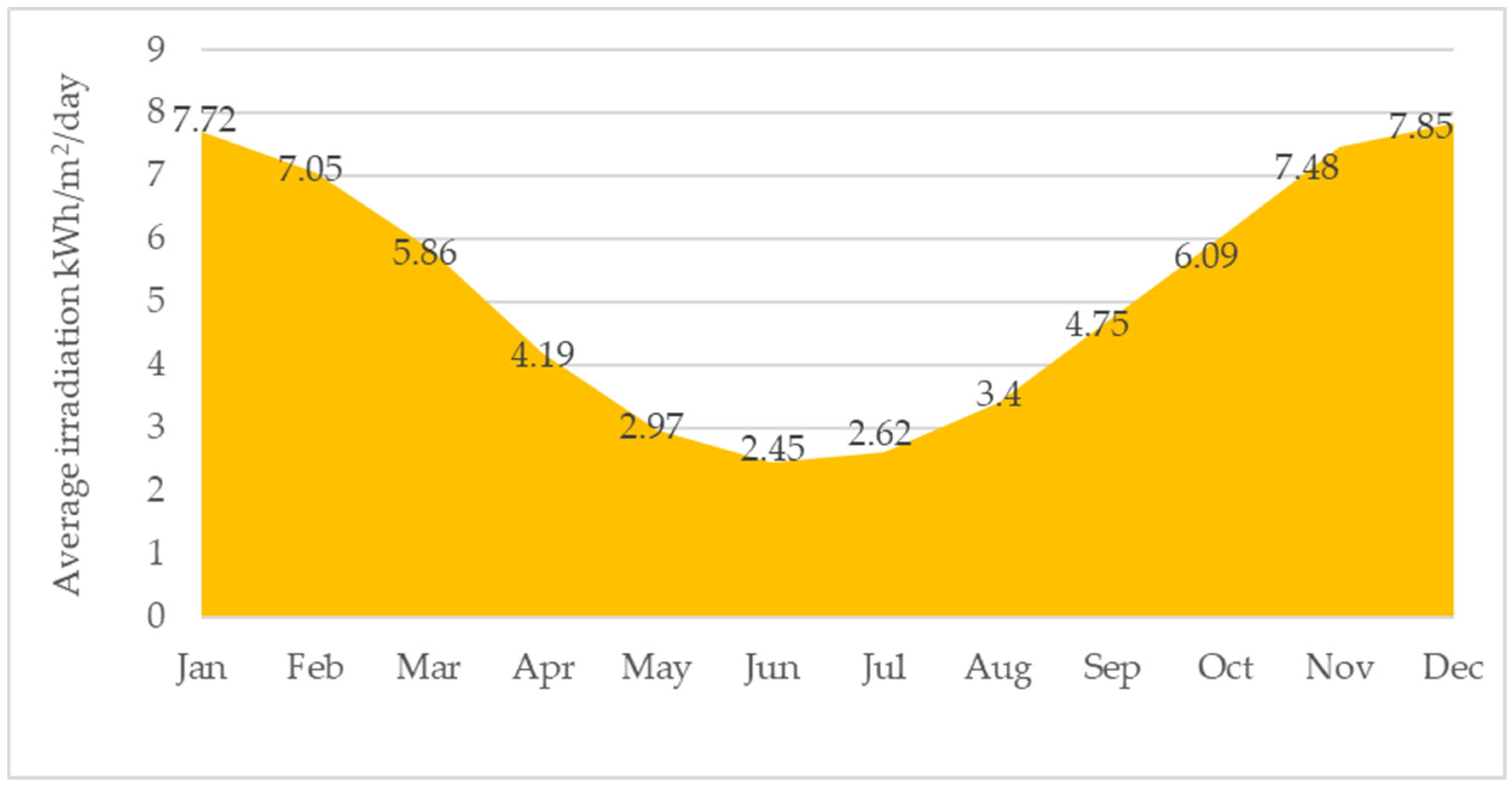

4.3. Cape Town Weather Data and Site Solar Photovoltaic Potential

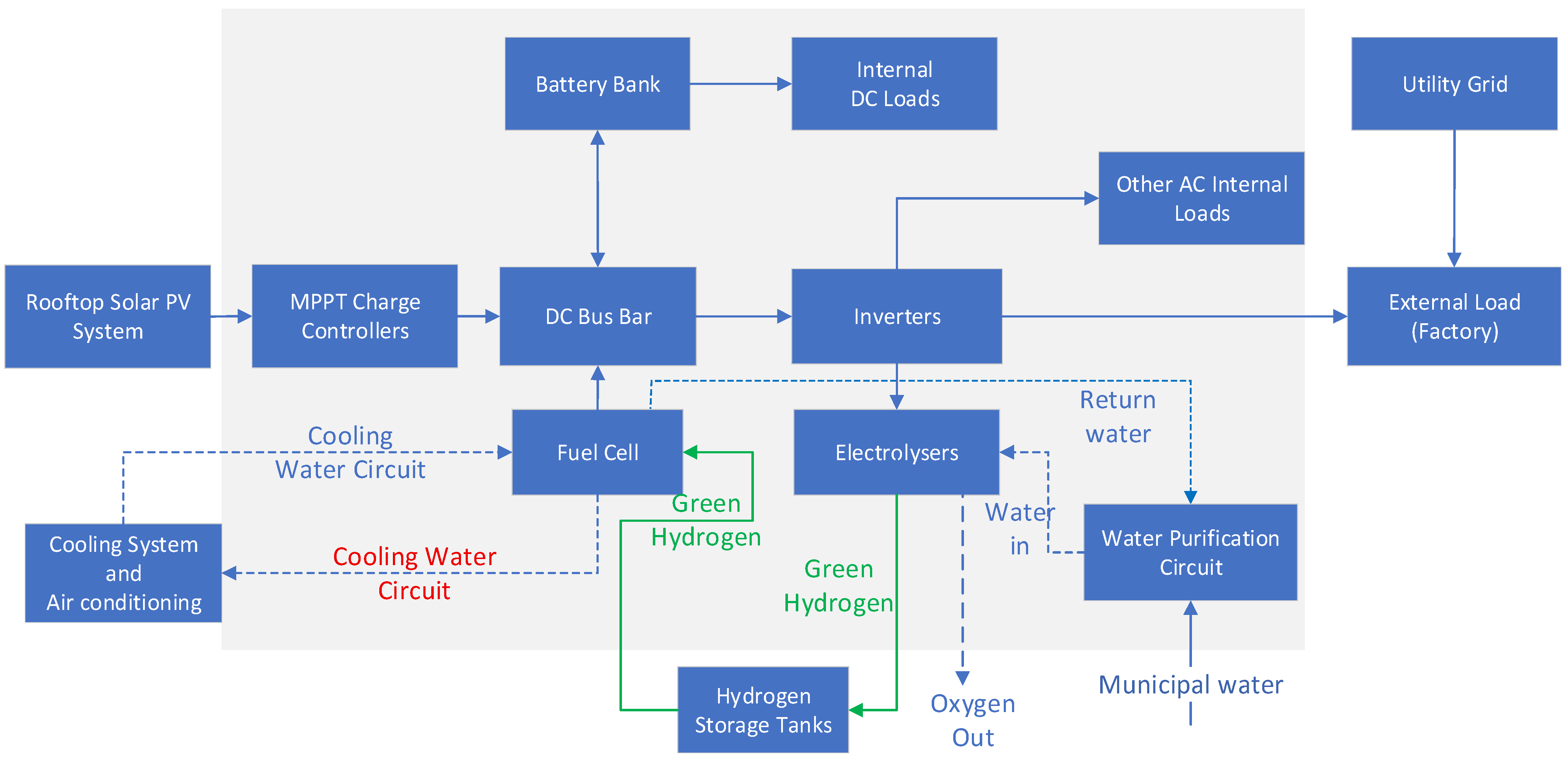

5. Conceptualisation of the Grid-Tied Solar PV-Green Hydrogen-Battery Storage Microgrid System

5.1. Solar Photovoltaic System Sizing

5.2. Inverter Sizing

5.3. Charge Controller Sizing

5.4. Battery Sizing

5.5. Fuel Cell Sizing

5.6. Electrolyser Sizing

5.7. Hydrogen Storage Sizing

5.8. Other Auxiliary Components of the Microgrid

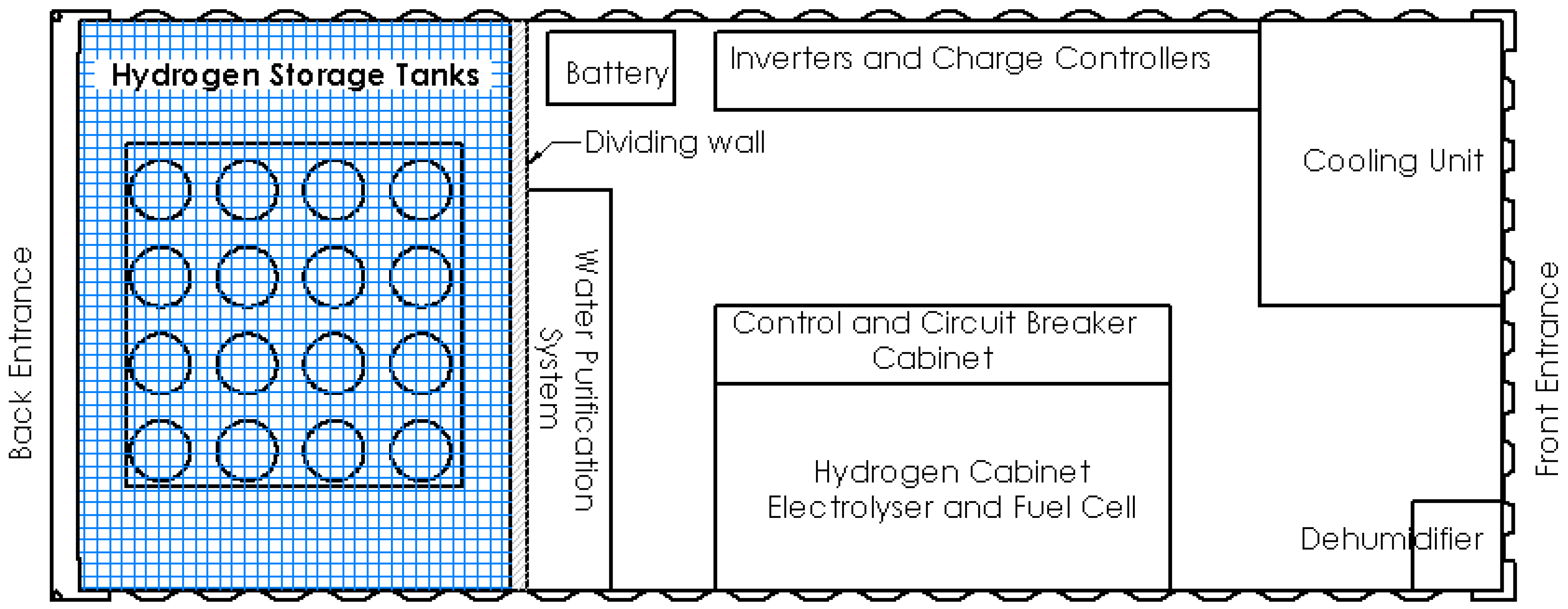

5.9. Microgrid Components Layout

6. Conclusions and Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AbouSeada, N.; Hatem, T.M. Climate Action: Prospects of Green Hydrogen in Africa. Energy Rep. 2022, 8, 3873–3890. [Google Scholar] [CrossRef]

- Furstenau, L.B.; Sott, M.K.; Kipper, L.M.; MacHado, E.L.; Lopez-Robles, J.R.; Dohan, M.S.; Cobo, M.J.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. Link between Sustainability and Industry 4.0: Trends, Challenges and New Perspectives. IEEE Access 2020, 8, 140079–140096. [Google Scholar] [CrossRef]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Carbon Neutrality and Hydrogen Energy Systems. Int. J. Hydrogen Energy 2024, 78, 1449–1467. [Google Scholar] [CrossRef]

- United Nations Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 19 July 2025).

- Ajeeb, W.; Costa Neto, R.; Baptista, P. Life Cycle Assessment of Green Hydrogen Production through Electrolysis: A Literature Review. Sustain. Energy Technol. Assess. 2024, 69, 103923. [Google Scholar] [CrossRef]

- Dyantyi-Gwanya, N.; Giwa, S.O.; Ncanywa, T.; Taziwa, R.T. Exploring Economic Expansion of Green Hydrogen Production in South Africa. Sustainability 2025, 17, 901. [Google Scholar] [CrossRef]

- Hamukoshi, S.S.; Mama, N.; Shimanda, P.P.; Shafudah, N.H. An Overview of the Socio-Economic Impacts of the Green Hydrogen Value Chain in Southern Africa. J. Energy South. Afr. 2022, 33, 12–21. [Google Scholar] [CrossRef]

- Klagge, B.; Walker, B.; Kalvelage, L.; Greiner, C. Governance of Future-Making: Green Hydrogen in Namibia and South Africa. Geoforum 2025, 161, 104244. [Google Scholar] [CrossRef]

- Dagnachew, A.G.; Yalew, S.G.; Tesfamichael, M.; Okereke, C.; Abraham, E. A Green Hydrogen Revolution in Africa Remains Elusive under Current Geopolitical Realities. Clim. Policy 2025, 25, 291–302. [Google Scholar] [CrossRef]

- Imasiku, K.; Farirai, F.; Olwoch, J.; Agbo, S.N. A Policy Review of Green Hydrogen Economy in Southern Africa. Sustainability 2021, 13, 13240. [Google Scholar] [CrossRef]

- Stamm, A.; Altenburg, T.; Strohmaier, R.; Oyan, E.; Thoms, K. Green Hydrogen: Implications for International Cooperation. With Special Reference to South Africa; German Institute of Development and Sustainability: Bonn, Germany, 2023. [Google Scholar] [CrossRef]

- Olifant, G.E.; Ngubevana, L.; Mathetsa, S. Navigating the Current Landscape of Green Hydrogen, Its Potential, and Challenges: A South African Perspective. Prog. Energy 2025, 7, 033002. [Google Scholar] [CrossRef]

- Germany Federal Ministry for Economic Affairs and Climate Action Germany and South Africa Sign Cooperation Agreement on Green Hydrogen. Available online: https://www.bundeswirtschaftsministerium.de/Redaktion/EN/Pressemitteilungen/2023/06/20230627-germany-south-africa-cooperation-green-hydrogen.html (accessed on 13 September 2025).

- Abdelsalam, R.A.; Abdallah, Y.S.; Shabar, N.M.; Afifi, O.A.; Fouda, M.H.; El-Deib, A.A. Energy Management and Techno-Economic Optimization of an Isolated Hybrid AC/DC Microgrid with Green Hydrogen Storage System. In Proceedings of the IEEE Conference on Power Electronics and Renewable Energy, CPERE 2023, Luxor, Egypt, 19–21 February 2023; pp. 1–7. [Google Scholar] [CrossRef]

- El Zoghby, H.M.; Safwat, A.; Afia, R.S.A.; Bendary, A.F.; Elmesalawy, M.M. Optimal Sizing and Operation Strategies for Isolated Microgrid Integrating Green Hydrogen. In Proceedings of the 2024 5th International Conference on Clean and Green Energy Engineering, CGEE 2024, Izmir, Turkey, 24–26 August 2024; pp. 54–58. [Google Scholar] [CrossRef]

- City of Cape Town. Rooftop Solar PV- Guidelines for Safe and Legal Installations in Cape Town; City of Cape Town: Cape Town, South Africa, 2022; pp. 1–8. [Google Scholar]

- Barbosa, L.T.; Vasconcelos, S.D.; Rosas, P.A.C.; Castro, J.F.C.; Barbosa, D.C.P. Assessment of Green Hydrogen as Energy Supply Alternative for Isolated Power Systems and Microgrids. Energies 2024, 17, 4774. [Google Scholar] [CrossRef]

- Valverde, L.; Rosa, F.; Bordons, C. Design, Planning and Management of a Hydrogen-Based Microgrid. IEEE Trans. Ind. Inform. 2013, 9, 1398–1404. [Google Scholar] [CrossRef]

- Alturki, A.A. Optimal Design for a Hybrid Microgrid-Hydrogen Storage Facility in Saudi Arabia. Energy Sustain. Soc. 2022, 12, 1–17. [Google Scholar] [CrossRef]

- El Monem Hazem, A.; El Zoghby, H.M.; Bendary, A.F.; Afia, R.S.A. Techno-Economic Study of a 100% Renewable Energy-Based Isolated Microgrid Involving Green Hydrogen Production. Sustain. Energy Technol. Assess. 2025, 76, 104303. [Google Scholar] [CrossRef]

- Khavari, F.; Hajipour, E.; Liu, J. Day-Ahead Energy Management in Green Microgrids: Impact of Long-Term Scheduling of Hydrogen Storage Systems. Sustain. Energy Technol. Assess. 2024, 72, 104072. [Google Scholar] [CrossRef]

- Tatar, S.M.; Akulker, H.; Sildir, H.; Aydin, E. Optimal Design and Operation of Integrated Microgrids under Intermittent Renewable Energy Sources Coupled with Green Hydrogen and Demand Scenarios. Int. J. Hydrogen Energy 2022, 47, 27848–27865. [Google Scholar] [CrossRef]

- Hasan, T.; Emami, K.; Shah, R.; Hassan, N.M.S.; Anderson, J.; Thomas, D.; Louis, A. A Study on Green Hydrogen-Based Isolated Microgrid. Energy Rep. 2022, 8, 259–267. [Google Scholar] [CrossRef]

- AEE Intec. Thermal Use of Solar Energy-SOLTRAIN Training Course for Experts & Professionals; AEE, Institute for Sustainable Technologies: Gleisdorf, Austria, 2014. [Google Scholar]

- WeatherSpark Cape Town Weather Data. Available online: https://weatherspark.com/y/82961/Average-Weather-in-Cape-Town-Western-Cape-South-Africa-Year-Round (accessed on 20 November 2022).

- Kafando, J.G.; Yamegueu, D.; Houdji, E.T. Review on Sizing and Management of Stand-Alone PV/WIND Systems with Storage. Heliyon 2024, 10, e38080. [Google Scholar] [CrossRef]

- David Tan, A.K.S. Handbook for Solar Photovoltaic Systems; Energy Market Authority, Singapore Publication: Singapore, 2011. [Google Scholar]

- Masters, G.M. Renewable and Efficient Electric Power Systems; Stanford University: Stanford, CA, USA, 2004. [Google Scholar] [CrossRef]

- Khatib, T.; Ibrahim, I.A.; Mohamed, A. A Review on Sizing Methodologies of Photovoltaic Array and Storage Battery in a Standalone Photovoltaic System. Energy Convers. Manag. 2016, 120, 430–448. [Google Scholar] [CrossRef]

- Handwerker, M.; Wellnitz, J.; Marzbani, H. Comparison of Hydrogen Powertrains with the Battery Powered Electric Vehicle and Investigation of Small-Scale Local Hydrogen Production Using Renewable Energy. Hydrogen 2021, 2, 76–100. [Google Scholar] [CrossRef]

- Sanni, O.; Dyosiba, X.; Ren, J. A Brief Overview of Hydrogen Production and Storage. South Afr. J. Chem. Eng. 2025, 53, 60–72. [Google Scholar] [CrossRef]

- Hancke, R.; Bujlo, P.; Holm, T.; Ulleberg, Ø. High-Pressure PEM Water Electrolyser Performance up to 180 Bar Differential Pressure. J. Power Sources 2024, 601, 234271. [Google Scholar] [CrossRef]

- Colozza, A.J. Hydrogen Storage for Aircraft; NASA: Washington, DC, USA, 2002; ISBN 3016210134. [Google Scholar]

| Period | Consumption (kWh) | Rand Cost/kWh | Total Energy Cost | Service Charge/Day | Total Service Charge | Sub Total | VAT | Total Bill |

|---|---|---|---|---|---|---|---|---|

| Month 1 | 3210.00 | R 1.8217 | R 5847.66 | R 63.89 | R 1469.47 | R 7317.13 | 15% | R 8414.70 |

| Month 2 | 2760.00 | R 1.8217 | R 5027.89 | R 63.89 | R 2108.37 | R 7136.26 | 15% | R 8206.70 |

| Month 3 | 3480.00 | R 1.8217 | R 6339.52 | R 63.89 | R 1788.92 | R 8128.44 | 15% | R 9347.70 |

| Month 4 | 3720.00 | Price Change | R 6922.13 | Price Change | R 2023.08 | R 8945.21 | 15% | R 10,286.99 |

| Month 5 | 4502.00 | R 1.9948 | R 8980.59 | R 69.96 | R 2028.84 | R 11,009.43 | 15% | R 12,660.84 |

| Month 6 | 5730.00 | R 1.9948 | R 11,430.20 | R 69.96 | R 2378.64 | R 13,808.84 | 15% | R 15,880.17 |

| Month 7 | 5100.00 | R 1.9948 | R 10,173.48 | R 69.960 | R 2028.84 | R 12,202.32 | 15% | R 14,032.67 |

| Before | After | Consumption (kWh) | Hours | Load (kW) | |

|---|---|---|---|---|---|

| Weekend 1 | 398,087.40 | 398,140.20 | 52.8 | 62 | 0.851 |

| Weekend 2 | 399,092.10 | 399,145.80 | 53.7 | 62 | 0.866 |

| Average Idle Load | Approx 1 kW | ||||

| Location | Equipment | Qnty | Power Rating (kW) | Total (kW) |

|---|---|---|---|---|

| Shopfloor | Welding Machine | 7 | 8.40 | 58.8 |

| Shopfloor | Pump | 7 | 0.22 | 1.54 |

| Shopfloor | Compressor | 2 | 7.50 | 15.0 |

| Training | Welding Machine | 2 | 8.40 | 16.8 |

| Training | Pump | 2 | 0.22 | 0.44 |

| Parameter | Reading |

|---|---|

| Generator Size | 50.00 kW |

| Total Energy (kWh) | 1582.00 kWh |

| Run Hrs | 195.28 Hrs |

| Average Power Load to the Generator | 8.10 kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarema, B.; Chirinda, G.P.; Scheffler, S.; Matope, S.; Beyer, U. Areal Assessment in the Design of a Try-Out Grid-Tied Solar PV-Green Hydrogen-Battery Storage Microgrid System for Industrial Application in South Africa. Sustainability 2025, 17, 8649. https://doi.org/10.3390/su17198649

Sarema B, Chirinda GP, Scheffler S, Matope S, Beyer U. Areal Assessment in the Design of a Try-Out Grid-Tied Solar PV-Green Hydrogen-Battery Storage Microgrid System for Industrial Application in South Africa. Sustainability. 2025; 17(19):8649. https://doi.org/10.3390/su17198649

Chicago/Turabian StyleSarema, Blessed, Gibson P. Chirinda, Sören Scheffler, Stephen Matope, and Ulrike Beyer. 2025. "Areal Assessment in the Design of a Try-Out Grid-Tied Solar PV-Green Hydrogen-Battery Storage Microgrid System for Industrial Application in South Africa" Sustainability 17, no. 19: 8649. https://doi.org/10.3390/su17198649

APA StyleSarema, B., Chirinda, G. P., Scheffler, S., Matope, S., & Beyer, U. (2025). Areal Assessment in the Design of a Try-Out Grid-Tied Solar PV-Green Hydrogen-Battery Storage Microgrid System for Industrial Application in South Africa. Sustainability, 17(19), 8649. https://doi.org/10.3390/su17198649