Experimental Study on Ultra-Light Sand Packing in Multi-Lateral Horizontal Well for Natural Gas Hydrate Reservoirs

Abstract

1. Introduction

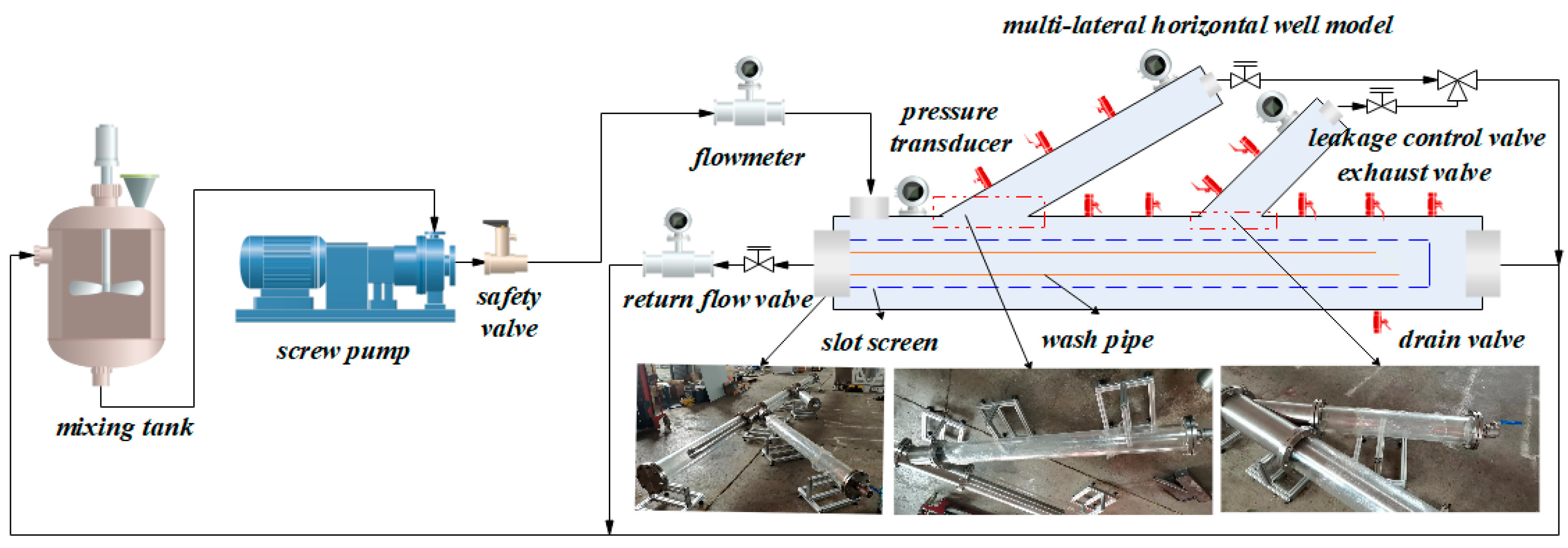

2. Experimental Work

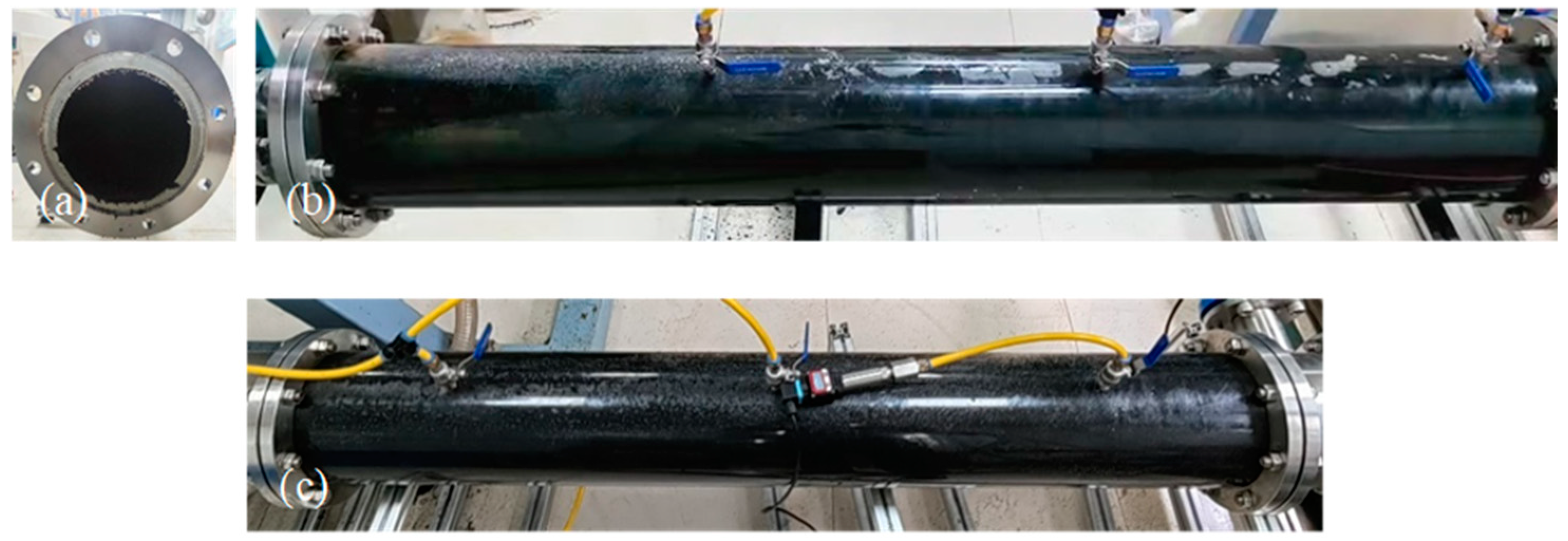

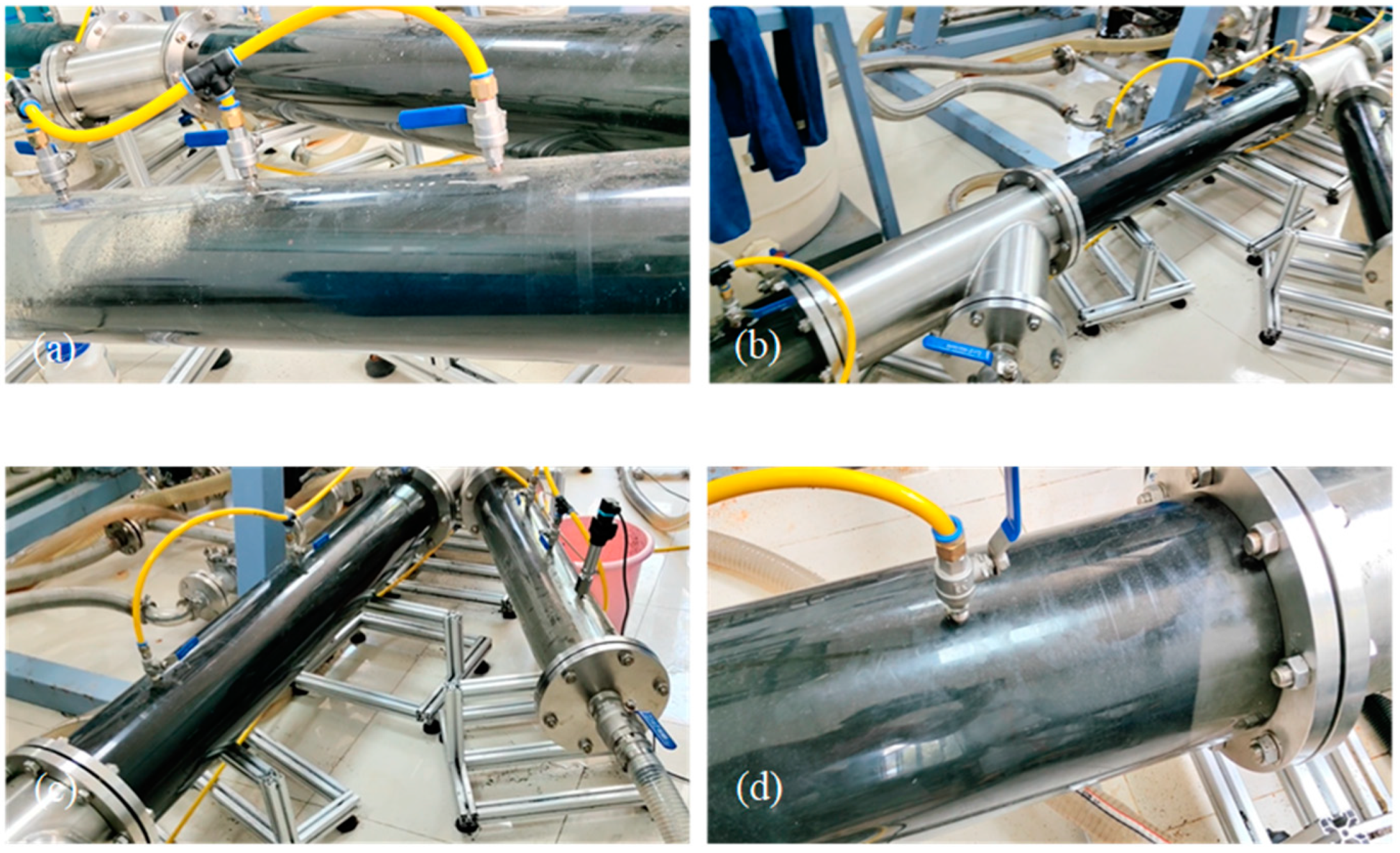

2.1. Apparatus

2.2. Materials

2.3. Determination of Gravel Packing Effectiveness

- (1)

- Air evacuation of the apparatus: A volume of 450 L of laboratory water was introduced into the mixing tank. The outlet valve and exhaust valve were then opened, while the drain valve was closed. The screw pump was activated at a low flow rate to supply water to the apparatus. The exhaust valves were closed upon the observation of water discharge at the valve outlet.

- (2)

- Leakage control: At low injection flow rates, leakage was controlled through the coordinated use of the return flow valve and the leak-off valve, with the leakage rate calculated based on readings from the injection and return flowmeters. The injection flow rate was subsequently increased to the specified design value, followed by the verification of the leakage rate and micro-adjustments to the return flow valve to ensure conformity with design requirements.

- (3)

- Gravel addition rate: The rate of gravel addition during experimentation was quantified through the multiplication of the injection flow rate and predetermined gravel concentration parameters.

- (4)

- Gravel packing: Once stable flow conditions had been achieved, the gravel packing operation was launched at the rate of gravel addition, determined in Step (3). The gravel packing was stopped when the sand-out pressure began to increase rapidly.

- (5)

- Cleaning: The water was released from the multi-lateral horizontal well model through the drain valve; then, we disassembled the outlet, flushed out the gravel in the model with the jetting machine, and reset the model.

- (6)

- Gravel packing effectiveness calculation: The gravel packing effectiveness (Rp) is defined as the ratio of the apparent volume of packing gravel to the theoretical volume of the packing section within the annulus, perforation, and sand production void zones near the well. The theoretical volume of the packing section is calculated as the sum of the annular volume between the casing and the blank tubing, the annular volume between the casing and the slot screen, the casing volume corresponding to the pocket length, and the theoretical packing volume outside the casing. In field operations, the apparent volume of packing gravel is determined by subtracting both the volume of gravel lost on the ground and the volume left in the work string from the total gravel volume used during the packing operation. For a visible multi-lateral horizontal well apparatus for gravel packing in the laboratory, the apparent volume of packing gravel can be determined by subtracting the unfilled space volume, which can be calculated based on the geometric parameters of the casing and screen, as well as the morphology of the unfilled space, from the total packing section volume of the apparatus. The calculation equation for gravel packing effectiveness is as follows:

3. Results

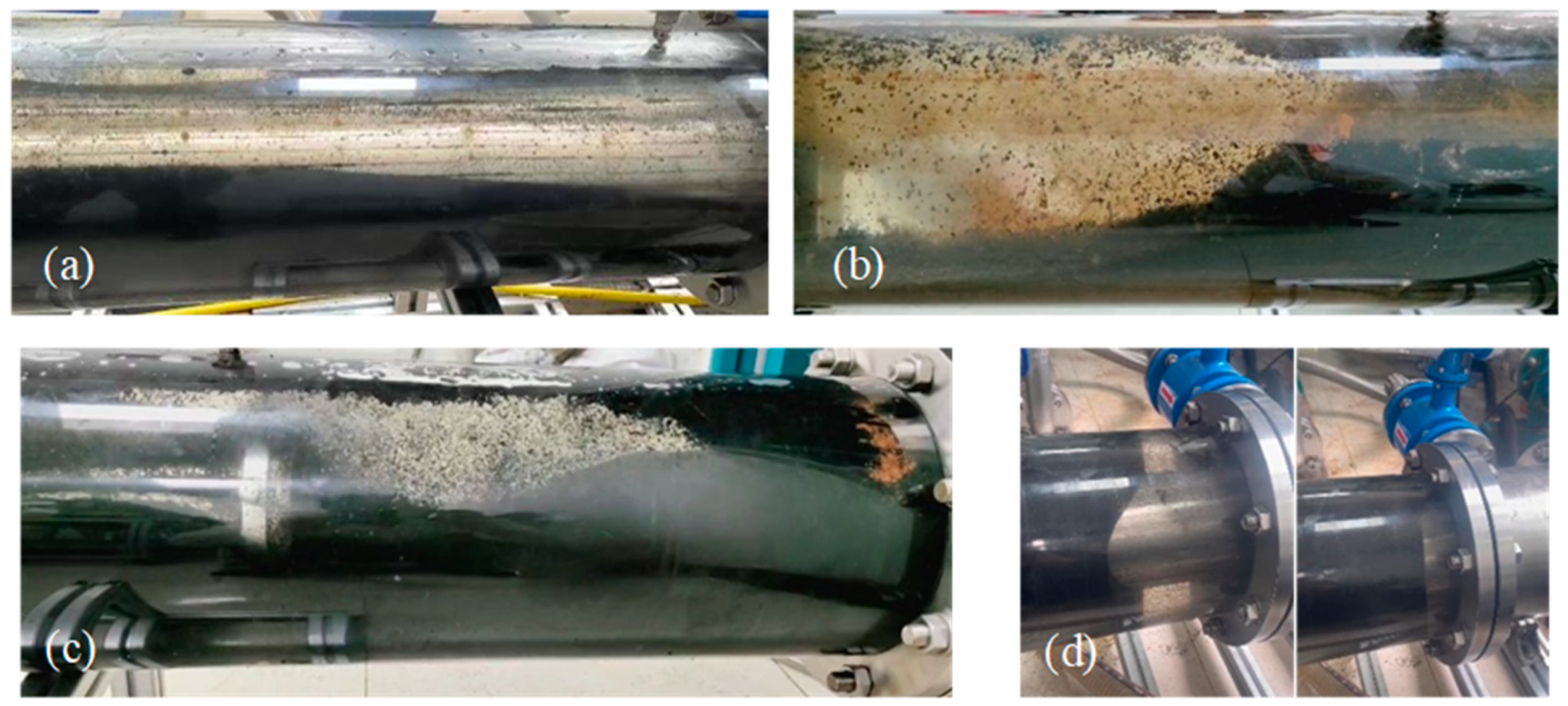

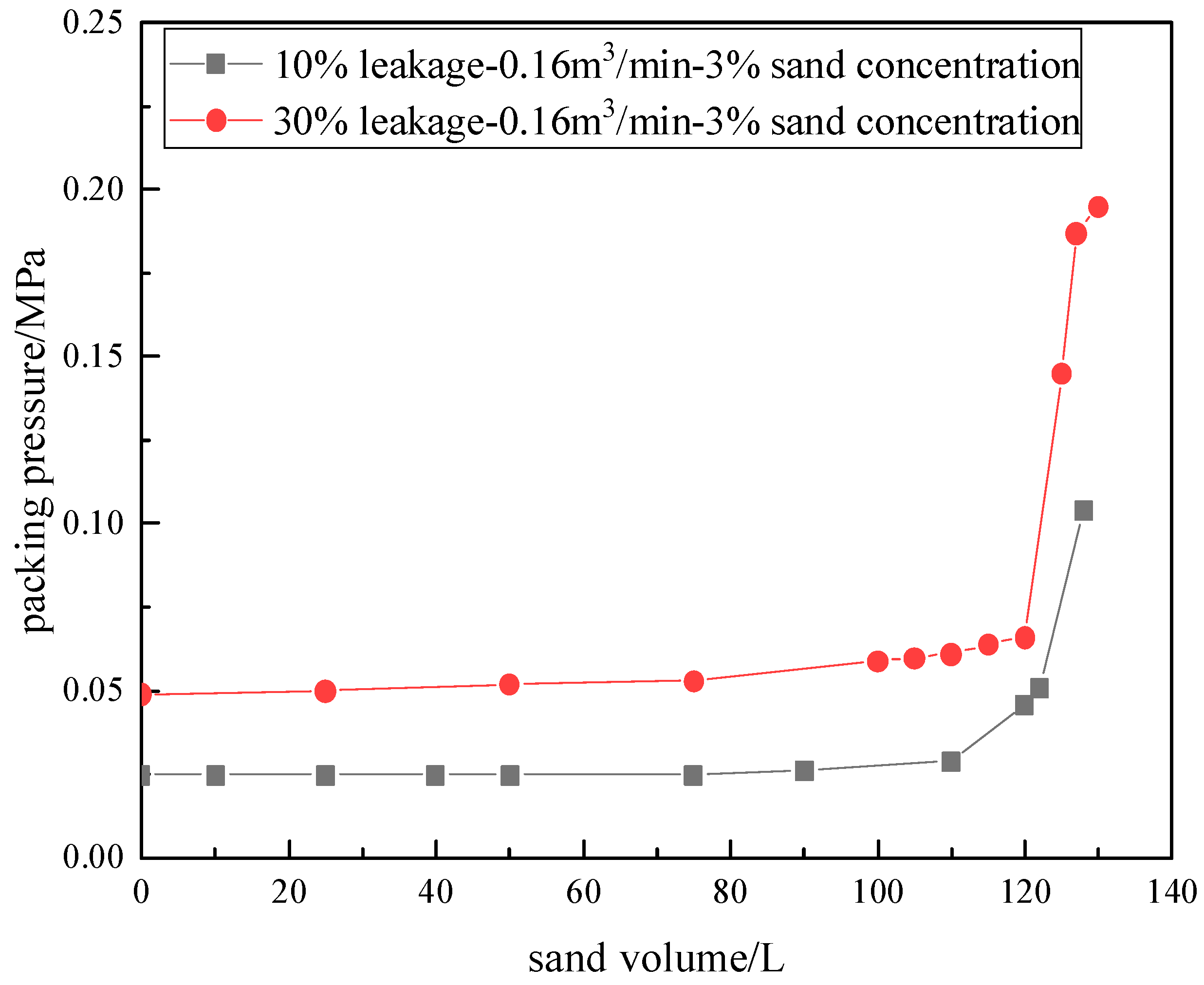

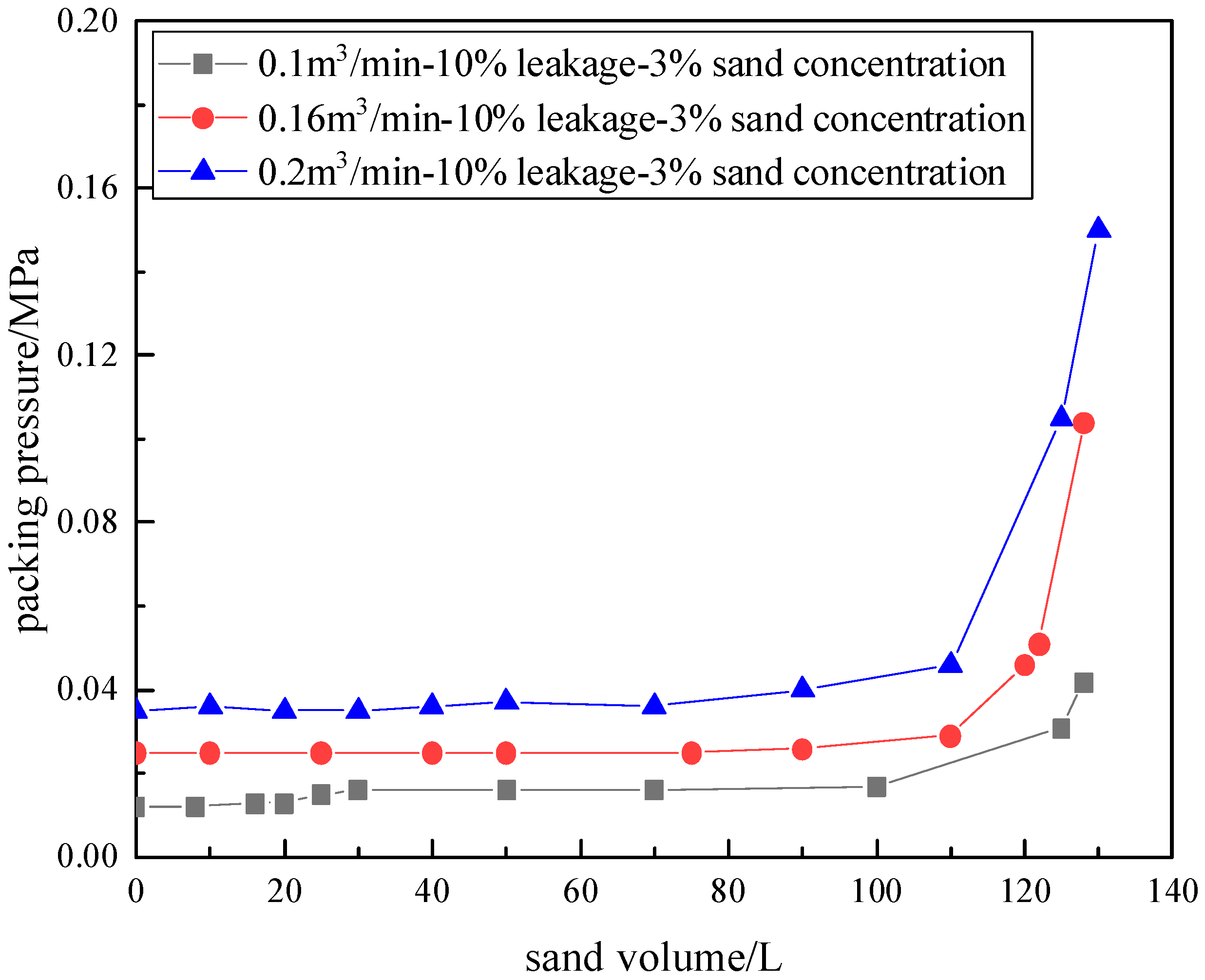

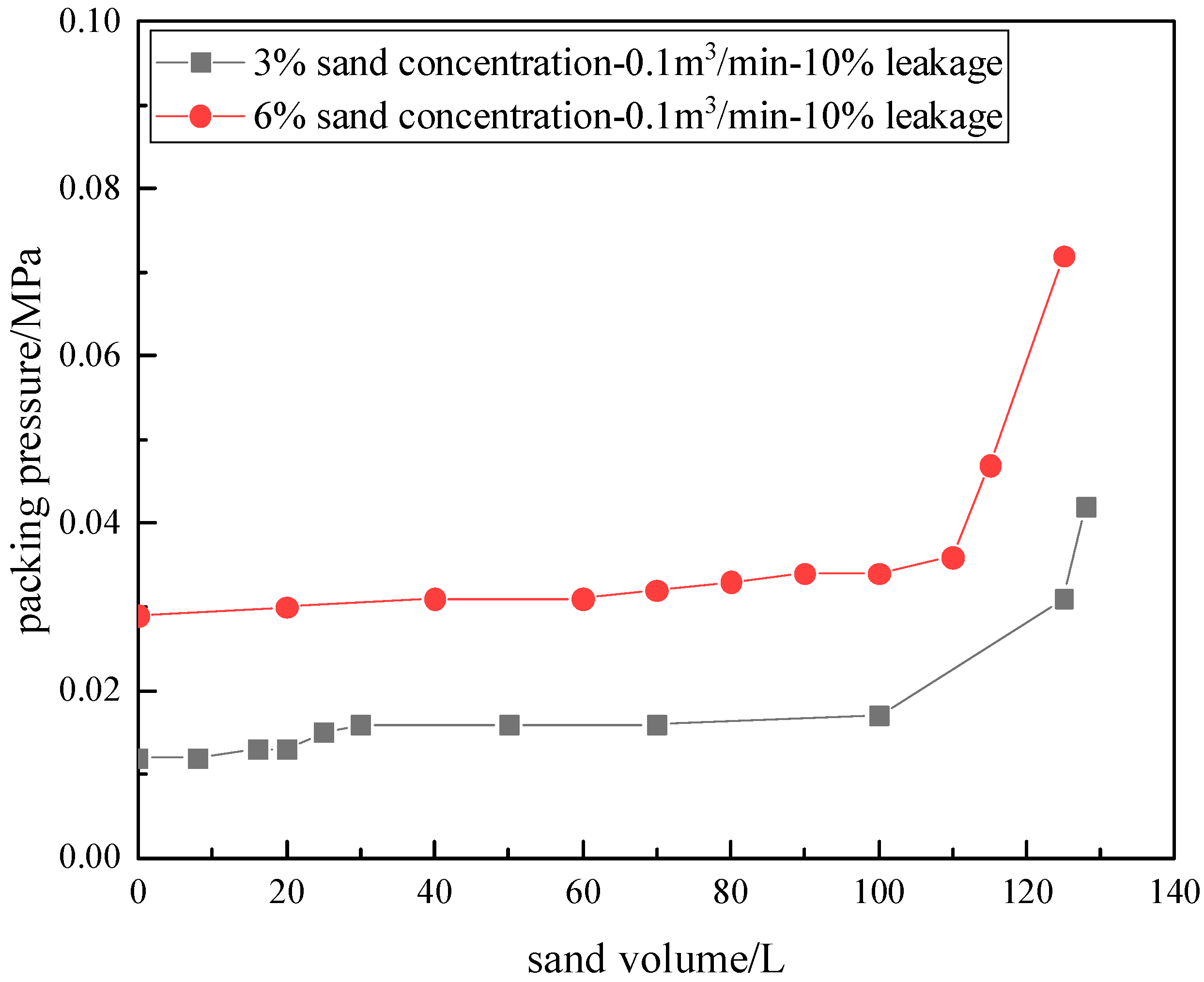

3.1. Ultra-Light Sand Packing in Single Horizontal Main Bore

3.2. Ultra-Light Sand Packing in Single-Lateral Well Configurations of Varying Lengths

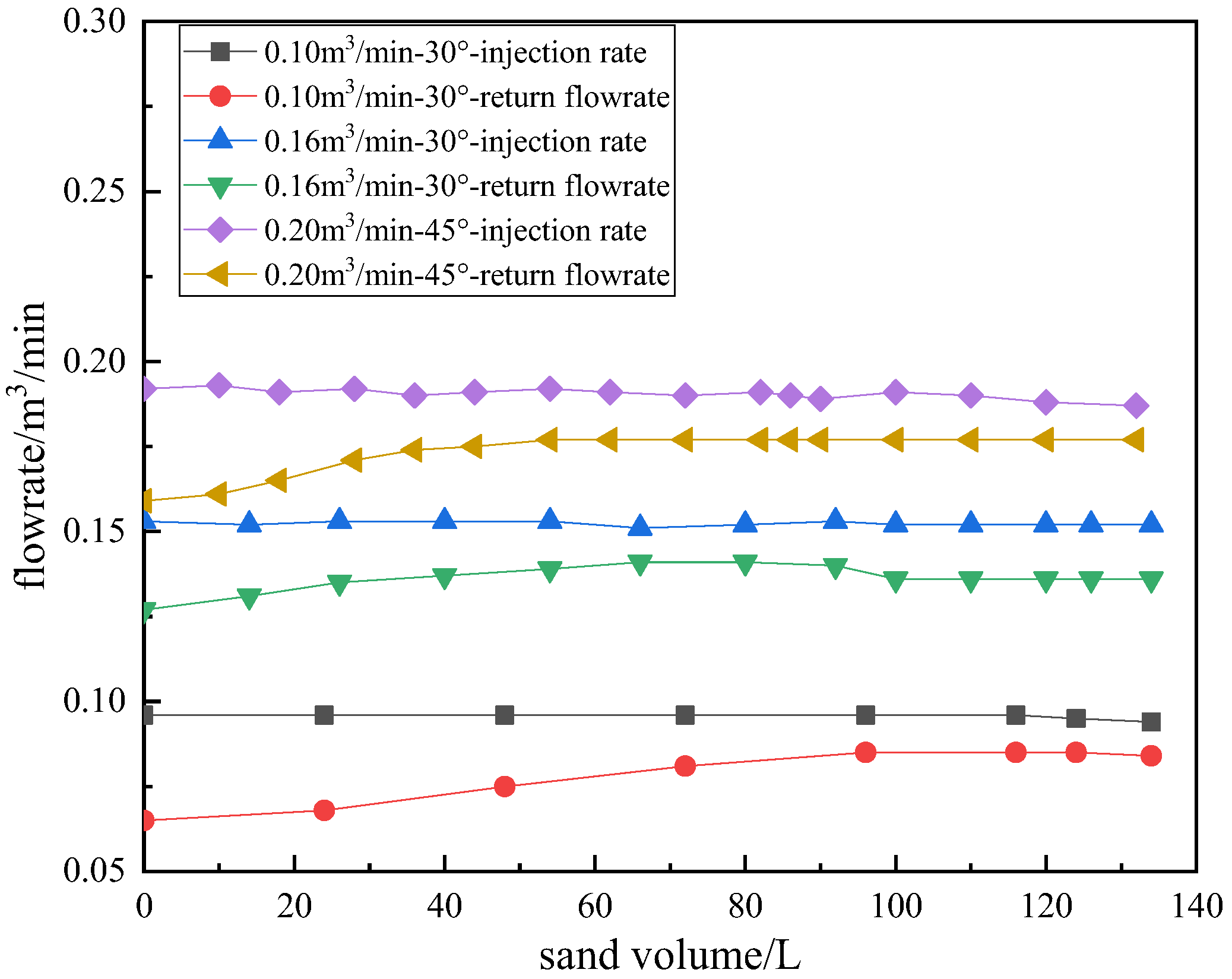

3.2.1. The 1 m Lateral Well Configuration

3.2.2. The 2 m Lateral Well Configuration

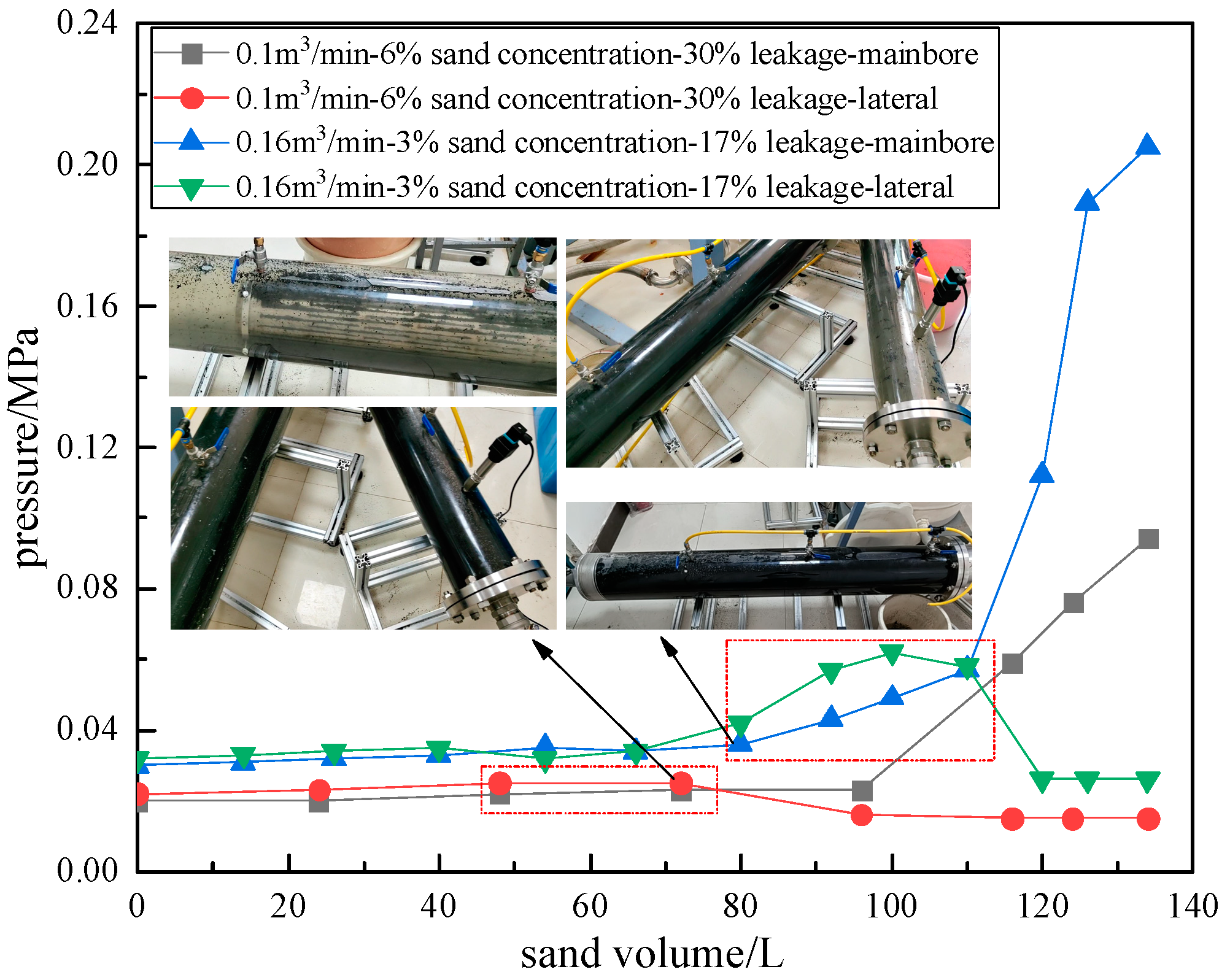

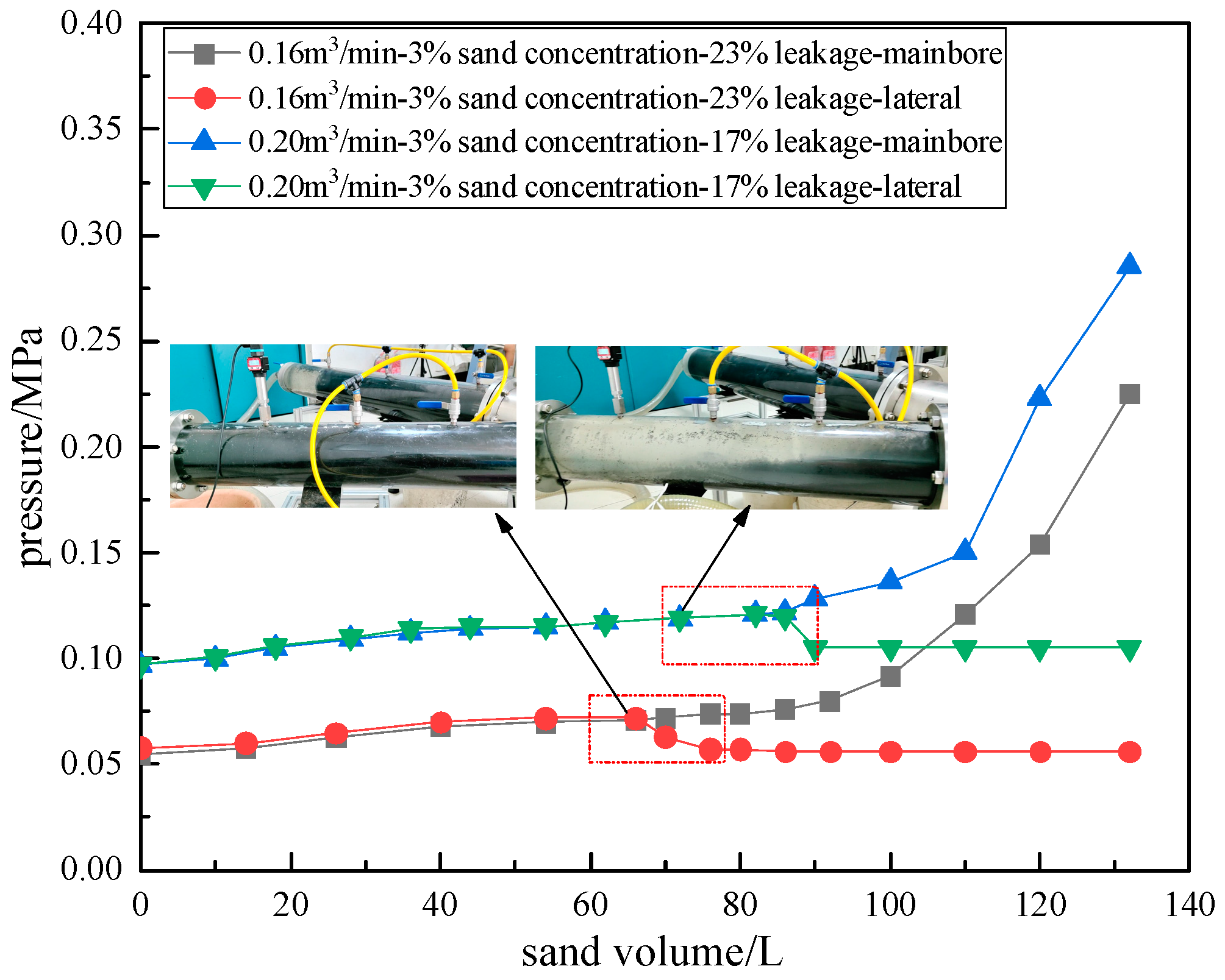

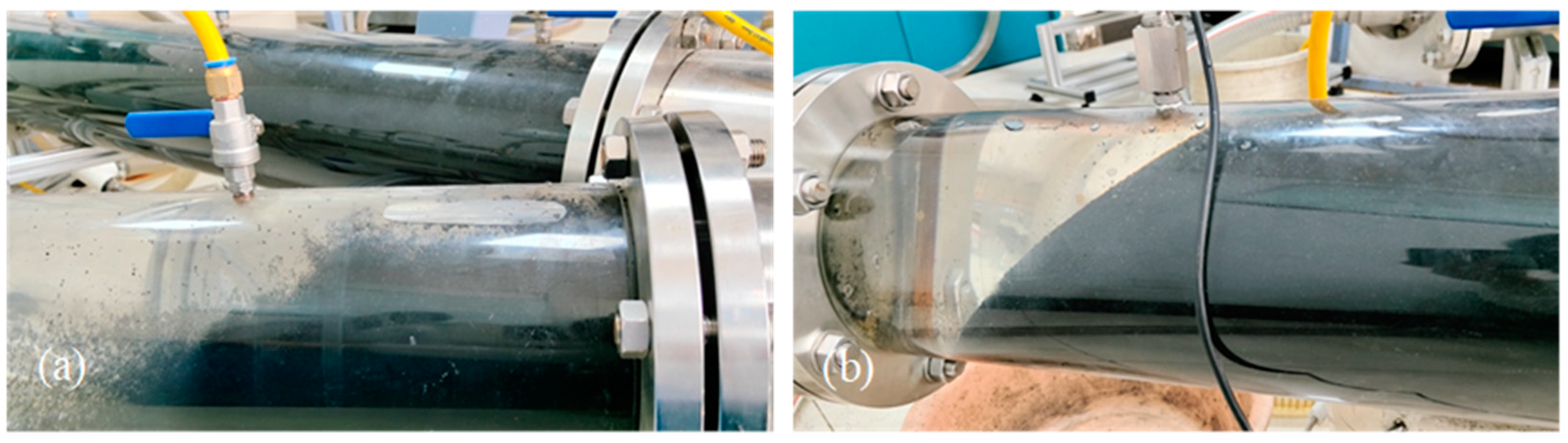

3.3. Ultra-Light Sand Packing in Dual-Lateral Well Configuration

4. Optimization of Operational Parameters

4.1. Determination of Similarity Criteria

4.2. Multi-Lateral Horizontal Well Configuration and Determination of Operational Parameters

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, Y.H.; Yang, S.X.; Wang, H.B.; Liang, J.Q.; Liang, J. Prospect of Gas Hydrate Resources in Qiong Dongnan Basin. Jilin Daxue Xuebao Diqiu Kexue Ban J. Jilin Univ. Earth Sci. Ed. 2018, 48, 1030–1042. [Google Scholar] [CrossRef]

- Chen, L.; Merey, S.; Pecher, I.; Okajima, J.; Komiya, A.; Diaz-Naveas, J.; Li, S.; Maruyama, S.; Kalachand, S.; Kvamme, B.; et al. A review analysis of gas hydrate tests: Engineering progress and policy trend. Environ. Geotech. 2022, 9, 242–258. [Google Scholar] [CrossRef]

- Hunter, R.B.; Collett, T.S.; Boswell, R.; Anderson, B.J.; Digert, S.A.; Pospisil, G.; Baker, R.; Weeks, M. Mount Elbert gas hydrate stratigraphic test well, Alaska North Slope: Overview of scientific and technical program. Mar. Pet. Geol. 2011, 28, 295–310. [Google Scholar] [CrossRef]

- Kvamme, B. Feasibility of simultaneous CO2 storage and CH4 production from natural gas hydrate using mixtures of CO2 and N2. Can. J. Chem. 2015, 93, 897–905. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Yamamoto, K.; Numasawa, M.; Ebinuma, T.; Narita, H.; Masuda, Y.; Dallimore, S.R.; et al. Analysis of production data for 2007/2008 Mallik gas hydrate production tests in Canada. In Proceedings of the SPE International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010; SPE: Richardson, TX, USA, 2010. [Google Scholar]

- Terao, Y.; Duncan, M.; Hay, B.; Dang, L. Deepwater methane hydrate gravel packing completion results and challenges. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; SPE: Richardson, TX, USA, 2014. [Google Scholar]

- Li, J.F.; Ye, J.L.; Qin, X.W.; Qiu, H.J.; Wu, N.Y.; Lu, H.L.; Xie, W.W.; Lu, J.A.; Peng, F.; Xu, Z.Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Shen, J.; Chiu, C.; Ng, C.; Lei, G.; Xu, J. A state-dependent critical state model for methane hydrate-bearing sand. Comput. Geotech. 2016, 75, 1–11. [Google Scholar] [CrossRef]

- Wan, Y.; Wu, N.; Hu, G.; Xin, X.; Jin, G.; Liu, C.; Chen, Q. Reservoir stability in the process of natural gas hydrate production by depressurization in the Shenhu area of the South China Sea. Nat. Gas Ind. B 2018, 5, 631–643. [Google Scholar] [CrossRef]

- Fang, X.; Ning, F.; Wang, L.; Liu, Z.; Lu, H.; Yu, Y.; Li, Y.; Sun, J.; Shi, H.; Zhao, Y.; et al. Dynamic coupling responses and sand production behavior of gas hydrate-bearing sediments during depressurization: An experimental study. J. Pet. Sci. Eng. 2021, 201, 108506. [Google Scholar] [CrossRef]

- Tong, S.; Ren, Y.; Jin, Y.; Yan, K.; Zhang, J.; Wang, Z. Investigation of synergistic inhibition effect of hydrate inhibitors and paraffin inhibitors on hydrate formation. Fuel 2025, 385, 134105. [Google Scholar] [CrossRef]

- Jin, Y.; Li, Y.; Wu, N.; Yang, D. Characterization of sand production for clayey-silt sediments conditioned to openhole gravel-packing: Experimental observations. SPE J. 2021, 26, 3591–3608. [Google Scholar] [CrossRef]

- Jin, Y.; Wu, N.; Li, Y.; Yang, D. Characterization of sand production for clayey-silt sediments conditioned to hydraulic slotting and gravel packing: Experimental observations, theoretical formulations, and modeling. SPE J. 2022, 27, 3704–3723. [Google Scholar] [CrossRef]

- Tong, S.; Yan, K.; Jin, Y.; Ren, Y.; Xie, H.; Zhang, J.; Liu, C.; Wang, Z. Microscopic interactions between hydrate particles/droplets in gas or heavy hydrocarbon under high pressure conditions: Cohesion, adhesion and tensile strength. Colloids Surf. A Physicochem. Eng. Asp. 2025, 710, 136264. [Google Scholar] [CrossRef]

- Wu, N.; Li, Y.; Wan, Y.; Sun, J.; Huang, L.; Mao, P. Prospect of marine natural gas hydrate stimulation theory and technology system. Nat. Gas Ind. B 2021, 8, 173–187. [Google Scholar] [CrossRef]

- Yamamoto, K. Overview and introduction: Pressure core-sampling and analyses in the 2012–2013 MH21 offshore test of gas production from methane hydrates in the eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 296–309. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Liu, C.; Sun, J.; Ye, Y.; Qiang, C. Sanding prediction and sand-control technology in hydrate exploitation: A review and discussion. Mar. Geol. Front. 2016, 32, 36–43. [Google Scholar]

- Wang, H.; Wang, J.; Yu, J.; Yu, C.; Liu, Y. Key technologies for natural gas hydrate mining. Drill. Prod. Technol. 2022, 45, 51–56. [Google Scholar]

- Li, Y.; Hu, Y.; Hu, G.; Liu, C.; Wu, C.; Wu, N.; Chen, Q.; Liu, L.; Li, C. Gravel sizing method for sand control packing in hydrate production test wells. Pet. Explor. Dev. 2017, 44, 1016–1021. [Google Scholar] [CrossRef]

- Zuo, R.; Li, Y. Japan’s sampling study and successful production test for NGH in Nankai through. Explor. Eng. Rock Soil Drill. Tunneling 2017, 44, 1–20. [Google Scholar]

- Mohamed, A.; Salehi, S.; Ahmed, R.; Li, G. Experimental study on rheological and settling properties of shape memory polymer for fracture sealing in geothermal formations. J. Pet. Sci. Eng. 2022, 208, 109535. [Google Scholar] [CrossRef]

- Farouk, S.; Saada, S.A.; Fagelnour, M.S.; Arafat, M. Petrophysical and Gas Chromatographic Analysis Integration for Hydrocarbon Identifications in Cretaceous Reservoirs, Azhar Field, Beni Suef Basin, Egypt. Egypt. J. Pet. 2024, 33, 7. [Google Scholar] [CrossRef]

- Farouk, S.; Sen, S.; Ahmed, F.; Qteishat, A.; Al-Kahtany, K.; Moreno, H.M.; Mitra, S.; Arafat, M. Assessment of the Upper Cretaceous Abu Roash carbonate source rocks from the Beni Suef field, Western Desert, Egypt. J. Afr. Earth Sci. 2024, 215, 105272. [Google Scholar] [CrossRef]

- Lu, J.; Lin, D.; Li, D.; Liang, D.; Zhang, Y.; Wu, S.; He, Y.; Shi, L. Research status on water controllina and sand controllina in horizontal well completion durina gas hydrate exploitation. Adv. New Renew. Energy 2022, 10, 447–455. [Google Scholar]

- Lu, J.S.; Wu, S.T.; Li, D.L.; Liang, D.Q.; Wei, W.; He, Y.; Shi, L.L.; Deng, F.C.; Xiong, Y.M. Solid phase control strategy during the exploitation of marine gas hydrates. Adv. New Renew. Energy 2022, 10, 137–145. [Google Scholar]

- Hancock, S.; Boswell, R.; Collett, T. Development of deepwater natural gas hydrates. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019; SPE: Richardson, TX, USA, 2019. [Google Scholar]

- Ayan, C.; Aktepe, S.; Cig, K.; Gokmen, M.; Ceyhan, A.; Tugan, M.; Shumakov, Y.; Dolu, A.; Theuveny, B. Frontiering Ultra-Deep Water Gas Field Development, Offshore Black Sea-Turkey: Solutions to Complex Well Testing Challenges and Proving Production Potential. In Proceedings of the SPE Annual Technical Conference and Exhibition? Houston, TX, USA, 16–18 October 2023; SPE: Richardson, TX, USA, 2023. [Google Scholar]

- Xin, X.; Shan, Y.; Xu, T.; Li, S.; Zhu, H.; Yuan, Y. Multi-Lateral Well Productivity Evaluation Based on Three-Dimensional Heterogeneous Model in Nankai Trough, Japan. Energies 2023, 16, 2406. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, G.; Yang, G.; Jiang, B.; Yue, G.; Mao, X. Exploration and research on long-term sand control completion in natural gas hydrate reservoir. Drill. Prod. Technol. 2022, 45, 67. [Google Scholar]

- Luo, Q.; Liu, Z.; Ning, F. Sand control and water drainage by ultrasonic atomization for gas recovery from hydrate reservoirs. Drill. Eng. 2022, 49, 23–28. [Google Scholar]

- Chen, N.; Xue, X.; Guan, H. Application analysis of ultra-short multilateral well drilling and completion technology in the Bohai oilfield. J. Shandong Inst. Pet. Chem. Technol. 2023, 7, 75–79. [Google Scholar]

- Zhang, S.; Guan, H.; Zhang, W. Research on operational parameters of gravel packing sand control completion for ultra-short multilateral Wells. J. Shandong Inst. Pet. Chem. Technol. 2024, 38, 77–83. [Google Scholar]

- Aragao, A.F.L.; Calderon, A.; Lomba, R.F.T.; Moreira, J.N.V.C.; de Sá, A.N.; Martins, A.L.; Quintero, L.; Moura, E. Field Implementation of Gravel Packing Horizontal Wells Using a Solids-Free Synthetic Fluid with Alpha/Beta Wave Technology. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007; SPE: Richardson, TX, USA, 2007. [Google Scholar]

- Thomas, D.G. A note on the viscosity of Newtonian suspensions of uniform spherical particles. J. Colloid Sci. 1965, 20, 267–277. [Google Scholar] [CrossRef]

- Hu, Z.-W. Theoretical study of prop-laden fluid flow resistance in hydraulic fracture. Nat. Gas Geosci. 2005, 16, 784–787. [Google Scholar]

- Kuang, J.; Wang, Z.; Dai, M. Review of coefficient of local resistance for pipe fittings in district cooling systems. Heat. Vent. Air Cond. 2022, 52, 88–95. [Google Scholar]

- Qin, H. Research on the local resistance coefficient of ventilation duct tees. Heat. Vent. Air Cond. 1980, 10–13. [Google Scholar] [CrossRef]

| Structure | Injection Rate/m3/min | Leakage/% | Sand Concentration/% | Packing Effectiveness/% |

|---|---|---|---|---|

| 6 m main bore with a 1 m, 30° lateral wellbore | 0.1 | 67 | 3 | 100 |

| 56 | 6 | 100 | ||

| 33 | 6 | 90.95 | ||

| 0.16 | 17 | 3 | 100 | |

| 11 | 6 | 100 | ||

| 10 | 6 | 100 | ||

| 0.2 | 7 | 3 | 100 | |

| 7 | 6 | 100 | ||

| 6 | 3 | 100 | ||

| 6 m main bore with a 1 m, 45° lateral wellbore | 0.1 | 26 | 3 | 85.49 |

| 27 | 6 | 86.93 | ||

| 0.16 | 12 | 3 | 95.05 | |

| 23 | 3 | 100 | ||

| 27 | 3 | 100 | ||

| 0.2 | 9 | 3 | 100 | |

| 12 | 6 | 100 | ||

| 17 | 3 | 100 | ||

| 16 | 6 | 100 |

| Structure | Injection Rate/m3/min | Leakage/% | Sand Concentration/% | Packing Effectiveness/% |

|---|---|---|---|---|

| 6 m main bore with a 2 m 30° lateral wellbore | 0.1 | 10 | 3 | 89.59 |

| 10 | 6 | 82.73 | ||

| 31 | 3 | 93.74 | ||

| 23 | 6 | 93.62 | ||

| 0.16 | 11 | 3 | 100 | |

| 10 | 6 | 96.24 | ||

| 28 | 3 | 100 | ||

| 26 | 6 | 100 | ||

| 0.2 | 12 | 3 | 100 | |

| 8 | 3 | 100 |

| Structure | Injection Rate/m3/min | Leakage/% | Sand Concentration/% | Packing Effectiveness/% |

|---|---|---|---|---|

| dual lateral well configuration | 0.1 | 30 | 3 | 85.71 |

| 10 | dynamic: 3-1 | 85.29 | ||

| 0.2 | 22 | dynamic: 3-1 | 100 | |

| 11 | dynamic: 1.5-1 | 100 |

| Structure | Injection Rate/m3/min | Leakage/% | Sand Concentration/% | Packing Efficiency/% | End-of-Packing Pressure/MPa |

|---|---|---|---|---|---|

| 6 m main bore with a 1 m, 30° lateral wellbore | 0.1 | 67 | 3 | 100 | 0.082 |

| 56 | 6 | 100 | 0.104 | ||

| 33 | 6 | 90.95 | 0.094 | ||

| 0.16 | 17 | 3 | 100 | 0.205 | |

| 11 | 6 | 100 | 0.185 | ||

| 10 | 6 | 100 | 0.225 | ||

| 0.2 | 7 | 3 | 100 | 0.142 | |

| 7 | 6 | 100 | 0.163 | ||

| 6 | 3 | 100 | 0.249 | ||

| 6 m main bore with a 1 m, 45° lateral wellbore | 0.1 | 26 | 3 | 85.49 | 0.022 |

| 27 | 6 | 86.93 | 0.059 | ||

| 0.16 | 12 | 3 | 95.05 | 0.119 | |

| 23 | 3 | 100 | 0.225 | ||

| 27 | 3 | 100 | 0.232 | ||

| 0.2 | 9 | 3 | 100 | 0.260 | |

| 12 | 6 | 100 | 0.227 | ||

| 17 | 3 | 100 | 0.285 | ||

| 16 | 6 | 100 | 0.310 | ||

| 6 m main bore with a 2 m, 30° lateral wellbore | 0.1 | 10 | 3 | 89.59 | 0.145 |

| 10 | 6 | 82.73 | 0.080 | ||

| 31 | 3 | 93.74 | 0.154 | ||

| 23 | 6 | 93.62 | 0.190 | ||

| 0.16 | 11 | 3 | 100 | 0.320 | |

| 10 | 6 | 96.24 | 0.363 | ||

| 28 | 3 | 100 | 0.334 | ||

| 26 | 6 | 100 | 0.341 | ||

| 0.2 | 12 | 3 | 100 | 0.297 | |

| 8 | 3 | 100 | 0.429 | ||

| 6 m main bore with a 1 m, 45° and 2 m, 30° lateral wellbores | 0.1 | 30 | 3 | 85.71 | 0.052 |

| 10 | dynamic: 3-1 | 85.29 | 0.045 | ||

| 0.2 | 22 | dynamic: 3-1 | 100 | 0.290 | |

| 11 | dynamic: 1.5-1 | 100 | 0.219 |

| Laboratory Model (6 m Main Bore with 1 m, 30° Lateral Wellbore) | Field Prototype (480 m Main Bore with 200 m, 30° Lateral Wellbore) | |||||||

|---|---|---|---|---|---|---|---|---|

| D/m | Q/m3/min | L/m | d/m | P/MPa | D/m | Q/m3/min | P/MPa | d/m |

| 0.1778 | 0.1 | 6 | 2 | 0.082 | 0.2445 | 1.69 | 6.56 | 160 |

| 0.104 | 8.32 | |||||||

| 0.16 | 0.205 | 2.71 | 16.40 | |||||

| 0.185 | 14.80 | |||||||

| 0.225 | 18.00 | |||||||

| 0.2 | 0.142 | 3.38 | 11.36 | |||||

| 0.163 | 13.04 | |||||||

| 0.249 | 19.92 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, P.; Wang, Z.; Guan, L.; Du, W.; Li, Z.; Zhang, J. Experimental Study on Ultra-Light Sand Packing in Multi-Lateral Horizontal Well for Natural Gas Hydrate Reservoirs. Sustainability 2025, 17, 8563. https://doi.org/10.3390/su17198563

Ji P, Wang Z, Guan L, Du W, Li Z, Zhang J. Experimental Study on Ultra-Light Sand Packing in Multi-Lateral Horizontal Well for Natural Gas Hydrate Reservoirs. Sustainability. 2025; 17(19):8563. https://doi.org/10.3390/su17198563

Chicago/Turabian StyleJi, Peng, Zhiyuan Wang, Liyong Guan, Weigang Du, Zeqin Li, and Jianbo Zhang. 2025. "Experimental Study on Ultra-Light Sand Packing in Multi-Lateral Horizontal Well for Natural Gas Hydrate Reservoirs" Sustainability 17, no. 19: 8563. https://doi.org/10.3390/su17198563

APA StyleJi, P., Wang, Z., Guan, L., Du, W., Li, Z., & Zhang, J. (2025). Experimental Study on Ultra-Light Sand Packing in Multi-Lateral Horizontal Well for Natural Gas Hydrate Reservoirs. Sustainability, 17(19), 8563. https://doi.org/10.3390/su17198563