The Productivity Paradox: How Sustainable Supply Chain Management Mediates the Link Between Enablers and Productivity

Abstract

1. Introduction

- Theory Insights: This research has extended the application of DOI theory beyond the traditional innovation-focused sectors into the pharmaceutical supply chain, aligning with a novel theoretical lens to understand how sustainability-enabling factors diffuse and interact within complex industry ecosystems.

- Industry Insights: This study plays a crucial role in industry-specific dynamics, organizational capacity, and regulatory environments in cases of shaping innovation adoption in resource-constrained economies, aligning with calls from different scholars for more embedded, context-sensitive applications of DOI [22,23].

- Managerial Insights: Similarly, this study brings practical insights to pharmaceutical supply chain managers and policymakers by identifying SSCM practices as the key pathway linking strategic enablers to productivity. In addition, it shows that investments in policy, technology, finance, and human resources only improve firm performance when embedded within sustainable practices.

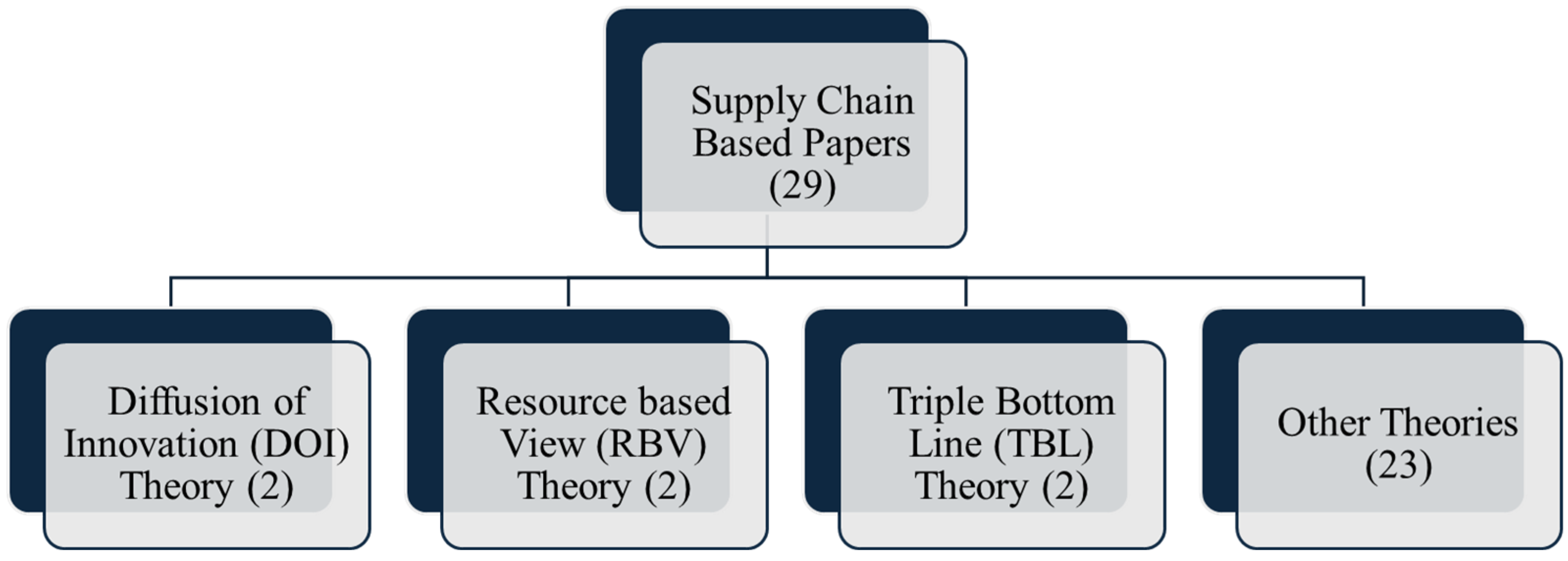

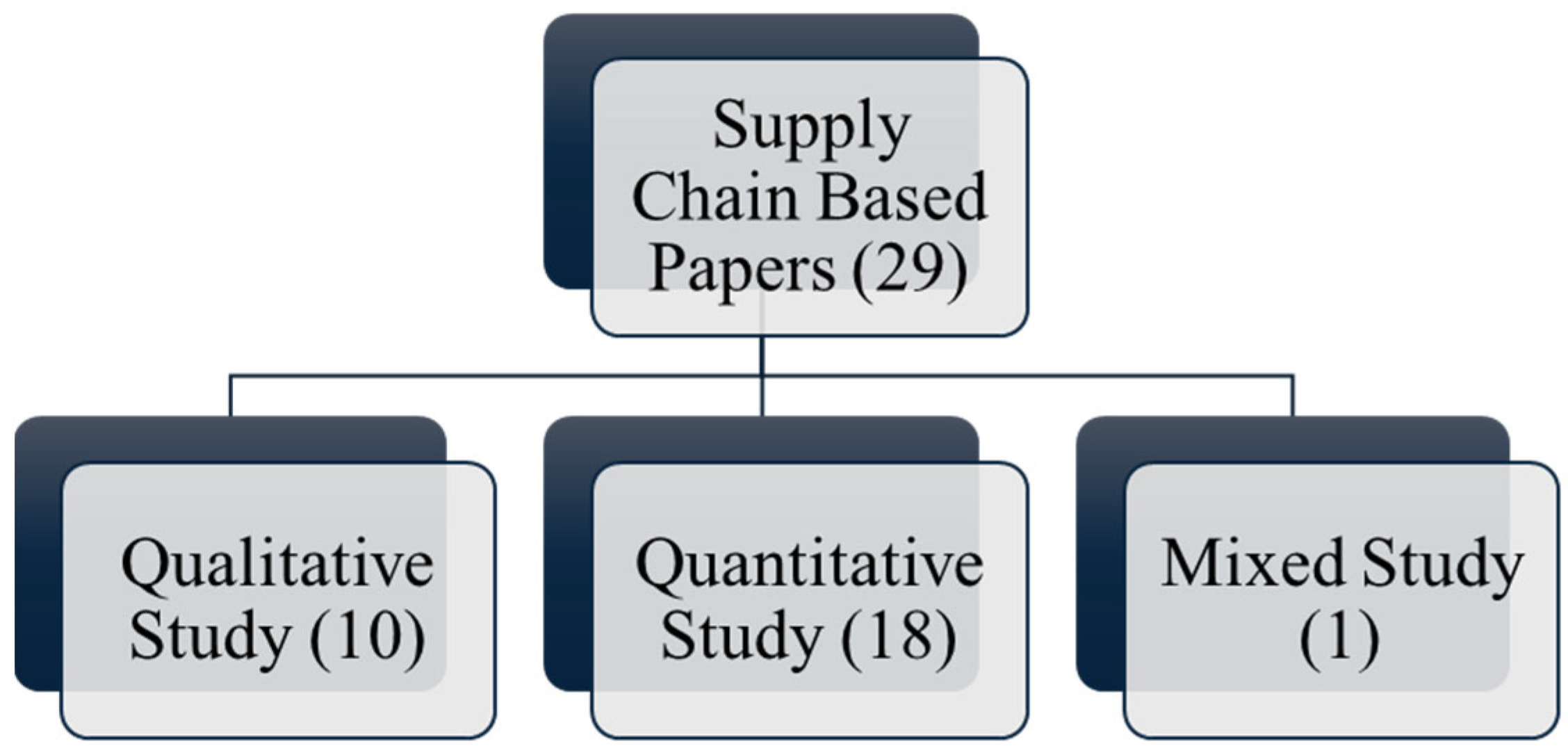

2. Literature Review

2.1. Theoretical Lens and Sustainable Supply Chain Management (SSCM) Enablers and Productivity

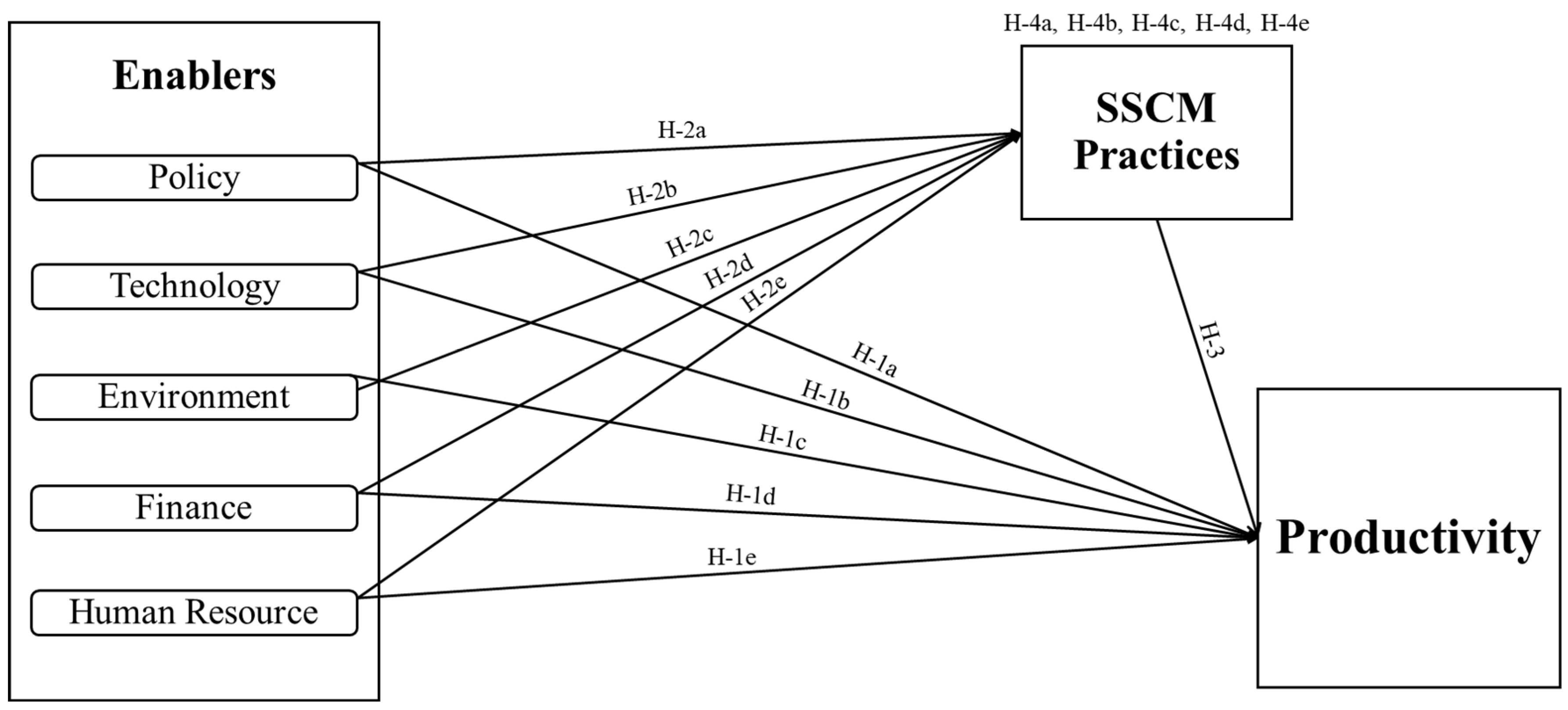

2.2. Development of Hypothesis

2.2.1. Policy Category Enabler

2.2.2. Technology Category Enabler

2.2.3. Environment Category Enabler

2.2.4. Finance Category Enabler

2.2.5. Human Resource Category Enabler

2.3. SSCM Practices as Mediator

2.4. Conceptual Framework

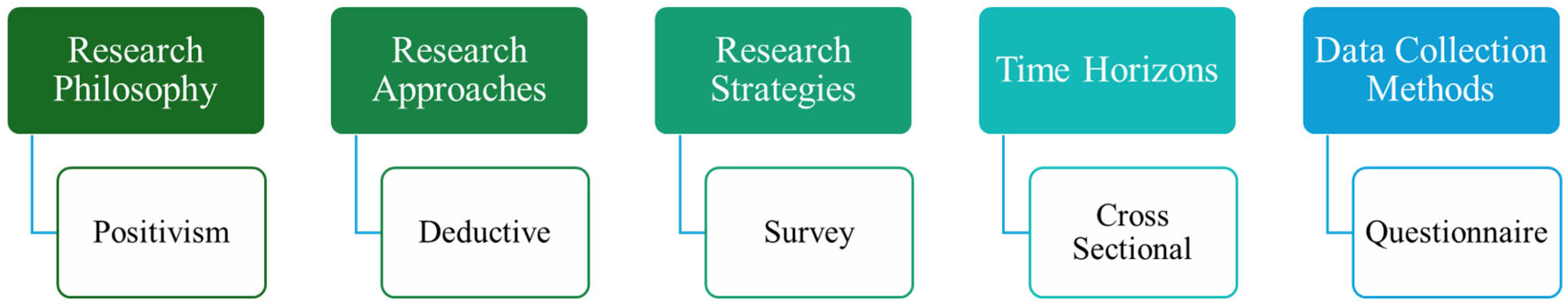

3. Materials and Methods

3.1. Instrument Design

3.2. Pre-Test, Pilot Survey, and Validation of Research Instrument

3.3. Sample and Data Collection with Regression Model

4. Results

4.1. Analysis of the Measurement Model

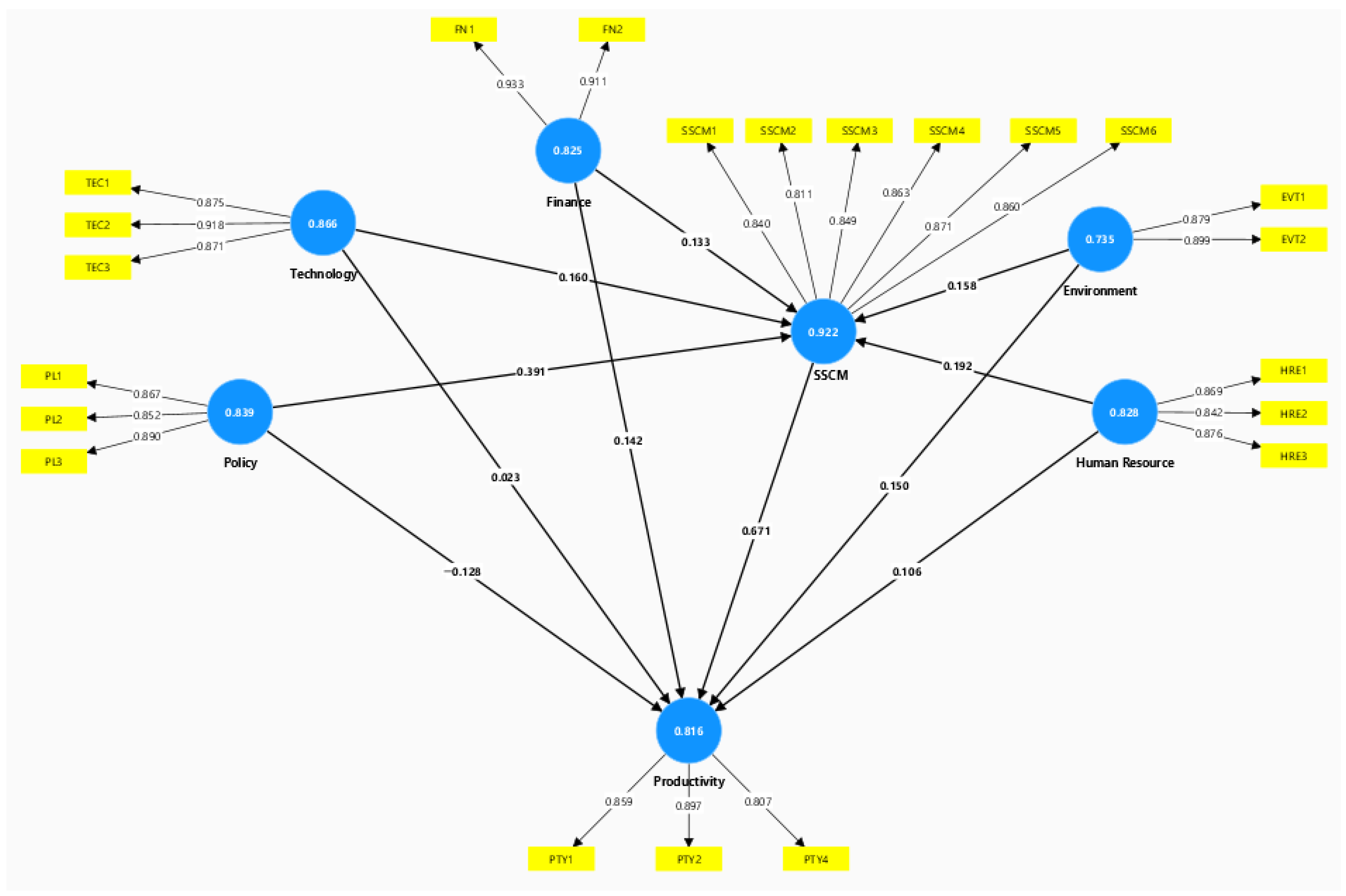

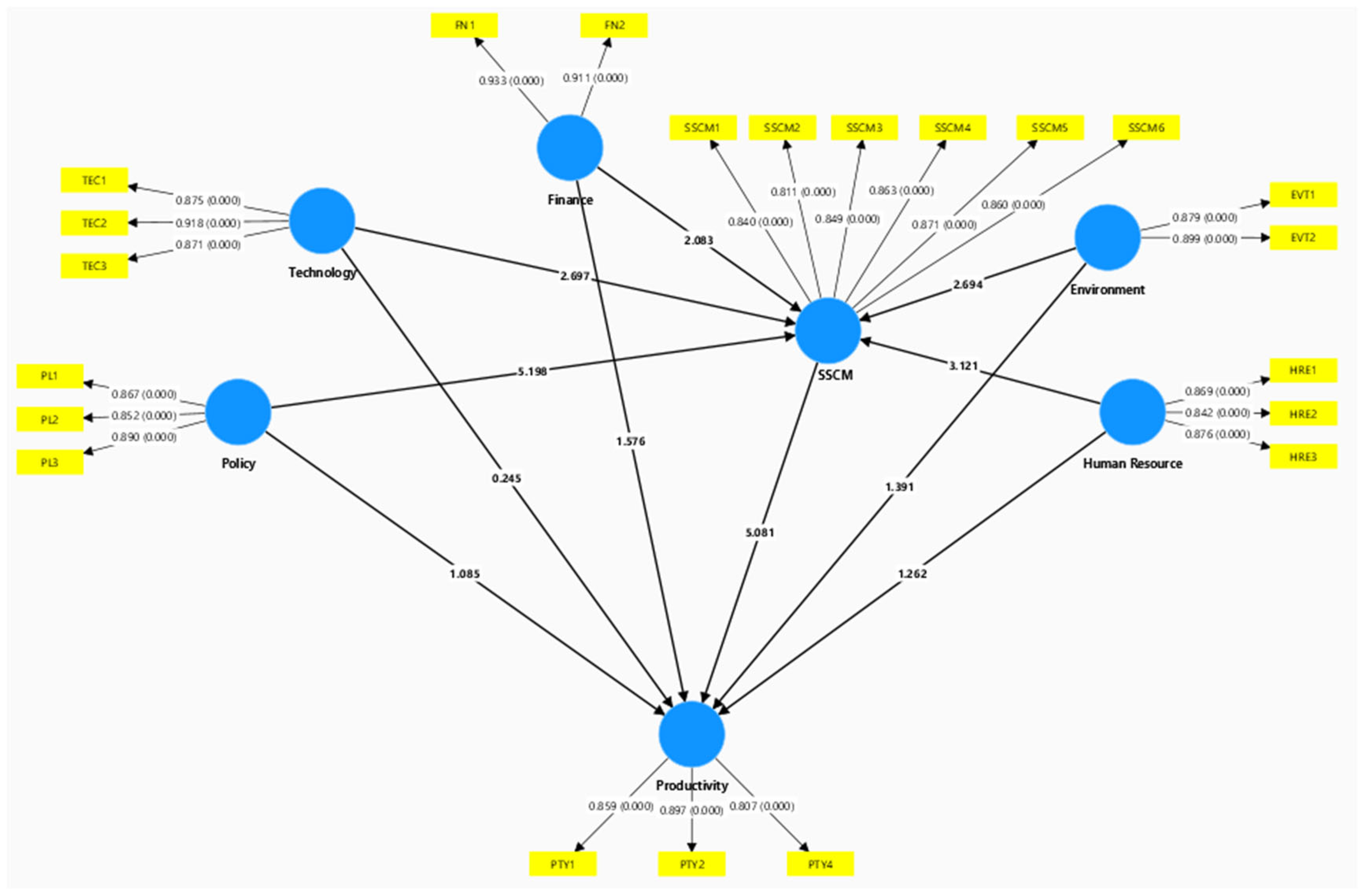

4.2. Analysis of the Structural Model

5. Discussion

6. Contribution, Limitations, and Future Areas

6.1. Theoretical Contribution

6.2. Contribution to the Industry

6.3. Limitations and Future Areas of the Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SSCM | Sustainable Supply Chain Management |

| SCM | Supply Chain Management |

| DOI | Diffusion of Innovation |

| RBV | Resource-Based View |

| TBL | Triple Bottom Line |

| GDP | Gross Domestic Product |

| KMO | Kaiser–Meyer–Olkin (Test) |

| VIF | Variance Inflation Factor |

| SPSS | Statistical Package for the Social Sciences |

| PLS | Partial Least Squares |

| SEM | Structural Equation Modeling |

| HTMT | Heterotrait–Monotrait Ratio |

| AVE | Average Variance Extracted |

| CR | Composite Reliability |

| PL | Policy |

| TEC | Technology |

| EVT | Environment |

| FN | Finance |

References

- Menon, R.R.; Ravi, V. Analysis of enablers of sustainable supply chain management in electronics industries: The Indian context. Clean. Eng. Technol. 2021, 5, 100302. [Google Scholar] [CrossRef]

- Razzak, M.R. Mediating effect of productivity between sustainable supply chain management practices and competitive advantage: Evidence from apparel manufacturing in Bangladesh. Manag. Environ. Qual. Int. J. 2023, 34, 428–445. [Google Scholar] [CrossRef]

- Uddin, M.H.; Razzak, M.R.; Rahman, A.A. Sustainable supply chain management practices, dynamic capabilities and competitive advantage: Evidence from Bangladesh READY-MADE garments industry. Bus. Strategy Dev. 2023, 6, 176–188. [Google Scholar] [CrossRef]

- Nishat, M. Faisal Sustainable supply chains: A study of interaction among the enablers. Bus. Process Manag. J. 2010, 16, 508–529. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of Ten Exemplars. J. Supply Chain Manag. 2009, 45, 37–56. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, L.; Feng, L.; Feng, J. A meta-analysis of sustainable supply chain management and firm performance: Some new findings on sustainable supply chain management. Sustain. Prod. Consum. 2023, 38, 312–330. [Google Scholar] [CrossRef]

- Sancha, C.; Longoni, A.; Giménez, C. Sustainable supplier development practices: Drivers and enablers in a global context. J. Purch. Supply Manag. 2015, 21, 95–102. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, V.; Kumar, S.; Haleem, A. Barriers to implement green supply chain management in automobile industry using interpretive structural modeling technique: An Indian perspective. J. Ind. Eng. Manag. 2011, 4, 231–257. [Google Scholar] [CrossRef]

- Qorri, A.; Mujkić, Z.; Kraslawski, A. A conceptual framework for measuring sustainability performance of supply chains. J. Clean. Prod. 2018, 189, 570–584. [Google Scholar] [CrossRef]

- Jabber, M.A.; Islam, M.T.; Hossain, T.; Sultana, R. Unveiling the power of enablers in enacting sustainable supply chain management practices. Clean. Logist. Supply Chain 2024, 13, 100190. [Google Scholar] [CrossRef]

- Hsu, C.; Tan, K.C.; Zailani, S.H.M.; Jayaraman, V. Supply chain drivers that foster the development of green initiatives in an emerging economy. Int. J. Oper. Prod. Manag. 2013, 33, 656–688. [Google Scholar] [CrossRef]

- Oelze, N. Sustainable Supply Chain Management Implementation–Enablers and Barriers in the Textile Industry. Sustainability 2017, 9, 1435. [Google Scholar] [CrossRef]

- Das, S.; Hassan, H.M.K. Impact of sustainable supply chain management and customer relationship management on organizational performance. Int. J. Product. Perform. Manag. 2022, 71, 2140–2160. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. Int. J. Prod. Econ. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Rambe, P.; Khaola, P. The impact of innovation on agribusiness competitiveness: The mediating role of technology transfer and productivity. Eur. J. Innov. Manag. 2022, 25, 741–773. [Google Scholar] [CrossRef]

- Kreuser, C.F.; Newman, C. Total Factor Productivity in South African Manufacturing Firms. S. Afr. J. Econ. 2018, 86, 40–78. [Google Scholar] [CrossRef]

- Varsei, M.; Soosay, C.; Fahimnia, B.; Sarkis, J. Framing sustainability performance of supply chains with multidimensional indicators. Supply Chain Manag. Int. J. 2014, 19, 242–257. [Google Scholar] [CrossRef]

- Laghouag, A. The maturity of sustainable supply chain management practices: An applied study on pharmaceutical firms. J. Money Bus. 2023, 3, 237–249. [Google Scholar] [CrossRef]

- Khanam, Z.; Ghosh, R. Impact of sustainable supply chain management on cost performance: Empirical evidence from manufacturing companies of Bangladesh. J. Econ. Adm. Sci. 2025, 41, 570–591. [Google Scholar] [CrossRef]

- Ding, H.; Fu, Y.; Zheng, L.; Yan, Z. Determinants of the competitive advantage of dairy supply chains: Evidence from the Chinese dairy industry. Int. J. Prod. Econ. 2019, 209, 360–373. [Google Scholar] [CrossRef]

- Zhu, Q.; Tian, Y.; Sarkis, J. Diffusion of selected green supply chain management practices: An assessment of Chinese enterprises. Prod. Plan. Control 2012, 23, 837–850. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations. J. Pharm. Sci. 1963, 52, 612. [Google Scholar] [CrossRef]

- Ali, I.M.A.; Attiaoui, I.; Khalfaoui, R.; Tiwari, A.K. The Effect of Urbanization and Industrialization on Income Inequality: An Analysis Based on the Method of Moments Quantile Regression. Soc. Indic. Res. 2022, 161, 29–50. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G.; Zhang, T. Governance pressures and performance outcomes of sustainable supply chain management—An empirical analysis of UK manufacturing industry. J. Clean. Prod. 2017, 155, 66–78. [Google Scholar] [CrossRef]

- Turker, D.; Altuntas, C. Sustainable supply chain management in the fast fashion industry: An analysis of corporate reports. Eur. Manag. J. 2014, 32, 837–849. [Google Scholar] [CrossRef]

- Benhabib, J.; Perla, J.; Tonetti, C. Reconciling Models of Diffusion and Innovation: A Theory of the Productivity Distribution and Technology Frontier. Econometrica 2021, 89, 2261–2301. [Google Scholar] [CrossRef]

- Okour, M.K.; Chong, C.W.; Fattah, F.A.M.A. Knowledge management systems usage: Application of diffusion of innovation theory. Glob. Knowl. Mem. Commun. 2021, 70, 756–776. [Google Scholar] [CrossRef]

- Asche, F.; Roll, K.H.; Tveteras, R. Productivity Growth in the Supply Chain—Another Source of Competitiveness for Aquaculture. Mar. Resour. Econ. 2007, 22, 329–334. [Google Scholar] [CrossRef]

- Blalock, G.; Veloso, F.M. Imports, Productivity Growth, and Supply Chain Learning. World Dev. 2007, 35, 1134–1151. [Google Scholar] [CrossRef]

- Serpa, J.C.; Krishnan, H. The Impact of Supply Chains on Firm-Level Productivity. Manag. Sci. 2018, 64, 511–532. [Google Scholar] [CrossRef]

- Sharma, M.; Alkatheeri, H.; Jabeen, F.; Sehrawat, R. Impact of COVID-19 pandemic on perishable food supply chain management: A contingent Resource-Based View (RBV) perspective. Int. J. Logist. Manag. 2022, 33, 796–817. [Google Scholar] [CrossRef]

- Chae, B.; Olson, D.; Sheu, C. The impact of supply chain analytics on operational performance: A resource-based view. Int. J. Prod. Res. 2014, 52, 4695–4710. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Jacobs, M.A.; Feng, M. Data-driven supply chain capabilities and performance: A resource-based view. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 371–385. [Google Scholar] [CrossRef]

- Yang, Y.; Jia, F.; Xu, Z. Towards an integrated conceptual model of supply chain learning: An extended resource-based view. Supply Chain Manag. Int. J. 2019, 24, 189–214. [Google Scholar] [CrossRef]

- Xu, D.; Huo, B.; Sun, L. Relationships between intra-organizational resources, supply chain integration and business performance: An extended resource-based view. Ind. Manag. Data Syst. 2014, 114, 1186–1206. [Google Scholar] [CrossRef]

- Marimin; Darmawan, M.A.; Machfud; Putra, M.P.I.F.; Wiguna, B. Value chain analysis for green productivity improvement in the natural rubber supply chain: A case study. J. Clean. Prod. 2014, 85, 201–211. [Google Scholar] [CrossRef]

- Nagurney, A. Optimization of investments in labor productivity in supply chain networks. Int. Trans. Oper. Res. 2022, 29, 2116–2144. [Google Scholar] [CrossRef]

- Wu, C.K.; Tsang, K.F.; Liu, Y.; Zhu, H.; Wei, Y.; Wang, H.; Yu, T.T. Supply Chain of Things: A Connected Solution to Enhance Supply Chain Productivity. IEEE Commun. Mag. 2019, 57, 78–83. [Google Scholar] [CrossRef]

- Munny, A.A.; Ali, S.M.; Kabir, G.; Moktadir, M.A.; Rahman, T.; Mahtab, Z. Enablers of social sustainability in the supply chain: An example of footwear industry from an emerging economy. Sustain. Prod. Consum. 2019, 20, 230–242. [Google Scholar] [CrossRef]

- Vargas, J.R.C.; Mantilla, C.E.M.; De Sousa Jabbour, A.B.L. Enablers of sustainable supply chain management and its effect on competitive advantage in the Colombian context. Resour. Conserv. Recycl. 2018, 139, 237–250. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z. Sustainability adoption through buyer supplier relationship across supply chain: A literature review and conceptual framework. Int. Strateg. Manag. Rev. 2015, 3, 110–127. [Google Scholar] [CrossRef]

- Gupta, H.; Kusi-Sarpong, S.; Rezaei, J. Barriers and overcoming strategies to supply chain sustainability innovation. Resour. Conserv. Recycl. 2020, 161, 104819. [Google Scholar] [CrossRef]

- Bai, C.; Satir, A.; Sarkis, J. Investing in lean manufacturing practices: An environmental and operational perspective. Int. J. Prod. Res. 2019, 57, 1037–1051. [Google Scholar] [CrossRef]

- Chkanikova, O.; Mont, O. Corporate Supply Chain Responsibility: Drivers and Barriers for Sustainable Food Retailing. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 65–82. [Google Scholar] [CrossRef]

- Wickramasinghe, G.L.D.; Wickramasinghe, V. Implementation of lean production practices and manufacturing performance: The role of lean duration. J. Manuf. Technol. Manag. 2017, 28, 531–550. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Duque-Uribe, V.; Sarache, W.; Gutiérrez, E.V. Sustainable Supply Chain Management Practices and Sustainable Performance in Hospitals: A Systematic Review and Integrative Framework. Sustainability 2019, 11, 5949. [Google Scholar] [CrossRef]

- Burki, U.; Ersoy, P.; Dahlstrom, R. Achieving triple bottom line performance in manufacturer-customer supply chains: Evidence from an emerging economy. J. Clean. Prod. 2018, 197, 1307–1316. [Google Scholar] [CrossRef]

- Harikannan, N.; Vinodh, S.; Gurumurthy, A. Sustainable industry 4.0—An exploratory study for uncovering the drivers for integration. J. Model. Manag. 2021, 16, 357–376. [Google Scholar] [CrossRef]

- Muduli, K.; Barve, A. Sustainable development practices in mining sector: A GSCM approach. Int. J. Environ. Sustain. Dev. 2013, 12, 222. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Dora, M.; Liu, M. Big Data Analytics as a mediator in Lean, Agile, Resilient, and Green (LARG) practices effects on sustainable supply chains. Transp. Res. Part E Logist. Transp. Rev. 2021, 145, 102170. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green Supply Chain Management, Environmental Collaboration and Sustainability Performance. Procedia CIRP 2015, 26, 695–699. [Google Scholar] [CrossRef]

- Sarkar, A.N. Green Branding and Eco-Innovations for Evolving a Sustainable Green Marketing Strategy. Asia-Pac. J. Manag. Res. Innov. 2012, 8, 39–58. [Google Scholar] [CrossRef]

- Soomro, R.B.; Mirani, I.A.; Ali, M.S.; Marvi, S. Exploring the green purchasing behavior of young generation in Pakistan: Opportunities for green entrepreneurship. Asia Pac. J. Innov. Entrep. 2020, 14, 289–302. [Google Scholar] [CrossRef]

- Madsen, H.; Ulhøi, J.P. Greening of human resources: Environmental awareness and training interests within the workforce. Ind. Manag. Data Syst. 2001, 101, 57–65. [Google Scholar] [CrossRef]

- Alamgir, F.; Banerjee, S.B. Contested compliance regimes in global production networks: Insights from the Bangladesh garment industry. Hum. Relat. 2019, 72, 272–297. [Google Scholar] [CrossRef]

- Maier, C.; Thatcher, J.B.; Grover, V.; Dwivedi, Y.K. Cross-sectional research: A critical perspective, use cases, and recommendations for IS research. Int. J. Inf. Manag. 2023, 70, 102625. [Google Scholar] [CrossRef]

- Rindfleisch, A.; Malter, A.J.; Ganesan, S.; Moorman, C. Cross-Sectional Versus Longitudinal Survey Research: Concepts, Findings, and Guidelines. J. Mark. Res. 2008, 45, 261–279. [Google Scholar] [CrossRef]

- Hair, J.F.; Money, A.H.; Samouel, P.; Page, M. Research Methods for Business. Educ. Train. 2007, 49, 336–337. [Google Scholar] [CrossRef]

- Saunders, J.; Wong, V.; Saunders, C. The Research Evaluation and Globalization of Business Research. Br. J. Manag. 2011, 22, 401–419. [Google Scholar] [CrossRef]

- Tanujaya, B.; Prahmana, R.; Mumu, J. Likert Scale in Social Sciences Research: Problems and Difficulties. FWU J. Soc. Sci. 2023, 16, 89–101. [Google Scholar] [CrossRef]

- Dawes, J. Do Data Characteristics Change According to the Number of Scale Points Used? An Experiment Using 5-Point, 7-Point and 10-Point Scales. Int. J. Mark. Res. 2008, 50, 61–104. [Google Scholar] [CrossRef]

- Jebb, A.T.; Ng, V.; Tay, L. A Review of Key Likert Scale Development Advances: 1995–2019. Front. Psychol. 2021, 12, 637547. [Google Scholar] [CrossRef]

- Bowden, A. Methods for pre-testing and piloting survey questions: Illustrations from the KENQOL survey of health-related quality of life. Health Policy Plan. 2002, 17, 322–330. [Google Scholar] [CrossRef]

- Rutten, G.M.; Harting, J.; Bartholomew, L.K.; Schlief, A.; Oostendorp, R.A.; De Vries, N.K. Evaluation of the theory-based Quality Improvement in Physical Therapy (QUIP) programme: A one-group, pre-test post-test pilot study. BMC Health Serv. Res. 2013, 13, 194. [Google Scholar] [CrossRef]

- Abbas, Z.; Sarwar, S.; Rehman, M.A.; Zámečník, R.; Shoaib, M. Green HRM promotes higher education sustainability: A mediated-moderated analysis. Int. J. Manpow. 2022, 43, 827–843. [Google Scholar] [CrossRef]

- Hair, J.; Alamer, A. Partial Least Squares Structural Equation Modeling (PLS-SEM) in second language and education research: Guidelines using an applied example. Res. Methods Appl. Linguist. 2022, 1, 100027. [Google Scholar] [CrossRef]

- Kock, N. Common Method Bias in PLS-SEM: A Full Collinearity Assessment Approach. Int. J. E-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Nulty, D.D. The adequacy of response rates to online and paper surveys: What can be done? Assess. Eval. High. Educ. 2008, 33, 301–314. [Google Scholar] [CrossRef]

- Parker, C.; Scott, S.; Geddes, A. Snowball Sampling. In Sage Research Methods Foundations; SAGE Publications Ltd.: London, UK, 2019; pp. 1–13. Available online: http://methods.sagepub.com/foundations/snowball-sampling (accessed on 12 April 2025).

- Kang, H. Sample size determination and power analysis using the G*Power software. J. Educ. Eval. Health Prof. 2021, 18, 17. [Google Scholar] [CrossRef] [PubMed]

- Lakens, D. Sample Size Justification. Collabra Psychol. 2022, 8, 33267. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef]

- Cheah, J.-H.; Sarstedt, M.; Ringle, C.M.; Ramayah, T.; Ting, H. Convergent validity assessment of formatively measured constructs in PLS-SEM: On using single-item versus multi-item measures in redundancy analyses. Int. J. Contemp. Hosp. Manag. 2018, 30, 3192–3210. [Google Scholar] [CrossRef]

- Hair, J.F.; Howard, M.C.; Nitzl, C. Assessing measurement model quality in PLS-SEM using confirmatory composite analysis. J. Bus. Res. 2020, 109, 101–110. [Google Scholar] [CrossRef]

- Magno, F.; Cassia, F.; Ringle, C.M. A brief review of partial least squares structural equation modeling (PLS-SEM) use in quality management studies. TQM J. 2024, 36, 1242–1251. [Google Scholar] [CrossRef]

- Emon, M.M.H.; Khan, T. The transformative role of Industry 4.0 in supply chains: Exploring digital integration and innovation in the manufacturing enterprises. J. Open Innov. Technol. Mark. Complex. 2025, 11, 100516. [Google Scholar] [CrossRef]

- Espahbod, S.; Tashakkori, A.; Mohsenibeigzadeh, M.; Zarei, M.; Arani, G.G.; Dzikuć, M.; Dzikuć, M. Blockchain-Driven Supply Chain Analytics and Sustainable Performance: Analysis Using PLS-SEM and ANFIS. Sustainability 2024, 16, 6469. [Google Scholar] [CrossRef]

- Roemer, E.; Schuberth, F.; Henseler, J. HTMT2—An improved criterion for assessing discriminant validity in structural equation modeling. Ind. Manag. Data Syst. 2021, 121, 2637–2650. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Min, H.; Park, J.; Kim, H.J. Common method bias in hospitality research: A critical review of literature and an empirical study. Int. J. Hosp. Manag. 2016, 56, 126–135. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Podsakoff, N.P.; Williams, L.J.; Huang, C.; Yang, J. Common Method Bias: It’s Bad, It’s Complex, It’s Widespread, and It’s Not Easy to Fix. Annu. Rev. Organ. Psychol. Organ. Behav. 2024, 11, 17–61. [Google Scholar] [CrossRef]

- Kock, F.; Berbekova, A.; Assaf, A.G. Understanding and managing the threat of common method bias: Detection, prevention and control. Tour. Manag. 2021, 86, 104330. [Google Scholar] [CrossRef]

- Bilal, M.A.; Khan, H.H.; Irfan, M.; Ul Haq, S.M.; Ali, M.; Kakar, A.; Ahmed, W.; Rauf, A. Influence of Financial Literacy and Educational Skills on Entrepreneurial Intent: Empirical Evidence from Young Entrepreneurs of Pakistan. J. Asian Financ. Econ. Bus. 2021, 8, 697–710. [Google Scholar] [CrossRef]

- Sauer, P.C.; Seuring, S. Sustainable supply chain management for minerals. J. Clean. Prod. 2017, 151, 235–249. [Google Scholar] [CrossRef]

- CCarter, R.; Liane Easton, P. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Gao, J. R-Squared (R2)—How much variation is explained? Res. Methods Med. Health Sci. 2024, 5, 104–109. [Google Scholar] [CrossRef]

- Ozili, P.K. The Acceptable R-Square in Empirical Modelling for Social Science Research. In Advances in Knowledge Acquisition, Transfer, and Management; Saliya, C.A., Ed.; IGI Global: Hershey, PA, USA, 2023; pp. 134–143. [Google Scholar] [CrossRef]

- Kalnins, A.; Praitis, K. Hill The VIF Score. What is it Good For? Absolutely Nothing. Organ. Res. Methods 2025, 28, 58–75. [Google Scholar] [CrossRef]

- Kyriazos, T.; Poga, M. Dealing with Multicollinearity in Factor Analysis: The Problem, Detections, and Solutions. Open J. Stat. 2023, 13, 404–424. [Google Scholar] [CrossRef]

- Rehman, F.U.; Al-Ghazali, B.M.; Haddad, A.G.; Qahwash, E.A.; Sohail, M.S. Exploring the Reverse Relationship Between Circular Economy Innovation and Digital Sustainability—The Dual Mediation of Government Incentives. Sustainability 2023, 15, 5181. [Google Scholar] [CrossRef]

- Islam, A.; Ghosh, R.; Hamid, M.K.; Kabir, S. Unveiling the impact of sustainable manufacturing on triple bottom line sustainability performance: A Bangladesh perspective. Glob. Knowl. Mem. Commun. 2024, 1–20. [Google Scholar] [CrossRef]

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management—A textile case. J. Clean. Prod. 2014, 83, 391–403. [Google Scholar] [CrossRef]

| Authors | Theory | Objective | Industry | Country Name and Type | Findings |

|---|---|---|---|---|---|

| [10] | Diffusion of Innovation (DOI) | To construct a conceptual model using the DOI theoretical framework, fitting enablers such as policy, technology, environment, human resource, and finance into DOI theory. | RMG | Bangladesh (Developing) | The study found that the environment and policy enablers have influenced SSCM significantly, while finance, technology, and HR enablers are found to be non-significant because of the lack of fund and resource availability for the adoption of technology in developing country context. |

| [4] | N/A | To adapt SSCM by analyzing the interactions among various enablers to convert the SC into a fully sustainable system. | Not Specified | Gulf (Developed) | According to the findings, some enablers of SSCM had a higher power of driving and lower dependence. And so, researchers needed a strategic focus on them, while some of the enablers had a high dependence. |

| [2] | Resource-Based View (RBV) | To integrate the dual theoretical framework of the SSCM practices view and RBV to develop a set of hypotheses concerning the environmental, social, and economic dimensions of SSCM sustainability practices’ effect on productivity and CA. | Export-oriented Fashion–Apparel Manufacturing | Bangladesh (Developing) | The study has found a direct relationship among the enablers of SSCM practices (social sustainability dimensions) and an organization’s competitive advantages, while economic and environmental SSCM were found as non-significant. Meanwhile, the mediating role of productivity found that social, economic, and environmental SSCM had a significant relationship with competitive advantages. |

| [42] | N/A | To find out the enablers of social sustainability in SC. | Leather | Bangladesh (Developing) | The findings suggest that safety and health practices within the workplace can be a significant factor for achieving SSC goals, closely considering the significance of wages and benefits for employees. |

| [1] | N/A | To analyze the critical success factors in SC that leverage sustainability. | Electronic | India (Developing) | This study concluded that government legislations and policies are significant enablers of SSCM. Here, the policy enabler had a significant impact on the other variables. |

| [43] | Resource-Based View (RBV) | To explore the impact that top/middle management support and purchasing strategy have on SSCM practices, as well as its influence on competitive advantage. | Not Specified | Colombia (Developing) | According to the study, the support of top and mid-level management was necessary to adopt SSCM practices. Organizations can obtain competitive advantages and enhance their capacity with the use of Social Supply Chain Practices. |

| [44] | N/A | To investigate the enablers which are effective for the implementation of SSCM. | Textile | Germany. Sweden, Norway, America, Canada (Developed) | The study found that the effectiveness of SSCM needed to be integrated with corporate strategies and organizational objectives and achieved by the goals of departments. However, key factors included informational connection and cross-functional teams for SSCM. |

| Enablers | Items | Adoption of DOI Theory | Sources |

|---|---|---|---|

| Policy | Commitment of Top-Level Management | Compatibility | [1,7,10,47,48,49,50] |

| Safety and Health Guidelines | |||

| Regulatory Policies by Government | |||

| Technology | Innovation and Development through Research | Relative advantage | |

| Intelligence Usage on Technologies, Resources, and Processes | |||

| Lean-Manufacturing Usage | |||

| Environment | Eco-Friendly Labeling and Packaging | Trialability | |

| Reverse Supply Chain Usage | |||

| Eco-friendly Collaboration | |||

| Finance | Sustainable Purchasing | Complexity | |

| Adequate Funding | |||

| Human Resource | Training | Observability | |

| Specialized Human Knowledge | |||

| Cultural Influences Adoption |

| Indicators | Sources | |

|---|---|---|

| Productivity | Capacity Utilization System | [2,15,16,52] |

| Level of Financial Productivity | ||

| Extent of Market Growth | ||

| Extent of Market Productivity Reputation |

| Indicators | References | |

|---|---|---|

| SSCM | Waste Minimization | [1,10,11,47,54] |

| Contamination Reduction | ||

| Energy Optimization | ||

| Working Environment | ||

| Cost Minimization | ||

| Competitive Advantage and Operational Efficiency |

| Designation | Qualification | Experience (In Years) |

|---|---|---|

| Professor | Ph.D. in Sustainable Supply Chain Management | 18 |

| Assistant Professor | Ph.D. in Pharmaceutical Supply Chain | 11 |

| Associate Professor | Ph.D. in Operations and Supply Chain Strategy | 12 |

| Head of Procurement and Logistics | BBA and MBA in Supply Chain Management | 8 |

| Managing Director (Pharma) | BBA and MBA in Pharmaceutical Management | 8 |

| Supply Chain Manager | BSc in Industrial and Production Engineering | 11 |

| Planning and Regulatory Manager | BSc in Pharmaceutical Engineering | 10 |

| Step | Analysis | Formula |

|---|---|---|

| Step 1 | Conduct a simple regression analysis with X predicting Y to test for path c alone, Y = β0 + β1X + ϵ | Productivity = β0 + β1 × Policy + β2 × Technology + β3 × Environment + β4 × Finance + β5 × Human Resource + ϵ |

| Step 2 | Conduct a simple regression analysis with X predicting M to test for path a, M = β0 + β1X + ϵ | SSCM = β0 + β1 × Policy + β2 × Technology + β3 × Environment + β4 × Finance + β5 × Human Resource + ϵ |

| Step 3 | Conduct a simple regression analysis with M predicting Y to test the significance of path b alone, Y = β0 + β1M + ϵ | Productivity = β0 + β1 × SSCM + ϵ |

| Step 4 | Conduct a multiple regression analysis with X and M predicting Y, Y = β0 + β1X + B2M + ϵ | Productivity = β0 + β1 × Policy + β2 × Technology + β3 × Environment + β4 × Finance + β5 × Human Resource + β6 × SSCM + ϵ |

| Characteristics | Categories | Frequencies | % |

|---|---|---|---|

| Age | 25 to 35 | 51 | 29.3% |

| 36 to 45 | 48 | 27.6% | |

| 46 to 55 | 39 | 22.4% | |

| Above 55 | 36 | 20.7% | |

| Gender | Male | 88 | 50.6% |

| Female | 86 | 49.4% | |

| Designations | Procurement Officer | 30 | 17.2% |

| Quality Control Manager | 26 | 14.9% | |

| Logistics Coordinator | 24 | 13.8% | |

| Production Manager | 28 | 16.1% | |

| Planning Manager | 24 | 13.8% | |

| Senior Supervisor | 20 | 11.5% | |

| Others | 22 | 12.6% | |

| Experience | 4 to 6 Years | 37 | 21.3% |

| 7 to 10 Years | 39 | 22.4% | |

| 10 to 12 Years | 51 | 29.3% | |

| Above 12 Years | 47 | 27.0% |

| Constructs | Items | Mean | SD | LOM | α | rho_a | rho_c | AVE |

|---|---|---|---|---|---|---|---|---|

| Policy | PL1 | 3.778 | 1.168 | 0.825 | 0.839 | 0.840 | 0.903 | 0.757 |

| PL2 | 3.747 | 1.095 | 0.862 | |||||

| PL3 | 3.879 | 1.066 | 0.870 | |||||

| Technology | TEC1 | 3.909 | 1.111 | 0.930 | 0.866 | 0.868 | 0.918 | 0.789 |

| TEC2 | 3.798 | 1.223 | 0.914 | |||||

| TEC3 | 3.960 | 1.072 | 0.867 | |||||

| Environment | EVT1 | 3.899 | 1.040 | 0.842 | 0.735 | 0.739 | 0.883 | 0.790 |

| EVT2 | 3.879 | 1.066 | 0.878 | |||||

| EVT3 | 3.899 | 1.159 | 0.882 | |||||

| Finance | FN1 | 3.808 | 1.203 | 0.890 | 0.825 | 0.836 | 0.919 | 0.850 |

| FN2 | 3.859 | 1.045 | 0.849 | |||||

| Human Resource | HRE1 | 3.768 | 1.136 | 0.850 | 0.828 | 0.828 | 0.897 | 0.744 |

| HRE2 | 3.798 | 1.128 | 0.865 | |||||

| HRE3 | 3.939 | 1.081 | 0.879 | |||||

| SSCM | SSCM1 | 3.879 | 1.066 | 0.857 | 0.922 | 0.923 | 0.939 | 0.721 |

| SSCM2 | 3.848 | 1.122 | 0.850 | |||||

| SSCM3 | 3.838 | 1.134 | 0.867 | |||||

| SSCM4 | 3.848 | 1.226 | 0.872 | |||||

| SSCM5 | 3.899 | 1.159 | 0.918 | |||||

| SSCM6 | 3.768 | 1.162 | 0.874 | |||||

| Productivity | PTY1 | 3.949 | 1.058 | 0.800 | 0.816 | 0.872 | 0.891 | 0.732 |

| PTY2 | 3.909 | 1.164 | 0.842 | |||||

| PTY3 | 3.828 | 1.129 | 0.807 | |||||

| PTY4 | 3.838 | 1.042 | 0.849 |

| Environment | Finance | Human Resource | Policy | Productivity | SSCM | Technology | |

|---|---|---|---|---|---|---|---|

| Environment | |||||||

| Finance | 0.754 | ||||||

| Human Resource | 0.604 | 0.763 | |||||

| Policy | 0.707 | 0.623 | 0.677 | ||||

| Productivity | 0.749 | 0.599 | 0.626 | 0.718 | |||

| SSCM | 0.040 | 0.675 | 0.721 | 0.598 | 0.717 | ||

| Technology | 0.023 | 0.684 | 0.679 | 0.649 | 0.652 | 0.697 |

| Hypotheses | Relations | β-Value | SD | t-Value | p Values | Decision | R2 | F2 | VIF |

|---|---|---|---|---|---|---|---|---|---|

| H-1a | Policy -> Productivity | −0.133 | 0.118 | 1.085 | 0.278 | Not supported | 0.678 | 0.071 | 4.335 |

| H-1b | Technology -> Productivity | 0.023 | 0.093 | 0.245 | 0.807 | Not supported | 0.052 | 2.772 | |

| H-1c | Environment -> Productivity | 0.149 | 0.108 | 1.391 | 0.164 | Not supported | 0.226 | 4.16 | |

| H-1d | Finance -> Productivity | 0.142 | 0.090 | 1.576 | 0.115 | Not supported | 0.071 | 2.807 | |

| H-1e | Human Resource -> Productivity | 0.108 | 0.084 | 1.262 | 0.207 | Not supported | 0.046 | 2.998 | |

| H-3 | SSCM -> Productivity | 0.674 | 0.132 | 5.081 | 0.000 | Supported | 0.22 | 4.306 | |

| H-2a | Policy -> SSCM | 0.394 | 0.075 | 5.198 | 0.000 | Supported | 0.714 | 0.269 | 4.147 |

| H-2b | Technology -> SSCM | 0.159 | 0.059 | 2.697 | 0.007 | Supported | 0.119 | 3.407 | |

| H-2c | Environment -> SSCM | 0.155 | 0.059 | 2.694 | 0.007 | Supported | 0.161 | 3.804 | |

| H-2d | Finance -> SSCM | 0.129 | 0.064 | 2.083 | 0.037 | Supported | 0.183 | 3.555 | |

| H-2e | Human Resource -> SSCM | 0.196 | 0.062 | 3.121 | 0.002 | Supported | 0.219 | 3.468 |

| Hypotheses | Relations | β-Value | SD | t-Value | p Values | Decision |

|---|---|---|---|---|---|---|

| H-4c | Policy -> SSCM -> Productivity | 0.267 | 0.078 | 3.359 | 0.001 | Accepted with Full Mediation |

| H-4a | Technology -> SSCM -> Productivity | 0.107 | 0.044 | 2.451 | 0.014 | Accepted with Full Mediation |

| H-4b | Environment -> SSCM -> Productivity | 0.104 | 0.044 | 2.387 | 0.017 | Accepted with Full Mediation |

| H-4d | Finance -> SSCM -> Productivity | 0.085 | 0.043 | 2.081 | 0.037 | Accepted with Full Mediation |

| H-4e | Human Resource -> SSCM -> Productivity | 0.133 | 0.053 | 2.43 | 0.015 | Accepted with Full Mediation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabber, M.A.; Islam, S.; Rahim, M.A.; Parvin, M.; Sufi, F. The Productivity Paradox: How Sustainable Supply Chain Management Mediates the Link Between Enablers and Productivity. Sustainability 2025, 17, 8572. https://doi.org/10.3390/su17198572

Jabber MA, Islam S, Rahim MA, Parvin M, Sufi F. The Productivity Paradox: How Sustainable Supply Chain Management Mediates the Link Between Enablers and Productivity. Sustainability. 2025; 17(19):8572. https://doi.org/10.3390/su17198572

Chicago/Turabian StyleJabber, Mohammad Abdul, Sumaiya Islam, Md Abdur Rahim, Marjuka Parvin, and Fahim Sufi. 2025. "The Productivity Paradox: How Sustainable Supply Chain Management Mediates the Link Between Enablers and Productivity" Sustainability 17, no. 19: 8572. https://doi.org/10.3390/su17198572

APA StyleJabber, M. A., Islam, S., Rahim, M. A., Parvin, M., & Sufi, F. (2025). The Productivity Paradox: How Sustainable Supply Chain Management Mediates the Link Between Enablers and Productivity. Sustainability, 17(19), 8572. https://doi.org/10.3390/su17198572