Sustainable Integrated Approach to Waste Treatment in Automotive Industry: Solidification/Stabilization, Valorization, and Techno-Economic Assessment

Abstract

1. Introduction

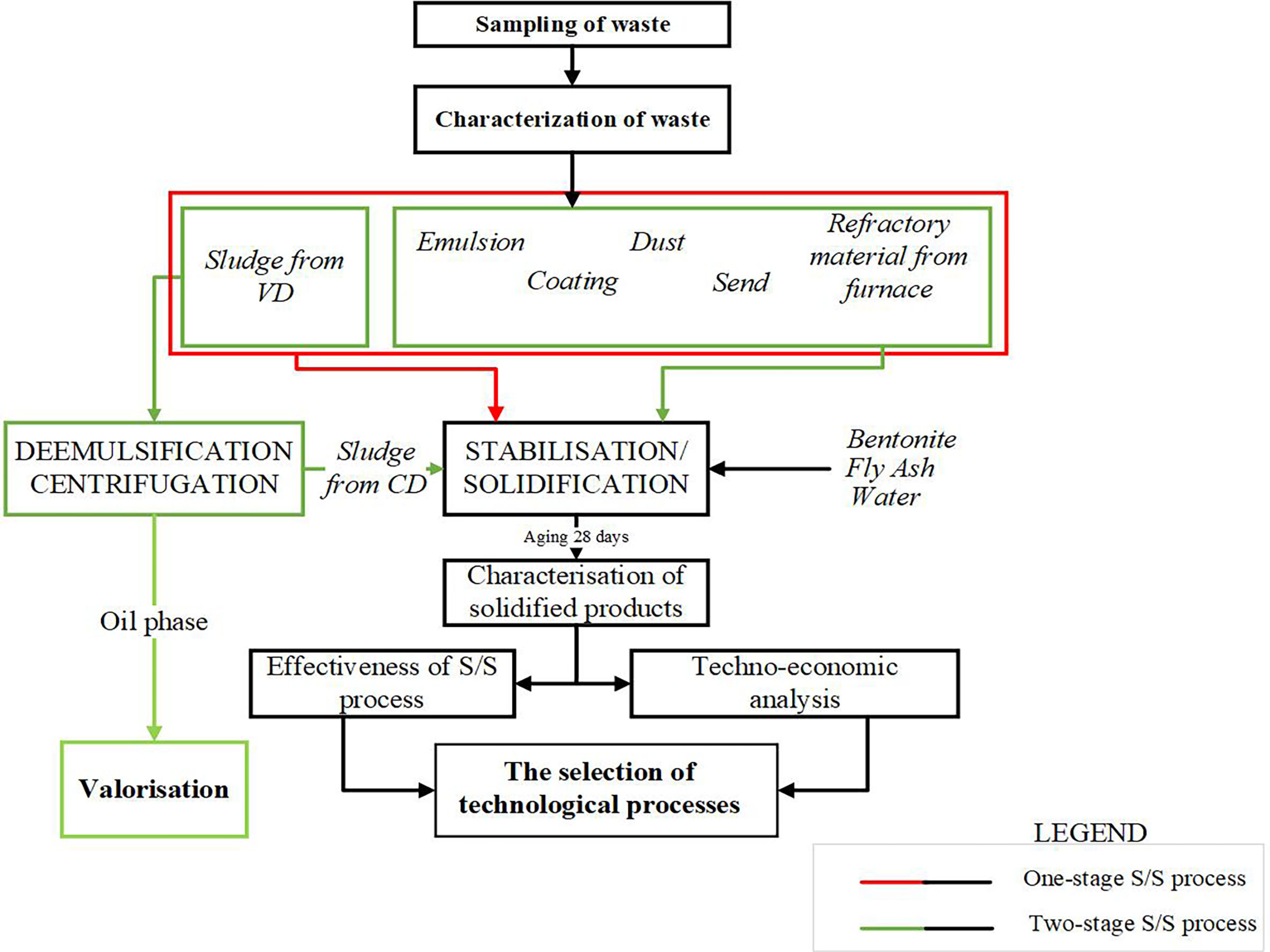

2. Materials and Methods

2.1. Waste Samples

2.2. Selected Additives

2.3. Treatment Process

2.3.1. One-Stage Treatment S/S Process

2.3.2. Two-Stage Treatment Process

2.4. Characterization of Treatment Products

2.5. Analytical Methods

2.6. Effectiveness of the S/S Process

2.7. Techno-Economic Analysis (TEA)

3. Results and Discussion

3.1. Characterization of Solidified Products

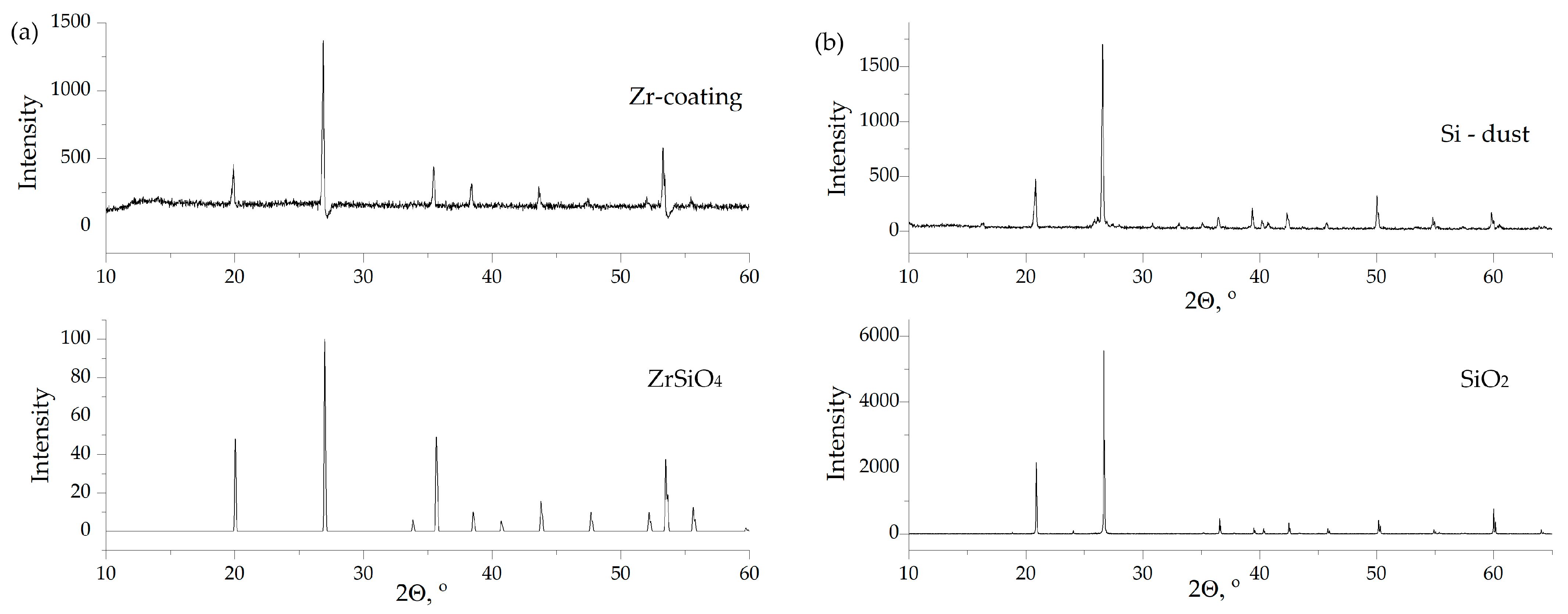

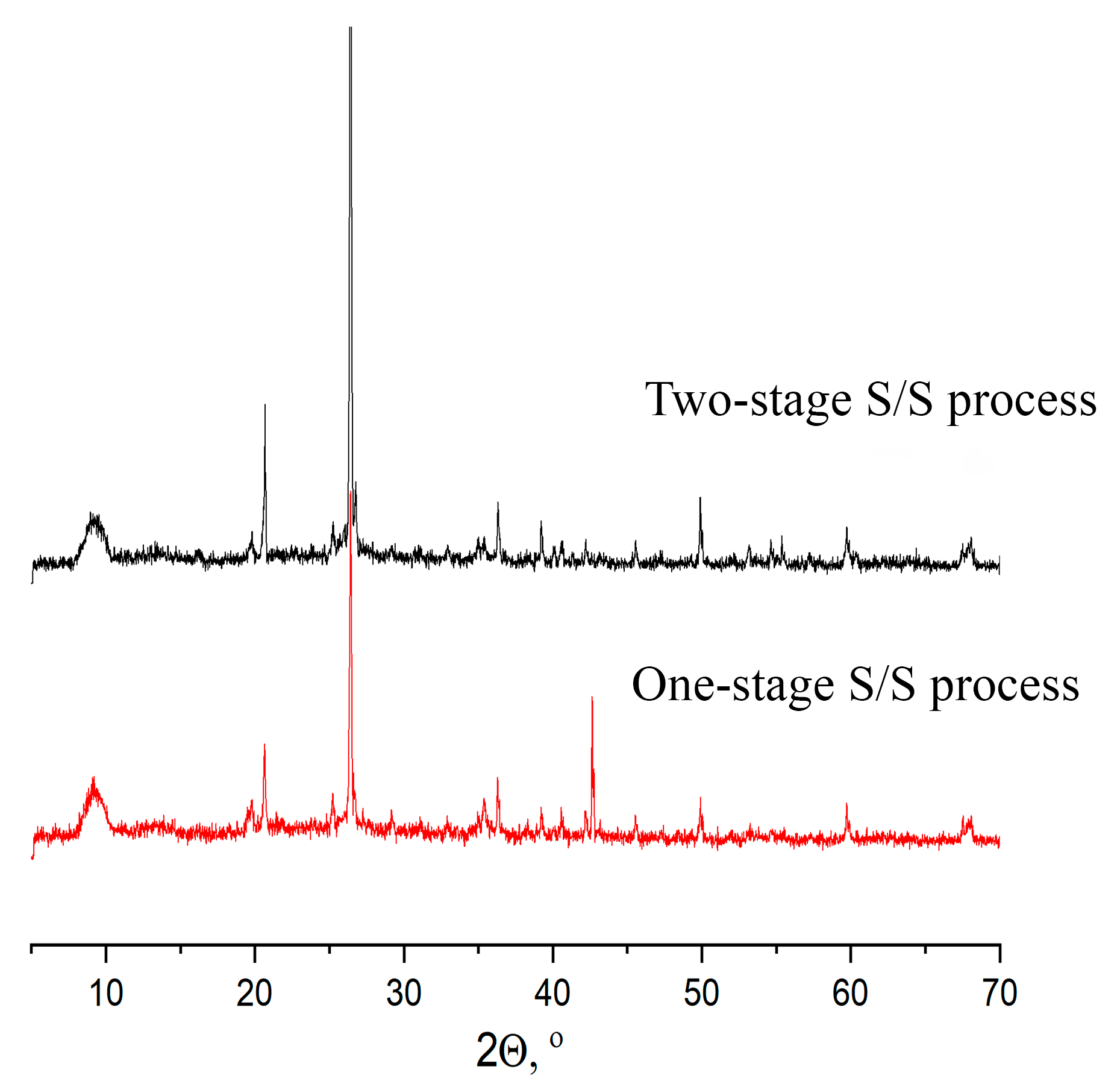

3.1.1. XRD Analysis

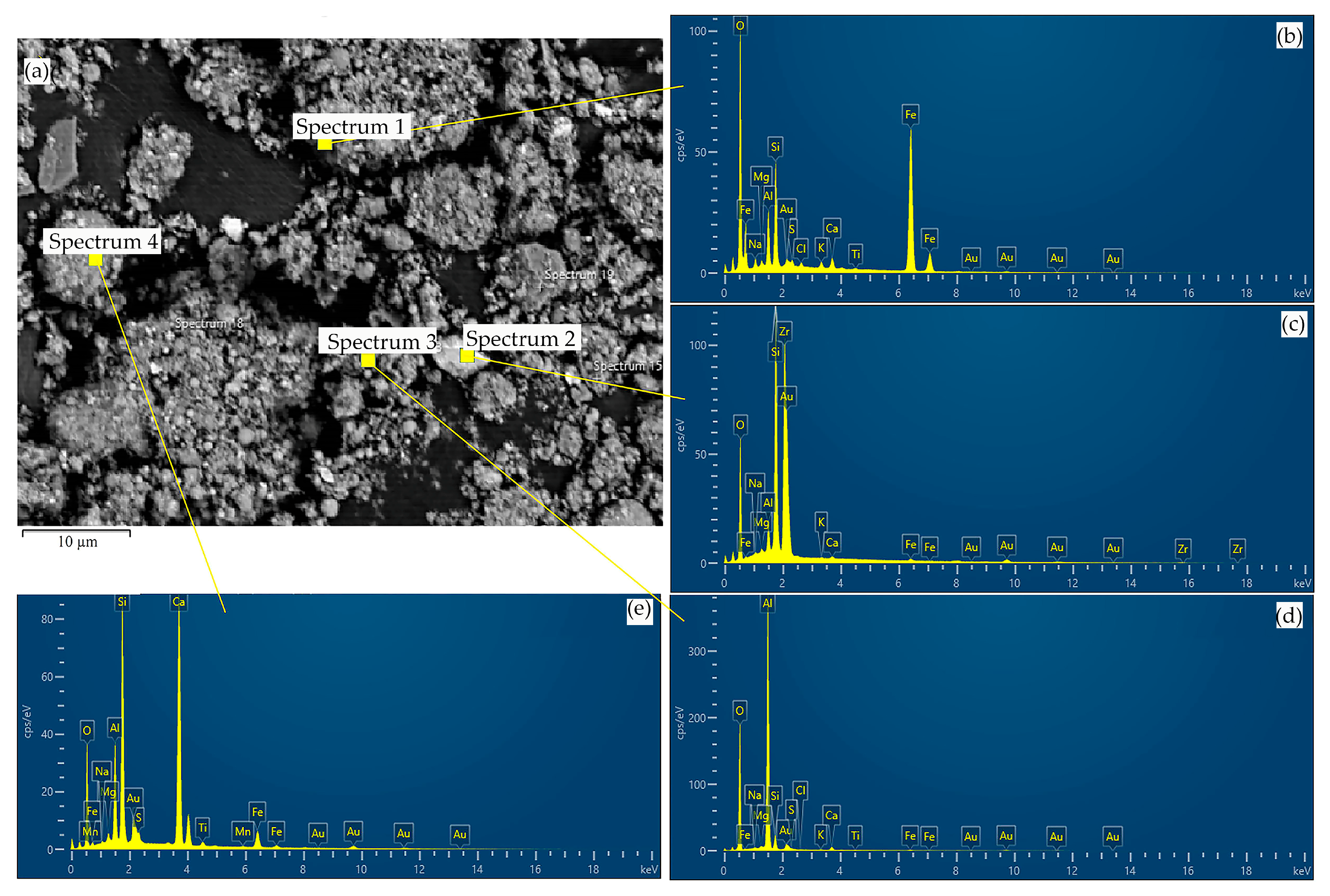

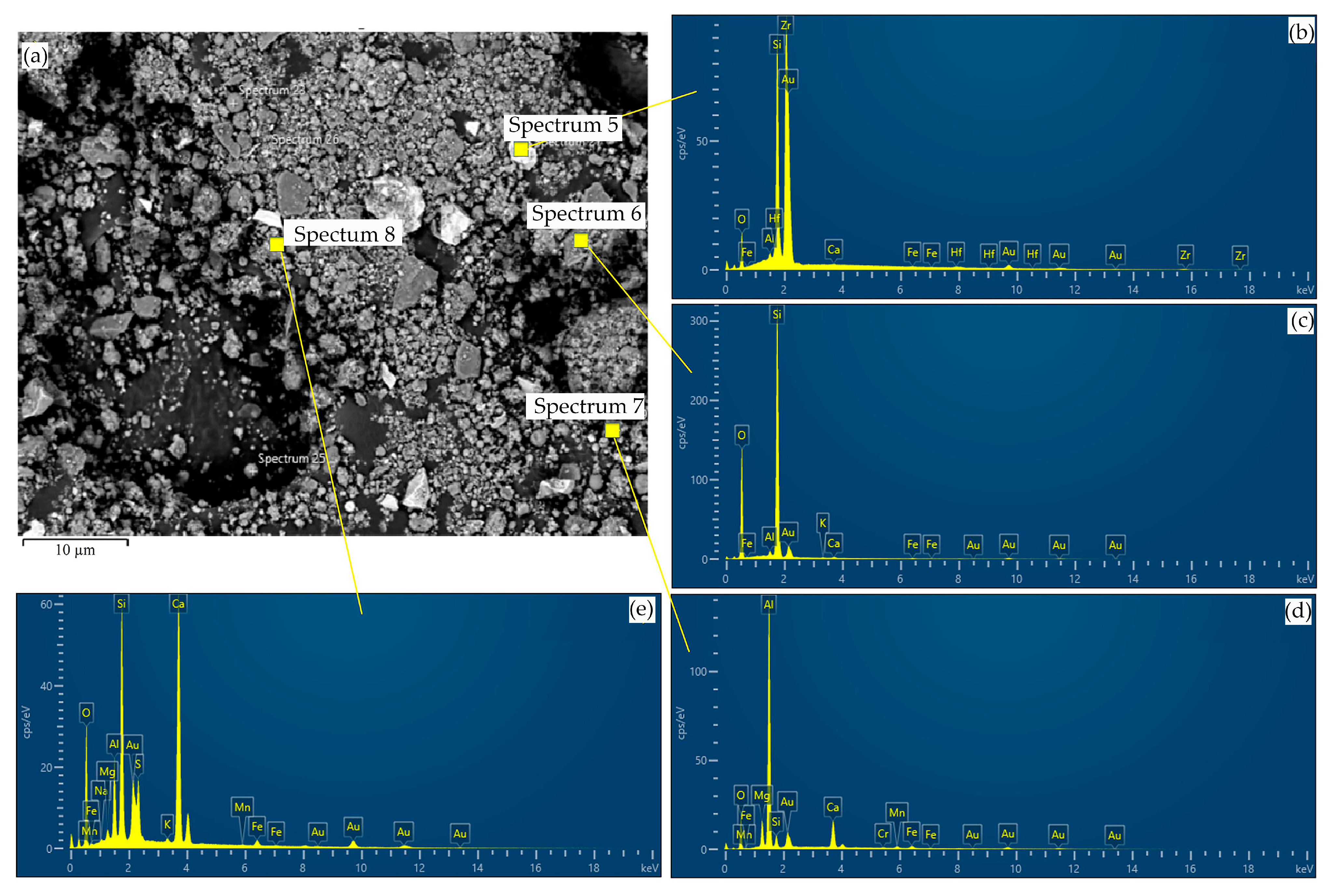

3.1.2. SEM-EDS Analysis

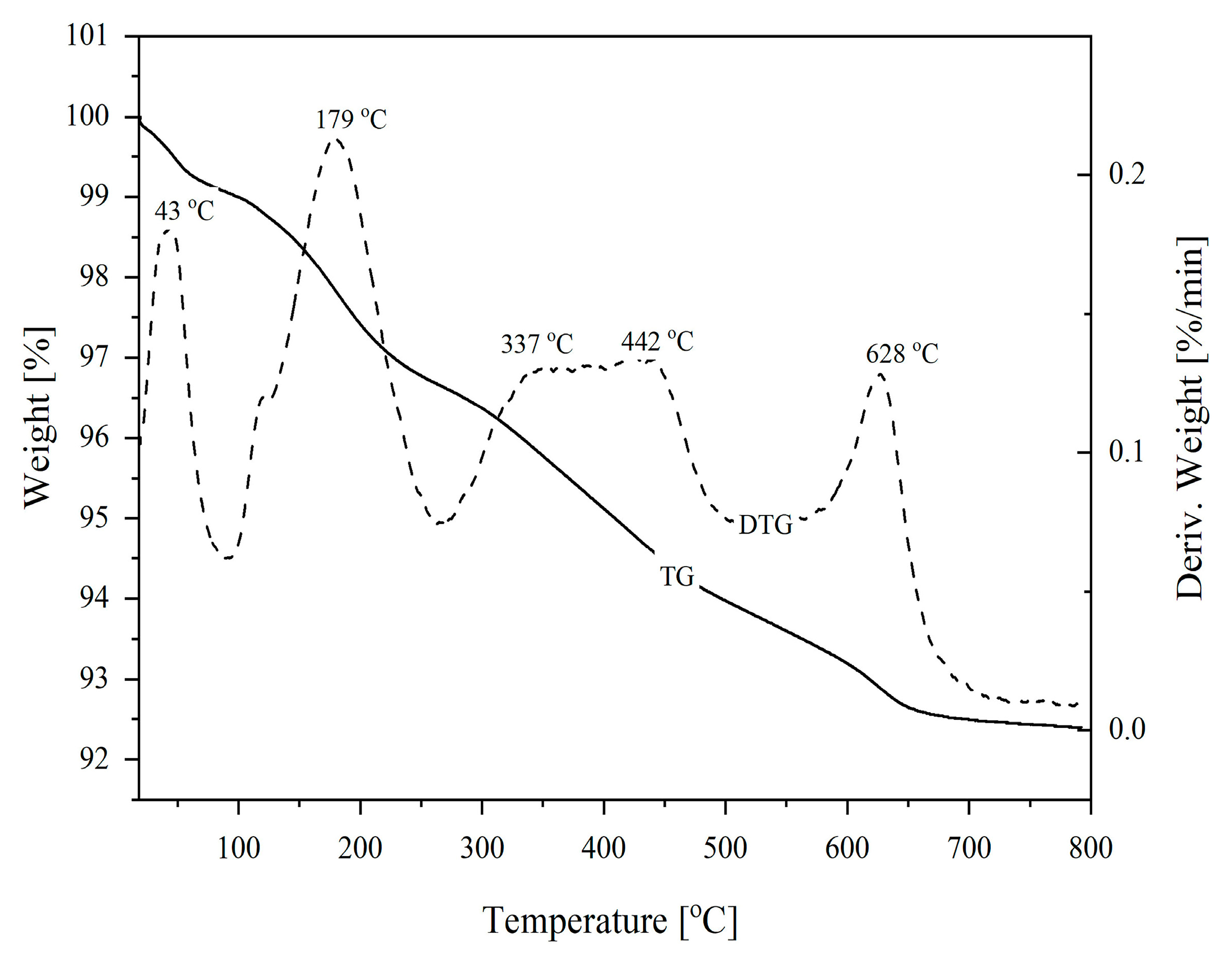

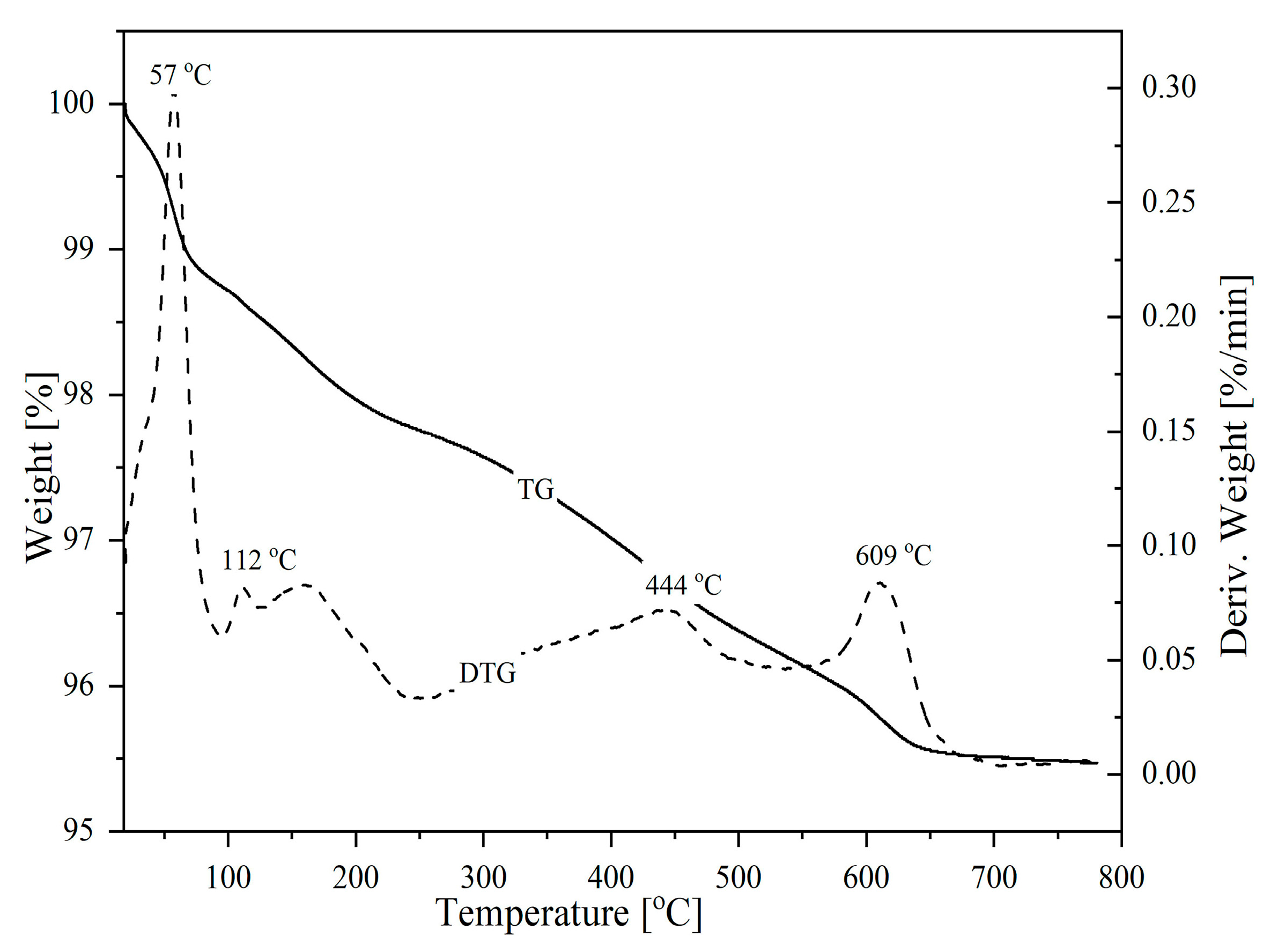

3.1.3. Thermogravimetric Analysis

3.1.4. The Mechanical Properties of the Solidified Products

3.1.5. Physico-Chemical Characterization of Solidified Products

3.2. Utilization of Organic Component

3.3. Techno-Economic Analysis (TEA)

- R1—one-stage S/S treatment of waste;

- R2—two-stage S/S treatment of waste with pre-treatment of waste sludge from the VD process.

- Net present value (NPV)—calculates the present value of all future savings or avoided costs minus the initial cost of the investment.

- Payback period—The time it takes to recover the initial investment from the accumulated savings.

- Internal rate of return (IRR), i.e., discount rate at which NPV = 0. This indicator shows the efficiency of the investment in percentages.

- Cost-benefit ratio (CBR)—cost-benefit ratio, useful for comparing alternatives. In the case of this study, the ratio of total benefits (savings) to total costs.

4. Conclusions

- The synergistic use of non-hazardous waste from the plant as a source of alumino-silicates for immobilization of hazardous fractions, thereby closing the internal material loops.

- Two-stage S/S waste treatment with oil valorization, where pre-treatment of sludge by chemical demulsification improved the safe disposal of the S/S product (reducing DOC below landfill limits) and generated an oil phase with a high calorific value (37.8 MJ/kg), suitable as an alternative energy source. This represents a practical application of circular economy principles in hazardous waste management.

- Integration of technical and economic assessments, where the study links laboratory-scale characterization of products (mechanical and physico-chemical properties) with techno-economic indicators (NPV, IRR, payback). Both the one-stage and two-stage options proved highly profitable, with payback periods shorter than one year.

- The scientific significance is reflected in demonstrating that:

- Industrial hazardous wastes with high organic content can be safely incorporated into solidified matrices at controlled levels (≤6%), overcoming the typical limitations of S/S processes.

- Recovered oil phases from waste streams can meet regulatory requirements and be reintroduced into energy systems, thereby reducing disposal volumes and creating added value.

- The developed methodology provides a scalable model applicable to other process industries facing complex mixed waste streams.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BAT | Best Available Technologies |

| BTEX | Benzene, Toluene, Ethylbenzene, and Xylenes |

| C-A-H | Calcium aluminate hydrates |

| CD | Chemical demulsification |

| C-S-H | Calcium silicate hydrates |

| DOC | Dissolved organic carbon |

| FA | Fly ash |

| LOI | Loss on ignition at 550 °C |

| PAH | A Polycyclic Aromatic Hydrocarbon |

| PCB | Polychlorinated biphenyls |

| SEM-EDS | Scanning electron microscopy Energy Dispersive Spectrometer |

| SS | The solidification/stabilization process |

| TEA | Techno-economic analysis |

| TDS | Total dissolved solids |

| TG-DTG | Thermogravimetry Analysis |

| TOC | Total organic carbon |

| UCS | The uniaxial compressive strength |

| USEPA | The U.S. Environmental Protection Agency |

| VD | Vacudest machine |

| WTE | Waste-to-energy |

| XRD | X-ray Powder Diffractometry |

| NPV | Net present value |

| IRR | Internal rate of return |

| CBR | Cost benefit ratio |

References

- Erdogan, B.; Salihoglu, G. Evaluation of the solid and hazardous wastes generated by the automotive industry in Turkey. Int. J. Therm. Environ. Eng. 2018, 16, 81–90. [Google Scholar]

- D’Arcy, J.B.; Dasch, J.M.; Gundrum, A.B.; Rivera, J.L.; Johnson, J.H.; Carlson, D.H.; Sutherland, J.W. Characterization of process air emissions in automotive production plants. J. Occup. Environ. Hyg. 2016, 13, 9–18. [Google Scholar] [CrossRef]

- US EPA. Engineering Bulletin—Solidification/Stabilization of Organic and Inorganic; EPA/540/S-92/015; US EPA: Washington, DC, USA, 1993.

- Radovanović, D.; Kamberović, Ž.; Korać, M.; Rogan, J. Solidified structure and leaching properties of metallurgical wastewater treatment sludge after solidification/stabilization process. J. Environ. Sci. Health 2015, 51, 34–43. [Google Scholar] [CrossRef]

- Dermatas, D.; Meng, X. Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng. Geol. 2003, 70, 377–394. [Google Scholar] [CrossRef]

- Szabó, R.; Mucsi, G. Effect of SiO2, Al2O3 and Na2O content and fly ash fineness on the structure and mechanical properties of fly ash based geopolymer. Recycl. Sustain. Dev. 2019, 12, 61–68. [Google Scholar] [CrossRef]

- Knežević-Štulović, M.; Ivšić-Bajčeta, D.; Ristić, M.; Kamberović, Ž.; Korać, M.; Anđić, Z. Leaching properties of secondary lead slag stabilized/solidified with cement and selected additives. Environ. Prot. Eng. 2013, 39, 149–163. [Google Scholar] [CrossRef]

- Radovanović, D.; Kamberović, Ž.; Anđić, Z.; Ranitović, M.; Marković, B. The effect of CaO and MgO addition and cooling rate on stability of slag obtained after jarosite and neutral leaching residue treatment in the Waelz process. Physicochem. Probl. Miner. Process. 2018, 54, 484–495. [Google Scholar]

- Chen, Q.; Zhang, L.; Ke, Y.; Hills, C.; Kang, Y. Influence of carbonation on the acid neutralization capacity of cements and cement-solidified/stabilized electroplating sludge. Chemosphere 2009, 74, 758–764. [Google Scholar] [CrossRef] [PubMed]

- Gineys, N.; Aouad, G.; Damidot, D. Managing trace elements in Portland cement—Part: Interactions between cement paste and heavy metals added during mixing as soluble salts. Cem. Concr. Compos. 2010, 32, 563–570. [Google Scholar] [CrossRef]

- Minocha, A.K.; Jain, N.; Verma, C.L. Effect of inorganic materials on the solidification of heavy metal sludge. Cem. Concr. Res. 2003, 33, 1695–1701. [Google Scholar] [CrossRef]

- Diet, J.N.; Moszkowicz, P.; Sorrentino, D. Behaviour of ordinary Portland cement during the stabilization/solidification of synthetic heavy metal sludge: Macroscopic and microscopic aspects. Waste Manag. 1998, 18, 17–24. [Google Scholar] [CrossRef]

- Štulović, M.; Radovanović, D.; Kamberović, Ž.; Korać, M.; Anđić, Z. Assessment of leaching characteristics of solidified products containing secondary alkaline lead slag. Int. J. Environ. Res. Public Health 2019, 16, 2005. [Google Scholar] [CrossRef]

- Štulović, M.; Radovanović, D.; Kamberović, Ž.; Korać, M.; Anđić, Z.; Ranitović, M. Leaching of toxic elements from secondary alkaline lead slag and stabilized/solidified products. J. Mater. Cycles Waste Manag. 2019, 21, 1402–1413. [Google Scholar] [CrossRef]

- Masrullita, R.Y.; Burhan, P.; Trihadiningrum, D.Y. Stabilization/solidification of waste containing heavy metals and hydrocarbons using OPC and land trass cement. J. Ecol. Eng. 2018, 19, 88–96. [Google Scholar] [CrossRef]

- Hon Yvain, C. Development of Emulsified Wastewater Treatment System. Bachelor’s Thesis, Universiti Malaysia Pahang, Kuantan, Malaysia, 2014. [Google Scholar]

- United States Patent. Metal Working Emulsion Cleaner. U.S. Patent 5,518,640, 21 May 1996. [Google Scholar]

- Trussell, S.; Spence, R.D. A review of solidification/stabilization interferences. Waste Manag. 1994, 14, 507–519. [Google Scholar] [CrossRef]

- Jiang, J.Q. The role of coagulation in water treatment. Current Opin. Chem. Eng. 2015, 8, 36–44. [Google Scholar] [CrossRef]

- European Commission. Integrated Pollution Prevention and Control; Reference document on Best Available Techniques for the Waste Treatment Industries; European Commission: Brussels, Belgium, 2006.

- European Commission. Reference Document for Waste Treatment (Industrial Emission Directive 2010/75/EU); European Commission: Brussels, Belgium, 2010.

- Kim, L.L.; Arama, G.M. Liquid waste management methodology. A waste-to-energy approach. Environ. Eng. Manag. J. 2019, 18, 2663–2671. [Google Scholar]

- Khanal, S.K.; Varjani, S.; Lin, C.S.K.; Awasthi, M.K. Waste-to-resources: Opportunities and challenges. Bioresour. Technol. 2020, 317, 123987. [Google Scholar] [CrossRef]

- Wilts, H.; Von Gries, N.; Bahn-Walkowiak, B. From waste management to resource efficiency—The need for policy mixes. Sustainability 2016, 8, 622. [Google Scholar] [CrossRef]

- Keskin, T.; Yilmaz, E.; Kasap, T.; Sari, M.; Cao, S. Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives. Minerals 2024, 14, 943. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Wilson, D.C.; Rodic, L.; Cowing, M.J.; Velis, C.A.; Whiteman, A.D.; Scheinberg, A.; Vilches, R.; Masterson, D.; Stretz, J.; Oelz, B. ‘Wasteaware’ benchmark indicators for integrated sustainable waste management in cities. Waste Manag. 2015, 35, 329–342. [Google Scholar] [CrossRef]

- Lai, Y.H.; Chew, I.M.L. Wastewater System Integration: A Biogenic Waste Biorefinery Eco-Industrial Park. Sustainability 2022, 14, 16347. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Linley, S.; Reisner, E. Solar Reforming as an Emerging Technology for Circular Chemical Industries. Nat. Rev. Chem. 2024, 8, 87–105. [Google Scholar] [CrossRef]

- Machin, E.B.; Pedroso, D.T.; Acosta, D.G.; Silva dos Santos, M.I.; de Carvalho, F.S.; Machín, A.B.; Neira Ortíz, M.A.; Arriagada, R.S.; Travieso Fernández, D.I.; Braga Maciel, L.B.; et al. Techno-Economic and Environmental Assessment of Municipal Solid Waste Energetic Valorization. Energies 2022, 15, 8900. [Google Scholar] [CrossRef]

- Đurđević, D.; Žiković, S.; Blecich, P. Sustainable Sewage Sludge Management Technologies Selection Based on Techno-Economic-Environmental Criteria: Case Study of Croatia. Energies 2022, 15, 3941. [Google Scholar] [CrossRef]

- Tomić, T.; Slatina, I.; Schneider, D.R. Techno-Economic Review of Pyrolysis and Gasification Plants for Thermochemical Recovery of Plastic Waste and Economic Viability Assessment of Small-Scale Implementation. Clean Technol. Environ. Policy 2024, 26, 171–195. [Google Scholar] [CrossRef]

- Bhatt, M.; Chakinala, A.G.; Joshi, J.B.; Sharma, A.; Pant, K.K.; Shah, K.; Sharma, A. Valorization of Solid Waste Using Advanced Thermo-Chemical Process: A Review. J. Environ. Chem. Eng. 2021, 9, 105434. [Google Scholar] [CrossRef]

- Ng, K.S.; Phan, A.N.; Iacovidou, E.; Ghani, W.A.W.A.K. Techno-Economic Assessment of a Novel Integrated System of Mechanical-Biological Treatment and Valorisation of Residual Municipal Solid Waste into Hydrogen: A Case Study in the UK. J. Clean. Prod. 2021, 298, 126706. [Google Scholar] [CrossRef]

- O’Dwyer, E.; Chen, K.; Wang, H.; Wang, A.; Shah, N.; Guo, M. Optimisation of Wastewater Treatment Strategies in Eco-Industrial Parks: Technology, Location and Transport. Chem. Eng. J. 2020, 381, 122643. [Google Scholar] [CrossRef]

- Arashiro, L.T.; Montero, N.; Ferrer, I.; Acién, F.G.; Gómez, C.; Garfí, M. Life Cycle Assessment of High Rate Algal Ponds for Wastewater Treatment and Resource Recovery. Sci. Total Environ. 2018, 622–623, 1118–1130. [Google Scholar] [CrossRef]

- Adeyemi, I.; Meribout, M.; Khezzar, L.; Kharoua, N.; AlHammadi, K. Techno-Economic Comparative Assessment of the Ultrasound, Electrostatic and Microwave Supported Coalescence of Binary Water Droplets in Crude Oil. Ultrason. Sonochem. 2023, 95, 106402. [Google Scholar] [CrossRef]

- Barroso-Solares, S.; Zahedi, M.G.; Pinto, J.; Nanni, G.; Fragouli, D.; Athanassiou, A. Oil Removal from Water–Oil Emulsions Using Magnetic Nanocomposite Fibrous Mats. RSC Adv. 2016, 6, 71100–71107. [Google Scholar] [CrossRef]

- Barroso-Solares, S.; Pinto, J.; Nanni, G.; Fragouli, D.; Athanassiou, A. Enhanced Oil Removal from Water in Oil Stable Emulsions Using Electrospun Nanocomposite Fiber Mats. RSC Adv. 2018, 8, 7641–7650. [Google Scholar] [CrossRef]

- Ou, L.; Li, S.; Tao, L.; Phillips, S.; Hawkins, T.; Singh, A.; Snowden-Swan, L.; Cai, H. Techno-Economic Analysis and Life-Cycle Analysis of Renewable Diesel Fuels Produced with Waste Feedstocks. ACS Sustain. Chem. Eng. 2021, 10, 382–393. [Google Scholar] [CrossRef]

- Moses, K.K.; Aliyu, A.; Hamza, A.; Mohammed-Dabo, I.A. Recycling of Waste Lubricating Oil: A Review of the Recycling Technologies with a Focus on Catalytic Cracking, Techno-Economic and Life Cycle Assessments. J. Environ. Chem. Eng. 2023, 11, 111273. [Google Scholar] [CrossRef]

- Global Industry Analysts, Inc. Automotive Oil Recycling; Product Code: 1742706; Global Industry Analysts, Inc.: San Jose, CA, USA, 2025; 605p. [Google Scholar]

- Nos. 56/2010, 93/2019, 39/2021; Regulation on Categories, Testing, and Classification of Waste. Official Gazette of the Republic of Serbia: Belgrade, Serbia, 2010.

- National Academy of Sciences. Risk-Based Waste Classification in California; The National Academies Press: Washington, DC, USA, 1999. [Google Scholar]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: Conshohocken, PA, USA, 2025.

- ASTM C109/C109M-20; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: Conshohocken, PA, USA, 2020.

- EN 12457-2:2004; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size Below 4 mm (without or with Size Reduction). European Commission: Brussels, Belgium, 2004.

- ISO 17313:2004; Soil Quality—Determination of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. International Organization for Standardization: Geneva, Switzerland, 2004.

- US EPA. Prohibition on the Placement of Bulk Liquid Hazardous Waste in Landfills—Statutory Interpretive Guidance; EPA 530-SW-86-016; US EPA: Washington, DC, USA, 1986.

- ASTM C 642-06; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: Conshohocken, PA, USA, 2013.

- Touite, A.; Labied, S.; El Ghailassi, T.; Guedira, T. Treatment of organic radioactive waste by stabilization/solidification into a cement/alumina based mortar. Mater. Today Proc. 2022, 58, 1485–1489. [Google Scholar] [CrossRef]

- No. 92/2010; The Regulation on the Waste Landfilling. Official Gazette of the Republic of Serbia: Belgrade, Serbia, 2010.

- Reeb, C.; Davy, C.A.; Pierlot, C.; Bertin, M.; Cantarel, V.; Lambertin, D. Emulsification of low viscosity oil in alkali-activated materials. Cem. Concr. Res. 2022, 162, 106963. [Google Scholar] [CrossRef]

- Cantarel, V.; Nouaille, F.; Rooses, A.; Lambertin, D.; Poulesquen, A.; Frizon, F. Solidification/stabilisation of liquid oil waste in metakaolin-based geopolymer. J. Nucl. Mater. 2015, 464, 16–19. [Google Scholar] [CrossRef]

- Razali, M.N.; Ahmad, M.F.A.; Salehan, N.A.M.; Anuar, A.E. Treatment of waste emulsion using coagulation method. IOP Conf. Ser. Earth Environ. Sci. 2019, 257, 012016. [Google Scholar] [CrossRef]

- Pérez-Cardona, J.R.; Deng, S.; Sutherland, J.W. Optimization of a parametric product design using techno-economic assessment and environmental characteristics with application to an electric traction motor. Resour. Conserv. Recycl. 2024, 206, 107626. [Google Scholar] [CrossRef]

- Deng, S.; Xiao, Z.; Zhang, W.; Noble, A.; Das, S.; Yih, Y.; Sutherland, J.W. Economic analysis of precious metal recovery from electronic waste through gas-assisted microflow extraction. Resour. Conserv. Recycl. 2023, 190, 106810. [Google Scholar] [CrossRef]

| Hazardous Waste | Non-Hazardous Waste | |||||

|---|---|---|---|---|---|---|

| Parameter | Sludge | Emulsion | Zr-Coatings | Dust | Sand | Refractory Material |

| Moisture content [%] | 73 | 32 | 53 | 0.5 | 0.14 | 4.3 |

| LOI (550 °C) [%] | 90 | 99 | 1.9 | 15 | 0.5 | 1.0 |

| Total PAH [mg/kg] | <6.0 | <6.0 | <6.0 | <1.0 | <1.0 | <6.0 |

| Total BTEX [mg/kg] | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Total hydrocarbons [%] | 2.9 | 12.0 | <0.05 | <0.05 | <0.05 | <0.05 |

| Metals content [mg/kg] | ||||||

| Pb | <0.2 | 3.1 | 2.0 | 49 | 1.1 | 2.9 |

| Cd | <0.09 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| Zn | 34.0 | 96 | 9.6 | 90 | 3.1 | 2.8 |

| Cu | 9.0 | 13 | 7.4 | 33 | 2.7 | 4.2 |

| Cr | <0.1 | 20 | 7.1 | 119 | 24 | 6.1 |

| Mn | 0.75 | 15 | 1.2 | 97 | 135 | 7.2 |

| Ni | 0.94 | 13 | 2.9 | 89 | 139 | 24 |

| As | <0.9 | <0.9 | <0.9 | 2.1 | <0.9 | <0.9 |

| Hg | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 |

| Phase compositions | ||||||

| ZrSiO2 [%] | - | - | 75–95 | - | - | - |

| SiO2 [%] | - | - | - | 60–90 | 70–95 | - |

| Al2O3 [%] | - | - | - | 1–5 | - | 70–90 |

| Component | CaO [%] | SiO2 [%] | Al2O3 [%] | Fe2O3 [%] | MgO [%] |

|---|---|---|---|---|---|

| FA | 7.52 | 55.15 | 13.45 | 4.33 | 4.06 |

| B | 3.41 | 52.23 | 24.33 | 5.21 | 1.28 |

| Type of Waste | One-Stage Treatment | Two-Stage Treatment |

|---|---|---|

| Demulsification | ||

| CD sludge * [%] | / | 1 |

| S/S process | ||

| Emulsion [%] | 6 | 5 |

| Waste sludge ** [%] | 5 | / |

| Coatings [%] | 6 | 3.6 |

| Silicate dust [%] | 28 | 25 |

| Sand [%] | 8 | 7.5 |

| Refractory material [%] | - | 12.3 |

| FA [%] | 30 | 27.4 |

| B [%] | 17 | 18.2 |

| Product | UCS [MPa] | Hydraulic Conductivity [m/s] | Density (g/cm3) |

|---|---|---|---|

| One-stage S/S process | 0.79 | 2.58 × 10−7 | 1.6 |

| Two-stage S/S process | 0.53 | 9.42 × 10−9 | 1.4 |

| Parameter | One-Stage Process | Two-Stage Process | Oil Phase |

|---|---|---|---|

| Moisture content [%] | 1.66 | <1 | 17 |

| LOI [%] | 4.95 | 2.78 | 98.5 |

| Ignition point [°C] | - | - | >66.5 |

| Calorific value [MJ/kg] | - | - | 37.8 |

| Total hydrocarbons C10-C40 [mg/kg] | 16,468.1 | 3142.0 | >100,000 |

| Total PCB [mg/kg] | <0.1 | <0.01 | <0.1 |

| Total PAH [mg/kg] | <0.1 | <0.1 | 1.67 |

| Total BTX [mg/kg] | <0.01 | <0.01 | 0.049 |

| Sulfur content [%] | - | - | 0.037 |

| Total halogens, Cl [%] | - | - | 1.62 |

| TOC [%] | 2.98 | 1.06 | - |

| Metals content [mg/kg] | |||

| Cu | 28.3 | 18.1 | 3.11 |

| Hg | <0.2 | <0.2 | <0.2 |

| Cd | 28.3 | <0.6 | <0.6 |

| Mn | 198 | 201 | - |

| Ni | 154 | 65.3 | 3.04 |

| Pb | 22.8 | 17.7 | <0.6 |

| Cr | 41.8 | 33.6 | 1.60 |

| Zn | 47.2 | 42.2 | 22.6 |

| Viscosity [mPa·s] | 185.4 | ||

| pH value | 9.90 | 10.5 | - |

| EN 12457 test (Metals content) [mg/kg] | |||

| Cu | 0.80 | 0.42 | - |

| Hg | <0.003 | <0.003 | - |

| Cd | <0.01 | <0.01 | - |

| Mn | 0.25 | 0.18 | - |

| Ni | 0.24 | <0.1 | - |

| Pb | <0.07 | <0.07 | - |

| Cr | 1.32 | 0.82 | - |

| Zn | <0.4 | <0.4 | - |

| TDS 105 °C [mg/kg] | 12,600 | 18,300 | - |

| DOC [mg/kg] | 4913 | 1829 | - |

| Cl− [mg/kg] | 460.9 | 567.2 | - |

| Type of Waste | t/Year | Price €/t | Total, € |

|---|---|---|---|

| Sludge from the VD process | 132 | 1.455 | 192,000 |

| Emulsion | 168 | 1.500 | 252,000 |

| Zr-based coatings | 180 | 500 | 90,000 |

| Silicate dust | 804 | 100 | 80,400 |

| Sand | 240 | 100 | 24,000 |

| Refractory material | 348 | 100 | 34,800 |

| Total | 673,200 | ||

| Waste Name | Transport Cost, €/km | Number of Batches of 20 t | Average km | Total, € |

|---|---|---|---|---|

| Industrial waste | 1.5 | 93.6 | 150 | 21,060 |

| Year | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 |

|---|---|---|---|---|---|---|

| Disposal costs without investment (current situation), € | 694.260 | 0 | 0 | 0 | 0 | 0 |

| R1—one-stage process | 0 | 1 | 2 | 3 | 4 | |

| Investment in equipment, € | 88,800 | 0 | 0 | 0 | 0 | |

| Equipment maintenance 3%, € | 2,664 | 2.664 | 2.664 | 2.664 | 2.664 | |

| Depreciation, € | 5.328 | 5.328 | 5.328 | 5.328 | 5.328 | |

| Staff costs, € | 57.984 | 57.984 | 57.984 | 57.984 | 57.984 | |

| Energy costs, € | 15,296.6 | 15,296.6 | 15,296.6 | 15,296.6 | 15,296.6 | |

| The costs of additives, € | 83.160 | 83.160 | 83.160 | 83.160 | 83.160 | |

| Costs of final disposal, € | 294.624 | 294.624 | 294.624 | 294.624 | 294.624 | |

| TOTAL, € | 459,056.6 | 459,056.6 | 459,056.6 | 459,056.6 | 459,056.6 | |

| Cash flow, € | −694,260 | −547,856.6 | −459,056.6 | −459,056.6 | −459,056.6 | −459,056.6 |

| Savings, € | 0 | 146,303.4 | 235,203.4 | 235,203.4 | 235,203.4 | 235,203.4 |

| R2—two-stage process | 0 | 1 | 2 | 3 | 4 | |

| Investment in equipment, € | 136.100 | 0 | 0 | 0 | 0 | |

| Equipment maintenance 3%, € | 4.083 | 4.083 | 4.083 | 4.083 | 4.083 | |

| Depreciation, € | 8.166 | 8.166 | 8.166 | 8.166 | 8.166 | |

| Staff costs, € | 57.984 | 57.984 | 57.984 | 57.984 | 57.984 | |

| Energy costs, € | 18,743.96 | 18,743.96 | 18,743.96 | 18,743.96 | 18,743.96 | |

| The costs of additives, € | 59,310.6 | 59,310.6 | 59,310.6 | 59,310.6 | 59,310.6 | |

| Costs of final disposal, € | 393.408 | 393.408 | 393.408 | 393.408 | 393.408 | |

| TOTAL, € | 541,695.56 | 541,695.56 | 541,695.56 | 541,695.56 | 541,695.56 | |

| Cash flow, € | −694,260 | −677,795.56 | −541,695.56 | −541,695.56 | −541,695.56 | −541,695.56 |

| Savings, € | 0 | 16,464.44 | 152,564.44 | 152,564.44 | 152,564.44 | 152,564.44 |

| R1—One-Stage Process | R2—Two-Stage Process | |

|---|---|---|

| NPV, € | 1,699,347.76 | 1,257,781.81 |

| Discount rate, % | 9 | 9 |

| IRR, % | 298 | 320 |

| Payback, years | 0.38 years 4 months 17 days | 0.89 years 10 months 20 days |

| CBR | 0.51 | 0.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Štulović, M.; Radovanović, D.; Anđić, Z.; Vujović, N.; Ivanović, J.; Jevtić, S.; Kamberović, Ž. Sustainable Integrated Approach to Waste Treatment in Automotive Industry: Solidification/Stabilization, Valorization, and Techno-Economic Assessment. Sustainability 2025, 17, 8553. https://doi.org/10.3390/su17198553

Štulović M, Radovanović D, Anđić Z, Vujović N, Ivanović J, Jevtić S, Kamberović Ž. Sustainable Integrated Approach to Waste Treatment in Automotive Industry: Solidification/Stabilization, Valorization, and Techno-Economic Assessment. Sustainability. 2025; 17(19):8553. https://doi.org/10.3390/su17198553

Chicago/Turabian StyleŠtulović, Marija, Dragana Radovanović, Zoran Anđić, Nela Vujović, Jelena Ivanović, Sanja Jevtić, and Željko Kamberović. 2025. "Sustainable Integrated Approach to Waste Treatment in Automotive Industry: Solidification/Stabilization, Valorization, and Techno-Economic Assessment" Sustainability 17, no. 19: 8553. https://doi.org/10.3390/su17198553

APA StyleŠtulović, M., Radovanović, D., Anđić, Z., Vujović, N., Ivanović, J., Jevtić, S., & Kamberović, Ž. (2025). Sustainable Integrated Approach to Waste Treatment in Automotive Industry: Solidification/Stabilization, Valorization, and Techno-Economic Assessment. Sustainability, 17(19), 8553. https://doi.org/10.3390/su17198553