Research on the Current Status of Waste Mineral Oil Management and Resource Utilization in China’s Railway Industry: A Case Study of the Beijing Railway Bureau

Abstract

1. Introduction

2. Research Subjects and Methods

2.1. Overview of Research Subjects

2.2. Research Methods

2.2.1. Survey Research Method

2.2.2. Case Study Method

2.2.3. Statistical Analysis Method

- (1)

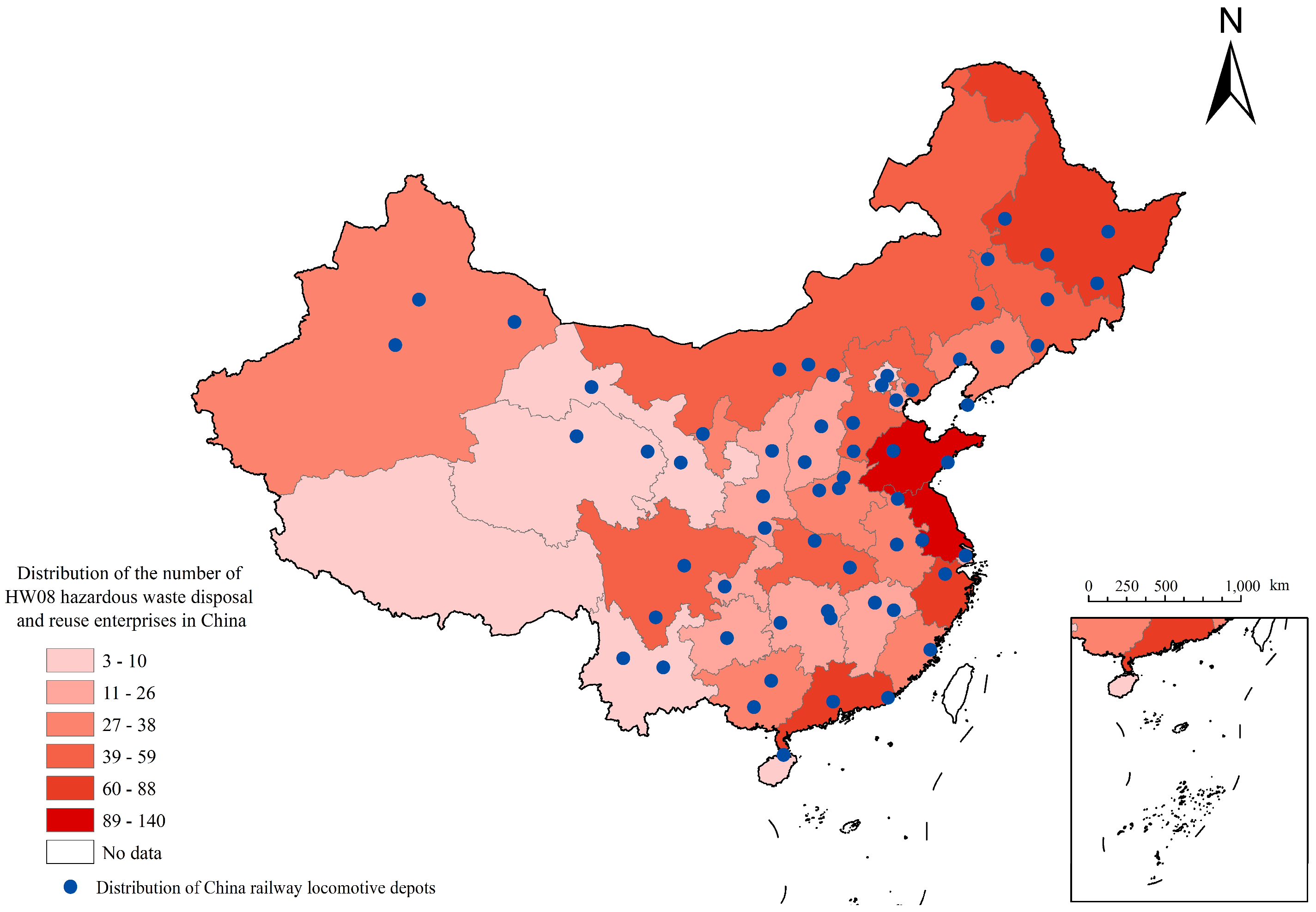

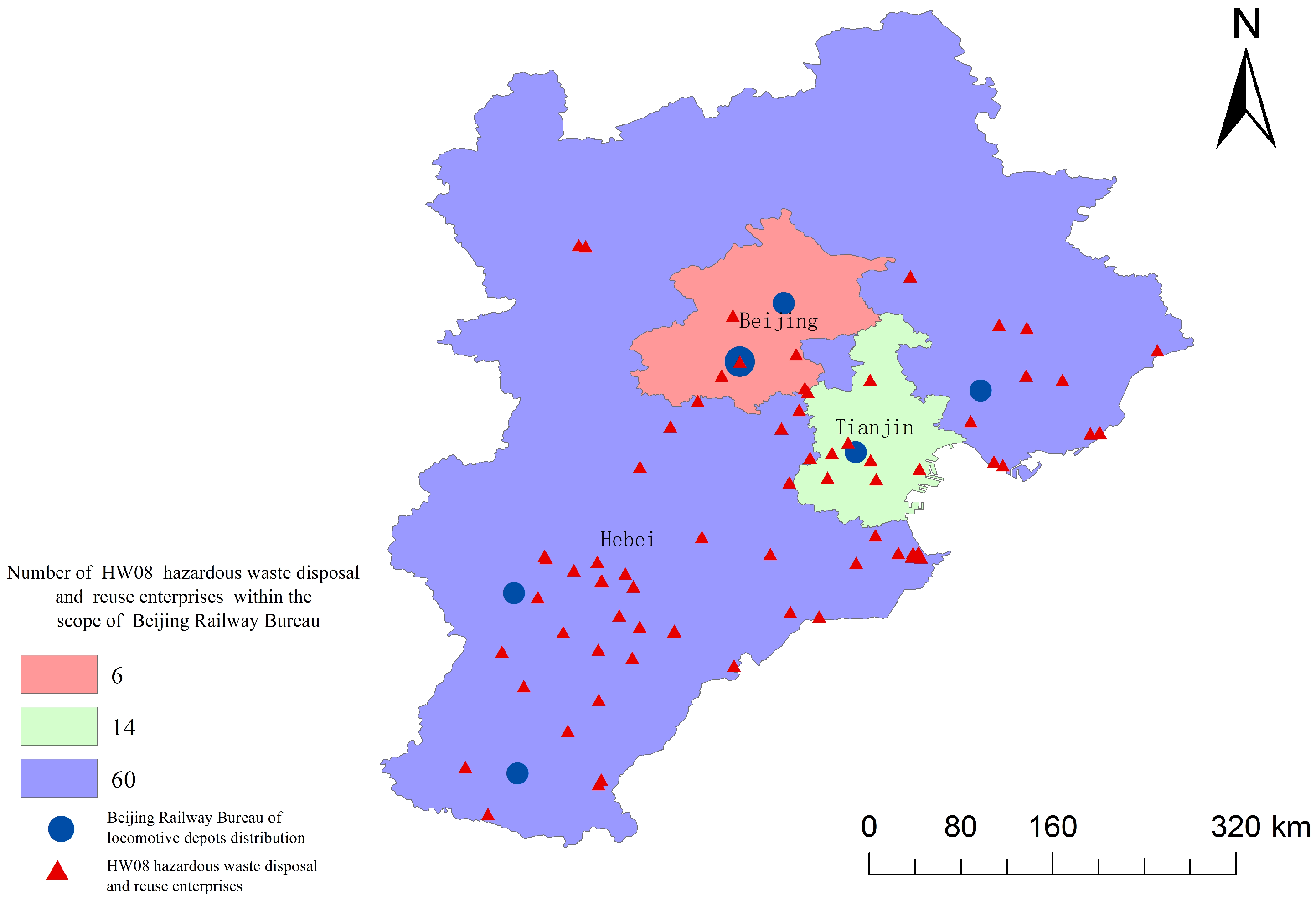

- The number of enterprises qualified for HW08 (waste mineral oil) disposal was identified and verified using the official “List of Hazardous Waste Business License Enterprises” released by the environmental authorities of 31 provinces, autonomous regions, and municipalities in mainland China (excluding Hong Kong, Macao, and Taiwan). Their spatial distribution was further visualized using a Geographic Information System (ArcGIS 10.8) to reveal regional disparities in disposal capacity [20,21].

- (2)

- Information on the number and geographical distribution of locomotive depots nationwide was obtained from the official websites of railway bureaus and their annual reports.

- (3)

- The average annual generation of waste mineral oil at representative locomotive depots in Beijing was estimated through a combination of field investigations and publicly available data released by local environmental protection bureaus.

- (4)

- Price differentials between new diesel engine oil and re-refined oil were analyzed using procurement price lists of railway enterprises, industry reports, and the Lubricating Oil Price Network. Furthermore, based on the IPCC (2019) [22] carbon emission factors and relevant literature, the environmental and economic benefits of substituting re-refined oil for virgin oil were quantitatively assessed.

2.2.4. Data Sources

3. Results and Analysis

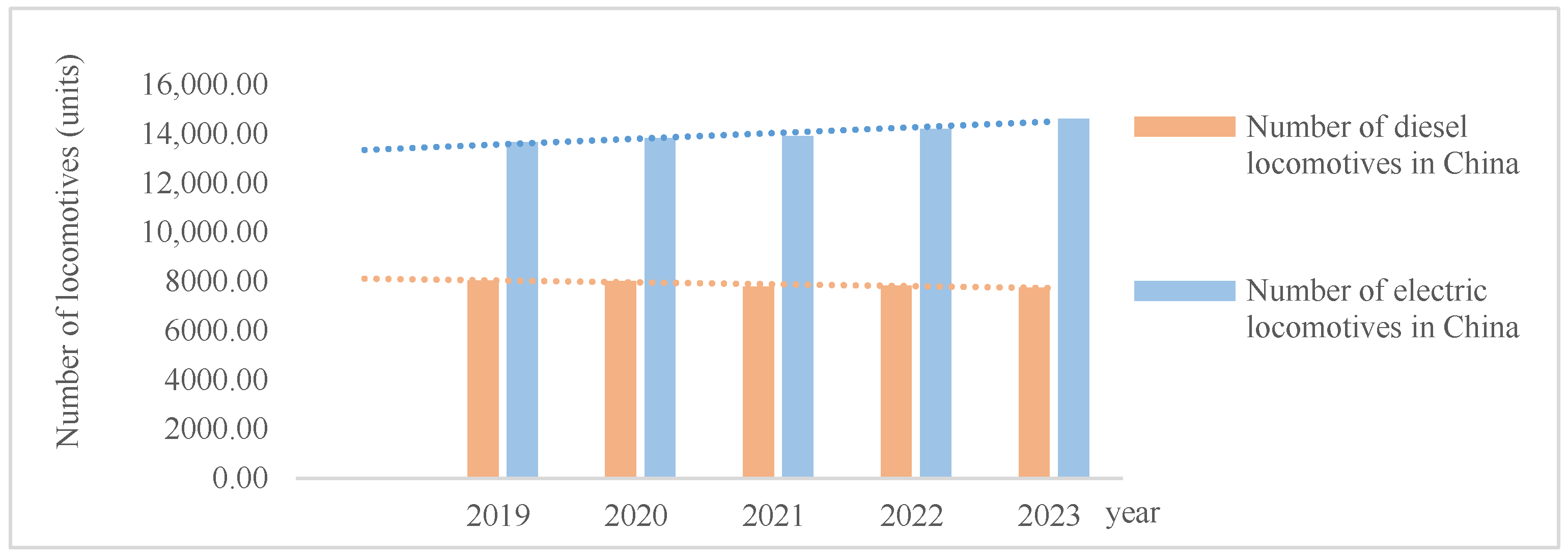

3.1. Analysis of Waste Mineral Oil Generation in Railway

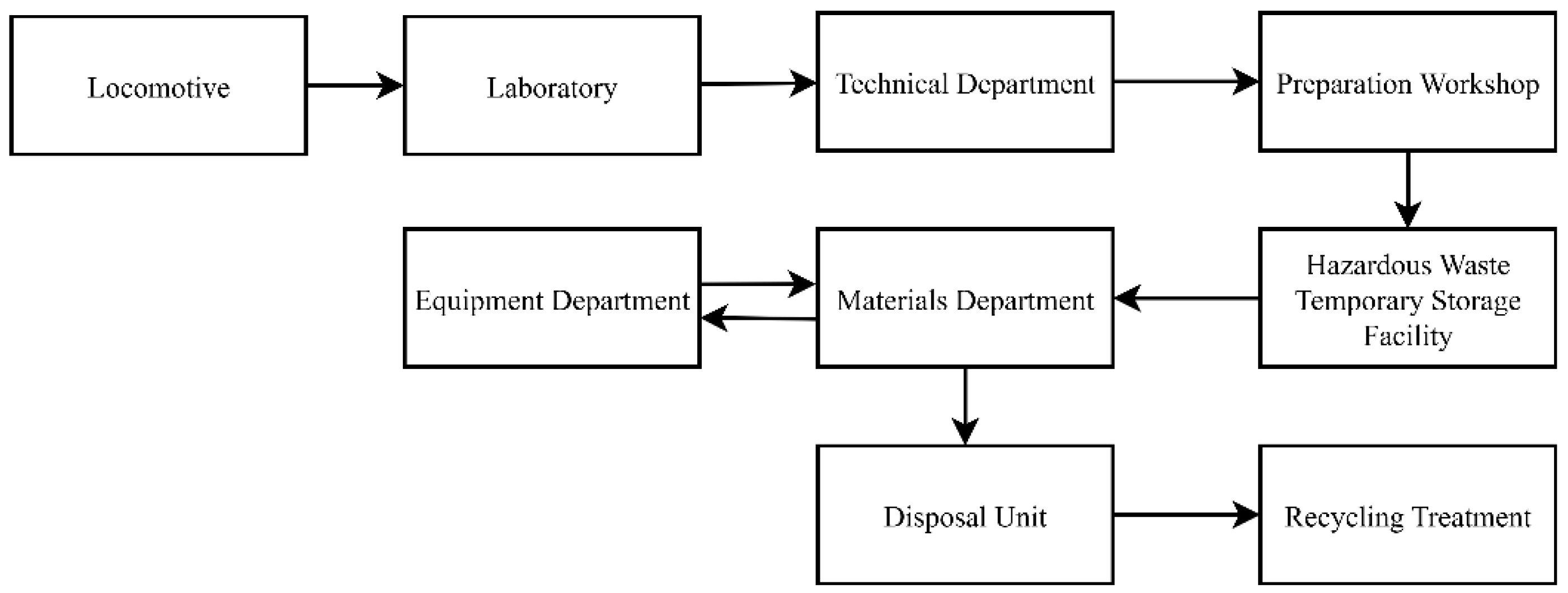

3.2. Current Status of Management and Disposal of Waste Mineral Oil in China’s Railway

3.3. Economic and Environmental Benefits of Recycling Waste Mineral Oil from Railways

- = Recycled oil production (t)

- = Waste oil generation (t)

- = Base oil yield rate (%)

- = Cost savings (yuan)

- = Price of new oil (yuan/t)

- = Price of recycled oil (yuan/t)

- Cred = Carbon emission reduction (tCO2)

- = Carbon emission coefficient of new oil (tCO2/t)

- = Carbon emission coefficient of recycled oil (tCO2/t)

4. Recommendations for the Management of Waste Mineral Oil and Future Improvement Measures

4.1. Upgrading Disposal Technology and Standardizing Products

4.2. Closed-Loop Management Throughout the Entire Life Cycle and Quantification of Carbon Emission Reduction Value

4.3. Economic Incentive Mechanisms and Digital Regulatory Platform Construction

5. Conclusions

6. Limitations and Future Work

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Jiang, W.; Zhao, W.; Gao, D.; Fang, F.; Liu, Y. Problems and new standardization trends of waste mineral oil recovery and recycling industry in China. Resour. Recycl. 2020, 29–32. (In Chinese) [Google Scholar]

- Xu, L.; Yu, J.; Wan, G.; Sun, L. Emission characteristics and source identification of polycyclic aromatic hydrocarbons (PAHs) from used mineral oil combustion. Fuel 2021, 304, 121357. [Google Scholar] [CrossRef]

- ChinaIRN.COM. Analysis of the Current Status and Competitive Landscape of the Waste Mineral Oil Recycling Industry in 2024. Available online: https://www.chinairn.com/hyzx/20240219/180249355.shtml (accessed on 20 July 2025). (In Chinese).

- Liu, D.; Ba, Q.; Li, J.; Wang, X. Discussion on new technologies for pretreatment of railway hazardous waste. Retard. Speed Control. Technol. 2023, 15–17. (In Chinese) [Google Scholar]

- National Railway Administration of China. Aim to Phase Out Old Internal Combustion Locomotives by 2027 and Strive to Achieve A Share of Over 70% for Electric Locomotives by 2030. Available online: http://www.rail-metro.com/index.php?c=content&a=show&id=25666 (accessed on 20 July 2025). (In Chinese).

- National Bureau of Statistics of China. China Statistical Yearbook—2024. Available online: http://www.stats.gov.cn (accessed on 20 July 2025). (In Chinese)

- Kanokkantapong, V.; Kiatkittipong, W.; Panyapinyopol, B.; Wongsuchoto, P.; Pavasant, P. Used lubricating oil management options based on life cycle thinking. Resour. Conserv. Recycl. 2009, 53, 294–299. [Google Scholar] [CrossRef]

- Zelenko, Y.; Bezovska, M.; Kuznetsov, V.; Muntian, A. Resource saving and eco-friendly technology for disposal of used railroad engine oils. Rocz. Ochr. Środow. 2020, 22, 171–180. [Google Scholar]

- Ministry of Ecology and Environment of China. National Directory of Hazardous Wastes (2025 Version). Available online: https://www.mee.gov.cn/gzk/gz/202411/t20241129_1097688.shtml (accessed on 20 July 2025). (In Chinese)

- Li, L.; Chen, C.; Tian, L.; Pan, J.; Zhang, G.; Qi, Y.; Qi, L. Discussion on standardized management of exemption and exclusion of railway hazardous waste. Railw. Energy Sav. Environ. Prot. Occup. Saf. Health. 2024, 14, 40–45. (In Chinese) [Google Scholar]

- Yu, M.; Ma, H.; Wang, Q. Research and recycling advancement of used oil in China and all over the world. Procedia Env. Sci. 2012, 16, 239–243. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Q.; Ke, L.; Peng, Y.; Liu, Y.; Wu, Q.; Tian, X.; Dai, L.; Ruan, R.; Jiang, L. Review on the catalytic pyrolysis of waste oil for the production of renewable hydrocarbon fuels. Fuel 2021, 283, 119170. [Google Scholar] [CrossRef]

- Mishra, A.; Siddiqi, H.; Kumari, U.; Behera, I.D.; Mukherjee, S.; Meikap, B.C. Pyrolysis of waste lubricating oil/waste motor oil to generate high-grade fuel oil: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 150, 111446. [Google Scholar] [CrossRef]

- Shanghai Chemical Industry. 2017 Domestic and International Oil and Gas Industry Development Report released: China’s crude oil import dependence reaches 67.4%. Shanghai Chem. Ind. 2018, 43, 5. (In Chinese) [Google Scholar]

- Botas, J.A.; Moreno, J.; Espada, J.J.; Serrano, D.P.; Dufour, J. Recycling of used lubricating oil: Evaluation of environmental and energy performance by LCA. Resour. Conserv. Recycl. 2017, 125, 315–323. [Google Scholar] [CrossRef]

- Liang, Y.; Li, J.; Dong, Q.; Wang, Z. Present situation and prospect of used lubricating oil recycling technology and management in China. J. Environ. Eng. Technol. 2018, 8, 282–289. (In Chinese) [Google Scholar]

- Beijing Railway Bureau Yearbook Editorial Committee. Beijing Railway Bureau Yearbook 2022; Beijing Railway Bureau Yearbook Editorial Department: Beijing, China, 2023; pp. 32–275. [Google Scholar]

- Han, D.; Kalantari, M.; Rajabifard, A. Identifying and prioritizing sustainability indicators for China’s assessing demolition waste management using modified Delphi–analytic hierarchy process method. Waste Manag. Res. 2023, 41, 1649–1660. [Google Scholar] [CrossRef]

- Younas, A.; Inayat, S. Choosing an analytical approach in case study research. Creat. Nurs. 2025, 31, 90–92. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Liu, Y.; Li, Z. Present situation of hazardous waste generation in China and grey model prediction. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 467, p. 012179. [Google Scholar]

- Guan, X.G.; Ren, F.R.; Fan, G.; Zhang, Q.Q.; Wu, T.F. Dynamic evaluation and sensitivity analysis of China’s industrial solid waste management efficiency based on ecological environment cycle perspective. Front. Environ. Sci. 2024, 12, 1462975. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc.ch/report/2019-refinement-to-the-2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 20 July 2025).

- Wang, T.; Zhang, Z.; Sun, X.; Shi, J. Alculation and evaluation of carbon footprint in lube base oil production stage. Pet. Process. Petrochem. 2024, 55, 111–118. (In Chinese) [Google Scholar]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/chinese/index.html (accessed on 20 July 2025).

- EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2022. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2022 (accessed on 20 July 2025).

- Grice, L.N.; Nobel, C.E.; Longshore, L.; Huntley, R.; DeVierno, A.L. Life cycle carbon footprint of re-refined versus base oil that is not re-refined. ACS Sustain. Chem. Eng. 2014, 2, 158–164. [Google Scholar] [CrossRef]

- Q/CR 182-2014; Oil-Change Criterion of Diesel Locomotive Engine Oils. Ministry of Railways of the People’s Republic of China: Beijing, China, 2014.

- TB/T 2956-2009; Diesel Engine Oils for Railway Diesel Locomotives. Ministry of Railways of the People’s Republic of China: Beijing, China, 2009.

- Chyxx.com. 2023 Analysis of the Current Status of China’s Waste Mineral Oil Industry: Stricter Environmental Regulations and Growing Demand for Lubricants Release Market Potential for Waste Mineral Oil Recycling. Available online: https://www.chyxx.com/industry/1164769.html (accessed on 20 July 2025).

- Rac, A.; Vencl, A. Ecological and technical aspects of the waste oils influence on environment. In Annals of “Dunărea de Jos” University of Galaţi. Fascicle VIII, Tribology; “Dunărea de Jos” University of Galați: Galați, Romania, 2012; Volume 18, pp. 5–11. [Google Scholar]

- Liu, X.; Liao, L. Issues on industrialization of regenerative resources in waste lubricating oil. Resour. Sci. 2006, 186–190. (In Chinese) [Google Scholar]

- Zhang, C.; Zhao, Y.; Deng, Y.; Wang, H. The status quo of regeneration technology for used lubricating oils and the thoughts of industry development. Lubr. Oil 2008, 9–12. Available online: https://link.cnki.net/doi/10.19532/j.cnki.cn21-1265/tq.2008.02.003 (accessed on 20 July 2025). (In Chinese).

- Han, L.; Sun, W.; Tian, T.; Fang, Y.; Tong, X.; Dai, H.; Zeng, X. Material flow analysis of the civil automotive lubricating oil in China. J. Basic Sci. Eng. 2025, 33, 103–110. (In Chinese) [Google Scholar]

- Pinheiro, C.T.; Quina, M.J.; Gando-Ferreira, L.M. Management of waste lubricant oil in Europe: A circular economy approach. Crit. Rev. Environ. Sci. Technol. 2021, 51, 2015–2050. [Google Scholar] [CrossRef]

- Sarkar, S.; Datta, D.; Deepak, K.S.; Mondal, B.K.; Das, B. Comprehensive investigation of various re-refining technologies of used lubricating oil: A review. J. Mater. Cycles Waste Manag. 2023, 25, 1935–1965. [Google Scholar] [CrossRef]

- Kupareva, A.; Mäki-Arvela, P.; Murzin, D.Y. Technology for rerefining used lube oils applied in Europe: A review. J. Chem. Technol. Biotechnol. 2013, 88, 1780–1793. [Google Scholar] [CrossRef]

- Wang, R.; Xu, Q.; He, C.; Liu, X.; Feng, Z.; Zhang, L.; Gao, J. Analysis of hazardous waste management elements in oil and gas enterprises based on the life-cycle management concept. Sustainability 2023, 15, 5504. [Google Scholar] [CrossRef]

| Data Category | Specific Data Items | Source |

|---|---|---|

| Case Data | Spectroscopic records of lubricating oil | Derived from field investigations at locomotive depots affiliated with the Beijing Railway Bureau |

| Macro Data | Number and spatial distribution of locomotive depots across China | Extracted from official websites of railway bureaus and their annual reports (detailed statistics are provided in the Supplementary Materials) |

| Number and spatial distribution of licensed HW08 disposal enterprises | Compiled from publicly available lists released by provincial, regional, and municipal environmental protection authorities (detailed statistics are provided in the Supplementary Materials) | |

| Annual waste oil generation at Tangshan Locomotive Depot | Obtained from publicly released data of the Tangshan Municipal Bureau of Ecology and Environment | |

| Market Data | Price of virgin diesel engine oil | Calculated as the average values from lubricating oil procurement price lists of railway enterprises (covering three major product types: multigrade Generation IV, multigrade Generation V, and monograde Generation V) |

| Price of re-refined diesel engine oil | Estimated from the Lubricating Oil Price Network (Mysteel), indicating that re-refined oil is priced at approximately 75% of virgin oil | |

| Environmental Data | Carbon emission factors of virgin and re-refined oils | Derived from the IPCC 2019 Guidelines for National Greenhouse Gas Inventories and related literature [22,23,24,25,26]; the emission factor for virgin oil was set at 3.5 tCO2/t, and that for re-refined oil at 1.1 tCO2/t |

| Sources of Waste Mineral Oil Generation in Locomotive Depots | Main Waste Categories | Basis for Waste Mineral Oil Generation | Reference Standards |

|---|---|---|---|

| Diesel locomotive maintenance | Waste engine oil | Oil changes and the identification of waste mineral oil are performed based on the maintenance protocols for different regions and locomotive models (DF-series locomotives for medium overhaul, minor repairs, and temporary repairs; ND-series locomotives for monthly, quarterly, semi-annual, annual overhauls, and temporary repairs; HX-series locomotives for C1–C3, C4, and C5 repairs), as well as the performance specifications of different lubricants. | Oil-change criterion of diesel locomotive engine oils (Q/CR 182-2014) Diesel locomotive hydraulic transmission oil change index(Q/CR 218-2014) Air compressor lubricating oil for railway locomotive (Q/CR 332-2014) Lubricating grease for railway locomotive wheelset rolling bearings (Q/CR 290-2022) Rolling Stock Special Lubricating Oil Silicone Oil for Brake Valve(Q/CR 761-2020) Rolling Stock Special Grease Traction Motor Bearing Grease (Q/CR 881-2022) Maintenance procedures for various types of electric locomotives, diesel locomotives, etc. |

| Waste gear oil, etc. | |||

| Electric locomotive maintenance | Waste gear oil, etc. |

| Locomotive Type | Cu | Al | Cr | Ni | Si | Na | Sn | Pb |

|---|---|---|---|---|---|---|---|---|

| HXN3B | 2.936 | 2.7 | 0.4 | 0 | 4.3 | 2.2 | 16.5 | 11.1 |

| HXN3B | 0.005 | 2.0 | 0.2 | 2.9 | 14.9 | 2.6 | 5.6 | 0.1 |

| HXN3B | 0.005 | 0.5 | 0.5 | 4.6 | 13.8 | 5.9 | 4.5 | 0 |

| HXN3B | 0.005 | 0.3 | 0.3 | 0 | 0 | 6.9 | 3.7 | 0 |

| HXN3 | 6.646 | 1.9 | 0.7 | 2.5 | 5.4 | 38.0 | 11.4 | 14.4 |

| HXN3 | 0.005 | 4.0 | 0.3 | 1.6 | 13.0 | 4.8 | 11.0 | 4.3 |

| HXN3 | 2.694 | 0 | 0.5 | 0.1 | 0 | 15.8 | 13.4 | 11.8 |

| Serial Number | Implementation Time | Name | Main Content |

|---|---|---|---|

| 1 | 2011 | Technical Specifications for Pollution Control of Used Mineral Oil Recovery, Recycle and Reuse | Regulate the collection, transportation, storage, utilisation, and disposal of waste mineral oil to prevent environmental pollution caused by waste mineral oil. This includes specifying pollution control technologies and environmental management requirements for the collection, transportation, storage, utilisation, and disposal of waste mineral oil. |

| 2 | 2015 | Standardized Management Indicator System for Hazardous Waste | Including the status of hazardous waste identification markings, the formulation of management plans, the implementation of management systems such as reporting and registration, transfer manifests, operating permits, and emergency response plan filings, as well as whether storage, utilisation, and disposal comply with relevant standards and specifications. |

| 3 | 2016 | Measures for the Administration of Permit for Operation of Dangerous Wastes (2016 Revision) | Establishes a tiered approval and categorized management licensing system; requires entities engaged in collection, storage, or disposal to obtain permits; defines application conditions, approval procedures, license content, modification and supervision requirements; imposes strict legal liabilities; prohibits unlicensed operations and illegal transfers. |

| 4 | 2016 | Industry standard conditions for comprehensive utilization of waste mineral oil | Mandates that waste mineral oil recycling enterprises avoid environmentally sensitive areas; sets minimum annual disposal capacity of 30,000 tons for new/renovation projects; requires mandatory environmental protection facilities; limits energy consumption to ≤900 kWh per ton of base oil; mandates possession of a hazardous waste operation license. |

| 5 | 2020 | Standard for pollution control on the hazardous waste landfill | Specifies waste acceptance criteria for hazardous waste landfills and environmental protection requirements for site selection, design, construction, operation, closure, and monitoring. |

| 6 | 2020 | Technical specifications on identification for hazardous waste | Defines technical requirements for sampling, testing, and result determination in hazardous waste characteristic identification. |

| 7 | 2020 | Law of the People’s Republic of China on the Prevention and Control of Environmental Pollution by Solid Wastes (2020 Revision) | Imposes mandatory requirements for the collection, storage, utilization, and disposal of hazardous waste. |

| 8 | 2021 | Pollution Control Standard for Hazardous Waste Incineration | Specifies environmental protection requirements for site selection, operation, monitoring, waste storage, and incineration processes of hazardous waste incineration facilities; includes implementation and supervision provisions. |

| 9 | 2022 | Measures for the Transfer of Hazardous Wastes | Establishes a full-process supervision system for hazardous waste transfers, covering transfer manifests, inter-provincial approvals, stakeholder responsibilities, and risk control requirements. |

| 10 | 2022 | Technical Guideline for Deriving Hazardous Waste Management Plans and Records | Guides hazardous waste generators in formulating management plans, establishing record systems, reporting waste-related data, and enhancing standardized environmental management. |

| 11 | 2023 | Standard for pollution control on hazardous waste storage | Specifies the general requirements, site selection, and pollution control requirements for storage facilities, pollution control requirements for containers and packaging, pollution control requirements for storage process, and environmental management requirements such as pollutant emission, environmental monitoring, environmental emergency planning, implementation, and supervision in terms of the pollution control of hazardous waste storage. |

| 12 | 2023 | Treatment and Disposal Methods for used Mineral Oil Lubricant | Specifies the process routes, method summaries, treatment and disposal methods, finished product control, and environmental protection requirements for the treatment and disposal of used mineral oil lubricant. It applies to the waste category ‘HW08 Waste Mineral Oil and Mineral Oil-Containing Waste’ listed in the National Directory of Hazardous Wastes (2025 Version) |

| 13 | 2023 | Notice by the General Office of the Ministry of Ecology and Environment of Further Strengthening the Standardized Environmental Management of Hazardous Wastes | Enhances full-process informatized supervision of hazardous waste and deepens standardized risk assessment for environmental risk prevention. |

| 14 | 2024 | Guidelines for recycling of used mineral oil | Specifies the general requirements for the recovery and recycling of waste mineral oil, recovery management requirements, recycling process requirements, environmental protection requirements, and recycling product management requirements. |

| 15 | 2025 | National Directory of Hazardous Wastes (2025 Version) | Classifies hazardous wastes by source, waste code, and hazardous characteristics. |

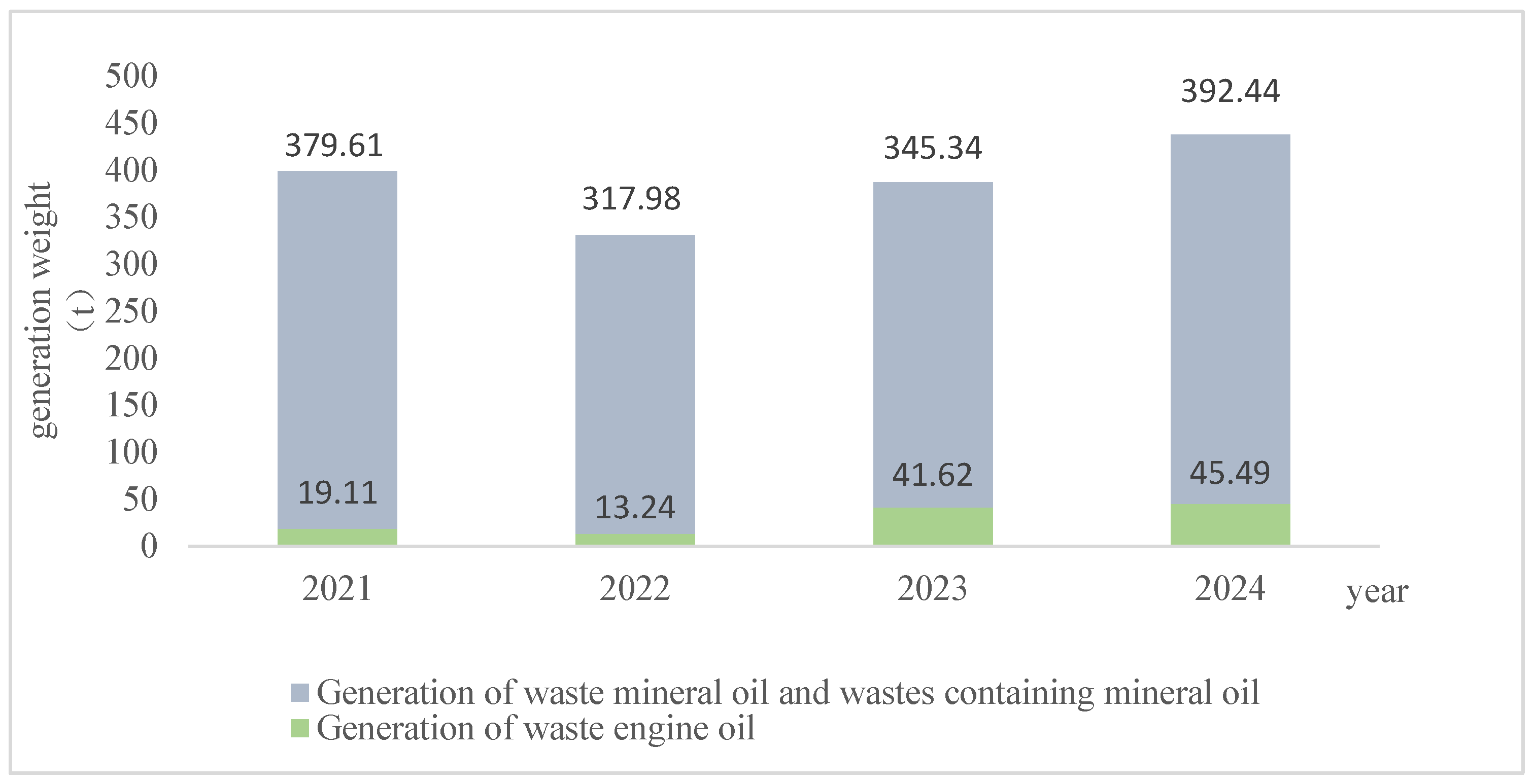

| Item | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| (t) | 19.10 | 13.24 | 41.62 | 45.49 |

| (yuan/t) | 22,788 | 22,433 | 22,433 | 22,433 |

| (yuan/t) | 17,091 | 16,824 | 16,824 | 16,824 |

| (yuan) | 76,200 | 52,000 | 163,400 | 178,600 |

| (tCO2) | 32.09 | 22.24 | 69.92 | 76.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, X.; Ren, F.; Wang, Y.; Cao, Y. Research on the Current Status of Waste Mineral Oil Management and Resource Utilization in China’s Railway Industry: A Case Study of the Beijing Railway Bureau. Sustainability 2025, 17, 8487. https://doi.org/10.3390/su17188487

Ge X, Ren F, Wang Y, Cao Y. Research on the Current Status of Waste Mineral Oil Management and Resource Utilization in China’s Railway Industry: A Case Study of the Beijing Railway Bureau. Sustainability. 2025; 17(18):8487. https://doi.org/10.3390/su17188487

Chicago/Turabian StyleGe, Xiaoyu, Fumin Ren, Yongze Wang, and Yujing Cao. 2025. "Research on the Current Status of Waste Mineral Oil Management and Resource Utilization in China’s Railway Industry: A Case Study of the Beijing Railway Bureau" Sustainability 17, no. 18: 8487. https://doi.org/10.3390/su17188487

APA StyleGe, X., Ren, F., Wang, Y., & Cao, Y. (2025). Research on the Current Status of Waste Mineral Oil Management and Resource Utilization in China’s Railway Industry: A Case Study of the Beijing Railway Bureau. Sustainability, 17(18), 8487. https://doi.org/10.3390/su17188487