Evaluating the Environmental Impacts and Social Risks of Limestone Calcined Clay Cement (LC3) Mortars

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Scenarios

3.2. Life Cycle Assessment

3.2.1. Goal and Scope

3.2.2. Life Cycle Inventory

3.2.3. Life Cycle Impact Assessment

3.2.4. Interpretation

3.3. Social Risk Assessment

SRA Procedure

4. Results

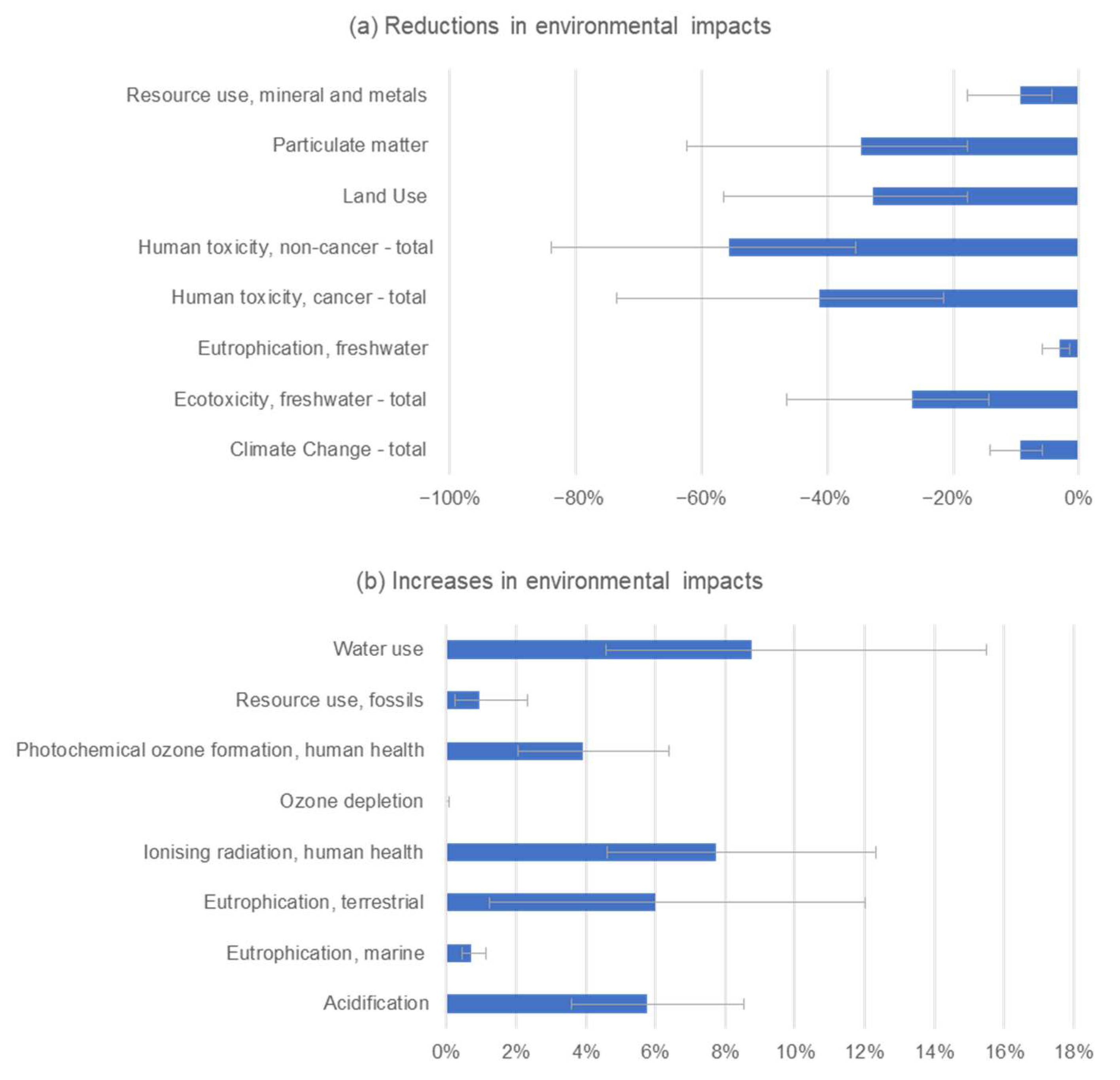

4.1. LCA

Sensitivity Analysis

4.2. SRA

5. Discussion

5.1. LCA

5.2. SRA

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFm | Carboaluminate |

| AFt | Calcium Aluminate Ferrite trisubstituted |

| CH | Portlandite |

| DBC | Deutsche Bauchemie |

| ECC | Engineered cementitious composite |

| EF 3.0 | Environmental Footprint, version 3.0 |

| EPD | Environmental Product Declaration |

| EVA | Economic Value Added |

| FAC | Fly ash cenosphere |

| GHG | Greenhouse Gases |

| HPMC | Hydroxypropylmethylcellulose |

| LC3 | Limestone Calcined Clay Cement |

| LC3–50 | LC3 formulation with 50% Ordinary Portland Cement |

| LC3–35 | LC3 formulation with 35% Ordinary Portland Cement |

| LC3–25 | LC3 formulation with 25% Ordinary Portland Cement |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LCSA | Life Cycle Sustainability Assessment |

| LW-ECC | Lightweight engineered cementitious composite |

| MC | Methylcellulose |

| OPC | Ordinary Portland Cement |

| PPC | Portland Pozzolana Cement |

| PSILCA | Product Social Impact Life Cycle Assessment |

| RAC | Recycled aggregate concrete |

| SCM | Supplementary cementitious materials |

| SHCC | Strain-hardening cementitious composites |

| SHDB | Social Hotspot Database |

| S-LCA | Social Life Cycle Assessment |

| S-LCI | Social Life Cycle Inventory Analysis |

| S-LCPA | Social Life Cycle Performance Assessment |

| S-LCIA | Life Cycle Impact Assessment |

| SRA | Social Risk Assessment |

| TRC | Textile-reinforced composites |

| VMA | Viscosity-modifying agent |

References

- Curbach, M.; Marx, S.; Mechtcherine, V. Beiträge zum 61. In Proceedings of the Forschungskolloquium mit 9, Jahrestagung des DAfStb, Dresden, Germany, 26–27 September 2022. [Google Scholar]

- Hilgers, C.; Becker, I. Ressourceneffizienter Beton—Zukunftsstrategien für Baustoffe und Baupraxis: 15. Symposium Baustoffe und Bauwerkserhaltung; Nolting, U., Dehn, F., Link, J., Mercedes Kind, V., Eds.; KIT Scientific Publishing: Karlsruhe, Germany, 2020. [Google Scholar]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of initial CaO/Al2O3 and SiO2/Al2O3 ratios on the properties of slag/fly ash-based geopolymer stabilized clay: Synergistic effects and stabilization mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, G.; Qu, B.; Gong, C. Characterization of a fly ash-based hybrid well cement under different temperature curing conditions for natural gas hydrate drilling. Constr. Build. Mater. 2024, 445, 137874. [Google Scholar] [CrossRef]

- Yang, L.; Gao, Y.; Chen, H.; Jiao, H.; Dong, M.; Bier, T.A.; Kim, M. Three-dimensional concrete printing technology from a rheology perspective: A review. Adv. Cem. Res. 2024, 36, 567–586. [Google Scholar] [CrossRef]

- Srivastava, A.; Kumar, R.; Lakhani, R. Low Energy/Low Carbon Eco-Cementitious Binders as an Alternative to Ordinary Portland Cement. In Handbook of Smart Materials, Technologies, and Devices: Applications of Industry 4.0; Mustansar Hussain, C., Di Sia, P., Eds.; Springer: Cham, Switzerland, 2022; ISBN 978-3-030-58675-1. [Google Scholar]

- INFRAS. LC3 A Sustainable Alternative for the Cement Industry. 2022. Available online: https://lc3.ch/wp-content/uploads/2022/11/LC3-A-sustainable-alternative-FINAL-WEB.pdf (accessed on 10 September 2025).

- Sun, J.; Zunino, F.; Scrivener, K. Hydration and phase assemblage of limestone calcined clay cements (LC3) with clinker content below 50%. Cem. Concr. Res. 2024, 177, 107417. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. Reactivity of kaolinitic clays calcined in the 650 °C–1050 °C temperature range: Towards a robust assessment of overcalcination. Cem. Concr. Compos. 2024, 146, 105380. [Google Scholar] [CrossRef]

- He, C.; Osbaeck, B.; Makovicky, E. Pozzolanic reactions of six principal clay minerals: Activation, reactivity assessments and technological effects. Cem. Concr. Res. 1995, 25, 1691–1702. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Maraghechi, H.; Avet, F.; Wong, H.; Kamyab, H.; Scrivener, K. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Mater. Struct. 2018, 51, 125. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Ahmed, A.H.; Nune, S.; Liebscher, M.; Köberle, T.; Willomitzer, A.; Noack, I.; Butler, M.; Mechtcherine, V. Exploring the role of dilutive effects on microstructural development and hydration kinetics of limestone calcined clay cement (LC3) made of low-grade raw materials. J. Clean. Prod. 2023, 428, 139438. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. The influence of the filler effect on the sulfate requirement of blended cements. Cem. Concr. Res. 2019, 126, 105918. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. The reaction between metakaolin and limestone and its effect in porosity refinement and mechanical properties. Cem. Concr. Res. 2021, 140, 106307. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. Microstructural developments of limestone calcined clay cement (LC3) pastes after long-term (3 years) hydration. Cem. Concr. Res. 2022, 153, 106693. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. Insights on the role of alumina content and the filler effect on the sulfate requirement of PC and blended cements. Cem. Concr. Res. 2022, 160, 106929. [Google Scholar] [CrossRef]

- Zhou, Y.; Gong, G.; Xi, B.; Guo, M.; Xing, F.; Chen, C. Sustainable lightweight engineered cementitious composites using limestone calcined clay cement (LC3). Compos. Part B Eng. 2022, 243, 110183. [Google Scholar] [CrossRef]

- Ahmed, A.H.; Signorini, C.; Chikhradze, M.; Liebscher, M.; Butler, M.; Mechtcherine, V. Employing limestone and calcined clay for preserving the strain-hardening response of PET fiber-reinforced cementitious composites. Constr. Build. Mater. 2024, 438, 137166. [Google Scholar] [CrossRef]

- Ahmed, A.H.; Liebscher, M.; Signorini, C.; Mechtcherine, V. Investigating the Potential of Limestone and Calcined Clay as a Substitute for Fly Ash in Strain-Hardening Cementitious Composites (SHCC). Syposium Paper 2024, 362, 321–330. Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/51740893 (accessed on 12 December 2024).

- Yu, J.; Wu, H.-L.; Leung, C.K. Feasibility of using ultrahigh-volume limestone-calcined clay blend to develop sustainable medium-strength Engineered Cementitious Composites (ECC). J. Clean. Prod. 2020, 262, 121343. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Zunino, F.; Martirena, F.; Scrivener, K. Limestone Calcined Clay Cements (LC3). Mater. J. 2021, 118, 49–60. [Google Scholar] [CrossRef]

- Alghamdi, H.; Shoukryb, H.; Uzzal Hossain, M.; Perumal, P.; Adediran, A.; Abadel, A.A.; Youssef, A.S. Reuse of waste rockwool for improving the performance of LC3-based mortars made with natural and recycled aggregates for sustainable building solutions. J. Build. Eng. 2024, 93, 109881. [Google Scholar] [CrossRef]

- Arruda Junior, E.S.; de Sales Braga, N.T.; Barata, M.S. Life cycle assessment to produce LC3 cements with kaolinitic waste from the Amazon region, Brazil. Case Stud. Constr. Mater. 2023, 18, e01729. [Google Scholar] [CrossRef]

- Martinez, D.M.; Horvath, A.; Monteiro, P.J.M. Comparative environmental assessment of limestone calcined clay cements and typical blended cements. Environ. Res. Commun. 2023, 5, 1–13. [Google Scholar] [CrossRef]

- Macachero Victor Rodrigues, A.L.; Mendes, Á.Á.F.; Gomes, V.; Battagin, A.F.; Mendes Saade, M.R.; Da Gomes Silva, M. Environmental and Mechanical Evaluation of Blended Cements with High Mineral Admixture Content. Front. Mater. 2022, 9, 880986. [Google Scholar] [CrossRef]

- Malacarne, C.S.; Cardoso da Silva, M.R.; Danieli, S.; Gonçalves Maciel, V.; Kirchheim, A.P. Environmental and technical assessment to support sustainable strategies for limestone calcined clay cement production in Brazil. Constr. Build. Mater. 2021, 310, 125261. [Google Scholar] [CrossRef]

- Sánchez Berriel, S.; Ruiz, Y.; Sánchez Machado, I.R.; Martirena Hernandez, J.F.; Dominguez, E.R.; Habert, G. Introducing Low Carbon Cement in Cuba—A Life Cycle Sustainability Assessment Study. In Calcined Clays for Sustainable Concrete, Proceedings of the 2nd International Conference on Calcined Clays for Sustainable Concrete, La Havana, Cuba, 5–7 December 2017; Martirena, F., Favier, A., Scrivener, K., Eds.; Springer: Dordrecht, The Netherlands, 2018; ISBN 978-94-024-1206-2. [Google Scholar]

- Jin, W.; Roux, C.; Ouellet-Plamondon, C.; Caron, J.-F. Life cycle assessment of limestone calcined clay concrete: Potential for low-carbon 3D printing. Sustain. Mater. Technol. 2024, 41, e01119. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Johnson Alengaram, U.; Samuvel Raj, R.; Karthick, S. Limestone calcined clay cement (LC3): A sustainable solution for mitigating environmental impact in the construction sector. Resour. Conserv. Recycl. Adv. 2024, 21, 200197. [Google Scholar] [CrossRef]

- Guo, M.; Gong, G.; Yue, Y.; Xing, F.; Zhou, Y.; Hu, B. Performance evaluation of recycled aggregate concrete incorporating limestone calcined clay cement (LC3). J. Clean. Prod. 2022, 336, 132820. [Google Scholar] [CrossRef]

- Pillai, R.G.; Gettu, R.; Santhanam, M.; Rengaraju, S.; Dhandapani, Y.; Rathnarajan, S.; Basavaraj, A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cem. Concr. Res. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Hafez, H.; Malchiodi, B.; Tosic, N.; Drewniok, M.; Purnell, P.; de la Fuente, A. Decarbonization potential of steel fibre-reinforced limestone calcined clay cement concrete one-way slabs. Constr. Build. Mater. 2024, 435, 136847. [Google Scholar] [CrossRef]

- Huang, X.; Jiao, Z.; Xing, F.; Sui, L.; Hu, B.; Zhou, Y. Performance assessment of LC3 concrete structures considering life-cycle cost and environmental impacts. J. Clean. Prod. 2024, 436, 140380. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, W.; Zhao, X.; Zhou, Y.; Xing, F.; Hou, P.; Chen, C. Shear design and life cycle assessment of novel limestone calcined clay cement reinforced concrete beams. Structual Concr. 2023, 24, 5063–5085. [Google Scholar] [CrossRef]

- Cancio Díaz, Y.; Sánchez Berriel, S.; Heierli, U.; Favier, A.R.; Sánchez Machado, I.R.; Scrivener, K.L.; Martirena Hernández, J.F.; Habert, G. Limestone calcined clay cement as a low-carbon solution to meet expanding cement demand in emerging economies. Dev. Eng. 2017, 2, 82–91. [Google Scholar] [CrossRef]

- Aitcin, P.-C. Cements of yesterday and today. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- EN 15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN: Brussels, Belgium, 2022.

- UN Environment; Scrivener, K.; Vanderley, J.; Gartner, E. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry: Eco-efficient cements. Cem. Concr. Res. 2017, 114, 2–26. [Google Scholar] [CrossRef]

- Ahmed, A.H.; Hübner, J.; Junger, D.; Signorini, C.; Butler, M.; Liebscher, M.; Scheffler, C.; Mechtcherine, V. Engineering low clinker Strain-Hardening cementitious composites (SHCC) using polyethylene and cost-effective polypropylene fibers: An experimental scale-linking analysis. Mater. Des. 2025, 254, 114051. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Chougan, M.; Al-kheetan, M.J.; Al-Mandhari, O.; Al-Saidi, W.; Al-Maqbali, M.; Al-Hosni, H.; Ghaffar, S.H. 3D printing of limestone-calcined clay cement: A review of its potential implementation in the construction industry. Results Eng. 2023, 18, 101115. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Zhang, Y.; Wan, Z.; Çopuroğlu, O.; Schlangen, E. 3D printing of calcined clay-limestone-based cementitious materials. Cem. Concr. Res. 2021, 149, 106553. [Google Scholar] [CrossRef]

- Yan, K.-T.; Wang, X.-P.; Ding, Y.; Li, L.-Z.; Bazarov, D.; Deng, B.-Y.; Nikolayevich, K.-S.; Yu, K.-Q. 3D-printed LC3-based lightweight engineered cementitious composites: Fresh state, harden material properties and beam performance. J. Build. Eng. 2024, 93, 109838. [Google Scholar] [CrossRef]

- Sika Deutschland GmbH. Sika® UW Compound-100. 2025. Available online: https://deu.sika.com/dam/dms/deaddconst01/6/sika-uw-compound-100.pdf (accessed on 26 August 2025).

- Vieira, J.G.; Oliveira, G.d.C.; Filho, G.R.; Assunção, R.M.N.d.; Da Meireles, C.S.; Cerqueira, D.A.; Silva, W.G.; Motta, L.A.d.C. Production, characterization and evaluation of methylcellulose from sugarcane bagasse for applications as viscosity enhancing admixture for cement based material. Carbohydr. Polym. 2009, 78, 779–783. [Google Scholar] [CrossRef]

- Li, L.; Hongwen, J.; Gao, Y.; Hu, T.; Meng, Y.; Fu, G. Influence of methylcellulose on the impermeability properties of carbon nanotube-based cement pastes at different water-to-cement ratios. Constr. Build. Mater. 2020, 244, 118403. [Google Scholar] [CrossRef]

- da Silva, M.G.; Battagin, A.F.; Gomes, V. Cimento Portland com Adições Minerais. In Materiais de Construção Civil e Princípios de Ciência e Engenharia de Materiais; Isaia, G.C., Ed.; Instituto Brasileiro do Concreto: São Paulo, Brazil, 2007. [Google Scholar]

- Engelke, C.; Lenz, T. bbs-Zahlenspiegel 2022: Daten und Fakten zur Baustoff-Steine-Erden-Industrie, Berlin. 2022. Available online: https://cdn.prod.website-files.com/664355396b105bd9a4e9cadb/666072c9190e1d26ee7e41ed_2022-06-20_BBS_Zahlenspiegel_klein_final.pdf (accessed on 10 September 2025).

- UBA. CO2-Emissionsfaktoren für Fossile Brennstoffe: Aktualisierung 2022. 2022. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/11850/publikationen/28_2022_cc.pdf (accessed on 10 September 2025).

- Hobart GmbH. Hobart HSM-20 Planetenrührmaschine Tischgerät 20 Liter. Available online: https://www.gastrouniversum.de/kuechenmaschinen/planetenruehrmaschinen/590/hobart-hsm-20-planetenruehrmaschine-tischgeraet-20-liter (accessed on 10 September 2025).

- Ngo, H.-T.; Kaci, A.; Kadri, E.-H.; Ngo, T.-T.; Trudel, A.; Lecrux, S. Energy consumption reduction in concrete mixing process by optimizing mixing time. Energy Procedia 2017, 139, 810–816. [Google Scholar] [CrossRef]

- Ökobaudat. Prozess-Datenbank: Holcim Sulfo 5 R Siloware Werk Lägerdorf. Available online: https://www.oekobaudat.de/OEKOBAU.DAT/datasetdetail/process.xhtml?uuid=f6ec90be-d755-42fe-b024-08dadef1256a&version=00.01.000;Holcim (accessed on 18 December 2024).

- IBU. PCR Guidance-Texts for Building-Related Products and Services: Part B: Requirements on the EPD for Cement; IBU: Berlin, Germany, 2017. [Google Scholar]

- ISO 14075; Environmental Management—Principles and Framework for Social Life Cycle Assessment. ISO: Geneva, Switzerland, 2024.

- UNEP. Guidelines for Social Life Cycle Assessment of Products and Organizations 2020. 2020. Available online: https://www.unep.org/resources/report/guidelines-social-life-cycle-assessment-products (accessed on 15 September 2025).

- Neugebauer, S.; Traverso, M.; Scheumann, R.; Chang, Y.-J.; Wolf, K.; Finkbeiner, M. Impact Pathways to Address Social Well-Being and Social Justice in SLCA—Fair Wage and Level of Education. Sustainability 2014, 6, 4839–4857. [Google Scholar] [CrossRef]

- GreenDelta GmbH. Product Social Impact Life Cycle Assessment. Available online: https://psilca.net (accessed on 18 December 2024).

- NewEarth, B. Social Hotspots Database (SHDB). Available online: http://www.socialhotspot.org (accessed on 18 December 2024).

- Loubert, M.; Maister, K.; Di Noi, C.; Radwan, L.; Ciroth, A.; Srocka, M. PSILCA v. 3.1: A Product Social Impact Life Cycle Assessment Database. 2023. Available online: https://www.researchgate.net/publication/370757136_PSILCA_v31_Database_documentation (accessed on 15 September 2025).

- Bosold, D.; Pickhardt, R. Zement-Merkblatt Betontechnik B1: Zemente und Ihre Herstellung. 2024. Available online: https://www.vdz-online.de/wissensportal/publikationen/zement-merkblatt-b1-zemente-und-ihre-herstellung (accessed on 10 September 2025).

- VDZ. Umweltdaten der Deutschen Zementindustrie 2022, Düsseldorf. 2023. Available online: https://www.bvse.de/dateien2020/2-PDF/01-Nachrichten/07-EBS-Holz-Bio/2022/VDZ_Umweltdaten_Environmental_Data_2022.pdf (accessed on 18 December 2024).

- Backes, J.G.; Schmidt, L.; Bielak, J.; Del Rosario, P.; Traverso, M.; Claßen, M. Comparative Cradle-to-Grave Carbon Footprint of a CFRP-Grid Reinforced Concrete Façade Panel. Sustainability 2023, 15, 11548. [Google Scholar] [CrossRef]

- Hanein, T.; Thienel, K.-C.; Zunino, F.; Marsh, A.T.M.; Maier, M.; Wang, B.; Canut, M.; Juenger, M.C.G.; Ben Haha, M.; Avet, F.; et al. Clay calcination technology: State-of-the-art review by the RILEM TC 282-CCL. Mater. Struct. 2022, 55, 3. [Google Scholar] [CrossRef]

- Gettu, R.; Basavaraj, A.S. Life Cycle Assessment of LC3: Parameters and Prognoses. In Calcined Clays for Sustainable Concrete, Proceedings of the 3rd International Conference on Calcined Clays for Sustainable Concrete, New Delhi, India, 15–17 October 2019; Springer: Singapore, 2020; pp. 277–281. [Google Scholar] [CrossRef]

- Nakhaei, M.; Hu, L.; Da Silva, W.; Laurini, B.; Zong, Y.; Træholt, C. Electrification of Calcined Clay Systems in the Cement Industry—Technical, Economic and Environmental Potentials. In Further Reduction of CO2—Emissions and Circularity in the Cement and Concrete Industry, Proceedings of the 16th International Congress on the Chemistry of Cement 2023—ICCC2023, Bangkok, Thailand, 18–22 September 2023; Thailand Concrete Association: Bangkok, Thailand, 2023; pp. 113–116. [Google Scholar]

- DGUV. Statistik—Arbeitsunfallgeschehen 2023, Berlin. 2024. Available online: https://publikationen.dguv.de/widgets/pdf/download/article/4990 (accessed on 10 September 2025).

- Buckley, M.; Zendel, A.; Biggar, J.; Frederiksen, L.; Wells, J. Migrant Work and Employment in the Construction Sector, 1st ed.; ILO: Geneva, Switzerland, 2016; ISBN 978-92-2-128889-3. [Google Scholar]

| No. | Source | Object | Sustainability Dimension(s) | Method(s) | Goal of Study |

|---|---|---|---|---|---|

| 1 | [27] | Cement | Environmental | LCA | Determine the cradle-to-gate environmental impact of LC3 cements produced with kaolinitic waste in Brazil, and quantify the associated carbon footprint and energy requirements of their production. |

| 2 | [28] | Cement | Environmental | LCA | Develop a life cycle inventory framework and a tool (MKC-LCA Tool) to evaluate the cradle-to-gate environmental impacts of metakaolin manufacturing, and assess the carbon emissions and energy requirements of ternary cement blends (clinker–metakaolin–limestone) with conventional ones. |

| 3 | [29] | Cement | Environmental | LCA | Investigate the combined influence of various SCMs in thirteen blended cement systems, across four blend series combining slag, calcined clay, limestone filler, and fly ash, by evaluating compressive strength over time and relating it to GHG emissions through LCA. |

| 4 | [30] | Cement | Environmental | LCA | Analyze the mechanical and environmental performance of LC3 cements produced from various Brazilian natural and waste clay materials by conducting a cradle-to-gate LCA, comparing their environmental benefits and performance against OPC. |

| 5 | [31] | Cement | Environmental, economic, and social | LCSA | Conduct the first Cuban LCSA implementation through a practical example on introducing LC3, developing a tailored framework to evaluate sustainability impacts specific to the cement industry. |

| 6 | [26] | Mortar | Environmental | LCA | Evaluate the thermophysical, mechanical, fire resistance properties, and carbon emissions of LC3-based mortars incorporating recycled waste and ferrochrome slag as substitutes for traditional materials. |

| 7 | [19] | Mortar | Environmental | LCA | Develop a sustainable lightweight engineered cementitious composite (LW-ECC) incorporating LC3 and FAC, and evaluate its material and environmental performance at varying LC3 replacement levels compared to conventional ECC. |

| 8 | [32] | Concrete | Environmental | LCA | Evaluate the environmental profile of using an LC3-based material for 3D concrete printing to determine its potential for reducing the environmental performance associated with this technology. |

| 9 | [33] | Concrete | Environmental and economic | LCA, LCC | Evaluate the economic and environmental impacts of concrete mixes produced with OPC, Portland Pozzolana Cement (PPC), and LC3 through optimized mix design, considering strength, workability, durability, and material availability. |

| 10 | [34] | Concrete | Environmental | LCA | Investigate the effects of replacing OPC with LC3 on the performance of concrete made with 100% recycled aggregate concrete (RAC) made with 100% RAC, focusing on mechanical strength, chloride resistance, hydration behavior, pore structure, reinforcement corrosion risk, and environmental impact through LCA. |

| 11 | [35] | Concrete | Environmental | LCA | Provide a holistic assessment of LC3 concrete’s suitability by combining service life estimates (based on chloride ingress and corrosion initiation data) with CO2 footprint analysis, comparing it to OPC concrete and OPC blended with 30% fly ash of similar strength grades. |

| 12 | [36] | Component–slabs | Environmental | LCA | Evaluate the decarbonization potential of using LC3-based concrete with steel fibers as an alternative to conventional OPC concrete with steel rebars using one-way slabs as the case study. Eurocode guidelines were applied to assess structural performance, and an LCA was conducted to quantify environmental impacts. |

| 13 | [37] | Component–beam | Environmental and economic | LCA, LCC | Assess the environmental and economic performance of LC3-based concrete and structural elements incorporating seawater, sea sand, RAC, and fiber-reinforced polymer bars. |

| 14 | [38] | Component–beam | Environmental | LCA | Evaluate the shear capacity of beams made with LC3 concrete beams implementing American, Chinese, and Eurocode standards, and assess their carbon emissions and environmental impact. |

| 15 | [39] | Component–building | Environmental and economic | LCA, Economic Value Added (EVA) | Assess the impacts of substituting OPC/PPC with LC3 in the Cuban context through an eco-efficiency analysis combining LCA and EVA, evaluating three construction methods under scenarios of partial and full LC3 substitution. |

| Material | Unit | OPC | LC3-50 | LC3-35 | LC3-25 |

|---|---|---|---|---|---|

| CEM I 52.5 R-SR3/NA | g/L | 1206 | 584 | 404 | 286 |

| Quartz sand | g/L | 271 | 262 | 259 | 257 |

| Limestone | g/L | - | 187 | 245 | 282 |

| Calcined clay | g/L | - | 375 | 490 | 564 |

| Gypsum | g/L | - | 18 | 12 | 9 |

| Water | g/L | 484 | 467 | 462 | 458 |

| Superplasticizer | g/L | 8 | 8 | 8 | 8 |

| VMA | g/L | 4 | 4 | 4 | 4 |

| Material | Amount | Unit | Dataset | Comment |

|---|---|---|---|---|

| Inputs | ||||

| Kaolinitic clay | 1.03 | kg | DE: Kaolin Sphera | Proxy for kaolinitic clay |

| Electricity | 0.09 | MJ | DE: Electricity grid mix (2020) Sphera | |

| Lignite | 0.0901 | kg | DE: Lignite mix Sphera | Proxy for lignite dust |

| Outputs | ||||

| Carbon dioxide | 0.208 | kg | Flow | The CO2 emissions were adjusted to represent the adjusted energy source. |

| Methane | 6.15 × 10−6 | kg | Flow | |

| Nitrous oxide | 1.23 × 10−6 | kg | Flow | |

| Water | 0.0003 | m3 | Flow |

| Impact Category | Unit | OPC | LC3-50 | LC3-35 | LC3-25 |

|---|---|---|---|---|---|

| Climate Change (total) | kg CO2 eq. | 1.13 | 8.04 × 10−1 | 7.11 × 10−1 | 6.49 × 10−1 |

| Acidification | Mole of H+ eq. | 1.12 × 10−3 | 7.86 × 10−4 | 6.89 × 10−4 | 6.26 × 10−4 |

| Ecotoxicity (freshwater) | CTUe | 1.86 | 1.59 | 1.50 | 1.44 |

| Eutrophication (freshwater) | kg P eq. | 6.63 × 10−6 | 6.51 × 10−6 | 6.48 × 10−6 | 6.45 × 10−6 |

| Eutrophication (marine) | kg N eq. | 3.56 × 10−4 | 2.72 × 10−4 | 2.47 × 10−4 | 2.31 × 10−4 |

| Eutrophication (terrestrial) | Mole of N eq. | 3.74 × 10−3 | 2.82 × 10−3 | 2.55 × 10−3 | 2.38 × 10−3 |

| Human toxicity (cancer) | CTUh | 7.22 × 10−11 | 6.30 × 10−11 | 6.01 × 10−11 | 5.83 × 10−11 |

| Human toxicity (non-cancer) | CTUh | 6.88 × 10−9 | 4.85 × 10−9 | 4.24 × 10−9 | 3.85 × 10−9 |

| Ionizing radiation (human health) | kBq U235 eq. | 1.32 × 10−2 | 1.00 × 10−2 | 9.08 × 10−3 | 8.46 × 10−3 |

| Land Use | Pt | 1.30 | 1.08 | 1.02 | 9.80 × 10−1 |

| Ozone depletion | kg CFC-11 eq. | 2.80 × 10−9 | 2.80 × 10−9 | 2.80 × 10−9 | 2.80 × 10−9 |

| Particulate matter | Disease incidences | 2.08 × 10−8 | 1.85 × 10−8 | 1.79 × 10−8 | 1.75 × 10−8 |

| Photochemical ozone formation | kg NMVOC eq. | 9.56 × 10−4 | 6.92 × 10−4 | 6.15 × 10−4 | 5.66 × 10−4 |

| Resource use (fossils) | MJ | 4.26 | 5.12 | 5.36 | 5.53 |

| Resource use (minerals and metals) | kg Sb eq. | 2.81 × 10−7 | 2.72 × 10−7 | 2.69 × 10−7 | 2.67 × 10−7 |

| Water use | m3 world eq. | 3.30 × 10−2 | 2.79 × 10−2 | 2.64 × 10−2 | 2.54 × 10−2 |

| Impact Category | Unit | OPC | LC3-50 | LC3-35 | LC3-25 |

|---|---|---|---|---|---|

| Climate Change (total) | kg CO2 eq./MPa | 1.64 × 10−2 | 1.54 × 10−2 | 2.07 × 10−2 | 2.64 × 10−2 |

| Acidification | Mole of H+ eq./MPa | 1.62 × 10−5 | 1.51 × 10−5 | 2.00 × 10−5 | 2.54 × 10−5 |

| Ecotoxicity (freshwater) | CTUe/MPa | 2.69 × 10−2 | 3.04 × 10−2 | 4.35 × 10−2 | 5.83 × 10−2 |

| Eutrophication (freshwater) | kg P eq./MPa | 9.59 × 10−8 | 1.25 × 10−7 | 1.88 × 10−7 | 2.62 × 10−7 |

| Eutrophication (marine) | kg N eq./MPa | 5.15 × 10−6 | 5.22 × 10−6 | 7.20 × 10−6 | 9.40 × 10−6 |

| Eutrophication (terrestrial) | Mole of N eq./MPa | 5.41× 10−5 | 5.41 × 10−5 | 7.44 × 10−5 | 9.68 × 10−5 |

| Human toxicity (cancer) | CTUh/MPa | 1.04 × 10−12 | 1.21 × 10−12 | 1.75 × 10−12 | 2.37 × 10−12 |

| Human toxicity (non-cancer) | CTUh/MPa | 9.96 × 10−11 | 9.29 × 10−11 | 1.23 × 10−10 | 1.56 × 10−10 |

| Ionizing radiation (human health) | kBq U235 eq./MPa | 1.92 × 10−4 | 1.92 × 10−4 | 2.64 × 10−4 | 3.43 × 10−4 |

| Land Use | Pt/MPa | 1.88 × 10−2 | 2.08 × 10−2 | 2.96 × 10−2 | 3.98 × 10−2 |

| Ozone depletion | kg CFC-11 eq./MPa | 4.06 × 10−11 | 5.37 × 10−11 | 8.14 × 10−11 | 1.14 × 10−10 |

| Particulate matter | Disease incidences/MPa | 3.01 × 10−10 | 3.55 × 10−10 | 5.21 × 10−10 | 7.12 × 10−10 |

| Photochemical ozone formation | kg NMVOC eq./MPa | 1.38 × 10−5 | 1.33 × 10−5 | 1.79 × 10−5 | 2.30 × 10−5 |

| Resource use (fossils) | MJ/MPa | 6.16 × 10−2 | 9.82 × 10−2 | 1.56 × 10−1 | 2.24 × 10−1 |

| Resource use (minerals and metals) | kg Sb eq./MPa | 4.06 × 10−9 | 5.21 × 10−9 | 7.82 × 10−9 | 1.09 × 10−8 |

| Water use | m3 world eq./MPa | 4.78 × 10−4 | 5.36 × 10−4 | 7.66 × 10−4 | 1.03 × 10−3 |

| Stakeholder Category | Sub-Category | Social Issue | Risk Indicator | Economic Sectors | ||||

|---|---|---|---|---|---|---|---|---|

| Q | T | E | L | M | ||||

| Value Chain Actors | Corruption | Active involvement of enterprises in corruption and bribery | Active involvement of enterprises in corruption and bribery | VH | VH | VH | ||

| Fair Competition | Anti-competitive behavior or violation of anti-trust and monopoly legislation | Presence of anti-competitive behavior or violation of anti-trust and monopoly legislation | VH | VH | ||||

| Workers | Freedom of association and collective bargaining | Association and bargaining rights | Right of Collective bargaining | H | ||||

| Right to Strike | H | |||||||

| Fair Salary | Fair Salary | Living wage, per month | VH | VH | VH | VH | VH | |

| Discrimination | Gender wage gap | Gender wage gap | H | |||||

| Health and Safety | Non-fatal accidents | Rate of non-fatal accidents at workplace | H | H | H | H | H | |

| Safety measures | Presence of sufficient safety measures | H | H | |||||

| Local Community | Access to material resources | Biomass consumption | Extraction of biomass (related to area) | VH | VH | VH | VH | VH |

| Certified environmental management system | Certified environmental management systems | VH | H | |||||

| Industrial water depletion | Level of industrial water use (related to renewable water resources) | VH | VH | VH | VH | VH | ||

| Level of industrial water use (related to total withdrawal) | VH | VH | VH | VH | VH | |||

| Safe and healthy living conditions | Contribution to environmental load | Contribution of the sector to environmental load, CO2-equiv, I-Greenhouse Gases (GHG)-CO2eTOTAL_agg | H | H | H | |||

| Contribution of the sector to environmental load, NMVOC, I-AIR-NMVOC_agg | H | |||||||

| Contribution of the sector to environmental load, CO, I-AIR-CO_agg | H | |||||||

| Migration | International migrant stock | International Migrant Stock | H | H | H | H | H | |

| Society | Contribution to economic development | Education | Public expenditure on education | H | H | H | H | H |

| Impact Category | Clay (Best Case) | Clay (Worst Case) | Cement (Best Case) | Cement (Ökobaudat) |

|---|---|---|---|---|

| Climate Change (total) | −16% | −11% | −7% | −8% |

| Acidification | −2% | 45% | 47% | 5% |

| Ecotoxicity (freshwater) | 3% | 55% | 132% | −20% |

| Eutrophication (freshwater) | 4% | 645% | 572% | −2% |

| Eutrophication (marine) | −8% | 4% | 36% | 1% |

| Eutrophication (terrestrial) | −9% | 1% | 42% | 4% |

| Human toxicity (cancer) | −25% | 5% | 7% | −31% |

| Human toxicity (non-cancer) | −20% | −8% | −5% | −47% |

| Ionizing radiation (human health) | 23% | 217% | 116% | 6% |

| Land Use | −12% | 12% | −11% | −25% |

| Ozone depletion | 3% | 377% | 136% | 0% |

| Particulate matter | −34% | −27% | −18% | −26% |

| Photochemical ozone formation | −8% | 5% | 41% | 3% |

| Resource use (fossils) | −34% | −18% | 1% | 0% |

| Resource use (minerals and metals) | −2% | 94% | 93% | −6% |

| Water use | 23% | 300% | 138% | 7% |

| Source | Compressive Strength at 28 Days [MPa] | Climate Change [kg CO2 eq./m3] | Relative Climate Change [kg CO2 eq./m3/MPa] | Comment |

|---|---|---|---|---|

| [26] | 45.5 | 265 | 5.82 | LC3 mixture with natural siliceous sand |

| [26] | 49.2 | 301 | 6.12 | LC3 with ferrochrome slag (recycled material) |

| [19] | 38 | 980 | 25.79 | OPC substitution of 35% |

| [19] | 36 | 850 | 23.61 | OPC substitution of 50% |

| [19] | 31 | 700 | 22.58 | OPC substitution of 65% |

| Current study | 52.2 | 804 | 15.42 | OPC substitution of 50% |

| Current study | 34.4 | 711 | 20.67 | OPC substitution of 35% |

| Current study | 24.6 | 649 | 26.38 | OPC substitution of 25% |

| Process | Eora Sector | Primary Data/Higher Data Resolution Needs |

|---|---|---|

| Fuel production (for clay calcination) | Mining of coal and lignite | Type and origin of fuel; deviation from sector averages |

| Clay extraction | Quarrying of stone and soil | Origin of clay Extraction and processing methods (e.g., wet versus dry extraction) |

| Calcination process | Manufacture of non-metallic mineral products | Calcination technology (e.g., static, rotary, flash calcination) |

| Dried quartz sand production | Quarrying of stone and soil | Origin and extraction methods |

| Gypsum production | Manufacture of non-metallic mineral products | Origin and production route |

| Cement production | Manufacture of non-metallic mineral products | Origin and production technology |

| Limestone production | Quarrying of stone and soil | Origin of limestone |

| Raw material transport | Road and pipeline transport | Transport mode, vehicle type and capacity, fuel, distance |

| Electricity generation and transmission | Electricity and district heat | Electricity mix and supplier-specific conditions |

| LC3 manufacture | Manufacture of non-metallic mineral products | Mixing and batching operations; variations not captured by sector-level data |

| LC3 transport | Road and pipeline transport | Transport mode, vehicle type and capacity, fuel, distance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haverkamp, P.; Traverso, M.; Ahmed, A.H.; Liebscher, M.; Mechtcherine, V. Evaluating the Environmental Impacts and Social Risks of Limestone Calcined Clay Cement (LC3) Mortars. Sustainability 2025, 17, 8364. https://doi.org/10.3390/su17188364

Haverkamp P, Traverso M, Ahmed AH, Liebscher M, Mechtcherine V. Evaluating the Environmental Impacts and Social Risks of Limestone Calcined Clay Cement (LC3) Mortars. Sustainability. 2025; 17(18):8364. https://doi.org/10.3390/su17188364

Chicago/Turabian StyleHaverkamp, Pamela, Marzia Traverso, Ameer Hamza Ahmed, Marco Liebscher, and Viktor Mechtcherine. 2025. "Evaluating the Environmental Impacts and Social Risks of Limestone Calcined Clay Cement (LC3) Mortars" Sustainability 17, no. 18: 8364. https://doi.org/10.3390/su17188364

APA StyleHaverkamp, P., Traverso, M., Ahmed, A. H., Liebscher, M., & Mechtcherine, V. (2025). Evaluating the Environmental Impacts and Social Risks of Limestone Calcined Clay Cement (LC3) Mortars. Sustainability, 17(18), 8364. https://doi.org/10.3390/su17188364