Abstract

The cement industry is a significant contributor to global carbon dioxide emissions, primarily due to the energy demands of its production process and its reliance on clinker, a material formed through the high-temperature calcination of limestone. Strategies to reduce emissions include the adoption of low-carbon fuels, the use of carbon capture and storage (CCS) technologies, and the integration of supplementary cementitious materials (SCMs) to reduce the clinker content. The effectiveness of these measures depends on a complex set of interactions involving technological feasibility, market dynamics, and regulatory frameworks. This study presents a system dynamics model designed to assess how various decarbonization approaches influence long-term emission trends within the cement industry. The model accounts for supply chains, production technologies, market adoption rates, and changes in cement production costs. This study then analyzes a number of scenarios where there is large-scale sustained investment in each of three carbon mitigation strategies. The results show that CCS by itself allows the cement industry to achieve carbon neutrality, but the high capital investment results in a large cost increase for cement. A combined approach using alternative fuels and SCMs was found to achieve a large carbon reduction without a sustained increase in cement prices, highlighting the trade-offs between cost, effectiveness, and system-wide interactions.

1. Introduction

Many countries are implementing a broad range of initiatives aimed at reducing total CO2 emissions to mitigate the effects of climate change. While many of these initiatives focus on energy production and the transportation sector, they also target emissions from specific industrial processes. One such process is cement production, which accounts for approximately eight percent of global CO2 emissions [1]. The global community has introduced several initiatives to reduce carbon emissions associated with cement production. These initiatives include the use of alternative fuels, the implementation of carbon capture and storage (CCS) technologies, and the expanded use of supplementary cementitious materials (SCMs).

Although each of these measures offers potential for emission reduction, they cannot be evaluated in isolation. Their effectiveness depends on a range of interrelated factors, including capital investment requirements, regulatory pressure, and market behavior. In many cases, actions taken to reduce emissions in one part of the system can create unintended consequences elsewhere. For example, increased implementation of CCS would require greater capital investment and operational costs, which could raise the overall cost of cement. This increase in cost might then lead to greater reliance on SCMs to offset the economic burden. However, the use of SCMs would reduce the efficacy of CCS.

This study examines cement’s carbon footprint and evaluates current strategies that show promise in reducing it. It then employs system dynamics modeling to analyze the interactions among key decarbonization measures within the cement industry. The objective is not to forecast a specific outcome, but to improve understanding of the complex dynamics that influence the effectiveness of these initiatives and to evaluate the trade-offs between the different approaches. The model offers insight into the conditions under which decarbonization pathways are likely to succeed or stall, providing guidance to industry stakeholders and policymakers as they develop long-term strategies.

2. Background

2.1. Carbon Emissions from the Cement Industry

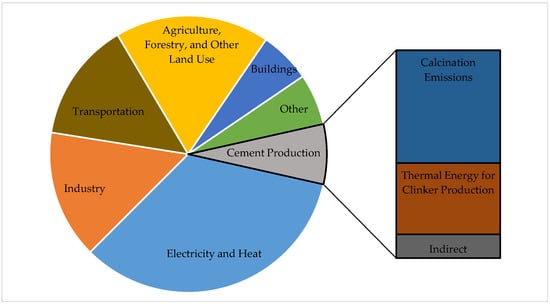

The production of cement results in a significant amount of carbon dioxide emissions, which many nations are targeting for reduction as part of broader global decarbonization efforts. Figure 1 displays the composition of the sources of global CO2 emissions, where cement production currently accounts for approximately eight percent [2].

Figure 1.

Sources of global carbon dioxide. Cement production is responsible for approximately 8 percent, with the bulk of that being from calcination emissions and thermal energy for clinker production.

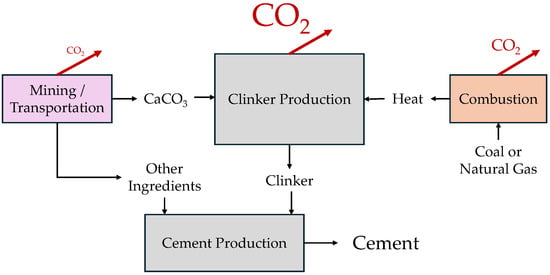

Figure 2 illustrates the sources of carbon emissions from cement manufacturing, which can broadly be grouped into three main categories. Underlying these emissions is clinker, which is the primary binding agent in most cements. Ordinary Portland Cement, the most widely used cement type, contains approximately 90 to 95 percent clinker by mass [3].

Figure 2.

Schematic of the steps for the production of cement with the sources of CO2.

The largest portion of carbon dioxide emissions, accounting for approximately 60 percent of the total, results from the process of calcination [4]. Calcination is the core chemical reaction in clinker production and involves the thermal decomposition of calcium carbonate (CaCO3), typically in the form of finely ground limestone. When heated to temperatures above 850 °C, calcium carbonate breaks down into calcium oxide (CaO), and carbon dioxide gas (CO2) is released as a byproduct:

CaCO3 (s) → CaO (s) + CO2 (g)

This reaction is chemically unavoidable in traditional clinker production because it is required to form the mineral phases responsible for the mechanical properties of cement. On a mass basis, approximately 44 percent of the original mass of CaCO3 is released as CO2 during this transformation.

The second major source of emissions, contributing approximately 30 percent, is related to the thermal energy input required to sustain the clinker production process [5]. While the decomposition of calcium carbonate begins near 850 °C, the complete formation of clinker minerals requires kiln temperatures near 1450 to 1500 °C. This energy is typically supplied through the combustion of fossil fuels such as coal, petroleum coke, or natural gas. The combustion process directly emits CO2, compounding the emissions released from calcination.

The third source of emissions arises from indirect activities associated with cement manufacturing. These include electricity consumption for grinding, milling, and material handling; the transportation of raw materials and finished products; and emissions associated with the operation of auxiliary plant systems [6]. These indirect emissions account for approximately 10 percent of the total carbon footprint of cement production. Although they represent a smaller share, they remain significant and are often targeted through improvements in energy efficiency and increased reliance on renewable electricity sources.

Collectively, these three sources define the carbon footprint associated with cement production. Because the dominant emissions arise from intrinsic chemical reactions and high-temperature thermal processes, comprehensive decarbonization of the sector requires a combination of technological innovations, alternative materials, and carbon capture solutions.

2.2. Efforts to Reduce Carbon Emissions from Cement Production

Between 1990 and 2020, global cement-related carbon dioxide emissions increased from approximately 1.2 to 2.9 gigatons, driven largely by construction growth in developing economies [7]. The 2.9 gigatons of CO2 is associated with 4.5 gigatons of cement, with each ton producing approximately 0.65 tons of CO2. Although energy efficiency improvements have helped slow the rate of increase, emissions continue to rise with global demand. Without significant change, emissions could exceed 3.5 gigatons by 2050 [6]. A moderate pathway involving limited adoption of new technologies to reduce carbon emissions could stabilize emissions around 2.5 gigatons. In contrast, aggressive implementation of these measures, supported by strong policy action, could reduce emissions to below 1 gigaton and align the industry with global net-zero targets [6].

This study focuses on three primary decarbonization strategies for cement production: the use of low-carbon fuels, the implementation of CCS technologies, and the increased integration of SCMs. Each targets a major emissions source: fuel combustion, process emissions from calcination, and clinker content, respectively. Together, these approaches form the foundation for deep emissions reductions across the cement sector.

2.2.1. Adoption of Low-Carbon Fuels

As cement manufacturers seek to reduce carbon emissions, many have adopted alternative fuels to replace coal and other fossil energy sources in clinker production. These substitutions vary in environmental benefit, technical feasibility, and economic viability depending on the local context and fuel characteristics.

Biomass fuels are among the most widely used alternatives. These include wood chips, agricultural residues such as rice husks and sugarcane bagasse, and processed organic waste. From a life cycle perspective, biomass is generally considered carbon neutral, since the carbon dioxide released during combustion roughly equals the carbon absorbed during plant growth [8]. However, biomass fuels typically have a lower energy density than coal and often contain a high moisture content, which reduces thermal efficiency. In regions without abundant agricultural waste, reliable supply chains must be developed. Transport, drying, and preprocessing increase the total cost, and kiln systems may require modifications to accommodate combustion variability and increased ash generation.

Waste-derived fuels include refuse-derived fuel, used tires, plastics, industrial textiles, and solvents. These materials can offer high calorific value and reduce landfill demand, aligning with circular economy objectives. However, maintaining a consistent and high-quality feedstock can be difficult, particularly where waste-sorting infrastructure is limited. Preprocessing requirements such as shredding, drying, and contaminant removal, particularly chlorine and heavy metals, can be substantial [9]. Additionally, facilities often require investment in air pollution control systems to meet emissions standards. Although waste-derived fuels can be cost-effective in regions with landfill fees or tipping incentives, regulatory compliance and operational risks can reduce economic advantages.

Industrial byproducts, including waste oils, petrochemical residues, and solvents, are attractive due to their high energy content and compatibility with existing burner systems. These fuels are often available at low or even negative cost when sourced from industries seeking disposal solutions. However, chemical variability and potential hazardous content may compromise process stability and environmental performance [10]. Facilities must implement strict quality control and continuous emissions monitoring to manage these risks. These fuels are most viable in areas with mature industrial infrastructure and regulatory frameworks that permit co-processing.

In addition to reducing direct emissions from fuel combustion, alternative fuels can also lower indirect emissions associated with the mining, handling, and transportation of conventional fossil fuels. Many alternative fuels can be sourced locally, reducing the reliance on coal imports and associated emissions from long-distance rail or maritime transport. This shift also decreases upstream emissions related to fuel extraction and logistics. In some cases, ash from alternative fuel combustion can be reused as a raw material input, further reducing emissions and resource consumption [11].

Despite these potential benefits, large-scale adoption of alternative fuels requires a careful evaluation of local market conditions, regulatory constraints, and technical compatibility with existing kiln systems. While some plants have achieved thermal substitution rates exceeding 50 percent, their long-term viability depends on balancing the cost, emissions reduction, and operational reliability [12]. Notably, while the industry continues to expand the use of alternative fuels, there is a persistent gap in standardized greenhouse gas accounting. Key protocols such as the CO2 Accounting and Reporting Standard for the Cement Industry developed under the Cement Sustainability Initiative (CSI) in 2005, and more recently, ISO/DIS 19694-3 (2023), remain underutilized [13,14]. These frameworks provide consistent methodologies for quantifying and reporting emissions reductions from alternative fuel use, and their broader adoption could improve transparency, comparability, and credibility in sustainability reporting.

2.2.2. Carbon Capture and Storage

Given that process emissions from calcination are inherent to clinker production, CCS remains one of the few viable pathways to significantly reduce carbon dioxide emissions in conventional cement manufacturing. Although CCS technologies have been applied in other industrial sectors, their use in cement plants presents unique technical and economic challenges.

Several CCS approaches are being adapted to the cement industry. The most mature is post-combustion capture, in which carbon dioxide is removed from the flue gas after clinker production. This is typically achieved using chemical solvents, such as amine-based scrubbing systems, that selectively absorb CO2. The absorbed CO2 is then separated and compressed for transport and storage. These systems are attractive because they can be retrofitted to existing plants with minimal process modification [15]. However, the energy penalty for solvent regeneration is substantial, and the added thermal load can increase fuel consumption unless supplied by low-carbon heat sources.

Oxy-fuel combustion is another promising method. In this approach, the kiln operates with pure oxygen instead of air, resulting in flue gas composed primarily of carbon dioxide and water vapor. This simplifies CO2 separation and compression and can improve thermal efficiency. However, producing oxygen on site using air separation units requires significant capital investment and energy input. Full integration of oxy-fuel systems remains limited to a pilot or demonstration scale, with few commercial applications to date [16].

A third method under development is calcium looping, which uses lime-based sorbents to capture carbon dioxide through a reversible chemical reaction. The system cycles between a carbonation reactor and a calciner, where the sorbent is regenerated. Calcium looping has the advantage of utilizing materials already present in cement production and may offer a high capture efficiency with minimal degradation across cycles [17]. Research is ongoing to improve sorbent durability, reactor integration, and scale-up for full-plant applications.

Despite technical progress, CCS in cement production faces significant challenges, the most substantial of which is cost. Capture systems often introduce high capital and operating expenses that exceed the baseline cost of clinker production [18]. Even when capture is technically feasible, many regions lack the necessary transport infrastructure and access to geological storage, limiting deployment [19]. Regulatory frameworks, permitting processes, and liability structures for long-term storage remain underdeveloped in several major cement-producing countries. In addition, CCS technologies demand substantial thermal or electrical energy, which can reduce net emissions benefits unless paired with renewable energy or waste heat recovery. These energy requirements further increase investment needs. Successful integration must also avoid disruptions to kiln operation and preserve clinker quality, which is essential for meeting structural performance standards.

Recent pilot and demonstration projects have advanced the feasibility of CCS in cement. The LEILAC (Low Emissions Intensity Lime and Cement) project, for example, uses indirect heating to separate CO2 from process gases without chemical solvents [20]. Full-scale demonstrations in Europe and North America are testing hybrid systems that combine post-combustion capture with low-carbon fuels and energy efficiency upgrades. These developments indicate that CCS is technically viable, but widespread deployment will depend on continued innovation, policy incentives, and carbon pricing mechanisms to improve cost competitiveness.

CCS remains a critical component of long-term decarbonization in cement manufacturing. While it may not be an immediate solution for all facilities, its development is essential for aligning the industry with global net-zero-emission targets.

2.2.3. Supplementary Cementitious Materials

Another major pathway for reducing emissions in cement production involves decreasing the proportion of clinker in finished cement through the use of SCMs. Since clinker production is both energy-intensive and chemically responsible for the majority of carbon dioxide emissions, substituting a portion of clinker with SCMs offers a direct and scalable strategy for reducing the overall carbon footprint of cement. It is important to note that clinker will still be required; however, there is the potential for up to 50 percent of clinker to be replaced by SCMs [21].

SCMs are finely ground materials that possess pozzolanic or latent hydraulic properties. When mixed with water and clinker, they react with calcium hydroxide during cement hydration to form additional calcium silicate hydrate (C–S–H), the primary binding phase that provides strength to hardened concrete. Common SCMs include industrial byproducts such as fly ash from coal combustion, ground granulated blast furnace slag from steelmaking, and silica fumes from silicon and ferrosilicon alloy production. Natural pozzolans, such as volcanic ash and calcined clay, can also be used depending on regional availability. Another key source of SCMs is concrete demolition waste, which reuses materials from the construction industry [21].

Incorporating SCMs reduces carbon emissions in two key ways. First, it decreases the amount of clinker required per ton of cement, directly reducing both process and combustion emissions. Second, many SCMs are byproducts of other industrial processes and therefore carry little to no additional embedded carbon from production. In some life cycle analyses, SCMs are even assigned negative carbon values due to their role in avoiding landfill disposal or reducing the environmental burden of waste streams [22].

Recent advances in SCM use include the development of blended cements with increasingly high levels of substitution. In particular, limestone calcined clay cement (LC3) has emerged as a promising formulation that replaces up to 50 percent of clinker with a combination of calcined clay and limestone. LC3 offers a comparable mechanical performance to Ordinary Portland Cement while significantly lowering carbon intensity. Ongoing research is also expanding the use of alkali-activated materials and industrial wastes such as red mud and waste glass, further broadening the portfolio of available SCMs [23].

Despite their potential, the widespread adoption of SCMs is constrained by several challenges. One major issue is material availability, as traditional SCMs like fly ash and slag rely on the coal and steel industries, which are in long-term decline in many regions. Natural pozzolans and calcined clays can help fill the gap but require additional mining and processing infrastructure [24]. Material variability, particularly in byproduct SCMs, also poses a concern. For instance, the chemical composition and fineness of fly ash can vary significantly depending on combustion conditions, affecting performance and requiring strict quality control and mix adjustments [25]. Economically, SCMs can be cost-effective when sourced and processed locally, but transportation costs may become prohibitive when long distances are involved. Additionally, building codes and standards in some regions limit the percentage of allowable clinker replacement, reducing the flexibility to adopt higher-SCM formulations [26].

To support long-term decarbonization, several national and international bodies are revising codes and performance-based standards to accommodate higher levels of SCM use. These policy changes, along with continued investment in materials science and supply chain development, are essential for scaling up the impact of SCMs on global emissions.

SCMs represent one of the most immediately deployable strategies for reducing carbon emissions in cement. When combined with clinker efficiency improvements and innovations in cement chemistry, they offer a practical and effective approach to lowering the environmental impact of cement-based construction.

2.2.4. System Dynamic Models of the Cement Industry

A number of prior studies have applied system dynamics modeling to explore the long-term carbon mitigation potential of various strategies in the cement industry. These efforts have focused on simulating interactions between technological, economic, and policy variables to support decision-making under uncertain or complex conditions.

Several studies have used system dynamics to evaluate the combined environmental and production impacts of national cement industries. Ige et al. developed an integrated life cycle assessment and system dynamics framework to predict the long-term emissions and sustainability trends of South Africa’s cement industry [27]. Their model translated life cycle outputs into dynamic variables to simulate future emissions under different policy scenarios. Similarly, Anand et al. constructed a system dynamics model to assess carbon emissions from India’s cement industry, incorporating policy interventions such as energy efficiency and structural changes in manufacturing [28]. Their analysis projected a 42 percent reduction in emissions by 2020 under an integrated mitigation scenario. Ansari and Seifi focused on Iran, analyzing the effects of energy price reforms and policy interventions such as blended cement, alternative fuels, and waste heat recovery. Their simulations showed substantial reductions in both energy consumption and emissions [29].

A more policy-focused lens was adopted in the study by Jokar and Mokhtar, who used system dynamics to simulate the impact of three decarbonization strategies, clinker substitution, alternative fuels, and waste heat recovery, on Iran’s cement industry [30]. Their model highlighted the importance of aligning energy efficiency with broader economic goals, such as improving trade balances through fossil fuel export. Clinker substitution was found to offer the greatest emissions reduction, while waste heat recovery provided economic benefits with more modest environmental gains.

Other studies have emphasized comparative assessments of system dynamics applications within the cement industry. Kunche and Mielczarek provided a comprehensive overview of current system dynamics models, identifying recurring mitigation strategies such as CCS, SCMs, and alternative fuels [31]. Their work emphasized the need for improved policy design and stakeholder engagement. A broader review by Ige et al. synthesized past modeling efforts and highlighted gaps in addressing the practical barriers to implementing emissions reduction strategies [32]. Although technical solutions were well-represented, the study pointed out a lack of integration with real-world policy levers and industry constraints.

While these previous studies applied system dynamics to national or regional cement industries, this study takes a more generalized, sector-wide approach. Rather than forecasting emissions under specific policy or economic conditions, the focus here is on quantitatively comparing the trade-offs among the three primary mitigation strategies: alternative fuels, SCMs, and CCS. This broader perspective allows for the exploration of system-level interactions that are not tied to a particular country or regulatory framework.

This work also introduces a streamlined system dynamics model that emphasizes the relationship between investment levels, cost, and emissions reduction across different strategies. Instead of incorporating a wide array of policy variables, the model isolates the effects of each mitigation approach and examines how various combinations influence overall system behavior. The goal is to identify investment pathways that approach carbon neutrality while minimizing long-term cost increases. By focusing on fundamental causal relationships, the model offers a practical decision support tool for evaluating decarbonization strategies within the cement sector.

3. System Dynamics Model

3.1. Overview of System Dynamics

System dynamics modeling is a method used to analyze complex systems that include feedback loops, time delays, and interdependencies. It is particularly well-suited for problems where actions taken in one part of a system influence outcomes elsewhere, often in ways that are not immediately apparent. The approach captures how changes accumulate over time and allows for the simulation of long-term outcomes under varying conditions. By representing systems as interacting stocks and flows, system dynamics provides a structured way to examine how elements evolve in response to both internal dynamics and external forces [33].

A key feature of system dynamics is the system diagram. This diagram identifies the variables relevant to the problem and illustrates their relationships using arrows. An arrow from Variable A to Variable B indicates that Variable A affects the value of Variable B. The arrow is marked with either a positive or negative sign to denote the nature of the relationship. A positive sign means that an increase in Variable A results in an increase in Variable B, while a negative sign indicates that an increase in Variable A leads to a decrease in Variable B.

This modeling technique is commonly used in policy analysis, strategic planning, and resource management, where outcomes depend not only on initial conditions but also on the structure of the system [34]. It is often applied to evaluate the effectiveness of interventions, identify leverage points, and understand unintended consequences. System dynamics is especially valuable in contexts where social, economic, and technological factors are closely linked, and where feedback mechanisms can either reinforce or inhibit change.

By simulating a range of scenarios, system dynamics helps decision-makers anticipate the long-term effects of policy and investment strategies. Rather than providing static predictions, it offers insights into how systems behave over time. This makes it an effective tool for studying complex transitions, including those related to large-scale decarbonization efforts.

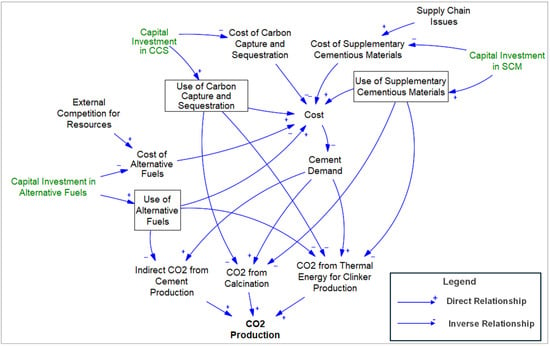

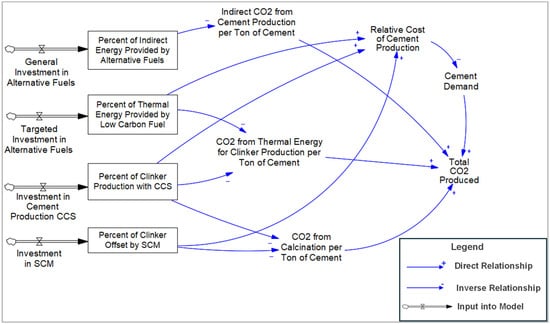

3.2. Causal Loop Diagram

Figure 3 displays the causal loop diagram for the carbon footprint associated with cement production with the incorporation of the three main mitigation strategies outlined in Section 2: the use of alternative fuels, CCS, and SCMs. The implementation of these strategies depends on capital investments in each area, shown in green. These investments support both the maturation of technology and the development of the necessary infrastructure. Although these mitigation approaches are more expensive than conventional methods, continued investment can reduce their associated costs over time.

Figure 3.

Causal loop diagram of the CO2 production from cement production with capital investments to reduce carbon production.

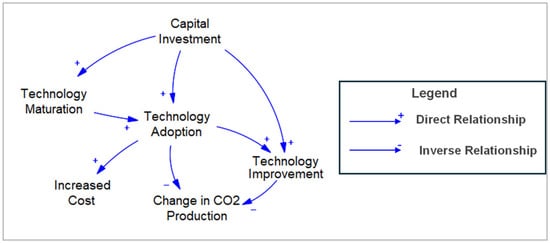

The boxed variables in Figure 3 represent the increasing use of alternative fuels, CCS, and SCMs. These processes involve multiple internal steps, which are detailed in Figure 4. For each variable, capital investment is required to advance technology, leading to its adoption and subsequent improvement. This progression reduces the CO2 produced at the corresponding stage of cement production. However, the adoption of these technologies also increases the cost of cement production.

Figure 4.

Causal loop diagram showing the interactions internal to the increasing use of alternative fuels, CCS, and SCMs (boxed variables in Figure 3).

Each mitigation strategy is linked to a specific source of CO2 emissions, reducing its contribution to total emissions. Alternative fuels reduce both indirect emissions and those associated with the thermal energy used in clinker production. CCS and SCMs reduce emissions from calcination and also from the thermal processes involved in clinker production. It is important to note that both SCMs and alternative fuels may be constrained by supply chain limitations, as these materials are in demand across multiple industries. Such constraints could increase costs and may affect the pace of adoption.

3.3. Stocks and Flows

Stocks and flows are fundamental components of a system dynamics model. Stocks represent the accumulations within a system, in this case, the impacts on cement production technologies following investments. Stocks change over time based on the influence of flows, which are the rates at which resources enter or leave a stock. In this case, the flows are capital investments targeting different aspects of cement production. These investments decrease the relative CO2 production. This section more thoroughly discusses these relationships.

It is important to note that the flows into the model are the effects of policies and investments put in place by the global community. On its own, the cement industry is unlikely to invest the large capital costs and increased operational costs associated with many of the sustainability initiatives. As such, these investments come from either government-funded initiatives or from government policies that either encourage the industry to take certain actions or penalize inaction through carbon taxes.

3.3.1. Use of Alternative Fuels

The alternative fuel sector presents a valuable opportunity for the cement industry to reduce indirect carbon emissions by aligning with broader investments in low-emission fuels. Global investment in biofuels, biogases, and hydrogen is projected to reach nearly USD 25 billion in 2025, supported by growth in the transportation and power sectors. The cement industry can leverage these advances to reduce emissions associated with indirect energy needs, which is related to the mining and transportation of raw materials [35]. These advances are projected to offset carbon-based fuels with alternative energy sources at a rate of approximately four percent per year, which is in line with many initiatives by the broader transportation community [36].

However, to use alternative fuels effectively, clinker production facilities must be retrofitted to handle different combustion characteristics and fuel properties. The estimated capital cost for these modifications ranges from USD 10 to USD 40 per ton of annual cement capacity [37]. With a global capacity of 4.5 billion tons per year, this equates to a total investment of USD 45 to USD 180 billion. This analysis will use the average value in this range of USD 112 billion. Operational costs are also expected to rise by USD 5 to USD 15 per ton of cement due to additional fuel handling, preprocessing, and monitoring requirements. This cost will likely be carried over to the consumer, resulting in a 15 percent increase in the cost of cement produced with alternative fuels [37].

A phased implementation strategy is necessary to manage cost, supply chain development, and technical integration. Converting five percent of global facilities each year over a 20-year period would allow producers to spread investment over time, adapt to evolving fuel markets, and gain experience with new systems [38]. This gradual transition would support broader decarbonization goals while maintaining production reliability and cost stability. It would also give supply chains time to adjust, helping to prevent shortages in the required raw materials.

3.3.2. Carbon Capture and Sequestration

Retrofitting all global clinker production facilities with CCS technology would require significant financial investment, driven by both the scale of global cement production and the complexity of CCS integration. The capital cost to install CCS systems is approximately USD 100 per ton of annual cement capacity, resulting in a total capital expenditure of roughly USD 450 billion [39].

The implementation of CCS would substantially raise the cost of cement due to both the upfront investment and increased operational expenses. While the average cement production cost is approximately USD 70 per ton, CCS would add an estimated USD 28 to USD 60 per ton. This represents approximately a 40 to 85 percent increase [39]. This analysis uses a 60 percent cost increase for cement produced through CCS.

Similar to modifying clinker-production facilities to use alternative fuels, a phased implementation strategy is essential for CCS. Converting all clinker production facilities at once is neither financially feasible nor logistically practical. A phased approach that retrofits approximately five percent of global facilities each year over a 20-year period allows for gradual investment, technology refinement, workforce training, and infrastructural development [38]. This timeline also provides flexibility to adapt to evolving carbon pricing policies, regulatory requirements, and innovations in capture efficiency. Such a strategy would spread capital and operating costs more manageably over time while ensuring that the cement sector moves steadily toward net-zero emissions targets.

3.3.3. Supplementary Cementitious Materials

The use of supplementary cementitious materials offers one of the most practical pathways to reduce emissions in the cement industry by directly reducing the volume of clinker required per unit of cement. Clinker production accounts for the majority of cement’s carbon footprint, so partially replacing clinker with materials like fly ash, slag, calcined clay, and natural pozzolans can significantly reduce emissions. This approach could eliminate as much as 800 million to 1.2 billion tons of CO2 annually, assuming that clinker substitution rates increase from current global averages of about 20 to near the technical limit of 50 percent, as identified by the International Energy Agency [40].

The capital costs for increasing SCM usage are relatively modest compared to CCS or fuel switching. Most modifications involve equipment for material handling, blending, and quality control, with estimated costs of USD 3 to USD 10 per ton of annual cement capacity. For global production of roughly 4.4 billion tons of cement per year, this implies a total investment of USD 30 billion. This cost increase would be offset with time, as the material costs of SCMs are typically less than clinker. When the clinker substitution rate is at 50 percent, the projected production cost would decrease by 10 percent [41].

Expanding SCM use also depends on local availability, regulatory standards, and customer acceptance. A phased approach, such as increasing clinker substitution by 1.5 percentage points per year, would allow producers to adapt formulations, certify performance, and manage supply chains. Over a 20-year period, this would enable the cement industry to reach or exceed a 50 percent global substitution rate [38]. SCMs are not only cost-effective but can also be implemented alongside other decarbonization strategies, making them a foundational component of any low-carbon cement roadmap.

3.4. Model

Figure 5 combines the causal loop diagrams with the stocks and flows to create a system dynamics model. The four flows are the injection of capital investment into the cement production industry. Note that the capital investments for alternative fuels are broken into two categories, since a significant portion of those capital investments can leverage sustainability advances from the transportation or electricity sectors.

Figure 5.

System dynamics model of the CO2 production from cement production with capital investments to reduce carbon production.

The variables for the four stocks are defined by the following equations:

The percent of indirect energy from alternative fuels is set to increase steadily at a rate of four percent per year, leveraging advances in other sectors. Meanwhile, the other stocks depend on the amount of targeted investment for that specific technology, based on the projected values provided in Section 3.3. Note that the percent of clinker offset by SCM increases from 20 percent, which is the current amount used, to 50 percent, which is the theoretical maximum. All other values are required to fall between 0 and 1.

With the stocks defined, the amount of CO2 per ton of cement can then be calculated using the following equations:

These values use a current rate of 0.6 tons of CO2 released per ton of cement. This value is divided into each of the three categories, with 10 percent being related to indirect energy requirements, 30 percent from thermal energy for calcination, and 60 percent for calcination. These values are then decreased by the use of alternative fuels, CCS, and SCMs.

From there, the relative cost of cement, cement demand, and total amount of CO2 produced can be calculated with the following equations:

The cost changes are in line with the increased operational costs discussed in Section 3.3. Note that the use of SCM results in a reduction in the cost of cement production. The change in relative cost will affect the overall cement demand, which will decrease as the cost increases. The model assumes a constant-elasticity demand function with a price elasticity of 0.3, which is commonly used for construction applications [42]. This value indicates that a 10 percent increase in cement cost reduces demand by 3 percent. Once the annual cement demand is known, the total CO2 produced can then be calculated.

4. Analysis of Different Carbon Reduction Strategies Using the System Dynamics Model

The completed model was used to evaluate a series of investment scenarios, each representing a different decarbonization pathway. The following sections explore the outcomes of these scenarios. The results offer a structured way to compare options, understand trade-offs, and identify where efforts are likely to have the greatest impact.

4.1. Strategy 1: Leverage Investments from Other Sectors, Focusing on Alternative Fuels

Of the different approaches to reducing the carbon footprint of cement production, the use of alternative fuels is the most capable of leveraging progress made in other sectors. The low-carbon fuel industry has seen significant advances, particularly in the transportation and electricity sectors. However, additional development will be required to meet the specific needs of cement production, which will necessitate targeted investments.

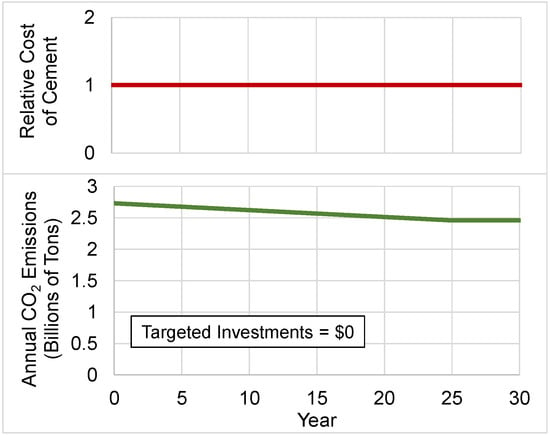

Figure 6 provides the model results for the strategy that only leverages external investments in alternative fuels, resulting in a reduction in the indirect CO2 emissions from cement production. This scenario does not result in any change in cement prices or demand, since it relies on external investments and the lifecycle costs of using alternative fuels for transportation are comparable to current methods. Over the 25-year period, with a steady investment rate of 4 percent per year, indirect CO2 emissions are driven down to zero, resulting in a 10 percent reduction in overall carbon emissions.

Figure 6.

System dynamics model output showing the impact of only leveraging external capital investment in alternative fuels on the relative cost of cement and overall carbon emissions.

While this strategy is the most cost-advantageous for the cement industry, it results in the smallest overall reduction in carbon emissions. The 10 percent reduction stabilizes emissions at 2.5 billion tons of CO2, which meets one of the model’s targets. However, if cement demand increases, particularly due to population growth and urbanization, this value could rise well above the threshold.

4.2. Strategy 2: Targeted Invest in Alternative Fuels

For the benefits of alternative fuels to be fully realized, the cement industry must make significant investments to convert clinker production facilities to run on these fuels. This would directly reduce the CO2 emissions associated with the thermal energy used in clinker production. The total cost of this strategy is estimated at USD 100 B, spread evenly over a 20-year period.

Figure 7 presents the model results for this strategy. There is a substantial reduction in annual CO2 emissions from cement production, with a total decrease of approximately 45 percent. Over the 20-year period, all CO2 emissions related to thermal energy use are eliminated. In addition, ongoing advances in the transportation sector help reduce indirect CO2 emissions. As shown in Figure 7, there is also a reduction due to decreased cement demand, which results from a 20 percent increase in cement prices.

Figure 7.

System dynamics model output showing the impact of only leveraging targeted capital investment in alternative fuels on the relative cost of cement and overall carbon emissions.

This approach leads to a significantly larger reduction in the carbon footprint of the cement industry compared to relying solely on external advances. However, because it does not address CO2 emissions from calcination, which remains the largest source, the overall reduction is still limited.

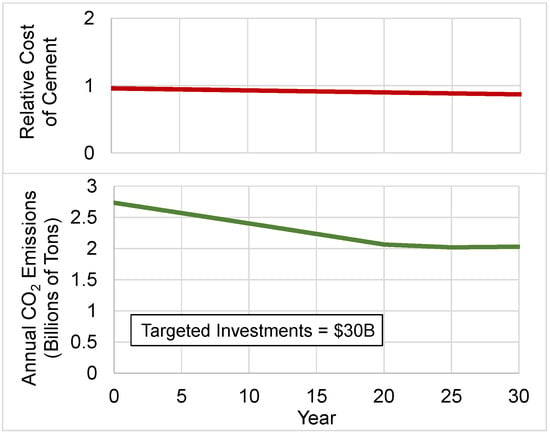

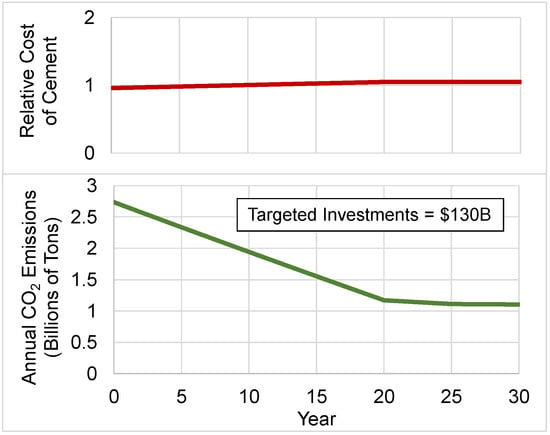

4.3. Strategy 3: Invest Primarily in SCM

Since the largest portion of carbon emissions from cement production comes from the calcination process, increasing the use of SCMs will directly reduce these emissions. A targeted investment in SCMs would not only lower the carbon associated with calcination but also reduce the overall cost of cement production, as SCMs are generally less expensive than clinker. Moreover, this strategy requires significantly less investment than other decarbonization options requiring USD 30 B spread out over 20 years.

Figure 8 presents the results of the system dynamics model for this approach. The use of SCMs reduces emissions to two billion tons of CO2 per year. This level aligns with many sustainability goals, though it still falls short of achieving net zero. The main limitation is that the investment only increases SCM use from 20 percent to 50 percent. In addition, some of the carbon savings are offset by increased demand, resulting from the lower cement price enabled by the use of SCMs.

Figure 8.

System dynamics model output showing the impact of capital investment in SCM on the relative cost of cement and overall carbon emissions.

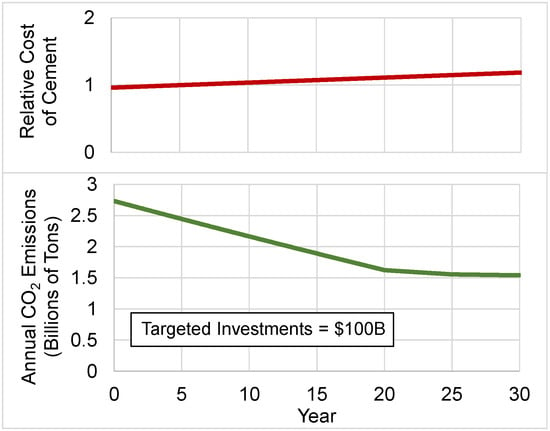

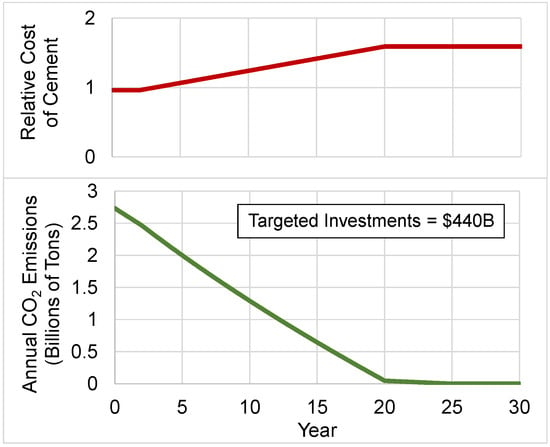

4.4. Strategy 4: Invest Primarily in CCS

Another alternative is to place a strong emphasis on CCS, with the system dynamics model results for this scenario shown in Figure 9. This strategy targets both the carbon released during the calcination process and the combustion emissions associated with supplying energy for the endothermic reaction. While CCS technology has been extensively developed for stationary power generation, it still requires significant adaptation to work effectively in cement production. These technical challenges contribute to a substantial capital investment of USD 440 billion over 20 years. In addition, ongoing operational costs are required to maintain and run the system. The resulting increase in cement prices leads to a reduction in demand, which in turn helps reduce emissions further.

Figure 9.

System dynamics model output showing the impact of capital investment in CCS on the relative cost of cement and overall carbon emissions.

As shown in Figure 9, CCS has the potential to capture nearly all of the carbon directly produced during clinker production, making it one of the most impactful strategies for total emissions reduction. However, the long-term rise in production costs could present challenges for sectors that rely heavily on cement. This would be especially difficult for developing regions, where affordability and access to construction materials remain essential.

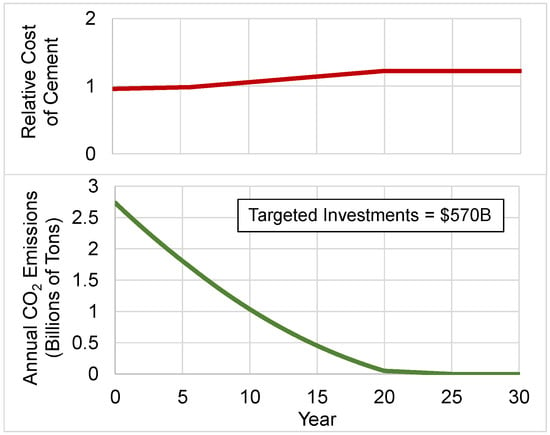

4.5. Strategy 5: Invest in All Areas

The most expensive option would be to invest in alternative fuels, CCS, and SCMs simultaneously. This multipronged approach, shown in Figure 10, requires a substantial upfront investment, which increases the cost of cement production. While some of these costs may decrease over time, particularly as SCMs have the potential to reduce overall production costs, CCS will continue to impose a recurring operational expense. Although this increased cost would reduce market demand, and hence carbon emissions from cement, it would have a negative impact on a number of industries.

Figure 10.

System dynamics model output showing the impact of capital investment in alternative fuels, SCM, and CCS on the relative cost of cement and overall carbon emissions.

Despite the high cost, this combined strategy brings carbon emissions from cement production close to zero by addressing all major sources of emissions. However, there is some degree of redundancy in this approach. Specifically, the use of low-carbon fuels and SCMs will reduce the emissions that CCS is intended to capture, which may limit the overall effectiveness of combining all three strategies.

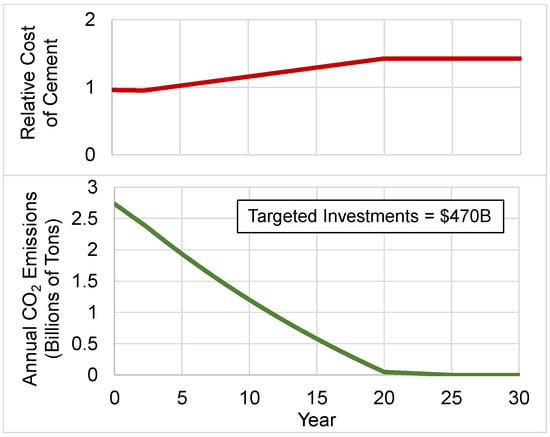

4.6. Strategy 6: SCM and Alternative Fuels

In the previous scenario, investments were made in alternative fuels, CCS, and SCMs. While this resulted in a significant reduction in carbon emissions, it also led to a net increase in the cost of cement, which can negatively affect industry. In addition, there was a degree of redundancy, as the use of alternative fuels or SCMs reduced the need for CCS. This scenario considers the removal of that redundancy by focusing investments solely on the two cheaper options, with SCMs and alternative fuels.

As shown in Figure 11, the increased cost of using alternative fuels is offset by the decreasing cost of implementing SCMs. This strategy addresses all three major sources of carbon emissions in cement production, resulting in a large net reduction. However, since calcination is still required albeit in smaller quantities, this approach does not achieve full carbon neutrality.

Figure 11.

Output plot from the system dynamics model showing the impact of capital investment in alternative fuels and SCM on the cost of cement and overall carbon emissions.

4.7. Strategy 7: SCM and CCS

Another permutation worth considering is combining SCM with CCS. This approach will allow for the decreasing cost associated with SCMs to partially offset the increasing cost of SCM, hence avoiding negative impacts on the cement industry.

As shown in Figure 12, the increased cost of using CCS is partially offset by the decreasing cost of implementing SCMs. This strategy addresses all three major sources of carbon emissions in cement production, resulting in the solution achieving full carbon neutrality.

Figure 12.

Output plot from the system dynamics model showing the impact of capital investment in CCS and SCM on the relative cost of cement and overall carbon emissions.

5. Analysis of Results

5.1. Comparison Between Different Strategies

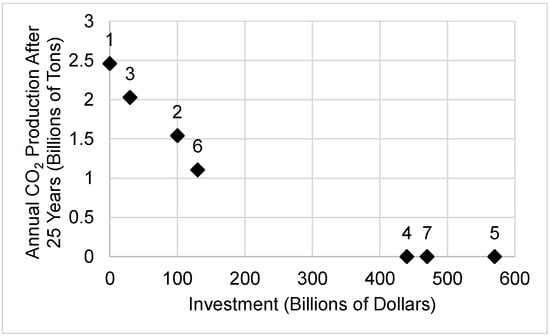

Figure 13 plots the cost of implementing each strategy alongside the associated annual CO2 production after 25 years. The results generally show that, assuming no increase in cement demand, the industry can reduce emissions to 2.5 billion tons annually, which aligns with one of its stated goals, by leveraging sustainability efforts from other sectors (Strategy 1). Larger reductions can be achieved through targeted investments in alternative fuels and supplementary cementitious materials (Strategies 2, 3, and 6). In particular, implementing both alternative fuels and SCMs can cut carbon emissions in half.

Figure 13.

Annual carbon production after 25 years following the implementation and the investment cost for each of the strategies discussed in Section 4.

To achieve carbon neutrality, however, carbon capture and storage is necessary (Strategies 4, 5, and 7). CCS will significantly increase the cost of cement. This increase can be reduced if CCS is implemented alongside SCMs and alternative fuels, although these combinations require greater capital investment.

5.2. Insights into Policy Levers

This type of analysis provides insights for policymakers to understand the trade-offs between the costs of different initiatives when developing policies. If the policymakers are fiscally conservative, they could select Strategy 1 or 3, which results in a modest reduction in carbon emissions. For a larger reduction at an intermediate cost, they could pursue Strategy 6, which cuts carbon emissions by 60 percent and requires only about one-quarter of the cost needed for full carbon neutrality. If the goal is complete carbon neutrality, CCS is required to capture the carbon produced from clinker production.

The analysis also provides policymakers with insights into how carbon taxes on cement could incentivize the industry to adopt more sustainable practices. If the goal is to encourage the adoption of CCS to achieve net neutrality, the carbon tax would need to exceed 50 percent of the current cost of cement. In that case, it would be more advantageous for the industry to raise cement prices to cover the tax rather than implement CCS, since the cost of cement with the tax is comparable to the cost of cement produced with CCS. This approach would also allow the cement industry to avoid the large capital investment required for CCS. On the other hand, a more modest carbon tax could still motivate companies to invest in SCMs or alternative fuels since these approaches do not create significant increases in the cost of cement.

6. Conclusions and Implications

As the world strives to reduce its carbon emissions to counter climate change, cement production, which accounts for approximately eight percent of global emissions, must be addressed. There are three major technology thrusts that can help reduce carbon emissions from cement production: alternative fuels, SCMs, and CCS. This study analyzed the complex relationships between these three initiatives and the broader cement production system using a system dynamics approach.

The results indicate that while implementing all three simultaneously is effective at achieving carbon neutrality, it introduces some redundancy, particularly as the adoption of alternative fuels and SCMs reduces the emissions that CCS would otherwise capture. This combined strategy also results in higher cement costs. Generally, the model indicates that to achieve full carbon neutrality, CCS is required, although it drives up the cost of cement and can have negative impacts on the industry. An alternative approach that uses only SCMs and alternative fuels was also analyzed. This approach is able to achieve a substantial reduction in carbon emissions with a much lower capital investment than CCS. This approach also does not significantly increase the price of cement.

System dynamics provides a powerful way to explore these trade-offs by capturing the feedback loops, delays, and nonlinear effects that define the cement industry’s response to different interventions. Rather than relying on static projections, the model offers insights into how different strategies interact over time and helps identify pathways that balance emissions reduction with economic viability.

Author Contributions

Conceptualization, V.M. and L.D.; methodology, V.M.; software, L.D.; validation, V.M. and L.D.; formal analysis, V.M. and L.D.; investigation, L.D.; resources, V.M.; writing—original draft preparation, V.M. and L.D.; writing—review and editing, V.M.; visualization, V.M. and L.D.; supervision, V.M.; project administration, V.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were generated in this study.

Conflicts of Interest

Both authors are currently employed by the United States Department of Defense. The views expressed in this paper are their own and do not reflect those of the United States government.

Abbreviations

The following abbreviations are used in this manuscript:

| CCS | Carbon Capture and Storage |

| SCM | Supplementary Cementitious Material |

References

- Lehne, J.; Preston, F. Making concrete change: Innovation in low-carbon cement and concrete. Chatham House Rep. 2018, 13, 138. [Google Scholar]

- Olivier, J.G.; Berdowski, J.J. Global emission sources and sinks. In The Climate System; Letcher, T.M., Ed.; CRC Press: Boca Raton, FL, USA, 2021; pp. 33–77. [Google Scholar]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2022, 15, 209. [Google Scholar] [CrossRef] [PubMed]

- Nikolakopoulos, A.; Steriotis, T.; Charalambopoulou, G.; Karagiannakis, G.; Dimitrakis, D.; Michalis, V.; Katsiotis, M. Reducing carbon emissions in cement production through solarization of the calcination process and thermochemical energy storage. Comput. Chem. Eng. 2024, 180, 108506. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef] [PubMed]

- Hanifa, M.; Agarwal, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. A review on CO2 capture and sequestration in the construction industry: Emerging approaches and commercialised technologies. J. CO2 Util. 2023, 67, 102292. [Google Scholar] [CrossRef]

- Mittal, V.; Lim, E. Aligning Advances in Biodiesel Technology with the Needs of the Defense Community. Eng 2024, 5, 2709–2727. [Google Scholar] [CrossRef]

- Clauser, N.M.; González, G.; Mendieta, C.M.; Kruyeniski, J.; Area, M.C.; Vallejos, M.E. Biomass Waste as Sustainable Raw Material for Energy and Fuels. Sustainability 2021, 13, 794. [Google Scholar] [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Khan, N.; Sudhakar, K.; Mamat, R. Role of Biofuels in Energy Transition, Green Economy and Carbon Neutrality. Sustainability 2021, 13, 12374. [Google Scholar] [CrossRef]

- Banaś, M.; Pająk, T.; Bator, J.; Wróbel, W.; Ciuła, J. Energy Efficiency Analysis of Waste-to-Energy Plants in Poland. Energies 2024, 17, 2390. [Google Scholar] [CrossRef]

- World Business Council for Sustainable Development. CO2 Accounting and Reporting Standard for the Cement Industry. 2005. Available online: https://ghgprotocol.org/sites/default/files/2023-03/co2_CSI_Cement_Protocol-V2.0_0.pdf (accessed on 10 July 2025).

- ISO 19694-3:2023; Stationary Source Emissions—Determination of Greenhouse Gas Emissions in Energy-Intensive Industries—Part 3: Cement Industry. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/70747.html (accessed on 10 July 2025).

- Bertone, M.; Stabile, L.; Buonanno, G. An Overview of Waste-to-Energy Incineration Integrated with Carbon Capture Utilization or Storage Retrofit Application. Sustainability 2024, 16, 4117. [Google Scholar] [CrossRef]

- Kheirinik, M.; Ahmed, S.; Rahmanian, N. Comparative Techno-Economic Analysis of Carbon Capture Processes: Pre-Combustion, Post-Combustion, and Oxy-Fuel Combustion Operations. Sustainability 2021, 13, 13567. [Google Scholar] [CrossRef]

- Toledo, R.C.; Arce, G.L.A.F.; Carvalho, J.A., Jr.; Ávila, I. Experimental Development of Calcium Looping Carbon Capture Processes: An Overview of Opportunities and Challenges. Energies 2023, 16, 3623. [Google Scholar] [CrossRef]

- Romasheva, N.; Ilinova, A. CCS Projects: How Regulatory Framework Influences Their Deployment. Resources 2019, 8, 181. [Google Scholar] [CrossRef]

- Witte, K. Social Acceptance of Carbon Capture and Storage (CCS) from Industrial Applications. Sustainability 2021, 13, 12278. [Google Scholar] [CrossRef]

- Hills, T.P.; Sceats, M.; Rennie, D.; Fennell, P. LEILAC: Low cost CO2 capture for the cement and lime industries. Energy Procedia 2017, 114, 6166–6170. [Google Scholar] [CrossRef]

- Chen, S.; Ye, Z.; Lu, W.; Feng, K. Exploring Performance of Using SCM Concrete: Investigating Impacts Shifting along Concrete Supply Chain and Construction. Buildings 2024, 14, 2186. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Jóźwiak-Niedźwiedzka, D. Special Issue: Supplementary Cementitious Materials in Concrete, Part I. Materials 2021, 14, 2291. [Google Scholar] [CrossRef]

- Ez-zaki, H.; Marangu, J.M.; Bellotto, M.; Dalconi, M.C.; Artioli, G.; Valentini, L. A Fresh View on Limestone Calcined Clay Cement (LC3) Pastes. Materials 2021, 14, 3037. [Google Scholar] [CrossRef]

- Al-Otaibi, A. Barriers and Enablers for Green Concrete Adoption: A Scientometric Aided Literature Review Approach. Sustainability 2024, 16, 5093. [Google Scholar] [CrossRef]

- Degefa, A.B.; Park, S.; Yang, B.; Park, S. Predicting the Degree of Reaction of Supplementary Cementitious Materials in Hydrated Portland Cement. Sustainability 2023, 15, 15471. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzén, J.; Toktarova, A.; Odenberger, M.; Johnsson, F.; Göransson, L. Roadmap for Decarbonization of the Building and Construction Industry—A Supply Chain Analysis Including Primary Production of Steel and Cement. Energies 2020, 13, 4136. [Google Scholar] [CrossRef]

- Ige, O.E.; Duffy, K.J.; Olanrewaju, O.A.; Collins, O.C. An Integrated System Dynamics Model and Life Cycle Assessment for Cement Production in South Africa. Atmosphere 2022, 13, 1788. [Google Scholar] [CrossRef]

- Anand, S.; Vrat, P.; Dahiya, R.P. Application of a system dynamics approach for assessment and mitigation of CO2 emissions from the cement industry. J. Environ. Manag. 2006, 79, 383–398. [Google Scholar] [CrossRef]

- Ansari, N.; Seifi, A. A system dynamics model for analyzing energy consumption and CO2 emission in Iranian cement industry under various production and export scenarios. Energy Policy 2013, 58, 75–89. [Google Scholar] [CrossRef]

- Jokar, Z.; Mokhtar, A. Policy making in the cement industry for CO2 mitigation on the pathway of sustainable development: A system dynamics approach. J. Clean. Prod. 2018, 201, 142–155. [Google Scholar] [CrossRef]

- Kunche, A.; Mielczarek, B. Application of System Dynamic Modelling for Evaluation of Carbon Mitigation Strategies in Cement Industries: A Comparative Overview of the Current State of the Art. Energies 2021, 14, 1464. [Google Scholar] [CrossRef]

- Ige, O.E.; Von Kallon, D.V.; Desai, D. Carbon emissions mitigation methods for cement industry using a systems dynamics model. Clean Technol. Environ. Policy 2024, 26, 579–597. [Google Scholar] [CrossRef]

- Sternan, J. Business Dynamics: Systems Thinking and Modeling for a Complex World; McGraw Hill: New York, NY, USA, 2018; pp. 41–79. [Google Scholar]

- Forrester, J. Lessons from system dynamics modeling. Syst. Dyn. Rev. 1987, 3, 136–149. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Investment 2025, 10th ed.; IEA: Paris, France, 2025; Available online: https://www.iea.org/reports/world-energy-investment-2025 (accessed on 12 July 2025).

- Mittal, V.; Shah, R. Modeling the Global Annual Carbon Footprint for the Transportation Sector and a Path to Sustainability. Modelling 2023, 4, 264–282. [Google Scholar] [CrossRef]

- Beguedou, E.; Narra, S.; Afrakoma Armoo, E.; Agboka, K.; Damgou, M.K. Alternative Fuels Substitution in Cement Industries for Improved Energy Efficiency and Sustainability. Energies 2023, 16, 3533. [Google Scholar] [CrossRef]

- Gross, R.; Hanna, R.; Gambhir, A.; Heptonstall, P.; Speirs, J. How long does innovation and commercialisation in the energy sectors take? Historical case studies of the timescale from invention to widespread commercialisation in energy supply and end use technology. Energy Policy 2018, 123, 682–699. [Google Scholar] [CrossRef]

- Gardarsdottir, S.O.; De Lena, E.; Romano, M.; Roussanaly, S.; Voldsund, M.; Pérez-Calvo, J.-F.; Berstad, D.; Fu, C.; Anantharaman, R.; Sutter, D.; et al. Comparison of Technologies for CO2 Capture from Cement Production—Part 2: Cost Analysis. Energies 2019, 12, 542. [Google Scholar] [CrossRef]

- IEA. Technology Roadmap: Low-Carbon Transition in the Cement Industry; International Energy Agency: Paris, France, 2018; Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 11 July 2025).

- Hammouche, R.; Belebchouche, C.; Hammoudi, A.; Douadi, A.; Hebbache, K.; Boutlikht, M.; Berkouche, A.; Khishe, M. Synergistic Effects and Optimization of Cement Kiln Dust and Glass Powder Incorporation in Self Compacting Mortar Using Central Composite Design. Sci. Rep. 2025, 15, 14529. [Google Scholar] [CrossRef]

- D’Arcangelo, F.M.; Pisu, M.; Raj, A.; van Dender, K. Estimating the CO2 Emission and Revenue Effects of Carbon Pricing: New Evidence from a Large Cross-Country Dataset. In OECD Economics Department Working Papers; OECD: Paris, France, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).