Scenario-Based Extended Cost–Benefit Analysis for E-Waste Metal Recovery in Low-Income Countries: Evidence from an Integrated Model in Burkina Faso

Abstract

1. Introduction

1.1. Informal E-Waste Management Realities in Low-Income Countries Like Burkina Faso

1.2. Intrinsic E-Waste Value in Low-Income Countries

1.3. Disparities in Formal and Informal E-Waste Recycling

1.4. Review of Existing Economic Analyses

1.5. The Gap and the Need for an Extended Cost–Benefit Analysis

1.6. Objectives and Research Questions

2. Materials and Methods

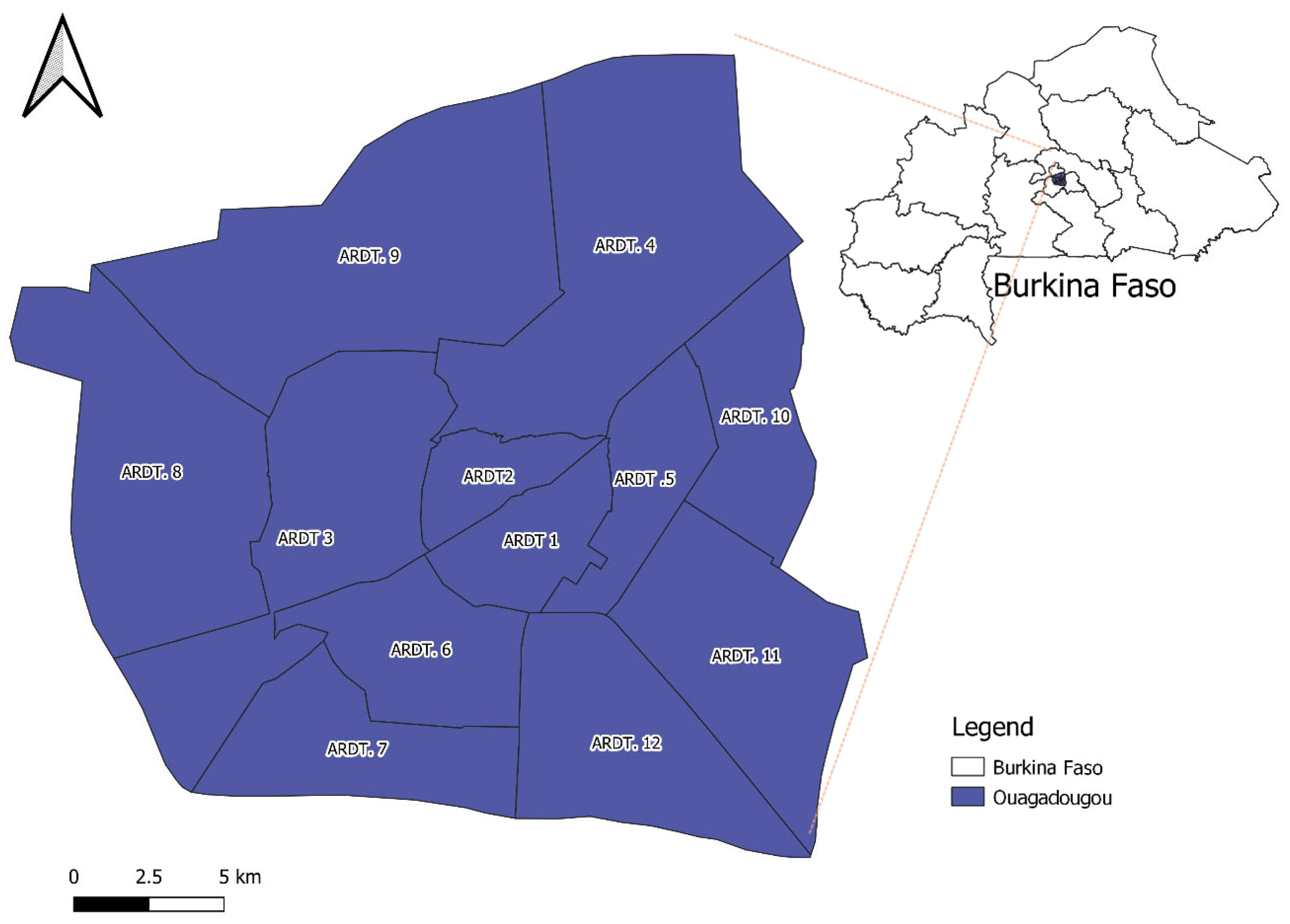

2.1. Study Area

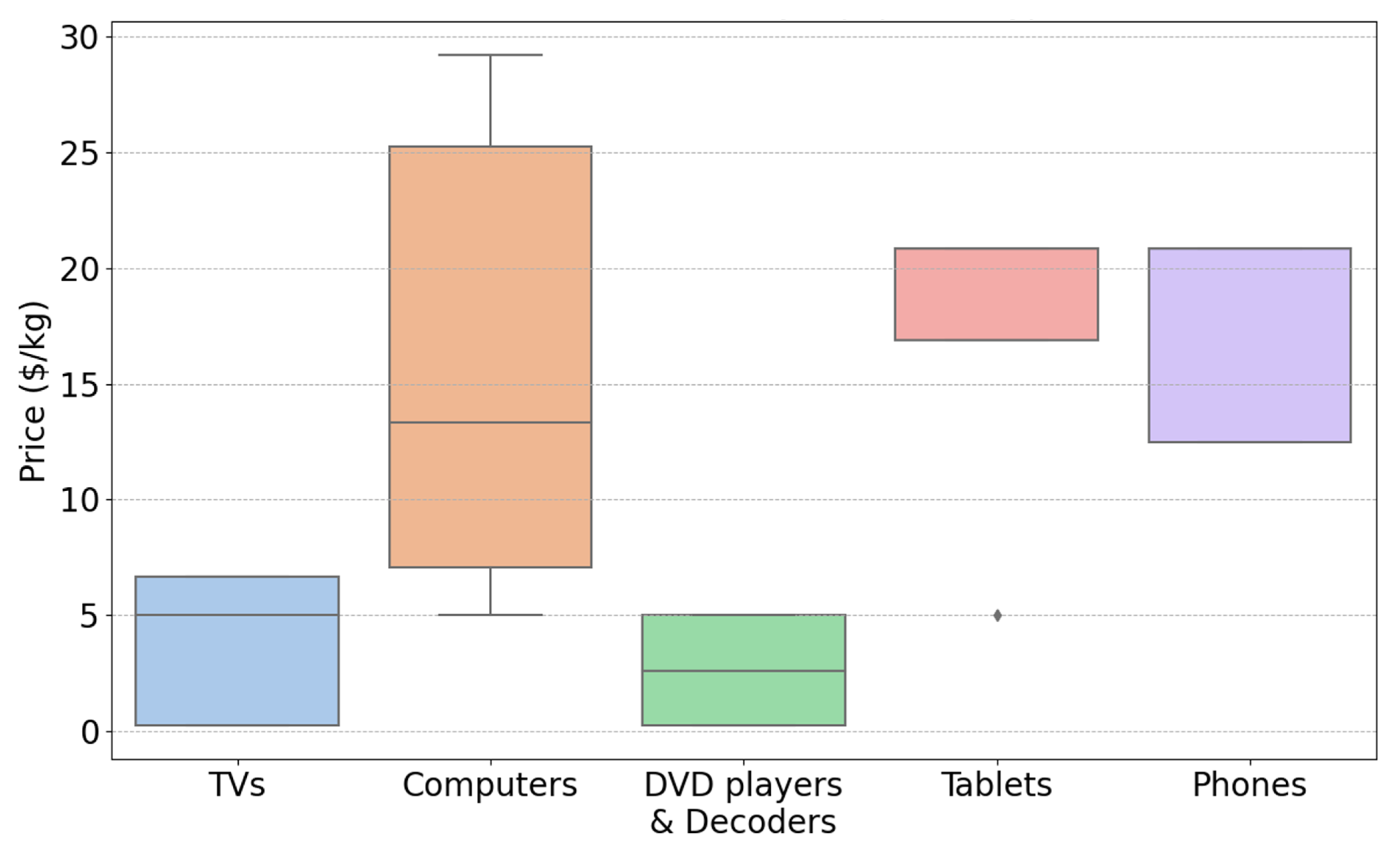

2.2. E-Waste Collection and Local Cost Information

2.3. Extended Cost–Benefit Analysis for Optimizing Metal Recovery Activities

- Average quantities of metals per kg of PCBs: They are variable according to the type of equipment (phones, computers, TVs, tablets and decoder and DVD players), and they were used to estimate the real extractive potential of electronic waste. These average metal quantities were derived from authors’ experimental data (in preparation for publication).

- The cost of purchasing e-waste: This is the price at which recyclers buy the PCBs from the collectors. Considering these factors made it possible to better assess the total costs related to recovery activities.

- The recovery rates of target metals were determined based on a combination of peer-reviewed literature sources [12,26,32,33,35,36,37,45] and local field insights gathered through collaboration with ABPEV, particularly regarding manual dismantling practices observed in Burkina Faso. The assumed recovery efficiencies for each treatment technology are summarized in Table 3 as follows:

- It is also important to consider the purity level of recovered metals, which directly influences their market value and acceptance by formal buyers. Technologies such as bioleaching and solvometallurgy can yield varying purity levels depending on operational conditions. Ref. [31] demonstrated that selective recovery processes can achieve industrial-grade purity for gold, which is assumed in this study.

- Processing and labor costs per technology: These include energy, reagents, equipment, and estimated wages per kilogram of PCBs. Based on studies on workers’ wages conducted by [29,46,47] for low-income countries in Africa, it was assumed that the labor costs for recovery by technology are 1.5 USD/kg, 1.2 USD/kg, 1.8 USD/kg, 2.5 USD/kg, and 0.8 USD/kg for pyrometallurgy, hydrometallurgy, solvometallurgy, manual dismantling and shredding, and bioleaching, respectively. Studies carried out by [26,32], allowed us to set reasonable reference values of e-waste treatment costs at 20 USD/kg, 15 USD/kg, 18 USD/kg, 5 USD/kg, and 10 USD/kg for pyrometallurgy, hydrometallurgy, solvometallurgy, manual dismantling and shredding, and bioleaching, respectively. As these amounts are subject to probable variations depending on the context, a sensitivity text was performed with a variation of ±20% to better understand its influence on the profitability of recovery activities.

- Socio-environmental impacts: These include (i) CO2 emissions avoided by recycling activities (vs. natural mining) valued at USD 50 per ton based on carbon market estimations [30], (ii) avoided pollution (soil, water, air) valued at USD 1.5 per kilogram of improperly managed e-waste [31], and (iii) locally created jobs considering that each full-time equivalent (FTE) position generates an average societal benefit of USD 2000 per year [29], scaled to the treated mass. Consideration of these impacts has made it possible to monetize the positive non-market externalities and integrate these benefits into the model to reveal the systemic value of recycling beyond the simple economic benefit. However, these valuations remain approximations based on generalized estimates that should be refined in further context-specific research using pilot projects reflecting real-world local socio-economic realities.

- EPR subsidy and an eco-tax: Based on the work of [21] and considering the context of low-income countries, we assumed an EPR subsidy of 3 USD/kg of treated PCBs to encourage recycling. Depending on the low purchasing power in low-income countries, an eco-tax of 1–3% maximum (converted to approximately 2 USD/kg of treated PCBs) is acceptable to encourage consumers to contribute to the management of the e-waste they produce.

| Technology | Cu | Fe | Ag | Au | Pd | Justifications |

|---|---|---|---|---|---|---|

| Manual dismantling | 70 | 90 | 30 | 60 | 10 | High recovery for visible metals like Cu and Fe; limited access to precious metals. |

| Bioleaching | 60 | 20 | 50 | 85 | 35 | Effective for Au, Cu, and Ag under optimized microbial conditions; Fe and Pd recovery remains low. |

| Hydrometallurgy | 85 | 40 | 60 | 95 | 40 | Proven efficiency for Au and Cu; moderate recovery for Ag and Pd; Fe is less targeted. |

| Pyrometallurgy | 95 | 50 | 40 | 90 | 30 | High recovery for Cu and Au; Ag and Pd partly lost in slag; Fe oxidized or diluted. |

| Solvometallurgy | 80 | 30 | 70 | 97 | 50 | High recovery for Cu; high selectivity for Au and Pd; emerging technique with promising results for Ag. |

| Sources: [12,26,32,33,35,36,37,45], and field observations with ABPEV | ||||||

| Scenario | Description |

|---|---|

| Scenario 0 | It made a gross cost–benefit assessment with the available data and serves as a basis to identify the aspects that could be improved with the aim to optimize the model. |

| Scenario 1 | This scenario focused only on the recovery of the most significant metals (based on quantities and market costs) to judge their economic impact on recovery. It simulated the recovery of the most significant metals in the richest equipment. |

| Scenario 2 | It simulated the recovery of the most significant metals in the richest equipment. |

| Scenario 3 | The scenario proposed a variation in the purchase price of e-waste by recyclers to optimize recovery revenues. |

| Scenario 4 | It was based on strategic and political recommendations proposing an EPR subsidy and an eco-tax on the purchase of equipment. |

| Scenario 5 | This scenario evaluated the economic impact of the EPR subsidy and eco-tax associated with the valuation of all socio-environmental benefits (CO2 emissions and pollution avoided as well as locally created jobs). This simulation was based on Scenario 2, without changing the current purchase costs of e-waste. |

| Scenario 6 | This scenario combined all the benefits and conditions to optimize the profitability of metal recovery activities. This included technical and operational adjustments (focusing on the recovery of the most significant metals in the richest equipment), EPR subsidies and eco-taxes, CO2 emissions and pollution avoided, and jobs created. Scenario 6 added fixed purchase prices for e-waste based on Scenario 3. |

3. Results and Discussion

3.1. Classification and Collection Prices of PCBs

3.2. Cost–Benefit Assessment for Metal Recovery from PCBs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABPEV | Association Burkinabè pour la Promotion des Emplois Verts |

| ACEA | African Circular Economy Alliance |

| CP | Computer |

| DD | Decoder and DVD Player |

| DVD | Digital Video Disc |

| ECBA | Extended Cost–Benefit Analysis |

| EPR | Extended Producer Responsibility |

| EU | European Union |

| E-waste | Electronic waste |

| IQR | Interquartile range |

| LED | Light-Emitting Diode |

| NDC | National Determined Contributions |

| PCB | Printed Circuit Boards |

| PH | Phone |

| RAM | Random Access Memory |

| TB | Tablet |

| TV | Television |

| XOF | West African CFA franc |

References

- Baldé, C.P.; Kuehr, R.; Yamamoto, T.; McDonald, R.; D’Angelo, E.; Althaf, S.; Bel, G.; Deubzer, O.; Fernandez-Cubillo, E.; Forti, V.; et al. The Global E-Waste Monitor 2024; United Nations Institute for Training and Research (UNITAR): Geneva, Switzerland; International Telecommunication Union (ITU): Geneva, Switzerland, 2024. [Google Scholar]

- Owusu-Sekyere, K.; Batteiger, A.; Afoblikame, R.; Hafner, G.; Kranert, M. Assessing data in the informal e-waste sector: The Agbogbloshie Scrapyard. Waste Manag. 2022, 139, 158–167. [Google Scholar] [CrossRef]

- Owusu-Sekyere, K.; Aladago, D.A.; Leverenz, D.; Oteng-Ababio, M.; Kranert, M. Environmental Impacts on Soil and Groundwater of Informal E-Waste Recycling Processes in Ghana. Sustainability 2024, 16, 4347. [Google Scholar] [CrossRef]

- Tiwari, D.; Raghupathy, L.; Khan, A.S.; Dhawan, N.G. A Study on the E-waste Collection Systems in Some Asian Countries with Special Reference to India. Nat. Environ. Pollut. Technol. 2019, 18, 149–156. [Google Scholar]

- Secrétariat de la Convention de Bâle. DEEE en Afrique: Etat des Lieux; Secrétariat de la Convention de Bâle: Geneva, Switzerland, 2012; p. 13. [Google Scholar]

- Sidwaya, J. Vente des Déchets Électroniques: Un Business «Juteux» Méconnu. Available online: https://www.sidwaya.info/vente-des-dechets-electroniques-un-business-juteux-meconnu/ (accessed on 29 March 2025).

- Konaté, F.O.; Ancia, P.; Soma, F.; Bougouma, M.; Buess-Herman, C.; Yonli, A.H.; Vitry, V. Waste electrical and electronic equipments as urban mines in Burkina Faso: Characterization and release of metal particles. Waste Manag. 2022, 139, 17–24. [Google Scholar] [CrossRef]

- Andrianisa, H.A.; Sossou, S.K.; Zorom, M.; Nare, L.; Ahossouhe, M.S.; Sanou, A. An alternative classification approach for waste electronic and electrical equipment (WEEE) recovery in low-income countries: Case study in Burkina Faso. Environ. Sci. Pollut. Res. 2024, 31, 39318–39330. [Google Scholar] [CrossRef] [PubMed]

- Duddek, M.; Freein Von Rössing, L.; Freitas Seabra Da Rocha, S.H. X-ray Based Robotic E-Waste Fractionation for Improved Material Recovery. Mater. Circ. Econ. 2023, 5, 1. [Google Scholar] [CrossRef]

- Parthasarathy, P. Resource recovery of engineering plastics from E-waste recycling. Int. J. Appl. Res. 2018, 4, 148–150. [Google Scholar]

- Jakobsson, L.K.; Kennedy, M.W.; Aune, R.E.; Tranell, G. Recovery of Rare Earth Elements from the Ferrous Fraction of Electronic Waste. In REWAS 2016: Towards Materials Resource Sustainability; Kirchain, R.E., Blanpain, B., Meskers, C., Olivetti, E., Apelian, D., Howarter, J., Kvithyld, A., Mishra, B., Neelameggham, N.R., Spangenberger, J., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 89–93. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Schluep, M.; Hagelüken, C.; Kuehr, R.; Magalini, F.; Maurer, C.; Meskers, C.; Mueller, E.; Wang, F. Recycling—From E-Waste to Ressources; United Nation University: Bonn, Germany, 2009. [Google Scholar]

- Mir, S.; Vaishampayan, A.; Dhawan, N. A review on recycling of end-of-life light-emitting diodes for metal recovery. Jom 2022, 74, 599–611. [Google Scholar] [CrossRef]

- Akor, J.E.; Balogun, A.F. Recovery of Critical Metals from E-Waste Printed Circuit Boards (PCBs) Via Acid Leaching. J. Sustain. Mater. Process. Manag. 2024, 4, 13–23. [Google Scholar] [CrossRef]

- Balde, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-waste Monitor 2017: Quantities, Flows and Resources; United Nations University: Shibuya, Japan; International Telecommunication Union: Geneva, Switzerland; International Solid Waste Association: Rotterdam, The Netherlands, 2017; ISBN 978-978-928-089-6. [Google Scholar]

- Mmereki, D.; Li, B.; Baldwin, A.; Hong, L.; Mmereki, D.; Li, B.; Baldwin, A.; Hong, L. The Generation, Composition, Collection, Treatment and Disposal System, and Impact of E-Waste. In E-Waste in Transition—From Pollution to Resource; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef]

- Oguchi, M.; Sakanakura, H.; Terazono, A. Toxic metals in WEEE: Characterization and substance flow analysis in waste treatment processes. Sci. Total Environ. 2013, 463–464, 1124–1132. [Google Scholar] [CrossRef]

- Ylä-Mella, J.; Poikela, K.; Lehtinen, U.; Keiski, R.L.; Pongrácz, E. Implementation of Waste Electrical and Electronic Equipment Directive in Finland: Evaluation of the collection network and challenges of the effective WEEE management. Resour. Conserv. Recycl. 2014, 86, 38–46. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Lenny Koh, S.C.; Rosa, P. Recycling of WEEEs: An economic assessment of present and future e-waste streams. Renew. Sustain. Energy Rev. 2015, 51, 263–272. [Google Scholar] [CrossRef]

- Leclerc, S.H.; Badami, M.G. Extended producer responsibility for E-waste management: Policy drivers and challenges. J. Clean. Prod. 2020, 251, 119657. [Google Scholar] [CrossRef]

- Ongondo, F.O.; Williams, I.D.; Cherrett, T.J. How are WEEE doing? A global review of the management of electrical and electronic wastes. Waste Manag. 2011, 31, 714–730. [Google Scholar] [CrossRef]

- ACEA. African Circular Economy Alliance. ACEA Africa. 2022. Available online: https://www.aceaafrica.org (accessed on 3 July 2025).

- African Union Agenda 2063: The Africa We Want. 2020. Available online: https://au.int/en/agenda2063/overview (accessed on 3 July 2025).

- European Commission. The European Green Deal. European Environment Agency. 2019. Available online: https://www.eea.europa.eu/policy-documents/com-2019-640-final (accessed on 3 July 2025).

- Li, H.; Eksteen, J.; Oraby, E. Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): Current status and perspectives—A review. Resour. Conserv. Recycl. 2018, 139, 122–139. [Google Scholar] [CrossRef]

- Yang, W.-D.; Sun, Q.; Ni, H.-G. Cost-benefit analysis of metal recovery from e-waste: Implications for international policy. Waste Manag. 2021, 123, 42–47. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- OIT. Les Salaires en Afrique: Evolutions Récentes des Salaires Moyens, Écarts Salariaux Entre Hommes et Femmes, et Disparités Salariales; Organisation internationale du Travail: Geneva, Switzerland, 2020; ISBN 978-92-2-032350-2. [Google Scholar]

- WBG. State and Trends of Carbon Pricing: International Carbon Markets 2024; World Bank: Washington, DC, USA, 2024. [Google Scholar] [CrossRef]

- Zueva, S.; Ippolito, N.M.; Passadoro, M.; Romano, P.; Ferella, F.; Vegliò, F. Selective Recovery of Gold from E-Waste Recycling Plants’ Waste Fractions: Waste-to-Resource Transition. Minerals 2024, 14, 518. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, S.; Liu, B.; Zheng, H.; Chang, C.; Ekberg, C. Recovery of precious metals from electronic waste and spent catalysts: A review. Resour. Conserv. Recycl. 2019, 141, 284–298. [Google Scholar] [CrossRef]

- Kumari, S.; Panda, R.; Prasad, R.; Alorro, R.D.; Jha, M.K. Sustainable Process to Recover Metals from Waste PCBs Using Physical Pre-Treatment and Hydrometallurgical Techniques. Sustainability 2024, 16, 418. [Google Scholar] [CrossRef]

- Mir, S.; Dhawan, N. A comprehensive review on the recycling of discarded printed circuit boards for resource recovery. Resour. Conserv. Recycl. 2022, 178, 106027. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T. Solvometallurgy: An Emerging Branch of Extractive Metallurgy. J. Sustain. Metall. 2017, 3, 570–600. [Google Scholar] [CrossRef]

- Sonule, B.B. Comparative Analysis of Pyrometallurgy, Hydrometallurgy and Bio-Hydro-Metallurgy for Extraction of Metals from E-Waste. Int. J. Res. Publ. Rev. J 2023, 4, 1970–1977. [Google Scholar]

- Ashiq, A.; Kulkarni, J.; Vithanage, M. Hydrometallurgical Recovery of Metals From E-waste. In Electronic Waste Management and Treatment Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 225–246. [Google Scholar] [CrossRef]

- KITCO Live Gold Prices|Gold News and Analysis|Mining News|KITCO. Available online: https://www.kitco.com/ (accessed on 15 March 2025).

- World Bank Group. World Bank Open Data. 2024. Available online: https://data.worldbank.org (accessed on 3 July 2024).

- World Bank Group. World Bank Country and Lending Groups—World Bank Data Help Desk. Available online: https://datahelpdesk.worldbank.org/knowledgebase/articles/906519-world-bank-country-and-lending-groups (accessed on 3 July 2024).

- RGPH. 5ème Récensement Général de la Population et de l’Habitation; Institut National de la Statistique et de la Démographie (INSD): Ouagadougou, Burkina Faso, 2019; p. 136. [Google Scholar]

- INSD. Monographie de la Commune de Ouagadougou; Institut National de la Statistique et de la Démographie (INSD): Ouagadougou, Burkina Faso, 2022; p. 136. [Google Scholar]

- SDAGO. Schéma Directeur d’Aménagement du Grand Ouaga Horizon 2025; Direction Générale de l’Urbanisme, de la Viabilisationet de la Topographie: Ouagadougou, Burkina Faso, 2019; p. 234. [Google Scholar]

- SOREVO Environnement. Tarif Ferrailleur—Prix D’achat des Métaux. Sorevo Environnement. 2024. Available online: https://www.sorevo.com/fr/tarifs (accessed on 17 March 2025).

- Kumari, A.; Jha, M.K.; Singh, R.P. Recovery of metals from pyrolysed PCBs by hydrometallurgical techniques. Hydrometallurgy 2016, 165, 97–105. [Google Scholar] [CrossRef]

- OCDE. Dynamiques du Développement en Afrique. Available online: https://www.oecd.org/fr/publications/dynamiques-du-developpement-en-afrique-2024_b25ee3a9-fr.html (accessed on 3 April 2025).

- WBG. Bureau de l’Administrateur du Groupe Afrique II: Rapport Annuel 2022; World Bank Group: Washington, DC, USA, 2022; p. 104. [Google Scholar]

- Akormedi, M.; Asampong, E.; Fobil, J.N. Working conditions and environmental exposures among electronic waste workers in Ghana. Int. J. Occup. Environ. Health 2013, 19, 278–286. [Google Scholar] [CrossRef]

- Amoyaw-Osei, Y.; Agyekum, O.O.; Pwamang, J.A.; Mueller, E.; Fasko, R.; Schluep, M. Ghana E-Waste Country Assessment. Ghana, 2011. 123p. Available online: https://www.basel.int/portals/4/basel%20convention/docs/ewaste/e-wasteassessmentghana.pdf (accessed on 3 July 2025).

- UNEP. Global Environment Outlook 6. Available online: https://www.unep.org/resources/global-environment-outlook-6 (accessed on 3 July 2025).

- OECD. Raw Materials Critical for the Green Transition. Available online: https://www.oecd.org/en/publications/raw-materials-critical-for-the-green-transition_c6bb598b-en.html (accessed on 3 July 2025).

| Context | Cu (g/kg) | Au (g/kg) | Ag (g/kg) | Pd (g/kg) | Equipment |

|---|---|---|---|---|---|

| Japan (high-income country) [18] | ~400 | 0.3–0.4 | ~0.5 | ~0.01 | Fresh e-waste (phones, computers) |

| Finland (high-income country) [19] | >400 | - | ~0.6 | - | Formally collected devices |

| Italy (high-income country) [20] | ~350 | ~0.25 | ~0.4 | ~0.015 | Old mobile phones |

| Africa (low-/middle-income countries) [16] | <300 | <0.02 | <0.3 | <0.01 | Used, obsolete imports |

| Local study (Burkina Faso) [7] | 295 | 0.021 | 0.373 | 0.001 | PCBs from phones, computers, RAM, and processors |

| Criteria | Pyrometallurgy | Hydrometallurgy | Solvometallurgy | Manual Dismantling | Bioleaching |

|---|---|---|---|---|---|

| Initial investment cost | High | Moderate | Variable | Low to moderate | Moderate |

| Processing cost per ton | High Energy and maintenance costs increase the cost per ton | Variable It depends on the cost of chemical reagents and effluent management | Non-available Specific data on costs per ton are limited | Low. Mainly related to labor costs | Low Microorganisms can be grown at low cost, but the process is slower |

| Local adaptability | Low Requires advanced industrial infrastructure | Medium Can be implemented with medium-sized facilities and proper management | Low Emerging technology requiring R&D investment | Very high Accessible to local waste pickers and artisans | Medium Requires technical support and knowledge of microbiology |

| Advantages | Effective for processing large volumes Capable of recovering multiple types of metals simultaneously | Suitable for processing smaller streams Allows for selective metal recovery | High selectivity for some precious metals Can operate at lower temperatures than pyrometallurgy | Low cost of entry Local job creation | Eco-friendly method with a reduced carbon footprint Capable of processing complex materials |

| Inconvenient | High energy consumption Potential toxic gas emissions requiring pollution control systems | Requires rigorous management of chemical waste to avoid pollution Can generate toxic effluents | Technology is still in development with limited availability Complex management of spent solvents | Slow and labor-intensive process Risk of exposure to toxic substances without adequate protective equipment | Slower process than chemical or thermal methods Requires precise control of biological conditions |

| Recovery Technology | Revenue (USD/kg) | Total Cost (USD/kg) | Net Benefit (USD/kg) | Net Benefit with Sensitivity Test (USD/kg) | |

|---|---|---|---|---|---|

| −20% Treatment Costs | +20% Treatment Costs | ||||

| Manual dismantling | 2.88 | 20.5 | −17.62 | −16.62 | −18.62 |

| Bioleaching | 3.14 | 23.8 | −20.66 | −18.66 | −22.66 |

| Hydrometallurgy | 3.94 | 29.2 | −25.26 | −22.26 | −28.26 |

| Solvometallurgy | 3.86 | 32.8 | −28.94 | −25.34 | −32.54 |

| Pyrometallurgy | 4.07 | 34.5 | −30.43 | −26.43 | −34.43 |

| Scenario | Technology Scope | PCB Price | Policy Instruments | Co-Benefits Included | Objective |

|---|---|---|---|---|---|

| 0 | All | 13 USD/kg | None | No | Baseline economic assessment |

| 1 | Cu and Au only | 13 USD/kg | None | No | Prioritize valuable metals |

| 2 | Cu and Au in richest devices | 13 USD/kg | None | No | Equipment-targeted optimization |

| 3 | Cu and Au in richest devices | 5 USD/kg or 10 USD/kg | None | No | Cost-based viability simulation |

| 4 | Cu and Au in richest devices | 13 USD/kg | EPR + Eco-tax | No | Policy-based incentive simulation |

| 5 | Cu and Au in richest devices | 13 USD/kg | EPR + Eco-tax | Yes | Policy + socio-environmental valuation |

| 6 | Cu and Au in richest devices | 5 USD/kg or 10 USD/kg | EPR + Eco-tax | Yes | Optimized integrated model |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahossouhe, M.S.; Andrianisa, H.A.; Damba, D.D.; Kouassi, D.; Narra, S.; Sanou, A. Scenario-Based Extended Cost–Benefit Analysis for E-Waste Metal Recovery in Low-Income Countries: Evidence from an Integrated Model in Burkina Faso. Sustainability 2025, 17, 8351. https://doi.org/10.3390/su17188351

Ahossouhe MS, Andrianisa HA, Damba DD, Kouassi D, Narra S, Sanou A. Scenario-Based Extended Cost–Benefit Analysis for E-Waste Metal Recovery in Low-Income Countries: Evidence from an Integrated Model in Burkina Faso. Sustainability. 2025; 17(18):8351. https://doi.org/10.3390/su17188351

Chicago/Turabian StyleAhossouhe, Mahugnon Samuel, Harinaivo Anderson Andrianisa, Djim Doumbe Damba, Dongo Kouassi, Satyanarayana Narra, and Alassane Sanou. 2025. "Scenario-Based Extended Cost–Benefit Analysis for E-Waste Metal Recovery in Low-Income Countries: Evidence from an Integrated Model in Burkina Faso" Sustainability 17, no. 18: 8351. https://doi.org/10.3390/su17188351

APA StyleAhossouhe, M. S., Andrianisa, H. A., Damba, D. D., Kouassi, D., Narra, S., & Sanou, A. (2025). Scenario-Based Extended Cost–Benefit Analysis for E-Waste Metal Recovery in Low-Income Countries: Evidence from an Integrated Model in Burkina Faso. Sustainability, 17(18), 8351. https://doi.org/10.3390/su17188351