Bridging Circular Design Strategies and Natural Fiber Reinforced Polymer Composites: A Preliminary Conceptual Framework

Abstract

1. Introduction

2. Theorical Background

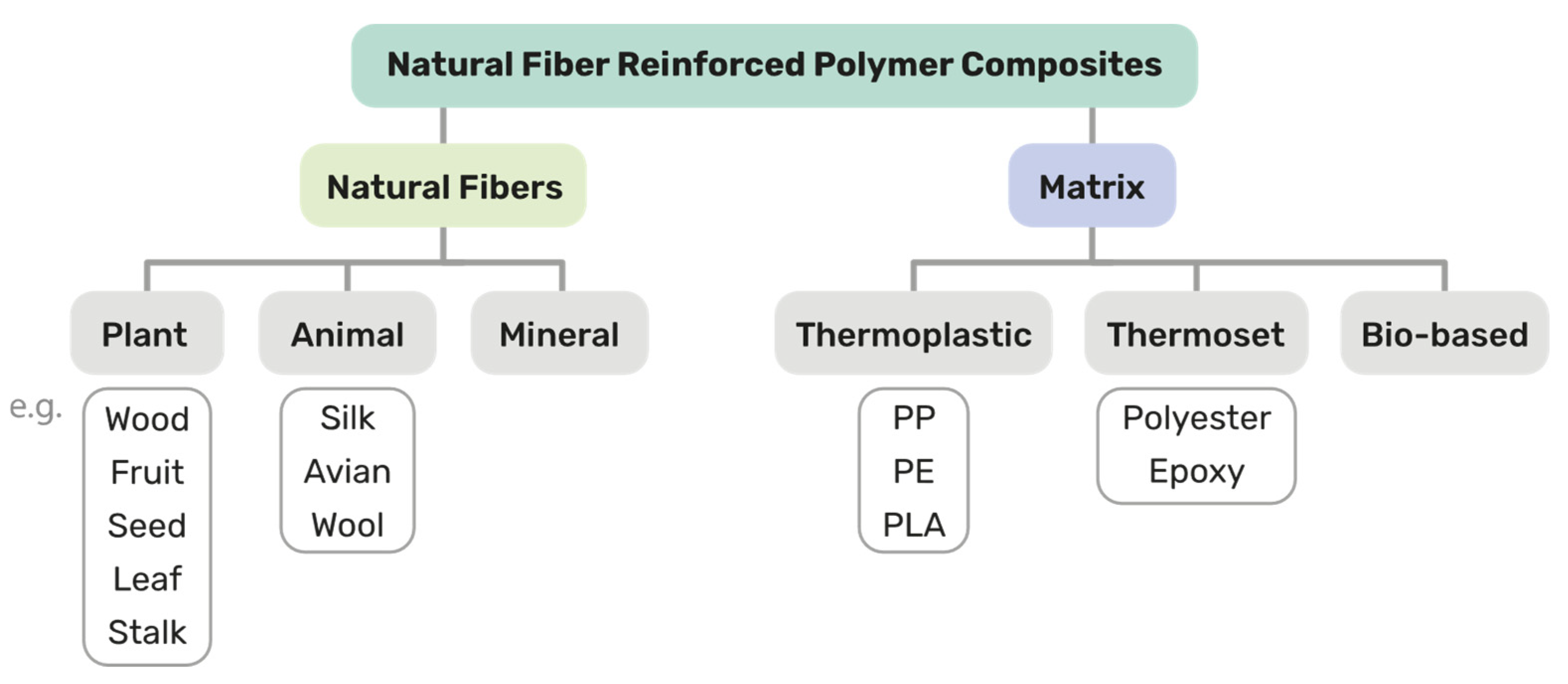

2.1. Definition and Characteristics of Natural Fiber Polymer Composites

2.2. Circular Design Principles

- Resource Conservation: focuses on designing for closed-loop material flows, reducing raw material extraction, and minimizing waste. It encourages the regeneration of natural systems and supports strategies such as recycling, upcycling, and cascading material use through multiple life cycles [16,39].

2.3. Gaps in Aligning NFRPCs with Circular Design Strategies

3. Method

3.1. Research Questions

- RQ1: What are the current challenges and opportunities associated with NFRPCs?

- RQ2: What Circular Design strategies, tools, or principles have been applied to materials or products with similar characteristics?

- RQ3: How can Circular Design principles be effectively adapted to the specificities of NFRPCs to support sustainable product development?

3.2. Development Process of the Framework

4. Results and Discussion

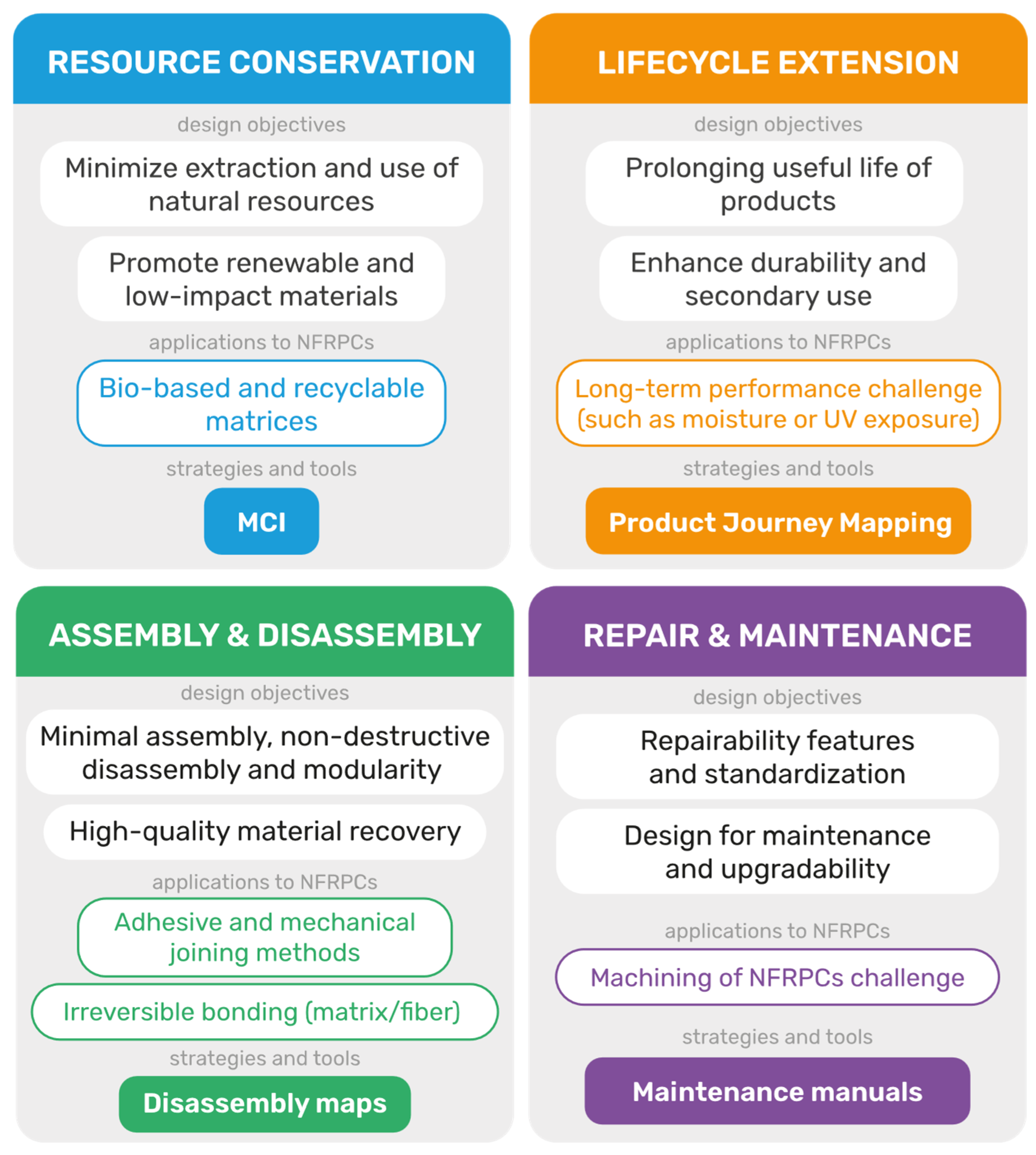

4.1. Mapped Circular Design Principles to NFRPC

- Resource Conservation: this principle focuses on minimizing the extraction and use of finite resources while promoting renewable and low-impact materials [16,39]. NFRPCs could offer an advantage in this area, as they often utilize agricultural by-products or renewable fibers such as jute, sisal or abaca [42,43]. Moreover, pairing these fibers with bio-based or recyclable polymer matrices can further reduce the environmental footprint of composite production. However, variability in fiber quality, geographical limitations of sourcing and the carbon intensity of some biopolymers require careful evaluation. In addition, the instability of agricultural by-product supply and the potential risk of contamination remain critical barriers to wider adoption. Resource efficiency can also be pursued by optimizing the material-to-performance ratio, for example, by reducing part thickness or weight without compromising function.To address these challenges, strategies such as green material selection matrices, eco-materials compasses and the Material Circularity Indicator (MCI) can support early-stage design and decision-making [44]. Likewise, digital tools such as CAD can aid in optimizing material efficiency. For performance assessment, a range of sustainability metrics can be applied, including renewable content (%), waste-derived input (%), reduction in material use, embodied energy (MJ/kg), land use, water use and other Life Cycle Assessment (LCA) indicators [45,46,47].

- Lifecycle Extension: prolonging the useful life of NFRPC products through enhanced durability or secondary use potential is a critical component of circularity [13,40,41]. While NFRPCs can offer competitive strength-to-weight ratios, their long-term performance is often challenged by environmental factors such as moisture or UV exposure [9,31,48,49]. Addressing these vulnerabilities requires strategies that increase both technical durability, through protective coatings, modular part replacement, or design for multi-use cycles [50] and emotional durability, by strengthening user perception and attachment to products [15]. Moreover, enabling circular business models such as take-back schemes, product-as-a-service and material traceability can support secondary use scenarios and extend product lifespans beyond their initial function [51,52].To operate these approaches, design tools such as Product Journey Mapping, LCA scenario analysis, the Circular Business Model and material or product passports provide actionable support for decision-making [14,32,53]. Corresponding sustainability metrics include estimated product lifespan, percentage of reused or refurbished components, durability testing results, business model return on investment, user retention and service life cycles.

- Assembly and Disassembly: ease of disassembly is essential for facilitating reuse, remanufacturing or high-quality material recovery [13]. In the case of NFRPCs, this principle presents both challenges and innovation potential. Minimal assembly, non-destructive disassembly and modularity are particularly valuable, as they ensure the proper, agile and efficient separation of parts [16,32,39]. This not only facilitates product recycling and reuse but also enables component replacement and functional upgrades. While adhesive and mechanical joining methods are generally compatible with NFRPC parts [54], the irreversible bonding often used in conventional composites (e.g., epoxy resins) can hinder separation [55].To overcome these limitations, strategies such as Design for Disassembly (DfD) guidelines, modular configurations and circular joining techniques can be employed. Tools such as Disassembly Maps [56] and Design of Circular Disassembly [16] can support the implementation of this principle. Suitable indicators include disassembly time, recovery rates and compatibility of joining techniques with material properties [16,56].

- Repair and Maintenance: the implementation of repairability features, standardization and design for maintenance and upgradability plays a pivotal role in enabling longer product lifecycles and fostering opportunities for reuse [50,57]. Within the context of NFRPCs, however, repairability remains a challenge, as these composites are often perceived as difficult to modify or unsuitable for remanufacturing [58,59,60]. Overcoming these limitations requires development strategies that emphasize modular configurations, part standardization, and the replaceability of worn components, together with the possibility of refinishing surfaces to extend functionality [50].The integration of maintenance manuals, design-for-repair checklists and context-specific toolkits tailored to the material characteristics of NFRPCs can facilitate accessibility and user engagement [56]. These measures not only enhance repairability but also support functional upgrades and encourage more sustainable usage patterns. Indicators such as repair rate, repair time, cost-to-repair ratios, maintenance frequency and part availability provide actionable insights into the feasibility and effectiveness of repair-oriented design strategies [50].

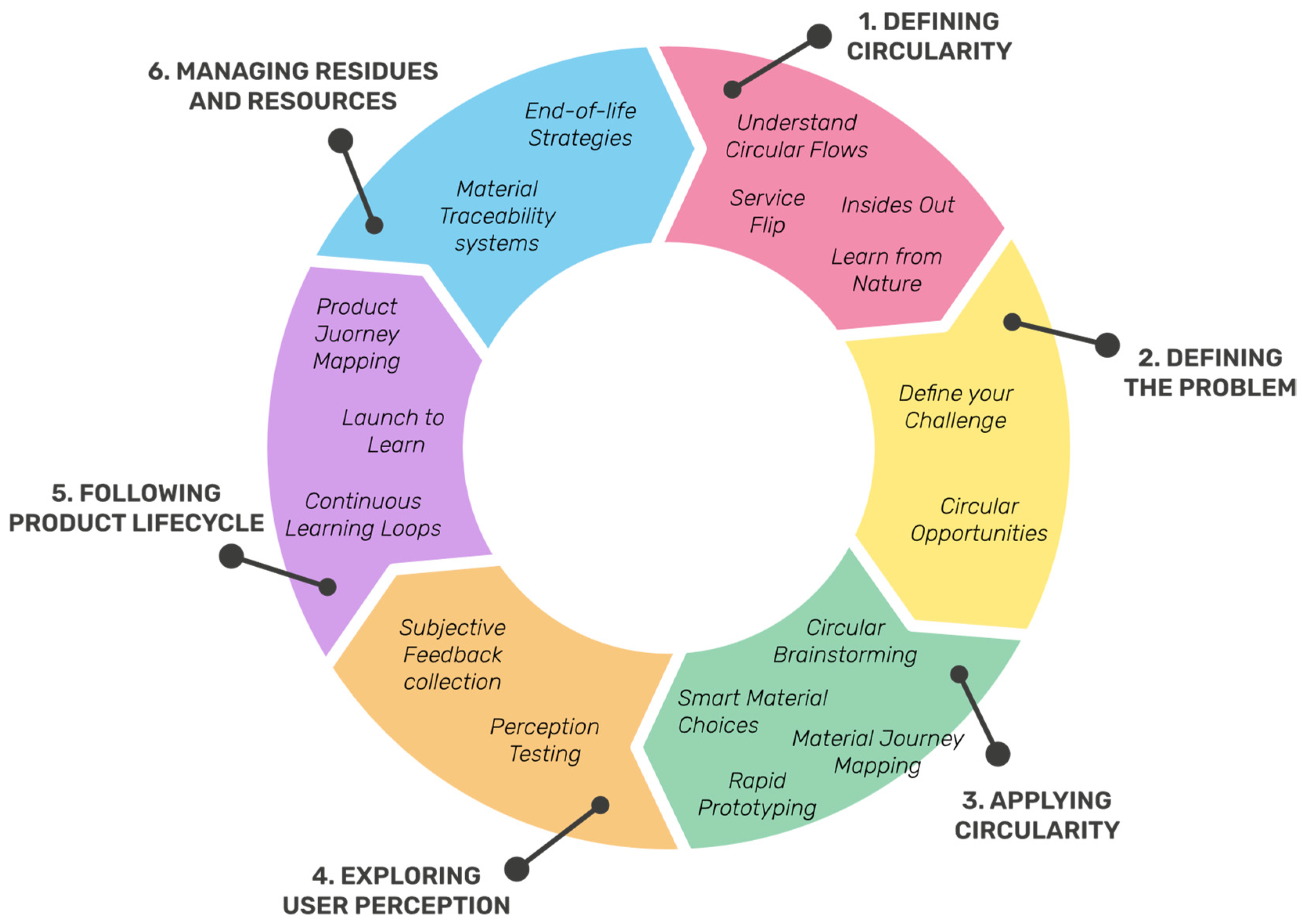

4.2. Proposed Preliminary Conceptual Framework

Structure of the Framework

- Understanding Circularity: This initial phase introduces key concepts of circularity while grounding them in local ecosystems and the availability of material resources. It encourages a systems-thinking approach and awareness of environmental impact across the product lifecycle. Four adapted tools guide this stage: Understand Circular Flows helps map material lifecycles to identify opportunities for regeneration and closed loops, particularly for natural fibers and polymer matrices; Service Flip invites designers to rethink products as services, supporting business models based on sharing, reuse, or leasing; Insides Out focuses on analyzing components and material choices; finally, Learn from Nature applies biomimicry to inspire efficient and regenerative design strategies. Together, these tools establish a critical foundation for making informed, sustainable decisions in subsequent design phases.

- Defining the Problem through Circularity: This phase focuses on framing a clear and strategic design brief explicitly grounded in circular principles. Rather than treating the brief as a purely functional or aesthetic exercise, it encourages designers to integrate environmental, systemic and material-specific considerations from the outset. Within the context of NFRPCs, this requires particular attention to issues such as variability in fiber quality, durability under environmental exposure and the challenges of repairability or end-of-life recovery. Addressing these aspects early ensures that the design intent is aligned not only with user needs but also with the long-term sustainability of the material. Two tools support this stage: Define Your Challenge helps identify the core problem and CD priorities, while Circular Opportunities guides exploration of impactful interventions, such as reducing waste or enhancing material reuse. Together, they orient the project toward meaningful outcomes by aligning the design intent with circular strategies from the earliest stages.

- Applying Circularity: This phase enables the practical implementation of CD through hands-on engagement with materials, ideation and testing. Within the context of NFRPCs, it requires balancing sustainability ambitions with the material’s challenges, such as variability in quality, susceptibility to environmental and machining degradation or limited repairability, while leveraging their advantages as renewable sources or lightweight composites. Several tools could guide this process. Circular Brainstorming facilitates idea generation guided by circular principles, such as reuse, modularity, or minimal material use, ensuring that creative exploration aligns with sustainability goals. Smart Material Choices helps designers evaluate NFRPCs based on sourcing, durability, recyclability, and environmental impact, promoting informed decisions that go beyond aesthetics or performance. Material Journey Mapping visualizes the entire lifecycle of a material within the product system, helping anticipate bottlenecks, waste points and opportunities for recovery. Rapid Prototyping supports early testing of concepts using NFRPCs, encouraging iterative development and material sensitivity. Collectively, these tools help bridge theory and practice, empowering designers to create circular solutions that are feasible, resource-conscious and aligned with user needs. These tools bridge theory and practice by encouraging experimentation while maintaining a systemic perspective. They empower practitioners to create solutions that are feasible, resource-efficient and grounded in the realities of working with NFRPCs, ultimately contributing to longer product lifecycles and more sustainable innovation.

- Exploring User Perception: This phase emphasizes the importance of user acceptance and emotional connection in the success of circular products made with NFRPCs. Beyond technical performance, the sensory qualities of these composites, their texture, natural aesthetics and tactile warmth, shape how users perceive and value them. User-centered tools, such as perception testing and feedback collection, are employed to evaluate responses not only to sustainability claims but also to the experiential aspects of interacting with the material [61,62,63,64]. Factors such as trust, usability and perceived authenticity influence both immediate acceptance and the long-term attachment to the product. By acknowledging and designing for these subjective and emotional dimensions, engineers and designers can address skepticism, strengthen emotional durability and cultivate a deeper sense of care and responsibility toward products, an essential driver of circularity in consumer culture [50].

- Following the Product Lifecycle: This phase focuses on tracking the product’s lifecycle beyond its initial release to ensure that circular strategies remain effective in real-world contexts. By integrating lifecycle extension principles with the specific characteristics of NFRPCs, it underscores the need to anticipate material degradation challenges, such as sensitivity to moisture or UV exposure, while actively enabling strategies for reuse, repair, and repurposing. Product Journey Mapping helps visualize each stage of the product’s life, from production to use, maintenance, and end-of-life, enabling the identification of circular interventions across the timeline such as modular upgrades, secondary use or recovery of fibers and matrices. Launch to Learn encourages early market introduction of prototypes to gather real user insights, revealing unforeseen challenges and validating assumptions about NFRPCs’ performance and perception. Continuous Learning Loops formalize feedback cycles, allowing iterative improvements based on actual user behavior and system-level outcomes. Together, these tools could support adaptive, evidence-based design processes, promoting the long-term viability and circular performance of NFRPC-based products.

- Managing Residues and Resources: This final phase addresses the end-of-life stage of products, focusing on recovering value and minimizing environmental impacts through strategies tailored to NFRPCs. While conventional composites often face significant barriers to recyclability [5,6], NFRPCs introduce both opportunities and challenges: their renewable fibers may enable biodegradation or energy recovery, yet their polymer matrices, whether thermoset or thermoplastic, bio-based or fossil-derived, determine the feasibility of material recovery [65]. Consequently, assessing compatibility with existing recycling systems and identifying alternative circular pathways such as reuse, modular remanufacturing, mechanical recycling, or controlled composting becomes essential. Equally critical is ensuring material traceability and transparency, providing clear information on fiber origin, polymer type and additives, which facilitates efficient sorting and specialized recycling streams. This becomes critical given fiber variability and the lack of harmonized compostability standards. Tools like end-of-life flow mapping or material passports support structured resource recovery from the design stage onward [66,67]. Key indicators, recovery efficiency, recyclability percentages, biodegradability potential and traceability scores, offer actionable insights to ensure that NFRPCs products transition from waste to resource, reinforcing systemic circularity.

4.3. Two Case Studies Feedback

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NFRPC | Natural Fiber-Reinforced Polymer Composites |

| CD | Circular Design |

| MCI | Material Circularity Indicators |

| LCA | Life Cycle Assessment |

| STEAM | Science, Technology, Engineering, Art and Mathematics |

References

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Santhosh, N.; Praveena, B.A.; Gowda, A.C.; Duhduh, A.A.; Rajhi, A.A.; Alamri, S.; Berwal, P.; Khan, M.A.; Wodajo, A.W. Innovative eco-friendly bio-composites: A comprehensive review of the fabrication, characterization, and applications. Rev. Adv. Mater. Sci. 2024, 63, 20240057. [Google Scholar] [CrossRef]

- Li, L.; Zuo, J.; Duan, X.; Wang, S.; Hu, K.; Chang, R. Impacts and mitigation measures of plastic waste: A critical review. Environ. Impact Assess. Rev. 2021, 90, 106642. [Google Scholar] [CrossRef]

- Koelmans, A.A.; Besseling, E.; Foekema, E.; Kooi, M.; Mintenig, S.; Ossendorp, B.C.; Redondo-Hasselerharm, P.E.; Verschoor, A.; van Wezel, A.P.; Scheffer, M. Risks of Plastic Debris: Unravelling Fact, Opinion, Perception, and Belief. Environ. Sci. Technol. 2017, 51, 11513–11519. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Circular design of composite products: A framework based on insights from literature and industry. Sustainability 2021, 13, 7223. [Google Scholar] [CrossRef]

- Marconi, M.; Bakshi, B.; Joustra, J.; Bakker, C.; Bessai, R.; Balkenende, R. Circular Composites by Design: Testing a Design Method in Industry. Sustainability 2022, 14, 7993. [Google Scholar] [CrossRef]

- Suárez, L.; Castellano, J.; Díaz, S.; Tcharkhtchi, A.; Ortega, Z. Article are natural-based composites sustainable? Polymers 2021, 13, 2326. [Google Scholar] [CrossRef]

- Kurien, R.A.; Anil, M.M.; Mohan, S.S.; Thomas, J.A. Natural fiber composites as sustainable resources for emerging applications—A review. Mater Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Mundhe, A.; Kandasubramanian, B. Advancements in natural fiber composites: Innovative chemical surface treatments, characterizaton techniques, environmental sustainability, and wide-ranging applications. Hybrid Adv. 2024, 7, 100282. [Google Scholar] [CrossRef]

- Sathish, S.; Karthi, N.; Prabhu, L.; Gokulkumar, S.; Balaji, D.; Vigneshkumar, N.; Ajeem Farhan, T.S.; Akilkumar, A.; Dinesh, V.P. A review of natural fiber composites: Extraction methods, chemical treatments and applications. Mater. Today Proc. 2021, 45, 8017–8023. [Google Scholar] [CrossRef]

- Grupo de Investigación de Fabricación Integrada y Avanzada (GIFIA). Inv2mac. Available online: https://www.inv2mac.com/index.php (accessed on 3 September 2025).

- Parque Tecnológico de Gran Canaria Área Experimental de Economía Circular. E-CircularCanarias. Available online: https://e-circularcanarias.es/ (accessed on 3 September 2025).

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A conceptual framework for circular design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Ellen McArthur Foundation. The Circular Design Guide. Available online: https://www.ellenmacarthurfoundation.org/circular-design-guide/overview (accessed on 31 July 2025).

- Wastling, T.; Charnley, F.; Moreno, M. Design for circular behaviour: Considering users in a circular economy. Sustainability 2018, 10, 1743. [Google Scholar] [CrossRef]

- Formentini, G.; Ramanujan, D. Design for circular disassembly: Evaluating the impacts of product end-of-life status on circularity through the parent-action-child model. J. Clean. Prod. 2023, 405, 137009. [Google Scholar] [CrossRef]

- Ritzen, L.; Sprecher, B.; Bakker, C.; Balkenende, R. Bio-based plastics in a circular economy: A review of recovery pathways and implications for product design. Resour. Conserv. Recycl. 2023, 199, 107268. [Google Scholar] [CrossRef]

- Dumée, L.F. Circular Materials and Circular Design—Review on Challenges Towards Sustainable Manufacturing and Recycling. Circ. Econ. Sustain. 2021, 2, 9–23. [Google Scholar] [CrossRef] [PubMed]

- Palanisamy, S.; Murugesan, T.M.; Palaniappan, M.; Santulli, C.; Ayrilmiş, N. Fostering sustainability: The environmental advantages of natural fiber composite materials—A mini review. Environ. Res. Technol. 2024, 7, 256–269. [Google Scholar] [CrossRef]

- Uppal, N.; Pappu, A.; Gowri, V.K.S.; Thakur, V.K. Cellulosic fibres-based epoxy composites: From bioresources to a circular economy. Ind. Crop. Prod. 2022, 182, 114895. [Google Scholar] [CrossRef]

- ISO 16620-1:2015; Plastics—Biobased Content. International Organization for Standarization: Geneva, Switzerland, 2015.

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable materials for emerging applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Ramachandran, A.R.; Mavinkere Rangappa, S.; Kushvaha, V.; Khan, A.; Seingchin, S.; Dhakal, H.N. Modification of Fibers and Matrices in Natural Fiber Reinforced Polymer Composites: A Comprehensive Review. Macromol. Rapid Commun. 2022, 43, e2100862. [Google Scholar] [CrossRef]

- Shebaz Ahmed, J.P.; Satyasree, K.; Rohith Kumar, R.; Meenakshisundaram, O.; Shanmugavel, S. A comprehensive review on recent developments of natural fiber composites synthesis, processing, properties, and characterization. Eng. Res. Express 2023, 5, 32001. [Google Scholar] [CrossRef]

- Ghalme, S.; Hayat, M.; Harne, M. A Comprehensive Review of Natural Fibers: Bio-Based Constituents for Advancing Sustainable Materials Technology. J. Renew. Mater. 2025, 13, 273–295. [Google Scholar] [CrossRef]

- Bhat, A.R.; Kumar, R.; Mural, P.K.S. Natural fiber reinforced polymer composites: A comprehensive review of Tribo-Mechanical properties. Tribol. Int. 2023, 189, 108978. [Google Scholar] [CrossRef]

- Manral, A.; Kumar Bajpai, P.; Ahmad, F.; Joshi, R. Processing of sustainable thermoplastic based biocomposites: A comprehensive review on performance enhancement. J. Clean. Prod. 2021, 316, 128068. [Google Scholar] [CrossRef]

- Govinda; Widiastuti, I. The Manufacturing Process of Recycled Polymer Composites reinforced with Natural Fibers—A Systematic Literature Review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Ortega, Z.; Romero, F.; Paz, R.; Suárez, L.; Benítez, A.N.; Marrero, M.D. Valorization of invasive plants from macaronesia as filler materials in the production of natural fiber composites by rotational molding. Polymers 2021, 13, 2220. [Google Scholar] [CrossRef]

- Ajayi, N.E.; Rusnakova, S.; Ajayi, A.E.; Ogunleye, R.O.; Agu, S.O.; Amenaghawon, A.N. A comprehensive review of natural fiber reinforced Polymer composites as emerging materials for sustainable applications. Appl. Mater. Today 2025, 43, 102666. [Google Scholar] [CrossRef]

- Munimathan, A.; Muthu, K.; Subramani, S.; Rajendran, S. Environmental behaviour of synthetic and natural fibre reinforced composites: A review. Adv. Mech. Eng. 2024, 16, 16878132241286020. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Sumter, D.; de Koning, J.; Bakker, C.; Balkenende, R. Key competencies for design in a circular economy: Exploring gaps in design knowledge and skills for a circular economy. Sustainability 2021, 13, 776. [Google Scholar] [CrossRef]

- Toth-Peter, A.; Torres de Oliveira, R.; Mathews, S.; Barner, L.; Figueira, S. Industry 4.0 as an enabler in transitioning to circular business models: A systematic literature review. J. Clean. Prod. 2023, 393, 136284. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Shin, C. A conceptual approach to the relationships between the social economy, social welfare, and social innovation. J. Sci. Technol. Policy Manag. 2016, 7, 154–172. [Google Scholar] [CrossRef]

- Husgafvel, R. Exploring social sustainability handprint—Part 1: Handprint and life cycle thinking and approaches. Sustainability 2021, 13, 11286. [Google Scholar] [CrossRef]

- Narganes-Pineda, A.; González-Suárez, P.; Hernández-Castellano, P.M. A Definition Approach to Circular Design for Product Design and Development. In Advances on Mechanics, Design Engineering and Manufacturing V; Springer Nature: Cham, Switzerland, 2025; pp. 309–322. [Google Scholar] [CrossRef]

- Chen, W.C.; Rau, H. A product evaluation and innovation process based on the circular design degree and patents evolution. J. Clean. Prod. 2023, 405, 136888. [Google Scholar] [CrossRef]

- Guerreschi, A.; Wielopolski, M. Importance of Knowing What Your Customers Know to Effective Circular Design. Environ. Eng. Manag. J. 2023, 21, 1673–1682. [Google Scholar] [CrossRef]

- Wang, J.X.; Burke, H.; Zhang, A. Overcoming barriers to circular product design. Int. J. Prod. Econ. 2022, 243, 108346. [Google Scholar] [CrossRef]

- Singh, R.; Singh, B.; Gupta, M.; Tarannum, H. Composite building materials from natural fibers/agro-forest residues. Indian J. Eng. Mater. Sci. 2020, 27, 137–149. [Google Scholar]

- Jeremiah Barba, B.D.; Madrid, J.F.; Penaloza, D.P., Jr. A Review of Abaca Fiber-Reinforced Polymer Composites: Different Modes of Preparation and Their Applications. J. Chil. Chem. Soc. 2020, 65, 3. [Google Scholar] [CrossRef]

- Niero, M.; Kalbar, P.P. Coupling material circularity indicators and life cycle based indicators: A proposal to advance the assessment of circular economy strategies at the product level. Resour. Conserv. Recycl. 2019, 140, 305–312. [Google Scholar] [CrossRef]

- Desing, H.; Braun, G.; Hischier, R. Resource pressure—A circular design method. Resour. Conserv. Recycl. 2021, 164, 105179. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.A.; Rashid, A.; Mihelič, A.; Kotnik, S. Towards circular economy implementation in manufacturing systems using a multi-method simulation approach to link design and business strategy. Int. J. Adv. Manuf. Technol. 2017, 93, 1953–1970. [Google Scholar] [CrossRef]

- Mansor, M.R.; Salit, M.S.; Zainudin, E.S.; Aziz, N.A.; Ariff, H. Life Cycle Assessment of Natural Fiber Polymer Composites; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Go, T.F.; Wahab, D.A.; Hishamuddin, H. Multiple generation life-cycles for product sustainability: The way forward. J. Clean. Prod. 2015, 95, 16–29. [Google Scholar] [CrossRef]

- Zeeuw Van Der Laan, A.; Aurisicchio, M. Designing product-service systems to close resource loops: Circular design guidelines. Procedia CIRP 2019, 80, 631–636. [Google Scholar] [CrossRef]

- Reigado, C.R.; Fernandes, S.D.C.; Saavedra, Y.M.B.; Ometto, A.R.; Da Costa, J.M.H. A Circular Economy Toolkit as an Alternative to Improve the Application of PSS Methodologies. Procedia CIRP 2017, 64, 37–42. [Google Scholar] [CrossRef]

- Nußholz, J.L.K. A circular business model mapping tool for creating value from prolonged product lifetime and closed material loops. J. Clean. Prod. 2018, 197, 185–194. [Google Scholar] [CrossRef]

- Kumar, J.; Singh, Y.; Naik, T.; Rana, R.S.; Rakesh, P.K.; Singh, I. Adhesive joining behaviour of banana/bagasse/epoxy composites with different joint designs. Biomass Convers. Biorefinery 2023, 14, 31827–31836. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; Mohan Kumar, K.; Ammarullah, M.I. Synergistic advances in natural fibre composites: A comprehensive review of the eco-friendly bio-composite development, its characterization and diverse applications. RSC Adv. 2024, 14, 17594–17611. [Google Scholar] [CrossRef]

- De Fazio, F.; Bakker, C.; Flipsen, B.; Balkenende, R. The Disassembly Map: A new method to enhance design for product repairability. J. Clean. Prod. 2021, 320, 128552. [Google Scholar] [CrossRef]

- van Dam, S.S.; Bakker, C.A.; de Pauw, I.; van der Grinten, B. The circular pathfinder: Development and evaluation of a practice-based tool for selecting circular design strategies. In Plate Product Lifetimes and the Environment 2017: Conference Proceedings; IOS Press: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Mohammed, M.; Oleiwi, J.K.; Mohammed, A.M.; Jawad, A.J.M.; Osman, A.F.; Adam, T.; Betar, B.O.; Gopinath, S.C.B. A Review on the Advancement of Renewable Natural Fiber Hybrid Composites: Prospects, Challenges, and Industrial Applications. J. Renew. Mater. 2024, 12, 1237–1290. [Google Scholar] [CrossRef]

- Slamani, M.; Chatelain, J.-F. A review on the machining of polymer composites reinforced with carbon (CFRP), glass (GFRP), and natural fibers (NFRP). Discov. Mech. Eng. 2023, 2, 4. [Google Scholar] [CrossRef]

- Varma, M.; Chandran, S.; Vijay Kumar, V.; Suyambulingam, I.; Siengchin, S. A comprehensive review on the machining and joining characteristics of natural fiber-reinforced polymeric composites. Polym. Compos. 2024, 45, 4850–4875. [Google Scholar] [CrossRef]

- Abella, A.; Llorach-Massana, P.; Pereda-Baños, A.; Marco-Almagro, L.; Barreda-Ángeles, M.; Clèries, L. Perception of Recycled Plastics for Improved Consumer Acceptance through Self-Reported and Physiological Measures. Sensors 2022, 22, 9226. [Google Scholar] [CrossRef]

- Pardo-Vicente, M.Á.; Rodríguez-Parada, L.; Mayuet-Ares, P.F.; Aguayo-González, F. Haptic hybrid prototyping (HHP): An AR application for texture evaluation with semantic content in product design. Appl. Sci. 2019, 9, 5081. [Google Scholar] [CrossRef]

- Nordvik, E.; Schütte, S.; Olof Broman, N. People’s Perceptions of the Visual Appearance of Wood Flooring: A Kansei Engineering Approach. For. Prod. J. 2009, 59, 67–74. [Google Scholar] [CrossRef]

- Eriksson, L.; Rosen, B.; Bergman, M. Affective Surface Engineering-Using Soft and Hard Metrologhy to Measure the Sensation and Perception in Surface Properties. In Proceedings of the NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Liedl, B.; Höftberger, T.; Burgstaller, C. Properties of Multiple-Processed Natural Short Fiber Polypropylene and Polylactic Acid Composites: A Comparison. Macromol 2024, 4, 723–738. [Google Scholar] [CrossRef]

- Mathur, N.; Last, N.; Morris, K.C. A process model representation of the end-of-life phase of a product in a circular economy to identify standards needs. Front. Manuf. Technol. 2023, 3, 988073. [Google Scholar] [CrossRef]

- Huang, Y.; Shafiee, M.; Charnley, F.; Encinas-Oropesa, A. Designing a Framework for Materials Flow by Integrating Circular Economy Principles with End-of-life Management Strategies. Sustainability 2022, 14, 4244. [Google Scholar] [CrossRef]

- Pinheiro, M.A.P.; Seles, B.M.R.P.; De Camargo Fiorini, P.; Jugend, D.; Lopes de Sousa Jabbour, A.B.; da Silva, H.M.R.; Latan, H. The role of new product development in underpinning the circular economy: A systematic review and integrative framework. Manag. Decis. 2019, 57, 840–862. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narganes-Pineda, A.; Hernández-Castellano, P.M.; González-Suárez, P. Bridging Circular Design Strategies and Natural Fiber Reinforced Polymer Composites: A Preliminary Conceptual Framework. Sustainability 2025, 17, 8260. https://doi.org/10.3390/su17188260

Narganes-Pineda A, Hernández-Castellano PM, González-Suárez P. Bridging Circular Design Strategies and Natural Fiber Reinforced Polymer Composites: A Preliminary Conceptual Framework. Sustainability. 2025; 17(18):8260. https://doi.org/10.3390/su17188260

Chicago/Turabian StyleNarganes-Pineda, Annabella, Pedro M. Hernández-Castellano, and Paula González-Suárez. 2025. "Bridging Circular Design Strategies and Natural Fiber Reinforced Polymer Composites: A Preliminary Conceptual Framework" Sustainability 17, no. 18: 8260. https://doi.org/10.3390/su17188260

APA StyleNarganes-Pineda, A., Hernández-Castellano, P. M., & González-Suárez, P. (2025). Bridging Circular Design Strategies and Natural Fiber Reinforced Polymer Composites: A Preliminary Conceptual Framework. Sustainability, 17(18), 8260. https://doi.org/10.3390/su17188260