Water Use Efficiency Assessment of Cement Production Based on Life Cycle Analysis

Abstract

1. Introduction

2. Data Collection and Methods

2.1. Data Collection

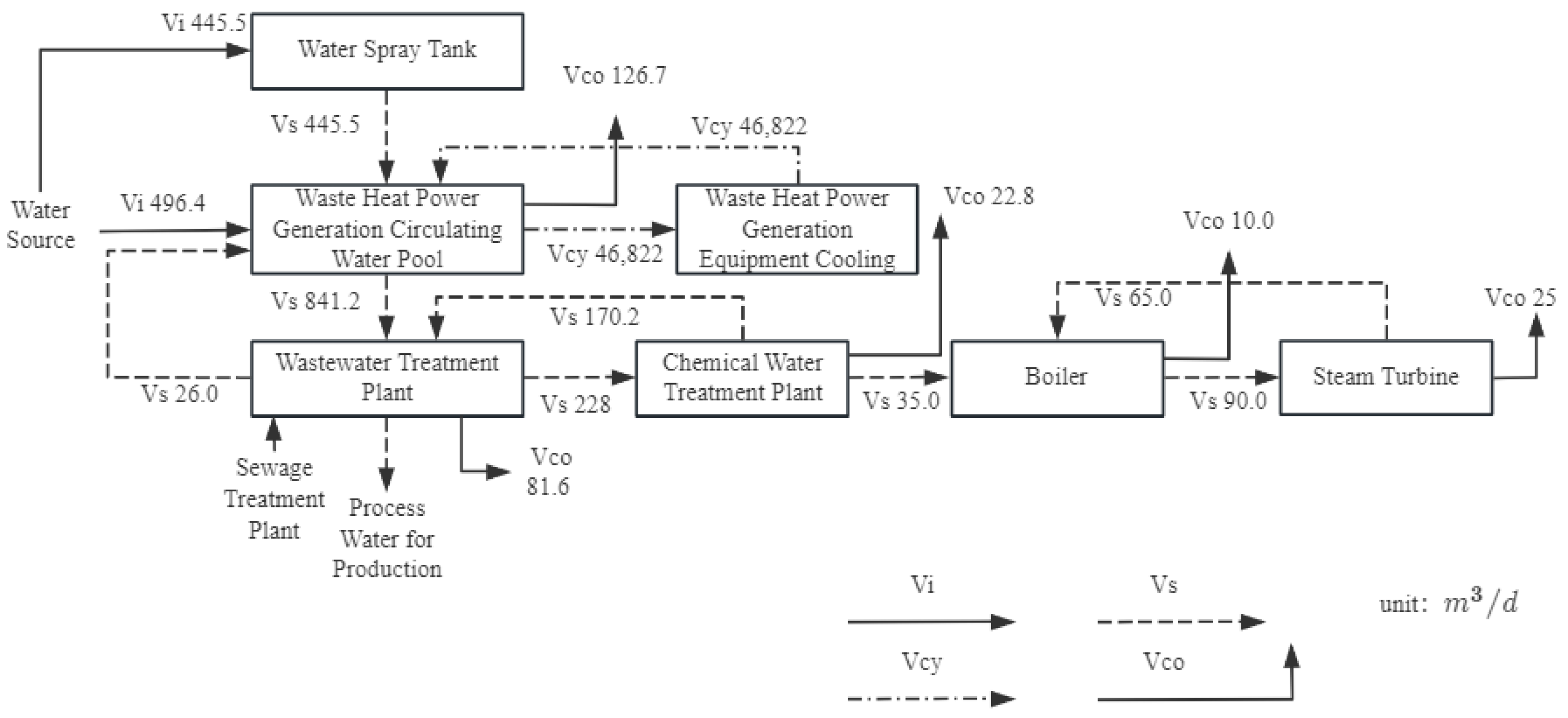

2.2. Water Balance Analysis

- Vcy—the input recycled water volume, measured in cubic meters (m3);

- —the output recycled water volume, measured in cubic meters (m3);

- Vi—the water intake volume, measured in cubic meters (m3);

- Vs—the input series water volume, measured in cubic meters (m3);

- —the output series water volume, measured in cubic meters (m3);

- Vt—the water usage volume, measured in cubic meters (m3);

- Vco—the water consumption volume, measured in cubic meters (m3);

- Vd—the drainage volume, measured in cubic meters (m3);

- Vl—the leakage and loss volume, measured in cubic meters (m3).

- —water intake per unit production, in cubic meters per ton (m3/t);

- —total cement or clinker production in the reporting period, in tons (t).

- —water reuse rate (%).

- —reuse rate of wastewater (%).

- —sewage reuse, in cubic meters per ton (m3/t).

- —integrated leakage rate of water use, (%).

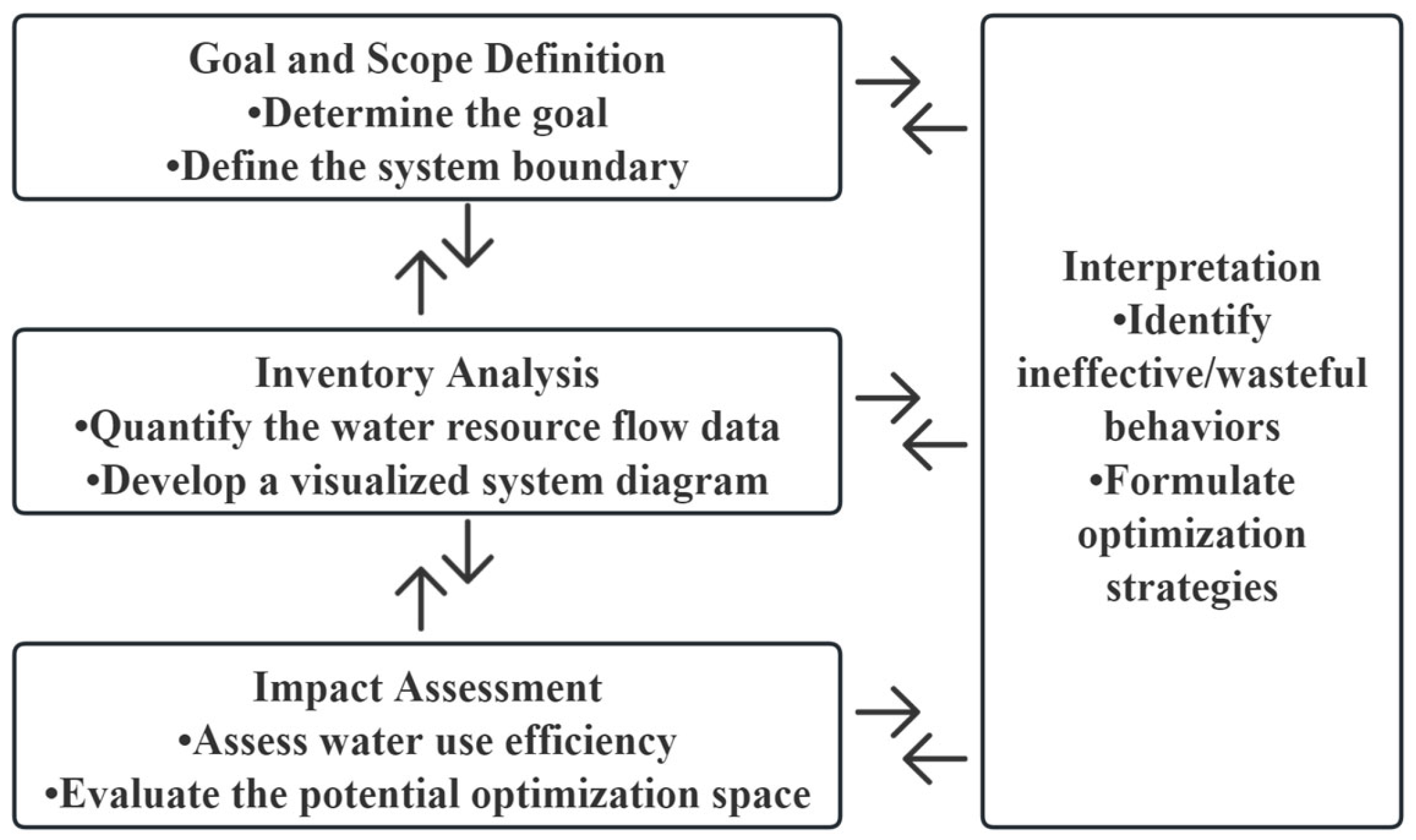

2.3. Water Life Cycle Assessment (WLCA)

3. Results

3.1. System Boundary Definition

- (a)

- Primary production system water, including raw material preparation, clinker calcination, cement grinding, etc.;

- (b)

- Auxiliary production system water, including power, water supply, laboratory, machine repair, warehouse, transportation, raw material yard, waste heat recovery, etc.;

- (c)

- Ancillary production system water, including office buildings, landscaping, employee canteens, dormitories, bathrooms, road sprinkling, etc.

3.2. Inventory Analysis

3.3. Water Efficiency Analysis

4. Discussion

4.1. System Boundary and Inventory Analysis

4.2. Analysis of Differences in Water-Use Efficiency

4.3. Suggestions and Optimization

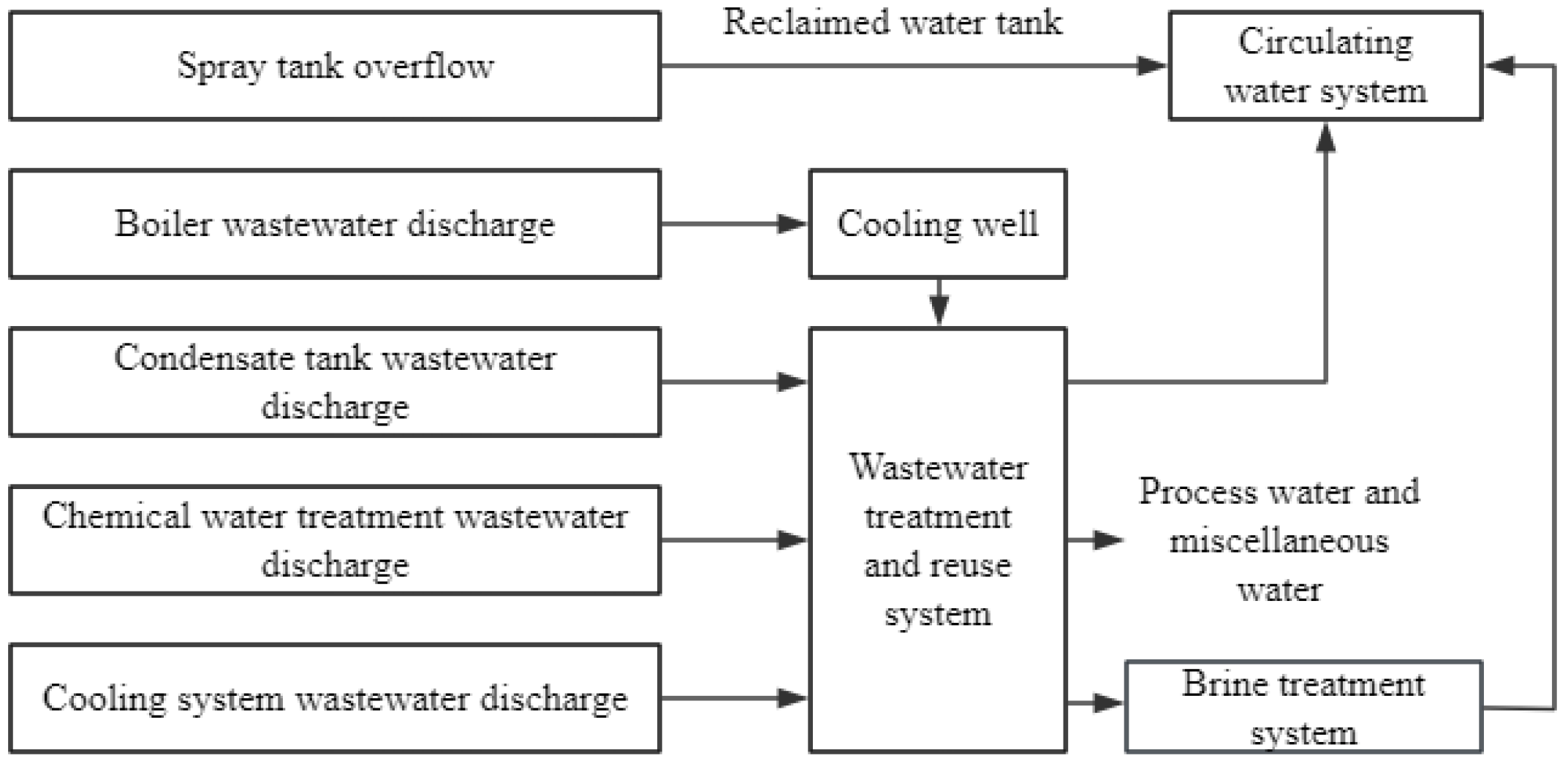

4.3.1. Wastewater Recovery and Treatment

4.3.2. Waste Heat Power Generation

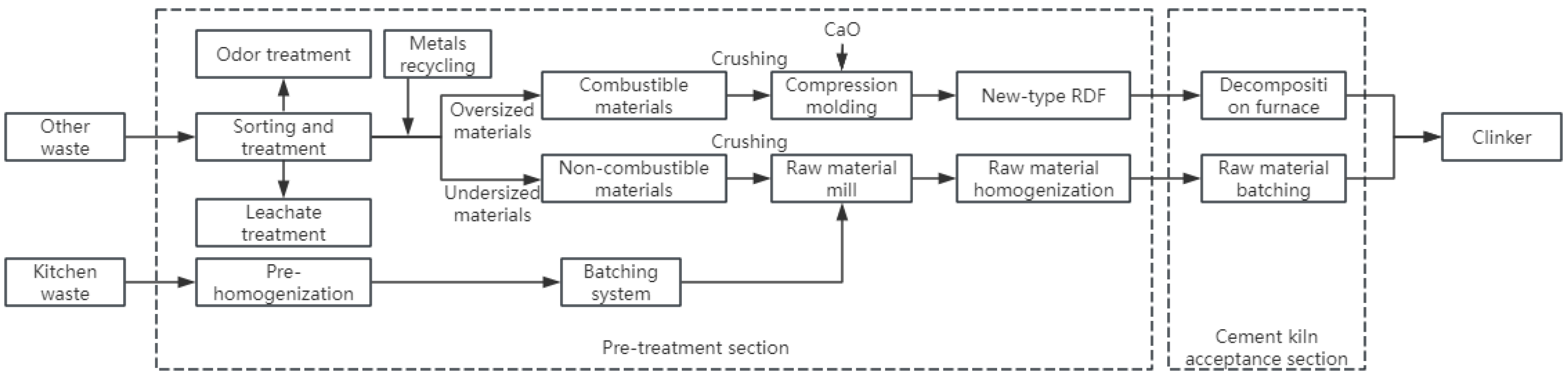

4.3.3. Co-Processing Solid Waste Treatment

5. Conclusions

- Through the analysis of water use indicators such as water intake per unit product at the overall level of the Yellow River Basin, the study finds that there are significant differences in water use efficiency among different enterprises, indicating substantial potential for optimization. Meanwhile, the results of water balance testing carried out on typical enterprises show that their water reuse and pipe network leakage control are in good condition.

- The application of wastewater recovery and treatment technologies is considered key to improving water efficiency. By classifying, collecting, and treating wastewater from different sources, not only can water resource waste be effectively reduced, but environmental pollution during the production process can also be minimized.

- Waste heat power generation technology not only improves energy utilization efficiency but also indirectly reduces the cooling water demand for external power generation.

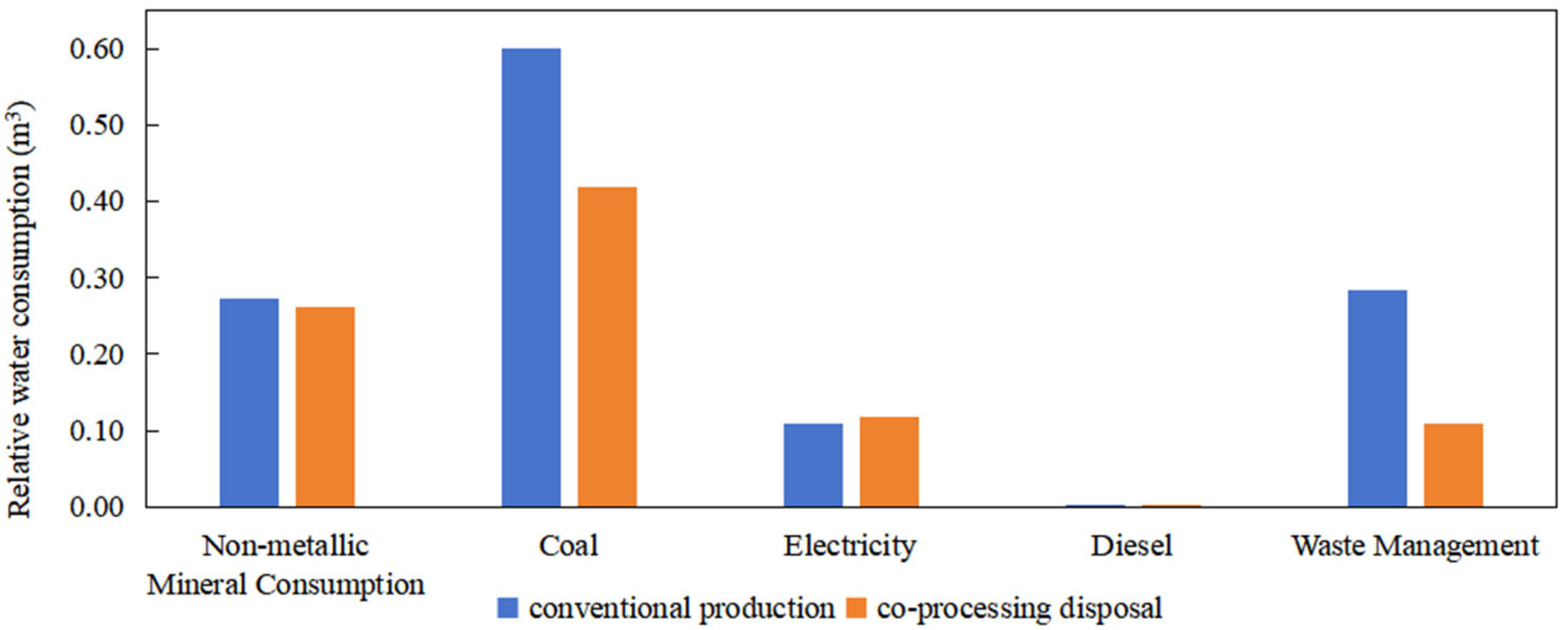

- Co-processing waste treatment technology, by replacing part of the coal and natural mineral raw materials, effectively reduces virtual water consumption in the cement production process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cosgrove, W.J.; Loucks, D.P. Water management: Current and future challenges and research directions. Water. Resour. Res. 2015, 51, 4823–4839. [Google Scholar] [CrossRef]

- Uwasu, M.; Hara, K.; Yabar, H. World cement production and environmental implications. Environ. Dev. 2014, 10, 36–47. [Google Scholar] [CrossRef]

- Ali, M.; Saidur, R.; Hossain, M. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Yan, B.; Wang, J.; He, P.; Zhou, C.; Huo, X.; Zhang, W.; Xu, G.; Ding, Q. Cement industry of China: Driving force, environment impact and sustainable development. Renew. Sustain. Energy Rev. 2017, 75, 618–628. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F. Analysis of material flow and consumption in cement production process. J. Clean. Prod. 2016, 112, 553–565. [Google Scholar] [CrossRef]

- Hosseinian, S.M.; Nezamoleslami, R. Water footprint and virtual water assessment in cement industry: A case study in Iran. J. Clean. Prod. 2018, 172, 2454–2463. [Google Scholar] [CrossRef]

- Wang, H.; Zentar, R.; Wang, D.; Dong, L.; Sun, D. Recycling single use surgical face mask waste for reinforcing cement-treated/untreated dredged marine sediments: Strength, deformation and micro-mechanisms analysis. Constr. Build. Mater. 2024, 449, 138450. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Wang, D.; Zentar, R.; Lang, L.; Sun, D.; Dong, L. Bibliometric analysis of research on recycling dredged sediment as construction material during the past three decades: Trends and focal points. J. Soils. Sediments 2025, 25, 2126–2151. [Google Scholar] [CrossRef]

- Lang, L.; Zhu, M.; Pu, S. Recycling engineering sediment waste as sustainable subgrade material using ground granulated blast-furnace slag, electrolytic manganese residue and cement. Environ. Technol. Innov. 2025, 37, 103969. [Google Scholar] [CrossRef]

- Rodrigues, L.P.; Holanda, J.N.F. Recycling of water treatment plant waste for production of soil-cement bricks. Procedia Mater. Sci. 2015, 8, 197–202. [Google Scholar] [CrossRef][Green Version]

- Djafari, D.; Semcha, A.; Zentar, R.; Mekerta, B.; Touzi, A.; Hannache, H.; Elharti, M.; Zarrouk, A. Characterization and valorization of sludge of wastewater treatment plant (WWTPs) into cement industry. J. Mater. Environ. Sci. 2017, 8, 1350–1358. [Google Scholar][Green Version]

- Drechsler, M.; Skinner, W. Commercialisation pathway for low energy wet/dry gyratory rolls crusher comminution technology. Miner. Eng. 2023, 204, 108419. [Google Scholar] [CrossRef]

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Carrara, M.; Pastore, T.; Coppola, L. Pathways towards sustainable concrete. Cem. Concr. Res. 2022, 154, 106718. [Google Scholar] [CrossRef]

- ISO 14046; Environmental Management–Water Footprint–Principles, Requirements and Guidelines. ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14046:ed−1:v1:en (accessed on 1 August 2014).

- Sui, X.; Zhang, Y.; Shao, S.; Zhang, S. Exergetic life cycle assessment of cement production process with waste heat power generation. Energy Convers. Manag. 2014, 88, 684–692. [Google Scholar] [CrossRef]

- GB/T 12452−2022; General Principles of Water Balance Test. State Administration for Market Regulation. Standardization Administration of the People’s Republic of China: China, 2022. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=AA6554B484D81862B2C8F624E92203FA (accessed on 11 July 2022).

- ISO 14040; Life Cycle Assessment (LCA)–Principles and Guidelines. ISO: Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 1 July 2006).

- GB/T 36536-2018; Test Method of Water Balance in Cement Production Enterprises. State Administration for Market Regulation, Standardization Administration of the People’s Republic of China: China, 2018. Available online: http://c.gb688.cn/bzgk/gb/showGb?type=online&hcno=7BD2C46992BEDF0B4F11E3ABC215C2FD (accessed on 13 July 2018).

- Amiri, A.; Vaseghi, M.R. Waste heat recovery power generation systems for cement production process. IEEE Trans. Ind. Appl. 2014, 51, 13–19. [Google Scholar] [CrossRef]

- Marenco-Porto, C.A.; Fierro, J.J.; Nieto-Londoño, C.; Lopera, L.; Escudero-Atehortua, A.; Giraldo, M.; Jouhara, H. Potential savings in the cement industry using waste heat recovery technologies. Energy 2023, 279, 127810. [Google Scholar] [CrossRef]

- Ma, W.; Opp, C.; Yang, D. Past, present, and future of virtual water and water footprint. Water 2020, 12, 3068. [Google Scholar] [CrossRef]

- Irungu, S.N.; Muchiri, P.; Byiringiro, J.B. The generation of power from a cement kiln waste gases: A case study of a plant in Kenya. Energy Sci. Eng. 2017, 5, 90–99. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Ryu, G.U.; Kim, H.J.; Yu, H.J.; Pyo, S. Utilization of steelmaking slag in cement clinker production: A review. J. CO2 Util. 2024, 84, 102842. [Google Scholar] [CrossRef]

- Genon, G.; Brizio, E. Perspectives and limits for cement kilns as a destination for RDF. Waste Manag. 2008, 28, 2375–2385. [Google Scholar] [CrossRef]

- Kara, M. Environmental and economic advantages associated with the use of RDF in cement kilns. Resour. Conserv. Recycl. 2012, 68, 21–28. [Google Scholar] [CrossRef]

- Hemidat, S.; Saidan, M.; Al-Zu’bi, S.; Irshidat, M.; Nassour, A.; Nelles, M. Potential utilization of RDF as an alternative fuel to be used in cement industry in Jordan. Sustainability 2019, 11, 5819. [Google Scholar] [CrossRef]

- Liang, X.; Dang, W.; Yang, G.; Zhang, Y. Environmental feasibility evaluation of cement co-production using classified domestic waste as alternative raw material and fuel: A life cycle perspective. J. Environ. Manag. 2023, 326, 116726. [Google Scholar] [CrossRef]

- Mahdi Hosseinian, S.; Nezamoleslami, R. An Empirical Investigation into Water Footprint of Concrete Industry in Iran. In Environmental Water Footprints; Muthu, S.S., Ed.; Springer: Singapore, 2019; pp. 47–75. [Google Scholar]

| Water Category | Water Used Vi + Vcy (m3/d) | Intake Water Vi (m3/d) | Recycled Water Vcy (Vcy’) (m3/d) | Water Consumption Vd + Vl + Vco (m3/d) | |

|---|---|---|---|---|---|

| Main Production Water | Mineral powder mill | 240.6 | 0.0 | 240.6 | 240.6 |

| Raw material mill | 443.2 | 0.0 | 443.2 | 443.2 | |

| Cement mill | 74.7 | 0.0 | 74.7 | 74.7 | |

| Circulating cooling water | 9708.3 | 267.3 | 9441.0 | 192.6 | |

| Auxiliary Production Water | Waste heat power generation | 48,653.4 | 941.9 | 47,711.5 | 184.5 |

| Chemical water treatment station | 228.0 | 0.0 | 228.0 | 22.8 | |

| Wastewater treatment station | 1019.4 | 0.0 | 1019.4 | 81.6 | |

| Sewage treatment station | 44.5 | 0.0 | 44.5 | 4.5 | |

| Boiler | 100.0 | 0.0 | 100.0 | 10.0 | |

| Steam turbine | 90.0 | 0.0 | 90.0 | 25.0 | |

| Laboratory | 3.8 | 3.8 | 0.0 | 0.4 | |

| Subsidiary Production Water | Canteen | 6.8 | 6.8 | 0.0 | 1.0 |

| Staff dormitory | 25.0 | 14.0 | 0.0 | 1.3 | |

| Office building | 10.6 | 10.6 | 0.0 | 1.1 | |

| Boiler room | 684.0 | 10.0 | 674.0 | 8.0 | |

| Transport fleet cleaning | 25.2 | 25.2 | 0.0 | 25.2 | |

| Watering truck | 38.1 | 38.1 | 0.0 | 38.1 | |

| Water Consumption Indicators | Water Reuse Rate | Reuse Rate of Wastewater | Integrated Leakage Rate of Water Use |

|---|---|---|---|

| Values | 97.7% | 100% | 2.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Bai, X.; Kong, L.; Bai, Y. Water Use Efficiency Assessment of Cement Production Based on Life Cycle Analysis. Sustainability 2025, 17, 8225. https://doi.org/10.3390/su17188225

Liu J, Bai X, Kong L, Bai Y. Water Use Efficiency Assessment of Cement Production Based on Life Cycle Analysis. Sustainability. 2025; 17(18):8225. https://doi.org/10.3390/su17188225

Chicago/Turabian StyleLiu, Jialin, Xue Bai, Lingsi Kong, and Yan Bai. 2025. "Water Use Efficiency Assessment of Cement Production Based on Life Cycle Analysis" Sustainability 17, no. 18: 8225. https://doi.org/10.3390/su17188225

APA StyleLiu, J., Bai, X., Kong, L., & Bai, Y. (2025). Water Use Efficiency Assessment of Cement Production Based on Life Cycle Analysis. Sustainability, 17(18), 8225. https://doi.org/10.3390/su17188225