Blockchain-Assisted Gene Expression Programming for Transparent Optimization and Strength Prediction in Fly Ash-Based Geopolymer Concrete

Abstract

1. Introduction

- (1)

- In what ways can block chain technology contribute to the reliability and traceability of simulated data and modeling results in durability studies of fly ash-based geopolymer concrete during the impact of silica modulus of alkaline activators?

- (2)

- Can GEP outperform traditional predictive models in forecasting the flexural strength of fly ash geopolymer concrete, and how does its integration with block chain support the impact of Silica modulus of alkaline activators for fly ash geopolymer concrete material?

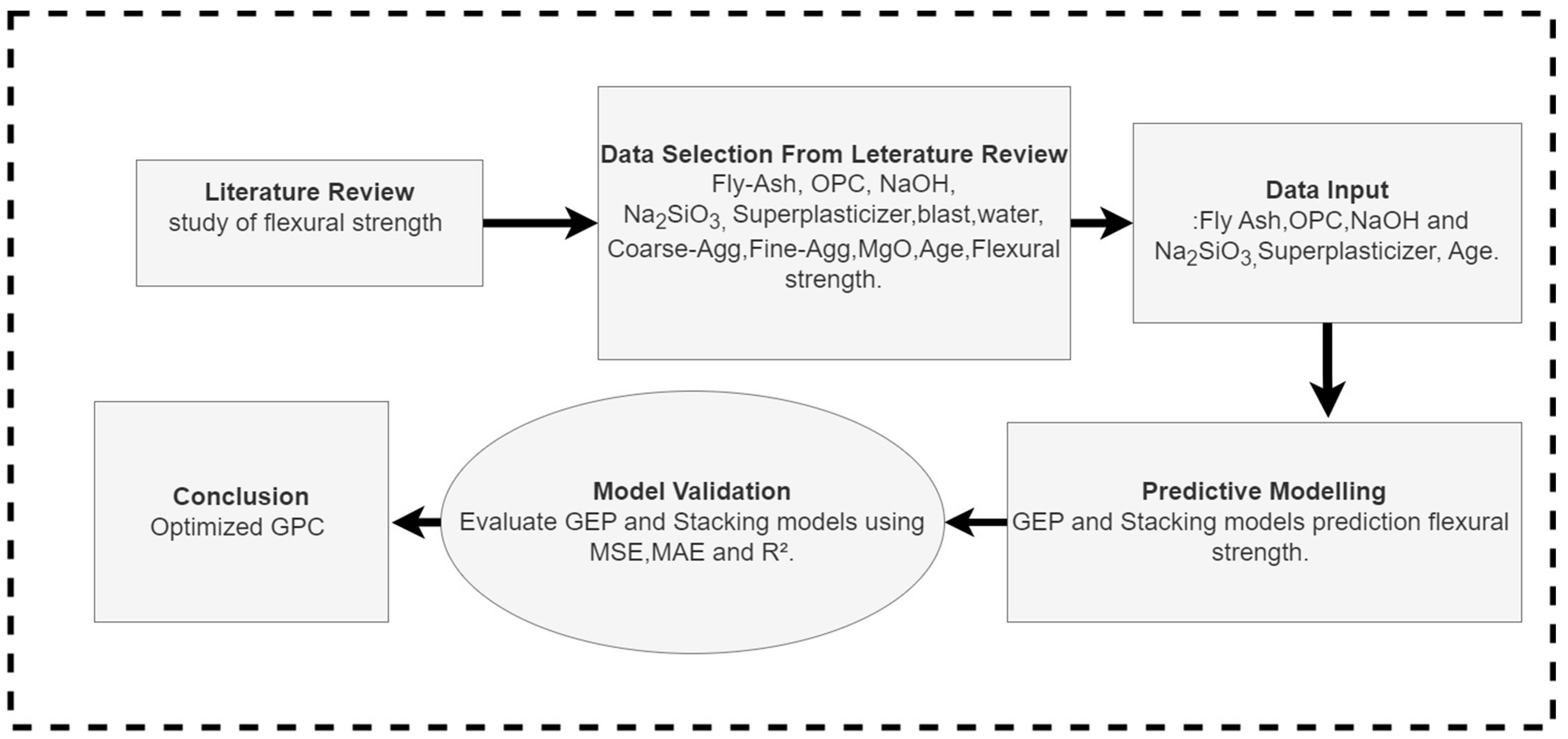

2. Materials and Methods

2.1. Fly Ash

2.2. Alkaline Liquid

2.3. Control and Geo-Polymer Concrete Preparation

2.4. Durability Anlysis

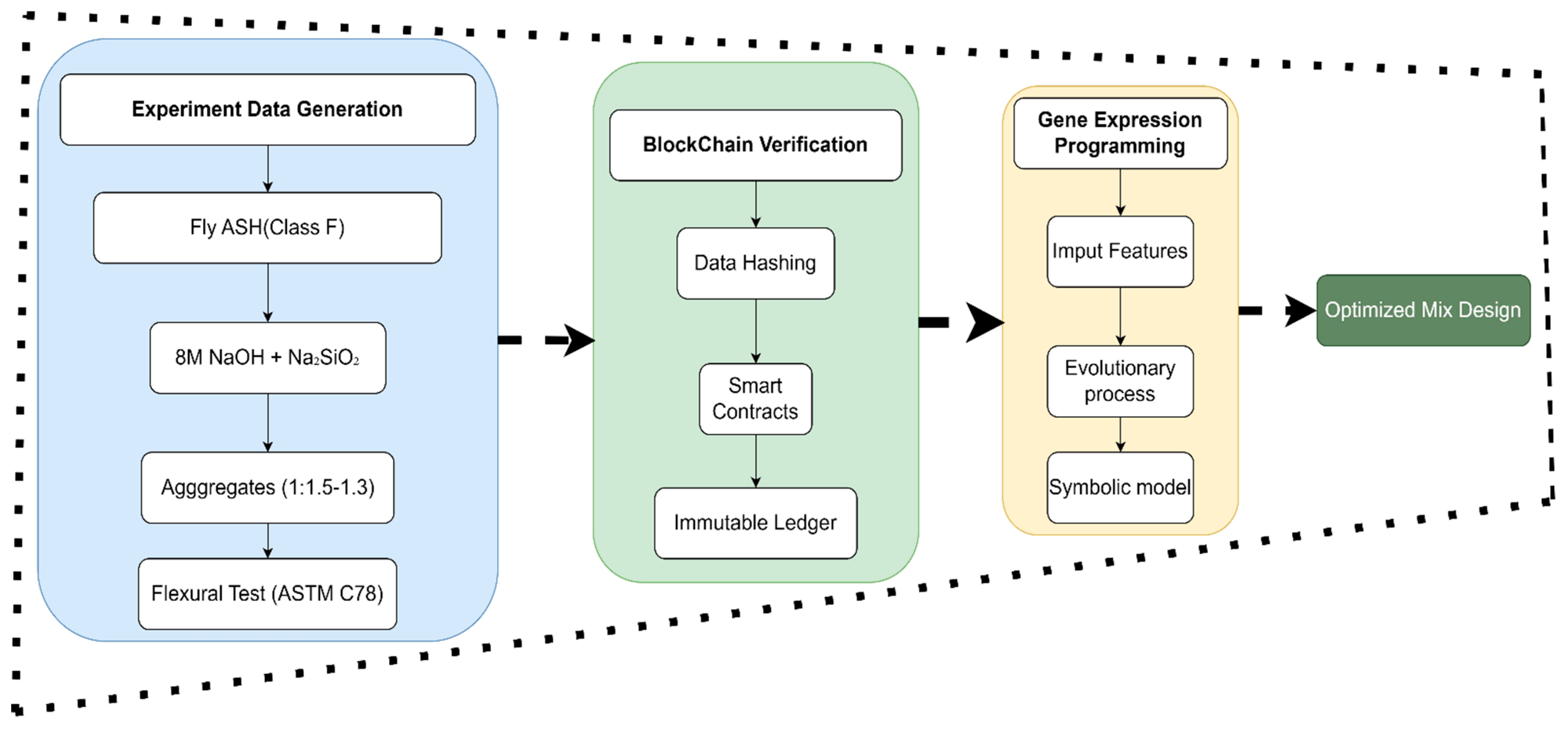

2.5. Genes Expression Programming and Block Chain

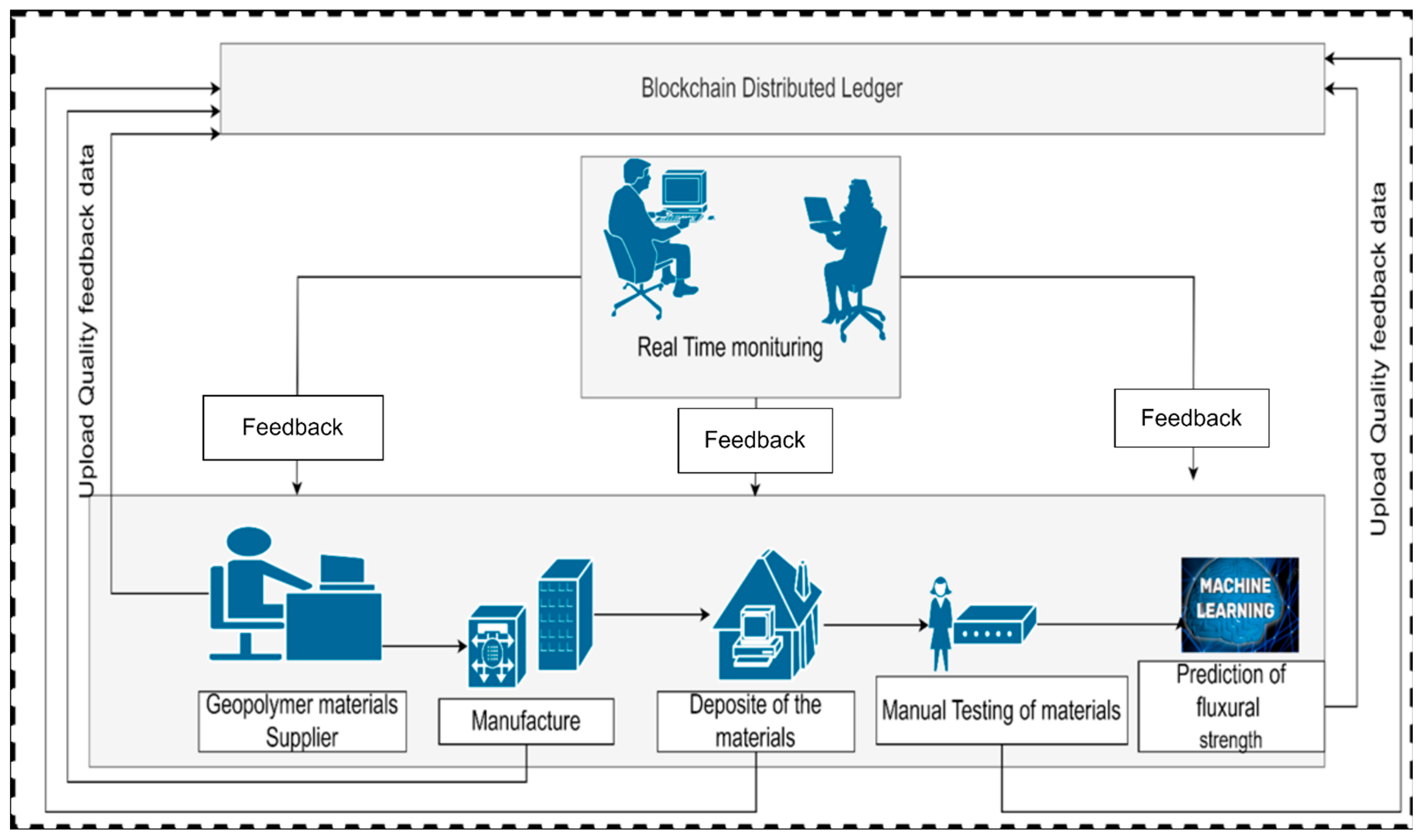

2.6. Blockchain-Based Quality Monitoring System Designed

3. Results and Discussions

3.1. Data Pre-Processing

3.2. Feature Selection

- (1)

- Cement

- (2)

- Fly Ash

- (3)

- NaOH and Na2SiO3

- (4)

- Superplasticizer

- (5)

- Age.

3.3. Proposed Method Modeling

- (1)

- Linear Regression.

- (2)

- Decision Trees Regressor.

- (3)

- Random Forest Regressor.

- (4)

- Support Vector Regressor (SVR).

| Prepare Data for Training # Prepare data for training X = data. drop (columns = [‘flexural ‘]) y = data [‘flexural ‘] Impute Missing Data for Training # Impute missing values in X using the mean imputer = SimpleImputer(strategy = ‘mean’) X = imputer.fit_transform(X) Split Data for Training and Testing # Split data into training and testing sets X_train, X_test, y_train, y_test=train_test_split (X, y, test_size = 0.2, random_state = 42) Feature Scaling # Feature Scaling (important for SVR) scaler = StandardScaler () X_train_scaled = scaler.fit_transform(X_train) X_test_scaled = scaler. transform(X_test) Model definition # Define the models models = { ‘Linear Regression’: LinearRegression (), Decision Tree Regressor’: DecisionTreeRegressor(random_state = 42), ‘Random Forest Regressor’: RandomForestRegressor(random_state = 42), ‘Support Vector Regressor’: SVR () } |

3.4. Hybrid Model

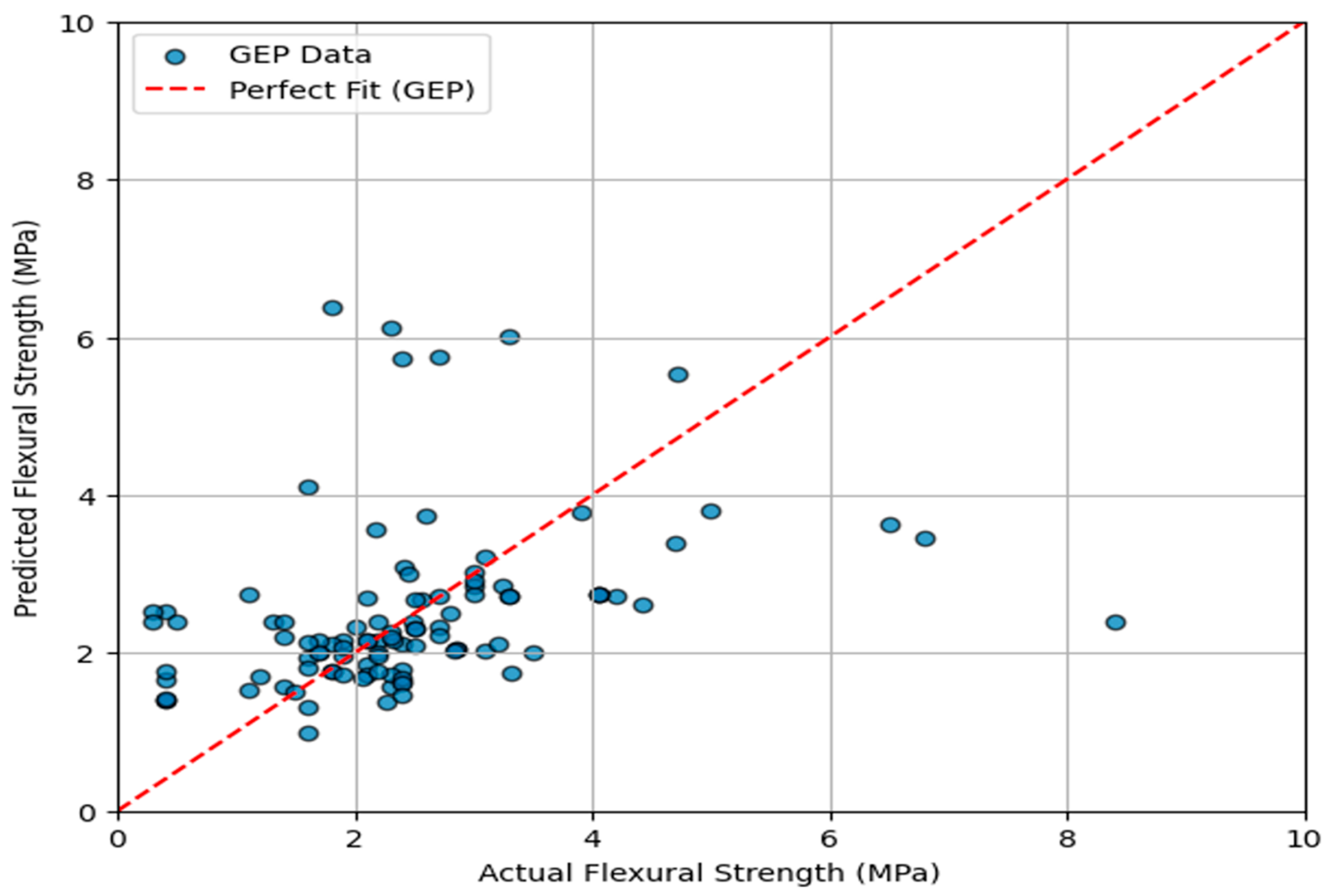

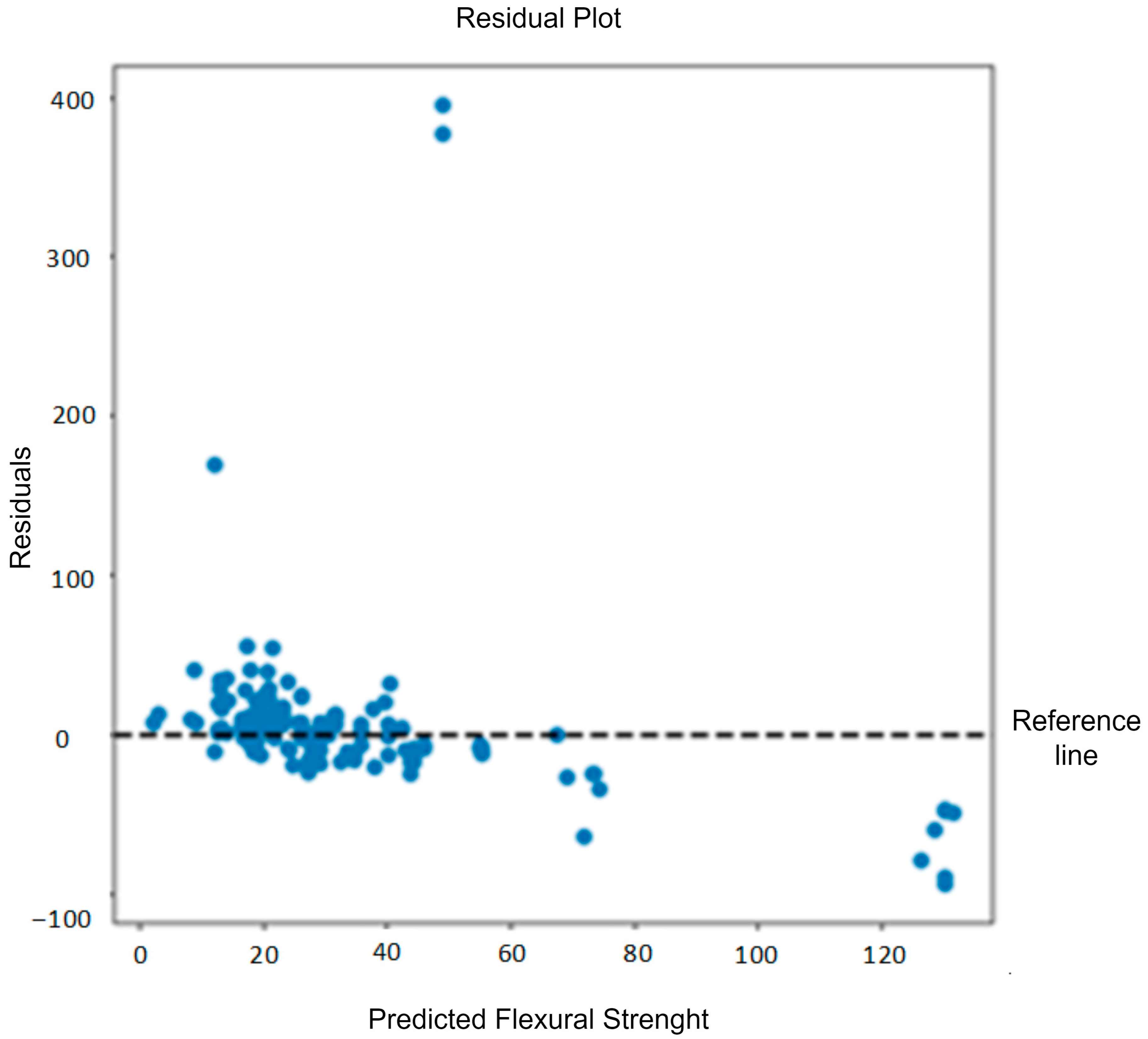

3.5. Simulated Results Analysis

3.6. Improvement in the Model

3.7. Overall GEP Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sofi, M.; Van Deventer, J.S.J.; Mendis, P.A.; Lukey, G.C. Bond performance of reinforcing bars in inorganic polymer concrete (IPC). J. Mater. Sci. 2007, 42, 3107–3116. [Google Scholar] [CrossRef]

- Chandra Kumar, B.S.; Ramesh, K. Analytical study on flexural behaviour of reinforced geopolymer concrete beams by ANSYS. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012065. [Google Scholar] [CrossRef]

- Prachasaree, W.; Limkatanyu, S.; Hawa, A.; Samakrattakit, A. Development of equivalent stress block parameters for fy-ash-based geopolymer concrete. Arab. J. Sci. Eng. 2014, 39, 8549–8558. [Google Scholar] [CrossRef]

- Rajendran, R.; Narasimharao, B.; Preethi, P.; Mohammed, S.; Naveen, D.; Prem, A.; Pratheba, S. Strength analysis of geo-polymer concrete based on GGBS/rise husk and p-sand. Mater. Today Proc. 2021, 47, 5499–5502. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Samantasinghar, S.; Singh, S. Fresh and hardened properties of fly ash-slag blended geopolymer paste and mortar. Int. J. Concr. Struct. Mater. 2019, 13, 47. [Google Scholar] [CrossRef]

- Sarker, P. A constitutive model for fly ash-based geopolymer concrete. Archit. Civ. Eng. Environ. 2008, 1, 113–120. [Google Scholar]

- Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious geopolymer concrete using recycled aggregates. Constr. Build. Mater. 2013, 42, 33–39. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Antoni, M.; Ankur, P. Flexural Behavior of Low-Calcium Fly Ash-Based Geopolymer Reinforced Concrete Beam. Int. J. Concr. Struct. Mater. 2022, 16, 53. [Google Scholar]

- Girawale, M.S. Effects of Alkaline Solution on Geopolymer Concrete. Int. J. Eng. Res. Gen. Sci. 2015, 3, 848–853. [Google Scholar]

- Vijaya Rangan, B. Mix Design and Production of Flyash Based Geopolymers Concrete. Indian Concr. J. 2008, 82, 7–15. [Google Scholar] [CrossRef]

- Lee, K.M.; Choi, S.; Choo, J.F.; Choi, Y.C.; Yoo, S.W. Flexural and Shear Behaviors of Reinforced Alkali-Activated Slag Concrete Beams. Adv. Mater. Sci. Eng. 2017, 2017, 5294290. [Google Scholar] [CrossRef]

- Brough, A.R.; Atkinson, A. Sodium silicate-based, alkali-activated slag mortars—Part I. Strength, hydration and microstructure. Cem. Concr. Res. 2002, 32, 865–879. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F. Setting of alkali-activated slag cement. Influence of activator nature. Adv. Cem. Res. 2001, 13, 115–121. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of shrinkage-reducing admixtures on the properties of alkali-activated slag mortars and pastes. Cem. Concr. Res. 2007, 37, 691–702. [Google Scholar] [CrossRef]

- Sharma, A.; Ahmad, J. Factors affecting compressive strength of geopolymer concrete—A review. Int. Res. J. Eng. Technol. 2017, 4, 2026–2031. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S. Geo-polymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Vijai, K.; Kumutha, R.; Vishnuram, B.G. Effect of types of curing on strength of geopolymer concrete. Int. J. Phy. Sci. 2010, 5, 1419–1423. [Google Scholar]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Const. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Hardjito, D. Studies of Fly Ash-Based Geopolymer Concrete. Ph.D. Dissertation, Curtin University, Perth, Australia, 2005. [Google Scholar]

- Fernandez-Jimenez, A.M.; Palomo, A.; Lopez Hombrados, C. Engineering Properties of Alkali-activated Fly Ash Concrete. ACI Mater. J. 2006, 103, 106–112. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, K.T.; Nguyen, Q.D.; Le, T.A.; Shin, J.; Lee, K. Analyzing the compressive strength of green fly ash based geopolymer concrete using experiment and machine learning approaches. Constr. Build. Mater. 2020, 247, 118581. [Google Scholar] [CrossRef]

- IS 456:2000; Plain and Reinforced Concrete Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- Ishak, S.; Lee, H.S.; Singh, J.K.; Ariffin, M.A.M.; Lim, N.H.A.S.; Yang, H.M. Performance of fly ash geopolymer concrete incorporating bamboo ash at elevated temperature. Materials 2019, 12, 3404. [Google Scholar] [CrossRef]

- Sadrossadat, E.; Ghorbani, B.; Hamooni, M.; Moradpoor Sheikhkanloo, M.H. Numerical formulation of confined compressive strength and strain of circular reinforced concrete columns using gene expression programming approach. Struct. Concr. 2018, 19, 783–794. [Google Scholar] [CrossRef]

- Saridemir, M. Genetic programming approach for prediction of compressive strength of concretes containing rice husk ash. Constr. Build. Mater. 2010, 24, 1911–1919. [Google Scholar] [CrossRef]

- Javed, M.F.; Amin, M.N.; Shah, M.I.; Khan, K.; Iftikhar, B.; Farooq, F.; Aslam, F.; Alyousef, R.; Alabduljabbar, H. Applications of gene expression programming and regression techniques for estimating compressive strength of bagasse ash based concrete. Crystals 2020, 10, 737–817. [Google Scholar] [CrossRef]

- Ferreira, C. Gene expression programming: A new adaptive algorithm for solving problems. Complex Syst. 2001, 13, 87–129. [Google Scholar]

- Emamian, S.A.; Eskandari-Naddaf, H. Effect of porosity on predicting compressive and flexural strength of cement mortar containing micro and nano-silica by ANN and GEP. Constr. Build. Mater. 2019, 218, 8–27. [Google Scholar] [CrossRef]

- Noori, R.; Hoshyaripour, G.; Ashrafi, K.; Araabi, B.N. Uncertainty analysis of developed ANN and ANFIS models in prediction of carbon monoxide daily concentration. Atmos. Environ. 2010, 44, 476–482. [Google Scholar] [CrossRef]

- Jaafari, A.; Panahi, M.; Pham, B.T.; Shahabi, H.; Bui, D.T.; Rezaie, F.; Lee, S. Meta optimization of an adaptive neuro-fuzzy inference system with grey wolf optimizer and biogeography-based optimization algorithms for spatial prediction of landslide susceptibility. Catena 2019, 175, 430–445. [Google Scholar] [CrossRef]

- Nwetlawung, Z.E.; Lin, Y.-H. Development of an Optimization Algorithm for Designing Low-Carbon Concrete Materials Standardization with Blockchain Technology and Ensemble Machine Learning Methods. Buildings 2025, 15, 2809. [Google Scholar] [CrossRef]

- Farooq, F.; Nasir Amin, M.; Khan, K.; Rehan Sadiq, M.; Javed, M.F.; Aslam, F.; Alyousef, R. A comparative study of random forest and genetic engineering programming for the prediction of compressive strength of high strength concrete (HSC). Appl. Sci. 2020, 10, 7330. [Google Scholar] [CrossRef]

- Miers, I.; Garman, C.; Green, M.; Rubin, A.D. Zerocoin: Anonymous distributed e-cash from bitcoin. In Proceedings of the 2013 IEEE Symposium on Security and Privacy, Berkeley, CA, USA, 19–22 May 2013; pp. 397–411. [Google Scholar]

- Sasson, E.B.; Chiesa, A.; Garman, C.; Green, M.; Miers, I.; Tromer, E.; Virza, M. Zerocash: Decentralized anonymous payments from bitcoin. In Proceedings of the 2014 IEEE Symposium on Security and Privacy, Berkeley, CA, USA, 18–21 May 2014; pp. 459–474. [Google Scholar]

- Yuan, Y.; Wang, F.Y. Blockchain: The state of the art and future trends. Acta Autom. Sin. 2016, 42, 481–494. [Google Scholar]

- Androulaki, E.; Barger, A.; Bortnikov, V.; Cachin, C.; Christidis, K.; De Caro, A.; Yellick, J. Hyperledger fabric: A distributed operating system for permissioned blockchains. In Proceedings of the Thirteenth EuroSys Conference, Porto, Portugal, 23 April 2018; pp. 1–15. [Google Scholar]

- Cai, L.; Sun, Y.; Zheng, Z.; Xiao, J.; Qiu, W. Blockchain in China. Commun. ACM 2021, 64, 88–93. [Google Scholar] [CrossRef]

- Plevris, V.; Lagaros, N.D.; Zeytinci, A. Blockchain in civil engineering, architecture and construction industry: State of the art, evolution, challenges and opportunities. Front. Built Environ. 2022, 8, 840303. [Google Scholar] [CrossRef]

- Skane, R.; Jones, F.; van Riessen, A.; Jamieson, E.; Sun, X.; Rickard, W.D.A. Optimisation of Activator Solutions for Geopolymer Synthesis: Thermochemical Stability, Sequencing, and Standardisation. arXiv 2025, arXiv:2506.12941. [Google Scholar] [CrossRef]

- Mishra, I.; Sahoo, A.; Anand, M.V. Digitalization of land records using Blockchain technology. In Proceedings of the 2021 International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 4–5 March 2021; pp. 769–772. [Google Scholar] [CrossRef]

- Mssassi, S.; El Kalam, A.A. Leveraging Blockchain for Enhanced Traceability and Transparency in Sustainable Development. In Proceedings of the International Conference on Advanced Intelligent Systems for Sustainable Development, Marrakech, Morocco, 15 October 2023; Springer Nature: Cham, Switzerland, 2023; pp. 162–177. [Google Scholar]

- Venkateswara Rao, J.; Nagalapalli, S.; Reddy, K.S.; Reddy, K.S.; Kumar, P.S. Compressive Strength Prediction of Fly Ash Geopolymer Concrete Using Support Vector and Random Forest Regression. J. Phys. Conf. Ser. 2024, 2779, 012048. [Google Scholar] [CrossRef]

- Atlam, H.F.; Ekuri, N.; Azad, M.A.; Lallie, H.S. Blockchain Forensics: A Systematic Literature Review of Techniques, Applications, Challenges, and Future Directions. Electronics 2024, 13, 3568. [Google Scholar] [CrossRef]

- Ahmad, A.; Chaiyasarn, K.; Farooq, F.; Ahmad, W.; Suparp, S.; Aslam, F. Compressive strength prediction via gene expression programming (GEP) and artificial neural network (ANN) for concrete containing RCA. Buildings 2021, 11, 324. [Google Scholar] [CrossRef]

- Pham, V.-N.; Oh, E.; Ong, D.E.L. Gene-Expression Programming-Based Model for Estimating the Compressive Strength of Cement-Fly Ash Stabilized Soil and Parametric Study. Infrastructures 2021, 6, 181. [Google Scholar] [CrossRef]

- Ahmed, M.; Rehman, S.; Khan, M.I. A review on data integrity and reproducibility issues in computational material science. Constr. Build. Mater. 2021, 294, 123600. [Google Scholar]

- Lee, J.H.; Kim, Y.S. Challenges in modeling the mechanical behavior of fly ash-based geopolymer concrete using traditional empirical approaches. Mater. Today Proc. 2020, 45, 2125–2131. [Google Scholar]

- GO Holdings Pte Ltd. Sodium Silicate Composition—Grade GOI-24. Go Holdings Technical Sheet; GO Holdings Pte Ltd.: Singapore, 2019. [Google Scholar]

- IS 8112:1989; Specification for 43 Grade Ordinary Portland Cement. Bureau of Indian Standards: New Delhi, India, 1989.

- Ho, V.D.; Gholampour, A.; Losic, D.; Ozbakkaloglu, T. Enhancing the performance and environmental impact of alkali-activated binder-based composites containing graphene oxide and industrial by-products. Constr. Build. Mater. 2021, 284, 122811. [Google Scholar] [CrossRef]

- Merugu, S.P.R.; Manjunath, Y.M. Granite powder as partial replacement of cement in M30 grade concrete mix using IS 10262: 2019. J. Struct. Fire Eng. 2024, 15, 192–212. [Google Scholar] [CrossRef]

- SNI 2847:2013; Requirements for Structural Concrete. Badan Standardizes Nasional: Jakarta, Indonesia, 2013.

- Su, J. Flexural behavior of alkali-activated ultra-high-performance geopolymer concrete (UHPGC) beams. Buildings 2024, 14, 701. [Google Scholar] [CrossRef]

- Alhijawi, B.; Awajan, A. Genetic algorithms: Theory, genetic operators, solutions, and applications. Evol. Intell. 2024, 17, 1245–1256. [Google Scholar] [CrossRef]

- Soundararajan, G.; Tyagi, A.K. Blockchain technology: An introduction. In Blockchain Technology in the Automotive Industry; CRC: Boca Raton, FL, USA, 2025; pp. 3–36. [Google Scholar]

- Analyst, D.; Researcher, E. Blockchain-enabled quality monitoring for AI-modeled geopolymer concrete: Enhancing traceability, prediction accuracy, and material lifecycle management. Autom. Constr. 2025, 157, 401–417. [Google Scholar]

- Zhang, T.; Li, A. Challenges in quality control for geopolymer concrete: A review. Constr. Build. Mater. 2020, 247, 118543. [Google Scholar]

- Kumar, S.; Pooniwala, V. Gaps in manual quality inspection: Need for blockchain-based solutions. J. Civ. Eng. Technol. 2021, 11, 103–115. [Google Scholar]

- Taylor, K.; Omar, M.Y. Blockchain in construction supply chains: A review of benefits and barriers. J. Constr. Innov. 2022, 20, 675–692. [Google Scholar]

- Singh, R.; Lin, H. Decentralized concrete test logging using blockchain. Autom. Constr. 2022, 140, 104226. [Google Scholar]

- Alameen, N.; Chen, J. AI-Blockchain integration for predictive quality assurance. Adv. Smart Mater. Struct. 2023, 8, 33–48. [Google Scholar]

- Lee, H.; Rao, G. Secure traceability in aerospace and pharma via blockchain feedback networks. Ind. Internet J. 2022, 5, 122–137. [Google Scholar]

| Material/Component | Description/Role | Composition/Properties | Notes/Significance |

|---|---|---|---|

| Fly Ash (Low-Calcium, ASTM Class F) | Principal binder in GPC | SiO2 + Al2O3 ≈ 80% of total mass SiO2~2 × Al2O3 CaO = 1.26% Fe2O3 = 10–20% Carbon < 2% | Promotes geopolymerization reactions, forms aluminosilicate gel matrix, low CaO prevents flash setting and improves workability, enhances long-term strength and durability. |

| Sodium Hydroxide (NaOH) | Part of alkaline activator, catalyst for geopolymerization | Purity: 97–98% Concentration: 8M (320 g NaOH in 1000 mL H2O) Molecular weight: 40 g/mol | Selected to optimize dissolution of silicate/aluminate phases while maintaining workability. |

| Sodium Silicate (Na2SiO3) | Part of alkaline activator, provides soluble silica | Na2O ≈ 14.7 wt.% SiO2 ≈ 29.4 wt.% Silica modulus (SiO2/Na2O) ≈ 2.0 | Commercial solution; combined with NaOH at mass ratio 2.5:1 to enhance gel formation and early strength. |

| Alkaline Activator Solution | Catalyst for geopolymerization | Prepared by mixing NaOH and Na2SiO3; cooled for 24 h before use | Promotes initial polymerization and ensures consistency with previous studies. |

| Metrics | Value (GEP) | Value (Stacking Model) | ||

|---|---|---|---|---|

| Train | Test | Train | Test | |

| MSE | 9.15 | 7.24 | 7.32 | 7.11 |

| MAE | 2.83 | 2.81 | 2.43 | 2.22 |

| R-squared | 0.93 | 0.89 | 0.98 | 0.80 |

| Generation (Gen) | Population Average Length | Population Average Fitness | Best Individual Length | Best Individual Fitness | OOB Fitness | Time Left |

|---|---|---|---|---|---|---|

| 0 | 27.76 | 1.37 × 1022 | 3 | 21.5804 | 19.168 | 8.75 |

| 1 | 10.18 | 7.80 × 109 | 7 | 20.9642 | 23.3157 | 6.22 |

| 2 | 7.44 | 1.96 × 106 | 11 | 18.527 | 13.0773 | 5.64 |

| 3 | 8.78 | 14,079 | 11 | 16.6496 | 29.6963 | 4.60 |

| 4 | 7.26 | 3354.46 | 11 | 16.7425 | 28.8745 | 4.32 |

| 5 | 12.04 | 35,517.4 | 15 | 16.0279 | 32.5952 | 5.14 |

| 6 | 15.43 | 1.29 × 108 | 15 | 15.5377 | 36.8854 | 4.30 |

| 7 | 18.39 | 16,923.3 | 29 | 15.7626 | 35.0544 | 1.66 |

| 8 | 19.92 | 15,645.6 | 23 | 15.8848 | 33.8132 | 0.87 |

| 9 | 20.01 | 9807.46 | 21 | 15.9525 | 36.182 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nwetlawung, Z.E.; Lin, Y.-H. Blockchain-Assisted Gene Expression Programming for Transparent Optimization and Strength Prediction in Fly Ash-Based Geopolymer Concrete. Sustainability 2025, 17, 8212. https://doi.org/10.3390/su17188212

Nwetlawung ZE, Lin Y-H. Blockchain-Assisted Gene Expression Programming for Transparent Optimization and Strength Prediction in Fly Ash-Based Geopolymer Concrete. Sustainability. 2025; 17(18):8212. https://doi.org/10.3390/su17188212

Chicago/Turabian StyleNwetlawung, Zilefac Ebenezer, and Yi-Hsin Lin. 2025. "Blockchain-Assisted Gene Expression Programming for Transparent Optimization and Strength Prediction in Fly Ash-Based Geopolymer Concrete" Sustainability 17, no. 18: 8212. https://doi.org/10.3390/su17188212

APA StyleNwetlawung, Z. E., & Lin, Y.-H. (2025). Blockchain-Assisted Gene Expression Programming for Transparent Optimization and Strength Prediction in Fly Ash-Based Geopolymer Concrete. Sustainability, 17(18), 8212. https://doi.org/10.3390/su17188212