Improvement of the Potato Protein Drying Process as an Example of Implementing Sustainable Development in Industry

Abstract

1. Introduction

2. Materials and Methods

2.1. Potato Protein

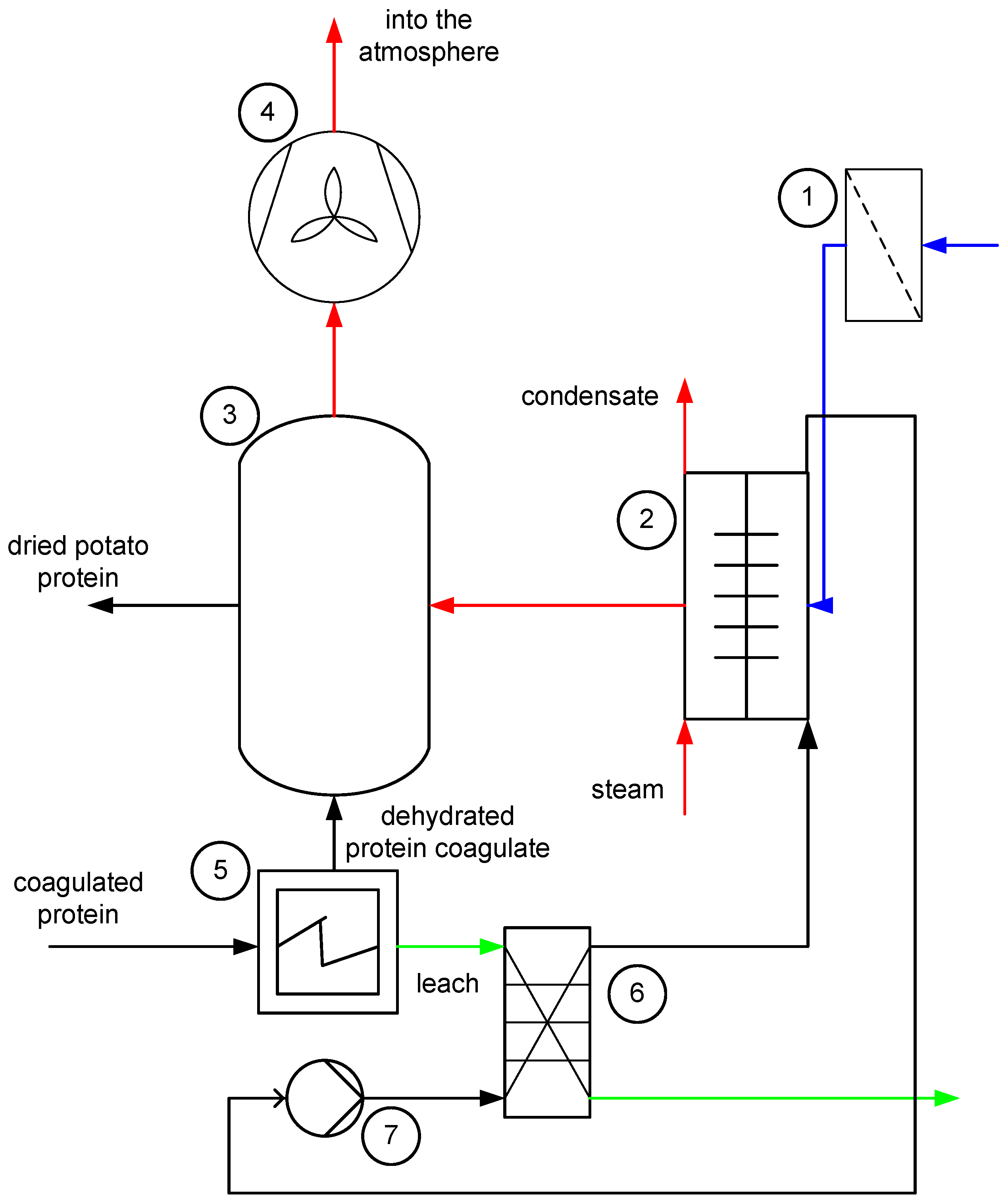

2.2. Dryer Before Modification

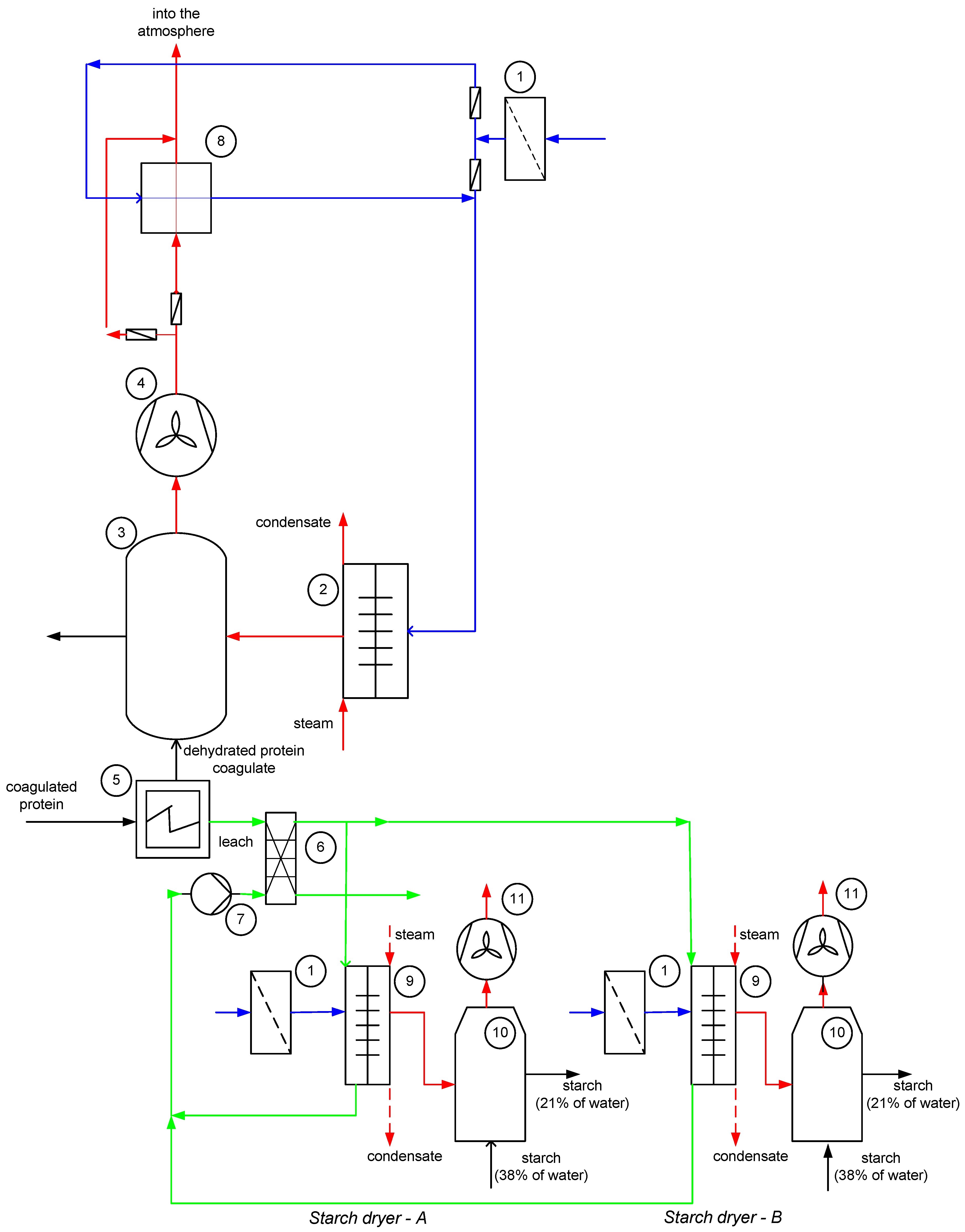

2.3. Description of the Dryer Modernization Concept

3. Results and Discussion

- (a)

- Improved energy efficiency of the protein dryer:

- -

- Before modernization: 2800 kWh/850 kg/h = 3.29 kWh/1 kg of protein.

- -

- After modernization and recovery of ~806 kWh of heat, the energy efficiency is 2000 kWh/850 kg/h = 2.35 kWh/1 kg of protein, reducing the energy input by ~28%.

- (b)

- Improved energy efficiency of the starch dryer:

- -

- Before modernization: heat demand: 5950 kWh/15,800 kg of starch (2 × 190 tons/day/24 h = 15,800 kg) = 0.38 kWh/1 kg of starch with 20% moisture.

- -

- After modernization: 5950 kWh−2000 kWh = 3950 kWh/15,800 kg = 0.25 kWh/1 kg of starch, with energy consumption reduced by ~34%.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Camacho-Otero, J.; Boks, C.; Pettersen, I.N. Consumption in the Circular Economy: A Literature Review. Sustainability 2018, 10, 2758. [Google Scholar] [CrossRef]

- Basta, E.; Szewczyk, P. The use of methane from landfill gas to generate energy and its management at the plant as a way to reduce climate change. Rocz. Ochr. Sr. 2024, 26, 236–250. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Gronba-Chyła, A.; Ciuła, J.; Wiewiórska, I.; Kwaśnicki, P.; Mala, M.; Chyła, K. Artificial Intelligence Methods for Analysis and Optimization of CHP Cogeneration Units Based on Landfill Biogas as a Progress in Improving Energy Efficiency and Limiting Climate Change. Energies 2023, 16, 5732. [Google Scholar] [CrossRef]

- Graz, K.; Gronba-Chyla, A.; Chyla, K. Microplastics found in compost as a barrier to the circular economy (CE). Przemysł Chem. 2023, 102, 381–383. [Google Scholar] [CrossRef]

- Ciuła, J. Modeling the migration of anthropogenic pollution from active municipal landfill in groundwaters. Archit. Civ. Eng. Environ. 2012, 14, 81–90. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Lobur, M.; Jaworski, N.; Ciuła, J.; Mzyk, T. Optimization of Biological Wastewater Treatment Process by Hierarchical Adaptive Control. In Proceedings of the 2019 IEEE XVth International Conference on the Perspective Technologies and Methods in MEMS Design, Polyana-Svalyava, Ukraine, 22–26 May 2019; pp. 119–122. [Google Scholar] [CrossRef]

- Navajas, A.; Uriarte, L.; Gandía, L.M. Application of Eco-Design and Life Cycle Assessment Standards for Environmental Impact Reduction of an Industrial Product. Sustainability 2017, 9, 1724. [Google Scholar] [CrossRef]

- Satyro, W.C.; Contador, J.C.; Monken, S.F.d.P.; Lima, A.F.d.; Soares Junior, G.G.; Gomes, J.A.; Neves, J.V.S.; do Nascimento, J.R.; de Araújo, J.L.; Correa, E.d.S. Industry 4.0 Implementation Projects: The Cleaner Production Strategy—A Literature Review. Sustainability 2023, 15, 2161. [Google Scholar] [CrossRef]

- Bubenik, P.; Capek, J.; Rakyta, M.; Binasova, V.; Staffenova, K. Impact of Strategy Change on Business Process Management. Sustainability 2022, 14, 11112. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular economy rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Osorio, L.L.D.R.; Flórez-López, E.; Grande-Tovar, C.D. The Potential of Selected Agri-Food Loss and Waste to Contribute to a Circular Economy: Applications in the Food, Cosmetic and Pharmaceutical Industries. Molecules 2021, 26, 515. [Google Scholar] [CrossRef] [PubMed]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Darlington, R.; Staikos, T.; Rahimifard, S. Analytical methods for waste minimisation in the convenience food industry. Waste Manag. 2009, 29, 1274–1281. [Google Scholar] [CrossRef]

- Gonçalves, M.L.M.B.B.; Maximo, G.J. Circular Economy in the Food Chain: Production, Processing and Waste Management. Circ. Econ. Sust. 2023, 3, 1405–1423. [Google Scholar] [CrossRef]

- Skawińska, E.; Zalewski, R.I. Combining the Water–Energy–Food and Food Waste–Food Loss–Food Security Nexuses to Reduce Resource Waste. Energies 2022, 15, 5866. [Google Scholar] [CrossRef]

- Menon, V.; Stojceska, S.A.; Tassou, A. systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Dehnad, D.; Jafari, S.M.; Afrasiabi, M. Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci. Technol. 2016, 57, 116–131. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced computational modelling for drying processes—A review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Jafari, S.M.; Azizi, D.; Mirzaei, H.; Dehnad, D. Comparing quality characteristics of oven-dried and Refractance Window-dried kiwifruits. J. Food Process. Preserv. 2016, 40, 362–372. [Google Scholar] [CrossRef]

- Jafari, S.M.; Ganje, M.; Dehnad, D.; Ghanbari, V. Mathematical, fuzzy logic and artificial neural network modeling techniques to predict drying kinetics of onion. J. Food Process. Preserv. 2016, 40, 329–339. [Google Scholar] [CrossRef]

- Azizi, D.; Jafari, S.M.; Mirzaei, H.; Dehnad, D. The influence of refractance window drying on qualitative properties of kiwifruit slices. Int. J. Food Eng. 2017, 13, 20160201. [Google Scholar] [CrossRef]

- Olejnik, T.P.; Mysakowski, T.; Tomtas, P.; Mostowski, R. Optimization of the beef drying process in a heat pump chamber dryer. Energies 2021, 14, 4927. [Google Scholar] [CrossRef]

- Bahmani, A.; Jafari, S.M.; Shahidi, S.A.; Dehnad, D. Mass transfer kinetics of eggplant during osmotic dehydration by neural networks. J. Food Process. Preserv. 2016, 40, 815–827. [Google Scholar] [CrossRef]

- Jafari, S.M.; Ghalenoei, M.G.; Dehnad, D. Influence of spray drying on water solubility index, apparent density, and anthocyanin content of pomegranate juice powder. Powder Technol. 2017, 311, 59–65. [Google Scholar] [CrossRef]

- Adeyeye, S.A.O.; Ashaolu, T.J.; Babu, A.S. Food drying: A review. Agric. Rev. 2022, R-2537, 1–8. [Google Scholar] [CrossRef]

- Bardy, E.; Hamdi, M.; Havet, M.; Rouaud, O. Transient energetic efficiency and moisture loss analysis of forced convection drying with and without electrohydrodynamic enhancement. Energy 2015, 89, 519–527. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.W. Computational fluid dynamics (CFD)—An effective and efficient design and analysis tool for the food industry: A review. Trends Food Sci. Technol. 2006, 17, 600–620. [Google Scholar] [CrossRef]

- Strumiłło, C. Perspectives on developments in drying. Dry. Technol. 2006, 24, 1059–1068. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous vide cooking: A review. Int. J. Gastron. Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef]

- Polak, N.; Kalisz, S.; Kruszewski, B. High-Temperature Short-Time and Ultra-HighTemperature Processing of Juices, Nectars and Beverages: Influences on Enzyme, Microbial Inactivation and Retention of Bioactive Compounds. Appl. Sci. 2024, 14, 8978. [Google Scholar] [CrossRef]

- Sergius-Ronot, M.; Michael, A.; Pitino, M.A.; Shyam Suwal, S.; Sara Shama, S.; Sharon Unger, S.; O’Connor, D.L.; Pouliot, Y.; Doyen, A. Impact of holder, high temperature short time and high hydrostatic pressure pasteurization methods on protein structure and aggregation in a human milk protein concentrate. Food Chem. 2022, 374, 131808. [Google Scholar] [CrossRef]

- Jasim, A.; Ramaswamy, H.S. Microwave pasteurization and sterilization of foods. In Handbook of Food Preservation, 3rd ed.; Rahman, M.S., Ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 713–732. [Google Scholar]

- Kręcisz, M.; Kolniak-Ostek, J.; Stępień, B.; Łyczko, J.; Pasławska, M.; Musiałowska, J. Influence of Drying Methods and Vacuum Impregnation on Selected Quality Factors of Dried Sweet Potato. Agriculture 2021, 11, 858. [Google Scholar] [CrossRef]

- Tian, X.; Tian, Y.; Meng, S.; Zhao, J.; Shao, L.; Li, Y.; Wang, W. A rethinking of nitrate, nitrite, and nitric oxide for food preservation and human health. Food Sci. Hum. Wellness 2025, 25, 9250434. [Google Scholar] [CrossRef]

- Chizoba Ekezie, F.-G.; Sun, D.-W.; Cheng, J.-H. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Technol. 2017, 69, 46–58. [Google Scholar] [CrossRef]

- Almena, A.; Goode, K.R.; Bakalis, S.; Fryer, P.J.; Lopez-Quiroga, E. Optimising food dehydration processes: Energy-efficient drum-dryer operation. Energy Procedia 2019, 161, 174–181. [Google Scholar] [CrossRef]

- Shahraki, M.; Jafari, S.M.; Mashkour, M.; Esmaeilzadeh, E. Optimization of closed-cycle fluidized bed drying of sesame seeds using response surface methodology and genetic algorithms. Int. J. Food Eng. 2014, 10, 167–181. [Google Scholar] [CrossRef]

- Jafari, S.M.; Ghanbari, V.; Ganje, M.; Dehnad, D. Modeling the drying kinetics of green bell pepper in a heat pump assisted fluidized bed dryer. J. Food Qual. 2016, 39, 98–108. [Google Scholar] [CrossRef]

- Malekjani, N.; Jafari, S.M. Simulation of food drying processes by Computational Fluid Dynamics (CFD); recent advances and approaches. Trends Food Sci. Technol. 2018, 78, 206–223. [Google Scholar] [CrossRef]

- Jamaleddine, T.J.; Ray, M.B. Application of computational fluid dynamics for simulation of drying processes: A review. Dry. Technol. 2010, 28, 120–154. [Google Scholar] [CrossRef]

- Martynenko, A.; Vieira, G.N.A. Sustainability of drying technologies: System analysis. Sustain. Food Technol. 2023, 1, 629–640. [Google Scholar] [CrossRef]

- Hnin KayKhaing, H.K.; Zhang Min, Z.M.; Mujumdar, A.S.; Zhu YueLin, Z.Y. Emerging food drying technologies with energy-saving characteristics: A review. Dry. Technol. 2019, 37, 1465–1480. [Google Scholar] [CrossRef]

- Caccavale, P.; de Bonis, M.V.; Ruocco, G. Conjugate heat and mass transfer in drying: A modeling Review. J. Food Eng. 2016, 176, 28–35. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Pathak, S.K.; Chopra, K.; Saxena, A.; Kalidasan, B.; Dwivedi, A.; Goel, V.; Sharma, R.K.; Agrawal, R.; Kandil, A.A.; et al. Sustainable growth of solar drying technologies: Advancing the use of thermal energy storage for domestic and industrial applications. J. Energy Storage 2024, 99, 113320. [Google Scholar] [CrossRef]

- Rashid, M.T.; Liu, K.; Jatoi, M.A.; Safdar, B.; Lv, D.; Li, Q. Energy efficient drying technologies for sweet potatoes: Operating and drying mechanism, quality-related attributes. Front. Nutr. 2022, 9, 1040314. [Google Scholar] [CrossRef]

- Potato Production and Trade—Market Analysis. Available online: https://foodcom.pl/en/potato-production-and-trade-market-analysis-2/ (accessed on 20 April 2021).

- Zhang, D.; Mu, T.; Sun, H. Calorimetric, rheological, and structural properties of potato protein and potato starch composites and gels. Starch/Stärke 2017, 69, 1600329. [Google Scholar] [CrossRef]

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B.K. Novel drying techniques for the food industry. Food Eng. Rev. 2014, 6, 43–55. [Google Scholar] [CrossRef]

- Mysakowski, T.; Olejnik, T.P. The impact of the selected methods of drying beef on the quality of the finished product. Przemysł Spożywczy 2019, 73, 22–26. [Google Scholar] [CrossRef]

- Perz, K. Possibilities of using waste heat in the food industry. Inż. Ap. Chem. 2009, 48, 110–111. Available online: https://bibliotekanauki.pl/articles/2070391 (accessed on 21 December 2024). (In Polish).

- Bhatia, L.; Jha, H.; Sarkar, T.; Sarangi, P.K. Food Waste Utilization for Reducing Carbon Footprints towards Sustainable and Cleaner Environment: A Review. Int. J. Environ. Res. Public Health 2023, 20, 2318. [Google Scholar] [CrossRef] [PubMed]

| Process Parameters and Their Values | |

|---|---|

| Volumetric output of the dryer fan (4), Qf | 55,000 m3/h |

| Outlet air temperature from the dryer, Tw | 90–95 °C |

| Temperature of circulating water after leachate cooling in the plate heat exchanger (6), To | 85 °C |

| Volumetric output of water circulation pump (7), cooling the leachate after protein decantation, Qo | 75, m3/h |

| Dry potato protein mass yield, Mb | 0.85 × 106, kg/h |

| Air Supply | Air Exhaust | ||

|---|---|---|---|

| Inlet | Standard flow, m3/h | 42,000 | 55,000 |

| Workflow, m3/h | 40,530 | 69,206 | |

| Temperature, °C | 10 | 95.0 | |

| Relative humidity, % | 75.0 | 2.0 | |

| Absolute humidity, g/kg | 5.70 | 10.56 | |

| Enthalpy, kJ/kg | 24.4 | 124.3 | |

| Outlet | Workflow, m3/h | 48,669 | 61076 |

| Temperature, °C | 66.9 | 51.8 | |

| Relative humidity, % | 3.4 | 12.6 | |

| Absolute humidity, g/kg | 5.70 | 10.56 | |

| Enthalpy, kJ/kg | 82.4 | 79.6 | |

| Air velocity–inlet, m/s | 1.88 | 3.20 | |

| Pressure drop, Pa | 148 | 272 | |

| Pressure drop for normal density, Pa | 137 | 225 | |

| Dry exchange efficiency, % | 66.9 | 50.9 | |

| Wet exchange efficiency, % | 66.9 | 50.9 | |

| Dry heat recovery, kW | 806.63 | −806.63 | |

| Wet heat recovery, kW | 806.63 | −806.63 | |

| Measurement No., - | T-1, °C | T-4, °C | T-2, °C | T-3, °C |

|---|---|---|---|---|

| 1 | 87.7 | 63.1 | 16.6 | 48.2 |

| 2 | 92.6 | 67.1 | 17 | 49.3 |

| 3 | 87 | 63 | 17.5 | 48 |

| 4 | 92.7 | 67.4 | 17.7 | 50 |

| 5 | 88.2 | 64.6 | 18 | 49.3 |

| 6 | 87.4 | 63.8 | 18.2 | 48.3 |

| 7 | 87.1 | 64.5 | 19.3 | 49 |

| 8 | 86 | 64.4 | 19.5 | 49.1 |

| 9 | 77.2 | 57.8 | 20 | 43 |

| 10 | 87 | 63.8 | 20.2 | 50.5 |

| 11 | 86.3 | 64.2 | 20.4 | 49.3 |

| 12 | 85.5 | 62.6 | 20.5 | 50 |

| 13 | 88.3 | 65.8 | 20.6 | 48.1 |

| 14 | 87.6 | 65 | 20.6 | 49.8 |

| 15 | 86.9 | 64.7 | 21.2 | 49.9 |

| 16 | 87.7 | 64.7 | 21.3 | 49.9 |

| 17 | 86.4 | 64.5 | 21.6 | 49.8 |

| 18 | 87.7 | 64.6 | 21.9 | 51.6 |

| 19 | 85.4 | 63.8 | 22.1 | 49.6 |

| 20 | 84.8 | 62.8 | 22.3 | 50.5 |

| Mean value | 86.67 | 64.00 | 18.33 | 48.00 |

| SD | 0.577 | 1.414 | 1.528 | 2.915 |

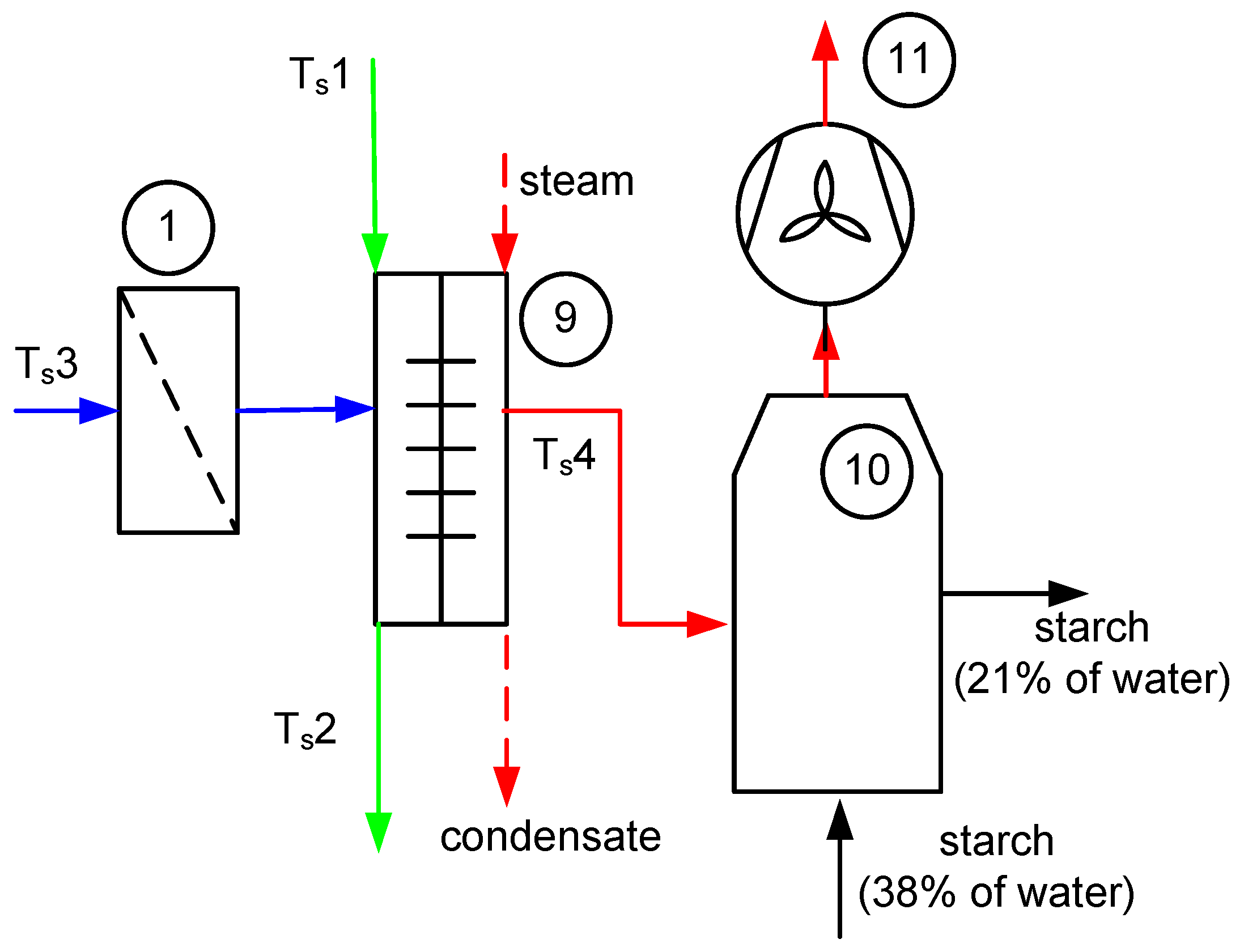

| Lp. | Ts1, °C | Ts2, °C | Ts3, °C | Ts4, °C |

|---|---|---|---|---|

| 1 | 82.2 | 60.0 | 20.0 | 77.2 |

| 2 | 84.4 | 59.9 | 20.0 | 76.0 |

| 3 | 85.3 | 60.2 | 19 | 78.2 |

| 4 | 83.4 | 59.1 | 18.5 | 76.5 |

| 5 | 84 | 59.4 | 18.0 | 77.2 |

| 6 | 87.0 | 62.0 | 19.7 | 80.2 |

| 7 | 88.3 | 61.6 | 22.2 | 79.6 |

| 8 | 84.7 | 61.4 | 23.0 | 77.8 |

| 9 | 83.8 | 61.4 | 23.0 | 77.8 |

| 10 | 79.3 | 59.3 | 23.0 | 71.0 |

| 11 | 81.7 | 59.7 | 22.3 | 72.8 |

| 12 | 80.7 | 58.0 | 21.5 | 74.2 |

| 13 | 72.7 | 53.1 | 19.0 | 65.0 |

| 14 | 81.7 | 59.4 | 21.5 | 75.9 |

| 15 | 81.4 | 59.3 | 21.0 | 77.2 |

| 16 | 84.3 | 61.6 | 21.0 | 77.5 |

| 17 | 84.5 | 61.9 | 22.8 | 77.8 |

| Mean value | 82.9 | 59.8 | 20.9 | 76.0 |

| SD | 3.46 | 2.10 | 1.69 | 3.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olejnik, T.P.; Ciuła, J.; Tomtas, P.; Wiewiórska, I.; Sobiecka, E. Improvement of the Potato Protein Drying Process as an Example of Implementing Sustainable Development in Industry. Sustainability 2025, 17, 8158. https://doi.org/10.3390/su17188158

Olejnik TP, Ciuła J, Tomtas P, Wiewiórska I, Sobiecka E. Improvement of the Potato Protein Drying Process as an Example of Implementing Sustainable Development in Industry. Sustainability. 2025; 17(18):8158. https://doi.org/10.3390/su17188158

Chicago/Turabian StyleOlejnik, Tomasz P., Józef Ciuła, Paweł Tomtas, Iwona Wiewiórska, and Elżbieta Sobiecka. 2025. "Improvement of the Potato Protein Drying Process as an Example of Implementing Sustainable Development in Industry" Sustainability 17, no. 18: 8158. https://doi.org/10.3390/su17188158

APA StyleOlejnik, T. P., Ciuła, J., Tomtas, P., Wiewiórska, I., & Sobiecka, E. (2025). Improvement of the Potato Protein Drying Process as an Example of Implementing Sustainable Development in Industry. Sustainability, 17(18), 8158. https://doi.org/10.3390/su17188158