Abstract

This article describes the implemented technological solution of utilizing waste heat by upgrading the potato protein drying line and using energy recuperation in the drying plant. In this article, the technological sequence of the potato starch and potato protein production plant was analyzed and the identification of possible solutions that lead to a reduction in energy demand was described. The method of analyzing the processing data is based on existing models describing the flow of mass and energy fluxes. The authors did not seek new mathematical descriptions of the physicochemical phenomena occurring during the drying processes, and only modification of the technological line based on the current state of knowledge in process engineering has been proposed. The full heat recovery of the production line was applied, and the exhaust air after drying and the heat from the decanter leachate after centrifugation of the coagulated potato protein, from two energy-coupled starch dryers, were used as the source of recovered heat energy. Temperature measurements were taken at key process nodes, and the energy effects were estimated after the process line upgrade. The solution proposed in the article fits with circular economy, bringing notable economic and environmental benefits consisting of utilizing waste heat from technological processes in the food industry.

1. Introduction

Circular economy constitutes an attempt at solving the problems of the contemporary world concerning the use of raw materials, covering economic and social aspects as well as environment protection, leading to minimizing and optimizing the use of raw materials and energy [1,2]. It is an innovative approach to managing resources and production, prioritizing sustainable development. This method of managing natural resources is aimed at extending the product life cycle, minimizing waste, and reusing materials [3]. This mainly concerns the method of managing industrial waste [4], water treatment systems [5], waste purification technologies, and shortening supply chains [6]. This issue also concerns the methods of generating, transmitting, and using energy, particularly the use of waste heat generated in technological processes [7,8]. Circular economy is successfully implemented in the food industry, in the processes of utilizing waste, in which a by-product of one process may become the raw material for another process [9,10]. Optimization of energy use and utilization of waste heat in the form of hot air, sewage, steam, and technological water constitute the foundation of energy self-sufficiency of plants and technological processes [11,12]. The use of innovative technological solutions in the food industry allows us to reduce the quantity of waste and its recycling in the closed circuit [13,14]. Experimental research related to the optimization of unit processes leads to design changes in the equipment and apparatuses in which such processes are carried out. The analysis of existing plants and the search for solutions to reduce the demand for technological utilities is an activity that requires multi-criteria analysis, which offers a range of possible solutions, varying in cost, which must be selected, taking into account the financial capabilities of the organization. The literature does not provide numerous examples documenting the redesign of existing process lines. This is due to a number of factors, one of which is the lack of time to take in-depth measurements of the changes occurring in the modernized section of the process line. Engineers have process data before and after modernization. The modernization and improvement of the existing technologies in the food industry should make them more environmentally friendly as they implement energy-saving systems of waste management and energy optimization of technological processes [15,16].

The rational use of energy is closely related to the manifestation of eco-efficiency, which involves improving environmental performance related to, among other things, energy conservation, reducing the consumption of natural resources, reducing emissions of pollutants, and reducing the amount of waste generated at each stage of raw material processing. Thus, measures leading to more efficient use of thermal energy consequently lead to a reduction in energy expenditures on production processes and lower manufacturing costs [17].

Drying is a unit operation that can be expressed as the heart of processing operations in many industries [18]. This process has versatile applications in the processing of food, textiles, pharmaceuticals, and chemical and biological materials [19]. In food processing, drying is also considered one of the most important unit operations, which is applied to a variety of food products, from agricultural crops with low moisture content (e.g., rice and corn) to intermediate moisture content (e.g., noodles, tea, and coffee) and high moisture products (milk, fruits, and vegetables) [20,21,22] or meat [23]. The main purpose of drying is to reduce the water content of the product to reach a safe level in order to protect it from deteriorating factors, such as microbiological and physical quality, while maintaining sensory and nutritional quality [24,25].

The drying process is complex in nature. According to Defraeye [17], drying is a multiphase operation, meaning that it involves different phases (solid food products, liquid water, and gas phase of drying air), the scale of the process, from the drier to the cell walls of the dried product, and multiphysics, including the simultaneous transport of heat, mass and momentum, as well as many biochemical and chemical processes, such as nutrient loss, enzymatic reactions, flavor and color changes, fat oxidation, and microbial degradation, which are so important for ensuring food quality and safety [26]. Drying is also an energy-intensive process and comprises 12–20% of industrial energy demand in developed countries [27], so it has always been a challenge in the food industry [28,29].

Among the possible innovations leading to the highest product quality while maintaining their acceptance in environmental and economic criteria are process solutions including (i) sous vide [30], (ii) HTST [31,32], (iii) microwave pasteurization [33], (iv) dehydration by vacuum heat [34], (v) nitric oxide treatment [35], and (vi) plasma treatment [36].

The study of physicochemical changes occurring during drying, along with the development of new strategies to optimize energy consumption, use renewable energy, recover heat used in the process, and use environmentally friendly technologies, is becoming increasingly important [37]. These achievements require a lot of time and expensive laboratories and experimental efforts.

Mathematical models and computer simulation tools are effective alternatives to experimental practices [38,39,40]. These approaches can provide an excellent understanding of transport phenomena during drying operations and improve process control, leading to optimized drying and improved food quality [41,42,43]. The main external parameters that affect heat and mass transfer are the velocity, temperature, and relative humidity of the ambient air or any drying media. At the same time, density, porosity, permeability, specific heat, mass diffusivity, and thermal conductivity are some of the internal parameters that characterize the dried material [44]. The search for solutions to optimize the use of thermal energy in industrial-scale drying requires an understanding of the complex issues of mass and energy transport inside and outside the dried material [45]. The smallest improvement expressed in terms of energy gain per unit mass of dried raw material can lead to significant economic savings, especially when drying significant amounts of raw material, such as potato starch [46].

For the described solution, prior to modernization, the heat demand was approximately 2800 kW per hour, which, at a protein production rate of 850 kg/h, resulted in a heat demand of 3.29 kWh/kg of potato protein at 20% moisture. Due to the specific nature of the food industry and the process solutions used during drying, it is extremely difficult to compare the described solution and its heat demand with other solutions used, for example, in the drying of soy protein. Soy protein is dried using spray drying, while potato protein is dried in air dryers.

This article describes the implemented technological solution of using waste heat by modernizing the potato protein drying line and applying energy recuperation in the starch drying plant. The full heat recovery of the production line was applied, and the exhaust air after drying and the heat from the decanter leachate after centrifugation of the coagulated potato protein, from two energy-coupled starch dryers, were used as the sources of recovered heat energy.

Temperature measurements were taken at key process nodes, and energy effects were estimated after the process line upgrade.

2. Materials and Methods

2.1. Potato Protein

The process of producing potato protein has been known for several decades (1970s) and is widely used on an industrial scale. Potato protein production offers two important benefits: (i) the extraction of potato protein, which is difficult for the soil to absorb, from the cell sap significantly reduces the nuisance of wastewater generated during potato starch production, and (ii) potato protein is an important ingredient used in the feed, food, and cosmetic industries. The potato protein market was estimated at more than USD 110 million in 2020 and is expected to grow at a 4.5% CAGR from 2021 to 2027, eventually reaching USD 150 million [47]. In Europe, major protein producers include Avebe, Emsalnd Group, Suedstaerke, PPZ Trzemeszno, and PEPEES Lomza, among others.

Potato protein is obtained from potato cell sap by thermal–acid coagulation, dehydration, and drying. The raw material contains about 90% dry matter, of which about 80% is protein. It is a protein of high biological value, with digestibility at about 70%. It contains significant amounts of lysine, methionine, threonine, and tryptophan. In terms of the content of essential amino acids, the composition of potato protein compares much more favorably than soybean or rapeseed proteins and is only slightly inferior to animal feed. We can venture to say that it is one of the most valuable sources of plant protein.

Potato protein is an excellent component of mixed feeds for piglets and pigs, providing an alternative to feeds of animal origin or partially replacing soybean meals in them. It is also used in the feeding of slaughter poultry in the initial periods of rearing. It contains a maximum of 10% water [48].

2.2. Dryer Before Modification

In industrial solutions, the most commonly used dryers are convection dryers, which use hot air or combustion gases as the drying medium [49,50]. The low quality of the final dried food products and low efficiency in this type of dryer forces producers to modify the design, including increasing the energy efficiency of the drying process.

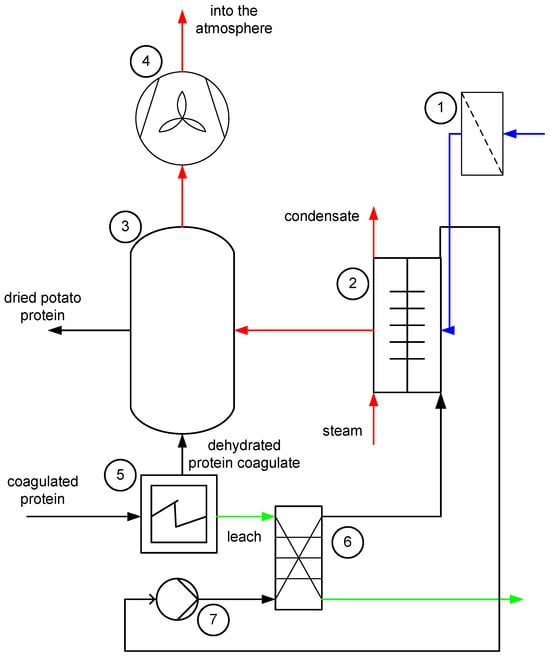

Figure 1 shows the schematic diagram of the potato protein dryer before modification.

Figure 1.

Schematic diagram of the potato protein dryer before modernization. Description in the text.

The process parameters mentioned in the article apply to the drying of potato protein only. Cold atmospheric air with a temperature of Tz = 10 °C was filtered in the filter (1), from where it moved to the shell exchanger (2). The air heated up in the heat exchanger was directed to the dryer (3). The shell exchanger (2) was supplied with steam and additionally with water with a temperature of To = 85 °C, which passed through the plate exchanger (6), cooling the leachate coming from the protein decanter (5). A circulating pump (7) was used to pump the water through the exchanger (6). The drying medium, air, was transported by an exhaust fan (4). Key parameters of the protein drying process are given in Table 1.

Table 1.

Selected parameters of the potato protein drying process in the dryer before modernization.

Potato plants operate in campaign mode, e.g., in Poland, it is about 100–130 days (September–December) and depends on many factors, primarily the availability of raw material. The remaining time of the year is allocated for modernization work, among other things, and this is when new technological solutions can be implemented. In general, the process of potato protein production takes place simultaneously with the process of potato starch production.

The points for measuring temperature and mass expenditures of media and raw material come from the actual plant and reflect its averaged performance. The location of the points was determined experimentally during plant operation.

2.3. Description of the Dryer Modernization Concept

The production process is carried out in the autumn months, a time from about early September to about mid-December. So the conditions for using waste heat are more or less similar. And the plant is designed for these conditions. The modification of the system did not reduce the efficiency of the dryer and did not change the quality of the final product.

Prior to the retrofit, the hot air from the protein dryer with temperature Tw was discharged to the atmosphere, while the heat from the leachate after the protein decanter was used to preheat the inlet air of the protein dryer. The heat flux, lost by directly exhausting hot air after heating in the dryer with an output of Qf and a temperature of Tw, was calculated based on Equation (1)

Taking the value of the specific heat of air cp = 1.009 kJ/(kg*K), the value of the atmospheric pressure pa = 1015 hPa, the average density of air ρp = 0.992 kg/m3, and the average temperature increment of ΔT = 82.5 °C, the energy flow demand was obtained:

If a protein dryer exhaust air exchanger is installed, it is assumed that the performance of the existing heat recovery line from cooling the protein decanter leachate would not be degraded. However, the recuperator’s preheated inlet air to the dryer would not draw enough heat from the system, resulting in hot leachate being discharged outside. In contact with other wastewater, this could lead to undesirable chemical and biological processes and cause large heat losses. In order to maximize the use of heat from the leachate, the project envisaged extending the existing system to supply the leachate with water heaters to preheat the air of starch dryers A and B (Figure 2).

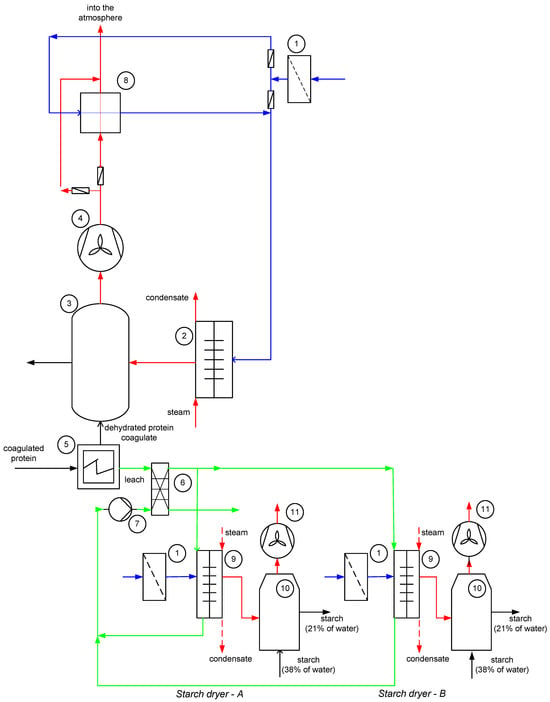

Figure 2.

Schematic diagram of the potato protein dryer after modernization. Description in the text.

For the retrofit process, the temperature of the air removed from the dryer was also assumed to be Tw = 95 °C, the volume flow rate of air flowing through each dryer was Qt = 55,000 m3/h, and the temperature of the outside air flowing through filter 1 was Tz = 10 °C. The listed process parameters are identical to those for the dryers before modification. In addition, a maximum volume flow rate of heated air flowing through the recuperator of Q = 42,000 m3/h was initially assumed.

After analyzing the dryer’s operation, a concept for increasing the efficiency of the drying process was adopted, consisting of two solutions, including (i) utilization of the exhaust heat from dryer 3, and (ii) heat recovery from protein decant leachate after centrifugation of coagulated potato protein. The first solution was realized through the use of a cross-flow heat exchanger, while heat recovery from the leachate after protein decanting was realized by installing additional water heaters coupled to starch dryers A and B. In the proposed upgrade, the inlet air to the starch dryer is heated by passing through heaters fed by heat from the leachate after the protein decanters. The following process conditions were adopted for this part of the process line: (i) temperature of the leachate water after protein decanters Td = 85° C, volumetric flow rate of cooling water Qo = 75 m3/h, volumetric flow rate of air to starch dryers A and B, amounting to Qs = 40,000 m3/h for each, and the temperature of the outside air drawn in for starch drying, also amounting to Tz = 10 °C.

Each starch dryer has a capacity of 190 Mkg/h of starch with a water content of 21%. In order to protect the system from insufficient air flow, pressure, and temperature meters integrated with the master control system were installed.

A schematic diagram of the solution for upgrading potato protein drying is shown in Figure 2.

The change in the concept of supplying waste heat to the potato protein dryer did not change the capacity of the potato protein dryer, which is still 0.85 Mkg/h.

Before the upgrade, the air from the protein dryer was vented to the atmosphere, while the heat from the leachate after the protein decanters was used to preheat the protein dryer’s inlet air.

Heat recovery from the exhaust air from the protein dryer was solved by installing a recuperator–cross plate heat exchanger Klingenburg type PWT 10/2000/3000-11.5. The basic operating parameters of the exchanger are given in Table 2.

Table 2.

Nominal technical and operational data of the heat exchanger.

The protein dryer is a pneumatic type of dryer operating on a vacuum caused by a fan (4). The intake cold air passes through a particulate filter (1) and is fed to a cross exchanger–recuperator (8) (Figure 2) in which it is preheated by blown hot air from the dryer with a temperature Tw of 90 ÷ 95 °C. The air is then fed to the steam heater unit (2), where it is reheated to its target temperature Tb = 85 °C. The warm air stream dries and then separates the dry protein, while the warm air is ejected into the atmosphere after passing through the recuperator (8), heating the air entering the dryer. A system of dampers in the air supply ducts allows emergency bypass of the recuperator and smooth regulation of the temperature of the air fed to the steam heaters (2). During normal operation of the plant, the pressure and temperature of the air flowing through the exchanger (2) and recuperator (8) are measured. At the same time, heat is recovered from the leachate system and from the protein decanters. The leachate from the decanter (5) heats water in plate heat exchanger (6). Hot water, heated by waste heat, is fed by the circulation pump (7) to the water heaters of both starch dryers (9). The air drawn in by the fans of the starch dryer (7), also of the pneumatic type, is heated, and the cooled water is returned to the plate heat exchanger. It is possible to use the air preheating system of the starch dryer (10) and the air preheating system of the protein dryer (3) interchangeably. This is performed only if the heat recovery system of the recuperator (8) is not used.

3. Results and Discussion

The food industry is one of the most energy-consuming branches of the economy, characterized by accessible low-temperature sources of waste energy, with stable temperature and appropriate availability. These sources include inter alia: hot post-process air carried away via installations outside to cold stores, the heat constituting loss suffered during the operation of machines and appliances in technology lines, the heat originating from raw materials during their processing (for example, in the process of boiling, brewing, warming up, pasteurizing, etc.), and the heat from the processes of production drying and draining. The above-mentioned sources of waste heat can be used for social and production purposes within a particular plant, thus fitting in with circular economy and the sustainable development of food processing. The energy obtained and saved within the plant is a vital element in environmental protection and energy optimization, which exponentially translates into a reduction in production costs in their economic aspect [51,52].

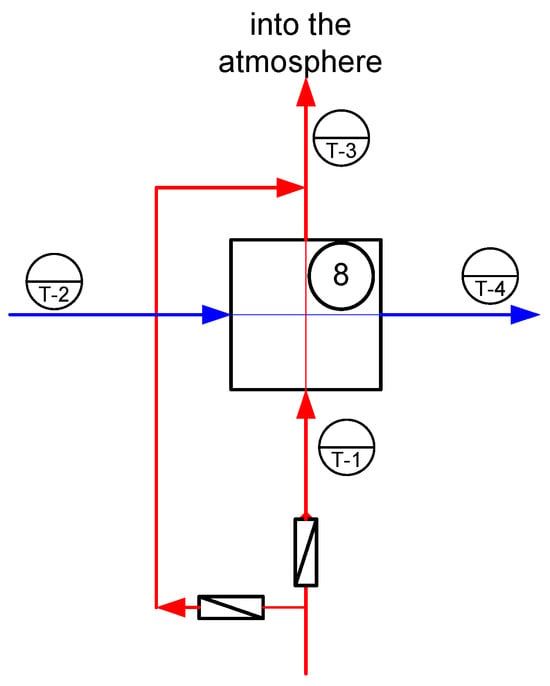

The modified method of supplying heat to the potato protein dryer made it possible to significantly reduce the temperature of the air leaving the protein dryer after passing through the Klingenburg recuperator type PWT 10/2000/3000-11.5. The temperature measurement locations are shown in Figure 3.

Figure 3.

Diagram of the location of temperature measurement points of the potato protein drying system. T-1—the temperature of the air leaving the dryer; T-2—the temperature of the outside air drawn into the recuperator; T-3—the temperature of the air exhausted to the atmosphere; T-4—the temperature of the air heated in the recuperator feeding the heat exchanger (2).

Measurements were taken randomly during 20 days of operation of the process line so as to account for the change in temperature of the air drawn into the recuperation system due to weather conditions. It was originally assumed that the average temperature of T-2 was 10 °C. A summary of the temperatures at the protein dryer recuperator measurement points is provided in Table 3. The measurements were ranked from the lowest to the highest observed temperature of the intake air to the recuperator (T-2). The measurements were read at 7:00 a.m. During the period of conducting the measurements, the ambient air temperatures, assumed initially in the calculations to be 10 °C, were not recorded.

Table 3.

Summary of temperatures measured at the measurement points.

The average temperature of atmospheric air entering the heat recuperation system on the process line was T-2 = 18.33 °C. The average temperature rise in the recuperator, measured as the difference between T-4 (64 °C) and T-2 (18.33 °C), was 46.67 °C.

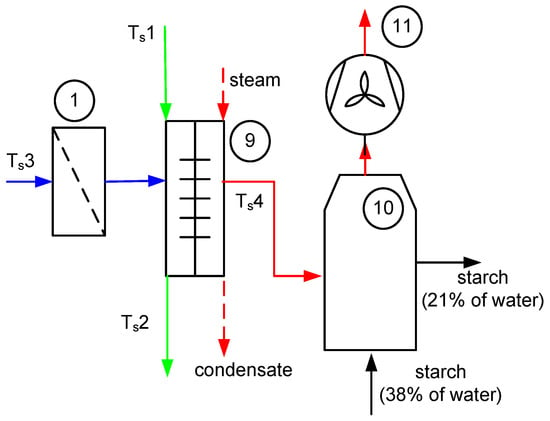

Along with measuring the temperature at the inlet and outlet of the recuperator, the temperatures of the media flowing through the two water heaters (9) operating in the potato starch dryer process line were measured. Figure 4 shows a schematic of the water heat exchanger of the starch dryer (9), along with the designation of the temperature measurement points.

Figure 4.

Diagram of the location of temperature measurement points of the potato starch drying system of the water heater (9). Ts1—temperature of water at the inlet of the heater; Ts2—temperature of water at the outlet of the heater; Ts3—temperature of external (atmospheric) air; Ts4—temperature of air entering the starch dryer 10; 1—air filter; 11—starch dryer fan.

The summary of the measured temperature values at the measurement points corresponding to the markings in Figure 4 is given in Table 4. Energy yields from the recuperation system enabled recovery of the waste heat stream. As a result of the retrofit, the capacity of dried protein, which is about 0.85 t/h, was not increased. As a result of the recuperation system, it was assumed by design to recover about 806 kW (4. HT-PWT 10 2000 3000 exchanger selection sheet 115.pdf), while redirecting the hot leachate stream to both starch dryers allowed the recovery by design of 2 × 1000 kW each. The modification of the drying room works as a result of recovering waste heat via using a recuperator, optimizing the temperature of the air supplied to the chamber, which contributes to the reduction in the demand for heat by nearly 3 MWh.

Table 4.

Temperature values measured in the process line of the starch dryer.

Considering the above, the benefits of using an energy recovery system for the modernized process line are as follows:

- (a)

- Improved energy efficiency of the protein dryer:

- -

- Before modernization: 2800 kWh/850 kg/h = 3.29 kWh/1 kg of protein.

- -

- After modernization and recovery of ~806 kWh of heat, the energy efficiency is 2000 kWh/850 kg/h = 2.35 kWh/1 kg of protein, reducing the energy input by ~28%.

- (b)

- Improved energy efficiency of the starch dryer:

- -

- Before modernization: heat demand: 5950 kWh/15,800 kg of starch (2 × 190 tons/day/24 h = 15,800 kg) = 0.38 kWh/1 kg of starch with 20% moisture.

- -

- After modernization: 5950 kWh−2000 kWh = 3950 kWh/15,800 kg = 0.25 kWh/1 kg of starch, with energy consumption reduced by ~34%.

These are, of course, production savings resulting from the reduction in the demand for thermal energy to produce 1 kg of protein or potato starch.

However, environmental savings are also crucial. The heat source is a coal-fired boiler producing steam at 12 bar. This translates to savings of 2800 kW for each hour of operation of the process line.

Assuming the average calorific value of black coal, the equivalent of 2800 kW of thermal energy per hour (800 kW for a protein dryer and 2000 kW for a starch dryer), and assuming that 1 kg of coal (medium quality) provides 4–5 kW of energy, for each hour of operation of the technological line, 560 to 700 kg less coal is burned. For a 2400 h potato campaign, the savings in solid fuel range from 1,344,000 to 1,680,000 kg or 1344 to 1680 tons, respectively.

The above results enable the reduction in CO2 emissions from coal combustion in the range from 3252.5 to 4065.6 tons.

4. Conclusions

The food industry and its technological processes, due to the type of raw materials and products, generate large amounts of waste and consume a considerable amount of energy, especially heat. On the other hand, these processes generate large amounts of waste heat, which, if used rationally, bring notable economic and environmental benefits. The implementation of optimizing heat energy consumption, as shown in this paper, is an example of circular economy, consisting of utilizing energy by using solutions that lead to its effective use. The solution presented here uses the waste heat constituting the air removed after drying and the heat from the decantation wash after whirling coagulated potato protein from two starch dryers. The utilization of waste heat in these processes constitutes an example of synergy of cooperation between the science and the industry sectors and may be implemented in other production plants and scaled down or up as necessary. The actions indicated in this paper are a vital step towards energy efficiency of technology processes, and as a result, of the whole production plant. The final quality and quantity outcomes, namely energy savings, will depend on a number of factors, including the level of production mechanization, the technical condition of machines and appliances, as well as particular technology processes. Therefore, it is of key importance, first, to make an inventory of the technical condition in order to indicate point sources of waste heat, to develop a schedule of research in the production plant, so as to make the proposed solution appropriate and dedicated to a selected technology process.

Author Contributions

Conceptualization, T.P.O., P.T., E.S., and J.C.; methodology, T.P.O., P.T., J.C., and I.W.; software, T.P.O., P.T., and J.C.; validation, T.P.O. and J.C.; formal analysis, P.T. and I.W.; investigation, T.P.O., J.C., and E.S.; writing—original draft preparation, T.P.O., E.S., and J.C.; writing—review and editing, T.P.O., E.S., and J.C.; visualization, E.S., P.T., and I.W.; supervision, T.P.O., E.S., and J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data is contained within the article.

Conflicts of Interest

Paweł Tomtas was employed by Mysak Group Sp. z o.o. sp. k. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Camacho-Otero, J.; Boks, C.; Pettersen, I.N. Consumption in the Circular Economy: A Literature Review. Sustainability 2018, 10, 2758. [Google Scholar] [CrossRef]

- Basta, E.; Szewczyk, P. The use of methane from landfill gas to generate energy and its management at the plant as a way to reduce climate change. Rocz. Ochr. Sr. 2024, 26, 236–250. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Gronba-Chyła, A.; Ciuła, J.; Wiewiórska, I.; Kwaśnicki, P.; Mala, M.; Chyła, K. Artificial Intelligence Methods for Analysis and Optimization of CHP Cogeneration Units Based on Landfill Biogas as a Progress in Improving Energy Efficiency and Limiting Climate Change. Energies 2023, 16, 5732. [Google Scholar] [CrossRef]

- Graz, K.; Gronba-Chyla, A.; Chyla, K. Microplastics found in compost as a barrier to the circular economy (CE). Przemysł Chem. 2023, 102, 381–383. [Google Scholar] [CrossRef]

- Ciuła, J. Modeling the migration of anthropogenic pollution from active municipal landfill in groundwaters. Archit. Civ. Eng. Environ. 2012, 14, 81–90. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Lobur, M.; Jaworski, N.; Ciuła, J.; Mzyk, T. Optimization of Biological Wastewater Treatment Process by Hierarchical Adaptive Control. In Proceedings of the 2019 IEEE XVth International Conference on the Perspective Technologies and Methods in MEMS Design, Polyana-Svalyava, Ukraine, 22–26 May 2019; pp. 119–122. [Google Scholar] [CrossRef]

- Navajas, A.; Uriarte, L.; Gandía, L.M. Application of Eco-Design and Life Cycle Assessment Standards for Environmental Impact Reduction of an Industrial Product. Sustainability 2017, 9, 1724. [Google Scholar] [CrossRef]

- Satyro, W.C.; Contador, J.C.; Monken, S.F.d.P.; Lima, A.F.d.; Soares Junior, G.G.; Gomes, J.A.; Neves, J.V.S.; do Nascimento, J.R.; de Araújo, J.L.; Correa, E.d.S. Industry 4.0 Implementation Projects: The Cleaner Production Strategy—A Literature Review. Sustainability 2023, 15, 2161. [Google Scholar] [CrossRef]

- Bubenik, P.; Capek, J.; Rakyta, M.; Binasova, V.; Staffenova, K. Impact of Strategy Change on Business Process Management. Sustainability 2022, 14, 11112. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular economy rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Osorio, L.L.D.R.; Flórez-López, E.; Grande-Tovar, C.D. The Potential of Selected Agri-Food Loss and Waste to Contribute to a Circular Economy: Applications in the Food, Cosmetic and Pharmaceutical Industries. Molecules 2021, 26, 515. [Google Scholar] [CrossRef] [PubMed]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Darlington, R.; Staikos, T.; Rahimifard, S. Analytical methods for waste minimisation in the convenience food industry. Waste Manag. 2009, 29, 1274–1281. [Google Scholar] [CrossRef]

- Gonçalves, M.L.M.B.B.; Maximo, G.J. Circular Economy in the Food Chain: Production, Processing and Waste Management. Circ. Econ. Sust. 2023, 3, 1405–1423. [Google Scholar] [CrossRef]

- Skawińska, E.; Zalewski, R.I. Combining the Water–Energy–Food and Food Waste–Food Loss–Food Security Nexuses to Reduce Resource Waste. Energies 2022, 15, 5866. [Google Scholar] [CrossRef]

- Menon, V.; Stojceska, S.A.; Tassou, A. systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Dehnad, D.; Jafari, S.M.; Afrasiabi, M. Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci. Technol. 2016, 57, 116–131. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced computational modelling for drying processes—A review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Jafari, S.M.; Azizi, D.; Mirzaei, H.; Dehnad, D. Comparing quality characteristics of oven-dried and Refractance Window-dried kiwifruits. J. Food Process. Preserv. 2016, 40, 362–372. [Google Scholar] [CrossRef]

- Jafari, S.M.; Ganje, M.; Dehnad, D.; Ghanbari, V. Mathematical, fuzzy logic and artificial neural network modeling techniques to predict drying kinetics of onion. J. Food Process. Preserv. 2016, 40, 329–339. [Google Scholar] [CrossRef]

- Azizi, D.; Jafari, S.M.; Mirzaei, H.; Dehnad, D. The influence of refractance window drying on qualitative properties of kiwifruit slices. Int. J. Food Eng. 2017, 13, 20160201. [Google Scholar] [CrossRef]

- Olejnik, T.P.; Mysakowski, T.; Tomtas, P.; Mostowski, R. Optimization of the beef drying process in a heat pump chamber dryer. Energies 2021, 14, 4927. [Google Scholar] [CrossRef]

- Bahmani, A.; Jafari, S.M.; Shahidi, S.A.; Dehnad, D. Mass transfer kinetics of eggplant during osmotic dehydration by neural networks. J. Food Process. Preserv. 2016, 40, 815–827. [Google Scholar] [CrossRef]

- Jafari, S.M.; Ghalenoei, M.G.; Dehnad, D. Influence of spray drying on water solubility index, apparent density, and anthocyanin content of pomegranate juice powder. Powder Technol. 2017, 311, 59–65. [Google Scholar] [CrossRef]

- Adeyeye, S.A.O.; Ashaolu, T.J.; Babu, A.S. Food drying: A review. Agric. Rev. 2022, R-2537, 1–8. [Google Scholar] [CrossRef]

- Bardy, E.; Hamdi, M.; Havet, M.; Rouaud, O. Transient energetic efficiency and moisture loss analysis of forced convection drying with and without electrohydrodynamic enhancement. Energy 2015, 89, 519–527. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.W. Computational fluid dynamics (CFD)—An effective and efficient design and analysis tool for the food industry: A review. Trends Food Sci. Technol. 2006, 17, 600–620. [Google Scholar] [CrossRef]

- Strumiłło, C. Perspectives on developments in drying. Dry. Technol. 2006, 24, 1059–1068. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous vide cooking: A review. Int. J. Gastron. Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef]

- Polak, N.; Kalisz, S.; Kruszewski, B. High-Temperature Short-Time and Ultra-HighTemperature Processing of Juices, Nectars and Beverages: Influences on Enzyme, Microbial Inactivation and Retention of Bioactive Compounds. Appl. Sci. 2024, 14, 8978. [Google Scholar] [CrossRef]

- Sergius-Ronot, M.; Michael, A.; Pitino, M.A.; Shyam Suwal, S.; Sara Shama, S.; Sharon Unger, S.; O’Connor, D.L.; Pouliot, Y.; Doyen, A. Impact of holder, high temperature short time and high hydrostatic pressure pasteurization methods on protein structure and aggregation in a human milk protein concentrate. Food Chem. 2022, 374, 131808. [Google Scholar] [CrossRef]

- Jasim, A.; Ramaswamy, H.S. Microwave pasteurization and sterilization of foods. In Handbook of Food Preservation, 3rd ed.; Rahman, M.S., Ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 713–732. [Google Scholar]

- Kręcisz, M.; Kolniak-Ostek, J.; Stępień, B.; Łyczko, J.; Pasławska, M.; Musiałowska, J. Influence of Drying Methods and Vacuum Impregnation on Selected Quality Factors of Dried Sweet Potato. Agriculture 2021, 11, 858. [Google Scholar] [CrossRef]

- Tian, X.; Tian, Y.; Meng, S.; Zhao, J.; Shao, L.; Li, Y.; Wang, W. A rethinking of nitrate, nitrite, and nitric oxide for food preservation and human health. Food Sci. Hum. Wellness 2025, 25, 9250434. [Google Scholar] [CrossRef]

- Chizoba Ekezie, F.-G.; Sun, D.-W.; Cheng, J.-H. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Technol. 2017, 69, 46–58. [Google Scholar] [CrossRef]

- Almena, A.; Goode, K.R.; Bakalis, S.; Fryer, P.J.; Lopez-Quiroga, E. Optimising food dehydration processes: Energy-efficient drum-dryer operation. Energy Procedia 2019, 161, 174–181. [Google Scholar] [CrossRef]

- Shahraki, M.; Jafari, S.M.; Mashkour, M.; Esmaeilzadeh, E. Optimization of closed-cycle fluidized bed drying of sesame seeds using response surface methodology and genetic algorithms. Int. J. Food Eng. 2014, 10, 167–181. [Google Scholar] [CrossRef]

- Jafari, S.M.; Ghanbari, V.; Ganje, M.; Dehnad, D. Modeling the drying kinetics of green bell pepper in a heat pump assisted fluidized bed dryer. J. Food Qual. 2016, 39, 98–108. [Google Scholar] [CrossRef]

- Malekjani, N.; Jafari, S.M. Simulation of food drying processes by Computational Fluid Dynamics (CFD); recent advances and approaches. Trends Food Sci. Technol. 2018, 78, 206–223. [Google Scholar] [CrossRef]

- Jamaleddine, T.J.; Ray, M.B. Application of computational fluid dynamics for simulation of drying processes: A review. Dry. Technol. 2010, 28, 120–154. [Google Scholar] [CrossRef]

- Martynenko, A.; Vieira, G.N.A. Sustainability of drying technologies: System analysis. Sustain. Food Technol. 2023, 1, 629–640. [Google Scholar] [CrossRef]

- Hnin KayKhaing, H.K.; Zhang Min, Z.M.; Mujumdar, A.S.; Zhu YueLin, Z.Y. Emerging food drying technologies with energy-saving characteristics: A review. Dry. Technol. 2019, 37, 1465–1480. [Google Scholar] [CrossRef]

- Caccavale, P.; de Bonis, M.V.; Ruocco, G. Conjugate heat and mass transfer in drying: A modeling Review. J. Food Eng. 2016, 176, 28–35. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Pathak, S.K.; Chopra, K.; Saxena, A.; Kalidasan, B.; Dwivedi, A.; Goel, V.; Sharma, R.K.; Agrawal, R.; Kandil, A.A.; et al. Sustainable growth of solar drying technologies: Advancing the use of thermal energy storage for domestic and industrial applications. J. Energy Storage 2024, 99, 113320. [Google Scholar] [CrossRef]

- Rashid, M.T.; Liu, K.; Jatoi, M.A.; Safdar, B.; Lv, D.; Li, Q. Energy efficient drying technologies for sweet potatoes: Operating and drying mechanism, quality-related attributes. Front. Nutr. 2022, 9, 1040314. [Google Scholar] [CrossRef]

- Potato Production and Trade—Market Analysis. Available online: https://foodcom.pl/en/potato-production-and-trade-market-analysis-2/ (accessed on 20 April 2021).

- Zhang, D.; Mu, T.; Sun, H. Calorimetric, rheological, and structural properties of potato protein and potato starch composites and gels. Starch/Stärke 2017, 69, 1600329. [Google Scholar] [CrossRef]

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B.K. Novel drying techniques for the food industry. Food Eng. Rev. 2014, 6, 43–55. [Google Scholar] [CrossRef]

- Mysakowski, T.; Olejnik, T.P. The impact of the selected methods of drying beef on the quality of the finished product. Przemysł Spożywczy 2019, 73, 22–26. [Google Scholar] [CrossRef]

- Perz, K. Possibilities of using waste heat in the food industry. Inż. Ap. Chem. 2009, 48, 110–111. Available online: https://bibliotekanauki.pl/articles/2070391 (accessed on 21 December 2024). (In Polish).

- Bhatia, L.; Jha, H.; Sarkar, T.; Sarangi, P.K. Food Waste Utilization for Reducing Carbon Footprints towards Sustainable and Cleaner Environment: A Review. Int. J. Environ. Res. Public Health 2023, 20, 2318. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).