1. Introduction

The coal industry is a multifaceted sector that integrates mining, transportation, processing, and environmental management [

1]. As a crucial supplier of fuel and raw materials, it is deeply embedded in national energy systems and closely interconnected with broader industrial frameworks, such as coal chemical engineering, thereby exerting a profound influence on modern society. Within China’s historically coal-dependent energy structure, the industry remains fundamental to ensuring energy security and sustaining rapid economic growth [

2]. By 2024, China’s raw coal production reached 4.76 billion tons, accounting for 83% of total energy consumption and generating an economic output exceeding 4 trillion yuan. The long-term extensive mining practices, low resource utilization efficiency, and lagging environmental governance have posed significant challenges to the sustainable development of the coal industry [

3]. However, the current sustainable transition of the coal industry is often limited to adjustments at individual stages, yielding only marginal improvements. The concept of circular economy, which emphasizes the feedback loop of “resources–products–recycled resources,” aligns closely with the integrated characteristics of production and consumption in the coal industry. As such, it holds great promise as an effective solution for the industry’s sustainable transition.

Integrating circular economy principles into the coal industry provides a comprehensive pathway toward sustainability. Scholars have highlighted its potential to mitigate the environmental externalities associated with the industry’s operations [

4]. For instance, Yu demonstrated that circular economy practices significantly reduce greenhouse gas emissions while enhancing the conservation and recycling of critical resources such as water and coal mine methane [

5]. Tayebi-Khorami et al. applied circular economy frameworks to mining waste management, effectively mitigating liability risks associated with waste generation [

6]. Moreover, the circular economy has facilitated the emergence of new value chains within the coal industry, addressing longstanding stagnation in industrial development. Marinina et al. developed a circular business model tailored to the coal production chain and empirically validated its efficacy in fostering value creation [

7]. Similarly, Kulczycka et al. examined waste management strategies in the coal industry under EU regulatory frameworks [

8], revealing that such measures not only promote industrial symbiosis but also contribute significantly to long-term economic growth [

9]. At the macro level, the circular economy serves as a policy-driven framework that provides strategic guidance for establishing green and sustainable development goals in the coal industry [

10], whereas at the micro level, it enables more efficient utilization of resources [

11]. It departs from the traditional linear model of “mining-manufacturing-consumption-disposal” and instead promotes a redesigned production-consumption model aligned with sustainability requirements [

12,

13].

To rigorously and accurately assess the development of the circular economy in the coal industry, researchers have employed a range of analytical methods. Among these, material flow analysis, grey correlation analysis, fuzzy comprehensive evaluation, and data envelopment analysis (DEA) are the most commonly employed approaches. Current research on measuring the circular economy in the coal industry primarily focuses on different scales, including national, industrial, and mining-area levels. These studies analyze the operational outcomes of the circular economy to identify key strategies for enhancing circularity in the coal industry. However, such studies often focus solely on revealing the overall score of the circular economy, without delving into its underlying mechanisms. Moreover, the evaluation process is often opaque, operating as a “black box” that obscures the identification of critical nodes within the system.

Accordingly, this study aims to evaluate the evolutionary mechanisms of circular economy efficiency in the coal industry from a systems perspective. It investigates how the internal processes of the circular economy—spanning mining, processing, utilization, and waste treatment and reuse—shape overall system efficiency. The research results provide new directions for the sustainable transformation of China’s coal industry. Specifically, the study aims to address three key questions: How has the circular economy development model evolved in China’s coal industry? What are the key links that influence the development of the circular economy in China’s coal industry? What underlying drivers account for the regional heterogeneity in circular economy efficiency across China’s coal industry? To address these questions, the paper constructs a material cycle network encompassing the entire production–consumption process, introduces efficiency indicators to uncover the evolutionary mechanisms of circular economy performance at the provincial level, and proposes targeted strategies to facilitate the sustainable transformation of China’s coal industry.

2. Literature Review

In 1978, Charnes et al. introduced the method of Data Envelopment Analysis (DEA), a non-parametric efficiency evaluation technique designed to assess the relative efficiency of decision-making units (DMUs) [

14]. This method is mainly based on linear programming and compares the decision-making unit with the efficient production frontier to determine its relative efficiency. Banker et al. expanded the model from constant returns to scale (CRS) to variable returns to scale (VRS), enabling the distinction between increasing and decreasing returns to scale [

15]. However, the CCR and BCC models in DEA do not account for slack improvements between the actual state of a DMU and its effective target value. Tone and Tsutsui introduced the Slack-Based Measure (SBM) model, which incorporates slack improvements of inputs and outputs into the inefficiency measurement of DMUs [

16]. Nonetheless, the SBM model typically treats non-desired output variables as negative input variables, leading to a projection point that is not the shortest path to the frontier. To address this issue, Chambers et al. and Chung et al. proposed the directional distance function (DDF) model, which uses a direction vector to project inefficient DMUs onto the frontier in any specified direction. Consequently, this study opts for the non-directional DDF model [

17,

18].

In actual operations, systems typically encompass multiple stages and intermediate links. However, traditional DEA models only consider system inputs and outputs, neglecting the overall internal structure. To address this limitation, Färe et al. introduced a network DEA model based on the concept of multi-link production, effectively describing the system’s internal operational processes [

19]. Fallah-Fini et al., and others observed that most existing models are static and overlook the correlations between consecutive periods [

20]. In response, Färe and Grosskopf proposed a dynamic DEA model that incorporates these inter-period correlations into the evaluation [

21]. The network DEA model accounts for the system’s internal structure, while the dynamic DEA model considers the temporal correlations [

22]. Combining network DEA with dynamic DEA provides a more accurate system evaluation by integrating internal structure and period correlations.

In recent years, the dynamic network DEA model has attracted increasing scholarly attention due to its ability to account for the internal operating structure of systems, thereby significantly reducing bias in efficiency measurement [

23,

24]. By incorporating structures such as multi-stage, serial, and parallel processes, this model can accurately capture the operational mechanisms of decision-making units (DMUs), and it has been widely applied in fields such as ecological economy [

25,

26], energy systems [

27,

28], and urban sustainability [

24]. Particularly in the evaluation of circular economy efficiency, the dynamic network DEA approach enables the construction of closed-loop network structures through material flows between subsystems, thus providing critical support for modeling complex systems [

29,

30,

31]. For example, Zhang et al. divided industrial operation systems into production processes and industrial waste treatment processes, further subdividing the latter into wastewater, exhaust gas, and solid waste subsystems. Based on this, they constructed a dynamic series-parallel circular DEA model to conduct an in-depth analysis of resource recycling performance in industrial systems [

32]. With the continuous development of DEA methods, researchers have increasingly sought to integrate DEA with other approaches to broaden the scope and depth of efficiency analysis [

33]. For instance, DEA has been combined with life cycle assessment [

34], artificial neural networks [

35], system dynamics [

25], and spatial econometric models [

36]. Notably, emergy analysis offers unified measurement units for heterogeneous inputs and outputs, which can enhance the accuracy and scientific rigor of efficiency evaluation when integrated into DEA models.

Nevertheless, significant gaps remain in the evaluation of circular economy efficiency within the coal industry. First, most existing models fail to reflect the core feature of resource recycling and reuse [

30]. Second, prior studies have primarily focused on single production stages, lacking a systematic depiction of the full “extraction–utilization–recycling–regeneration” process [

33]. Third, traditional DEA models struggle to simultaneously address the multi-period dynamic characteristics and networked structures inherent in circular economy systems. To address these limitations, this paper integrates the structural flexibility of dynamic network DEA models with the unified measurement units provided by emergy analysis. This integration enables a more comprehensive and comparable evaluation of the circular economy in the coal industry, effectively capturing system operation and recycling characteristics while overcoming inconsistencies in inputs and outputs in conventional DEA models, thereby improving the robustness of efficiency measurement.

3. Methodology

3.1. Emergy Analysis

American ecologist Odum proposed the emergy theory, which standardizes various forms of energy and material inputs into a common emergy unit [

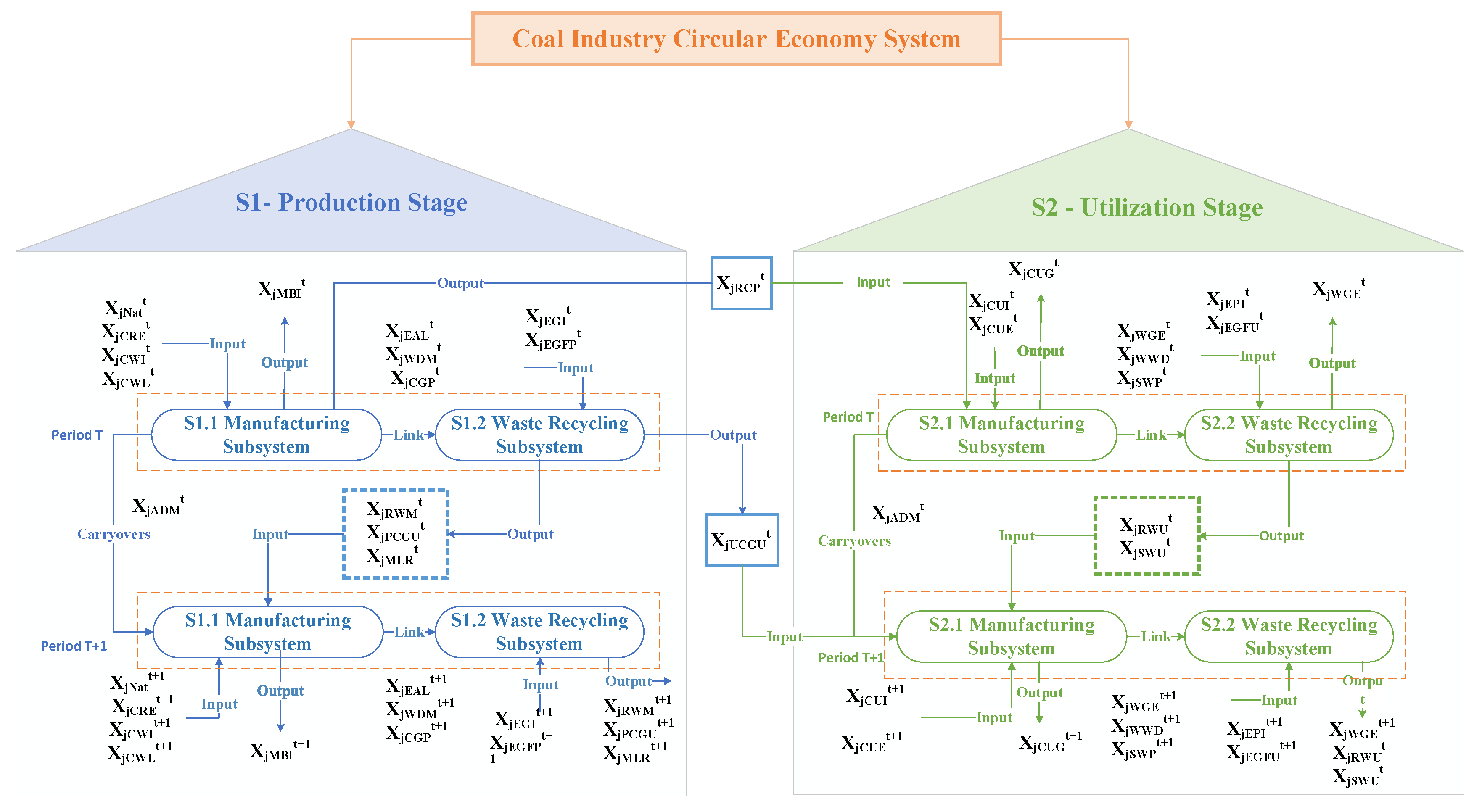

37]. The emergence of this theory provides crucial theoretical support for a deeper understanding and optimization of the interactions among natural resource utilization, economic development, and ecological conservation. This study constructs an emergy analysis diagram for the operation process of the coal industry (

Figure 1). The operation process mainly consists of two parts: (1) Internal energy flow. During the coal production stage, natural resources are converted into raw coal to supply the utilization phase. The manufacturing subsystem serves as the primary driver of material and energy flows within the coal industry’s circular economy system, while the waste recycling subsystem acts as a crucial bridge, facilitating energy exchanges between the manufacturing subsystem and the ecological environment. (2) Energy transfer between internal flows and the external environment. The natural ecosystem provides essential resources, environmental support, and ecological functions for the operation of the coal industry’s circular economy, while the socio-economic system contributes key inputs such as materials, energy, and capital. Throughout this process, dynamic exchanges occur between coal production, utilization, and waste recycling and the external environment. These interactions not only enhance resource efficiency but also generate substantial economic, social, and environmental benefits.

3.2. The Dynamic Double Closed-Loop Network DEA Model

3.2.1. The Dynamic Double Closed-Loop Network Structure and Input-Output Indicators

As shown in

Figure 2, the dual closed-loop network structure divides the internal framework of the coal industry’s circular economy system into two key stages: coal production and coal utilization. Each stage consists of a manufacturing subsystem and a waste recycling subsystem, which are interconnected to form a comprehensive dual closed-loop network. By conducting an integrated evaluation of subsystem efficiency, the overall operational efficiency of the circular economy system in the coal industry can be comprehensively assessed. The efficiency of each subsystem is quantified using distinct input-output indicators, while the interconnections between subsystems are characterized through linking indicators and intertemporal metrics, providing a more precise representation of the system’s dynamic characteristics and operational mechanisms.

Coal Production Stage (PS):

- (1)

Considering the evaluation of DMUj (j = 1, …, j). In the manufacturing subsystem of the coal production stage, the input variables include natural energy (XjNatt), coal reserves (XjCREt), fixed asset investment in the coal mining industry (XjCWIt), and the number of employees in the coal mining industry (XjCWLt), with the output being the main business income of the coal mining industry (XjMBIt).

- (2)

In the waste recycling subsystem of the coal production stage, the input variables include environmental management investment (XjEGIt) and the number of environmental management facilities (XjEGFPt), with outputs such as reused water (XjRWMt), coal gangue utilized in the production stage (XjPCGUt), mine land restoration area (XjMLRt), and coal gangue utilized in the utilization stage (XjUCGUt).

- (3)

Subsystem links and period links: mining-damaged land area (XjEALt), wastewater discharge (XjWDMt), and coal gangue production (XjCGPt) are intermediate linking variables from the manufacturing subsystem to the waste recycling subsystem. Reused water (XjRWMt), coal gangue utilized (XjPCGUt), and mine land restoration area (XjMLRt) are intermediate linking variables from the waste recycling subsystem in period t to the manufacturing subsystem in period t + 1. Raw coal production (XjRCPt) serves as an intermediate linking variable between the manufacturing subsystem of the coal production stage and the manufacturing subsystem of the coal utilization stage. The amount of coal gangue reused in the utilization stage (XjUCGUt) serves as an intermediate linking variable from the waste recycling subsystem of period t to the manufacturing subsystem of period t + 1 in the coal utilization stage. Depreciation of coal mining equipment (XjADMt) is a carryover variable of the manufacturing subsystem and serves as a link for DMUj from period t to period t + 1.

Coal Utilization Stage (US):

- (1)

In the manufacturing subsystem of the coal utilization stage, the input variables include fixed asset investment in the coal utilization industry (XjCUIt) and the average number of employees in the coal utilization industry (XjCUEt), with the output being the GDP generated by coal utilization (XjCUGt). The coal utilization industry includes: Production and Supply of Electric Power and Heat Power; Manufacture of Raw Chemical Materials and Chemical Products; Manufacture of Non-metallic Mineral Products; Smelting and Pressing of Metals; Processing of Petroleum, Coking, and Processing of Nuclear Fuel.

- (2)

In the waste recycling subsystem of the coal utilization stage, the input variables include environmental management investment (XjEPIt) and the number of environmental management facilities (XjEGFUt), with outputs such as waste gas treatment volume (XjWGEt), wastewater utilization volume (XjRWUt), and solid waste utilization volume (XjSWUt).

- (3)

Subsystem links and period links: Waste gas emissions (XjWGEt), wastewater discharge (XjWWDt), and solid waste produced (XjSWPt) are intermediate linking variables from the manufacturing subsystem to the waste recycling subsystem. Wastewater utilization volume (XjRWUt), solid waste utilization volume (XjSWUt) are intermediate linking variables from the waste recycling subsystem of period t to the manufacturing subsystem of period t + 1. Depreciation of coal utilization equipment (XjADUt) serves as a carryover variable of the manufacturing subsystem and serves as a link for DMUj from period t to period t + 1.

3.2.2. Expression for DMUo

The production possibility set of a coal industry circular economy system is

. The model assumes the variable returns to scale for production. This indicates that the proportion of change in the input and output of the

is not equal. Thus, we list input, output, linking, and carry-over constraints of

(

) ∈ Pt below.

represent the inputs of four subsystems: coal production manufacturing subsystem (PSMS), waste recycling subsystem in the production stage (PSWRS), coal utilization manufacturing subsystem (USMS), and waste recycling subsystem in the utilization stage (USWRS). denote the outputs of each corresponding subsystem, which include both desirable (good) and undesirable (bad) outputs depending on the indicator. are the intermediate link variables connecting different subsystems within the same period, reflecting resource flows such as wastewater, coal gangue, or reused materials. are the carry-over variables, representing resources or effects transferred from period t − 1 to t. Here, ∀j, t − 1, t for Equation (1a–r); and are the intensity vectors of corresponding to PSMS, PSWRS, USMS and USWRS, respectively. We term these outputs as being good, because they indicate increased subsystem efficiency. The main business income and the Reuse of water. We term the output of wastewater discharge as bad because of the decreased subsystem efficiency.

3.2.3. Objective Function

Referring to the recycling DDF model and the dynamic two-stage recycling model in the efficiency of the

is [

32,

38]:

Here, ≥ 0 is a weight given to period t, represent the positive relative weights of development of production and utilization stages, PS and US in period t, respectively; , , and , . Each stage weight represents the importance of the performance of the subsystem to the overall performance of circular economy development system in the coal industry.

The following formula represents the efficiency of PSMS, PSWRS, USMS, and USWRS of the

in period t, respectively. PSMS efficiency is denoted by

. PSWRS efficiency is denoted by

. USMS efficiency is denoted by

. USWRS efficiency is denoted by

. The notation is theta in the objective function. In this group, to assess the overall efficiency of period t of the

being assessed, we denote the period efficiency through the following:

In this group for period t, we denote the overall efficiency of the coal industry circular economy system by the weighted sum of period efficiency by:

represents the overall efficiency of the decision-making unit (DMU). denotes the total number of periods under investigation. indicates the period index (t = 1, 2, …, T). denotes the efficiency value in period (period efficiency). denotes the weight of period (period weight), subject to, , which is used to aggregate the period efficiencies into the overall efficiency.

3.3. Data Collection

The raw data for the indicators listed in

Table 1 are from the “China Statistical Yearbook,” the “China Energy Statistical Yearbook,” the “China Industrial Statistical Yearbook,” and statistical yearbooks of each province (autonomous region, and municipality directly under the central government). Individual missing year data is filled in using the linear interpolation method. The coal production stage includes coal mining and washing industries. The coal utilization stage includes production and supply of electric power and heat power; manufacture of raw chemical materials and chemical products; manufacture of non-metallic mineral products; smelting and pressing of metals; processing of petroleum, coking, and processing of nuclear fuel. Based on the availability of data, selects panel data from 25 provinces in China from 2011 to 2021 as the research sample.

4. Empirical Analysis

4.1. Key Factors and Development Trends in Enhancing Circular Economy Efficiency in China’s Coal Industry

The average circular economy efficiency of China’s coal industry from 2011 to 2021 was only 0.51, and there is still significant room for improvement (

Figure 3a). In both the production and utilization stages, the efficiency of waste reuse is lower than the manufacturing efficiency, which shows that improving the level of waste reuse is the key to promoting the circular economy efficiency of the coal industry.

Figure 3b shows the changing trends of the overall efficiency of the circular economy and the efficiency of each subsystem, showing a fluctuation pattern of “first reduction-then expansion-then reduction”. This trend reflects the three stages of circular economic development: transformation period, strengthening period, and rising period.

Figure 3c shows the performance of the circular economy in the production stage of the coal industry. Among them, the manufacturing efficiency showed a “single peak” trend, reaching a peak in 2015 and then rapidly declining, and remained at a low level. The overall waste recycling efficiency showed a fluctuating upward trend. Although it showed a significant decline in 2021, it rebounded quickly afterwards and gradually narrowed the gap with the manufacturing efficiency. This change shows that, under the background of the national supply side structural reform and the elimination of backward production capacity, the production model of the coal industry is transforming from the traditional extensive to the clean mode, and at the same time promoting the circular economy efficiency from a single linear model that relies on the manufacturing stage to a closed-loop model of manufacturing-waste recycling.

Figure 3d shows the performance of the circular economy in the utilization stage of the coal industry. Among them, the manufacturing efficiency is relatively stable, while the waste reuse efficiency shows a trend of first rising and then falling, and is always significantly lower than the manufacturing efficiency, indicating that the coal utilization stage is still dominated by a high-emission linear model, which is far from the low-pollution closed-loop model, reflecting that the waste treatment level has not yet fully matched the manufacturing level. The above results further emphasize that to improve the circular economy efficiency of the coal industry, special attention should be paid to the waste recycling process, especially the optimization and improvement of the utilization stage.

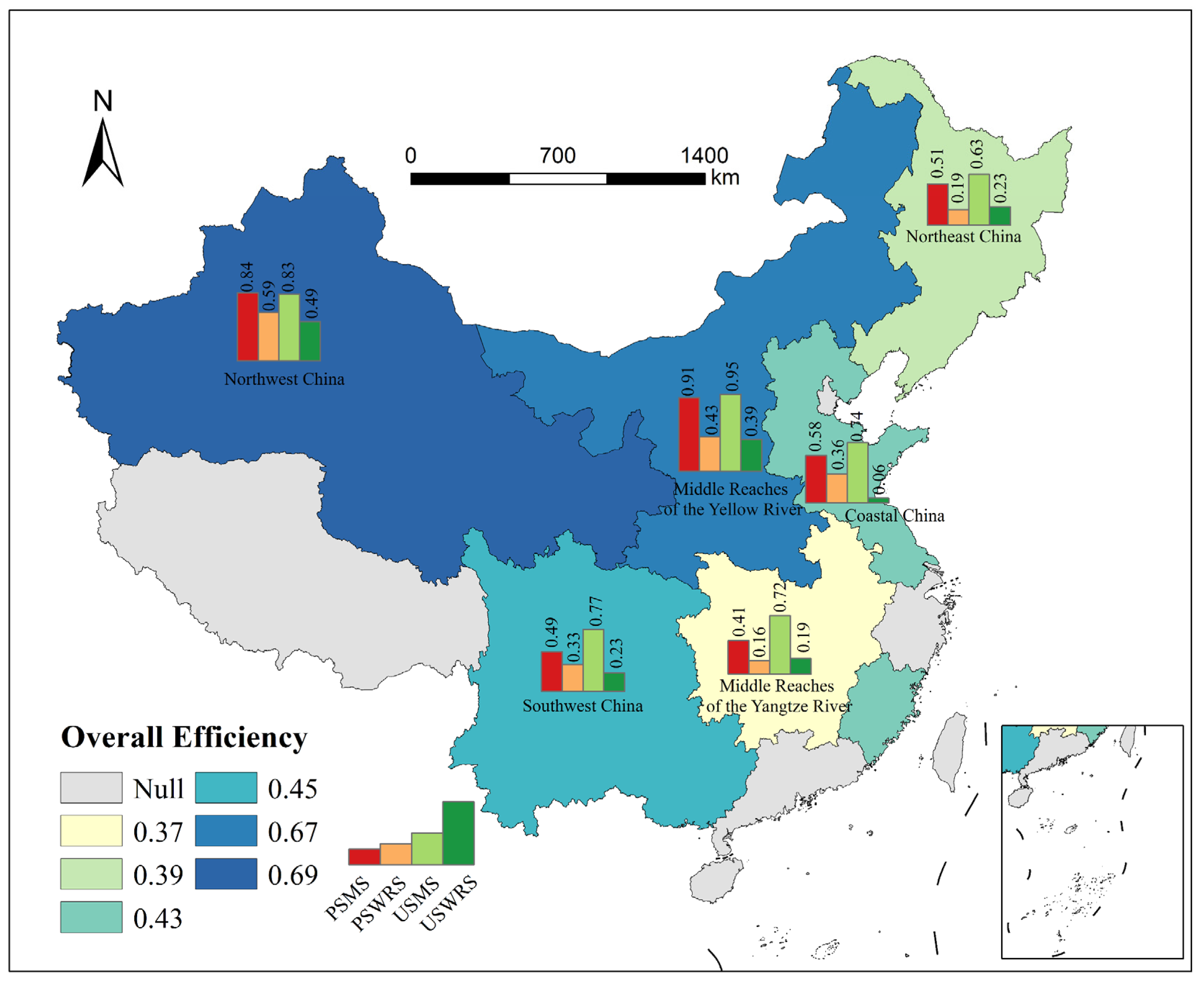

4.2. Regional Disparities and Underlying Causes of Circular Economy Efficiency in China’s Coal Industry

The significant differences in the manufacturing and waste recycling links are the main reason for the regional heterogeneity of the circular economy efficiency of China’s coal industry.

Figure 4 illustrates that the circular economy efficiency scores of the coal industry in the Northwest and the middle reaches of the Yellow River are the highest, 0.69 and 0.67, respectively. However, the waste recycling efficiency in the middle reaches of the Yellow River is lower than that in the Northwest, but the manufacturing efficiency is higher than that in the Northwest. The main reason is that the middle reaches of the Yellow River have the largest coal development base in China, and advanced coal mining and utilization technologies have improved manufacturing efficiency. However, long-term high-intensity and intensive resource exploitation have made it difficult for waste to be effectively and timely treated, resulting in reduced recycling efficiency. In contrast, the Northwest has a relatively fragile ecological background and stricter environmental supervision, which makes waste recycling efficiency higher. The circular economy efficiency of the coal industry in the southwest and coastal regions is close to and at a medium level, with efficiency values of 0.454 and 0.434, respectively. The manufacturing efficiency in the production stage in the southwest is lower than that in the coastal regions, while the waste reuse efficiency in the coal utilization stage in the coastal regions is extremely low. The main reason is that coal mining in the southwest is difficult, the regional economic foundation is relatively weak, and capital investment is insufficient, but the manufacturing efficiency is backward. The proportion of high-energy-consuming industries in the coastal regions is large, which has intensified the use of coal, but the efforts to deal with the generated waste are still insufficient. The circular economy efficiency of the coal industry in the northeast and the middle reaches of the Yangtze River is the lowest, at 0.39 and 0.37, respectively. The main reason for the low values in the two regions is that the waste reuse efficiency in the production stage is significantly lower than that in other regions. In addition, the subsystem efficiencies in the utilization stage of the two regions are heterogeneous. The manufacturing efficiency in the middle reaches of the Yangtze River is higher than that in the northeast, but the waste reuse efficiency is lower. The reason is that although the coal utilization technology in the middle reaches of the Yangtze River is relatively advanced, due to the single industrial structure, there is a lack of diversified reuse channels for waste. As China’s old industrial base, Northeast China has low manufacturing efficiency due to slowing economic development, but environmental supervision and relatively rich waste utilization channels have led to a high efficiency in waste recycling.

4.3. Provincial Characteristics and Influencing Factors of Circular Economy Efficiency in the Coal Industry

Figure 5 illustrates the overall circular economy efficiency and the efficiency characteristics at different stages of the coal industry across various provinces in China. The study reveals that the overall circular economy efficiency in Shaanxi, Shanxi, Inner Mongolia, Qinghai, and Ningxia all exceed 0.70, ranking among the highest nationwide. Although the differences in overall circular economy efficiency among these provinces are relatively small, there are notable disparities in efficiency between the production and utilization stages. Notably, Qinghai ranks first with an efficiency score of 0.85, exhibiting a high degree of balance across all subsystem efficiencies. This can be primarily attributed to the synchronized development of coal production and utilization processes in the province. Furthermore, as a key ecological conservation region, Qinghai enforces stringent regulations on coal mining approvals and waste management, which have significantly contributed to its well-balanced and high overall circular economy efficiency. In contrast, although Shanxi is China’s most important coal-producing province, the overall efficiency of its coal industry’s circular economy is only 0.760, mainly due to the low efficiency of waste reuse in the production and utilization stages, which are only 0.48 and 0.56, respectively, nearly half lower than that of Qinghai Province. This shows that although Shanxi has achieved intelligent mining of more than 50% of its coal production capacity, making its manufacturing efficiency in coal mining and utilization stages reach the forefront of the industry, the overall circular economy efficiency has not yet reached the optimal level due to the low efficiency of waste reuse. In addition, although Shanxi has implemented a series of waste treatment measures, the implementation strength and governance effect of these measures have not yet met expectations due to the large scale of waste in the coal industry. Therefore, further strengthening waste governance and improving waste reuse efficiency are still crucial to promoting the high-quality development of the circular economy in Shanxi’s coal industry. The overall circular economy efficiency of the coal industry in Jilin, Hebei, Shandong, and Hubei is lower than 0.35. Among the four provinces, Hubei, which has a smaller scale of coal mining, has significantly lower manufacturing and waste recycling efficiency in the production stage than in the utilization stage. This shows that the inefficiency in the production stage is the main factor restricting the circular economy of the coal industry. This can be alleviated by increasing the import of coal from other provinces, continuing to expand and improve the coal supply chain, and using the Yangtze River ports to establish a coal reserve base.

4.4. Comparative Analysis and Discussion

In order to clarify the advantage of the dynamic double closed-loop DEA model over the previous model, we compare its results with the DEA model without considering the double closed-loop structure (

Figure 6). The comparison indicates that the introduction of the double-loop structure led to improvements in overall efficiency for most provinces, with particularly notable increases in resource-based regions such as Shanxi, Henan, Heilongjiang, and Ningxia, suggesting that the loop structure better captures the potential benefits of waste reutilization in major coal-producing provinces. In contrast, the efficiency of consumption-oriented regions such as Beijing, Jiangsu, Shandong, and Gansu declined, which is likely attributable to insufficient waste reutilization. The results also reflect the role of contextual economic and policy conditions. In resource-based provinces, higher efficiency scores are not only driven by waste reutilization but also supported by strong policy incentives for ecological restoration and corporate investment in environmental governance. In contrast, consumption-oriented regions with limited recycling practices and weaker policy enforcement tend to exhibit lower efficiency. Therefore, the model outcomes should be interpreted within the broader framework of China’s national circular economy strategy, provincial-level environmental regulations, and firm-level governance efforts. These contextual factors highlight the importance of aligning model-based evaluations with real-world economic structures and policy environments.

Compared with traditional DEA models and standard network DEA approaches, the proposed dynamic double closed-loop DEA model possesses several distinctive functional capabilities. First, it simultaneously evaluates the production and utilization subsystems as well as their corresponding waste recycling subsystems, thus capturing the circular characteristics of the coal industry. Second, the incorporation of good and bad outputs enables a more realistic treatment of desirable outcomes (e.g., GDP, reused water) and undesirable ones (e.g., wastewater, solid waste). Third, the dynamic setting with carry-over variables allows for the intertemporal tracking of investments, assets, and land restoration, thereby reflecting both short-term efficiency and long-term sustainability. These functional features make the model more comprehensive and robust in assessing circular economy efficiency.

Nevertheless, the model has certain limitations: (1) the system boundary is relatively closed, neglecting cross-industry and cross-regional external recycling pathways; and (2) the coverage of indicators is limited, failing to fully account for diverse undesirable outputs such as carbon emissions and methane leakage. Future research may improve the scientific rigor of coal industry circular economy efficiency assessment by expanding system boundaries and broadening the range of indicators.

5. Conclusions and Policy Implications

This paper innovatively constructs a comprehensive material cycle network framework for the circular economy system of the coal industry. By integrating emergy analysis with dynamic network data envelopment analysis (DEA), we develop a comprehensive evaluation model to assess the circular economy efficiency of China’s provincial coal industry from 2011 to 2021. The study unveils the evolutionary characteristics and development patterns of the circular economy within the sector and precisely identifies the fundamental causes of inefficiency. Based on these findings, the following conclusions are drawn:

(1) This study demonstrates the practical relevance of the comprehensive evaluation model. By integrating the internal operational mechanisms of decision-making units (DMUs) with their temporal continuity, the dynamic dual-loop DEA model overcomes the limitations of traditional models in accurately capturing the efficiency of subsystems within the circular economy. This model enhances the transparency and comprehensiveness of the operational process of the coal industry’s circular economy system, effectively eliminating the “black-box” issue in evaluation. As a result, the assessment outcomes better reflect real-world conditions, significantly improving the accuracy and reliability of efficiency evaluations.

(2) The development of the circular economy in China’s coal industry can be categorized into three phases: the transformation period, the strengthening period, and the growth period. Among these, inefficiencies in waste reutilization have been identified as the key constraint on overall improvements in circular economy efficiency. In the production phase, the development model is gradually transitioning from a traditional extensive linear approach to a cleaner, closed-loop system. However, in the utilization phase, a significant gap persists between the high-emission linear model and the low-pollution closed-loop model. The pronounced disparities between the manufacturing and waste reutilization stages are the primary drivers of spatial heterogeneity in circular economy efficiency across the coal industry. Furthermore, these differences vary across regions and provinces, necessitating tailored optimization strategies to enhance circular economy efficiency effectively.

Based on the above findings, we propose several policy recommendations.

- (1)

Strengthen waste recycling and utilization as a priority.

The analysis highlights that low waste reuse efficiency, particularly in the utilization stage, is the main bottleneck restricting overall circular economy efficiency. Policymakers should accelerate the establishment of comprehensive waste treatment and reuse systems, expand diversified utilization channels for coal by-products, and promote technological innovations in waste reduction and recycling. Encouraging the development of industrial symbiosis among coal, power, chemical, and construction industries can significantly improve resource reutilization.

- (2)

Promote differentiated regional strategies.

Significant disparities across regions indicate the need for region-specific policies. In the Northwest, policies should focus on consolidating existing advantages in waste recycling efficiency while enhancing production efficiency through technological upgrading. In the middle reaches of the Yellow River, stricter environmental regulations and enhanced waste treatment infrastructure are required to mitigate the negative impact of intensive coal exploitation. For coastal regions, the urgent task is to address low waste reuse efficiency by enforcing stricter environmental supervision and strengthening incentives for clean utilization technologies.

- (3)

Address provincial-level imbalances in subsystem efficiencies.

Provinces such as Qinghai have demonstrated the benefits of balanced development across production and utilization subsystems. In contrast, provinces like Shanxi, despite their advanced mining technology, still lag behind due to weak waste reuse efficiency. Targeted measures should, therefore, be taken to improve waste treatment effectiveness, such as enhancing governance capacity, scaling up investment in recycling facilities, and encouraging technological upgrading in waste utilization. For provinces with relatively low overall efficiency (e.g., Jilin, Hebei, Shandong, and Hubei), the priority should be to improve production-stage efficiency through upgrading mining technologies, optimizing the industrial structure, and leveraging interprovincial coal trade and logistics to alleviate local inefficiencies.