1. Introduction

The EU strategy for sustainable and circular textiles [

1] aims to create a greener and more competitive textile sector. The goal is for all textile products placed on the EU market to be durable, repairable, and recyclable, made to a large extent from recycled fibers, free of hazardous substances, and produced in compliance with social and environmental standards, all at an affordable price. The strategy also aims to promote widely available and profitable reuse and repair services, with producers taking responsibility for their products along the value chain and ensuring sufficient recycling capacities while minimizing incineration and landfilling. The strategy intends to reverse overproduction and overconsumption, introduce clear product information and digital passports, and empower consumers and raise awareness about sustainable fashion.

With the planned amendment of the Waste Framework Directive [

2], each EU member state will be required to set up an Extended Producer Responsibility (EPR) scheme for textile and footwear products. Under such schemes, textile producers will contribute to the management of used and waste textiles. By being responsible for the end of life of the products they sell, producers will be encouraged to design longer-lasting textile products that are easier to reuse, repair, and recycle. This contribution will also foster investment in separate collection, sorting, reuse, and recycling capacities, contributing to the creation of a circular economy for textiles.

The European Commission is also planning to revise Regulation (EU) 1007/2011 to ensure consumers have access to accurate, intelligible, and comparable information on the textile and related products they purchase without any misleading information. This revision aims to harmonize requirements at the EU level, reducing compliance costs for companies and ensuring regulatory clarity and consistency, in line with current legislation and forthcoming regulatory developments. Aspects being considered in this revision include new fibers (e.g., recycled fibers), environmental impact, social sustainability concerns, presence of allergenic substances, deforestation, presence of nanomaterials, durability, information for easier sorting and recycling, digital labels, organic fibers, authenticity of leather and fur, commercial guarantees, and repair instructions [

3].

Encouraging sustainable consumer behaviour is a legal obligation under new European legislation. These regulations emphasize comprehensive consumer information to support informed decision-making, especially in the textile industry, known for its significant environmental impact. Tools like digital product passports are crucial for providing transparent details about a product’s footprint. The Ecodesign for Sustainable Products Regulation [

4] introduces the concept of a product digital passport, although it is not yet well-defined whether it should include information about a product’s technical performance, materials and their origins, repair activities, recycling capabilities, and life cycle environmental impacts.

With the proposed new European law on green claims and the new directive on empowering consumers in the green transition, clear criteria are being defined on how companies should prove their environmental claims and labels, including requirements for these claims and labels to be checked by an independent and accredited verifier, and new rules on the governance of environmental labelling schemes to ensure they are solid, transparent, and reliable [

5]. Although, the European Commission has recently announced its intention to withdraw the proposed EU Green Claims Directive, citing significant concerns about its potential negative impact on sustainability communication. Recognizing that the initial directive’s requirements could create substantial administrative complexity and financial burdens, the Commission is reassessing its approach. The proposed regulatory framework, originally designed to combat greenwashing and ensure transparent environmental claims, now appears to risk hindering rather than supporting genuine sustainability efforts. By potentially introducing overly intricate procedures and costly compliance mechanisms, the directive might inadvertently discourage businesses from openly communicating their environmental initiatives. This strategic reconsideration reflects the Commission’s commitment to developing more pragmatic and effective sustainability communication guidelines that balance regulatory oversight with practical implementation, ultimately aiming to promote genuine environmental transparency without creating unnecessary bureaucratic obstacles [

3]. Product sustainability claims should be built on a reliable basis; relevant, clear, transparent, and easily accessible to consumer; as much as possible consider environmental, social, and economic dimensions of sustainability; promote behavior change and longer-term impact; communicated in different channels; result from a collaborative cooperation between different stakeholders; and help consumers choose between similar products [

4].

Beyond the regulatory scope, there are more than 300 different product sustainability voluntary standards registered at ITC Standards Map; however, it is possible to realize that only two standards cover all the environmental, social, and technical quality aspects: the Certified Sustainable Economics (CSE) certification and the cradle-to-cradle Certified Product Standard, Version 4.0 (Silver Level) [

5]. The first is a quality label for products of a certified sustainable company with origin scope only applicable for Germany and Switzerland, and the former has restrictions in terms of effectively assessing environmental aspects [

6].

In academia, there are some studies about sustainability indexes encompassing environmental and social aspects but applied to companies or other product categories. Indeed, literature lacks scientific studies about how the fashion product sustainability index should be assessed considering the multiple involved criteria across all the supply chain [

7].

Despite progressive efforts, significant challenges persist in the textile sustainability domain. Current limitations include:

Limited standardized sustainability assessment methodologies;

Insufficient comprehensive evaluation frameworks;

Lack of transparent communication mechanisms;

Inadequate integration of the several sustainability metrics (as environmental, social, and durability).

This research is motivated by the critical need to develop a robust, holistic methodology for assessing fashion product sustainability. The study aims to address fundamental gaps in existing assessment approaches by creating a comprehensive multidimensional evaluation framework that integrates environmental, social, and durability considerations.

This paper aims to contribute to answering the following research questions:

RQ1. How can a methodology be developed to score the sustainability of fashion products in a reliable and transparent way, including environmental, social, and durability dimensions?

RQ2. Is there a correlation between individual social KPIs related to workers and the international composite indices related to a country’s well-being and development?

RQ3. What is the best methodology to evaluate the durability of a fashion product?

RQ4. How can product sustainability scoring be managed and improved in the textile supply chain, given its high dynamism and complexity?

The first research question is our main goal. The second research question arose from the need to have a publicly accessible methodology to assess the social risk of each product supply chain site, based on the country where each manufacturing process is located, since independent audit reports for each facility are usually not available or confidential. The third research question examines what the best methodology is to evaluate the durability of a fashion product and, in the real case, whether the use of recycled cotton can result in a final product with lower durability, potentially offsetting the environmental benefits gained from using recycled cotton fibers instead of virgin cotton fibers. Finally, the fourth question deals with sustainability index improvement in dynamic markets and policies that constantly impact the supply chain.

The research introduces a methodological approach characterized by:

Multicriteria analytical framework for systematic integration of multiple sustainability dimensions;

Practical solution development for sustainability assessment, tested with a real case study;

Potential certification scheme methodologies.

The aim is to identify practical solutions for scoring and communicating fashion product sustainability by using multicriteria analysis as a method to systematically incorporate and assess different sustainability dimensions. The study results also intend to assist in the development of certification schemes and to support private label programs for companies seeking to offer and transparently communicate the sustainability of their fashion products to customers.

By addressing critical knowledge gaps, this research offers a structured, innovative approach to understanding and implementing comprehensive product sustainability assessment in the textile sector. The study bridges existing methodological limitations and provides a robust framework for future sustainability initiatives.

The proposed methodology, despite being applied to a specific case study of a specific piece of clothing and specific material, represents a step toward creating more transparent, accountable, and environmentally responsible textile production systems, aligning with global sustainability objectives and emerging regulatory landscapes.

Ultimately, this research contributes to the broader goal of transforming the textile industry into a more sustainable, circular, and socially responsible sector. By providing a comprehensive methodology for assessing product sustainability, the study offers valuable insights for manufacturers, policymakers, and stakeholders committed to driving meaningful environmental and social change.

The paper begins with an introduction, followed by a comprehensive methodological section detailing the materials, methods, and inputs of the case study, and then presents results across environmental, social, and durability scores, culminating in a substantive discussion and conclusive insights. The use of a real case study combined with simulations pinpoints advantages and disadvantages identified in the proposed methodology. The time and localization dependency of the scoring is also discussed.

2. Materials and Methods

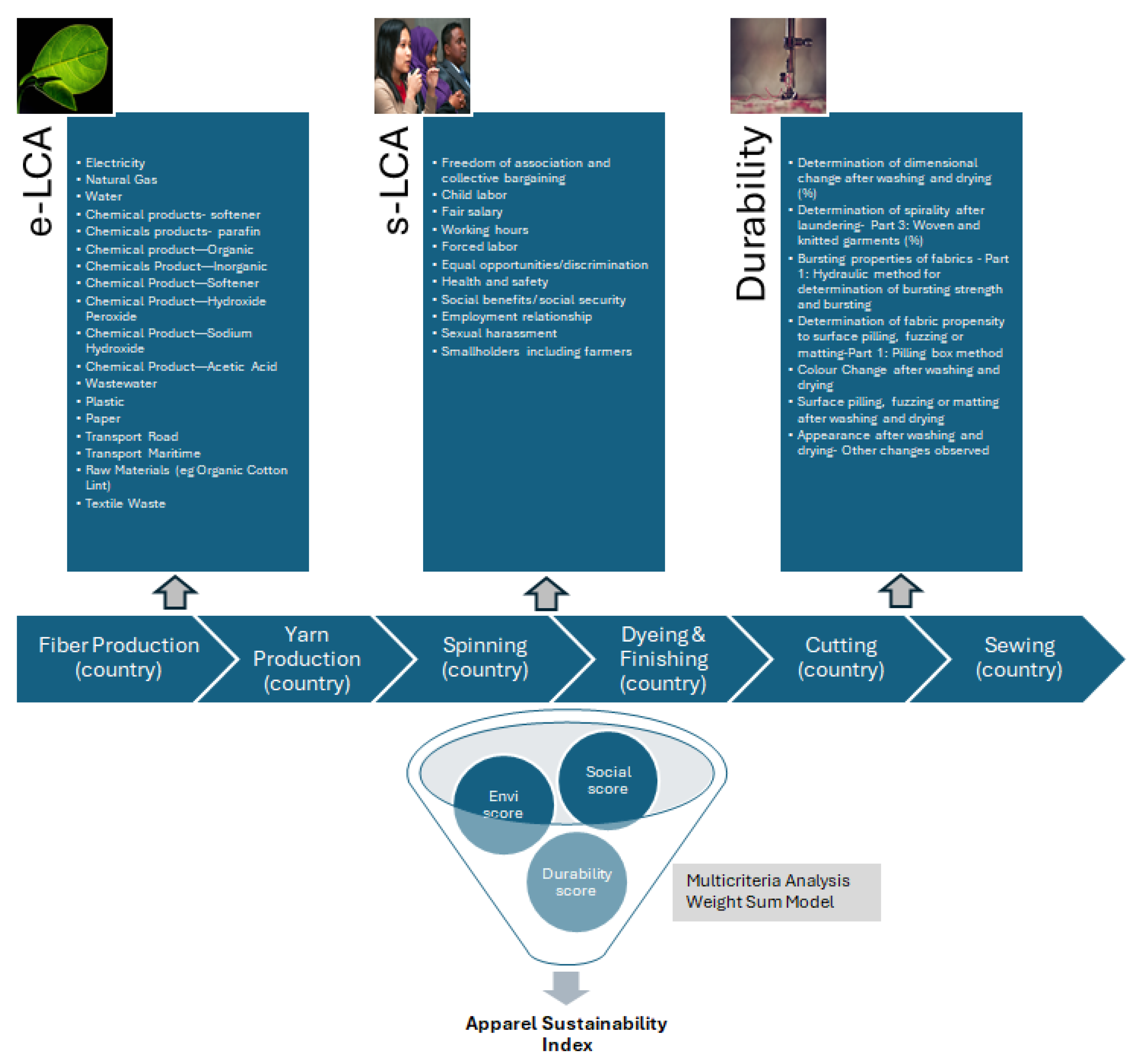

The objective of the study is to contribute to a transparent and reproducible methodology to assess the potential social performance and/or social impacts of an apparel product to be used in the product sustainability score, combined with the environmental life cycle assessment [

8] and durability. The methodology will be developed by means of a case study of a white T-shirt fabricated with 50% recycled cotton and 50% organic cotton, manufactured in Portugal by RDD [

9], which is part of a comprehensive Portuguese textile network capable of transforming cotton textile waste into innovative yarn, subsequently converted into new jersey fabrics, ultimately utilized for creating more environmentally conscious apparel. These Portuguese textile enterprises manage the complete garment production process and maintain strategic collaborative relationships with specialized knitting and dyeing facilities.

This study uses multicriteria analysis to combine the environmental and social life cycle assessment with durability to calculate sustainability scoring for apparel. Materials and methods are detailed described in the sections below.

2.1. Environmental Life Cycle Assessment (e-LCA)

Under the emerging European Union regulatory framework, sustainability labels addressing environmental or social dimensions must now undergo rigorous third-party verification or be established by governmental entities utilizing life cycle analysis techniques, including the Product Environmental Footprint (PEF) methodology [

10]. Concurrently, the initiative for substantiating green claims proposes implementing a standardized approach based on product and organizational environmental footprint methods to ensure environmental assertions and performance metrics are reliable, comparable, and verifiable. The Commission Recommendation (EU) 2021/2279 from 15 December 2021 actively encourages the adoption of environmental footprint methodologies, such as ISO 14040 [

11] and ISO 14044 [

12], across relevant policies and schemes designed to measure and communicate the comprehensive environmental performance of products and organizations [

3,

4].

e-LCA represents a comprehensive standardized methodology that quantifies potential environmental impacts, aiming to identify critical bottlenecks and provide a robust framework for comparative decision-making processes. This approach can be employed to enhance supply chain efficiency and enable comparative analyses across different supply chain configurations for functionally equivalent products. The life cycle assessment can range from highly intricate multi-stage evaluations covering a product’s entire lifecycle—from purchase through use to disposal—to more focused assessments concentrating solely on raw material extraction and manufacturing stages. The complexity of such analyses escalates significantly when considering multi-layered supply chains, inter-stage transportation, diverse use patterns, reverse logistics, and potential secondhand retail channels [

11].

The European Commission crafted the PEF as a strategic initiative to standardize approaches for evaluating and communicating a product’s potential environmental consequences throughout its life cycle. The Product Environmental Footprint Category Rules (PEFCRs) serve as comprehensive technical guidelines, offering detailed instructions for conducting environmental assessments specific to each product category. For this research, the e-LCA methodology draws upon internationally recognized standards, including ISO 14040 and 14044; adheres to the specific PEF guidelines for apparel and footwear [

13]; and utilizes openLCA software v1.11.0 for computational analysis [

14].

To gain deeper insights into the methodological challenges and optimal strategies for establishing environmental impact benchmarks in the apparel sector, a dedicated research investigation was conducted through a case study in Portugal, employing a “cradle-to-gate” analytical framework. The study focused on evaluating the environmental implications of a T-shirt fabricated from a blend of recycled and organic cotton, subsequently comparing its performance against T-shirts composed exclusively of organic or conventional cotton, as detailed in the research article “Looking for Environmental Scoring: A Case Study of a Portuguese Cotton White T-Shirt Made with Recycled Fiber” [

8]. The research proposed an innovative labelling mechanism designed to provide transparent and clear communication about product environmental performance, with the aim of mitigating greenwashing practices through the introduction of the “Envi-Score” rating system, complemented with carbon footprint, land utilization, and water depletion metrics.

After the harmonization of all the quantities, the inventory of the “cradle-to-gate” product life cycle is available in

Table 1.

As it is possible to see in

Table 1, the processes with higher consumption of power and heat (burning of natural gas) are Spinning and Dyeing and Finishing, while the former is also driving the major water and chemical consumption. In this real case, the company uses solar energy for some processes.

The inventory for the organic cotton imported from Turkey was not available, and environmental impacts were assessed based on the Ecoinvent database. The downfall of this aspect is the use of a proprietary database “Ecoinvent” to be able to compute the impact categories other than climate change (CC). However, if only the CC impact category is to be estimated, a simple Excel spreadsheet can be used to accommodate the inventory flows and respective public emission factors. This inventory is not static in time. For example, the processes can become more efficient in terms of energy needs or different chemicals, and the impact categories will also vary due to policy constraints, such as the use of more renewables at the detriment of fossil fuels, in a “energy transition” setting.

2.2. Social Life Cycle Assessment (s-LCA)

The United Nations Environmental Programme (UNEP) defines a Social and Socio-Economic Life Cycle Assessment as a comprehensive analytical approach that systematically evaluates the broader human and economic implications of a product’s entire journey. This methodology critically examines the social dimensions and potential consequences at each stage of a product’s existence, ranging from initial raw material extraction and processing through manufacturing, distribution, and active use to subsequent phases of reuse, maintenance, recycling, and, ultimately, final disposal. By mapping out both positive and negative social impacts, this assessment technique provides a holistic understanding of how products interact with and influence human and economic systems throughout their complete life cycle [

15]. Although it is the methodology proposed by the United Nations to assess the social impacts of a product along all the supply chain, the utilization is reduced by the limited number of free databases and difficult access to process and production site data [

16].

To contribute to the development of an open-source methodology in this study, the authors applied the UNEP 2020 Guidelines [

16] and the UNEP 2021 Methodological sheets [

17], the country-level social KPIs based on the International Labour Organization (IOL), and a proposal for production-site KPIs based on the Ethical Trade Initiative (ETI) code of conduct. ILO is a specialized agency of the United Nations, devoted to promoting social justice and internationally recognized human and labour rights, sets labour standards, develops policies, and devises programs promoting decent work for all women and men. The ETI is an alliance of companies, trade unions, and non-governmental organizations (NGOs) that promotes respect for workers’ rights globally and collectively tackles a few challenging issues that cannot be addressed by individual companies working alone.

The T-shirts in Portugal case study goal, scope, functional unit, boundaries, and stakeholders are defined in

Table 2.

The reference scale s-LCIA was selected as the impact assessment method, as the aim is to describe a product system with a focus on its social performance or social risk within its supply chain. The reference scale S-LCIA methodology provides a nuanced framework for evaluating organizational social performance within product systems by systematically analysing specific operational practices and their potential social implications. This approach focuses on examining organizational activities through predefined performance reference points, utilizing diverse data sources, including empirical evidence, contextual information, and expert evaluations, to generate immediate assessments of social performance indicators. Unlike comprehensive impact analyses, the reference scale approach primarily concentrates on current organizational practices and their direct observable characteristics, offering a snapshot of potential social consequences without extensively tracing long-term ripple effects. By leveraging available information, this methodology aims to estimate the probable magnitude and significance of potential social impacts, providing stakeholders with a pragmatic, snapshot-style understanding of an organization’s social performance within its specific product system context, while acknowledging the limitations of not fully exploring extended downstream consequences [

16].

Workers are the only stakeholder group considered in the study, defined as personnel working both in the cultivation and processing stages of raw materials at the final production of the T-shirt according to the product system and boundaries identified in

Figure 1.

The data collected is not dependent on the FU, i.e., the collected inventory data and the subsequent impact assessment results shall not be expressed per FU.

In opposition, to score the social performance of the product, this study suggests a country-level risk assessment, complemented with specific data of each organization in the supply chain. This means that for a precise calculation of the social score of the product, it is expected to have each facility of the supply chain audited by a third party and checking the compliance level with the ILO standards. The downfall of relying solely on this third-party audits is that generally they are not available due to costs or are not disclosed to the public.

2.2.1. Country Social Performance

To calculate the social performance at country level, it is considered the set of KPIs in each country, linked with the “farm-to-gate” supply chain of the product and in alignment with the s-LCA impact subcategories for the workers’ stakeholders group in the s-LCA methodology. The main part of the KPIs was collected from the ILOSTAT database [

18] and from the Sustainable Development Goals (SDG) Indicators Database [

19], complemented with World Bank database [

20], World Health Organization (WHO) [

21], Georgetown Institute for Women, Peace and Security [

22], and Walk Free [

23] for the topics related to child labour, sexual harassment, and forced labour.

ILOSTAT is leveraged by the International Labour Organization, the United Nations agency dedicated to promoting decent work and social justice worldwide.

The SDG Indicators are the global indicator framework for the Sustainable Development Goals and targets of the 2030 Agenda for Sustainable Development.

WHO Global Database on Prevalence of Violence against Women is a comprehensive database on the prevalence of the two most common forms of violence against women globally: intimate partner violence and sexual violence by someone other than a partner, referred to as non-partner sexual violence.

Georgetown University’s Institute for Women, Peace and Security is an academic institute that seeks to promote a more stable, peaceful, and just world by focusing on the important role women play in preventing conflict and building peace, growing economies, and addressing global threats like climate change and violent extremism.

Walk Free is an international human rights group focused on the eradication of modern slavery in all its forms.

To have a wider analysis for the country risk assessment, the KPIs were collected for Portugal and Turkey as producing countries for the T-shirts case study, but also for China and India as main producers for fashion products. In the real case study, organic cotton is imported from Turkey, while recycling and spinning, knitting, dyeing and finishing, and cutting and sewing units are in Portugal, as detailed in

Figure 1. For the simulations and tests of the scoring, another traceability option was taken, cotton fiber (organic and conventional) imported from India to China for recycling and spinning, knitting, dyeing and finishing, and cutting and sewing, a similar supply chain, as in the RDD case, only with different locations.

The data available in

Table 3 pertains to the most recent figures from each relevant database. In cases where a country did not report the related data, the worst-case scenario was assumed. As can be observed, the performance indices exhibit significant variability in their representation, with some expressed as percentages and others as numerical values. Moreover, the interpretation of these indices demonstrates contrasting evaluation criteria: for certain categories (e.g., C, D, E, F, and K), a lower index indicates superior performance, whereas in other categories (including A, B, H, I, and J), a higher numerical value signifies better outcomes. This inherent methodological heterogeneity introduces substantial challenges when attempting to conduct comprehensive comparative analyses of a product’s social impact across different country contexts.

The first column of the table lists the s-LCA impacts for the “workers” subcategory. The second column shows the individual KPIs selected as relevant to the impact subcategories. The subsequent columns present the KPI values for Portugal, Turkey, China, and India. This table can also change with time.

Unfortunately, it is not possible to find complete and up-to-date data for all the countries. Therefore, it would be crucial to define social KPIs that are widely available per country and for several years, allowing for acceptable comparisons between countries. To address this issue, the authors have examined several internationally recognized composite indicators that combine different dimensions of a country’s well-being and development. This led to the following research question:

RQ2. Is there a correlation between the individual social KPIs related to workers and the international composite indices related to a country’s well-being and development?

The

Table 4 illustrates composite metrics designed to assess multiple dimensions of a country’s social and economic advancement.

The Human Development Index (HDI) uses a scale of 0 to 1, with 1 representing the highest level of human development. Countries are typically categorized based on their HDI score: Low (0 to 0.55), Medium (0.55 to 0.70), High (0.70 to 0.80), and Very High (0.80 and above).

The Human Rights Index is a scale used to measure the extent to which people are free from government oppression and have their rights protected. It typically ranges from 0 to 1, where 0 represents the lowest level of human rights and 1 represents the highest.

The ITUC Global Rights Index rates countries on a scale from 1 to 5+, with 1 indicating the best respect for worker rights and 5+ indicating the worst. A high rating (closer to 5+) signifies that workers in the country have limited or no right to collective action due to government failure to guarantee those rights.

The Social Progress Index ranges from 0 to 100, with higher scores indicating better social progress. The index measures a country’s performance on social and environmental aspects, encompassing basic human needs, foundations of well-being, and opportunity.

The Gender Development Index, calculated by the United Nations Development Programme, ranges from 0 to 1. A GDI of 1 indicates that women and men have equal human development achievements, while a GDI below 1 suggests men have higher human development achievements, and a GDI above 1 indicates the opposite. Lower GDI values (closer to 0) indicate absolute gender inequality, where one gender experiences significantly lower human development outcomes across all dimensions.

The Human Freedom Index measures freedom on a scale of 0 to 10, where 10 represents the highest level of freedom and 0 represents the lowest. The index uses 86 indicators to assess both personal and economic freedoms.

The Index of Economic Freedom scores countries on a scale of 0 to 100. A score of 100 indicates the most economic freedom, while 0 represents the least. The Index measures the degree of economic freedom in a country based on four main areas: rule of law, government size, regulatory efficiency, and open markets. The Index of Economic Freedom is calculated by averaging component scores across the four main areas. The components are further broken down into subcomponents, each of which is assigned a score.

By analyzing the values of these composite indices for the countries of interest, it is possible to gain a broader understanding of their social performance and potential social risks. This information can be used to complement the specific KPIs listed in

Table 3 and provide a more comprehensive assessment of the social sustainability of these countries.

2.2.2. Producer Social Performance

In this study, organizational-level performance is defined based on primary data collected through independent audits performed by third parties. These audits are aligned with the ILO Standards, such as the ETI, the Sedex Members Ethical Trade Audit (SMETA), or the amfori Business Social Compliance Initiative (BSCI) audit [

31]. This approach ensures that the social risk assessment is conducted in an independent manner rather than relying on self-assessments, which may fail to identify the real social risks in the supply chain.

RDD has provided the SMETA 2-pillar social audit reports for their recycling and spinning partners, as well as the knitting unit, both located in Portugal. Dyeing and finishing, as well as the cutting and sewing processes, are subcontracted. The SMETA 2-pillar audit report for the subcontracting company was shared, but not for the individual subcontracted companies. As a result, the subcontracted operations have not been considered here.

After aligning the SMETA 2-pillar results with the s-LCA subcategories for the workers stakeholder group, the findings are summarized in

Table 5.

A SMETA 2-pillar audit focuses on two core areas: labour standards and health and safety, providing a thorough review of these critical areas to ensure fair treatment and safe working conditions.

Table 5 presents the number of non-conformities (NC), observations (O), and good examples (GE) identified in each section, corresponding to the selected s-LCA subcategories

According to the reports shared, only a very reduced number of non-conformities were detected in the case study production sites.

The study is limited to the “workers” stakeholder group and does not include other stakeholders like consumers, local communities, society, children, and other value chain actors. Additionally, positive social impacts that may result from the product production process were not considered, as they can be more challenging to quantify. These limitations present opportunities for more focused studies to explore the social impacts across a broader range of stakeholders and to investigate the positive contributions in greater detail.

2.3. Assessment of the Product Durability and Performance

Product lifetime is defined as the period during which a product can be used for its intended function with appropriate use. The product lifetime is influenced by several factors: the intrinsic product-specific attributes that contribute to its potential lifetime (e.g., physical toughness and design features); the extrinsic factors that influence the likelihood of a product reaching its potential lifetime; and the repairability potential of the product [

13].

Extending the use of products, often referred to as increasing product lifespans, is one of the most effective environmental strategies, as it has great potential to prevent waste and reduce production, consumption (acquisition and disposal), and transport.

The paper focuses on functional durability, which is anchored in many characteristics such as tear/tensile/seams/bursting strengths, yarn and seam slippage, abrasion resistance, pilling, dimension stability, colour fastness, and quality of trimming. Textile functional durability represents a complex, multifaceted assessment of a fabric’s ability to maintain its essential physical and performance characteristics under diverse environmental and usage conditions, encompassing a comprehensive evaluation of multiple interconnected factors. This intricate analysis extends beyond simple wear resistance, integrating sophisticated assessments of material composition, structural parameters, and performance metrics, including fiber characteristics (e.g., fiber composition and length), yarn configuration, fabric construction techniques, chemical treatments, and finishing processes. Durability testing methodologically examines critical performance dimensions like mechanical strength, abrasion resistance, seam integrity, visual degradation (including pilling and color stability), laundering effects, dimensional consistency, and additional functional properties such as absorbency, thermal regulation, moisture vapor transmission, and air permeability. The ultimate goal is to determine how long the garment will last and how well it will perform its specific function, ensuring it meets user needs and maintains its quality over time [

32,

33]. The relevant scope of properties to determine the durability of a product differs based on the intended use and type of material tested. Some ISO Type 1 labelling, as EU Ecolabel requirement for textiles, Nordic Swan, and Blue Angel, identify the methods they use, the categorization, and thresholds already available. The Refashion has implemented in France a system with bonuses and penalties based on the durability of products, offering detailed rules for evaluating durability by product type. The European Commission has recently officially approved the final version of the Product Environmental Footprint Category Rules (PEFCR) for apparel and footwear version 3.1. The PEFCR aims to standardize sustainability metrics. The rules introduce a science-based and impartial method to assess the environmental impact of clothing and shoes across their entire life cycle, identifying the testing plan and scoring rules for durability evaluation per type of product.

As a general guideline, the average number of wears (uses) for a T-shirt is assumed to be 45, with 2 uses before washing [

34]. However, for a more precise evaluation of product sustainability, it is important to assess the actual durability of each product.

Recycled cotton fibers usually need to be blended with other virgin fibers to improve strength and durability [

35]. It was considered important to understand if T-shirts made with 50% recycled cotton have a reduced lifetime compared to T-shirts made with 100% organic cotton or 100% conventional cotton, as this could impact the environmental benefits of using recycled cotton.

To address this, a study was conducted to compare the physical durability of T-shirts with the following compositions: 50% recycled cotton and 50% organic cotton, 100% organic cotton, and 100% conventional cotton. The T-shirts were subjected to laboratory tests according to the testing plan defined in

Table 6.

The testing plan was based on the PEFCR [

13] for knit non-sport T-shirts, with some adaptations to the laboratory’s technical capabilities. Specifically, the tests according to EN ISO 12947-2 [

43] for the determination of abrasion resistance were not performed since out of laboratory capability and the ISO 15487 [

44] test method was replaced by ISO 6330 [

36], complemented with the ISO 105-A02 [

42] for colour change, the ISO 12945-1 [

41] for pilling assessment, and appearance visual assessment, which are commonly used in the textile industry.

A total of 54 T-shirts were manufactured for the testing process, with 18 T-shirts produced for each composition. From these, samples consisting of 6 T-shirts per composition were selected for laboratory testing. Each test was repeated three times to ensure accuracy and reliability of the results.

For the cotton T-shirts, a domestic washing cycle at 40 °C was applied, followed by air-drying without ironing, with conditions below:

Type of washing machine: A horizontal-axis front-loading type

Washing procedure: 4N (40 °C)

Drying procedure: A line dry

Detergent used: Reference detergent 3 (detergent ECE) + Sodium-perborate tetra-hydrate + TAED

Number of revolutions: 10,800 (Pilling box)

After performing the laboratory tests, the physical durability score of each sample is calculated by taking the average of the “test points” reached in each test result, as shown in

Table 7. For results lower than the “basic score,” zero points are assigned, and no weight will be applied.

For different product categories, the durability score calculation leverages the Product Environmental Footprint Category Rules (PEFCR), which already provide comprehensive testing plans and detailed scoring tables specific to various fashion product types. While the PEFCR framework offers a robust methodology for different apparel and footwear categories, some adaptations will be necessary to ensure precise durability evaluation across diverse product ranges.

The garment’s lifespan can also be influenced by the social aspects that denote the time the garment is deemed socially acceptable or “in trend.” Socially durable garments are those that can be used over a long period of time and still be appreciated or accepted [

45]. This social dimension of durability was not included in this case study since it is subjective and not relevant when comparing the same type of product, as in the cotton T-shirts case study.

The analysis of e-LCA results of several scientific studies reveals that, with the current technologies, reuse allows for saving more impacts than recycling, but the two strategies do not exclude each other and should be integrated because they are addressed to different qualities of textile waste [

46]. Despite the challenges inherent in recycling blended textiles, which arise from the fundamental structural incompatibilities between natural and synthetic polymers, current textile waste recycling methodologies remain limited. Mono-material recycling techniques, while more sophisticated and well-established, predominantly yield downcycled products rather than achieve comprehensive material regeneration, thus highlighting the persistent technological and engineering obstacles in creating truly sustainable textile recycling processes. Ongoing research is progressively addressing these limitations through technological innovations, including refined sorting mechanisms, advanced chemical processing, and emerging biochemical methodologies. Nevertheless, comprehensive valorization strategies for mixed-fiber textile waste remain predominantly unexplored, creating a significant impediment to both scientific research and industrial textile recycling development [

47] and making it even more important to focus on the product’s durability in use and reuse phase.

2.4. Multicriteria Analysis

Multicriteria analysis (MCA) is advocated by several authors as a valuable tool for assessing sustainability because it allows for the consideration of multiple, often conflicting, qualitative and quantitative criteria across different dimensions (economic, environmental, and social) [

48]. This approach helps in making more informed and robust decisions related to sustainability, especially given the complex and multifaceted nature of sustainability itself.

The weighted sum model (WSM) is a widely used multicriteria decision analysis (MCDA) method due to its simplicity and ease of implementation [

48,

49]. It assumes that the decision-maker has a set of criteria, each with a specific weight or importance; the performance of each alternative is measured on each criterion through normalization; and these performances are then aggregated into a single score for each alternative. The aggregation is done by multiplying the performance of each alternative on each criterion by the weight of that criterion and then summing these weighted performances.

For normalization, the min-max feature scaling can be applied, a data preprocessing technique that transforms numerical features to a range between 0 and 1. This is achieved by subtracting the minimum value of the feature and dividing by the range (maximum value minus minimum value). It is a linear transformation that preserves the relationships among the original data values.

The score (S) of an alternative (A) is calculated as per Equation (1):

where w

i is the weight of the i-th criterion, a

ij is the performance of alternative A on the i-th criterion, and Σ represents the sum of the weighted performances across all criteria.

The alternative with the highest score is considered the best option.

Simplicity, transparency, allowing the incorporation of different criteria (quantitative and qualitative), units and scale, and providing a clear ranking of the alternatives make this method a good option for a product sustainability index incorporating the triple bottom-line sustainability approach based on well-defined and measurable criteria to be easily verified and understandable by the consumer. While the WSM has some limitations, such as the assumption of independent and linearly aggregated criteria and the potential subjectivity in weight determination, these limitations can be addressed through sensitivity analyses and stakeholder engagement. For the purposes of the product sustainability index, an equal weighting scheme for the criteria can be considered to ensure a balanced and transparent assessment, and normalization considers the KPI’s range for a broader score. The A to E rating system conversion, with 20 percentile increments spanning 0 to 100%, is set for each aspect separately, for e-LCA, s-LCA, durability, and, finally, the sustainability score.

3. Results

In this section, the results are presented after applying the methodology described previously to the real case study and to simulations. This includes the e-LCA, the s-LCA, and the durability tests for the T-shirt made with 50% recycled cotton and 50% organic cotton, in comparison with the results for T-shirts made with 100% organic cotton and 100% conventional cotton. The application of the methodology to the T-shirts case study provides a contribution toward validating the methodology and offers input for future improvements.

3.1. Environmental Life Cycle Assessment

The environmental impact assessment for this study utilized a modified EF method, specifically version 2.0, designed to enable comprehensive normalization of environmental data. This analytical approach encompasses an extensive evaluation framework that considers 16 distinct environmental impact categories, allowing for a holistic aggregation of complex environmental metrics into a single, comprehensible score. The normalization process was conducted by applying standardized normalization factors sourced from the 2017 Joint Research Centre (JRC) Technical Report [

50], which provides a rigorous scientific basis for comparing environmental performance, as shown in

Table 8. Notably, the methodology deliberately avoided applying weighting techniques when calculating the environmental score for individual T-shirts or when comparing them against the reference PEFC (PEF RP) [

8] benchmark, ensuring a neutral and transparent assessment of environmental impact that preserves the integrity of the raw data without introducing potential bias through subjective scoring mechanisms.

The normalization analysis reveals that incorporating recycled cotton can significantly diminish environmental consequences compared to T-shirts manufactured exclusively with organic cotton and demonstrates an even more pronounced reduction when juxtaposed against T-shirts produced entirely from conventional cotton. These findings were benchmarked against the PEFCR standard T-shirt, normalized for a 200 g garment and excluding the use phase, which registered 2.32 × 10

−2 person-years of normalized environmental impact. The most significant impact categories for each product variant are prominently highlighted in the accompanying analytical

Table 8.

A proposed scoring mechanism ranging from A to E could be developed to enhance consumer comprehension by utilizing the normalized impact of the PEF-RP (person-years) as the most adverse scenario, representing classification E. The hypothetical optimal scenario (A) would conceptually represent zero environmental impact, with intermediate classifications B, C, and D incrementally escalating by 20% until reaching the most unfavorable environmental performance level of E. The following Envi-scores were calculated based on the percentage of improvement versus PEFCR standard T-shirt:

T-shirt 50% Recycled cotton + 50% organic cotton: B score (74%);

T-shirt 100% organic cotton: B score (66%);

T-shirt 100% conventional cotton: D score (37%).

The detailed results of this study are available in the article of the same authors, “Looking for Environmental Scoring: A Case Study of a Portuguese Cotton White T-Shirt Made with Recycled Fiber” [

8].

3.2. Social Performance in the Production

To address the research question RQ2, “Is there a correlation between the individual KPIs listed in

Table 3 and the international indices listed in

Table 4” the Excel Data Analysis ToolPak’s Correlation tool (available in the version Microsoft® Excel® for Microsoft 365 MSO (Version 2507 Build 16.0.19029.20136) 32-bit) was applied to all the KPIs. The Pearson correlation coefficients (r) greater than +0.5 or lower than −0.5 were identified, as correlation coefficients closer to −1 or +1 indicate a stronger relationship, while values closer to 0 indicate a weaker relationship [

51]. The Pearson correlation is a statistical measure that quantifies the strength and direction of the linear relationship between two continuous variables.

This analysis revealed the following high correlations (|r| ≥ 0.9) between the combined international indices:

Human Development Index and the Gender Development Index;

Human Rights Index and the Human Freedom Index;

Global Rights Index, the Social Progress Index, and the Human Freedom Index.

Considering the existence of higher correlation coefficients with the remaining social KPIs but also acknowledging that individual KPIs for some countries were not available, we only discarded the Human Development Index and retained all the other combined international indices. This was done to maintain more consistency in the capability to predict the individual social KPIs. The Human Development Index had the lowest combined correlation with all individual indicators compared to the other indices.

Table 9 shows the list of proposed KPIs to evaluate the country’s social risk, along with their correlation with the other individual indicators. Each KPI is identified with the letter assigned in

Table 3, followed by the correlation factor in the format “letter (r).” Additionally, the “Prevalence—Modern Slavery Index (Number per 1000 people)” was added to the list, as its correlation is below 0.50 with all the other composite indicators. This index is established by the dedicated organization Walk Free, which focuses on eradicating modern slavery by combining several factors.

On the other hand, the KPI “Poor persons covered by social protection systems (%)” was discarded, as it did not show a high correlation with any of the other KPIs.

With the normalization of the proposed social KPIs, a score for the social performance of each country was calculated. The normalization was done as a percentage, with the range of each index as shown in

Table 4.

The Prevalence—Modern Slavery Index was considered as a penalization index, to be subtracted from the average of the other normalized indices. The range for this index was set as [105, 0], where 105 represents the estimated number of persons per 1000 population living in situations of modern slavery for the worst-performing country, North Korea, in 2021.

The resulting social performance scores per country are presented in

Table 10.

Turkey, China, and India score below 50%, indicating high-risk countries in terms of risk for human and/or workers’ rights violations and where there is no guarantee of rights. Portugal scores 82%, showing some weaknesses in social terms and where it can happen some repeated violations of some rights, but with far less risks in social terms.

The SMETA audit results, considered as primary data, provide an indication of a company’s compliance with ethical standards, particularly in areas such as labour practices, health and safety, environmental impact, and business ethics. The SMETA results are not a simple pass/fail rating, but rather a detailed report that highlights both areas of compliance and non-compliance, along with recommendations for improvement.

To score the company’s compliance according to the s-LCA subcategories, the following approach was taken:

100% compliance was assigned when no non-conformities were found.

If no immediate corrective action was requested, the percentage of compliance was calculated based on the number of non-conformities found per number of questions, per subcategory.

For non-conformities that required immediate remediation, a 30% penalty was applied to the overall score. This is because these non-conformities are related to breaches of local or national law, as opposed to a failure to meet the expectations of the ethical code, representing legal and reputational risks to the customer and the employer [

52].

No positive effects from “good examples” identified in the audits were considered in the factory social score to avoid masking the results.

The following social performance scores were found per company, as only one non-conformity was detected in each facility, and no immediate correction was required:

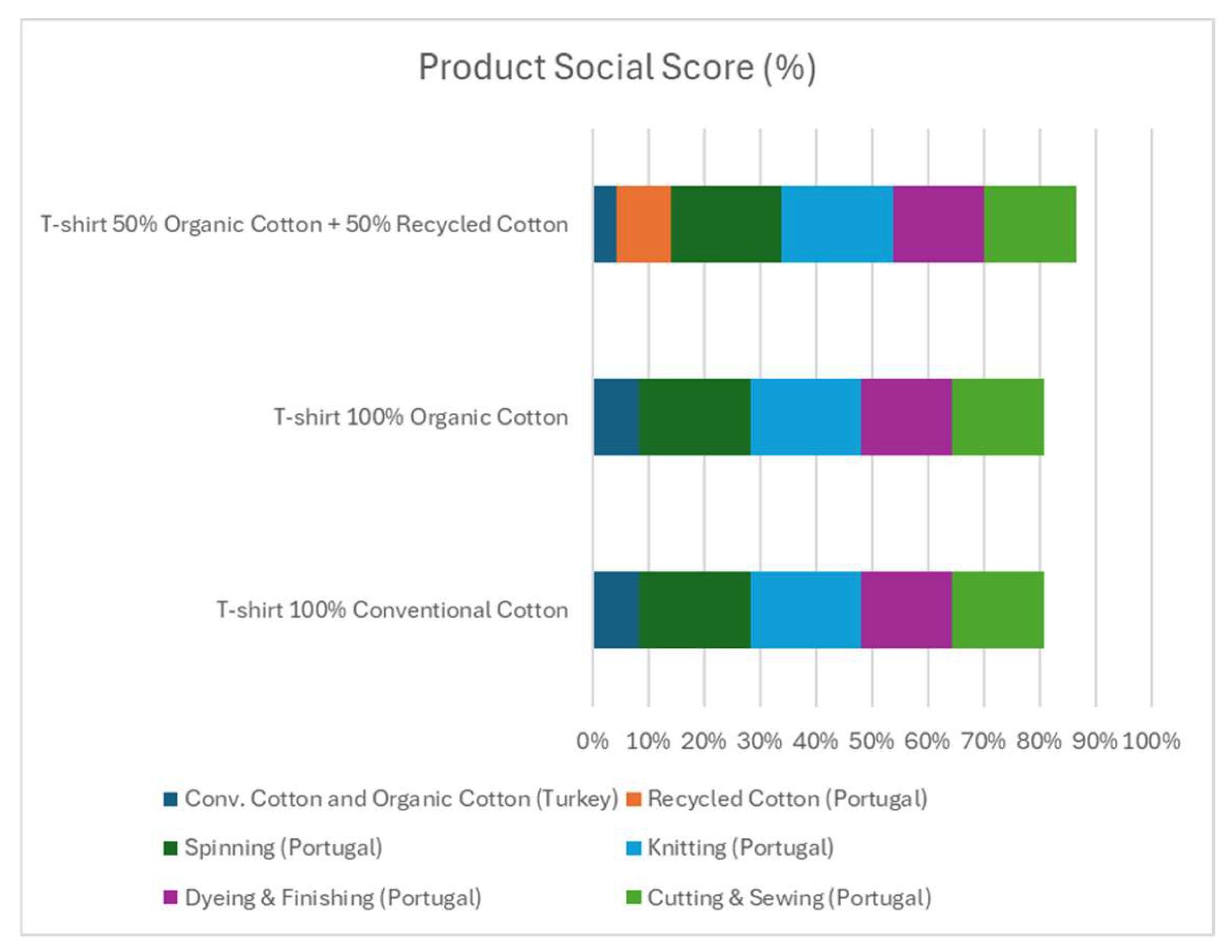

Country and factory scores were aggregated as shown at

Figure 2 to calculate the product social score for the T-shirt made with 50% recycled cotton produced in Portugal and 50% organic cotton imported from Turkey and comparison with the other two scenarios as applied for the e-LCA: the T-shirt made with 100% conventional cotton and the T-shirt made with 100% organic cotton both imported from Turkey.

Based on the Guidelines for Social Life Cycle Assessment [

16] and in parallel with the approach used for the environmental life cycle assessment, a reference scale for social performance evaluation was defined, ranging from A to E:

A (Low Risk): 80–100% score

B (Medium Risk): 60–80% score

C (High Risk): 40–60% score

D (Very High Risk): 20–40% score

E (Critical Risk): 0–20% score

The T-shirt made with 50% recycled cotton and 50% organic cotton achieved a better social performance score of 87%, classified as low risk. The other two T-shirts (100% organic cotton and 100% conventional cotton) also achieved a low-risk classification, with a score of 81%. Both cases considered recycled cotton fibers produced in Portugal and virgin cotton fibers imported from Turkey.

However, it is important to note that even with these relatively high social performance scores, there are no absolute guarantees against social incidents in the supply chain, especially related to the primary production of cotton in Turkey, which is classified as a high-risk country based on the same reference scale. This risk can be mitigated if the methodology requires a third-party social audit report of the supply chain hotspot, which is, in this case, the cotton production in Turkey.

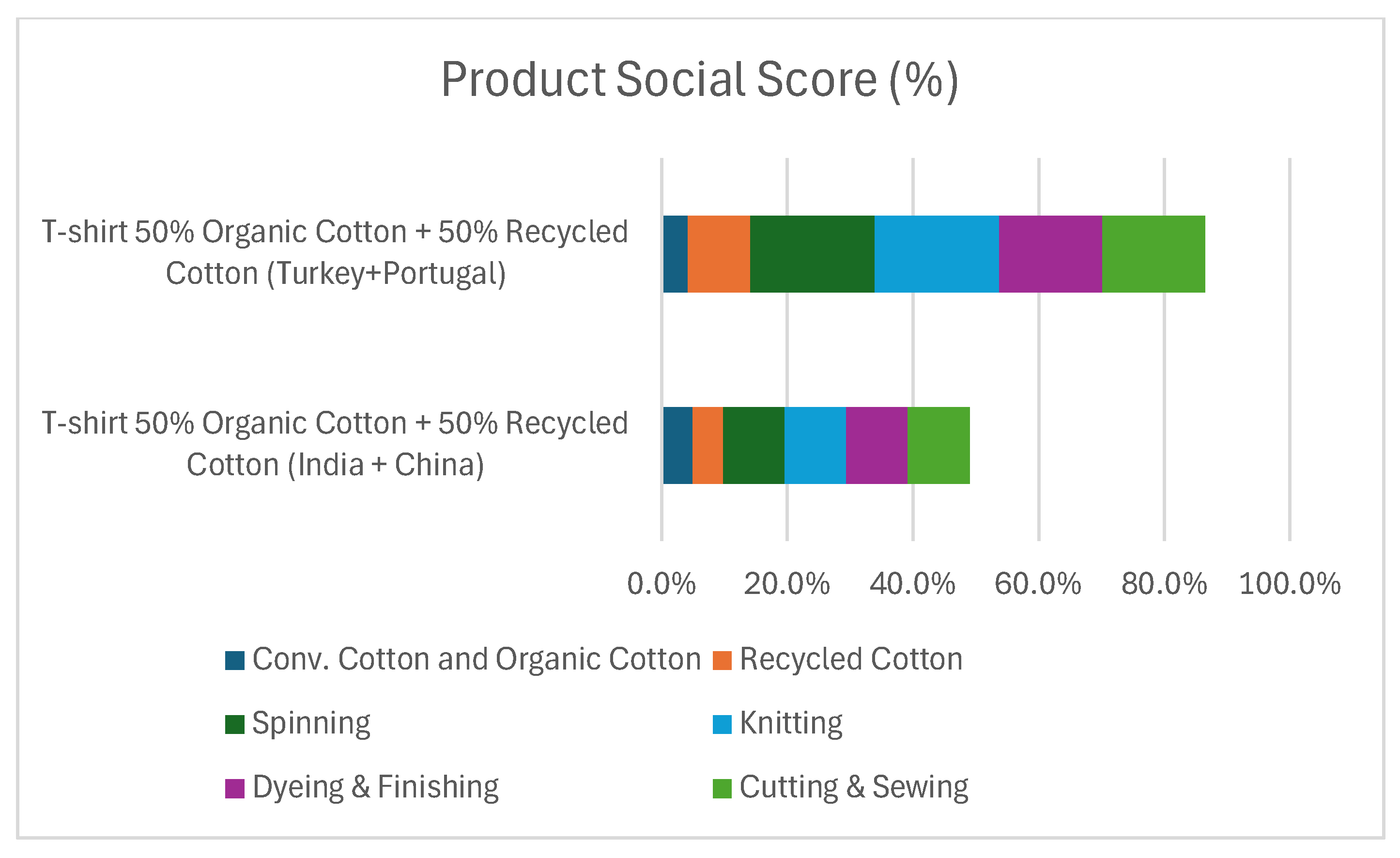

For analytical modeling and impact assessment, a comprehensive simulation was executed using a hypothetical supply chain scenario. Within this theoretical framework, organic cotton sourced from India undergoes international export to China, where it is subsequently integrated with recycled cotton fibers through a spinning process. The manufacturing trajectory then progresses through sequential stages of knitting, dyeing, surface finishing, cutting, and final assembly, each performed within China’s industrial manufacturing ecosystem. As shown in

Figure 3, only the country social scores were used for this case since no audit reports were available.

In this hypothetical scenario, the product’s social score decreases from 87% to 49%, indicating a shift from a product with low social risk to one with high social risk.

Cotton Sourcing: Moving the sourcing of virgin cotton from Turkey to India may benefit the product’s social score, as Turkey currently shows a slightly lower social score compared to India.

T-Shirt Production: However, relocating the production of T-shirts from Portugal to China could result in a significant increase in social risk. This risk may be mitigated through third-party social audits of the facilities involved in the production process. According to existing consolidated social KPIs, production in China presents much higher social risks compared to production in Portugal.

To the ILO, a higher social risk typically signifies significant issues related to labour practices, worker rights, and overall social impact in the production process. These issues may include child labour, the use of children in production, which is strictly prohibited by ILO standards; forced labour, where workers are coerced into labour against their will; poor working conditions, such as hazardous or unsafe environments that do not meet ILO standards; and low wages, where workers are paid below the living wage, affecting their quality of life.

3.3. Durability and Performance

The research investigating the performance of recycled cotton garments through repeated domestic washing cycles reveals a complex transformation process characterized by dynamic material behaviour, demonstrating a significant mass increase during the first 10 wash cycles, followed by mass reduction beyond the tenth washing cycle, with dimensional changes proving more influential than fiber loss. Also document substantial variations in critical fabric attributes, including thickness, density, and air permeability, highlighting a nuanced interaction between laundering conditions and textile properties. Particularly noteworthy were the pronounced changes in air permeability and unrecovered elongation, which indicated the fabric’s structural sensitivity to repeated washing processes [

53]. Compared to 100% virgin cotton yarns, blend yarns containing pre-consumer recycled fibers in a ring spinning showed increased coefficient of mass variation (CVm%) and imperfections, along with reduced strength and elongation values proportional to the recycled fiber percentage [

54]. The research determined that blend yarns containing up to 25% pre-consumer recycled fibers were suitable for producing both knit and woven fabrics, offering a viable approach to incorporating recycled materials while maintaining acceptable yarn performance [

55]. In another study, it was determined that there was a decrease of nearly 45% in the tear strength of fabrics obtained by mixing 40% recycled fiber, although the loss in tensile strength was less than the loss in tear strength [

56]. Another study compared the physical properties of different jersey fabrics using conventional, post-industrial, and post-consumer recycled cotton fibers for weight, spirality, dimensional stability, burst resistance, and pilling. Differences in weight were minimal, but in contrast, in dimensional stability (shrinkage), spirality, and pilling box test, we observed some variations; however, this does not indicate a significant decline in the product characteristics, even because recycled cotton yarn was produced using open-end (rotor) spinning, which is more likely to produce yarns more prone to pilling. Regarding the bursting resistance, the fabrics containing recycled cotton exhibited lower performance when compared with the fabrics made with virgin cotton [

57].

Laboratory tests to evaluate product durability and performance were conducted by a laboratory accredited according to ISO/IEC 17025 [

58] for textile testing.

The tests were conducted on three replicates of each T-shirt composition, each approximately 1.70 m in width and weighing 150 g per square meter. For dimensional change and the fabric’s propensity to surface pilling, fuzzing, or matting, the results presented represent the worst-case scenario found. Specifically, this includes the modulus of the largest deviation observed in the first test and the results for fuzzing in the second test.

After performing the tests, the physical durability score of each sample was calculated by taking the average of the “test points” achieved in each test result, as shown in

Table 7. For results lower than the “basic score,” zero points should be assigned.

Samples were awarded points per test, as presented in

Table 11.

The T-shirt made with recycled cotton exhibited better results and earned more points in terms of dimensional change after five care cycles. However, it showed the worst results and fewer points regarding fuzzing after one care cycle. While it is generally expected that fuzzing would increase with more care cycles due to the cumulative effect of mechanical stress on the fabric, there can be scenarios where the rate of new fuzz formation slows down after the initial loose fibers are removed. Therefore, it is possible, though not guaranteed, that fuzzing results could be better (less pronounced) after 15 care cycles compared to after just one, depending on the specific characteristics of the cotton and the care conditions [

54,

59].

In terms of spirality and bursting properties, the fabric with recycled content achieved slightly lower results, though this did not impact the number of points awarded. For the other tests, the results were comparable to those of T-shirts made with virgin cotton fibers, leading to similar final durability scores across all T-shirts.

This indicates that, in this case, producing a T-shirt with 50% recycled cotton and 50% organic cotton did not significantly affect the overall durability of the T-shirt. Although performance in some tests was slightly lower, the general durability remained consistent, close to the aspirational level as defined at PEFCR, and achieved with a score of A in the A to E scale.

For simulation purposes, an additional theoretical scenario was examined where samples were assigned points under the assumption that repeated washing can diminish the performance of certain characteristics, as well as the use of recycled bursting properties and cotton fibers, as indicated in the previous literature review.

In this simulation, the authors consider a hypothetical T-shirt made with recycled cotton and organic cotton, which demonstrates a durability level one step lower compared to T-shirts made with virgin cotton across all tests, except for color change after washing and appearance after care, as it is assumed that all T-shirts can resist the formation of holes or broken yarn. This assessment is grounded in the previous comprehensive literature review, which consistently suggests that the incorporation of recycled cotton yarn may result in reduced performance, although it does not consider the improvement in fuzzing or pilling as observed in the real tests and also described in the bibliography in some cases. The results are summarized in

Table 12.

Consequently, the overall durability score for the T-shirt with recycled cotton fiber is 57% (or C on the A to E scale), lower when compared to alternative compositions, which is 81% (or A on the A to E scale) when calculated with the MCA WSM methodology.

These insights provide critical understanding for textile manufacturers and designers, highlighting the importance of anticipating and accounting for the complex material transformations occurring throughout the life cycle of recycled cotton textiles.

While durability is product-specific and independent of geographical supply chain variations, potential improvements could include:

Conducting tests under more efficient conditions;

Implementing alternative testing parameters (e.g., washing at 30 °C for 30 min).

Empirical testing remains essential for precise product durability evaluation, offering crucial insights that enable manufacturers to better understand and optimize textile performance. This approach ultimately contributes to more informed product development and performance predictions.

3.4. Product Sustainability Index (ProdSI)—Combining Environmental and Social Life Cycle Assessment with Durability

The product Sustainability Index is calculated using the WSM method, which is often used as a starting point for MCDA, especially in cases where the decision-making problem is relatively straightforward and the criteria are well-defined and measurable.

The score (S) of each alternative (A) is calculated as per Equation (1), considering:

S is the Product Sustainability Index (%);

A is the alternative, A1 is the T-shirt made with 50% recycled cotton and 50% organic cotton, A2 is the T-shirt made with 100% organic cotton, and A3 is the T-shirt made with conventional cotton.

w

i is the 1/3 weight since, for the calculations, it will be three criteria: the product environmental score as calculated at

Section 3.1, the product social score as calculated in

Section 3.2, and the durability score as calculated at

Section 3.3.

aij is the score of each alternative A on the i-th criterion.

To harmonize the methodology, in real cases when durability tests are not performed, it is suggested to consider the durability score as 0%, implying a significant reduction of the overall sustainability index.

The ProSI for each alternative is shown in

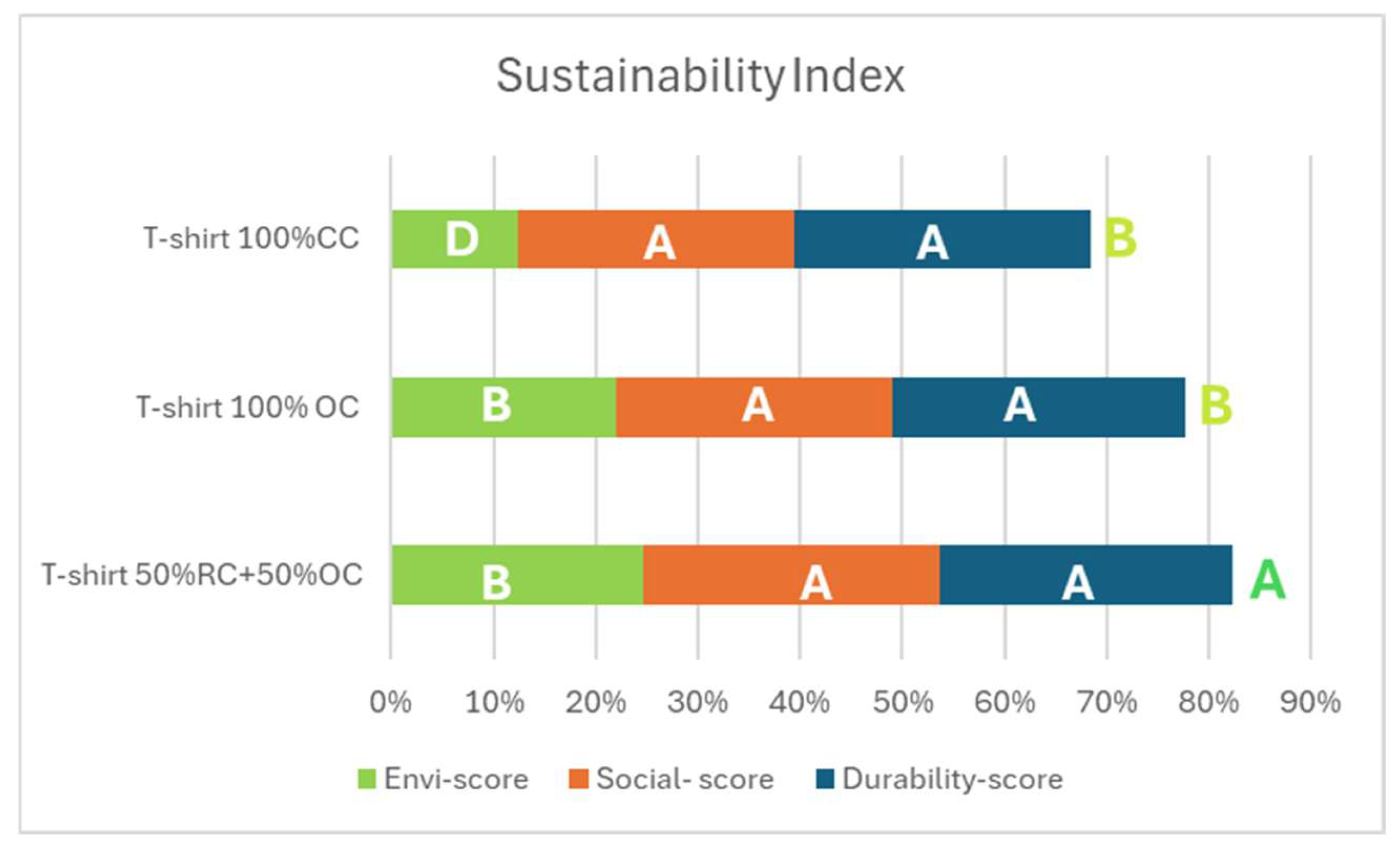

Table 13.

The alternative with the highest score is considered the best option. This refers to the T-shirt made with 50% recycled cotton and 50% organic cotton, produced in Portugal with organic cotton fiber imported from Turkey. This T-shirt achieved the best scoring in terms of sustainability when considering environmental and social impacts combined with durability. It received a score of 82%, which can be ranked as an A on the A to E scale.

In comparison, the T-shirt made with 100% organic cotton achieved a ProdSI of 70%, while the T-shirt made with 100% conventional cotton only achieved a ProdSI of 68%. Both were ranked as B on the A to E scale.

In the hypothetical case of the T-shirt made with recycled cotton and organic cotton, the better environmental and social scoring was offset by the lower simulated durability, resulting in a ProdSI of 73%, also ranked as a B. This result underscores the necessity of performing durability tests to gain a broader perspective on the product’s sustainability.

In the context of the circular economy, durable products are advantageous as they reduce resource utilization and mitigate social risks associated with frequent production. They conserve raw materials and energy and enhance worker safety while minimizing environmental degradation. Conversely, less durable products, even those made from recycled materials, can offset the environmental benefits of recycling due to the need for more frequent manufacturing, leading to increased resource consumption and waste generation. Therefore, designing for durability and recyclability is essential for achieving true sustainability in product manufacturing, as highlighted by life cycle assessments and advancements in material science.

The sustainability index for the real T-shirts case under study is summarized in

Figure 4. The T-shirts made with virgin cotton fiber (organic and conventional) got the same sustainability index B, although they have different performance in the individual environmental, social, and durability scores, meaning they have equivalent sustainability performance under this model.

A product sustainability index that incorporates environmental, social, and durability aspects aims to provide a comprehensive evaluation of a product’s overall sustainability. However, this approach carries inherent risks. One significant risk is, for example, the potential for a product with very poor performance on the environmental vectors, such as intensive utilization of coal or fossil fuels, or produced under high social risk conditions, like child labour or modern slavery, to be offset by exceptionally good durability. This offsetting effect can misleadingly elevate the product’s overall sustainability score, thereby obscuring critical ethical and environmental concerns. It is recommended that the sustainability index also displays the individual environmental, social, and durability scores for clear communication with consumers. This transparency helps avoid the pitfalls associated with a system that could otherwise lead to misleading assessments. Transparent reporting and rigorous third-party verifications are essential to mitigate these risks and maintain the integrity of the sustainability assessment.

For communication with the consumer, we proposed the label format in

Figure 5.

This label is modelled after the Nutri-Score system, which is widely recognized and accepted by consumers in several countries. It incorporates the overall sustainability index along with partial scores for environmental, social, and durability performance of the product. This approach reduces the risk of hidden negative impacts by providing transparent and detailed information. The methodology can incorporate weighting factors to influence the overall result if partial scores fall below a predefined acceptable level. However, these weighting factors have not been proposed to avoid increasing subjectivity, as they may vary depending on the priorities of different stakeholder groups.

Additionally, the label includes the date of final product production, as the environmental and social partial scores are significantly influenced by the time of production. Factors such as the electricity mix of the country, shifts in the supply chain, or changes in political policies can greatly affect these scores. By including the final production date, consumers can better understand the context in which the product was made, enhancing the overall transparency and reliability of the sustainability assessment.

4. Discussion

With the objective to contribute to the development of a reliable scientific methodology to score the sustainability (environmental, social, and durability) of fashion products, the developed methodology results in measurable KPIs that can be easily converted to an A to E benchmark label that is understandable by consumers globally, answering the research question RQ1, “How can a methodology be developed to score the sustainability of fashion products in a reliable and transparent way, including environmental, social, and durability dimensions?”

This straightforward score enhances consumer confidence by communicating sustainability information in a clear and accessible way, effectively guiding consumers toward the most sustainable products.

The methodology to calculate the sustainability index of a product, including its environmental footprint, social impacts, and durability as an aspect with an impact on the product’s economic cost, applying the weight sum model of the multicriteria analysis, includes the below steps and is summarized in

Figure 6 for the case of the T-shirts:

- Step 1.

Environmental Life Cycle Assessment and Calculation of the Envi-score

- Step 2.

Social Life Cycle Assessment and Calculation of the Product Social Score

- Step 3.

Durability Tests According to the PEFC (Tests Defined Per Type of Products) and Calculation of the Product Durability Score

- Step 4.

Multicriteria Analysis to Calculate the Product Sustainability Index

Understanding performance measurement and management control systems is challenging, even in stable environments and even more so in dynamic ones [

60]. Also, this is the case of the fashion product sustainability measurement, highly affected by environmental dynamism, marked by rapid and unpredictable changes, stemming from new competitors, geopolitical disruptions, and policy uncertainties. Climate change, demographic shifts, and sustainability concerns further complicate this dynamic. In such environments, performance measurement is difficult due to unpredictable external and internal changes and shifting organizational priorities; for this reason, it is very important to understand how these changes can affect the final product sustainability score. This study makes a relevant contribution to answering the research question RQ4, “How can product sustainability scoring be managed and improvement in the textile supply chain be promoted, given its high dynamism and complexity?”

The normalized e-LCA results for T-shirts made with a blend of 50% organic cotton and 50% recycled cotton reveal that freshwater eutrophication and freshwater ecotoxicity contribute approximately 73% to the final environmental score (Envi-score). In contrast, climate change and water scarcity each contribute only 1% to the product’s Envi-score.

This indicates that reducing wastewater, minimizing the use of chemicals and dyes in dyeing and finishing processes, and improving cotton cultivation practices (e.g., reducing pesticides and fertilizers) can significantly enhance the Envi-score and, consequently, the overall sustainability score of the product [

8].

In the context of this comprehensive sustainability study examining cotton cultivation in Turkey and subsequent manufacturing processes in Portugal, the research reveals that carbon and water footprints have a remarkably limited impact on the final Product Sustainability Index (ProdSI). Even a substantial 50% reduction in these environmental footprints would result in a minimal change of less than 1% in the overall index.

The e-LCA results demonstrate significant variability, heavily dependent on temporal and geographic factors such as annual variations in electricity generation mix and regional energy production characteristics. Consequently, the study emphasizes that these environmental impact assessments can dramatically shift if production is relocated to a different country or conducted in a different year.

To ensure the highest level of credibility and accuracy in the Envi-score calculation, independent verification of critical data parameters is proposed. These include a comprehensive verification of chemical usage in manufacturing processes, specifically detailing the types and quantities of chemicals employed, as well as documenting wastewater released during dyeing and finishing stages. Additionally, rigorous verification of energy consumption is recommended, encompassing precise measurements of electricity, fossil fuel, and coal usage across spinning, dyeing, and finishing processes, while also accounting for the specific country’s electricity mix used in the analyses.

Social composite indexes—encompassing the Human Rights Index, Global Rights Index, Social Progress Index, Gender Development Index, Human Freedom Index, Index of Economic Freedom, and Prevalence of Modern Slavery Index—provide sophisticated multidimensional analytical frameworks that reveal profound variations in national social performance across complex geopolitical landscapes. These intricate metrics systematically capture and quantify nuanced dimensions of societal development, institutional effectiveness, and structural human rights dynamics.

These comprehensive indexes offer a holistic, granular perspective on a country’s social ecosystem, meticulously illuminating both institutional strengths and critical vulnerability zones. By synthesizing complex data points across multiple social domains, they enable stakeholders—including policymakers, international organizations, academic researchers, and global governance institutions—to develop evidence-based strategies for targeted social innovation and structural improvement.

Production shifts can significantly impact a product’s social score. For example, organic cotton produced in India and transported to China for further production processes might result in a product with a high social risk, in contrast to cotton cultivation in Turkey and further production in Portugal. However, the low social performance of production in China can be offset by third-party social audit reports according to ILO standards demonstrating compliance with regulations and good practices, thereby reducing or eliminating social risks.

Answering to RQ2, “Is there a correlation between individual social KPIs related to workers and international composite indices related to a country’s well-being and development?” and showing the correlation between the individual KPIs selected to support the s-LCA workers’ subcategory is crucial. This correlation is an important conclusion, as individual KPIs may not always be available for all countries and years. Nevertheless, knowing the location of each tier in the supply chain allows for a quicker evaluation of the social performance of the product supply chain.

For an accurate assessment of the social risks associated with the product supply chain, we highlighted the importance of having independent social audits for the processes performed in countries with a social performance index lower than 60%.

Durability is a fundamental aspect of fashion product sustainability, serving as a critical metric that directly influences environmental, social, economic, and circular economy principles. By extending a garment’s life cycle, durability significantly reduces waste generation, minimizes carbon footprint, and decreases the frequency of resource-intensive manufacturing processes. Longer-lasting clothing means fewer items in landfills, lower energy consumption, and reduced raw material extraction. From an economic perspective, durable products offer cost-effectiveness for consumers and promote a more sustainable consumption model. Ultimately, durability transforms fashion from a disposable commodity to a more responsible, resource-efficient system that balances consumer needs with environmental stewardship. In evaluating fashion product durability, the PEFCR Apparel and Footwear methodology emerges as the most comprehensive and widely applicable approach, offering significant advantages for extensive cross-product comparisons, resulting in the answer to the research question RQ3, “What is the best methodology to evaluate the durability of a fashion product?” Approved by the European Union, PEF provides a standardized durability assessment framework that enables systematic evaluation across multiple categories. By offering a standardized protocol, PEF allows brands, researchers, and policymakers to benchmark product durability objectively, supporting more informed sustainability decisions. While other methodologies like WRAP and Refashion Eco modulation provide valuable insights, PEF’s comprehensive and harmonized approach makes it the preferred methodology for assessing and comparing fashion product durability on a broad, systematic scale.

Through the durability tests conducted on real-case T-shirts, it was possible to apply and adapt the PEFCR methodology, albeit with necessary adaptations to align with the laboratory’s capabilities. The tests revealed that while the use of recycled cotton fibers can slightly influence the test results, this does not significantly impact the overall product durability compared to T-shirts made with virgin fibers.

In the simulated T-shirt scenario, it became evident that although recycled materials offer substantial environmental advantages, their durability must be meticulously engineered to prevent any potential offset of environmental gains. To validate these findings and substantiate the need for such careful design, it is imperative that studies like this be conducted under real-world conditions.

A nuanced, holistic approach considering material science, life cycle assessment, and performance engineering is essential to maximize sustainability benefits.

In the context of circular economic principles, durability supports strategies of repair, reuse, and extended product life, challenging the traditional fast-fashion paradigm. The lifetime of a product can also be extended through repair to maintain it in “good condition.” Repairability suitability can be influenced by several factors, including intrinsic repairability, which assesses the capacity of a product to be repaired regardless of whether the repair occurs, and external repairability, which evaluates the availability and quality of after-sales service for repair. According to the PEFCR, intrinsic repairability includes two criteria: the repair cost, which measures the cost of repair using the EU average repair cost of the product subcategory and the average EU product selling price, and spare parts (SP). External repairability includes two criteria: repair service (RS), which assesses the quality of the repair service, and “right to repair” communication (RRC), which evaluates communication about the right to repair. For example, in the context of this study, the repair costs of a T-shirt can be very relevant compared to the cost of a new T-shirt, especially if high-quality repair services are required to correct dimensional or spirality damages. In such cases, extending the T-shirt’s lifetime effectively through reparability may not always be cost-effective or technically feasible due to specificities. For these reasons, the reparability of the product may be a relevant topic under the evaluation of its sustainability score, but it should be subject to future academic studies.

This paper does not cover emotional durability. The textile industry and academia imperatively needs to address the low level of “emotional durability” of textile products, which significantly contributes to the decision to discard clothes after a short period, although its functional durability, as well as the consumer Also, while jeans are expected to fade and abrade, T-shirts would be disposed of if they faded and aged in the same way that denim does [

33].