Abstract

Although logistics underpins the spatial architecture of supply chains, the causal contribution of logistics industry clustering to green total factor productivity (GTFP) remains under-identified relative to aggregate or manufacturing clustering. This study investigates both the local and spatial spillover effects of logistics industry clustering on green total factor productivity, utilizing panel data from 30 Chinese provinces spanning 2010 to 2023. The empirical results demonstrate that logistics industry clustering significantly enhances green total factor productivity within the local province and generates robust positive spillover effects in adjacent regions. Regional heterogeneity analysis reveals that in the eastern provinces, clustering of the logistics industry bolsters green total factor productivity both locally and regionally. In contrast, in the central region, such clustering only benefits neighboring provinces, while in the western region, its impact is not statistically significant for either local or neighboring green total factor productivity. Temporal heterogeneity analysis further indicates that the positive influence of logistics industry clustering on green total factor productivity has become more pronounced since 2018.Additionally, spatial mediation effect analysis uncovers that improvements in local green total factor productivity stem from logistics industry clustering’s capacity to enhance resource allocation efficiency and foster industrial upgrading. Notably, the spatial spillover effect dissipates entirely beyond a distance of 350 km. These findings establish logistics industry clustering as a high-leverage, cross-boundary tool for aligning regional logistics planning with green objectives, delineating the effective radius of collaboration to internalize externalities and providing practical guidance for developing economies.

1. Introduction

Over the past few decades, China has achieved remarkable industrialization and rapid economic growth, primarily driven by substantial energy inputs and resource consumption. However, this extensive growth model has given rise to a series of severe environmental challenges, including air pollution, water contamination, soil degradation, and ecosystem destruction, all of which have significantly constrained the country’s sustainable economic development [1]. According to the 2024 Report on the State of China’s Ecological Environment, 34.5% of Chinese cities exceeded national air quality standards, and the average proportion of days characterized by excessive air pollution reached 12.8%. Furthermore, data from the International Energy Agency indicate that China remains the world’s largest consumer of coal, accounting for more than 50% of global consumption, with total coal use estimated at 4.954 billion tons in 2024. In addition, China was responsible for approximately 34% of global carbon dioxide emissions in 2023, ranking first worldwide. Amid intensifying environmental pressures and the increasing imperative for green and low-carbon development, the question of how to effectively reduce resource consumption and environmental pollution while sustaining economic growth has become a critical challenge in China’s ongoing process of economic transformation and upgrading [2]. In this context, enhancing green total factor productivity (GTFP) is widely regarded as an essential pathway for China to achieve high-quality economic growth and environmental protection [3]. As a key indicator for evaluating the efficiency of resource allocation and technological progress under environmental constraints, GTFP not only comprehensively reflects the green quality of economic growth, but also unlocks the potential for effective environmental governance, playing a pivotal role in China’s pursuit of sustainable development [4,5].

In recent years, industrial clustering has emerged as a critical strategy for enhancing regional production efficiency, fostering innovation diffusion, and supporting sustainable development. Among various industries, the logistics sector has progressively assumed a central role in advancing green development, owing to its unique capacity to interconnect manufacturing, distribution, and retail segments throughout the supply chain across geographic regions [6,7]. The clustering of the logistics industry represents an advanced spatial organizational model that arises as the sector develops; by clustering logistics enterprises and associated supporting industries within defined areas, it enables the efficient circulation and sharing of key production resources. In principle, logistics industry clustering can generate economies of scale, thereby exerting a positive influence on green total factor productivity (GTFP). Such clustering promotes the sharing of resources and the efficient allocation of production factors, reduces unit logistics costs and energy consumption through operational intensification, and consequently enhances overall green production efficiency [8]. Furthermore, the concentration of logistics enterprises can facilitate robust information exchange and technological spillovers, drive green technological innovation, and foster the adoption of cleaner production practices, thus accelerating the transition to low−carbon development. Nevertheless, logistics industry clustering is not devoid of potential drawbacks. The concentration of transportation infrastructure and warehousing activities may give rise to congestion effects, such as traffic bottlenecks, increased vehicle emissions, noise pollution, and excessive land use, all of which may adversely affect GTFP [9]. Consequently, it is imperative to conduct an in-depth examination of both the effects and underlying mechanisms of logistics industry clustering on GTFP. Moreover, the logistics industry is inherently characterized by pronounced spatial linkages: its infrastructure networks, transport corridors, and information flows frequently cross administrative borders, thereby potentially generating external effects that extend into adjacent regions. As a result, investigating the spatial spillover effects of logistics industry clustering on GTFP has become a crucial avenue for informing regional sustainable development policies.

Against this backdrop, this study poses a focused question: in the current context where logistics services have become foundational to green and high-quality growth, do regional logistics industry clusters measurably enhance green total factor productivity (GTFP), and to what spatial extent? Using province-level evidence from China, we examine whether logistics activities exhibit spatial clustering and whether such clustering confers positive spillover effects on GTFP. Given limited understanding in the academic literature—and occasional misinterpretation among policymakers and firms—regarding how logistics clustering shapes green productivity, this study pursues two aims. First, it provides an innovative, data-driven assessment of whether logistics cluster status exists across regions and whether cluster status raises GTFP both locally and in neighboring areas. Second, it elucidates the operational pathway by testing whether logistics clustering improves GTFP primarily through alleviating resource misallocation-specifically, by enhancing labor matching and capital deployment—and by quantifying a finite spatial decay boundary beyond which spillovers dissipate. To address these aims, we integrate spatial econometric analysis with a mediation perspective, enabling simultaneous identification of local and cross-border effects, the allocation-efficiency channel, and the distance-bounded reach of spillovers.

Accordingly, this study adopts panel data from 30 Chinese provinces covering the period from 2010 to 2023 to systematically investigate both the local and neighboring effects of logistics industry clustering on green total factor productivity (GTFP), utilizing the spatial Durbin model. In addition, a spatial mediation effect model is employed to explore the underlying mechanisms through which logistics industry clustering impacts GTFP. The marginal contributions of this paper are manifested in the following three aspects. First, this study is the first to systematically incorporate logistics industry clustering into a unified analytical framework for examining its effects on GTFP. This approach not only addresses a notable gap in the existing literature but also provides robust empirical evidence to inform logistics industry management and further promote sustainable development. Second, by rigorously analyzing the spatial spillover effects of logistics industry clustering on GTFP, this paper elucidates the complex spatial interrelationships between logistics clustering and GTFP. These findings have important implications for enabling policymakers to design more targeted and effective strategies for promoting coordinated regional development. Third, by examining the mechanisms of resource allocation and industrial upgrading, this paper clarifies the pathways through which logistics industry clustering influences GTFP. This refined causal account of logistics cluster development and green productivity directly informs policy and practice, enabling policymakers to target incentives where they are most effective while helping firms prioritize investments that yield the highest green productivity returns. Fourth, we identify an approximately 350-km spatial decay boundary for spillovers: beyond 350 km, the effect of logistics industry clustering on GTFP disappears. This previously unquantified boundary provides a policy-salient radius for cross-jurisdictional coordination, for industry, it offers a concrete planning horizon for hub siting, satellite deployment, and routing design to maximize GTFP improvements within the effective radius.

The remainder of the paper is organized as follows. Section 2 reviews the relevant literature. Section 3 develops the theoretical framework and research hypotheses. Section 4 presents the research design. Section 5 reports and discusses the empirical results. Section 6 conclusions and recommendations.

2. Literature Review

2.1. Research on the Measurement and Impact of GTFP

Green total factor productivity (GTFP) extends total factor productivity by incorporating undesirable outputs and environmental constraints, so a suitable measurement approach must handle multiple inputs and outputs and explicitly treat emissions. Early work commonly employed data envelopment analysis (DEA) to construct an empirical frontier without imposing a functional form, which is attractive for high-dimensional, green settings [10]; however, classical radial DEA relies on proportional expansion or contraction, making all inputs and outputs adjust at the same rate and thus masking indicator-specific adjustment needs. To address this, the slack-based measure (SBM) replaces the radial proportionality with a non-radial slack formulation, reporting required adjustments separately for each input, desirable output, and undesirable output; In green applications this yields more faithful and policy-useful diagnostics. Yet standard SBM assigns a score of one to all frontier units, offering no further discrimination among high performers. The super-efficiency SBM resolves this by temporarily excluding the evaluated unit from the reference set, allowing frontier scores to exceed one and enabling meaningful ranking and benchmarking among frontier regions—useful when GTFP later serves as an outcome in comparative and spatial analyses [11]. Nevertheless, measures based solely on period-specific frontiers can suffer from intertemporal incomparability and frontier instability, especially in long panels. Coupling super-efficiency SBM with the Global Malmquist–Luenberger (GML) index addresses this by constructing a global technology set common to all periods, thereby preserving the non-radial, indicator-specific diagnostics and frontier discrimination while substantially improving time-series consistency and stability [12].

On determinants, existing research links GTFP to a suite of structural and institutional drivers. Frequently examined factors include economic development and industrial structure [13], technological progress and innovation capability [14]. energy structure and efficiency [15], environmental regulation and governance quality [16,17,18]. openness and trade, urbanization and infrastructure, and policies such as emissions trading or green finance [19]. These drivers influence GTFP by reallocating resources toward cleaner technologies, diffusing eco-efficient practices, and shifting activity into higher value-added, lower-emission segments.

Within this literature, industrial is increasingly recognized as a salient force for green productivity, operating through knowledge spillovers, thicker factor markets, and supply-chain coordination that reduce transaction costs and misallocation [20,21,22]. This trajectory naturally motivates attention to industry clustering [23]. As a connective sector that orchestrates cross-regional flows of goods, information, and capital, industry clustering can transmit operational know-how and green practices across administrative boundaries, implying both local and neighboring consequences for GTFP. Yet evidence specific to logistics clustering and GTFP remains limited, and many studies rely on non-spatial estimators that do not fully address spatial dependence [24].

2.2. Research on the Measurement and Impact of Logistics Industry Clustering

Logistics industry clustering refers to the spatial concentration and functional coupling of logistics firms and related services, such as transportation, warehousing, distribution, information platforms, and supply-chain finance−within a delineated area, where co-location, shared infrastructure, and interoperable digital systems generate scale and network efficiencies. In contrast to isolated facilities, a logistics cluster operates as an integrated system: firms specialize along different service niches, draw on common assets, and coordinate flows of goods, information, and capital across regions, thereby thickening factor markets, standardizing processes, and enabling rapid diffusion of operational and technological practices [25].

Research on the effects of logistics clustering spans macro–meso–micro layers. At the macro and meso levels, clustering is associated with lower transport and inventory costs, shorter lead times, and deeper supply-chain integration, which reinforce regional competitiveness, support industrial upgrading, and facilitate knowledge diffusion with externalities that often cross administrative boundaries. At the micro level, co-location reduces marginal, verification, and coordination costs via standardized processes and shared practices; it accelerates the adoption of automation and data−driven operations and improves access to specialized labor and complementary capital, jointly raising firm-level efficiency [26].

From a green development perspective, however, the literature has yet to examine logistics clustering through a dedicated green total factor productivity (GTFP) lens. Most studies evaluate “green growth” or environmental indicators in general rather than GTFP [27,28], which jointly captures desirable output and undesirable emissions and aligns more closely with the quality−of−growth agenda. Moreover, many empirical designs remain non-spatial despite the intrinsically interregional structure of logistics networks, which hampers clear identification of local versus neighboring effects and limits credible inference on the geographic propagation of impacts across administrative boundaries. To complement this review, Appendix A (Table A1) synthesizes prior studies on clustering, logistics, and green productivity.

2.3. Literature Gaps

The foregoing review indicates growing attention to green total factor productivity (GTFP) and to clustering phenomena, yet the specific nexus between logistics industry clustering and GTFP remains insufficiently articulated. Three gaps stand out.

First, while prior studies have documented many determinants of GTFP and recognized that clustering can enhance green productivity, logistics industry clustering has not been consistently incorporated into a unified analytical framework focused on GTFP. This omission matters because logistics clusters coordinate cross-regional flows of goods, information, and capital; if clustering transmits operational know-how and green practices across administrative boundaries, both local and neighboring GTFP may be affected. Clarifying this relationship is directly relevant for transport-hub planning, multimodal corridor design, cross−jurisdictional coordination, and targeted green upgrades of logistics infrastructure and services.Second, existing work that links logistics clustering to “green growth” typically evaluates broad environmental outcomes rather than GTFP specifically, and often relies on non-spatial estimators. Given the inherently networked and interregional nature of logistics, spatial dependence and spillovers are central to credible identification. A spatial econometric perspective is therefore needed to separate local from spillover effects, to avoid biased inference from unmodeled spatial autocorrelation, and to align empirical strategy with the cross-boundary connectivity of logistics systems.Third, the causal channels through which logistics clustering influences GTFP are under-specified. In particular, the allocation-efficiency mechanism-alleviating resource misallocation by improving labor matching and capital deployment-has received limited attention in the logistics context, despite its centrality to green productivity. Moreover, few studies quantify the spatial reach of logistics−induced spillovers. For policy design, knowing whether effects attenuate with distance and where they effectively vanish is as important as establishing their existence.

In response, the present study: (i) embeds logistics industry clustering within a unified framework for explaining GTFP, (ii) employs spatial econometric models to identify both local and neighboring effects consistent with logistics’ cross-regional nature, (iii) tests a mediation pathway centered on allocation efficiency via labor and capital, and (iv) quantifies a finite spatial decay boundary for spillovers, translating statistical evidence into an actionable coordination radius for regional planning and green supply-chain governance.

3. Theoretical Analysis and Research Hypotheses

3.1. The Local Effects of Logistics Industry Clustering on GTFP

Logistics industry clustering refers to the spatial concentration and dense clustering of logistics-related enterprises within a given region. This phenomenon fosters intensive development by enabling resource sharing and business synergies, thus effectively improving green total factor productivity (GTFP) and promoting sustainable development. Specifically, logistics firms situated within agglomerated areas benefit from shared access to transportation infrastructure (such as highways, railways, and ports), warehousing facilities, and information service platforms. Such arrangements help avoid redundant construction and resource idleness, leading to substantial reductions in fixed asset investment and maintenance costs, and markedly enhancing production efficiency [29,30,31]. For example, when multiple logistics enterprises jointly utilize large-scale logistics parks or public distribution centers, they share the costs associated with land leasing, warehousing equipment, and information management systems, thereby achieving scale−based cost savings. Furthermore, clustering enables a networked distribution of logistics enterprises, facilitating more rational route planning, reduced empty-load rates and detour mileage, greater transport efficiency, and lower per-unit transport costs as well as energy consumption [32].

In addition, logistics industry clustering contributes to the formation of robust green supply chain systems, thus exerting a positive influence on GTFP. clustering supports the establishment of unified information platforms, enhancing real-time data sharing and transparency, which in turn underpins green logistics management and environmental performance monitoring [33]. Leveraging shared data, supply chain participants can co−develop optimized green transport plans, implement dynamic inventory management, and design packaging reduction strategies, thereby improving the efficiency of green supply chain operations. clustering also encourages the diffusion of green technologies and equipment among firms, including new energy vehicles, energy-efficient warehousing, and intelligent dispatching systems−thereby expediting the adoption of green logistics innovations throughout the supply chain. Enterprises in agglomerated areas often establish unified green standards and environmental management systems, advancing the standardization of green procurement, packaging, and transportation. Through collaborative standard-setting and implementation, logistics industry clustering effectively curbs environmental pollution and conserves resources, improving the environmental performance of the entire supply chain.

Logistics industry clustering further generates technological spillovers and facilitates knowledge sharing, which continuously enhance GTFP. On one hand, it intensifies interactions among enterprises, accelerating the adoption of environmentally friendly transport tools and smart delivery technologies. On the other hand, the presence of both heightened competition and collaborative networks incentivizes firms to increase investments in research and development, as well as to adopt novel technologies such as green packaging, sustainable warehousing, and low-carbon delivery−collectively improving technological efficiency [34]. Additionally, the promising development prospects, robust industrial support, and innovation-oriented environment in agglomerated regions attract greater green investment and high−caliber logistics talent, creating a virtuous cycle of continual optimization and advancement that further boosts GTFP [35]. Therefore, the following is proposed:

H1.

Logistic industry clustering positively influences local Green Total Factor Productivity (GTFP).

3.2. Logistics Industry Clustering, Resource Allocation, and Local GTFP

As a spatial organizational form in the logistics sector, logistics industry agglomeration reshapes regional resource allocation and can thereby enhance green total factor productivity (GTFP) [36]. A key manifestation of improved allocation is the mitigation of labor misallocation. First, agglomeration fosters large-scale, networked logistics systems that attract high-skill managerial and technical workers and deepen local skill pools; dense labor markets reduce search frictions and facilitate better worker-firm matching, lowering misallocation arising from information asymmetries across firms and locations [37]. Consistent with the agglomeration literature on human-capital mobility and matching efficiency, tighter spatial clustering improves job, skill matching and raises productivity through knowledge spillovers and thicker labor markets [38]. Second, agglomerated logistics regions exhibit more frequent inter-firm mobility and broader access to shared training resources, which sustain continuous upskilling and reduce skill mismatches; such mechanisms are known to elevate service quality and accelerate firm-level green innovation and the adoption of energy-saving and emission-reduction practices [39]. Third, synergy effects in clusters−via standardized processes, shared best practices, and diffusion of automation−raise labor productivity and reduce redundant tasks; higher operational efficiency translates into lower energy and material inputs per unit of output, thereby easing environmental burdens and aligning economic and ecological objectives, ultimately improving GTFP [40].

Moreover, logistics industry clustering can further promote GTFP by alleviating capital misallocation. Firstly, industry clustering raises the overall creditworthiness and information transparency of enterprises within agglomerated regions, thereby reducing inter-firm information asymmetry [41,42]. This increased transparency enables financial institutions to better identify high-quality projects and enterprises, thus optimizing the allocation of credit resources. Efficient capital allocation allows firms to secure timely financial support necessary for green logistics technology upgrades, equipment renewal, and sustainable infrastructure development, thereby increasing green technology adoption rates and intensifying environmental investments−culminating in improvements to GTFP. Secondly, economies of scale and synergy effects generated within agglomerated regions reinforce firms’ profit expectations and their capacity to withstand risks, thereby lowering the risk premiums required by financial institutions. Reduced financing costs then stimulate greater investment in low−carbon technologies, recycling infrastructure, and energy−efficient projects. Not only does this improve the efficiency of capital inputs, but it also alleviates financial constraints encountered during green transformation processes, thus fostering broader adoption of green production models.Thirdly, logistics industry clustering can catalyze the development of diversified financial instruments tailored to the green logistics sector, such as green bonds, supply chain finance, and carbon emissions rights financing. The availability of diversified financing tools broadens enterprises’ access to funding for green technological research and development, emissions control initiatives, and green supply chain construction; this, in turn, mitigates capital misallocation, facilitates the diffusion and practical application of environmentally friendly technologies, and ultimately drives improvements in overall GTFP. On this basis, the following hypothesis is proposed:

H2.

Logistics industry clustering enhances GTFP by alleviating resource misallocation.

3.3. Logistics Industry Clustering, Industrial Upgrading, and Local GTFP

As a crucial component of the regional industrial chain, the logistics industry can enhance green total factor productivity (GTFP) by facilitating transformational upgrading across the entire industrial system. Under the impetus of logistics industry clustering, regional economies tend to shift from traditional, low value-added sectors toward high-tech, high value−added, and environmentally advanced industries. Firstly, logistics industry clustering markedly reduces firms’ transaction and operating costs by improving transportation networks, establishing efficient logistics infrastructure, and creating shared innovation platforms [43,44]. These improvements boost resource allocation efficiency and the overall business climate, thereby enhancing the region’s capacity to attract high-end factors−such as advanced technologies, sophisticated equipment, and skilled human capital. The resulting concentration of advanced production elements accelerates the upgrading of traditional industries toward high-value segments of the value chain, including research and development, design, and brand management, thereby achieving high-end industrial chain transformation [45]. Such upgrading not only increases product value added but also encourages the adoption of cleaner and more efficient production and logistics technologies, ultimately optimizing resource utilization, lowering energy consumption and emissions, and exerting a significant positive impact on GTFP. Secondly, logistics industry clustering improves the flexibility and efficiency of regional resource allocation by further reducing transaction costs and expediting the flow of information and knowledge. This highly efficient collaborative and sharing environment facilitates the convenient movement of capital, labor, and technology among enterprises and industries, driving the concentration of production factors into greener, smarter, and more digitalized sectors with superior environmental performance and higher technological content [46]. Simultaneously, the heightened competitive pressures inherent in clusterings accelerate the exit or upgrading of high-pollution, low-efficiency enterprises. As a result, the industrial structure transitions more rapidly from large-scale, low-efficiency development to high-quality, low-carbon, and sustainable growth, substantially improving resource allocation efficiency and providing a robust foundation for sustained GTFP enhancement. Thirdly, through spatial clustering effects, logistics industry clusters lower inter-industry transaction costs and communication barriers, thereby reinforcing the foundation for inter-firm collaboration [47]. Furthermore, the presence of advanced information infrastructure and shared digital platforms within clusters facilitates efficient data and resource exchange, promoting resource integration and business cooperation among manufacturing, retail, finance, and other related industries. Consequently, enterprises within these clusters can realize cross-industry innovation and integration, giving rise to new business models such as service-oriented manufacturing, supply chain finance, and green supply chain management. These innovations expedite coordination throughout upstream and downstream industries and accelerate the green transformation of the entire industrial chain.

Illustrative example from China. In the Yangtze River Delta, the co-location of national-level logistics parks, bonded logistics platforms, and multimodal hubs has been accompanied by a steady migration of surrounding manufacturing toward higher value−added functions linked to just-in-time and vendor−managed inventory. On the logistics side, practices such as automated sorting, slotting optimization, and cold-chain energy management diffused from leading facilities to adjacent firms; on the production side, cleaner process technologies and low-carbon distribution routines scaled with deeper supplier integration. The combined outcome has been shorter lead times, lower unit energy and material intensities in handling and transport, and tighter upstream-downstream coordination through shared digital platforms. This pattern maps directly onto the upgrading pathway articulated above, providing a concrete setting in which logistics clustering and industrial structure evolve jointly and, in turn, support sustained improvements in local GTFP. Accordingly, the following hypothesis is proposed:

H3.

Logistics industry clustering can improve local GTFP by promoting industrial structure upgrading.

3.4. The Spatial Spillover Effects of Logistics Industry Clustering on GTFP

According to the theory of new economic geography, logistics industry clustering not only transforms factor allocation patterns and industrial structures within agglomerated regions, but also exerts substantial spillover effects on the green total factor productivity (GTFP) of neighboring areas through spatial spillover mechanisms. Firstly, logistics industry clustering significantly lowers transaction and transportation costs in adjacent regions by enhancing transportation networks and improving the efficiency of logistics infrastructure [48,49]. The reduction in costs facilitates more efficient cross-regional flows of production factors−including capital, labor, and technology−thereby easing factor misallocation in neighboring regions and optimizing overall resource allocation efficiency. Within the context of green development objectives, these improvements in resource allocation directly support the adoption of cleaner production practices and low-carbon input structures, contributing to the sustained enhancement of GTFP. Secondly, logistics industry clustering accelerates knowledge spillovers and the diffusion of green technologies [50]. Agglomerated regions serve as hubs for logistics enterprises equipped with advanced management practices and green technologies, which continuously accumulate expertise in areas such as green logistics, intelligent dispatching, and energy-efficient transportation. Through channels such as human capital mobility, inter-firm cooperation, and supply chain linkages, these green technologies and management practices disseminate outward, gradually radiating and spilling over to adjacent regions. This diffusion process enhances the green innovation capabilities of surrounding enterprises and produces significant improvements in the GTFP of neighboring areas. Thirdly, logistics industry clustering deepens industrial collaboration and strengthens green supply chain synergy. The new economic geography framework highlights the externalities and network effects generated by industrial clustering. In the context of logistics industry clustering, these positive externalities are not confined to core urban areas but also extend to peripheral regions via supply chain nodes. Specifically, the sharing of logistics resources, advancements in informatization, and establishment of standardized service systems within agglomerated clusters enable neighboring firms to reduce redundant investments, optimize energy consumption structures, and improve recycling efficiencies−further promoting GTFP gains in adjacent areas. In light of these theoretical underpinnings, this study proposes the following hypothesis:

H4.

Logistics industry clustering can improve the GTFP of neighboring regions.

4. Data and Models

4.1. Variables

4.1.1. Dependent Variable: GTFP

This study employs the super-efficiency slacks-based measure–global Malmquist–Luenberger (SBM−GML) framework to evaluate green total factor productivity (GTFP). Methodologically, SBM−GML ensures comparability across heterogeneous input–output scales and jointly accommodates conventional economic performance and environmental objectives, delivering a more comprehensive assessment of development quality. We adopt SBM–GML over common alternatives because it (i) is non-radial and explicitly captures input, output slacks and undesirable outputs, avoiding proportional-scaling biases in radial DEA and omissions in conventional productivity indices; (ii) constructs a global technology frontier, thereby securing intertemporal comparability and mitigating period-specific frontier issues that affect standard Malmquist/Luenberger measures; and (iii) enables discrimination among frontier decision-making units via the super-efficiency extension, which is valuable for cross-provincial differentiation in an environmental setting. In the measurement of GTFP, based on Liu et al. [12], energy consumption is incorporated as an expected input indicator, whereas pollutant emissions are treated as undesirable outputs. Specifically, the primary input variables include labor input, capital input, and energy input, with regional gross domestic product (GDP) representing the desirable output. Indicators such as industrial wastewater discharge, industrial sulfur dioxide emissions, and industrial soot and dust emissions are included as undesirable outputs. To ensure consistency and comparability of data, all price-related variables are deflated to constant 2010 prices. Furthermore, variables such as energy consumption, pollutant emissions, and labor input are adjusted for their respective natural growth rates. This approach allows for the accurate measurement of GTFP and its interprovincial variations over the study period.

4.1.2. Independent Variable: Logistics Industry Clustering

This study employs the location quotient (LQ) indicator to quantify the degree of logistics industry clustering across regions, refer to Guan et al. [51]. The location quotient reflects the specialization level of a specific industry within a region relative to the national average and is widely recognized in quantitative analyses of regional industrial clustering and spatial distribution patterns. Specifically, the location quotient is calculated as follows:

The numerator represents the proportion of logistics employment in region i during period t to the total logistics employment nationwide in period t, while the denominator represents the proportion of total employment in region i to the total employment across all industries nationwide.

4.1.3. Control Variables

GTFP is shaped by multiple structural and institutional factors. Prior studies highlight that urban dynamics, human capital, regulatory pressure, market institutions, and development stage can jointly condition green productivity improvements [52]. Drawing on related research, we include the following indicators as control variables to mitigate omitted-variable bias and isolate the net effect of logistics industry clustering on GTFP.

- Urbanization rate (URB). Rapid urban expansion can either exacerbate environmental pressure under extensive growth or, under new-type urbanization, facilitate low-carbon, smart, and livable development. Accordingly, a higher urbanization level may systematically affect provincial GTFP in the long run. We measure URB by the proportion of the urban permanent resident population at year-end to the total population (%).

- Human capital (HUM). A richer skill endowment supports technological upgrading, green innovation, and eco-efficiency improvements, thereby fostering gains in GTFP. We proxy HUM by the number of students enrolled in regular higher education institutions.

- Environmental regulation (ENV). Regulatory stringency-via standards, monitoring, and enforcement can induce cleaner production and pollution-control investment, improving green productivity. We capture ENV by the ratio of investment in industrial pollution control to the value added of industrial output (%).

- Marketization level (MA). Deeper market institutions and factor price liberalization enhance allocative efficiency, competition, and the diffusion of green technologies, which are conducive to GTFP. We measure MA by the ratio of employment in private enterprises and self-employed individuals to total regional employment (%).

- Level of economic development (PGDP). Higher income levels influence GTFP through scale, composition, and technique effects, including the capacity to finance cleaner technologies and upgrade industrial structure. We proxy PGDP by regional GDP per capita.

4.1.4. Mediating Variables

Resource allocation efficiency includes both labor allocation and capital allocation. Following Jiang et al. [53], this study calculates the labor allocation index (LIT) and the capital allocation index (KIT) to measure these two dimensions. Industrial structure upgrading refers to the dynamic evolution of the industrial structure from lower- to higher-level stages. Accordingly, this study adopts the industrial structure sophistication index proposed by Dai et al. [54] to measure industrial upgrading (IS).

4.1.5. Data Description

This study employs a balanced panel dataset comprising 30 Chinese provinces over the period 2010 to 2023 to examine the impact of logistics industry clustering on green total factor productivity (GTFP). Owing to data limitations, the provinces of Taiwan, Hong Kong, Macao, and Tibet are excluded from the analysis. The primary data sources utilized in this research include the China Statistical Yearbook, the China Energy Statistical Yearbook, the China Science and Technology Statistical Yearbook, and the CNRDS database. Missing values are supplemented using linear interpolation methods, which preserve the temporal ordering and smooth trend of annual provincial series without imposing parametric assumptions and help avoid information loss from listwise deletion. Descriptive statistics for all variables are summarized in Table 1.

Table 1.

Descriptive statistics.

4.2. Model

4.2.1. Spatial Durbin Model

Tobler’s first law of geography asserts that “everything is related to everything else, but near things are more related than distant things.” This principle encapsulates the pervasive spatial dependence and spillover effects that characterize regional economic activities and industrial distributions. As previously discussed, the logistics industry, functioning as an essential node within regional economic networks, not only directly shapes local resource allocation efficiency, technological innovation, and environmental outcomes, but may also indirectly influence the green total factor productivity (GTFP) of neighboring regions. Such indirect effects may arise through mechanisms including information diffusion, factor mobility, and technological spillovers.Given these considerations, refer to the research base of existing scholars [55], which adopts the Spatial Durbin Model (SDM) to empirically examine the impact of logistics industry clustering on GTFP. The SDM is particularly suitable for this research context, as it effectively accounts for both the spatial lag of the dependent variable and the direct as well as indirect (spatial lag) effects of the explanatory variables. The model thereby enables a comprehensive assessment of the spatial interactions inherent in regional economic systems. The specific model specification is as follows:

In this model specification, i and t denote the province and year, respectively, while j indexes neighboring provinces (j ≠ i). The variable represents the green total factor productivity (GTFP) of province i in year t. The parameter captures the regression coefficient associated with the primary explanatory variable. The coefficient reflects the effect of the spatially lagged term. The variable indicates the degree of logistics industry clustering, whereas represents the vector of control variables. The spatial weight matrix is denoted by W. The terms and correspond to spatial and temporal fixed effects, respectively. Finally, denotes the stochastic error term.

4.2.2. Spatial Mediation Effect Model

To empirically test the aforementioned hypothesis, this study constructs the following mediation effect model to elucidate the mechanisms by which logistics industry clustering influences green total factor productivity (GTFP). Referring to the research practice of existing scholars [56], the specific model formulation is presented as follows:

where, represents the mediating variables, including the labor allocation index (LIT), the capital allocation index (KIT), and industrial structure upgrading (IS).

5. Results and Discussion

5.1. The Spatiotemporal Evolution Characteristics of GTFP

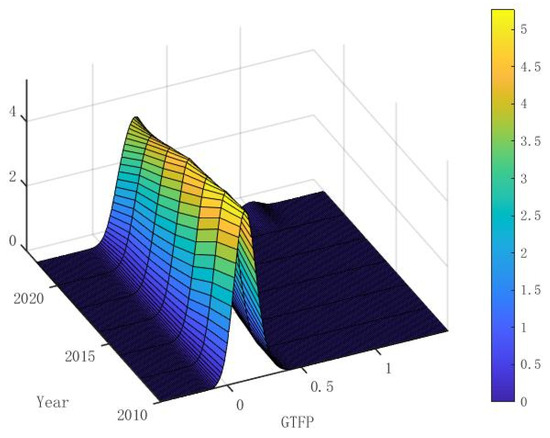

This study initially employs the kernel density estimation method to analyze the temporal evolution of green total factor productivity (GTFP) in China. As a non-parametric estimation technique, kernel density estimation systematically and objectively captures the temporal dynamics and distributional characteristics of GTFP across regions. The results, as depicted in Figure 1, reveal a noticeable rightward shift in the main peak of the kernel density curve, indicating a marked upward trend in China’s GTFP from 2010 to 2023. Concurrently, the height of the kernel density curve declines and its spread broadens, reflecting a substantial increase in regional disparities in GTFP. These findings highlight the growing need for the Chinese government to formulate targeted and effective regional coordination policies aimed at narrowing these widening regional gaps and promoting balanced green development.

Figure 1.

Kernel density estimates of China’s GTFP from 2010 to 2023.

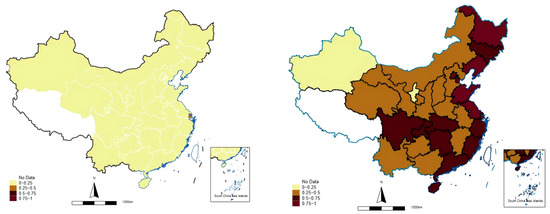

In addition, this study employs visualized maps to analyze the spatial distribution characteristics of green total factor productivity (GTFP) across China. The results, as illustrated in Figure 2, demonstrate a substantial improvement in GTFP nationwide from 2010 to 2023, corroborating the upward trend identified by the kernel density estimation analysis. Notably, GTFP in the eastern region is markedly higher than that in the central and western regions. The comparatively elevated GTFP observed in the eastern region can be attributed to several key factors. First, the eastern provinces possess a more advanced economic structure and higher levels of industrial modernization, which facilitate the adoption of green technologies and promote efficient resource allocation. Second, this region benefits from more developed infrastructure, greater innovation capacity, and stronger integration into international markets, all of which are conducive to improvements in green total factor productivity. Third, stricter environmental regulations and heightened public environmental awareness further incentivize enterprises in the east to enhance their green production efficiency. By contrast, the central and western regions tend to be more reliant on resource- and energy-intensive industries, and continue to face constraints such as limited technological capacity, lower levels of human capital, and weaker market mechanisms. These structural challenges contribute to the relatively lower levels of GTFP observed in these regions.

Figure 2.

The spatial distribution of GTFP in China in 2010 and 2023.

5.2. Analysis of Spatial Spillover Effects

5.2.1. Spatial Autocorrelation Test

The existence of spatial correlation in the dependent variable constitutes a critical prerequisite for the application of spatial econometric models in assessing the impact of logistics industry clustering on green total factor productivity (GTFP). To this end, we first compute the global Moran’s I statistic for China’s GTFP from 2010 to 2023, employing a geographical distance matrix. The results, reported in Table 2, indicate that the global Moran’s I values for GTFP remain significantly positive across all years in the study period. This persistent positivity reflects the presence of pronounced and widespread positive spatial associations in GTFP among Chinese provinces, thereby justifying the use of spatial econometric techniques in subsequent analyses.

Table 2.

Global Moran’s I.

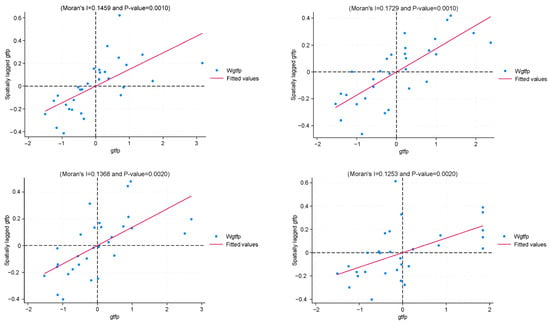

We further examine the local Moran’s I statistics for China’s green total factor productivity (GTFP) in the years 2010, 2014, 2019, and 2023. The results, as depicted in Figure 3, reveal that the local Moran’s I values are predominantly distributed within the first and third quadrants. This pattern indicates that China’s GTFP mainly exhibits “high-high” and “low-low” spatial clustering characteristics. In other words, provinces with high GTFP levels tend to be geographically clustered with other high-performing provinces, creating positive spatial spillover effects. Conversely, provinces with low GTFP levels are typically surrounded by similarly underperforming neighbors, which reinforces the persistence of local low-efficiency traps. These spatial clustering patterns underscore the combined effects of regional disparities in economic development, heterogeneity in technological innovation capacities, and variations in the stringency of environmental regulations across different provinces. Consequently, these findings highlight an urgent need for the central government to advance coordinated regional green development policies, strengthen mechanisms for interregional technology diffusion, and provide targeted support for capacity building in lagging areas. Such measures are essential for alleviating spatial inequalities in green total factor productivity and fostering more balanced and sustainable national development.

Figure 3.

Local Moran’s I of China’s GTFP in 2010, 2014, 2019, and 2023.

5.2.2. Spatial Model Test

Preceding diagnostics based on Global Moran’s I indicate statistically significant positive spatial autocorrelation in GTFP and logistics industry clustering, motivating the use of spatial econometric specifications. In light of these dependence patterns, we proceed to model selection within the standard spatial framework. Spatial econometric models commonly include the Spatial Durbin Model (SDM), the Spatial Lag Model (SLM), and the Spatial Error Model (SEM). Notably, the SDM can be reduced to either the SLM or the SEM under specific conditions. To ascertain the suitability of the SDM for investigating the impact of logistics industry clustering on green total factor productivity (GTFP), we first conduct a series of specification tests. The results are displayed in Table 3. The significantly positive outcomes of the Lagrange Multiplier (LM) test, Likelihood Ratio (LR) test, and Wald test indicate that the SDM does not degenerate into either the SLM or SEM, affirming the necessity of simultaneously considering both the spatial lag of the dependent variable and the spatial lag of the explanatory variables when analyzing spatial spillover effects. Furthermore, the results of the Hausman test strongly support the adoption of a fixed-effects specification for the SDM. This approach effectively controls for unobserved heterogeneity across provinces and over time, enhancing the accuracy and reliability of parameter estimates. Collectively, these test results provide robust justification for employing a fixed-effects SDM framework to fully capture the complex spatial interactions and to rigorously estimate the impact of logistics industry clustering on GTFP.

Table 3.

Diagnostics for the spatial model.

5.2.3. Baseline Regression Results

Table 4 presents the baseline regression results. Column (1) reports the estimates obtained using the ordinary least squares (OLS) method to assess the impact of logistics industry clustering on green total factor productivity (GTFP). The coefficient for logistics industry clustering (LQ) is found to be significantly positive, indicating that logistics industry clustering contributes to improvements in local GTFP. This empirical evidence supports Hypothesis 1. Column (2) displays the estimation results from the Spatial Durbin Model (SDM). Both the coefficient of the local logistics industry clustering variable (LQ) and its spatially lagged counterpart (WLQ) are significantly positive. This finding suggests that logistics industry clustering not only enhances GTFP within the focal province but also exerts a positive spillover effect on the GTFP of neighboring regions. These results provide strong evidence for the existence of significant spatial spillover effects resulting from logistics industry clustering. On one hand, the concentration of logistics enterprises can improve resource allocation efficiency, lower transaction and transportation costs, and foster technological innovation within the local area, thereby directly promoting local GTFP. On the other hand, through channels such as knowledge diffusion, demonstration effects, and the formation of integrated regional supply chain networks, logistics industry clustering can indirectly enhance GTFP in adjacent provinces. Furthermore, the presence of advanced logistics infrastructure and services can facilitate the diffusion of green technologies and environmentally friendly practices across regions, amplifying positive externalities in surrounding areas. Taken together, these findings underscore the importance of accounting for spatial interdependencies in policy formulation aiming to promote green productivity through the development of the logistics industry. The results also provide empirical support for Hypothesis 4.

Table 4.

Baseline regression results.

In spatial econometric analysis, decomposing the estimated effects into direct and indirect (spillover) components is essential for elucidating the mechanisms through which explanatory variables influence the dependent variable across space. Unlike conventional regression models, spatial econometric models explicitly account for spatial interactions, whereby a change in an explanatory variable in one region can affect not only outcomes within the same region (direct effect) but also outcomes in neighboring regions (indirect or spillover effect). The direct effect measures the average impact of a unit change in an explanatory variable on the dependent variable within the focal spatial unit, incorporating feedback effects attributable to spatial dependence. By contrast, the indirect effect quantifies the extent to which changes in an explanatory variable in one region are transmitted through the spatial structure to influence outcomes in other regions. The total effect is defined as the sum of the direct and indirect effects, thus capturing the comprehensive impact of the explanatory variable across the entire spatial system. The results are reported in Table 5. It can be observed that both the estimated direct and indirect effects are statistically significant, further corroborating the existence of spatial spillover effects associated with logistics industry clustering. These findings provide additional empirical support for Hypothesis 4, underscoring the necessity of accounting for both local and interregional interactions when evaluating the determinants of green total factor productivity.

Table 5.

Decomposition of spatial effects.

5.2.4. Robustness Test

In spatial econometric analysis, the specification of the spatial weight matrix is pivotal to accurately capturing the underlying spatial dependence structure among observational units. Given the absence of a universally accepted approach to constructing the spatial weight matrix, empirical results may be sensitive to the particular specification chosen. Consequently, it is essential to conduct robustness checks by substituting the original spatial weight matrix with alternative forms to ensure the stability and reliability of the estimated spatial effects. This practice helps to ascertain that the conclusions drawn from the spatial models are not merely artifacts of a specific spatial weighting scheme, but instead reflect authentic spatial relationships embedded in the data. Accordingly, we conduct robustness analyses by replacing the original geographical spatial weight matrix with several alternative specifications, including the adjacency matrix, the inverse squared distance matrix, and the economic-geographical nested matrix. We then re-estimate the effect of logistics industry clustering on green total factor productivity (GTFP) under these different spatial weighting frameworks. The results are reported in Table 6. It is evident that the estimated effects remain consistent with the baseline regression results, thereby confirming the robustness and reliability of our primary findings.

Table 6.

Robustness test.

5.3. Heterogeneity Analysis

5.3.1. Regional Homogeneity

China’s vast geographic expanse and pronounced regional disparities are likely to result in heterogeneous effects of logistics industry clustering on green total factor productivity (GTFP). To account for this heterogeneity, the sample is divided into eastern, central, and western regions, and the differential impacts of logistics industry clustering on GTFP are systematically analyzed. The results, presented in Table 7, reveal distinct regional patterns. In the eastern region, logistics industry clustering significantly enhances both local GTFP and exerts positive spillover effects on neighboring provinces’ GTFP. This outcome can be attributed to the advanced level of economic development, higher degrees of marketization, and well-established logistics infrastructure characteristic of the east, which collectively facilitate strong economies of scale and scope. Logistics clustering in this context encourages technological innovation, promotes knowledge spillovers, and enables more efficient resource sharing, thereby fostering improvements in both local and adjacent provinces’ green productivity. Moreover, the presence of extensive interregional transportation networks and integrated supply chains further amplifies the capacity for positive externalities to diffuse across spatial boundaries. By contrast, in the central region, logistics industry clustering primarily generates spillover effects that benefit neighboring provinces, while its direct impact on local GTFP is not statistically significant. This may reflect constraints associated with relatively limited local absorptive capacity, weaker innovation systems, and less-developed supporting institutions, which impede the translation of clustering advantages into substantive local green productivity gains. In the western region, logistics industry clustering has no significant effect on either local or neighboring provinces’ GTFP. The absence of significant impacts can be explained by several factors, including underdeveloped industrial bases, inadequate logistics infrastructure, lower levels of technological advancement, and limited interregional connectivity. These structural challenges hinder the realization of clustering economies and restrict the transmission of potential positive spillovers. Overall, these findings underscore that the effects of logistics industry clustering on green development are heavily conditioned by underlying regional economic fundamentals and institutional environments. Consequently, policymakers are advised to design differentiated, region-specific strategies that take into account local characteristics and development stages in order to fully harness the green productivity benefits of logistics clustering.

Table 7.

Regional homogeneity.

5.3.2. Temporal Heterogeneity

To further examine the temporal heterogeneity in the impact of logistics industry clustering on green total factor productivity (GTFP), the sample is divided into two periods, with 2018 serving as the cutoff year. The relevant results are presented in Table 8. The findings reveal that the positive effect of logistics industry clustering on GTFP is significantly more pronounced in the post-2018 period. This observed temporal heterogeneity can be attributed to several key factors. First, since 2018, China has substantially intensified its commitment to green development and the construction of an ecological civilization, as evidenced by the implementation of more stringent environmental regulations and the introduction of stronger policy incentives to foster green transformation. These institutional shifts have heightened both the motivation and regulatory pressure on enterprises to enhance their environmental performance, thereby amplifying the beneficial effects of logistics industry clustering on GTFP. Second, the rapid advancement and adoption of digital technologies and intelligent logistics systems in recent years have markedly improved the efficiency of resource allocation as well as the potential for technological innovation within agglomerated logistics clusters. Such technological progress has augmented not only the direct positive impacts of clustering on local GTFP, but also reinforced positive spillover effects on neighboring regions. Third, rising public awareness regarding environmental protection, together with growing market demand for green products and services, has contributed to creating a more favorable environment for firms to embrace green practices and participate in sustainable supply chains, particularly in the period following 2018. Taken together, these factors have jointly contributed to the stronger positive influence of logistics industry clustering on GTFP observed after 2018, underscoring the critical importance of evolving policy contexts and technological advancements in shaping the green development benefits derived from clustering effects.

Table 8.

Temporal homogeneity.

5.4. Analysis of Spatial Mediation Effect

Preceding heterogeneity analyses show that the total effect of logistics industry clustering on GTFP varies systematically across eastern/central/western regions and strengthens after 2018, suggesting that underlying transmission channels may operate with different intensities across space and time. To probe whether these patterns are driven by distinct propagation mechanisms, we next estimate a spatial mediation effect model, with the results summarized in Table 9. The estimates in columns (1) and (3) reveal that the coefficients of logistics industry clustering (LQ) are significantly positive, indicating that clustering effectively enhances resource allocation efficiency in both labor and capital dimensions. This demonstrates that logistics industry clustering facilitates the optimal matching of production factors by reducing mismatches and by improving the flexibility and efficiency of resource flows. Additionally, the results in columns (2) and (4) show that logistics industry clustering promotes higher green total factor productivity (GTFP) through improvements in resource allocation efficiency. These findings collectively suggest that resource allocation efficiency acts as a key mediating mechanism linking logistics industry clustering to GTFP enhancement. The spatial mediation analysis thus confirms that logistics industry clustering not only exerts a direct positive effect on GTFP, but also generates significant indirect effects through the improvement of factor allocation efficiency, providing robust empirical support for the hypothesized mechanism. Hypothesis 2 is therefore supported. Moreover, the results presented in column (5) indicate that logistics industry clustering significantly promotes industrial upgrading. This is consistent with the view that the concentration of logistics activities enables the reallocation of resources towards higher value-added and more technologically advanced sectors. clustering fosters enhanced connectivity, knowledge exchange, and collaboration among firms, thereby accelerating the structural transformation of regional economies. Furthermore, the findings in column (6) demonstrate that industrial upgrading serves as a critical mechanism through which logistics industry clustering improves GTFP, thus validating Hypothesis 3 [57]. By driving the transition from low-level, resource-intensive industries to higher-level, cleaner, and more efficient sectors, industrial upgrading contributes simultaneously to economic growth and environmental sustainability. This mechanism highlights the imperative of fostering logistics clusters not only to enhance operational efficiency, but also to support the broader goals of green and sustainable development [58].

Table 9.

Spatial mediation effect.

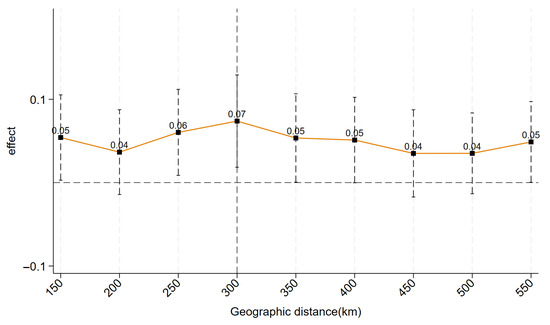

5.5. The Spatial Decay Boundary of Spillover Effects

This study corroborates that logistics industry clustering exerts a significant positive effect on the green total factor productivity (GTFP) of neighboring regions. Nevertheless, this positive spatial spillover is not boundless [59]. To delineate the spatial boundary of the spillover effect, we follow the approach of Yu et al. [48]. and employ a variable geographical distance matrix. The results, presented in Figure 4, indicate that the spillover effect of logistics industry clustering on GTFP fluctuates and ultimately dissipates at approximately 350 km. The observed fluctuations in the spillover effect can be attributed to heterogeneities in regional economic structures, technological capacities, and infrastructure connectivity across different distance intervals. In proximate regions, enterprises are more likely to benefit from knowledge diffusion, supply chain integration, technological spillovers, and the shared use of green logistics infrastructure−all of which facilitate the adoption of environmentally friendly production practices and enhance GTFP. However, as geographical distance increases, the intensity of economic linkages and inter-firm collaboration diminishes, owing to higher transaction and transportation costs, greater institutional and regulatory discrepancies, and reduced opportunities for face-to-face interactions. This pattern of spatial attenuation aligns with the “first law of geography,” which posits that “everything is related to everything else, but near things are more related than distant things.” The finding that the positive spillover effect becomes negligible beyond 350 km implies the existence of a spatial decay boundary, indicating that the effectiveness of logistics industry clustering in fostering green development is geographically constrained. From a policy perspective, these results suggest that strengthening interregional cooperation and enhancing cross-regional infrastructure within the 350 km boundary can maximize the positive externalities associated with logistics clustering. Moreover, targeted policy interventions should be formulated for more distant regions to overcome connectivity barriers and to disseminate the benefits of green development more broadly.

Figure 4.

Spatial spillover boundary.

6. Discussion and Conclusions

6.1. Conclusions

Improving green total factor productivity (GTFP) is essential for attaining sustainable economic growth and advancing environmental objectives. Although logistics industry clustering has the potential to optimize resource allocation and foster technological innovation, its impact on GTFP has not been sufficiently explored. Utilizing balanced panel data from 30 Chinese provinces from 2010 to 2023, this study adopts a spatial Durbin model (SDM) to systematically examine both the local and neighboring (spillover) effects of logistics industry clustering on GTFP. Additionally, a spatial mediation effect model is employed to elucidate the mechanisms by which logistics industry clustering influences local GTFP. To further delineate the extent of spatial externalities, a variable geographical distance matrix is leveraged to identify the spatial boundary of spillover effects. The baseline regression results demonstrate that logistics industry clustering significantly enhances both local GTFP and the GTFP of neighboring regions. This finding remains robust under a variety of spatial weight matrix specifications. Analysis of regional heterogeneity indicates that, in the eastern region, logistics industry clustering generates positive effects on both local and neighboring GTFP. In the central region, the positive effect is limited to neighboring areas, while in the western region, no significant impact is observed for either local or neighboring GTFP. Temporal heterogeneity analysis reveals that the influence of logistics industry clustering on GTFP has become more pronounced in the period after 2018, likely in response to recent policy and technological trends. Spatial mediation analysis further indicates that logistics industry clustering enhances local GTFP primarily through improved resource allocation efficiency and the promotion of industrial upgrading. Moreover, the spatial spillover boundary of logistics industry clustering’s influence on GTFP is found to be approximately 350 km.

Our findings can be benchmarked against prior studies on industrial clustering and green development. Consistent with Yuan et al. (2020) [40], who identified a U-shaped relationship between metropolitan agglomeration and green economic efficiency, we also document that clustering exerts nonlinear and region-specific effects, with the eastern region benefiting more strongly. Similarly, Fang et al. (2024) [34] reported that bonded zones stimulate innovation through competitive spillovers, echoing our evidence that logistics clustering generates positive knowledge diffusion across provincial boundaries. Moreover, our identification of a 350-km spatial decay boundary extends the insights of Eriksson et al. (2008) [38] on localized labor mobility by providing a concrete spatial threshold for green productivity spillovers. Finally, whereas most prior research has emphasized manufacturing or general agglomeration effects (Nielsen et al. 2021; Rigby et al. 2015) [29,39], our study is the first to systematically establish logistics industry clustering as a distinct and high-leverage driver of green total factor productivity, thereby expanding the empirical frontier of clustering research into the logistics domain.

6.2. Policy Recommendations

First, in light of the significant positive impact of logistics industry clustering on both local and neighboring GTFP, regional governments should actively support the development of logistics clusters. Strategic investments in logistics infrastructure, adoption of advanced technologies, and innovation incentives within such clusters can effectively advance green productivity and promote sustainable regional development. Second, recognizing the salient regional heterogeneity in observed effects, policy interventions should be tailored to local contexts. In the eastern region, emphasis should be placed on consolidating and expanding existing logistics clustering to fully leverage both local and spillover benefits. For the central region, targeted measures should aim to strengthen local absorptive capacity and technological capabilities, thereby transforming external spillover effects into tangible local gains. In the western region, addressing infrastructure deficits and promoting foundational economic development are imperative for unlocking potential benefits from logistics industry clustering. Third, the more pronounced positive effects observed after 2018 underscore the importance of recent environmental policies and technological advancements. Policymakers should continue to reinforce environmental regulations, encourage green technological innovation, and provide appropriate incentives within the logistics industry to sustain and amplify the observed improvements in GTFP. Finally, the identification of a spatial spillover boundary at approximately 350 km highlights the need for enhanced cross-regional coordination within this distance. Establishing robust interregional cooperation mechanisms can facilitate knowledge sharing, improve infrastructure connectivity, and enable coordinated environmental governance, thereby maximizing the spatial benefits of logistics industry clustering for regional green development.

6.3. Study Limitations

While this study offers policy-relevant evidence on how logistics industry clustering enhances GTFP and informs coordinated regional logistics strategies−particularly for developing and emerging economies—it has several boundaries. First, the focus on China at the provincial level (2010−2023) limits external validity and precludes cross-country benchmarking. Second, clustering and GTFP are measured with aggregate proxies, which may understate network embeddedness and firm-level heterogeneity, potentially attenuating estimated spillovers. Third, spatial dependence is identified using standard weight matrices that may not perfectly mirror actual logistics interaction networks. These caveats are typical for research in this domain; future work can extend the present framework to finer-grained data, alternative identification strategies, and broader comparative settings.

Author Contributions

Conceptualization, Y.C., W.L., Y.G., Y.Z. and F.L.; methodology, Y.C. and W.L.; software, Y.G. and Y.Z.; validation, Y.Z. and F.L.; formal analysis, W.L.; investigation, Y.C. and Y.G.; resources, F.L.; data curation, Y.Z.; writing—original draft preparation, Y.C., W.L., Y.G., Y.Z. and F.L.; writing—review and editing, Y.C., W.L., Y.G., Y.Z. and F.L.; visualization, Y.Z.; supervision, F.L.; funding acquisition, Y.G. and F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Georgia Tech Foundation Grant on Graduate Research, grant number 2024120701X.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data used in the study are publicly available from the sources cited in the text.

Acknowledgments

We thank seminar participants from the Georgia Institute of Technology and Ocean University of China for their helpful comments on earlier versions of this paper.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Review of Key Studies.

Table A1.

Review of Key Studies.

| Authors | Main Findings |

|---|---|

| Cricelli et al. (2021) [47] | Vertical and horizontal collaborations, along with partnerships with research institutions, significantly promote reverse logistics innovation. In contrast, a wider collaboration breadth negatively affects its adoption. These findings highlight the nuanced role of collaboration in enhancing reverse logistics performance. |

| Eriksson et al. (2008) [38] | Localization economies, driven by the concentration of similar activities, and urbanization economies, linked to labor market size, positively influence job mobility. Localization effects in small regions significantly enhance intraregional job mobility, compensating for disadvantages associated with small populations. This impact is even stronger compared to localization effects in large, diversified metropolitan areas. |

| Fang et al. (2024) [34] | The establishment of BZs promotes significantly patent applications and citations of firms in leading industries located within and outside of BZs, providing suggestive evidence that the innovation spillovers are mainly due to competition among firms within and outside of BZs, namely, the Marshallian externalities. |

| Nefs et al. (2023 ) [35] | The corridor saw significant logistics growth and job creation, especially where policies favored distribution centers. These policies drove regional economic expansion, highlighting their importance. |

| Nielsen et al. (2021) [29] | Agglomeration is a complex phenomenon that merits further study. It can be differentiated between domestic and foreign agglomeration, as well as between Marshall-type externalities (specialization economies) and Jacobs-type externalities (diversification economies). These distinctions help clarify the varied mechanisms through which agglomeration influences firm location and performance. |

| Rigby et al. (2015) [39] | Most manufacturing plants benefit from co-location, but the benefits vary by plant type. |

| Setiawan et al. (2025) [49] | Achieving true economies of scale in transportation between hub ports requires using larger vehicles to consolidate shipments. Optimizing tactical and operational planning is essential to realize these economies of scale. |

| van den Heuvel et al. (2013) [30] | Co-location of logistics establishments brings societal benefits, but the main barrier to municipal cooperation is loss of control. Nevertheless, municipalities that cooperate report positive outcomes. |

| Wang et al. (2025) [31] | High-speed rail (HSR) improves connectivity and reduces travel times, lowering transaction costs and expanding access to markets. This promotes industry clustering near HSR stations, fostering knowledge spillover, innovation, and regional economic growth. HSR also enhances resource allocation and infrastructure, though manufacturing firms see limited impact due to their stable production needs. |

| Yu et al. (2024) [33] | Identify and evaluate freight areas in cities using geospatial data, develop mobility indicators, analyze spatial distributions, and explore the relationship among freight areas, built environments, and socioeconomic conditions. |

| Yuan et al. (2020) [40] | There is a significant positive U-shaped relationship between metropolitan agglomeration (MA) and green economic efficiency (GEE) both short- and long-term. For traditional economic efficiency, MA initially inhibits then promotes it in the short term, but no significant U-shaped effect exists long term. Industrial structure upgrading mediates 31.992% of the MA–GEE relationship. |

References

- Nhan, D.T.; Lu, W.M.; Kuo, K.C.; Nguyen, D.T. Special economic zones and sustainable development: A study in provinces of China. Sustain. Futures 2025, 10, 100864. [Google Scholar]

- Lin, B.; Sun, A.; Xie, Y. Digital transformation and green total factor productivity of heavy pollution enterprises: Impact, mechanism and spillover effect. J. Environ. Manag. 2025, 373, 123619. [Google Scholar] [CrossRef] [PubMed]

- Sharma, H.; Padhi, B.; Sharif, A.; Bashir, M.F. Striving towards green total factor productivity: A bibliometric and systematic literature review for future research agenda. J. Environ. Manag. 2025, 377, 124639. [Google Scholar] [CrossRef]

- Cui, X.; Li, P. Digital economy, environmental expenditure, and green total factor productivity. Financ. Res. Lett. 2025, 73, 106624. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Q. Material balance and correction for the measurement of green total factor productivity growth. Energy Econ. 2025, 148, 108647. [Google Scholar] [CrossRef]

- Liu, S.; He, N.; Cao, X.; Li, G.; Jian, M. Logistics cluster and its future development: A comprehensive research review. Transp. Res. Part E Logist. Transp. Rev. 2022, 168, 102974. [Google Scholar] [CrossRef]

- Hylton, P.J.; Ross, C.L. Agglomeration economies’ influence on logistics clusters’ growth and competitiveness. Regional studies. 2018, 52, 350–361. [Google Scholar] [CrossRef]

- Rivera, L.; Sheffi, Y.; Knoppen, D. Logistics clusters: The impact of further agglomeration, training and firm size on collaboration and value added services. Int. J. Prod. Econ. 2016, 179, 285–294. [Google Scholar] [CrossRef]

- Ding, H.; Liu, C. Carbon emission efficiency of China’s logistics industry: Measurement, evolution mechanism, and promotion countermeasures. Energy Econ. 2024, 129, 107221. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Yuan, Y.; Goto, M. A literature study for DEA applied to energy and environment. Energy Econ. 2017, 62, 104–124. [Google Scholar] [CrossRef]

- Li, H.; Shi, J.F. Energy efficiency analysis on Chinese industrial sectors: An improved Super-SBM model with undesirable outputs. J. Clean. Prod. 2014, 65, 97–107. [Google Scholar] [CrossRef]

- Liu, H.; Yang, R.; Wu, D.; Zhou, Z. Green productivity growth and competition analysis of road transportation at the provincial level employing Global Malmquist-Luenberger Index approach. J. Clean. Prod. 2021, 279, 123677. [Google Scholar] [CrossRef]

- Yang, K.; Kuang, J. How artificial intelligence applications enhance enterprise green total factor productivity? A perspective on human-machine matching and labor skill structure. Econ. Anal. Policy 2025, 87, 926–947. [Google Scholar] [CrossRef]

- Hunjra, A.I.; Zhao, S.; Tan, Y.; Bouri, E.; Liu, X. How do green innovations promote regional green total factor productivity? Multidimensional analysis of heterogeneity, spatiality and nonlinearity. J. Clean. Prod. 2024, 467, 142935. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, H.; Li, X. Which productivity can promote clean energy transition—Total factor productivity or green total factor productivity? J. Environ. Manag. 2024, 366, 121899. [Google Scholar] [CrossRef] [PubMed]