Abstract

The exponential increase in global solid waste generation poses significant environmental, economic, and social challenges, particularly in rapidly urbanizing regions. Traditional waste management methods that focus on handling and disposal have proven unsustainable because of their negative impacts on air, soil, and water quality, and their contribution to greenhouse gas emissions. In response, the concept of zero-waste cities, rooted in circular economy principles, has gained increasing attention in recent years. This study proposes a comprehensive and integrated waste management system designed to optimize resource recovery across four distinct waste streams: household, healthcare, green/organic, and inert. The system integrates four specialized facilities: a Secondary Sorting Facility, Energy Recovery Facility, Composting Facility, and Inert Processing Facility, coordinated through a central Primary Sorting Hub. By enabling interconnectivity between these processing units, the system facilitates material cascading, maximizes the reuse and recycling of secondary raw materials, and supports energy recovery and circular nutrient flow. The anticipated benefits include enhanced operational efficiency, reduced environmental degradation, and generation of multiple revenue streams. However, the implementation of such a system faces challenges related to high capital investment, technological complexity, regulatory fragmentation, and low public acceptance. Overcoming these limitations will require strategic planning, stakeholder engagement, and adaptive governance.

1. Introduction

Urbanization and economic growth have led to an exponential increase in solid waste generation worldwide. According to the World Bank, global annual municipal solid waste (MSW) generation is expected to rise from 2.01 billion tons in 2018 to over 3.40 billion tons by 2050 if no significant interventions are made [1,2]. This trend poses serious environmental, economic, and social challenges, particularly in rapidly urbanizing regions, where infrastructure and governance systems struggle to keep pace with rising waste volumes [3].

Traditional waste management methods employed across generations have predominantly focused on handling and disposal without incorporating the core principles of the 3R strategy: reduce, reuse, and recycle [4]. Conventional practices, such as landfilling, open dumping, and unregulated incineration, have proven unsustainable because of their negative impacts on air, soil, and water quality [5,6] and their contribution to greenhouse gas emissions [7,8]. Landfills alone account for approximately 11% of global methane emissions [9,10], a potent greenhouse gas with a global warming potential 28.5 times higher than that of carbon dioxide over a 100-year period [11]. In addition, these conventional methods represent a linear flow of materials—extract, produce, consume, and dispose—which results in unnecessary loss of valuable resources and contributes to ecological degradation [12], underscoring the urgent need to transition towards more sustainable and circular waste management models.

In response to these challenges, the concept of zero-waste cities has gained increasing attention among researchers, policymakers, and urban planners [13,14,15]. Rooted in circular economy principles [16], zero-waste strategies aim to eliminate waste through systemic design, prioritizing resource recovery, material reuse, and energy valorization over disposal [17]. Closely aligned with these principles is the waste-to-energy approach [18], which supports the five Rs of the circular economy—reduce, reuse, recycle, repurpose, and recover—by transforming non-recyclable waste fractions into usable forms of energy [19]. However, the implementation of such systems faces several challenges, including inefficient waste collection, the need for extensive pretreatment, and limitations in conversion technologies, all of which can hinder the economic viability and scalability of waste-to-energy processes [20]. To fully realize the vision of sustainable urban environments, a paradigm shift is required from fragmented, end-of-pipe solutions to integrated, multi-stream, and circular waste management systems that align with the Sustainable Development Goals (SDGs), such as SDG 11 (“Make cities inclusive, safe, resilient and sustainable”) and SDG 12 (“Ensure sustainable consumption and production patterns”) [21].

Despite notable advancements in individual waste treatment technologies, such as automated sorting for recyclables [22], composting of organic waste [23], thermal treatment of non-recyclables [24], and inert recycling in construction [25], these processes are often implemented in isolation. This lack of integration results in missed synergies, operational inefficiencies, and suboptimal environmental performance. Furthermore, regulatory fragmentation, insufficient funding mechanisms, and limited public engagement continue to hinder the adoption of holistic models that integrate diverse waste streams and treatment technologies in urban contexts.

This research introduces a holistic and unified waste management approach aimed at enhancing resource recovery across four specific waste categories: household waste, healthcare waste, organic/green waste, and inert waste. The system incorporates four dedicated facilities: a Secondary Sorting Facility for recyclables, an Energy Recovery Facility equipped with pollution control measures, a Composting Facility for biological processing, and an Inert Processing Facility for the valorization of construction waste, all coordinated by a central Primary Sorting Hub. By fostering connectivity among these processing units, the system enables material cascading, thereby maximizing the reuse and recycling of secondary raw materials. It also facilitates energy recovery by deriving value from non-recyclable waste through controlled incineration. Moreover, the system promotes circular nutrient flow through two distinct pathways: biologically, by converting organic waste into compost for agricultural use; and technically, by substituting virgin aggregates with recycled materials, thereby reducing reliance on quarrying activities.

The proposed approach builds on established analytical frameworks, such as industrial ecology, life cycle assessment (LCA), and material flow analysis, which are essential for evaluating environmental and economic burdens and optimizing resource recovery processes [26]. This foundation is also rigorously supported by extensive research in the field, including studies on evaluating the sustainability of diverse solid waste management systems [27,28,29]. This conceptual framework makes a significant contribution to the expanding discourse on circular urban metabolism by providing a scalable, adaptable, and technically feasible pathway for achieving zero-waste cities. This aligns with the vision of a fully functional circular economy, which can lead to substantial reductions in CO2 emissions and significant carbon sequestration. While empirical validation remains a subject for future work, this study outlines the anticipated benefits, challenges, and policy implications based on current technological capabilities and best-practice case studies.

2. Methodology

The development of the proposed system adhered to a structured methodological framework, transitioning from descriptive insights to a robust evidence-based system. This process encompasses three primary phases. Initially, a comprehensive literature review was meticulously conducted to acquire a thorough understanding of the current challenges and identify the best practices in sustainable waste management. These best practices, which include established technologies and operational benchmarks from advanced waste treatment systems, are explicitly documented and integrated in Section 3 and Section 4. Specifically, Section 3.2 details the design and technological components of each facility, directly derived from an integrative review of current global practices in solid waste management. Furthermore, Section 4 elaborates on the anticipated recovery rates and environmental benefits, making comparisons to the performance benchmarks reported in the scientific literature and sector guidelines. Subsequently, we focused on defining the largest waste streams that exhibit both significant environmental impact and high potential for resource recovery within urban contexts, leading to the identification of household, healthcare, green/organic, and inert waste as the primary streams for this study. This selection was systematically informed by a comprehensive review of waste generation patterns and resource recovery potential in urban settings, as evidenced by studies such as those by Zargar et al. [30] on the characterization of municipal solid waste. Specifically, healthcare waste, while requiring specialized handling due to its hazardous and infectious nature, was included due to its significant environmental impact if improperly disposed of and substantial energy recovery potential through controlled thermal treatment. This approach aligns with the established literature, where the thermal treatment of healthcare waste is recognized as a viable method for both pathogen destruction and energy valorization. The operationalization of these criteria is further elaborated in Section 3.1, where the distinct processing pathways and resource recovery potentials for each selected waste stream are presented in detail. Finally, we identified the most advanced and sustainable technologies applicable to each specific waste type or stream, deliberately excluding industrial waste. Industrial waste typically requires highly diverse and often large-scale specialized treatment protocols that fall outside the scope of a general urban waste management system, which is focused on common municipal waste streams. In contrast, healthcare waste, despite necessitating specialized treatment due to its hazardous nature, is consistently generated within urban contexts and can be effectively integrated into an advanced urban waste management system through dedicated thermal treatment technologies within the Energy Recovery Facility. This distinction underscores our focus on comprehensive urban waste management, where specific, albeit hazardous, urban waste streams are managed through integrated, specialized components within the broader municipal framework, as opposed to highly variable and large-volume industrial effluents that often require distinct industrial ecology solutions. This included a detailed examination of technologies for secondary sorting, energy recovery, composting, and the processing of inert materials. A critical phase of the methodology involved assessing the integration potential between the identified technologies and the interconnection potential between the different waste streams and processing units. This ensured the proposed system’s capacity for seamless material flow, optimized resource recovery, energy synergy, and the practical application of industrial symbiosis principles.

3. Proposed Approach

3.1. System Overview

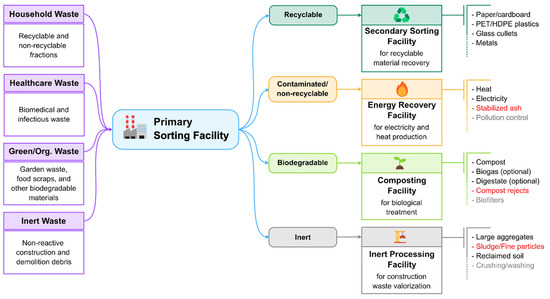

The proposed waste management system adopts a holistic, integrated, and circular approach designed to optimize the handling, treatment, and valorization of four distinct waste streams. At the core of the system lies a Primary Sorting Facility, which acts as a central hub for receiving, segregating, and directing waste materials to specialized downstream facilities. Four specific waste streams can be managed by the system, as shown in Figure 1. These streams were selected because of their dominance in urban waste generation, distinct processing pathways, and high resource recovery potential.

Figure 1.

Flowchart of the proposed solid waste management approach, incorporating the full spectrum of material and energy flows across the four specialized facilities. The diagram illustrates the primary sorting facility, followed by dedicated treatment pathways for household, healthcare, green/organic, and inert waste streams. Secondary raw materials recovered from these processes can either be directly reused (e.g., intact glass bottles, clean metal containers) or recycled (e.g., shredded plastics, crushed aggregates), depending on their condition and market demand. Residual fractions—including stabilized fly ash, non-recyclable fines, and compost rejects—are depicted in red color, highlighting the need for secure landfilling or alternative stabilization techniques.

Household Waste: Mixed municipal solid waste generated from residential areas, typically containing both recyclable and non-recyclable fractions.

Healthcare Waste: Biomedical and infectious waste originating from hospitals, clinics, and other healthcare institutions that requires special handling due to its hazardous nature.

Green/Organic Waste: Garden waste, food scraps, and other biodegradable materials primarily suitable for biological treatment.

Inert Waste: Non-reactive construction and demolition (C&D) debris such as concrete, bricks, soil, and stones, which can be processed into secondary raw materials.

Although some overlap exists between these streams (e.g., inert materials may be found within household waste, and garden waste can originate from households), the classification in this model is primarily source-based rather than compositional. This ensures that each category is associated with a dedicated collection and processing strategy, thereby enhancing operational efficiency and environmental performance.

Upon arrival at the Primary Sorting Facility, these waste streams are initially inspected, weighed, and stored in designated zones to prevent cross-contamination. The facility employs a combination of manual sorting and automated separation technologies, such as conveyor belts, optical sorters, magnets, and air classifiers, to identify and isolate materials based on their physical and chemical properties. Following the initial sorting process at the Primary Sorting Facility, each waste fraction is dispatched to one of four dedicated treatment facilities tailored to handle specific types of waste with optimized recovery and processing technologies. Recyclable components, such as glass, paper, plastic, and metals, are directed to the Secondary Sorting Facility for further separation and refinement before being sent to recycling industries. Contaminated, non-recyclable, and hazardous waste (mainly from the healthcare stream) is directed to the Energy Recovery Facility, where it undergoes controlled incineration to generate thermal and electrical energy. Organic and green waste is transported to the Composting Facility, where it is transformed into nutrient-rich compost through aerobic decomposition processes. Inert materials, such as concrete, bricks, and soil, are processed at the Inert Processing Facility, where they undergo crushing, screening, and washing to produce secondary construction materials.

The proposed integrated waste management model aligns with and builds on several established zero-waste and circular economy frameworks. Frameworks for zero-waste cities in China emphasize waste prevention, reuse, and recycling, particularly highlighting composting and material recovery as key strategies for reducing landfill dependency [13,31]. Similarly, our model integrates organic valorization and multi-stream sorting to achieve high resource recovery rates. However, it extends beyond this framework by incorporating regulated energy recovery from non-recyclable fractions and addressing waste streams that are often excluded from pure zero-waste strategies. In contrast, the circular urban metabolism model focuses on mapping and optimizing urban material flows to enhance resource efficiency [32]. Our system enhances this concept through real-time coordination between processing units, enabling the cascading use of materials and cross-sectoral synergies. Meanwhile, the Kalundborg Symbiosis, a leading example of industrial ecology, demonstrates how by-product exchange among industries can create closed-loop systems [33]. While primarily applicable to industrial parks, our model adapts this principle at the municipal level by repurposing incineration bottom ash, recovering heat for composting, and integrating inert valorization into the construction supply chain. Finally, the EU Circular Economy Action Plan provides a policy-driven roadmap for sustainable production and consumption [34], which our system operationalizes through digital traceability, regulatory compliance, and stakeholder engagement. Unlike many existing models, which focus on specific sectors or material flows, our approach offers a unified, scalable blueprint that combines diverse waste treatment technologies under a single governance and operational framework.

3.2. Integrated Waste Processing Facilities

The proposed integrated waste management system consists of four specialized processing facilities, each tailored to manage a specific category of waste through optimized recovery and treatment technologies. Table 1, Table 2, Table 3 and Table 4 provide a summary of the functional roles, input streams, technological components, output streams, and environmental considerations for each facility. The design and technological components outlined herein are derived from an integrative review of current global practices in solid waste management [35].

Table 1.

Secondary Sorting Facility—material recovery from recyclables.

Table 2.

Energy Recovery Facility—thermal treatment of contaminated waste.

Table 3.

Composting Facility—biological treatment of organic waste.

Table 4.

Inert Processing Facility—valorization of construction and demolition waste.

The integration strategy underpinning the proposed waste management system was meticulously designed to ensure seamless coordination across all four specialized processing facilities, enabling efficient material flow, energy recovery, data exchange, and environmental performance optimization. Material flows are strategically managed through modular design and synchronized logistics, with each facility functioning as both a processing node and a source of input for downstream valorization. Recyclable materials, such as glass, paper, plastics, and metals, recovered at the Secondary Sorting Facility are directed towards external recycling industries or internal pre-processing units, ensuring their reintroduction into the production cycle. The contaminated and non-recyclable fractions are routed to the Energy Recovery Facility, where they undergo controlled incineration to generate thermal or electrical energy. Organic matter processed at the Composting Facility yields nutrient-rich compost that supports agricultural and landscaping applications, whereas digestate from optional anaerobic digestion can be further refined or returned to soil enhancement systems. Inert materials treated at the Inert Processing Facility are transformed into secondary construction aggregates, effectively substituting virgin resources in civil infrastructure projects. This cascading flow of materials minimizes landfilling, enhances resource utilization, and reduces dependency on primary raw materials.

In addition to material integration, the system incorporates a strategic approach to energy recovery and cogeneration. The thermal and electrical energy generated at the Energy Recovery Facility is distributed throughout the complex to support auxiliary operations. Excess heat is utilized via district heating networks or applied in drying processes within composting and inert washing units, whereas steam-driven turbines produce electricity that powers sorting, crushing, and monitoring systems. Any surplus energy can be fed into the grid or stored using battery systems or thermal storage tanks to manage the peak load demand. This combined heat and power (CHP) integration significantly improves the overall system efficiency and contributes to carbon neutrality by displacing fossil fuel-based energy sources.

To enhance operational transparency, real-time decision-making, and waste stream traceability, the system integrates a centralized digital control platform. A Waste Management Information System (WMIS) combines RFID-tagged bins, automated weighbridges, GPS-tracked collection vehicles, and SCADA-based process monitoring tools to ensure end-to-end visibility and control. Advanced data analytics support the prediction of waste inflow patterns, optimize routing strategies, and improve sorting efficiency. Furthermore, the digital twins of each facility enable predictive maintenance and allow for simulation-based analyses of process variability, contributing to higher throughput, reduced downtime, and enhanced compliance with regulatory reporting standards.

Waste valorization pathways are embedded within the system through the application of industrial symbiosis principles, promoting the cross-facility reuse of by-products and minimizing residual outputs. For example, bottom ash generated during incineration is repurposed for road base construction after undergoing leaching tests to confirm environmental safety. Dust and fine particles produced during inert processing are stabilized and incorporated into cement manufacturing, whereas reject fractions from composting may be co-fired with other combustibles in an incinerator, maximizing energy recovery. Similarly, metals and glass cullet recovered from sorting operations are reintroduced into manufacturing supply chains, reinforcing circularity and reducing the reliance on new raw materials. These synergies not only improve economic returns but also significantly reduce the environmental footprint of the system.

Beyond technological and material integration, the proposed model incorporates a robust governance framework aimed at aligning the system with municipal policies, community engagement initiatives and international regulatory standards. Coordination with local governments ensures adherence to zoning regulations and facilitates the achievement of waste diversion targets. Collaboration with recycling industries, agricultural cooperatives, and construction firms supports the market absorption of secondary materials and enhances the economic viability of the system. Public education campaigns play a critical role in improving participation in source separation programs, thereby enhancing feedstock quality at primary sorting facilities. Moreover, the system complies with key international directives, such as the EU Waste Framework Directive, the Basel Convention on Transboundary Movement of Hazardous Waste, and WHO guidelines for healthcare waste management, thereby ensuring legal conformity and operational legitimacy.

This multidimensional integration strategy, encompassing material, energy, digital, and stakeholder dimensions, forms the backbone of a truly circular waste management system. By fostering interconnectivity, optimizing resource use, and embedding sustainability at every stage, the proposed model provides a scalable and replicable blueprint for transitioning to zero-waste cities.

4. Expected Outcomes of the Proposed Approach

The integrated waste management system proposed in this study represents a comprehensive model designed to transition from linear waste disposal methods to a circular economy paradigm. Although no empirical data or simulations were performed within the scope of this study, the expected outcomes were derived from the established operational benchmarks of similar systems, technological capabilities, and environmental impact assessments reported in the scientific literature and sector guidelines.

4.1. Operational Efficiency and Material Recovery

A core objective of the proposed integrated waste management system is to enhance resource recovery by maximizing the efficiency of sorting, processing, and valorization across various waste streams. The design leverages established technologies and operational benchmarks from advanced waste treatment systems to project realistic recovery rates for key recyclable materials at the Secondary Sorting Facility. Based on performance data from mechanical and optical sorting plants in Europe and North America, it is anticipated that the facility can recover 80–90% of paper and cardboard, 70–85% of plastics (PET/HDPE), over 90% of both ferrous and non-ferrous metals, and 75–85% of glass cullet [36,37,38,39]. These figures reflect the optimal operating conditions and assume effective pre-sorting at the Primary Sorting Facility to minimize contamination and improve separation accuracy.

The high recovery rate for metals, particularly ferrous and non-ferrous types such as aluminum and copper underscores the economic and environmental value of this stream given the energy-intensive nature of primary metal production [40,41]. Similarly, the recycling of PET and HDPE plastics contributes to reducing plastic pollution and conserving petroleum-based resources, although challenges related to mixed polymer composition and residual contaminants may affect their yield and quality [42,43]. Glass recycling is highly efficient in modern facilities because of its inert properties and compatibility with optical sorting technologies. However, breakage during handling and transport can slightly reduce overall recovery rates [44].

In addition to material recovery, the Energy Recovery Facility is expected to contribute significantly to system-wide efficiency by converting non-recyclable and contaminated fractions into usable energy sources. Under controlled combustion conditions, approximately 9.5–13.2 GJ of thermal energy and up to 650–873 kWh of electricity per ton of municipal solid waste can be generated via steam turbines [45]. This aligns with the best practices observed in waste-to-energy plants in Japan and Germany, where energy recovery supports district heating networks and local power grids while minimizing reliance on fossil fuels [46,47].

Organic waste treatment through composting is another critical component of operational efficiency. The Composting Facility is expected to stabilize over 85% of organic matter, yielding 40–60% of compost based on dry input weight depending on the initial moisture content, contamination levels, and process efficiency [48]. This aligns with findings from centralized composting operations in urban settings, which demonstrate that aerobic decomposition can produce nutrient-rich soil amendments suitable for agriculture and landscaping, provided that source separation minimizes plastic and chemical residues [49].

Finally, the Inert Processing Facility plays a vital role in construction sustainability by transforming demolition debris into secondary raw material. It is projected that 85–95% of the incoming construction and demolition waste (CDW) can be processed into reusable aggregates, with up to 50% substitution potential for natural sand and gravel in civil infrastructure applications [50,51]. This not only reduces landfill pressure but also mitigates environmental degradation associated with quarrying activities. However, dust generation, equipment wear, and variability in feedstock composition must be carefully managed to maintain product consistency and market acceptance of these pellets.

4.2. Environmental Performance and Impact Reduction

One of the most notable anticipated benefits is the reduction in methane emissions from organic waste decomposition in landfills. Diverting food scraps, green waste, and other biodegradable materials to the Composting Facility could prevent the release of approximately 0.9–14 Tco2eq per ton of food waste through controlled aerobic decomposition [52]. This aligns with the findings of life cycle assessments that highlight composting as an effective mitigation strategy for urban organic waste [53,54].

In addition to organic waste diversion, the Energy Recovery Facility plays a crucial role in climate change mitigation by substituting fossil fuels with energy derived from non-recyclable municipal solid waste [55]. Under optimal conditions, the facility is projected to generate up to 8 MWh of electricity per ton of processed waste, potentially avoiding 230–500 kgCO2eq per ton of emissions compared to coal- or oil-based power generation [56]. These figures are consistent with the performance benchmarks observed in modern waste-to-energy plants in Europe and East Asia, where combined heat and power (CHP) systems further enhance efficiency and reduce reliance on carbon-intensive energy sources [45,57]. Moreover, the Energy Recovery Facility integrates advanced emission control technologies, including selective catalytic reduction (SCR), dry scrubbing with activated carbon injection, and fabric filtration systems. These measures ensure compliance with the strictest international standards, such as the EU Directive 2010/75/EU and its recent amendments under Directive (EU) 2024/1785 [58]. Specifically, NOₓ reduction can reach over 90% efficiency through SCR [59], whereas dioxin and furan levels are controlled to <0.1 ng TEQ/Nm3 via activated carbon adsorption [60]. Particulate matter emissions are limited to <10 mg/m3 due to high-efficiency filtration [61]. Continuous Emission Monitoring Systems (CEMS) are employed to ensure ongoing compliance, enabling real-time adjustments and transparent regulatory reporting.

Beyond direct emission reductions, the system contributes to resource conservation and reduced ecological footprints by promoting the reuse and recycling of secondary materials. The Secondary Sorting Facility enables the recovery of valuable raw materials, such as paper, plastics, metals, and glass, each of which represents a reduction in the demand for virgin extraction. For instance, aluminum recycling alone can save up to 95% of the energy required to produce primary metals [62,63]. Similarly, the use of recycled aggregates in construction reduces the need for quarrying activities, which are associated with habitat destruction, soil erosion and biodiversity loss [64]. Based on existing data, substituting up to 50% of natural sand and gravel with recycled alternatives could lower the embodied carbon of infrastructure projects by approximately 20% per ton of the aggregate produced [65].

Pollution control is another key environmental benefit of the system, particularly in terms of air, water, and soil contamination. The Energy Recovery Facility incorporates advanced flue gas cleaning technologies, including scrubbers, electrostatic precipitators, and selective catalytic reduction units, which are designed to meet or exceed the emission limits defined by EU Directive 2010/75/EU [58,59]. These systems significantly reduce the release of particulate matter, acid gases, heavy metals, and dioxins, addressing concerns related to public health and environmental justice that are often associated with incineration facilities [66]. Meanwhile, the Composting Facility through rotary drum reactors employs biofilters and leachate collection systems to minimize odor emissions and prevent groundwater contamination, ensuring compliance with local and international environmental standards [29].

Finally, the system enhances waste valorization pathways and industrial symbiosis, reinforcing its role in supporting circular economy objectives. For example, bottom ash generated during incineration can be repurposed for road base construction after leaching tests to confirm environmental safety [67]. Dust and fine particles recovered from inert processing can also be stabilized and incorporated into cement manufacturing, thereby minimizing residual waste and maximizing resource utilization [68]. These cascading uses of by-products not only reduce the environmental burden but also support sustainable production models across multiple sectors.

4.3. Economic Viability and Revenue Streams

In addition to its environmental advantages, the proposed integrated waste management system exhibits significant economic potential through various revenue-generating opportunities. By converting waste into valuable resources, such as recyclables, compost, secondary construction materials, and energy, the model promotes financial sustainability while simultaneously reducing the long-term expenditures associated with landfilling and pollution mitigation. Although the initial capital investment required for infrastructure development, automation, and pollution control technologies is considerable, the anticipated revenues and cost-saving mechanisms indicate that full-cost recovery and operational self-sufficiency may be attainable within five to ten years. For example, Abu-Qdais et al. [69] reported that by adopting circular economy strategies, specifically through recycling and composting, full-cost recovery can be achieved within the first three years.

A key source of income lies in the marketability of the recovered materials from the Secondary Sorting Facility. Paper, plastics, metals, and glass cullet can be reintroduced into manufacturing supply chains, generating steady revenue streams based on current commodity prices and demand. In particular, metal recycling, including ferrous and non-ferrous types such as steel and aluminum, offers high economic returns owing to the significant energy savings compared to primary production [70]. Similarly, the resale of clean glass and plastic fractions supports circular consumption models and contributes to industrial resource security [71]. Based on market valuations in Europe, the sale of these materials alone could generate significant revenue per ton, particularly when supported by stable procurement contracts and extended producer responsibility (EPR) schemes [72].

In addition to material sales, energy generation from non-recyclable waste is a promising financial avenue. The Energy Recovery Facility is expected to convert residual municipal solid waste into approximately 0.5–0.8 MWh of electricity or equivalent thermal energy per ton, depending on the combustion efficiency and facility scale [55]. In regions with favorable policies for renewable energy feed-in tariffs or carbon credits, this output can serve as a reliable source of income while simultaneously displacing fossil fuel-based power generation [73,74,75]. Furthermore, the surplus heat generated during incineration can be distributed via district heating networks or used internally for drying organic waste at the Composting Facility, enhancing overall energy efficiency and lowering operational costs [76].

Another economically viable stream arises from the production of high-quality compost derived from green waste and food waste. With the growing demand for organic farming, landscaping, and urban greening initiatives, compost has emerged as a competitive soil conditioner that can substitute synthetic fertilizers and peat-based amendments [77]. Assuming an average yield of 40–60% compost from dry organic input, the system could support both local agriculture and commercial markets, depending on regional policy incentives and certification standards [78]. However, it is crucial to note that variations in compost quality standards across regions, especially in developing countries, may hinder cross-border trade and inter-regional scalability [79]. Establishing harmonized regulatory frameworks and adopting internationally recognized benchmarks, such as PAS 100 or its equivalent, are essential to ensure product consistency and facilitate broader market access [80]. Additionally, the integration of anaerobic digestion prior to composting could further enhance value creation by enabling biogas production, which can be utilized for on-site energy needs or injected into the natural gas grid [81].

Finally, valorization of CDW presents a major opportunity for cost recovery and industry collaboration. As mentioned earlier, the Inert Processing Facility is projected to recover 85–95% of incoming C&D materials, with up to 50% substitution potential for natural aggregates in road bases, concrete mixes, and other civil engineering applications [82,83]. Given the rising costs associated with quarrying and transportation, recycled aggregates are increasingly viewed as sustainable and economically attractive alternatives for urban infrastructure projects [84]. Moreover, public procurement policies mandating the use of recycled materials in government-funded construction can further stimulate demand and improve return on investment [85,86].

From a systemic perspective, the proposed system offers significant indirect economic benefits, including job creation, reduced landfill fees, and eligibility for climate financing instruments. Employment opportunities span waste collection, sorting, processing, logistics, maintenance, and monitoring, providing stable employment in sectors that are often accessible to workers with diverse skill levels [87]. Simultaneously, reduced reliance on landfills translates into lower gate fees, remediation costs, and environmental penalties, enhancing fiscal resilience at the municipal level. When combined with potential carbon credits or emissions trading incentives, these factors further strengthen the business case for integrated waste-management systems.

4.4. Policy, Regulatory, and Social Considerations

The successful implementation and long-term sustainability of the proposed integrated waste management system are closely related to supportive policy frameworks, regulatory alignment, and active public participation. While technological and economic feasibility are essential, institutional backing and societal acceptance play equally critical roles in ensuring the effective adoption and operation of these systems across diverse urban contexts.

From a policy perspective, the system aligns with several international and regional sustainability frameworks, thereby reinforcing its legitimacy and potential for integration into national or municipal strategies. This supports the objectives of the EU Circular Economy Action Plan, which emphasizes resource efficiency, material recovery, and sustainable production models [34]. Furthermore, compliance with the Basel Convention on the Transboundary Movement of Hazardous Waste ensures the responsible handling of contaminated and healthcare-derived waste streams, particularly in cross-border settings [88]. The model also adheres to the World Health Organization (WHO) Guidelines for Healthcare Waste Management, promoting safe disposal practices and minimizing public health risks associated with infectious materials [89].

In addition to international agreements, national and local regulations must be harmonized to facilitate the smooth implementation of these agreements [90]. The licensing requirements for waste treatment facilities, particularly incineration units, often involve lengthy approval processes owing to environmental and community concerns. Streamlining these procedures through dedicated regulatory sandboxes or fast-track approvals can accelerate project development while maintaining safety and environmental standards. Moreover, establishing clear quality benchmarks for compost, recycled aggregates, and secondary raw materials is essential to ensure marketability and prevent inconsistencies that could hinder the confidence of stakeholders.

Legislative support further enhances the viability of such systems by creating an enabling environment for circular economy practices. Policies such as extended producer responsibility (EPR) schemes, green public procurement mandates, and landfill tax incentives have proven effective in driving investments towards sustainable waste solutions [91,92]. In particular, EPR programs shift responsibility from municipalities to manufacturers, encouraging product design improvements and end-of-life recovery strategies that align with the principles of closed-loop resource management (CLRM). Similarly, carbon pricing mechanisms and renewable energy credits can provide additional financial incentives for energy recovery and emission reduction initiatives [93,94].

Beyond formal policies, community engagement and behavioral change are crucial for the system’s success, especially in source separation and waste minimization. Public awareness campaigns, school-based education programs, and digital platforms that track recycling performance can significantly improve feedstock quality at primary sorting facilities and enhance overall system efficiency. Transparent communication about the benefits and safety measures of waste treatment technologies, particularly regarding incineration and composting, can also help mitigate NIMBY (“Not In My Backyard”) attitudes and foster broader social acceptance [95,96]. Community involvement in decision-making processes, including siting decisions and benefit-sharing mechanisms, further strengthens the trust and cooperation between stakeholders.

Finally, the integration of digital monitoring tools, such as RFID tracking, SCADA systems, and predictive maintenance platforms, supports regulatory compliance, facilitates reporting, and enables adaptive governance. Real-time data on waste inflows, processing efficiency, and environmental performance not only enhance operational transparency but also assist policymakers in identifying gaps and adjusting their strategies. These technologies also contribute to smart city initiatives, which are integrated data ecosystems that support evidence-based planning and responsive urban governance.

5. Challenges and Limitations

Despite the anticipated environmental, economic, and policy benefits of the proposed integrated waste management system, its implementation and long-term success are constrained by several technical, financial, regulatory, and sociocultural challenges. Recognizing and addressing these limitations is essential for guiding future planning, investment decisions, and governance strategies.

One of the most significant barriers is the high initial capital investment required to establish infrastructure and acquire advanced technologies. The development of a centralized Primary Sorting Facility, along with four specialized downstream treatment units—recycling, energy recovery, composting, and inert valorization— incurs considerable costs related to land acquisition, engineering design, equipment procurement, and pollution control systems. These financial demands can be particularly prohibitive for municipalities in low- and middle-income countries, where public budgets may not support large-scale investments without external funding or private sector involvement [97]. Although projected revenue streams from material sales, energy generation, and secondary construction materials offer long-term financial viability, the upfront cost barrier remains a critical constraint that must be addressed through innovative financing models, green bonds, or public-private partnerships [98].

In addition to financial constraints, technological and operational complexities present major limitations. The efficient functioning of the system requires high levels of coordination, skilled labor, and maintenance expertise across multiple facilities. For instance, the effectiveness of optical sorting at the Secondary Sorting Facility depends on both the quality of the feedstock and the performance of near-infrared (NIR) sensors, which can be affected by contamination and mixed waste composition [99]. Similarly, energy recovery facilities require precise combustion control and continuous emission monitoring to ensure compliance with air quality standards [100,101]. Failure to maintain optimal conditions across all processing stages can result in reduced throughput, lower product quality, or increased emissions. Moreover, the integration of digital tools, such as SCADA systems, RFID tracking, and predictive maintenance platforms, requires both technical capacity and institutional readiness, which may be lacking in many urban settings [102,103].

The handling of hazardous and contaminated waste, particularly healthcare-derived materials, poses specific risks and operational difficulties. Incineration of medical waste, while effective in reducing volume and destroying pathogens, generates fly ash containing heavy metals and potentially toxic compounds such as dioxins and furans [104]. This byproduct requires stabilization or secure landfilling, which adds to operational complexity and cost. Furthermore, the possibility of equipment failure, incomplete combustion, or unplanned emissions can lead to secondary pollution, particularly if not adequately monitored and controlled. Although this study focuses on the conceptual design and integration of advanced waste treatment technologies, real-world implementation would necessitate comprehensive risk assessment frameworks. Such assessments should evaluate the potential environmental and public health impacts arising from operational anomalies, material mismanagement, or unforeseen interactions within and between processing units. In addition, composting facilities that process mixed organic waste may encounter contamination from plastics, metals, or chemical residues, affecting compost quality and marketability [105]. Effective protocols for waste segregation at the source, combined with robust pretreatment and monitoring mechanisms, are necessary to mitigate these risks and ensure safe operation.

From a regulatory and policy perspective, inconsistent legislation, a lack of harmonized standards, and insufficient enforcement mechanisms often hinder the adoption of integrated waste management systems. Environmental licensing for incineration facilities or composting operations can involve lengthy approval processes owing to community concerns regarding emissions or land use. Furthermore, variability in regulations regarding compost quality, recycled construction materials, and waste classification can impede cross-border trade and interregional scalability. The absence of supportive legislation, such as extended producer responsibility (EPR) schemes, green procurement mandates, or landfill tax incentives, may also discourage private investment and slow the transition towards circular models.

Public acceptance and behavioral factors are equally important, as they play a crucial role in the success of any waste management initiative. Source separation programs depend heavily on public participation and education; inadequate awareness or resistance to behavioral changes can compromise feedstock quality and system efficiency. Additionally, local opposition to siting waste facilities near residential areas (NIMBY syndrome) can delay project implementation and increase logistical complexity. Trust in municipal authorities and transparency in decision-making are essential for overcoming resistance and fostering broader social acceptance.

Finally, the scalability and adaptability of the proposed system vary depending on geographic, demographic, and economic contexts. Densely populated cities may face spatial constraints in locating multiple treatment facilities within close proximity, whereas rural or peri-urban areas may lack the waste volumes needed to justify full-scale infrastructure development. Variability in waste composition across regions, such as differences in per capita generation rates, recyclable content, and organic fraction, also necessitates customized facility design. Furthermore, climatic conditions, such as humidity, rainfall, and temperature, can influence composting performance, material stability, and air pollution dispersion patterns, requiring localized adaptations to ensure system resilience.

In summary, although the proposed model offers a promising pathway towards sustainable and zero-waste cities, it must navigate the complex landscape of financial, technological, regulatory, and socio-cultural challenges. Overcoming these limitations will require strategic planning, stakeholder engagement, and adaptive governance that integrates technical innovation, social inclusion, and supportive policy frameworks.

6. Conclusions

The transition towards zero-waste cities is a pivotal aspect of sustainable urban development in the 21st century. This study introduced an integrated circular waste management system designed to optimize resource recovery, mitigate environmental degradation, and facilitate the shift from linear to closed-loop material flows. By incorporating four specialized treatment facilities—recycling (Secondary Sorting Facility), energy recovery (Incineration Facility), organic valorization (Composting Facility), and inert reutilization (Inert Processing Facility)—the proposed model enables the coordinated processing of multiple waste streams while maximizing material and energy recovery. The primary anticipated benefits include the following:

- -

- A substantial reduction in landfill dependency through advanced sorting and valorization.

- -

- Enhanced climate change mitigation via reductions in greenhouse gas emissions from organic waste diversion, energy recovery, and substitution of virgin materials.

- -

- Resource conservation supported by high recovery rates of paper, plastics, metals, and glass, as well as the cascading use of industrial by-products.

- -

- Economic viability demonstrated through diverse revenue streams from recyclables, compost, secondary aggregates, and energy generation.

- -

- Alignment with international regulatory frameworks, such as the EU Circular Economy Action Plan, the Basel Convention, and the WHO Guidelines for Healthcare Waste Management, ensuring legal conformity and operational legitimacy.

Despite these advantages, the implementation of such systems faces several challenges, including high initial capital investment, technological complexity, regulatory fragmentation, and public acceptance. Addressing these limitations requires strategic planning, institutional coordination, and adaptive governance that integrate technical innovation with social engagement and supportive policy frameworks.

The conceptual framework presented herein builds on the emerging literature on circular urban metabolism by defining a model that is technologically viable, flexible, and reproducible for transitioning towards zero-waste cities. Although empirical validation remains a subject for future work, the theoretical basis and anticipated outcomes provide a robust foundation for pilot-scale implementation, life cycle assessment, and detailed socio-economic analysis. Yet, a crucial preliminary step should involve conducting a multidisciplinary expert panel validation. This will strengthen the robustness and applicability of the proposed system by incorporating diverse perspectives and expertise, thereby refining the model before any empirical implementation.

Ultimately, achieving the vision of zero-waste cities demands systemic thinking, cross-sector collaboration and long-term commitment. The proposed integrated approach not only enhances operational efficiency but also supports the broader goals of sustainability, resilience, and inclusive urban development. Future research should focus on real-world testing, performance monitoring, and policy integration to refine and scale this model across diverse urban contexts.

Author Contributions

Conceptualization, A.M.; methodology, A.M. and Y.S.; validation, A.M.; formal analysis, M.M. and F.Z.M.; investigation, A.M. and Y.S.; resources, M.M. and F.Z.M.; data curation, F.Z.M. and Y.S.; writing—original draft preparation, A.M.; writing—review and editing, A.M., Y.S. and F.Z.M.; figure design, M.M.; supervision, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

This article contains all original contributions to the study and any additional questions can be addressed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kaza, S.; Bhada-Tata, P.; Yao, L.C.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Ashokkumar, V.; Flora, G.; Venkatkarthick, R.; Senthilkannan, K.; Kuppam, C.; Mary Stephy, G.; Kamyab, H.; Chen, W.-H.; Thomas, J.; Ngamcharussrivichai, C. Advanced Technologies on the Sustainable Approaches for Conversion of Organic Waste to Valuable Bioproducts: Emerging Circular Bioeconomy Perspective. Fuel 2022, 324, 124313. [Google Scholar] [CrossRef]

- Offenhuber, D. Waste Is Information: Infrastructure Legibility and Governance; MIT Press: Cambridge, MA, USA, 2023. [Google Scholar]

- Agya, B.A.; Rückert, A.; Dornack, C. Effectiveness of Traditional Solid Waste Management System of Rural Communities: A Case Study in the Kwahu East District, Ghana. Environ. Chall. 2024, 15, 100869. [Google Scholar] [CrossRef]

- Di Maria, F.; Mastrantonio, M.; Uccelli, R. The Life Cycle Approach for Assessing the Impact of Municipal Solid Waste Incineration on the Environment and on Human Health. Sci. Total Environ. 2021, 776, 145785. [Google Scholar] [CrossRef] [PubMed]

- Siddiqua, A.; Hahladakis, J.N.; Al-Attiya, W.A.K.A. An Overview of the Environmental Pollution and Health Effects Associated with Waste Landfilling and Open Dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef]

- Guo, H.; Xu, H.; Liu, J.; Nie, X.; Li, X.; Shu, T.; Bai, B.; Ma, X.; Yao, Y. Greenhouse Gas Emissions in the Process of Landfill Disposal in China. Energies 2022, 15, 6711. [Google Scholar] [CrossRef]

- Anshassi, M.; Sackles, H.; Townsend, T.G. A Review of LCA Assumptions Impacting Whether Landfilling or Incineration Results in Less Greenhouse Gas Emissions. Resour. Conserv. Recycl. 2021, 174, 105810. [Google Scholar] [CrossRef]

- Blair, J.; Mataraarachchi, S. A Review of Landfills, Waste and the Nearly Forgotten Nexus with Climate Change. Environments 2021, 8, 73. [Google Scholar] [CrossRef]

- Gupta, J.; Ghosh, P.; Kumari, M.; Thakur, I.S.; Swati, S. Chapter 14—Solid Waste Landfill Sites for the Mitigation of Greenhouse Gases. In Biomass, Biofuels, Biochemicals; Elsevier: Amsterdam, The Netherlands, 2022; pp. 315–340. [Google Scholar] [CrossRef]

- Lu, Z.-Q.; Wu, C.-G.; Wu, N.-Y.; Lu, H.-L.; Wang, T.; Xiao, R.; Liu, H.; Wu, X.-H. Change Trend of Natural Gas Hydrates in Permafrost on the Qinghai-Tibet Plateau (1960–2050) under the Background of Global Warming and Their Impacts on Carbon Emissions. China Geol. 2022, 5, 475–509. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Circular Economy Strategies for Combating Climate Change and Other Environmental Issues. Environ. Chem. Lett. 2022, 21, 55–80. [Google Scholar] [CrossRef]

- Gu, B.; Tang, X.; Liu, L.; Li, Y.; Fujiwara, T.; Sun, H.; Gu, A.; Yao, Y.; Duan, R.; Song, J.; et al. The Recyclable Waste Recycling Potential towards Zero Waste Cities—A Comparison of Three Cities in China. J. Clean. Prod. 2021, 295, 126358. [Google Scholar] [CrossRef]

- Rodríguez-Guerreiro, M.-J.; Torrijos, V.; Soto, M. A Review of Waste Management in Higher Education Institutions: The Road to Zero Waste and Sustainability. Environments 2024, 11, 293. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Chen, G.; Tan, Q.; Duan, L. The Road to “Zero-Waste” in Coastal Tourism Cities—Taking Sanya as an Example. Circ. Econ. 2025, 4, 100139. [Google Scholar] [CrossRef]

- Giordano, V.; Castagnoli, A.; Pecorini, I.; Chiarello, F. Identifying Technologies in Circular Economy Paradigm through Text Mining on Scientific Literature. PLoS ONE 2024, 19, e0312709. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, A.; Bhattacharya, A. Navigating the Shift: The Zero-Waste Paradigm in Apparel Manufacturing; Springer Nature: Cham, Switzerland, 2024; pp. 99–115. [Google Scholar] [CrossRef]

- Castagnoli, A.; Salem, A.M.; Desideri, U.; Pecorini, I. Environmental Assessment of Gasification and Green Hydrogen Potential Role in Waste Management Decarbonization. J. Clean. Prod. 2024, 482, 144174. [Google Scholar] [CrossRef]

- Fernando, Y.; Tseng, M.-L.; Aziz, N.; Ikhsan, R.B.; Wahyuni-Td, I.S. Waste-to-Energy Supply Chain Management on Circular Economy Capability: An Empirical Study. Sustain. Prod. Consum. 2022, 31, 26–38. [Google Scholar] [CrossRef]

- Lisbona, P.; Pascual, S.; Pérez, V. Waste to Energy: Trends and Perspectives. Chem. Eng. J. Adv. 2023, 14, 100494. [Google Scholar] [CrossRef]

- Lee, B.X.; Kjaerulf, F.; Turner, S.; Cohen, L.; Donnelly, P.D.; Muggah, R.; Davis, R.; Realini, A.; Kieselbach, B.; MacGregor, L.S.; et al. Transforming Our World: Implementing the 2030 Agenda Through Sustainable Development Goal Indicators. J. Public Health Policy 2016, 37 (Suppl. S1), 13–31. [Google Scholar] [CrossRef]

- Kim, J.; Latif, M.; Song, J.; Park, G.; Lee, J. Automated Sorting of Recyclable Domestic Waste; Elsevier: Amsterdam, The Netherlands, 2025; pp. 417–426. [Google Scholar] [CrossRef]

- Yin, J.; Xie, M.; Yu, X.; Feng, H.; Wang, M.; Zhang, Y.; Chen, T. A Review of the Definition, Influencing Factors, and Mechanisms of Rapid Composting of Organic Waste. Environ. Pollut. 2023, 342, 123125. [Google Scholar] [CrossRef]

- Serrano, D.; Sánchez-Delgado, S.; Horvat, A.; Marugán-Cruz, C.; Batuecas, E.; Kelebopile, L.; Kwapinska, M. Non-Recyclable Municipal Solid Waste Characterization and Pyrolysis for Energy Recovery. Bioresour. Technol. 2024, 415, 131641. [Google Scholar] [CrossRef]

- Rabnawaz Ahmed, R.; Zhang, X. Multi-Layer Value Stream Assessment of the Reverse Logistics Network for Inert Construction Waste Management. Resour. Conserv. Recycl. 2021, 170, 105574. [Google Scholar] [CrossRef]

- Zaki, M.T.; Rowles, L.S.; Adjeroh, D.A.; Orner, K.D. A Critical Review of Data Science Applications in Resource Recovery and Carbon Capture from Organic Waste. ACS EST Eng. 2023, 3, 1424–1467. [Google Scholar] [CrossRef] [PubMed]

- Makan, A.; Malamis, D.; Assobhei, O.; Loizidou, M.; Mountadar, M. Multi-Criteria Decision Aid Approach for the Selection of the Best Compromise Management Scheme for the Treatment of Municipal Solid Waste in Morocco. Int. J. Environ. Waste Manag. 2013, 12, 300–317. [Google Scholar] [CrossRef]

- Makan, A.; Fadili, A. Sustainability Assessment of Healthcare Waste Treatment Systems Using Surrogate Weights and PROMETHEE Method. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 39, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Makan, A.; Fadili, A. Sustainability Assessment of Large-Scale Composting Technologies Using PROMETHEE Method. J. Clean. Prod. 2020, 261, 121244. [Google Scholar] [CrossRef]

- Zargar, T.I.; Alam, P.; Khan, A.H.; Alam, S.S.; Abutaleb, A.; Abul Hasan, M.; Khan, N.A. Characterization of municipal solid waste: Measures towards management strategies using statistical analysis. J. Environ. Manag. 2023, 342, 118331. [Google Scholar] [CrossRef]

- Lee, R.P.; Meyer, B.; Huang, Q.; Voss, R. Sustainable Waste Management for Zero Waste Cities in China: Potential, Challenges and Opportunities. Clean Energy 2020, 4, 169–201. [Google Scholar] [CrossRef]

- Ragazou, K.; Zournatzidou, G.; Sklavos, G.; Sariannidis, N. Integration of Circular Economy and Urban Metabolism for a Resilient Waste-Based Sustainable Urban Environment. Urban Sci. 2024, 8, 175. [Google Scholar] [CrossRef]

- Tolstykh, T.; Shmeleva, N.; Gamidullaeva, L. Evaluation of Circular and Integration Potentials of Innovation Ecosystems for Industrial Sustainability. Sustainability 2020, 12, 4574. [Google Scholar] [CrossRef]

- Spani, R.C. The New Circular Economy Action Plan. FEEM Policy BRIEF, No. 09-2020. Available online: https://ssrn.com/abstract=3711331 (accessed on 15 May 2025).

- Chandrappa, R.; Das, D.B. Solid Waste Management: Principles and Practice; Springer Nature: Cham, Switzerland, 2024. [Google Scholar]

- Lederer, J.; Schuch, D. The Contribution of Waste and Bottom Ash Treatment to the Circular Economy of Metal Packaging: A Case Study from Austria. Resour. Conserv. Recycl. 2024, 203, 107461. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of Post-Consumer Plastic Packaging Waste in the EU: Recovery Rates, Material Flows, and Barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Gadaleta, G.; De Gisi, S.; Todaro, F.; D’Alessandro, G.; Binetti, S.; Notarnicola, M. Assessing the Sorting Efficiency of Plastic Packaging Waste in an Italian Material Recovery Facility: Current and Upgraded Configuration. Recycling 2023, 8, 25. [Google Scholar] [CrossRef]

- Tallentire, C.W.; Steubing, B. The Environmental Benefits of Improving Packaging Waste Collection in Europe. Waste Manag. 2020, 103, 426–436. [Google Scholar] [CrossRef] [PubMed]

- Strezov, V.; Zhou, X.; Evans, T.J. Life Cycle Impact Assessment of Metal Production Industries in Australia. Sci. Rep. 2021, 11, 10116. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Berrill, P.; Zimmerman, J.B.; Hertwich, E.G. Copper Recycling Flow Model for the United States Economy: Impact of Scrap Quality on Potential Energy Benefit. Environ. Sci. Technol. 2021, 55, 5485–5495. [Google Scholar] [CrossRef]

- Milios, L.; Esmailzadeh Davani, A.; Yu, Y. Sustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in Sweden. Recycling 2018, 3, 33. [Google Scholar] [CrossRef]

- Bułkowska, K.; Zielińska, M.; Bułkowski, M. Blockchain-Based Management of Recyclable Plastic Waste. Energies 2024, 17, 2937. [Google Scholar] [CrossRef]

- Yao, Z.; Qin, B.; Huang, Z.; Ruan, J.; Xu, Z. Green Combined Resource Recycling System for the Recycling of Waste Glass. ACS Sustain. Chem. Eng. 2021, 9, 7361–7368. [Google Scholar] [CrossRef]

- Bourtsalas, A.C.; Wei, J. Exhaust Steam Utilization in Waste-to-Energy Strategies: From District Heating to Desalination. J. Clean. Prod. 2023, 428, 139389. [Google Scholar] [CrossRef]

- Pelda, J.; Stelter, F.; Holler, S. Potential of Integrating Industrial Waste Heat and Solar Thermal Energy into District Heating Networks in Germany. Energy 2020, 203, 117812. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P.; Hanewinkel, J.; Flamme, S. Status of Waste-to-Energy in Germany, Part I—Waste Treatment Facilities. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 38 (Suppl. S1), 23–44. [Google Scholar] [CrossRef]

- Makan, A.; Fadili, A.; Oubenali, M. Interaction of Physicochemical Parameters during Pressurized In-Vessel Composting of Food Waste. Bioresour. Technol. Rep. 2019, 10, 100350. [Google Scholar] [CrossRef]

- Porterfield, K.K.; Hobson, S.A.; Neher, D.A.; Niles, M.T.; Roy, E.D. Microplastics in Composts, Digestates, and Food Wastes: A Review. J. Environ. Qual. 2023, 52, 225–240. [Google Scholar] [CrossRef] [PubMed]

- Barbudo, A.; Ayuso, J.; Lozano, A.; Cabrera, M.; López-Uceda, A. Recommendations for the Management of Construction and Demolition Waste in Treatment Plants. Environ. Sci. Pollut. Res. 2019, 27, 125–132. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J. Recycled Aggregates Produced from Construction and Demolition Waste for Structural Concrete: Constituents, Properties and Production. Materials 2021, 14, 5748. [Google Scholar] [CrossRef]

- Pérez, T.; Vergara, S.E.; Silver, W.L. Assessing the Climate Change Mitigation Potential from Food Waste Composting. Sci. Rep. 2023, 13, 7608. [Google Scholar] [CrossRef]

- Rotthong, M.; Takaoka, M.; Oshita, K.; Rachdawong, P.; Gheewala, S.H.; Prapaspongsa, T. Life Cycle Assessment of Integrated Municipal Organic Waste Management Systems in Thailand. Sustainability 2022, 15, 90. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Li, S.; Bai, Z.; Ma, L. Advanced Composting Technologies Promotes Environmental Benefits and Eco-Efficiency: A Life Cycle Assessment. Bioresour. Technol. 2021, 346, 126576. [Google Scholar] [CrossRef]

- Lombardi, L.; Castaldi, M.J. Energy Recovery from Residual Municipal Solid Waste: State of the Art and Perspectives within the Challenge to Climate Change. Energies 2024, 17, 395. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Kumar, R.; Behnia, M. Environmental Impact Assessment of Solid Waste to Energy Technologies and Their Perspectives in Australia. Sustainability 2022, 14, 15971. [Google Scholar] [CrossRef]

- De Souza, R.; Casisi, M.; Micheli, D.; Reini, M. A Review of Small–Medium Combined Heat and Power (CHP) Technologies and Their Role within the 100% Renewable Energy Systems Scenario. Energies 2021, 14, 5338. [Google Scholar] [CrossRef]

- Directive (EU) 2024/1785 of the European Parliament and of the Council of 24 April 2024 Amending Directive 2010/75/EU of the European Parliament and of the Council on Industrial Emissions (Integrated Pollution Prevention and Control) and Council Directive 1999/31/EC on the Landfill of Waste (Text with EEA Relevance), Official Journal of the European Union, 2024/1785. Available online: http://data.europa.eu/eli/dir/2024/1785/oj (accessed on 5 May 2025).

- Schiavon, M.; Ravina, M.; Zanetti, M.; Panepinto, D. State-of-the-Art and Recent Advances in the Abatement of Gaseous Pollutants from Waste-to-Energy. Energies 2024, 17, 552. [Google Scholar] [CrossRef]

- Guo, X.; Ma, Y.; Lin, X.; Li, X.; Xiang, Y.; Wu, A. Reduction of Polychlorinated Dibenzo-p-Dioxins and Dibenzofurans by Chemical Inhibition and Physisorption from a Municipal Solid Waste Incineration System. Energy Fuels 2020, 34, 11237–11247. [Google Scholar] [CrossRef]

- Tang, L.; Qu, J.; Mi, Z.; Bo, X.; Chang, X.; Anadon, L.D.; Wang, S.; Xue, X.; Li, S.; Wang, X.; et al. Substantial Emission Reductions from Chinese Power Plants after the Introduction of Ultra-Low Emissions Standards. Nat. Energy 2019, 4, 929–938. [Google Scholar] [CrossRef]

- Al-Alimi, S.; Yusuf, N.K.; Ghaleb, A.M.; Lajis, M.A.; Shamsudin, S.; Zhou, W.; Altharan, Y.M.; Abdulwahab, H.S.; Saif, Y.; Didane, D.H.; et al. Recycling Aluminium for Sustainable Development: A Review of Different Processing Technologies in Green Manufacturing. Results Eng. 2024, 23, 102566. [Google Scholar] [CrossRef]

- Borgert, T.; Homberg, W. Energy Saving Potentials of an Efficient Recycling Process of Different Aluminum Rejects. Energy Rep. 2022, 8, 399–404. [Google Scholar] [CrossRef]

- Sevelka, T. Sustainable Land Use Planning in Ontario: Protecting Against Aggregate Extraction Operations. Grassroots J. Nat. Resour. 2025, 8, 82–137. [Google Scholar] [CrossRef]

- Bampanis, I.; Vasilatos, C. Recycling Concrete to Aggregates. Implications on CO2 Footprint. Mater. Proc. 2023, 15, 28. [Google Scholar] [CrossRef]

- Jakhar, R.; Samek, L.; Styszko, K. A Comprehensive Study of the Impact of Waste Fires on the Environment and Health. Sustainability 2023, 15, 14241. [Google Scholar] [CrossRef]

- Wei, W.; Liu, Q.; Zhang, Z.; Lisak, G.; Yin, K.; Fei, X. Evaluation of Long-Term Leaching of a Full-Scale Carriageway Using Treated Incineration Bottom Ash as Subbase Material. Waste Manag. 2025, 196, 80–92. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Bagcal, O.; Beycioğlu, A.; Goulias, D.; Köksal, F.; Niedostatkiewicz, M.; Ürünveren, H. Influence of Rock Dust Additives as Fine Aggregate Replacement on Properties of Cement Composites-A Review. Materials 2022, 15, 2947. [Google Scholar] [CrossRef]

- Abu-Qdais, H.A.; Shatnawi, N.; Al-Shahrabi, R. Modeling the Impact of Fees and Circular Economy Options on the Financial Sustainability of the Solid Waste Management System in Jordan. Resources 2023, 12, 32. [Google Scholar] [CrossRef]

- Hagelüken, C.; Goldmann, D. Recycling and Circular Economy—Towards a Closed Loop for Metals in Emerging Clean Technologies. Miner. Econ. 2022, 35, 539–562. [Google Scholar] [CrossRef]

- Lizárraga-Mendiola, L.; López-León, L.D.; Vázquez-Rodríguez, G.A. Municipal Solid Waste as a Substitute for Virgin Materials in the Construction Industry: A Review. Sustainability 2022, 14, 16343. [Google Scholar] [CrossRef]

- Pandey, D. Recycled Glass Market Size, Trends, Share, and Innovations 2034. Available online: https://www.towardspackaging.com/insights/recycled-glass-market-sizing (accessed on 5 May 2025).

- Couture, T.; Cory, K.; Williams, E.; Kreycik, C. A Policymaker’s Guide to Feed-in Tariff Policy Design; Office of Scientific Technical Information: Oak Ridge, TN, USA, 2010. [Google Scholar] [CrossRef]

- Nakano, S.; Arai, S.; Washizu, A. Economic Impacts of Japan’s Renewable Energy Sector and the Feed-in Tariff System: Using an Input–Output Table to Analyze a Next-Generation Energy System. Environ. Econ. Policy Stud. 2016, 19, 555–580. [Google Scholar] [CrossRef]

- Kim, S.-K.; Huh, J.-H. Blockchain of Carbon Trading for UN Sustainable Development Goals. Sustainability 2020, 12, 4021. [Google Scholar] [CrossRef]

- Hirvonen, J.; Kosonen, R. Waste Incineration Heat and Seasonal Thermal Energy Storage for Promoting Economically Optimal Net-Zero Energy Districts in Finland. Buildings 2020, 10, 205. [Google Scholar] [CrossRef]

- Sitzmann, T.J.; Sica, P.; Grignani, C.; Magid, J. Testing Biowaste Materials as Peat Replacement in Organo-Mineral Fertilizers. Front. Sustain. Food Syst. 2024, 8, 1330843. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Pastore, V.; Palese, A.M.; D’Adamo, C.; De Falco, E.; Celano, G. Sustainability Assessment of the Green Compost Production Chain from Agricultural Waste: A Case Study in Southern Italy. Agronomy 2020, 10, 230. [Google Scholar] [CrossRef]

- Van Fan, Y.; Lee, C.T.; Klemeš, J.J.; Bong, C.P.C.; Ho, W.S. Economic Assessment System towards Sustainable Composting Quality in the Developing Countries. Clean Technol. Environ. Policy 2016, 18, 2479–2491. [Google Scholar] [CrossRef]

- Stehouwer, R.; Cooperband, L.; Rynk, R.; Biala, J.; Bonhotal, J.; Antler, S.; Lewandowski, T.; Nichols, H. Chapter 15—Compost Characteristics and Quality. In The Composting Handbook; Elsevier: Amsterdam, The Netherlands, 2022; pp. 737–775. [Google Scholar] [CrossRef]

- Cucina, M. Integrating Anaerobic Digestion and Composting to Boost Energy and Material Recovery from Organic Wastes in the Circular Economy Framework in Europe: A Review. Bioresour. Technol. Rep. 2023, 24, 101642. [Google Scholar] [CrossRef]

- Contreras Llanes, M.; Romero Pérez, M.; Gázquez González, M.J.; Bolívar Raya, J.P. Construction and Demolition Waste as Recycled Aggregate for Environmentally Friendly Concrete Paving. Environ. Sci. Pollut. Res. 2021, 29, 9826–9840. [Google Scholar] [CrossRef] [PubMed]

- Haider, H.; Almarshod, S.Y.; Alsaleem, S.S.; Ali, A.A.M.; Alinizzi, M.; Alresheedi, M.T.; Shafiquzzaman, M. Life Cycle Assessment of Construction and Demolition Waste Management in Riyadh, Saudi Arabia. Int. J. Environ. Res. Public Health 2022, 19, 7382. [Google Scholar] [CrossRef] [PubMed]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinari, P. Using Recycled Aggregates from Construction and Demolition Waste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Wong, P.S.P.; Bettini, L. Application of Sustainable Procurement Policy to Improve the Circularity of Construction and Demolition Waste Resources in Australia. Mater. Circ. Econ. 2022, 4, 27. [Google Scholar] [CrossRef]

- Alhola, K.; Ryding, S.O.; Salmenperä, H.; Busch, N.J. Exploiting the Potential of Public Procurement: Opportunities for Circular Economy. J. Ind. Ecol. 2018, 23, 96–109. [Google Scholar] [CrossRef]

- Jagun, Z.T.; Daud, D.; Ajayi, O.M.; Samsudin, S.; Jubril, A.J.; Rahman, M.S.A. Waste Management Practices in Developing Countries: A Socio-Economic Perspective. Environ. Sci. Pollut. Res. 2022, 30, 116644–116655. [Google Scholar] [CrossRef]

- Sundram, M.S. Basel Convention on Transboundary Movement of Hazardous Wastes: Total Ban Amendment. Pace Int. Law Rev. 1997, 9, 1. [Google Scholar] [CrossRef]

- Chartier, Y. (Ed.) Safe Management of Wastes from Health-Care Activities; World Health Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Vehlow, J.; Bergfeldt, B.; Visser, R.; Wilén, C. European Union Waste Management Strategy and the Importance of Biogenic Waste. J. Mater. Cycles Waste Manag. 2007, 9, 130–139. [Google Scholar] [CrossRef]

- Kumar, A.; Thakur, A.K.; Gaurav, G.K.; Klemeš, J.J.; Sandhwar, V.K.; Pant, K.K.; Kumar, R. A Critical Review on Sustainable Hazardous Waste Management Strategies: A Step towards a Circular Economy. Environ. Sci. Pollut. Res. Int. 2023, 30, 105030–105055. [Google Scholar] [CrossRef]

- Okedu, K.E.; Barghash, H.F.; Al Nadabi, H.A. Sustainable Waste Management Strategies for Effective Energy Utilization in Oman: A Review. Front. Bioeng. Biotechnol. 2022, 10, 825728. [Google Scholar] [CrossRef]

- Okedele, P.O.; Aziza, O.R.; Oduro, P.; Ishola, A.O. Carbon Pricing Mechanisms and Their Global Efficacy in Reducing Emissions: Lessons from Leading Economies. Open Access Res. J. Eng. Technol. 2024, 7, 114–125. [Google Scholar] [CrossRef]

- Perez, A.P.; Sauma, E.E.; Munoz, F.D.; Hobbs, B.F. The Economic Effects of Interregional Trading of Renewable Energy Certificates in the U.S. WECC. Energy J. 2016, 37, 267–296. [Google Scholar] [CrossRef]

- Bao, W.; Chen, Y.; Cui, C.; Xia, B.; Ke, Y.; Skitmore, M.; Liu, Y. How to Shape Local Public Acceptance of Not-in-My-Backyard Infrastructures? A Social Cognitive Theory Perspective. Sustainability 2023, 15, 15835. [Google Scholar] [CrossRef]

- Eranti, V. NIMBY—“Not in My Backyard”. In Elgar Encyclopedia of Environmental Sociology; Edward Elgar: Cheltenham, UK, 2024; pp. 426–431. [Google Scholar] [CrossRef]

- Abubakar, I.R.; Maniruzzaman, K.M.; Dano, U.L.; AlShihri, F.S.; AlShammari, M.S.; Ahmed, S.M.S.; Al-Gehlani, W.A.G.; Alrawaf, T.I. Environmental Sustainability Impacts of Solid Waste Management Practices in the Global South. Int. J. Environ. Res. Public Health 2022, 19, 12717. [Google Scholar] [CrossRef]

- Gubernatorov, A.M.; Kuznetsov, D.V.; Makunina, I.V.; Bystrenina, I.E. Funding the Management of Municipal Solid Waste Through Public-Private Partnerships. In Towards an Increased Security: Green Innovations, Intellectual Property Protection and Information Security; Springer: Cham, Switzerland, 2022; pp. 467–473. [Google Scholar] [CrossRef]

- Lubongo, C.; Alexandridis, P. Assessment of Performance and Challenges in Use of Commercial Automated Sorting Technology for Plastic Waste. Recycling 2022, 7, 11. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Liu, Q.; Luo, H.; Li, B.; Cheng, J.; Huang, Y. Emission Characteristics and Impact Factors of Air Pollutants from Municipal Solid Waste Incineration in Shanghai, China. J. Environ. Manag. 2022, 310, 114732. [Google Scholar] [CrossRef]

- Fu, Z.; Lin, S.; Tian, H.; Hao, Y.; Wu, B.; Liu, S.; Luo, L.; Bai, X.; Guo, Z.; Lv, Y. A Comprehensive Emission Inventory of Hazardous Air Pollutants from Municipal Solid Waste Incineration in China. Sci. Total Environ. 2022, 826, 154212. [Google Scholar] [CrossRef]

- Raffik, R.; Rakesh, D.; Venkatesh, M.; Samvasan, P. Supply Chain Control and Inventory Tracking System Using Industrial Automation Tools and IIoT. In Proceedings of the 2021 International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), Coimbatore, India, 8–9 October 2021; Volume 3, pp. 1–5. [Google Scholar] [CrossRef]

- Akbari, A. The Application of Radio-Frequency Identification (RFID) Technology in the Petroleum Engineering Industry: Mixed Review. Pet. Res. 2025. [Google Scholar] [CrossRef]

- Shaik, S.R.; Mahalingam, A.K.; Palanisamy, M.; Kalita, P.C. Comprehensive Review on Medical Waste Incineration. Int. J. Glob. Warm. 2022, 27, 16–54. [Google Scholar] [CrossRef]

- Manea, E.E.; Bumbac, C.; Dinu, L.R.; Bumbac, M.; Nicolescu, C.M. Composting as a Sustainable Solution for Organic Solid Waste Management: Current Practices and Potential Improvements. Sustainability 2024, 16, 6329. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).