Sustainable Indoor Thermal Regulation with Hybrid Desiccant and Post-Cooling Technologies

Abstract

1. Introduction

2. Methodology

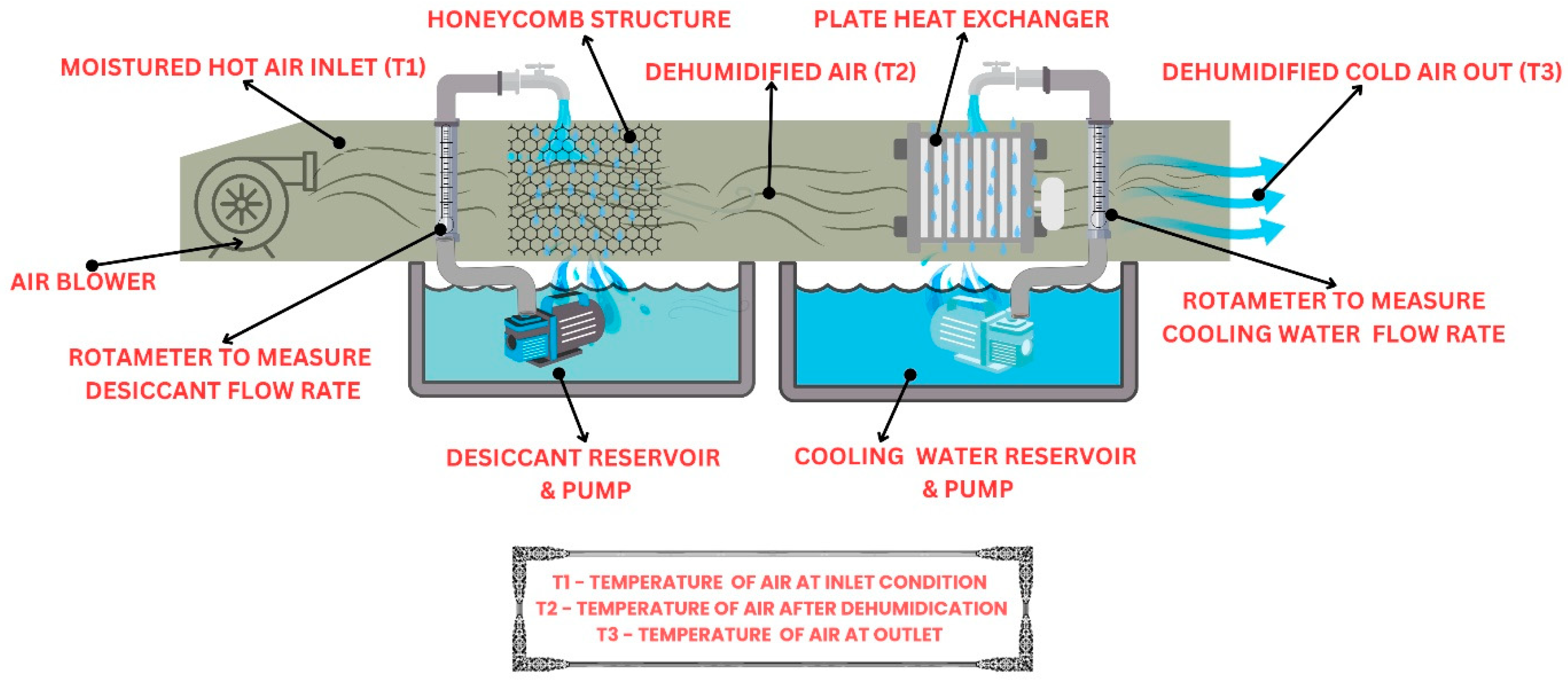

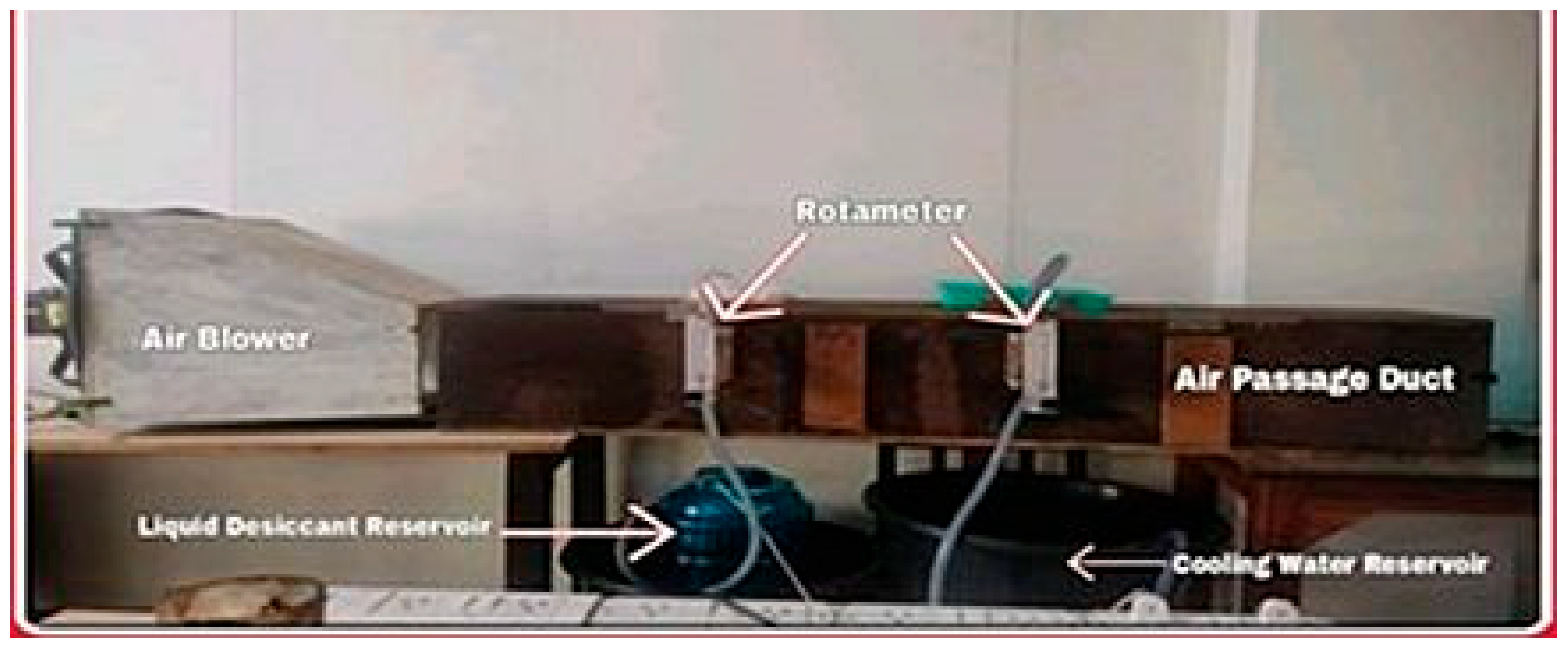

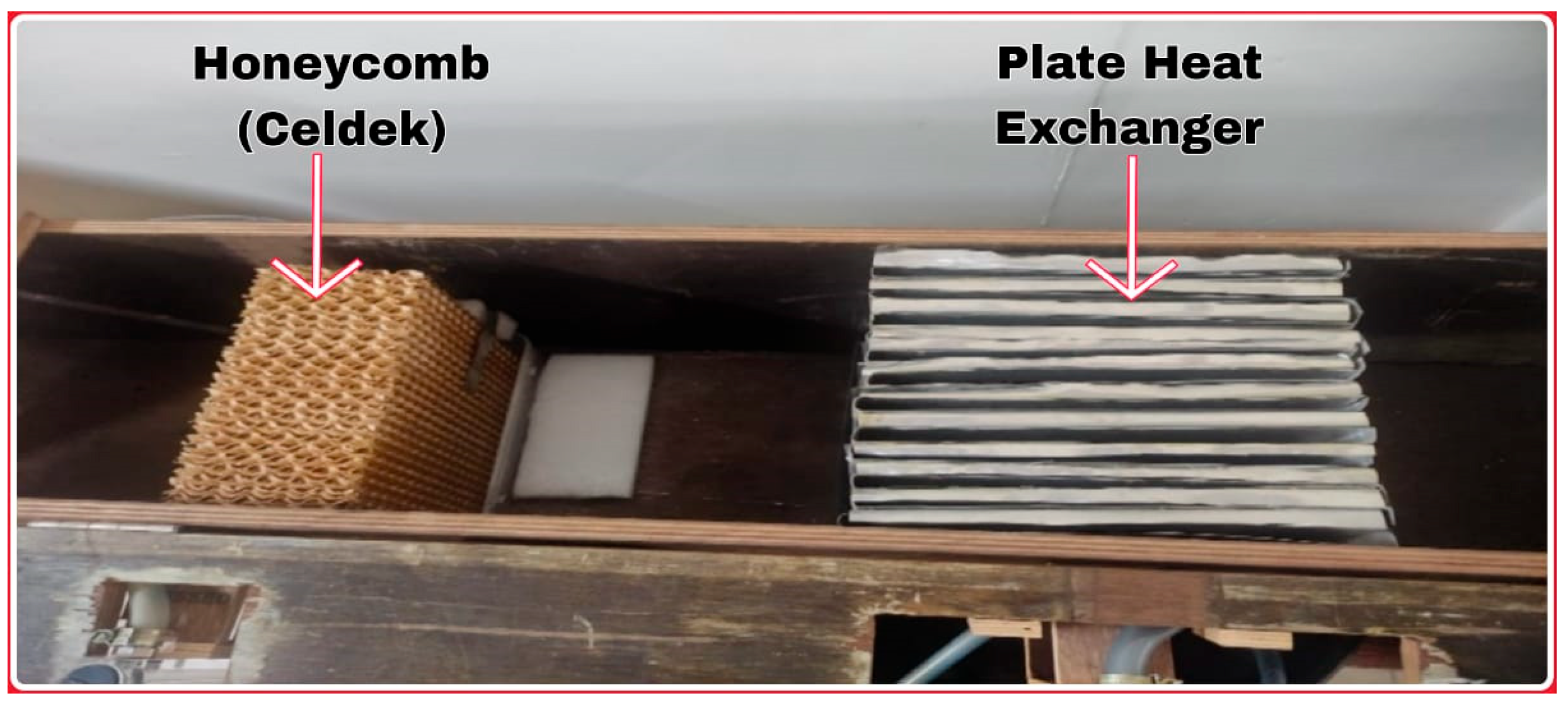

2.1. Experimental Test Rig

2.2. Data Collection

2.3. Experimental Conditions

2.4. Equations Used

- Change in temperature after dehumidification

- T2 = dehumidified air temperature in °C;

- T1 = entry air temperature in °C.

- 2.

- Change in temperature after post-cooling

- T3 = exit air temperature in °C;

- T1 = entry air temperature in °C.

- Δω2 = humidity ratio after dehumidification condition, kg/kg;

- Δω3 = humidity ratio at outlet condition, kg/kg;

- ΔωI = humidity ratio difference between inlet and after dehumidification, kg/kg;

- ΔωII = humidity ratio difference between exit and after dehumidification, kg/kg;

- Δω = humidity ratio difference between inlet and exit dehumidification, i.e., specific humidity, kg/kg.

- 3.

- Change in enthalpy

- h1 = enthalpy at inlet condition in kJ/kg;

- h2 = enthalpy at outlet condition in kJ/kg.

- 4.

- Mass of air

- ρ = air density in kg/m3;

- A = area of cross section in m3;

- V = air velocity in m/s.

- 5.

- Mass of water vapor

- ω = humidity ratio at inlet, middle, and exit, in kg/kg;

- mv = mass of water vapor in kg/h.

- 6.

- Moisture removal rate (MRR)

- Δω = humidity ratio difference between inlet and exit dehumidification, i.e., specific humidity, kg/kg.MRR = moisture removal rate in kg/h

- 7.

- Dehumidification efficiency

- ∆ω max = ω1 − ωequ in kg/kg;

- η = efficiency in %;

- ωequ: Equilibrium specific humidity corresponding to the desiccant’s properties and conditions, in kg/kg.

- 8.

- Coefficient of performance (COP)

- Δh = change in enthalpy in kJ/kg;

- de = desired effect in KW.

3. Results and Discussion

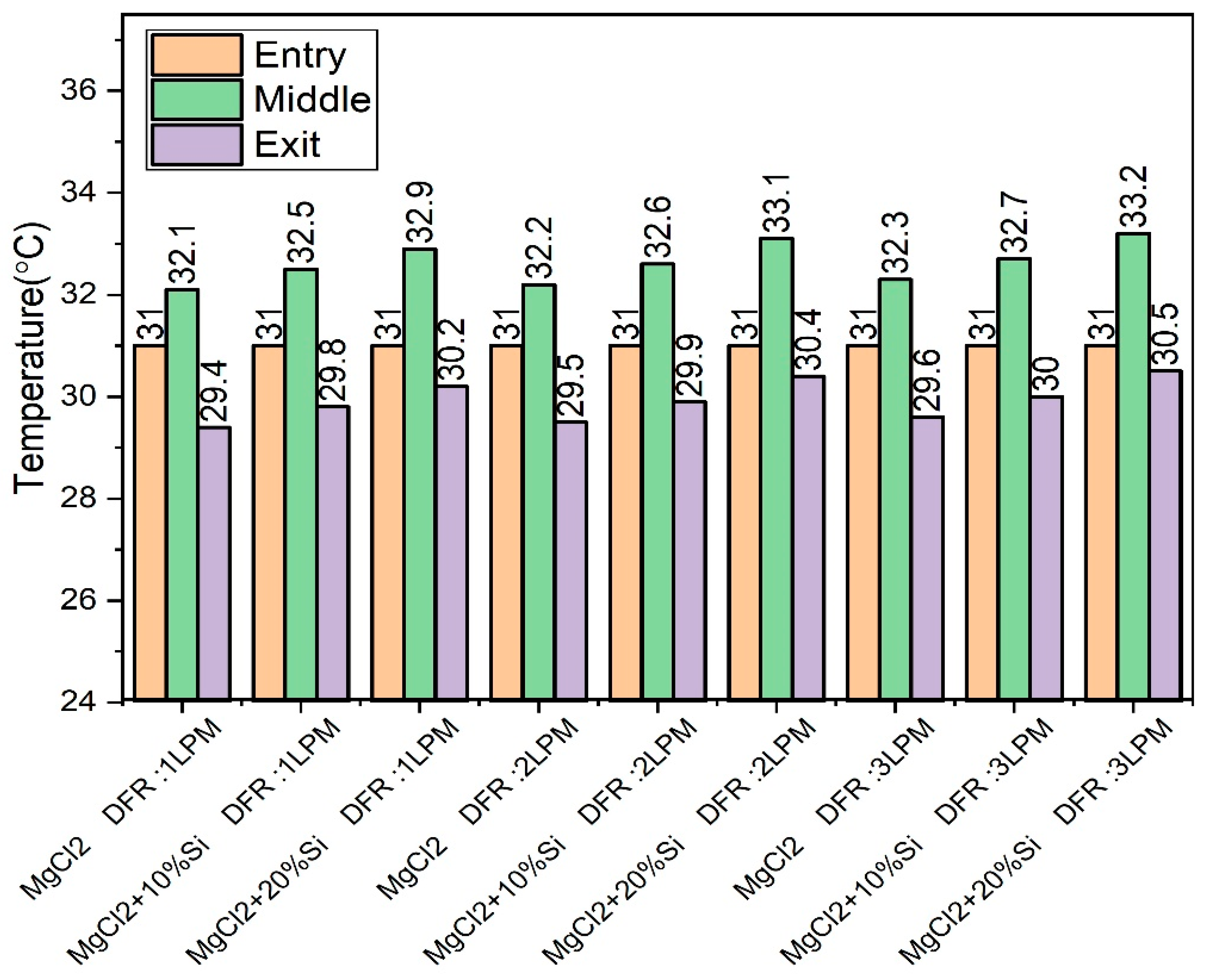

3.1. Temperature Variation

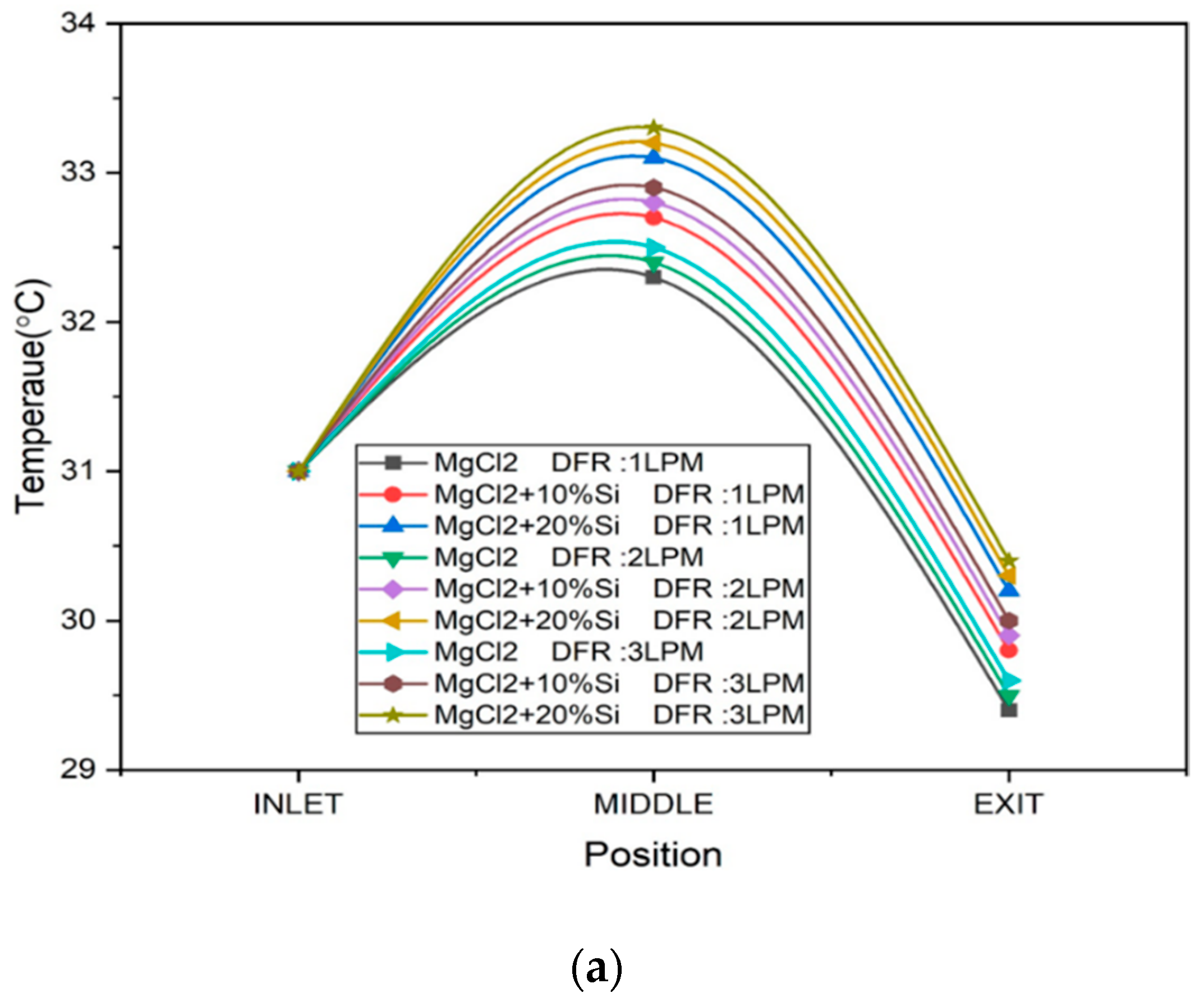

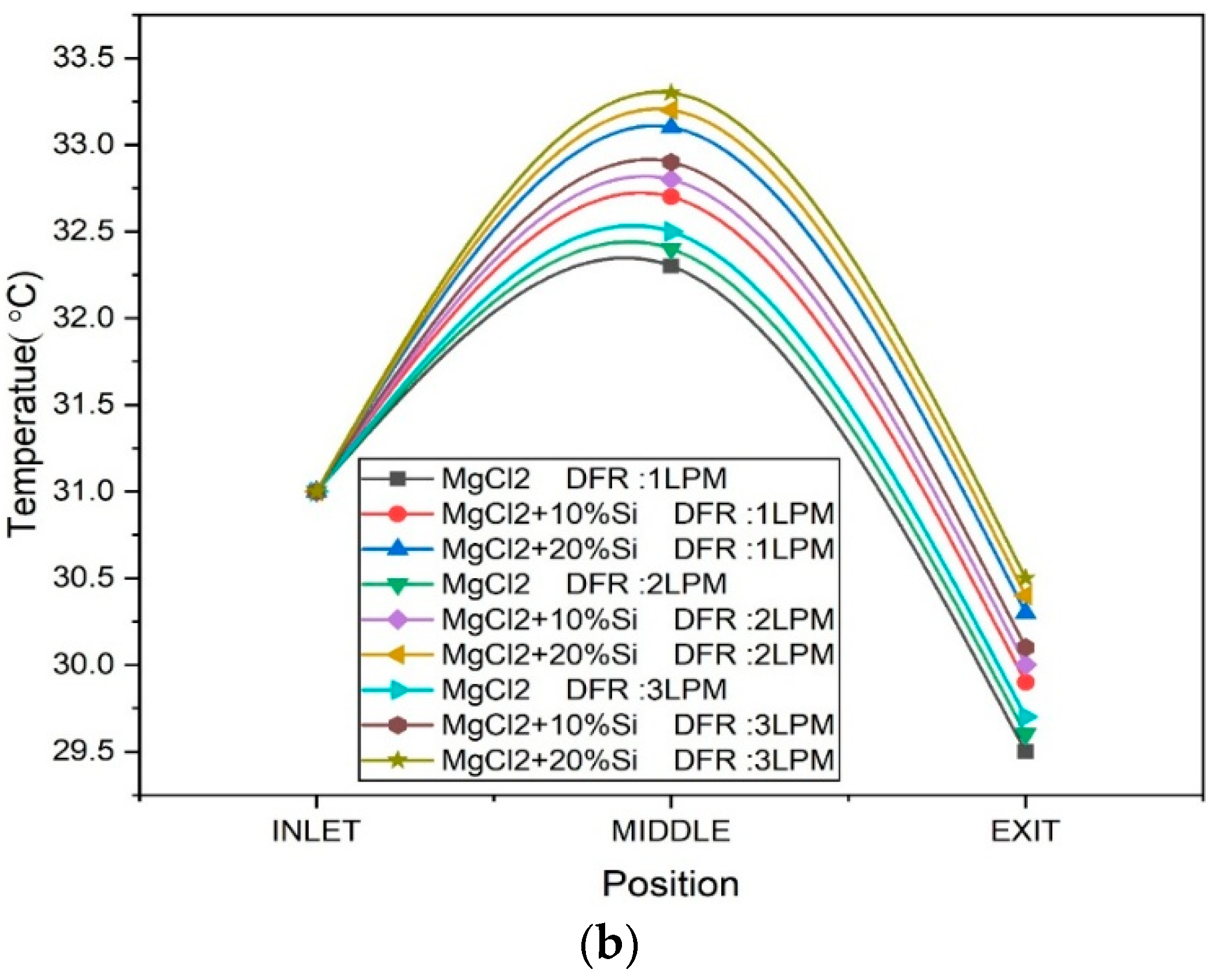

3.1.1. Influence of Desiccant Flow Rate

3.1.2. Cooling Water Flow Rate

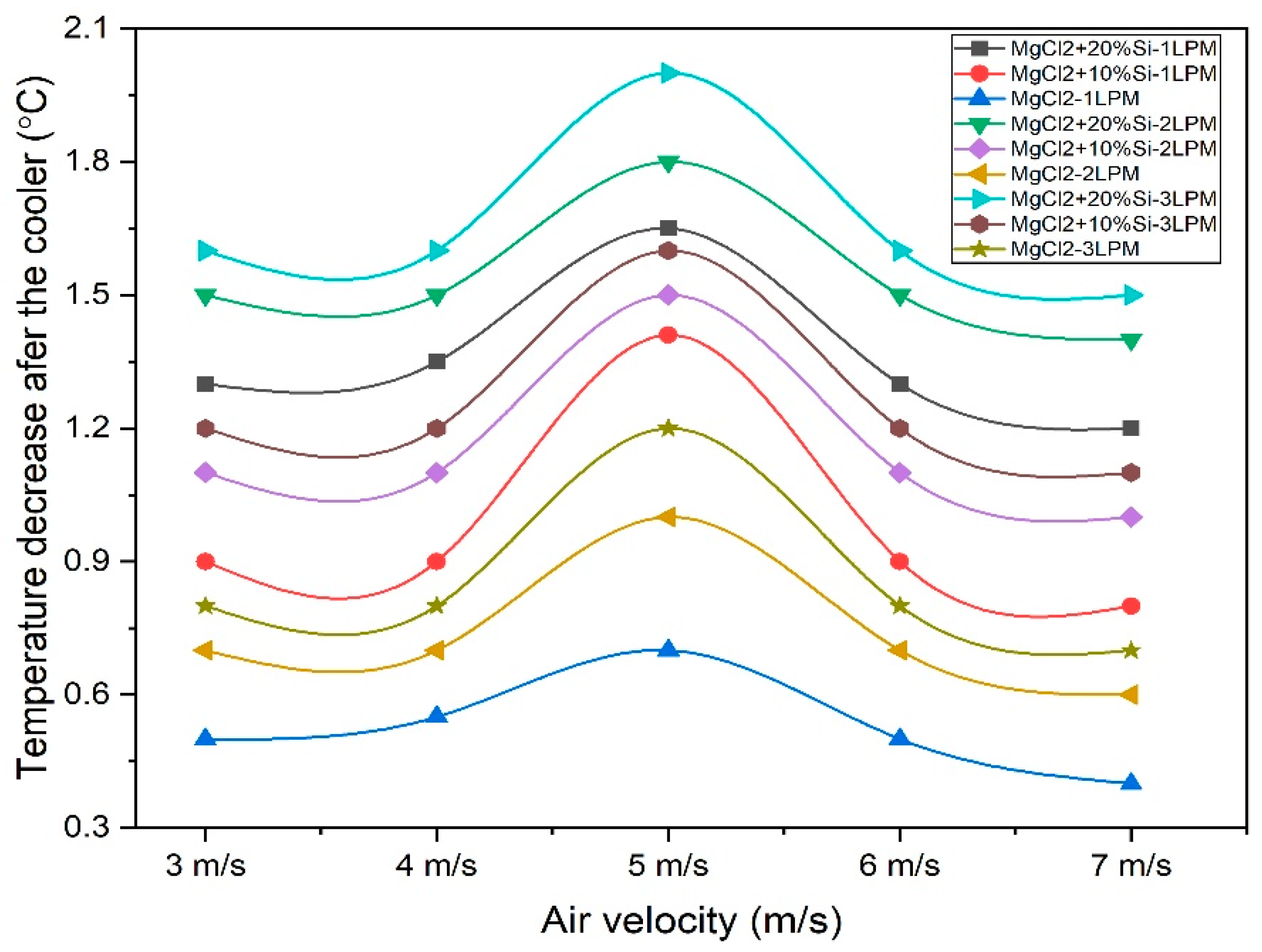

3.1.3. Air Velocity

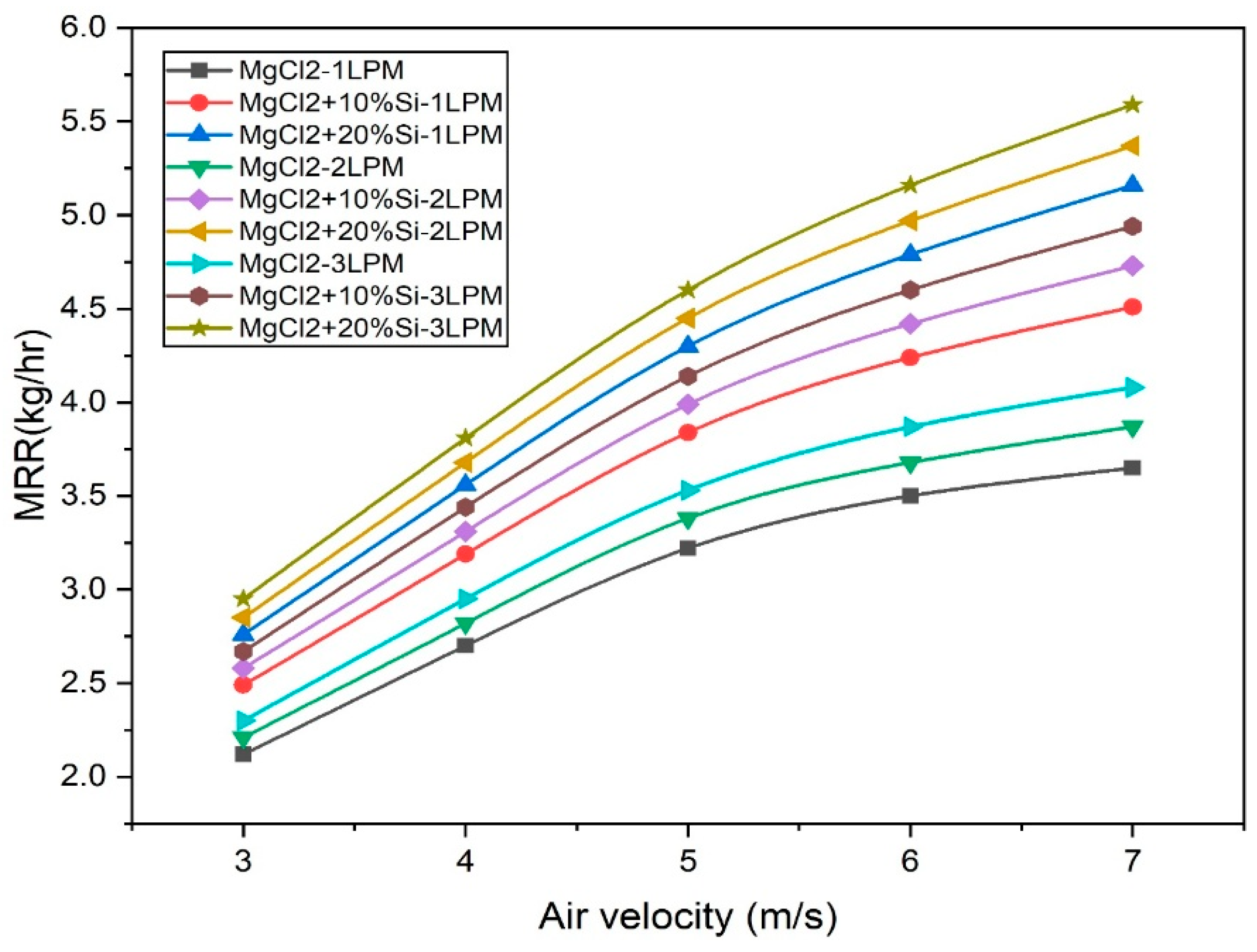

3.2. Moisture Removal Rate (MRR)

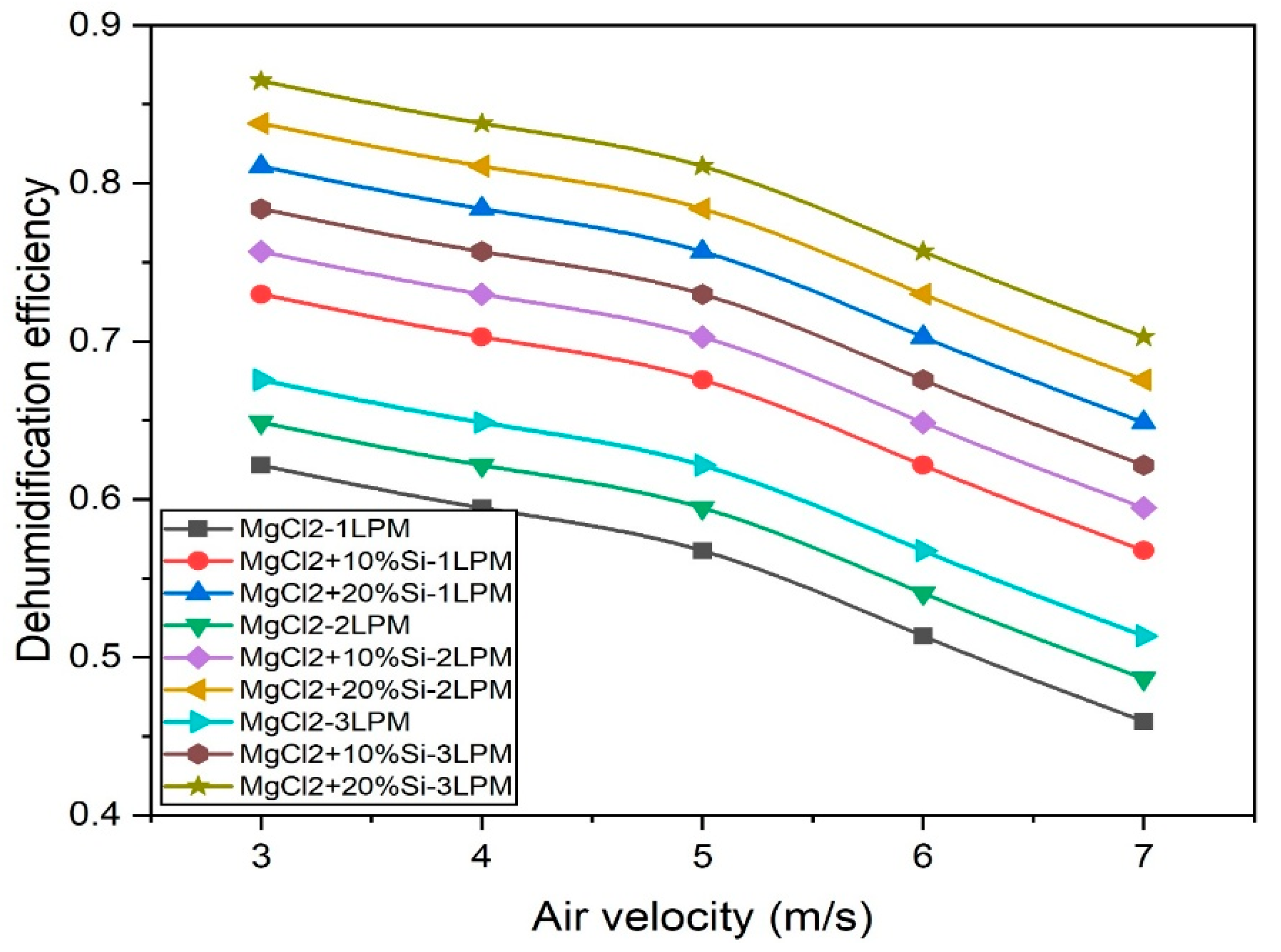

3.3. Dehumidification Efficiency

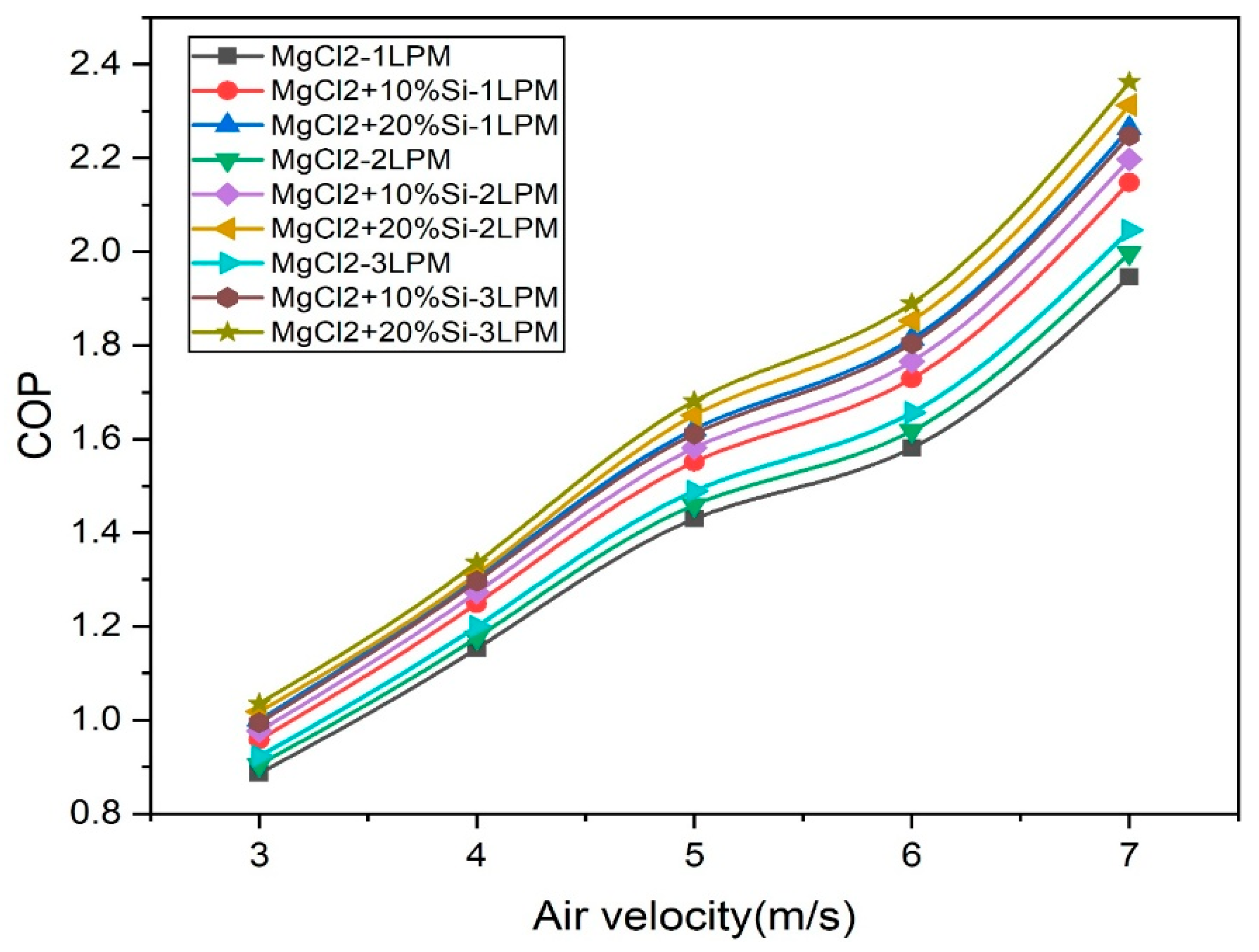

3.4. Coefficient of Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fekadu, G.; Subudhi, S. Renewable energy for liquid desiccants air conditioning system: A review. Renew. Sustain. Energy Rev. 2018, 93, 364–379. [Google Scholar] [CrossRef]

- Rafique, M.M.; Gandhidasan, P.; Bahaidarah, H.M.S. Liquid desiccant materials and dehumidifiers—A review. Renew. Sustain. Energy Rev. 2016, 56, 179–195. [Google Scholar] [CrossRef]

- Shukla, D.L.; Modi, K.V. A technical review on regeneration of liquid desiccant using solar energy. Renew. Sustain. Energy Rev. 2017, 78, 517–529. [Google Scholar] [CrossRef]

- Jain, S.; Bansal, P.K. Performance analysis of liquid desiccant dehumidification systems. Int. J. Refrig. 2007, 30, 861–872. [Google Scholar] [CrossRef]

- Liu, X.H.; Chang, X.M.; Xia, J.J.; Jiang, Y. Performance analysis on the internally cooled dehumidifier using liquid desiccant. Build. Environ. 2009, 44, 299–308. [Google Scholar] [CrossRef]

- Gandhidasan, P. A simplified model for air dehumidification with liquid desiccant. Sol Energy 2004, 76, 409–416. [Google Scholar] [CrossRef]

- Liu, X.H.; Yi, X.Q.; Jiang, Y. Mass transfer performance comparison of two commonly used liquid desiccants: LiBr and LiCl aqueous solutions. Energy Convers. Manag. 2011, 52, 180–190. [Google Scholar] [CrossRef]

- Mohammad, A.T.; Mat, S.B.; Sulaiman, M.Y.; Sopian, K.; Al-abidi, A.A. Historical review of liquid desiccant evaporation cooling technology. Energy Build. 2013, 67, 22–33. [Google Scholar] [CrossRef]

- Sharma, A.; Kaushal, R. Experimental investigation of a novel multi-channel flat plate liquid desiccant dehumidification system. Energy Sources, Part A Recover. Util. Environ. Eff. 2024, 46, 11148–11166. [Google Scholar] [CrossRef]

- Yin, Y.; Qian, J.; Zhang, X. Recent advancements in liquid desiccant dehumidification technology. Renew. Sustain. Energy Rev. 2014, 31, 38–52. [Google Scholar] [CrossRef]

- Bai, Z.; Chinnappan, A.; Deng, J.; Shu, C.-M.; Ghomi, E.R.; Yao, S.; Duan, X.; Chinnappan, B.; Ramakrishna, S. Recent progress in ionic liquids as desiccants for energy consumption in cooling applications. J. Mol. Liq. 2023, 383, 122033. [Google Scholar] [CrossRef]

- Abdel-Salam, A.H.; Simonson, C.J. State-of-the-art in liquid desiccant air conditioning equipment and systems. Renew. Sustain. Energy Rev. 2016, 58, 1152–1183. [Google Scholar] [CrossRef]

- Wen, T.; Lu, L.; Li, M.; Zhong, H. Comparative study of the regeneration characteristics of LiCl and a new mixed liquid desiccant solution. Energy 2018, 163, 992–1005. [Google Scholar] [CrossRef]

- Pratama, N.N.; Ariyadi, H.M.; Waluyo, J.; Hayatullah, W. Numerical Performance Evaluation of Aqueous LiCl and CaCl2 Solutions as Liquid Desiccants in Dehumidification Systems. Eng. Proc. 2024, 67, 24. [Google Scholar] [CrossRef]

- Kumar, N.; Ganesha, A.; Girish, H.; Harsha, A.K.; Shekar, M.V.; Salins, S.S. The synergy of hybrid desiccants and membrane-assisted techniques for enhancing dehumidifier efficiency. Int. J. Sustain. Eng. 2024, 17, 1140–1153. [Google Scholar] [CrossRef]

- Fahad, F.G.; Al-Humairi, S.T.; Al-Ezzi, A.T.; Majdi, H.S.; Sultan, A.J.; Alhuzaymi, T.M.; Aljuwaya, T.M. Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications. Sustainability 2023, 15, 14021. [Google Scholar] [CrossRef]

- Abdelgaied, M.; Saber, M.A.; Bassuoni, M.M.; Khaira, A.M. Adsorption air conditioning: A comprehensive review in desiccant materials, system progress, and recent studies on different configurations of hybrid solid desiccant air conditioning systems. Environ. Sci. Pollut. Res. 2023, 30, 28344–28372. [Google Scholar] [CrossRef]

- Shivaprasad, K.V.; Roy, S.; Giampieri, A.; Smallbone, A.; Roskilly, A.P. Experimental and numerical investigation to optimise liquid desiccant system for advanced air conditioning. Sci. Rep. 2025, 15, 7151. [Google Scholar] [CrossRef]

- Guan, B.; Zhang, Q.; Li, M.; Zhang, T.; Liu, X.; Wang, X. Investigation on liquid desiccant regeneration for advanced air-conditioning: Aerodynamic thermal method versus mechanical vapor recompression method. Energy Convers. Manag. 2024, 305, 118253. [Google Scholar] [CrossRef]

- Lowenstein, A. Review of Liquid Desiccant Technology for HVAC Applications. HVAC&R Res. 2008, 14, 819–839. [Google Scholar] [CrossRef]

- Riffat, S.B.; Shehata, H.A.; Srivastava, N.C. The desiccant air-conditioning system. Int. J. Ambient Energy 2004, 25, 163–168. [Google Scholar] [CrossRef]

- Zheng, X.; Ge, T.S.; Wang, R.Z.; Hu, L.M. Performance study of composite silica gels with different pore sizes and different impregnating hygroscopic salts. Chem. Eng. Sci. 2014, 120, 1–9. [Google Scholar] [CrossRef]

- Kumar, S.; Salins, S.S.; Reddy, S.V.K. Influence of the velocity ratio and rotational speed on the polymer based desiccant dehumidifier. Discov. Appl. Sci. 2025, 7, 687. [Google Scholar] [CrossRef]

| Instrument | Maker/Model | Range | Accuracy | Resolution |

|---|---|---|---|---|

| Air blower | Havell’s turbo force | 0.4–7 m/s | ||

| Thermocouple | Chromel-Alumel (K-type) | 0–200 °C | 0.1 °C | 0.1 °C |

| Rotameter | Transforum engg | 5 kg/cm2 | 3% FS | 0.1 LPM |

| Hygrometer | UNI-TUT 333 | 0–100% | 2.5% RH | 0.1% RH |

| Temperature indicator | System Controls | 0–300 °C | ||

| Digital | Work zone AVM-03 | 0.45 m/s | 0.1 m/s | 0.01 m/s |

| Variable frequency drive | Mitsubhi D700 | 0–50 Hz |

| Measurement | Location | Device |

|---|---|---|

| Air Temperature | Entry—after honeycomb packaging—and exit. | K-type thermocouple |

| Air Velocity | Inlet and exit of air passage duct. | Anemometer |

| Relative Humidity | Entry—after honeycomb packaging—and exit. | Hygrometer |

| Desiccant Flow Rate | Before honeycomb packaging (attached to the duct). | Rotameter |

| Cooling Water Flow Rate | After honeycomb packaging (attached to the duct). | Rotameter |

| Parameter | Parameter Variation |

|---|---|

| Liquid Desiccant | MgCl2 (30% concentration) |

| MgCl2 (30% concentration) + silica gel (10% concentration) | |

| MgCl2 (30% concentration) + silica gel (20% concentration) | |

| Air Velocity | 3 m/s, 4 m/s, 5 m/s, 6 m/s, and 7 m/s |

| Cooling Water Flow Rate | 1 lpm, 2 lpm, and 3 lpm |

| Desiccant Flow Rate | 1 lpm, 2 lpm, and 3 lpm |

| Reference | Desiccant System | Efficiency | COP | MRR | Notes |

|---|---|---|---|---|---|

| [1] | Silica gel (packed bed) | 72% | 1.12 | 0.21 g/s | Standard passive adsorption system |

| [4] | LiCl (flat-plate channel) | 80% | 1.6 | 0.26 g/s | Hybrid crossflow geometry |

| [5] | Internally cooled CaCl2 | 78% | 2.9 | 0.28 g/s | Enhanced hybrid cooling design |

| [23] | Polymer rotary desiccant system | 83.7% | 5.36 | 0.23 g/s | Velocity-tuned polymer wheel (rotary) |

| This study | MgCl2 + 20% silica gel | 86% | 2.36 | 0.33 g/s | Stationary crossflow + post-cooling setup |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shettigar, L.; Kumar, N.; Nagaraj, M.; Gowrishankar, M.C.; Kumar, S.; Salins, S.S. Sustainable Indoor Thermal Regulation with Hybrid Desiccant and Post-Cooling Technologies. Sustainability 2025, 17, 7805. https://doi.org/10.3390/su17177805

Shettigar L, Kumar N, Nagaraj M, Gowrishankar MC, Kumar S, Salins SS. Sustainable Indoor Thermal Regulation with Hybrid Desiccant and Post-Cooling Technologies. Sustainability. 2025; 17(17):7805. https://doi.org/10.3390/su17177805

Chicago/Turabian StyleShettigar, Lolaksha, Nitesh Kumar, Madhwesh Nagaraj, Mandya Channegowda Gowrishankar, Shiva Kumar, and Sampath Suranjan Salins. 2025. "Sustainable Indoor Thermal Regulation with Hybrid Desiccant and Post-Cooling Technologies" Sustainability 17, no. 17: 7805. https://doi.org/10.3390/su17177805

APA StyleShettigar, L., Kumar, N., Nagaraj, M., Gowrishankar, M. C., Kumar, S., & Salins, S. S. (2025). Sustainable Indoor Thermal Regulation with Hybrid Desiccant and Post-Cooling Technologies. Sustainability, 17(17), 7805. https://doi.org/10.3390/su17177805