Identifying Root Causes and Sustainable Solutions for Reducing Construction Waste Using Social Network Analysis

Abstract

1. Introduction

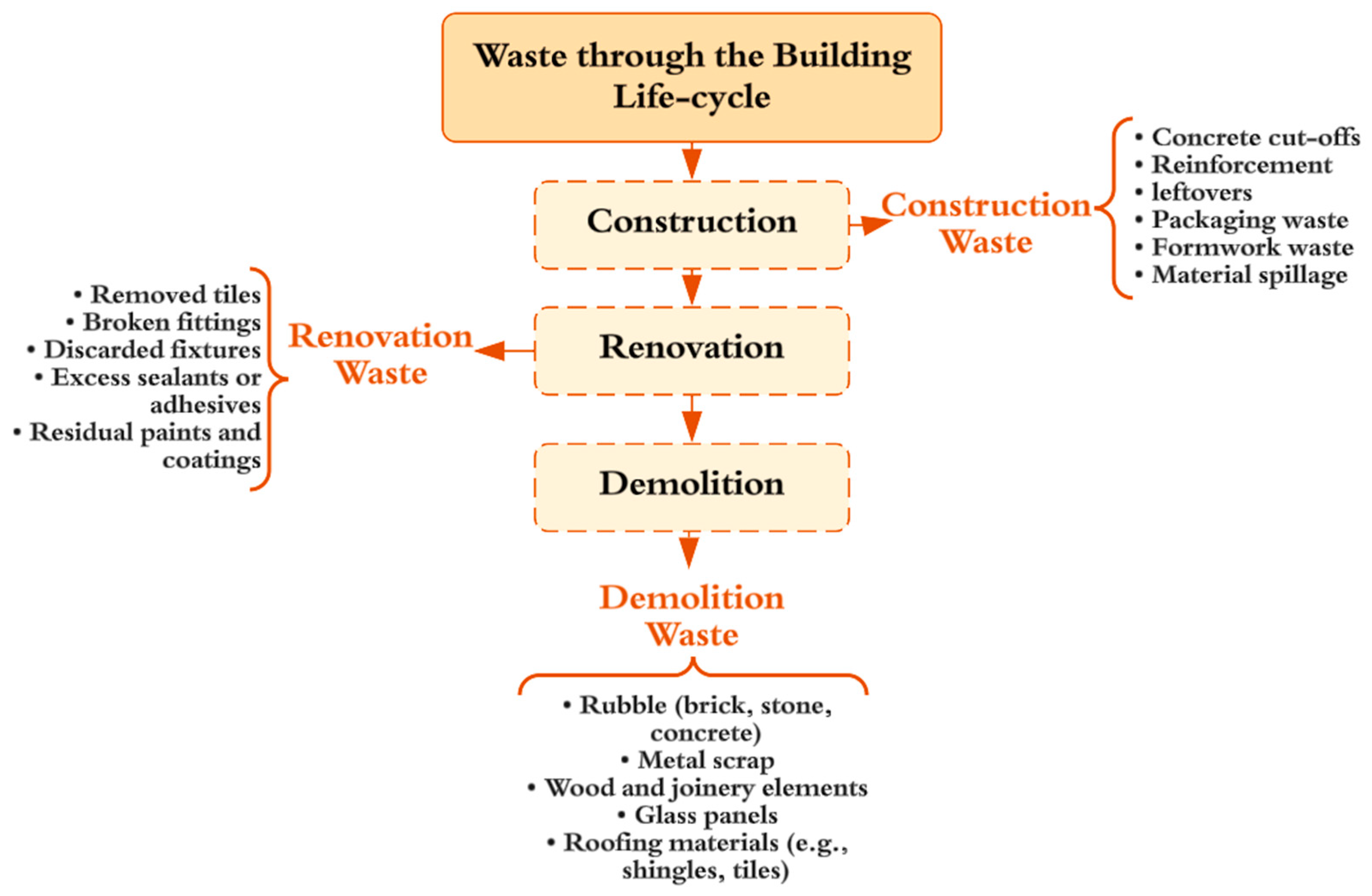

2. The Problem of CW

2.1. CW Classifications and Types

2.2. CW Measurements

2.3. Reuse and Recycling Practices in CW Management

2.4. CW Disposal

2.5. Integration of Digital Tools and Policy Frameworks in CW Management

2.6. Knowledge Gap and Objectives

- Systematically extracting and classifying 25 CW source factors from the literature (1995–2025) using PRISMA guidelines.

- Applying SNA to quantify CW sources’ influence and co-occurrence patterns is a novel technique rarely used in CW reviews.

- Identifying both consensus and blind spots across academia and industry practices.

- Recommending actionable guidelines based on integrated digital tools (e.g., BIM, RFID) and CE principles.

- What are the most influential and frequently co-occurring factors contributing to CW in the literature?

- How do academic findings align with real-world site practices and expert perceptions?

- What digital and regulatory frameworks can address the most critical CW sources?

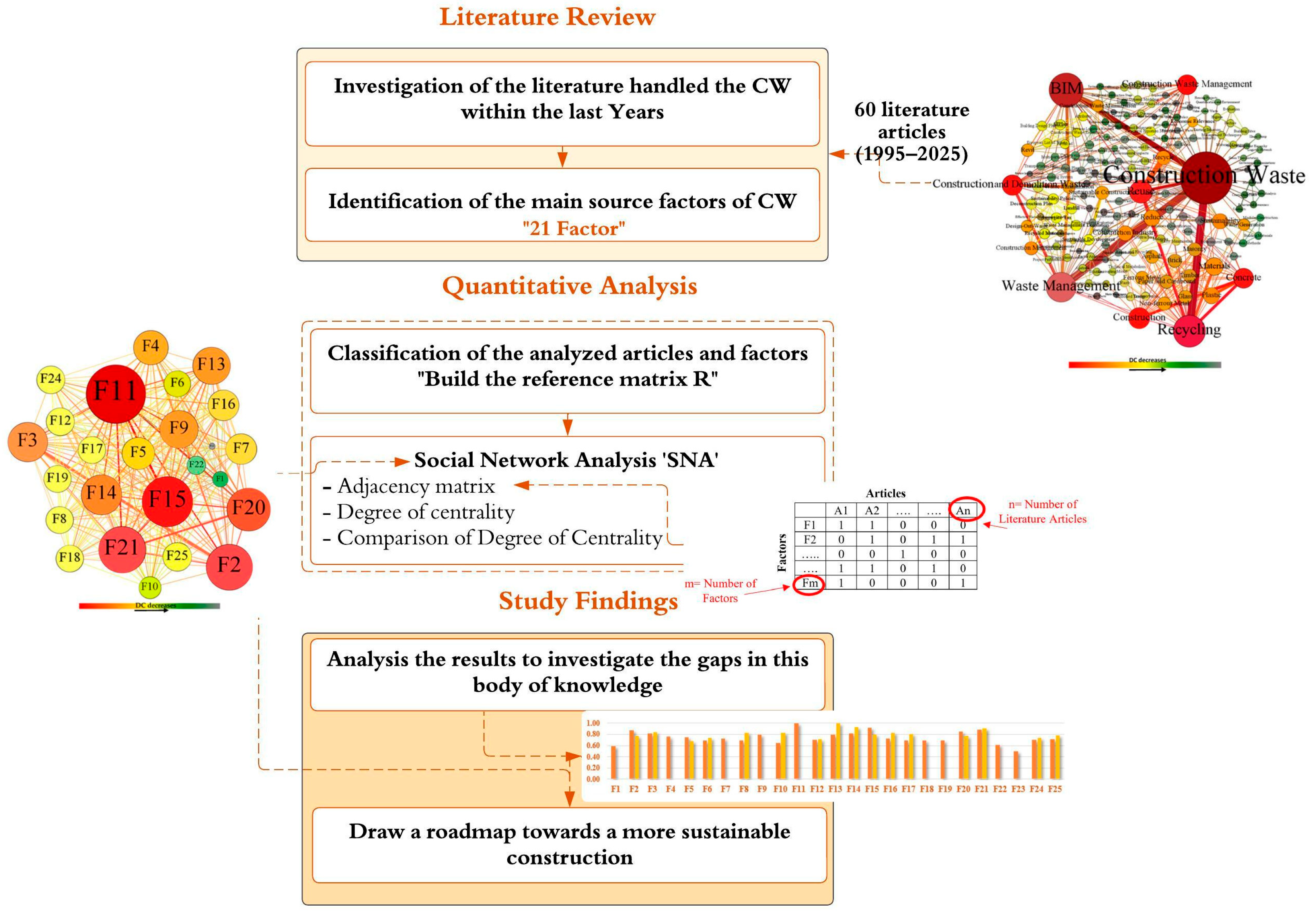

3. Research Methodology

3.1. Literature Analysis

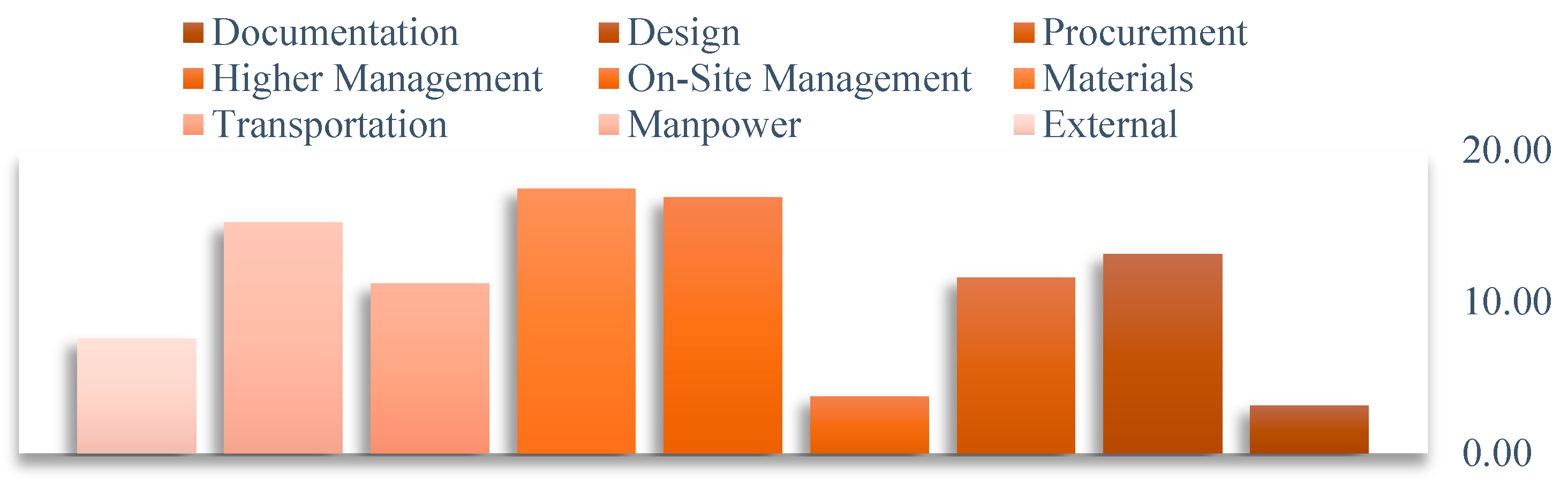

3.2. CW Source Categories and Factors

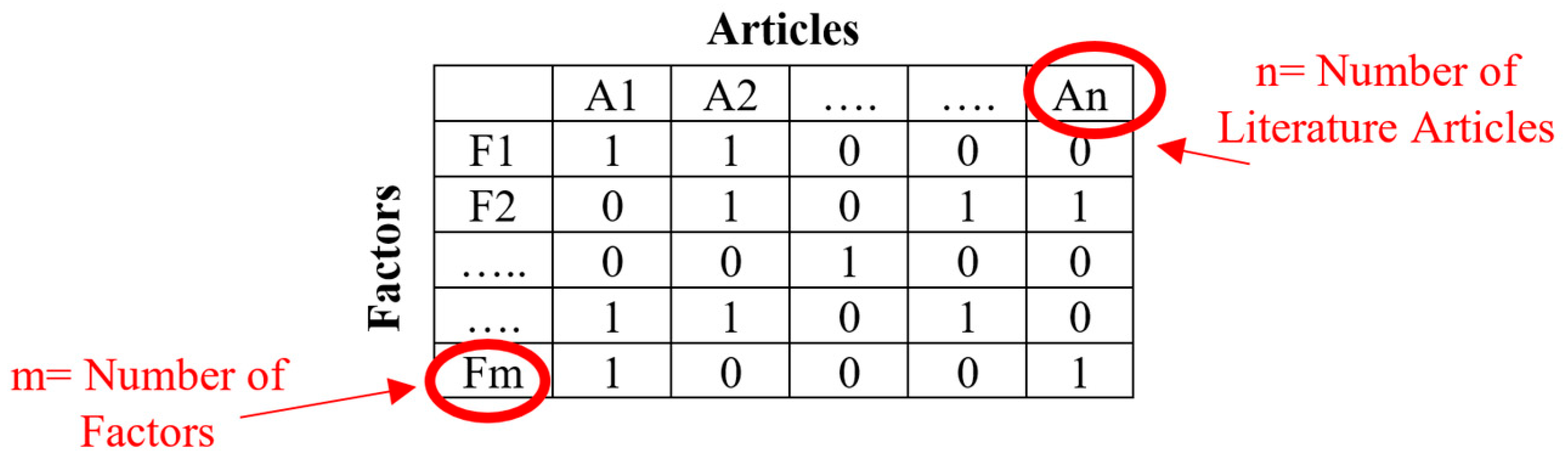

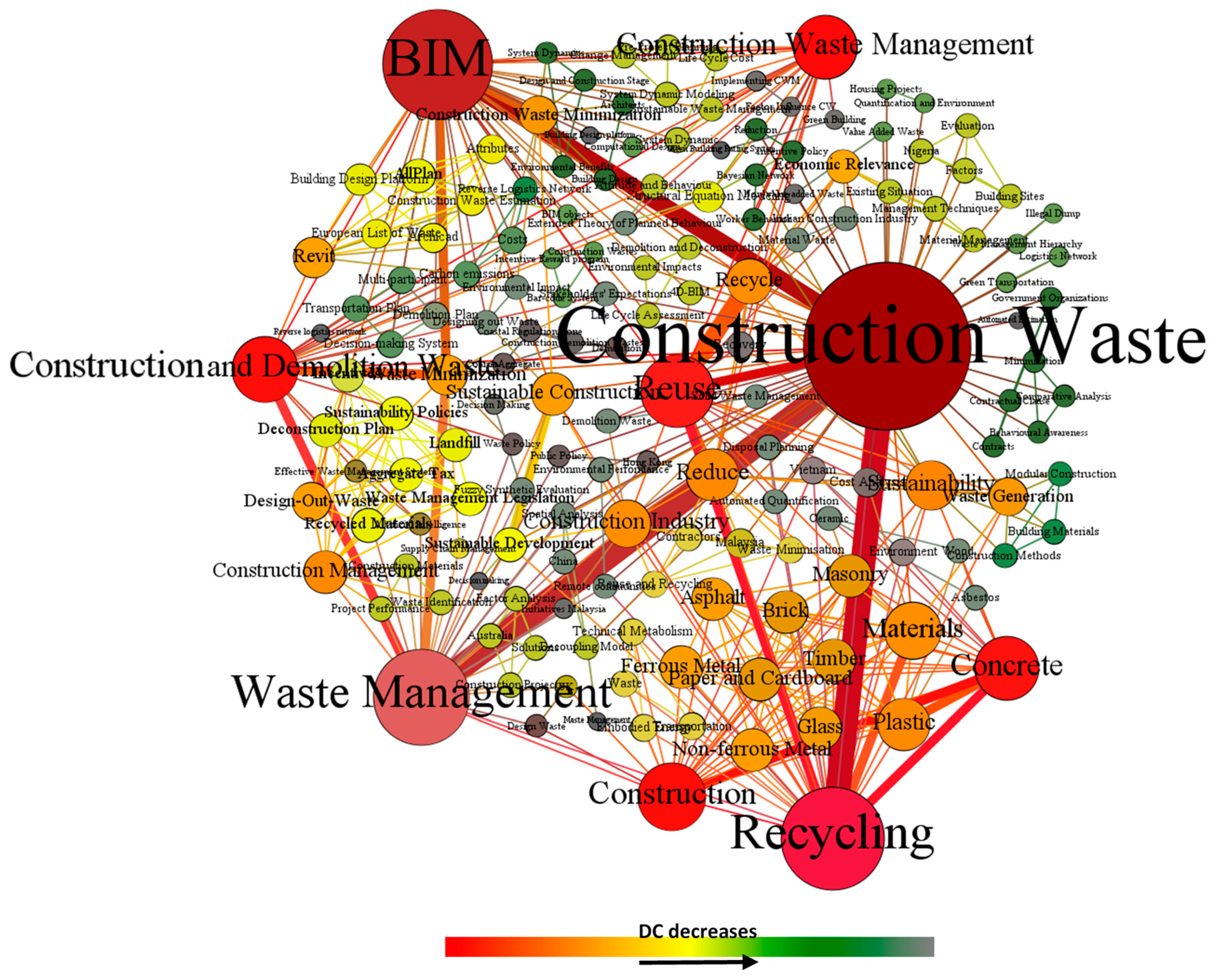

3.3. Developing the Social Network Analysis

3.4. Comparative Analysis

4. Analysis of Results and Discussion

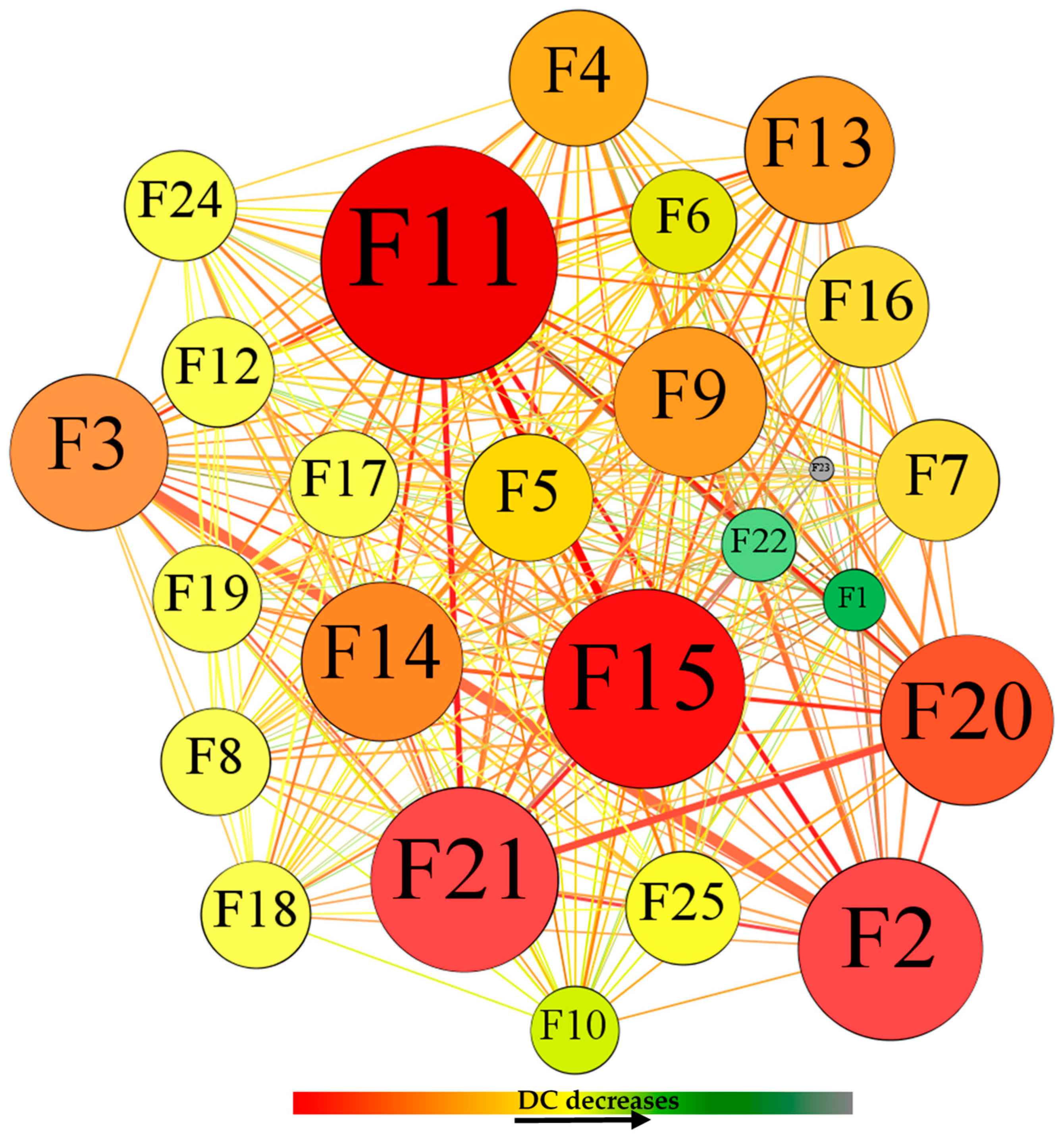

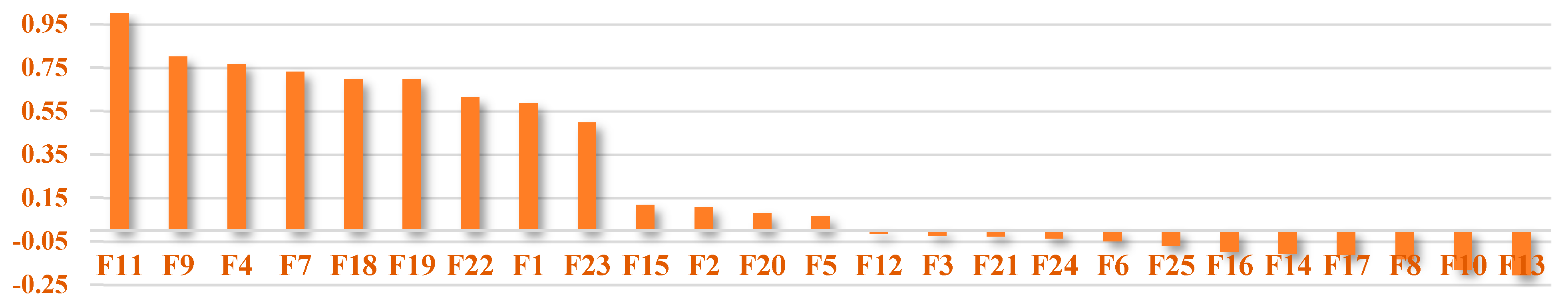

4.1. SNA Results

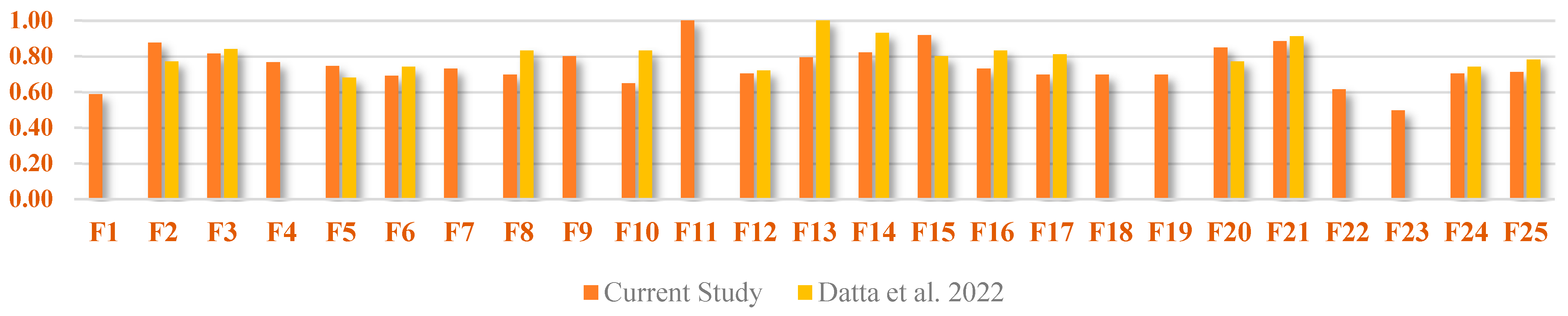

4.2. Results of the Comparative Analysis

- Embedding CW-related clauses in contractual and regulatory documents to formalize responsibility.

- Mandating site-specific training on supervision, planning, and documentation best practices.

- Incorporating CW performance indicators into routine audits and project evaluations.

- Enhancing collaboration between academia and industry via joint knowledge-exchange forums.

4.3. Conceptual Cross-Mapping with Lean Waste Typologies

4.4. Mapping High-Centrality CW Factors to CE Pathways

5. Main Guidelines and Recommendations

5.1. Standardized Waste Management Planning

- Assigned responsibilities across project teams.

- Phased implementation milestones aligned with construction stages.

- Key Performance Indicators (KPIs) to monitor material efficiency, waste reduction, and compliance with waste-related targets.

5.2. Digital Integration for Residual Material Traceability

- Enable real-time tracking of excess or reusable materials.

- Trigger automated alerts for reuse or reallocation opportunities.

- Support closed-loop material recovery aligned with circular economy models.

5.3. Enhancing Material Handling and Logistics

5.4. Strategic Focus Areas for Future Research

- Regulatory Frameworks and Governmental Incentives: Regulators must develop enforceable waste audit protocols, material reuse benchmarks, and transparent reporting mechanisms. Fiscal instruments—such as landfill levies, tax incentives, or procurement subsidies—should be empirically evaluated for their behavioral impact on industry practices.

- Executive Commitment and Institutional Leadership: CW minimization should be embedded into organizational policy from project inception. Future research could examine the impact of executive engagement on design coordination, procurement efficiency, and overall site sustainability performance.

- Design-Centered Waste Prevention: The design phase offers early intervention potential. Future inquiries should investigate how modular construction, design-for-disassembly, and the use of recycled-content materials can be systematically embedded without compromising aesthetics or structural integrity.

- Climate Adaptation and Resilience: Climatic variability contributes to material damage and delays. Research should examine how climate-resilient planning, predictive scheduling, and weather-adaptive storage systems can reduce waste under extreme conditions.

- Workforce Capacity, Training, and Ethical Culture: Human behavior remains central to on-site waste outcomes. Structured training in material handling, environmental ethics, and daily operational discipline should be institutionalized across project teams.

5.5. Toward a Unified Waste Management Framework

- Synthesis of the most influential waste source factors.

- Leveraging digital tools such as BIM, RFID, and IoT for process monitoring.

- Alignment with regional regulatory, cultural, and operational conditions.

- Local level: Municipal authorities can implement incentive programs for on-site waste sorting, such as reduced landfill fees for projects achieving specified segregation rates, and enforce selective demolition permits requiring material recovery targets.

- National level: National governments can introduce tax reductions or subsidies for contractors and developers adopting CE practices, such as using recycled aggregates or integrating BIM-based waste tracking into project workflows. Public procurement policies should prioritize projects that demonstrate verifiable waste minimization outcomes.

- International level: Regional and global bodies (e.g., UNEP, ISO) can work toward harmonized CW reporting standards, cross-border certification systems for recycled materials, and collaborative knowledge-sharing platforms to exchange best practices and performance benchmarks.

5.6. Future Research Directions and Opportunities

6. Conclusions

- Thematic Mapping of CW Factors: A total of 25 CW source factors were extracted from the literature and categorized into major thematic domains, emphasizing material inefficiencies, design flaws, procedural gaps, and stakeholder-related issues.

- Social Network Analysis (SNA) Results: The SNA approach revealed that the absence of structured on-site waste management plans (F11) is the most central factor, followed by poor workmanship, inadequate training, and design inaccuracies, demonstrating systemic interdependencies.

- Implications for Site Practice: Improving material handling, site organization, and on-site logistics can significantly reduce CW. Contractor-led initiatives such as tiered waste management protocols and real-time material monitoring are essential.

- BIM and Circular Economy Integration: Integrating BIM and CE principles provides a viable pathway for proactive waste reduction. BIM-enabled traceability can improve material reuse, while CE strategies promote resource recovery and process efficiency.

- Research–Practice Gap: A disconnect remains between theoretical models and actual industry implementation. Bridging this gap requires the development of unified CW management frameworks supported by empirical data, digital tools, and regional policy alignment.

- Call for Collaborative Action: The findings of this study offer a strategic roadmap for construction firms, policymakers, and researchers to collaboratively advance CW minimization as a core component of sustainable construction, rather than a post-construction obligation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Womack, J.P.; Jones, D.T. How to Root Out Waste and Pursue Perfection. In Harvard Business Review; Harvard Business Publishing: Brighton, MA, USA, 1996; pp. 140–151. [Google Scholar]

- Eurostat, the Statistical Office of the E.U. Waste generation, Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 20 July 2023).

- Fang, Y.; Shi, X.; Chen, Y.; He, J. Quantity Prediction of Construction and Demolition Waste Using Weighted Combined Grey Theory and Autoregressive Integrated Moving Average Model. Sustainability 2024, 16, 5255. [Google Scholar] [CrossRef]

- Islam, N.; Sandanayake, M.; Muthukumaran, S.; Navaratna, D. Review on Sustainable Construction and Demolition Waste Management—Challenges and Research Prospects. Sustainability 2024, 16, 3289. [Google Scholar] [CrossRef]

- Liu, Z.; Osmani, M.; Demian, P.; Baldwin, A. A BIM-aided construction waste minimisation framework. Autom. Constr. 2015, 59, 1–23. [Google Scholar] [CrossRef]

- Ramaswamy, K.P.; Kalidindi, S.N. Waste in Indian Building Construction Projects. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction (IGLC 17), Taipei, Taiwan, 15–17 July 2009; Available online: https://www.researchgate.net/publication/288077458_Waste_in_Indian_building_construction_projects (accessed on 15 July 2024).

- Lam, P.T.I.; Yu, A.T.W.; Wu, Z.; Poon, C.S. Methodology for upstream estimation of construction waste for new building projects. J. Clean. Prod. 2019, 230, 1003–1012. [Google Scholar] [CrossRef]

- Akhund, M.A.; Memon, A.H.; Ali, T.H.; Memon, N.A.; Kazi, S. Waste Management in Construction Projects of Pakistan. Pak. J. Sci. 2019, 71, 59–63. [Google Scholar]

- Viana, D.D.; Formoso, C.T.; Kalsaas, B.T. Waste in Construction: A Systematic Literature Review on Empirical Studies. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction (IGLC 20), San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Swarnakar, V.; Khalfan, M. Circular economy in construction and demolition waste management: An in-depth review and future perspectives in the construction sector. Smart Sustain. Built Environ. 2024. [Google Scholar] [CrossRef]

- Elgizawy, S.M.; El-Haggar, S.M.; Nassar, K. Approaching Sustainability of Construction and Demolition Waste Using Zero Waste Concept. Low Carbon Econ. 2016, 7, 1–11. [Google Scholar] [CrossRef]

- Basuyau, V. Construction and demolition waste recycling in Europe: Long-term trends and challenges ahead. Indian Concr. J. 2020, 94, 8–18. [Google Scholar]

- Ma, Z.; Wu, Y.; Fang, K.; Zhang, Y.; Wang, C. Developing fully recycled alkali-activated mortar made with waste concrete fines as a substitute for both binder and sand: Multi-properties evaluation. Constr. Build. Mater. 2025, 477, 141323. [Google Scholar] [CrossRef]

- Gulghane, A.; Sharma, R.L.; Borkar, P. Quantification analysis and prediction model for residential building construction waste using machine learning technique. Asian J. Civ. Eng. 2023, 24, 1459–1473. [Google Scholar] [CrossRef]

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life cycle environmental impact assessment to manage and optimize construction waste using Building Information Modeling (BIM). Int. J. Constr. Manag. 2019, 21, 784–801. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Y.; Dai, Y.; Wu, H.; Ma, Z. In-situ 4D CT analysis of microcrack evolution in carbonated fiber-reinforced recycled aggregate concrete. Cem. Concr. Compos. 2025, 163, 106161. [Google Scholar] [CrossRef]

- Napier, T. Construction Waste Management; National Institute of Building Sciences (NIBS): Washington, DC, USA, 2016; Available online: https://www.wbdg.org/resources/construction-waste-management (accessed on 12 January 2023).

- Al-Otaibi, A.; Bowan, P.A.; Alabdullatief, A.; Albaiz, M.; Salah, M. Barriers to Sustainable Building Project Performance in Developing Countries: A Case of Ghana and the Kingdom of Saudi Arabia. Sustainability 2025, 17, 3539. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Formoso, C.T.; Soibelman, L.; De Cesare, C.; Isatto, E.L. Material Waste in Building Industry: Main Causes and Prevention. J. Constr. Eng. Manag. 2002, 128, 316–325. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). Sustainable Management of Construction and Demolition Materials. Available online: https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (accessed on 23 December 2023).

- Nagapan, S.; Rahman, I.A.; Asmi, A. A review of construction waste cause factors. In Proceedings of the Sustainable Growth Managing Challenges, University Tun Hussein, Johor Bahru, Malaysia, 3–5 October 2011; pp. 967–987. Available online: https://scholar.google.com/scholar?hl=ar&as_sdt=0%2C5&q=Nagapan%2C+S.%2C+Rahman%2C+I.+A.%2C+%26+Asmi%2C+A.+%282011%2C%29.+A+review+of+construction+waste+cause+factors.+In+Asian+Conference+on+Real+Estate%3A+Sustainable+Growth+Managing+Challenges+%28ACRE%29+%28pp.+967-987%29.%E2%80%8F&btnG= (accessed on 29 March 2025).

- Poon, C.-S.; Chan, D. The use of recycled aggregate in concrete in Hong Kong. Resour. Conserv. Recycl. 2007, 50, 293–305. [Google Scholar] [CrossRef]

- Katz, A.; Baum, H. A novel methodology to estimate the evolution of construction waste in construction sites. Waste Manag. 2011, 31, 353–358. [Google Scholar] [CrossRef]

- Denerolle, S. The 8 Wastes of Lean Construction. FieldWire, 2023. Available online: https://www.fieldwire.com/blog/eight-wastes-of-lean-construction/ (accessed on 30 October 2023).

- Lau, H.H.; Whyte, A.; Law, P.L. Composition and Characteristics of Construction Waste Generated by Residential Housing Project. Int. J. Environ. Res. 2008, 2, 261–268. [Google Scholar]

- Foo, L.C.; Khalid, K.I.; Nagapan, S.; Asmi, A.; Abdul Rahman, I. Classification and Quantification of Construction Waste at Housing Project Site. ZW 2013, 1, 1–4. [Google Scholar]

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Hao, J.; Chen, Z.; Zhang, Z.; Loehlein, G. Quantifying construction waste reduction through the application of prefabrication: A case study in Anhui, China. Environ. Sci. Pollut. Res. 2021, 28, 24499–24510. [Google Scholar] [CrossRef] [PubMed]

- Bakshan, A.; Srour, I.; Chehab, G.; El-Fadel, M. A field based methodology for estimating waste generation rates at various stages of construction projects. Resour. Conserv. Recycl. 2015, 100, 70–80. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Estimation of construction waste generation and management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ding, Z.; Mi, X.; Wang, J. A model for estimating construction waste generation index for building project in China. Resour. Conserv. Recycl. 2013, 74, 20–26. [Google Scholar] [CrossRef]

- Gasparri, E.; Arasteh, S.; Kuru, A.; Stracchi, P.; Brambilla, A. Circular economy in construction: A systematic review of knowledge gaps towards a novel research framework. Front. Built Environ. 2023, 9, 1239757. [Google Scholar] [CrossRef]

- Sapuay, S.E. Construction Waste—Potentials and Constraints. Procedia Environ. Sci. 2016, 35, 714–722. [Google Scholar] [CrossRef]

- Brewer, G.; Mooney, J. A best practice policy for recycling and reuse in building. Proc. Inst. Civ. Eng. Eng. Sustain. 2008, 161, 173–180. [Google Scholar] [CrossRef]

- Kanyilmaz, A.; Birhane, M.; Fishwick, R.; del Castillo, C. Reuse of Steel in the Construction Industry: Challenges and Opportunities. Int. J. Steel Struct. 2023, 23, 1399–1416. [Google Scholar] [CrossRef]

- Lockrey, S.; Nguyen, H.; Crossin, E.; Verghese, K. Recycling the construction and demolition waste in Vietnam: Opportunities and challenges in practice. J. Clean. Prod. 2016, 133, 757–766. [Google Scholar] [CrossRef]

- Feng, Y. Game study on the evolution of subsidy strategies for on-site construction waste recycling management. Eng. Lett. 2023, 31, 794–805. [Google Scholar]

- Naji, K.K.; Gunduz, M.; Hamaidi, M.F. Major Factors Affecting Construction Waste Management in Infrastructure Projects Using Structural Equation Model. J. Constr. Eng. Manag. 2022, 148, 04022101. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Wang, H.; Xia, S.; Zhang, Q.; Zhang, P. Has China’s Construction Waste Change Been Decoupled from Economic Growth? Buildings 2022, 12, 147. [Google Scholar] [CrossRef]

- Salah, M.; Alabdullatief, A. Architecture of tomorrow: The construction industry in the era of artificial intelligence. Autom. Constr. 2025, 178, 106429. [Google Scholar] [CrossRef]

- Lins, E.J.M.; Palha, R.P.; Sobral, M.D.C.M.; Araújo, A.G.D.; Marques, É.A.T. Application of Building Information Modelling in Construction and Demolition Waste Management: Systematic Review and Future Trends Supported by a Conceptual Framework. Sustainability 2024, 16, 9425. [Google Scholar] [CrossRef]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-based automated construction waste estimation algorithms: The case of concrete and drywall waste streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef]

- Patel, S.; Oza, H.; Sharma, Y.; Patel, T.; Agrawal, S.; Oza, P. IoT-Enabled Smart Waste Management using Renewable Energy. Procedia Comput. Sci. 2025, 259, 1973–1982. [Google Scholar] [CrossRef]

- Zhao, W.; Hao, J.L.; Gong, G.; Fischer, T.; Liu, Y. Applying digital technologies in construction waste management for facilitating sustainability. J. Environ. Manage. 2025, 373, 123560. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Improving waste management in construction projects: An Australian study. Resour. Conserv. Recycl. 2015, 101, 73–83. [Google Scholar] [CrossRef]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. Implementation of waste management and minimisation in the construction industry of Malaysia. Resour. Conserv. Recycl. 2007, 51, 190–202. [Google Scholar] [CrossRef]

- Nagapan, S.; Abdul Rahman, I.; Asmi, A.; Memon, A.H.; Zin, R.M. Identifying Causes of Construction Waste – Case of Central Region of Peninsula Malaysia. Int. J. Integr. Eng. 2012, 4, 22–28. Available online: https://penerbit.uthm.edu.my/ojs/index.php/ijie/article/view/190 (accessed on 29 March 2025).

- Saadi, N.; Ismail, Z.; Alias, Z. A review of construction waste management and initiatives in Malaysia. J. Sustain. Sci. Manag. 2016, 11, 101–114. [Google Scholar]

- Tam, V.W.Y.; Shen, L.Y.; Fung, I.W.H.; Wang, J.Y. Controlling construction waste by implementing governmental ordinances in Hong Kong. Constr. Innov. 2007, 7, 149–166. [Google Scholar] [CrossRef]

- Lu, W.; Tam, V.W.Y. Construction waste management policies and their effectiveness in Hong Kong: A longitudinal review. Renew. Sustain. Energy Rev. 2013, 23, 214–223. [Google Scholar] [CrossRef]

- Jain, M. Economic Aspects of Construction Waste Materials in terms of cost savings–A case of Indian construction Industry. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- Swetha, S.K.; Tezeswi, T.P.; Kumar, S.M.V.N. Implementing construction waste management in India: An extended theory of planned behaviour approach. Environ. Technol. Innov. 2022, 27, 102401. [Google Scholar] [CrossRef]

- Shrivastava, S.; Chini, A. Construction Materials and C&D Waste in India. In Proceedings of the Lifecycle Design of Buildings, Systems and Materials, Enschede, The Netherlands, 12–15 June 2009; pp. 72–76. [Google Scholar]

- Mohd Nasir, S.R.; Othman, N.H.; Mat Isa, C.M.; Che Ibrahim, C.K. The Challenges of Construction Waste Management in Kuala Lumpur. J. Teknol. 2016, 78, 115–119. [Google Scholar] [CrossRef]

- Kulatunga, U.; Amaratunga, D.; Haigh, R.; Rameezdeen, R. Attitudes and perceptions of construction workforce on construction waste in Sri Lanka. Manag. Environ. Qual. Int. J. 2006, 17, 57–72. [Google Scholar] [CrossRef]

- Quiñones, R.; Llatas, C.; Montes, M.V.; Cortés, I. A Multiplatform BIM-Integrated Construction Waste Quantification Model during Design Phase. The Case of the Structural System in a Spanish Building. Recycling 2021, 6, 62. [Google Scholar] [CrossRef]

- Datta, S.D.; Rana, M.J.; Assafi, M.N.; Mim, N.J.; Ahmed, S. Investigation on the generation of construction wastes in Bangladesh. Int. J. Constr. Manag. 2023, 23, 2260–2269. [Google Scholar] [CrossRef]

- Véliz, K.D.; Busco, C.; Walters, J.P.; Esparza, C. Circular Economy for Construction and Demolition Waste in the Santiago Metropolitan Region of Chile: A Delphi Analysis. Sustainability 2025, 17, 1057. [Google Scholar] [CrossRef]

- Idir, R.; Djerbi, A.; Tazi, N. Optimising the Circular Economy for Construction and Demolition Waste Management in Europe: Best Practices, Innovations and Regulatory Avenues. Sustainability 2025, 17, 3586. [Google Scholar] [CrossRef]

- Mitera-Kiełbasa, E.; Zima, K. Optimising Construction Efficiency: A Comprehensive Survey-Based Approach to Waste Identification and Recommendations with BIM and Lean Construction. Sustainability 2025, 17, 4027. [Google Scholar] [CrossRef]

- Reda Ismail, E.; Mohamed El-Mahdy, G.; Hussein Ibrahim, A.; Osama Daoud, A. A comprehensive framework towards safe disposal of construction and demolition waste: The case of Egypt. Alex. Eng. J. 2023, 74, 359–369. [Google Scholar] [CrossRef]

- Olubambi, A.; Akinradewo, O.; Aigbavboa, C.; Ikotun, B. Quantitative Evaluation of Sustainable Construction and Demolition Waste Management System Performance in South Africa. Infrastructures 2025, 10, 150. [Google Scholar] [CrossRef]

- Hasselsteen, L.; Stapel, E.B.; Birgisdóttir, H.; Sørensen, C.G.; Kanafani, K. Evaluating the environmental impact of construction waste: A comprehensive analysis of End-of-Life scenarios in Environmental Product Declarations. Build. Environ. 2025, 280, 113159. [Google Scholar] [CrossRef]

- Bossink, B.A.G.; Brouwers, H.J.H. Construction Waste: Quantification and Source Evaluation. J. Constr. Eng. Manag. 1996, 122, 55–60. [Google Scholar] [CrossRef]

- Ekanayake, L.; Ofori, G. Construction material waste source evaluation. In Proceedings of the Strategies for a Sustainable Built Environment, Pretoria, South Africa, 23–25 August 2000; pp. 23–25. [Google Scholar]

- Faniran, O.O.; Caban, G. Minimizing waste on construction project sites. Eng. Constr. Archit. Manag. 1998, 5, 182–188. [Google Scholar] [CrossRef]

- Formoso, C.T.; Isatto, E.L.; Hirota, E.H. Method for Waste Control in the Building Industry. In Proceedings of the Method for Waste Control in the Building Industry, Berkeley, CA, USA, 26–28 July 1999; Volume 7, pp. 325–330. Available online: https://iglc.net/papers/Details/69 (accessed on 29 March 2025).

- Gavilan, R.M.; Bernold, L.E. Source Evaluation of Solid Waste in Building Construction. J. Constr. Eng. Manag. 1994, 120, 536–552. [Google Scholar] [CrossRef]

- Keys, A.; Baldwin, A.; Austin, S.A. Designing to encourage waste minimisation in the construction industry. In Proceedings of the CIBSE National Conference 2000, Dublin, Ireland, 20–22 September 2000; Available online: https://hdl.handle.net/2134/4945 (accessed on 22 February 2025).

- Alwi, S.; Mohamed, S.; Hampson, K. Waste in the Indonesian construction projects. In Proceedings of the 1st CIB-W107 International Conference-Creating a Sustainable Construction Industry in Developing Countries, Pretoria, South Africa, 11–13 November 2002; pp. 305–315. Available online: https://eprints.qut.edu.au/4163/ (accessed on 22 February 2025).

- Dainty, A.R.J.; Brooke, R.J. Towards improved construction waste minimisation: A need for improved supply chain integration? Struct. Surv. 2004, 22, 20–29. [Google Scholar] [CrossRef]

- Innes, S. Developing tools for designing out waste pre-site and on-site. In Proceedings of the Developing Resource Efficiency and Waste Minimisation in Design and Construction, London, UK, 21 October 2004; Available online: https://scholar.google.com/scholar_lookup?title=Developing%20tools%20for%20designing%20out%20waste%20pre-site%20and%20on-site&publication_year=2004&author=S.%20Innes (accessed on 29 March 2025).

- Li, W. Composition Analysis of Construction & Demolition Waste and Enhancing Waste Reduction and Recycling in Construction Industry in Hong Kong; Hong Kong Polytechnic University: Hong Kong, China, 2002. [Google Scholar]

- Osmani, M.; Glass, J.; Price, A.D.F. Architects’ perspectives on construction waste reduction by design. Waste Manag. 2008, 28, 1147–1158. [Google Scholar] [CrossRef] [PubMed]

- Polat, G.; Ballard, G. Waste in Turkish construction: Need for lean construction techniques. In Proceedings of the 12th Annual Conference of the International Group for Lean Construction IGLC-12, Helsingør, Denmark, 3–5 August 2004; pp. 488–501. [Google Scholar]

- Poon, C.S.; Yu, A.T.W.; Ng, L.H. Comparison of low-waste building technologies adopted in public and private housing projects in Hong Kong. Eng. Constr. Archit. Manag. 2003, 10, 88–98. [Google Scholar] [CrossRef]

- Tam, V.W.Y. On the effectiveness in implementing a waste-management-plan method in construction. Waste Manag. 2008, 28, 1072–1080. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization in construction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef]

- Bakshan, A.; Srour, I.; Chehab, G.; El-Fadel, M.; Karaziwan, J. Behavioral determinants towards enhancing construction waste management: A Bayesian Network analysis. Resour. Conserv. Recycl. 2017, 117, 274–284. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F.; Faust, K.M. 4D-BIM to enhance construction waste reuse and recycle planning: Case studies on concrete and drywall waste streams. Waste Manag. 2020, 116, 79–90. [Google Scholar] [CrossRef]

- Gulghane, A.A.; Khandve, P.V. Management for Construction Materials and Control of Construction Waste in Construction Industry: A Review. J. Eng. Res. Appl. 2015, 5, 59–64. [Google Scholar]

- Kaliannan, S.; Nagapan, S.; Abdullah, A.H.; Sohu, S.; Jhatial, A.A. Determining Root Cause of Construction Waste Generation: A Global Context. Civ. Eng. J. 2018, 4, 2539. [Google Scholar] [CrossRef]

- Lieu, Z.; Osmani, M.; Demian, P.; Baldwin, A.N. The Potential use of Bim to Aid Construction Waste Minimisation. In Proceedings of the CIB W78–W102 2011 International Conference, Sophia Antipolis, France, 26–28 October 2011; Available online: https://scholar.google.com/scholar?hl=ar&as_sdt=0%2C5&q=Lieu%2C+Z.%2C+Osmani%2C+M.%2C+Demain%2C+P.%2C+and+Baldwin%2C+A.+%282011%29.+The+Potential+use+of+BIM+to+aid+construction+waste+minimization.+In+proceedings+of+the+CIB+W78-W102+2011%3A+INTERNATIONAL+Conference+%2826-28+October%2C+pp.+1-13%29%2C+Sophia+Antipolis%2C+France.%E2%80%8F&btnG= (accessed on 26 March 2025).

- Liu, J.; Yi, Y.; Wang, X. Exploring factors influencing construction waste reduction: A structural equation modeling approach. J. Clean. Prod. 2020, 276, 123185. [Google Scholar] [CrossRef]

- Lu, W.; Chen, X.; Ho, D.C.W.; Wang, H. Analysis of the construction waste management performance in Hong Kong: The public and private sectors compared using big data. J. Clean. Prod. 2016, 112, 521–531. [Google Scholar] [CrossRef]

- Luangcharoenrat, C.; Intrachooto, S.; Peansupap, V.; Sutthinarakorn, W. Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective. Sustainability 2019, 11, 3638. [Google Scholar] [CrossRef]

- Nagapan, S.; Rahman, I.A.; Asmi, A.; Adnan, N.F. Study of Site’s Construction Waste in Batu Pahat, Johor. Procedia Eng. 2013, 53, 99–103. [Google Scholar] [CrossRef]

- Nawaz, A.; Chen, J.; Su, X. Exploring the trends in construction and demolition waste (C&DW) research: A scientometric analysis approach. Sustain. Energy Technol. Assess. 2023, 55, 102953. [Google Scholar] [CrossRef]

- Osmani, M. Design waste mapping: A project life cycle approach. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2013, 166, 114–127. [Google Scholar] [CrossRef]

- Osmani, M. Construction Waste Minimization in the UK: Current Pressures for Change and Approaches. Procedia Soc. Behav. Sci. 2012, 40, 37–40. [Google Scholar] [CrossRef]

- Osmani, M. Construction Waste. In Waste; Elsevier: Amsterdam, The Netherlands, 2011; pp. 207–218. ISBN 978-0-12-381475-3. [Google Scholar]

- Osmani, M.; Sáez, V.P. Current and Emerging Construction Waste Management Status, Trends and Approaches. In Waste; Elsevier: Amsterdam, The Netherlands, 2019; pp. 365–380. ISBN 978-0-12-815060-3. [Google Scholar]

- Panos, K.; Danai, G.I. Survey regarding control and reduction of construction waste. In Proceedings of the Opportunities, Limits and Needs Towards an Environmentally Responsible Architecture, Lima, Peru, 7–9 November 2012; Available online: https://scholar.google.com/scholar?hl=ar&as_sdt=0%2C5&q=Survey+regarding+control+and+reduction+of+construction+waste.&btnG= (accessed on 20 May 2024).

- Porwal, A.; Parsamehr, M.; Szostopal, D.; Ruparathna, R.; Hewage, K. The integration of building information modeling (BIM) and system dynamic modeling to minimize construction waste generation from change orders. Int. J. Constr. Manag. 2020, 23, 156–166. [Google Scholar] [CrossRef]

- Rajendran, P.; Gomez, C.P. Implementing Bim for Waste Minimisation in the Construction Industry: A Literature review. In Proceedings of the 2nd International Conference on Management, Langkawi, Malaysia, 11–12 June 2012; pp. 557–570. [Google Scholar]

- Sadi, K.M.A.; Abdullah, A.; Navazandeh Sajoudi, M.; Kamal, M.F.M.; Torshizi, F.; Taherkhani, R. Reduce, Reuse, Recycle and Recovery in Sustainable Construction Waste Management. Adv. Mater. Res. 2012, 446–449, 937–944. [Google Scholar] [CrossRef]

- Sawant, R.; Chandgude, S.; Shewale, M.; Kumar, M.L.; Thakkar, K.; Ram, C. Improvement in Construction Contract Management to Reduce the Construction Waste. Des. Eng. 2021, 16497–16519. [Google Scholar]

- Wang, Z.; Hu, T.; Liu, J. Decoupling economic growth from construction waste generation: Comparative analysis between the EU and China. J. Environ. Manage. 2024, 353, 120144. [Google Scholar] [CrossRef]

- Xu, J.; Lu, W. Design for construction waste management. In Sustainable Buildings and Structures: Building a Sustainable Tomorrow; Taylor & Francis Group: London, UK, 2019; pp. 271–276. ISBN 978-0-367-43019-1. [Google Scholar]

- Otte, E.; Rousseau, R. Social network analysis: A powerful strategy, also for the information sciences. J. Inf. Sci. 2002, 28, 441–453. [Google Scholar] [CrossRef]

- Freeman, L.C. Centrality in social networks conceptual clarification. Soc. Netw. 1978, 1, 215–239. [Google Scholar] [CrossRef]

- Elsayegh, A.; El-adaway, I.H. Holistic Study and Analysis of Factors Affecting Collaborative Planning in Construction. J. Constr. Eng. Manag. 2021, 147, 04021023. [Google Scholar] [CrossRef]

- Salah, M.; Khallaf, R.; Elbeltagi, E.; Wefki, H. Construction Site Layout Planning: A Social Network Analysis. Buildings 2023, 13, 2637. [Google Scholar] [CrossRef]

| Researchers | Country | The Research Area |

|---|---|---|

| [41] | China | The study classified China into three policy zones and proposed various recommendations as decision-based policies for CW management in China and similar countries on the road to a zero-waste society. |

| [47] | Australia | Defined 26 decision policies for CW management through qualitative and quantitative approaches by eliminating and/or minimizing CW generation. |

| [48] | Malaysia | Identified 12 CW minimization factors, indicating the most and least significant and practiced factors of waste minimization in Malaysia. |

| [27] | Malaysia | Discussed the identification and estimation of the waste accumulated from construction sites. |

| [49] | Malaysia | Presented the issues surrounding CW generation in Malaysia, such as illegal dumping and waste management strategies through disposal methods into landfills. |

| [50] | Malaysia | Reviewed the existing literature on CW and various initiatives implemented in Malaysia. |

| [19] | Hong Kong | Discussed some policies for waste reduction in Hong Kong, such as prefabrication in construction buildings. The study reported a 52% average waste reduction level by applying prefabrication. |

| [51] | Hong Kong | Investigated the effectiveness of CW management policies in Hong Kong by conducting some interviews and questionnaires. |

| [52] | Hong Kong | Examined various CW policies and their effects on the construction industry in Hong Kong using qualitative data from interviews and previous case studies. |

| [53] | India | Focused on the economic feasibility and cost savings from CW minimization policies in India. |

| [54] | India | Explored the motivators of individuals in the workforce for implementing CW management in India. |

| [55] | India | An overview of the Indian construction industry and some construction and demolition waste generation statistics were reported. |

| [5] | UK | Developed a BIM-based framework for minimizing CW in the design stage through the results of a literature review, questionnaire, and interview data with 100 top engineers in the UK. |

| [56] | Kuala Lumpur | Studied the main CW management challenges for contractors in Kuala Lumpur and provided some recommendations to face them. |

| [57] | Sri Lanka | The study focused on attitudes and perceptions of the workforce towards CW management applications. |

| [58] | Spanish | Proposed a BIM method to identify and estimate CW quantities during the design stage. |

| [59] | Bangladesh | Identified various CW-generating factors and developed the appropriate management strategies for the Bangladesh construction industry by interviewing construction professionals and rigorously reviewing the previous literature. |

| [60] | Chile | Applied the Delphi method to uncover that technical, regulatory, financial, and socio-environmental factors influence the adoption of sustainable CW practices in Chile. |

| [61] | Europe | Explored how European countries can enhance the management of construction and demolition waste by adopting CE strategies through improved policies, technologies, and industry practices. |

| [62] | Poland | Investigated key inefficiencies within construction projects in Poland and targeted recommendations grounded in BIM and Lean principles to address recurring issues such as schedule delays and coordination challenges through integrated digital and process-driven solutions. |

| [63] | Egypt | Quantified construction and demolition waste in Egypt across various project types, identifying timber, sand, and bricks/blocks as the most wasted materials, with infrastructure projects showing the highest waste and cost losses. It finds that stronger waste-reduction practices, awareness, and legislation are linked to lower waste amounts. |

| [64] | South Africa | Employed a quantitative approach to evaluate the effectiveness of existing construction and demolition waste management practices in South Africa and to identify areas for improvement to enhance sustainability in the construction sector. |

| [65] | Nordic countries | Assessed how recent energy policy changes in Nordic countries influence the environmental effects of construction waste, highlighting the need for more sustainable waste management practices. |

| Year Range | Articles | Number |

|---|---|---|

| 1995–2000 | [66,67,68,69,70,71] | 6 |

| 2001–2010 | [20,23,35,48,57,72,73,74,75,76,77,78,79] | 13 |

| 2011–2025 | [4,8,14,27,34,37,41,44,46,47,49,50,52,53,54,56,58,61,65,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101] | 41 |

| Category | ID | Factor (Original) | Description |

|---|---|---|---|

| Documentation | F1 | Contract documentation error and incompleteness | Most construction contracts ignore CW management clauses. Errors and incompleteness at the project start also generate CW [93]. |

| Design | F2 | Design inaccuracies, Complex detailing | One-third of CW arises from design decisions, primarily when changes or poor technical understanding exist [76]. |

| F3 | Design changes | Last-minute changes from clients or other stakeholders often require rework, generating CW. | |

| F4 | Poor coordination and communication | Poor coordination among design and construction teams causes errors and overlapping work [71]. | |

| Procurement | F5 | Over and under-ordering | Ordering excess or insufficient quantities causes material waste or delays. |

| F6 | Ordering errors and supplier errors | Errors in quantity/type or supplier mistakes lead to wrong deliveries, generating waste. | |

| F7 | Unclear specifications | Vague specifications cause low-quality or unsuitable materials, resulting in rework and waste. | |

| Higher Management | F8 | The negative attitude of higher management | Lack of early stakeholder involvement and undefined roles contribute to CW generation. |

| On-Site Management | F9 | Lack of supervision | Weak supervision allows for poor labor practices and improper material use. |

| F10 | Lack of safety precautions | Unsafe practices lead to material damage and accidents. | |

| F11 | Lack of on-site waste management plans | The absence of formal waste management increases uncontrolled waste generation. | |

| F12 | Improper planning for required quantities | Poor material forecasting leads to overordering or shortages. | |

| Materials | F13 | Improper material storage, sorting, or handling | Materials stored or mismanaged deteriorate or become unusable. |

| F14 | Depositing materials in unappropriated places | Materials placed in unsuitable areas may be damaged or cause obstruction. | |

| F15 | Residual (Reinforcement, formworks, finishing works, concrete) | Cutoffs, leftovers, or unused material arise from inefficient usage or estimation. | |

| F16 | Packaging waste | Excessive or unmanaged packaging contributes to physical waste on-site. | |

| Transportation | F17 | Improper transportation handling, Loading, and Unloading | Poor loading/unloading methods lead to physical damage to materials. |

| F18 | Delivery difficulties accessing the construction site | Difficult access results in delayed and risky handling, increasing the chances of damage. | |

| F19 | Poor on-site transportation from storage | Inefficient or careless movement of materials leads to breakage or wastage. | |

| Manpower | F20 | Workers’ lack of incentives or proper guidelines | Unmotivated workers may neglect best practices, leading to careless waste. |

| F21 | Workers’ lack of training and poor craftsmanship | Inadequate training results in frequent errors and material misuse. | |

| F22 | Poor work ethic | Negligence and carelessness cause unnecessary waste. | |

| F23 | Accidents due to negligence | Site incidents damage materials and delay progress. | |

| External | F24 | Theft and vandalism | Security lapses lead to material loss through theft or destruction. |

| F25 | Unforeseen situations and accidents | External events like rain or storms damage materials or cause delays that result in waste. |

| Current Study Factors | Corresponding Factors by [59] | |

|---|---|---|

| F1 | Contract documentation error and incompleteness | Not Considered |

| F2 | Design inaccuracies, Complex detailing | Inaccuracies in design |

| F3 | Design changes | Change in design by the owner, change in design by the architect |

| F4 | Poor coordination and communication | Not Considered |

| F5 | Over and under-ordering “Poor Supply Chain” | Over and under-ordering |

| F6 | Ordering errors and supplier errors | Unpacked supply |

| F7 | Unclear specifications | Not Considered |

| F8 | The negative attitude of higher management | The negative attitude of higher management |

| F9 | Lack of supervision | Not Considered |

| F10 | Lack of safety precautions | Lack of safety precautions |

| F11 | Lack of on-site waste management plans | Not Considered |

| F12 | Improper planning for required quantities | Default packaging |

| F13 | Improper material storage, sorting, or handling | Deposited material in a public place |

| F14 | Depositing materials in inappropriate places | improper material storage |

| F15 | Residual (Reinforcement, formworks, finishing works, concrete) | Formwork management, cutting the reinforcement, solid waste, finishing works, plastic works, tile works, metalwork, chemical waste, glasswork, and organic materials |

| F16 | Packaging waste | Packaging Waste |

| F17 | Improper transportation handling, loading, and unloading | Improper handling during transportation |

| F18 | Difficulties with delivery vehicles accessing the construction site | Not Considered |

| F19 | Poor on-site transportation from storage | Not Considered |

| F20 | Workers’ lack of incentives or proper guidelines | Lack of incentive for employees |

| F21 | Workers’ lack of training and poor craftsmanship | Absence of proper guidelines for workers |

| F22 | Poor work ethic | Not Considered |

| F23 | Accidents due to negligence | Not Considered |

| F24 | Theft and vandalism | Theft and vandalism |

| F25 | Unforeseen situations and accidents | Unforeseen situations (act of God) |

| Rank | Factor’s Label | Category | ID |

|---|---|---|---|

| 1 | Lack of on-site waste management plans | On-Site Management | F11 |

| 2 | Residual (Reinforcement, formworks, finishing works, concrete) | Materials | F15 |

| 3 | Workers’ lack of training and poor craftsmanship | Manpower | F21 |

| 4 | Design inaccuracies, Complex detailing | Design | F2 |

| 5 | Workers’ lack of incentives or proper guidelines | Manpower | F20 |

| 6 | Depositing materials in unappropriated places | Materials | F14 |

| 7 | Design changes | Design | F3 |

| Source Factors | Normalized DC | Normalized RII | Differences |

|---|---|---|---|

| F1 | 0.59 | - | 0.59 |

| F2 | 0.88 | 0.77 | 0.11 |

| F3 | 0.81 | 0.84 | −0.03 |

| F4 | 0.77 | - | 0.77 |

| F5 | 0.74 | 0.68 | 0.06 |

| F6 | 0.69 | 0.74 | −0.05 |

| F7 | 0.73 | - | 0.73 |

| F8 | 0.70 | 0.83 | −0.13 |

| F9 | 0.80 | - | 0.80 |

| F10 | 0.65 | 0.83 | −0.18 |

| F11 | 1.00 | - | 1.00 |

| F12 | 0.70 | 0.72 | −0.02 |

| F13 | 0.79 | 1 | −0.21 |

| F14 | 0.82 | 0.93 | −0.11 |

| F15 | 0.92 | 0.8 | 0.12 |

| F16 | 0.73 | 0.83 | −0.10 |

| F17 | 0.70 | 0.81 | −0.11 |

| F18 | 0.70 | - | 0.70 |

| F19 | 0.70 | - | 0.70 |

| F20 | 0.85 | 0.77 | 0.08 |

| F21 | 0.88 | 0.91 | −0.03 |

| F22 | 0.61 | - | 0.61 |

| F23 | 0.50 | - | 0.50 |

| F24 | 0.70 | 0.74 | −0.04 |

| F25 | 0.71 | 0.78 | −0.07 |

| Lean Waste Type (Muda) | Definition (Lean Construction) | Associated SNA Factor(s) | Rationale |

|---|---|---|---|

| Overproduction | Producing more than is needed or earlier than required | F5: Over and under-ordering. F12: Improper planning for required quantities. F15: Residual material. | Surplus orders and inaccurate quantity planning generate excess materials and offcuts. |

| Waiting | Idle time due to material, labor, or information delays | F18: Delivery difficulties accessing the construction site. F6: Ordering errors and supplier errors. F3: Design changes. F4: Poor coordination and communication. F23: Accidents due to negligence. | Access and supplier issues, late design changes, poor coordination, and incidents stall workflows. |

| Transportation | Unnecessary movement of materials or tools | F17: Improper transportation and handling. F19: Poor on-site transportation from storage. F18: Delivery difficulties accessing the site. | Ineffective logistics and handling increase trips and material movement. |

| Inventory | Excess materials are stored on-site unnecessarily | F15: Residual. F16: Packaging waste. F5: Over and under-ordering. F13: Improper material storage or handling. F11: Lack of on-site waste management plans. | Over-ordering and weak storage/WM plans create stockpiles prone to damage. |

| Motion | Unnecessary movement of people | F14: Depositing materials in unappropriated places. F13: Improper material storage, or handling. F11: Lack of on-site waste management plans. | Poor placement/storage and absent WM plans force extra walking/searching. |

| Overprocessing | Doing more work than necessary or redundant work | F1: Contract error and incompleteness. F2: Design inaccuracies, complex detailing. F3: Design changes. F7: Unclear specifications. F21: Workers’ lack of training. | Documentation/spec/design flaws and low skills cause rework beyond what is needed. |

| Defects | Efforts caused by errors or mistakes | F2: Design inaccuracies, complex detailing. F21: Workers’ lack of training. F9: Lack of supervision. F17: Improper transportation handling. F10: Lack of safety precautions. F22: Poor work ethics. | Errors in design/execution and damage during handling yield defective outcomes and waste. |

| Underutilized Skills | Failure to leverage the workforce’s full capabilities | F21: Workers’ lack of training. F20: Workers’ lack of incentives or guidelines. F9: Lack of supervision. F8: The negative attitude of higher management. | Skills not developed or guided; weak supervision and management attitudes suppress workforce potential. |

| SNA Factor | Description | Mapped CE Strategy | Circular Mechanism |

|---|---|---|---|

| F11 | Lack of on-site waste management plans | Reduce/Reuse/Recycle | Implementing comprehensive waste management plans can minimize waste generation by improving on-site practices and optimizing material flow. |

| F15 | Residual materials (reinforcement, formworks, finishing works, concrete) | Reuse/Recycle | Residual materials can be tracked and recovered through digital tools (e.g., BIM), enabling their reuse or recycling in a closed-loop system. |

| F21 | Workers’ lack of training and poor craftsmanship | Reduce/Underutilized Talent | Enhancing worker training can reduce errors and rework, thus lowering material waste and optimizing the use of human resources. |

| F2 | Design inaccuracies and complex detailing | Reduce | Improving design quality minimizes errors and rework, thereby reducing unnecessary material consumption and waste generation. |

| F20 | Workers’ lack of incentives or proper guidelines | Reduce | Better incentivization and clear guidelines can improve efficiency, reducing waste from improper practices. |

| F14 | Depositing materials in unappropriated places | Reduce/Reuse | Improving storage practices and on-site handling minimizes damage, making materials more suitable for reuse or recycling. |

| F3 | Design changes causing rework | Reduce | Minimizing design changes through early-stage validation and stakeholder coordination helps avoid re-work and thus reduces material waste. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salah, M.; Elbeltagi, E.; Almoshaogeh, M.; Alharbi, F.; Elnabwy, M.T. Identifying Root Causes and Sustainable Solutions for Reducing Construction Waste Using Social Network Analysis. Sustainability 2025, 17, 7638. https://doi.org/10.3390/su17177638

Salah M, Elbeltagi E, Almoshaogeh M, Alharbi F, Elnabwy MT. Identifying Root Causes and Sustainable Solutions for Reducing Construction Waste Using Social Network Analysis. Sustainability. 2025; 17(17):7638. https://doi.org/10.3390/su17177638

Chicago/Turabian StyleSalah, Mona, Emad Elbeltagi, Meshal Almoshaogeh, Fawaz Alharbi, and Mohamed T. Elnabwy. 2025. "Identifying Root Causes and Sustainable Solutions for Reducing Construction Waste Using Social Network Analysis" Sustainability 17, no. 17: 7638. https://doi.org/10.3390/su17177638

APA StyleSalah, M., Elbeltagi, E., Almoshaogeh, M., Alharbi, F., & Elnabwy, M. T. (2025). Identifying Root Causes and Sustainable Solutions for Reducing Construction Waste Using Social Network Analysis. Sustainability, 17(17), 7638. https://doi.org/10.3390/su17177638