Potential Use of Brewer’s Spent Grain By-Product as a Component for Sustainable Thermal Mortars

Abstract

1. Introduction

2. Materials

3. Test Methodologies

4. Results and Discussion

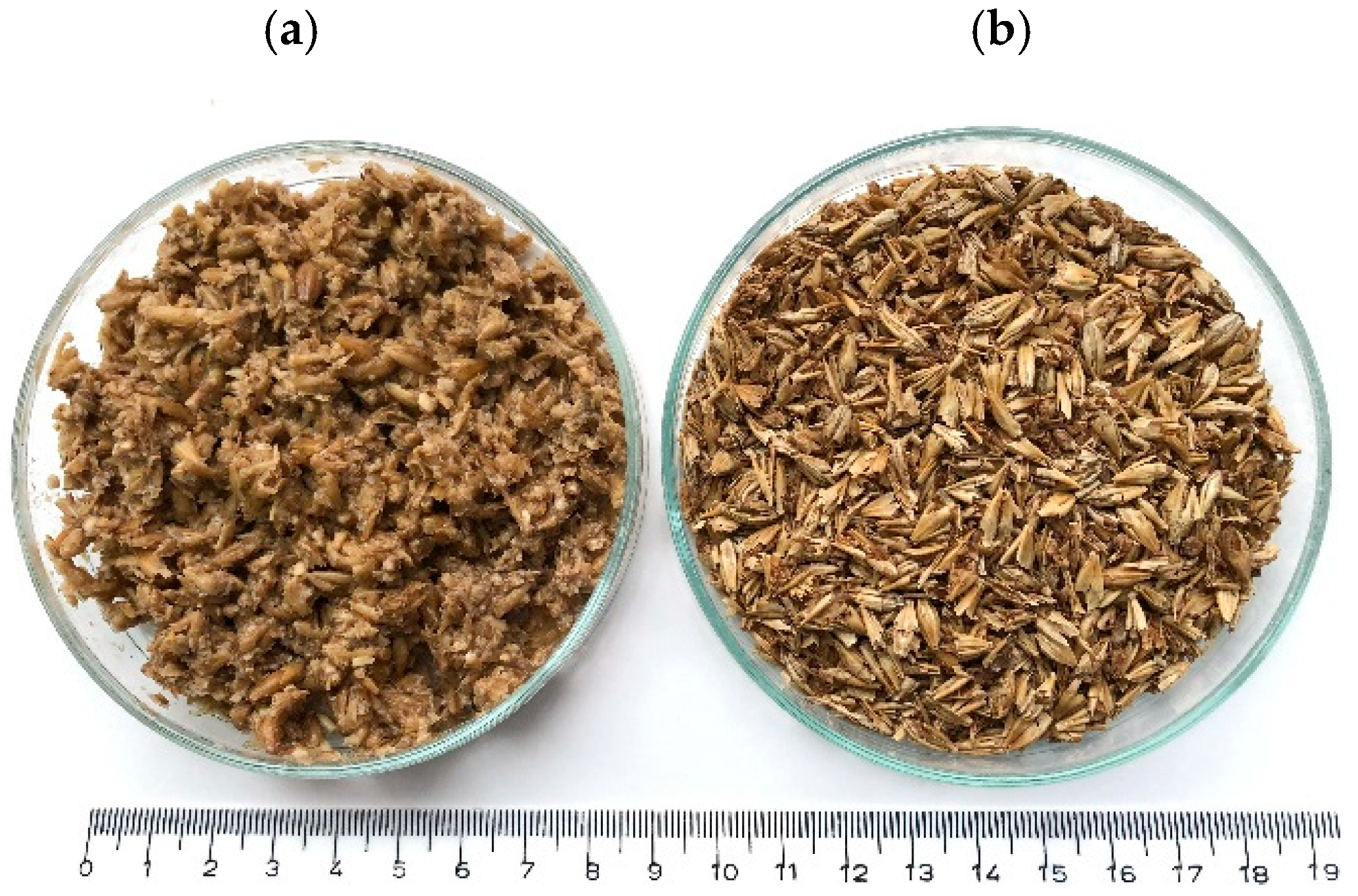

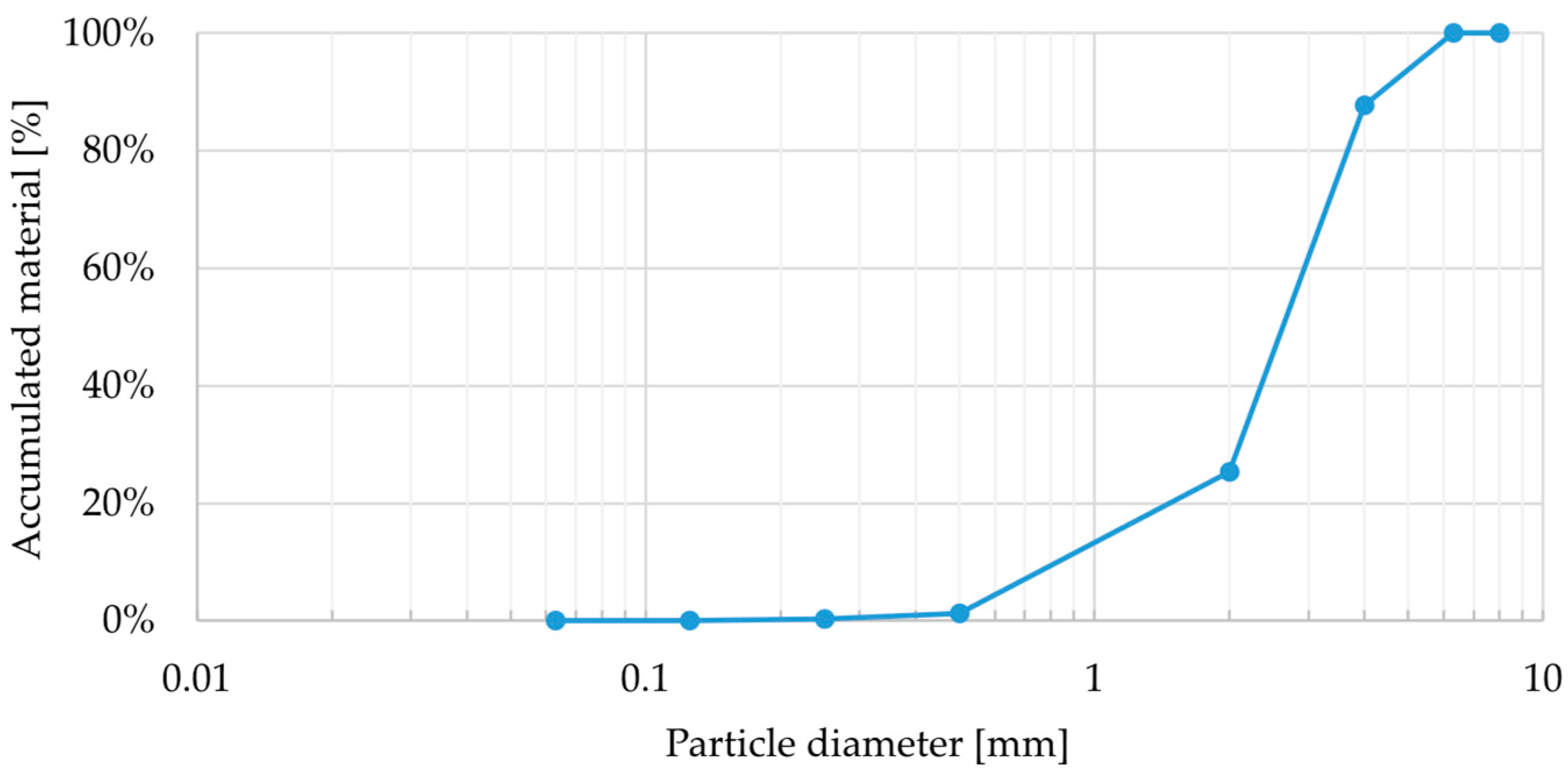

4.1. BSG Characterization

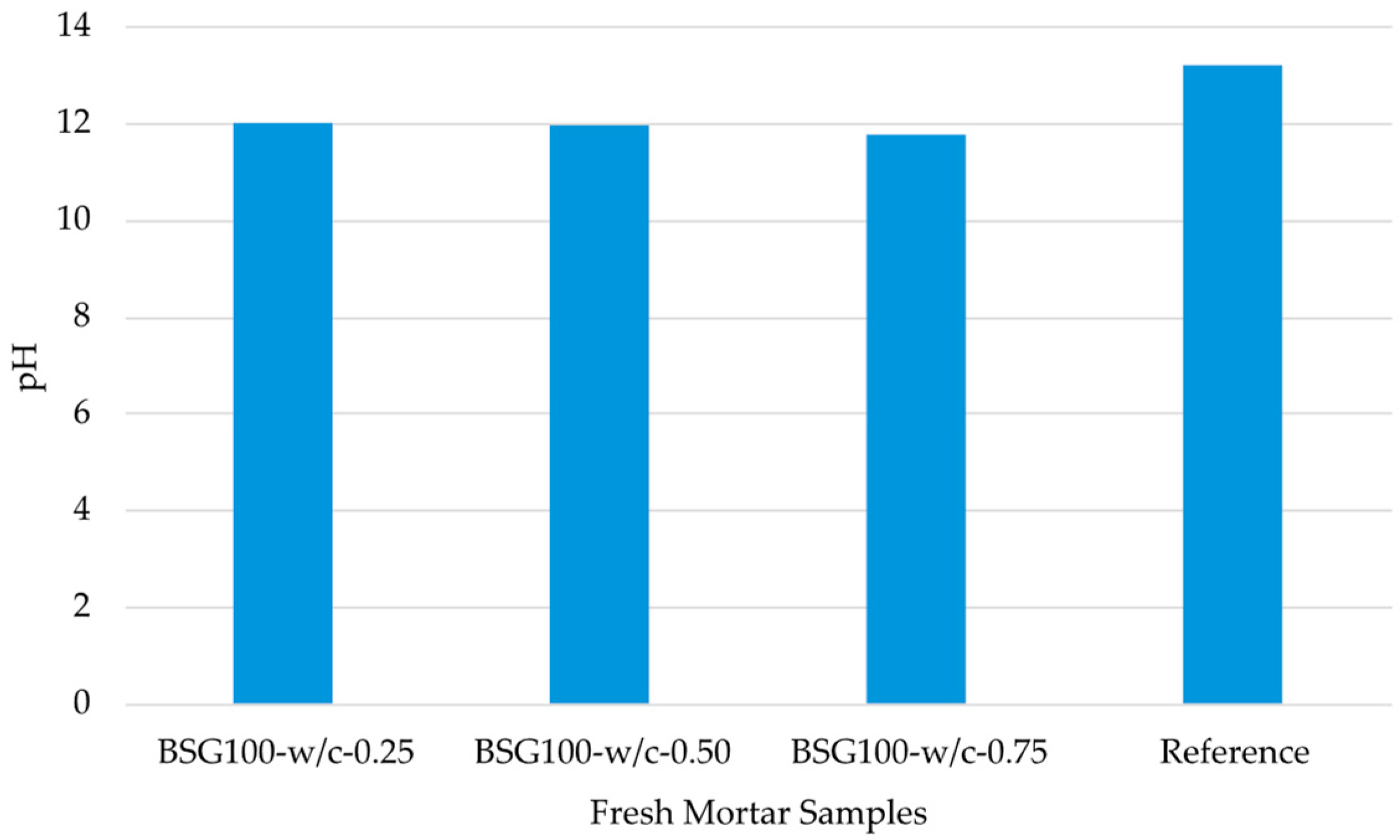

4.2. Characterization of Mortars in the Fresh State

4.3. Characterization of Mortars After Curing

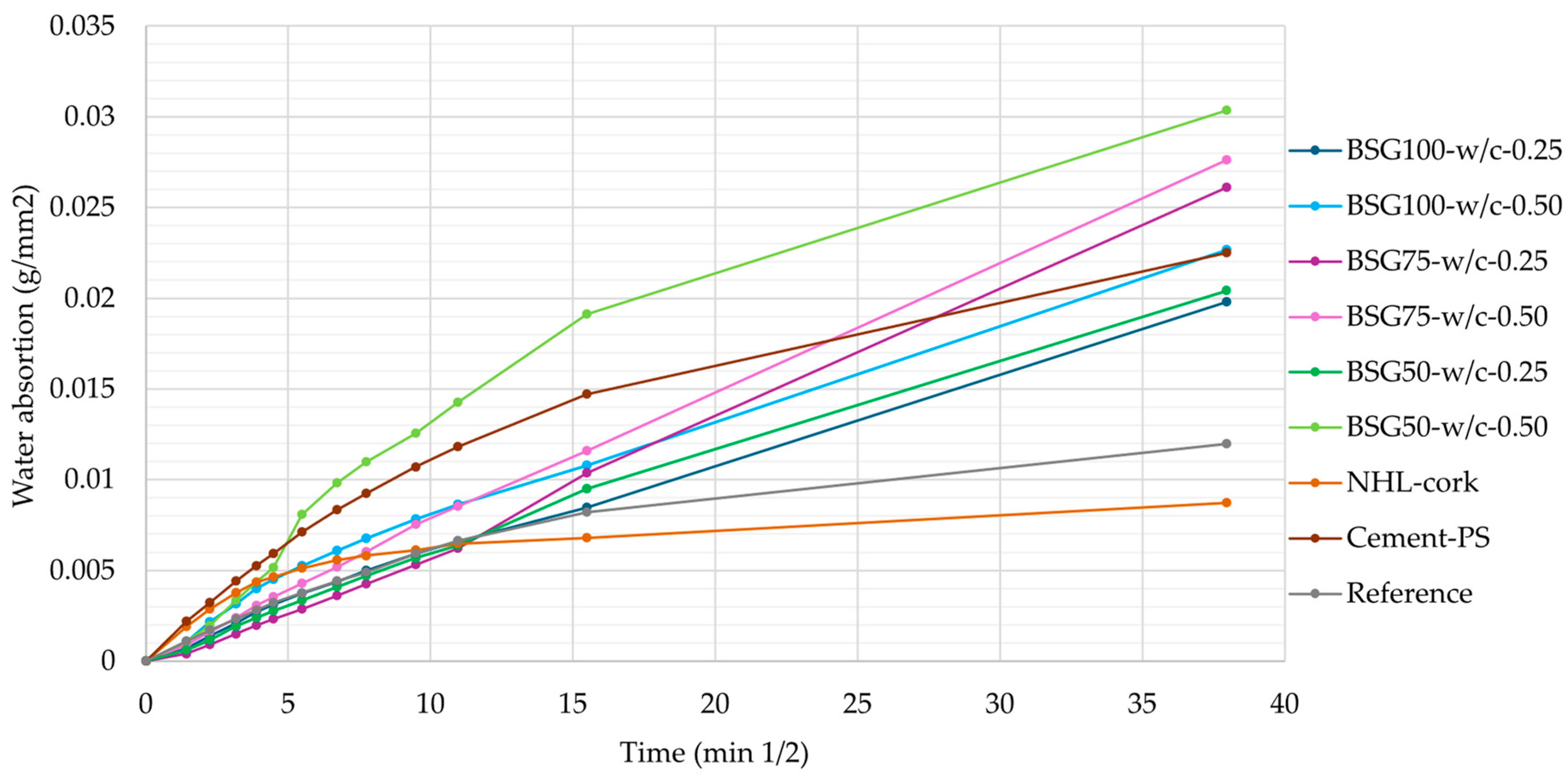

4.3.1. Water Absorption

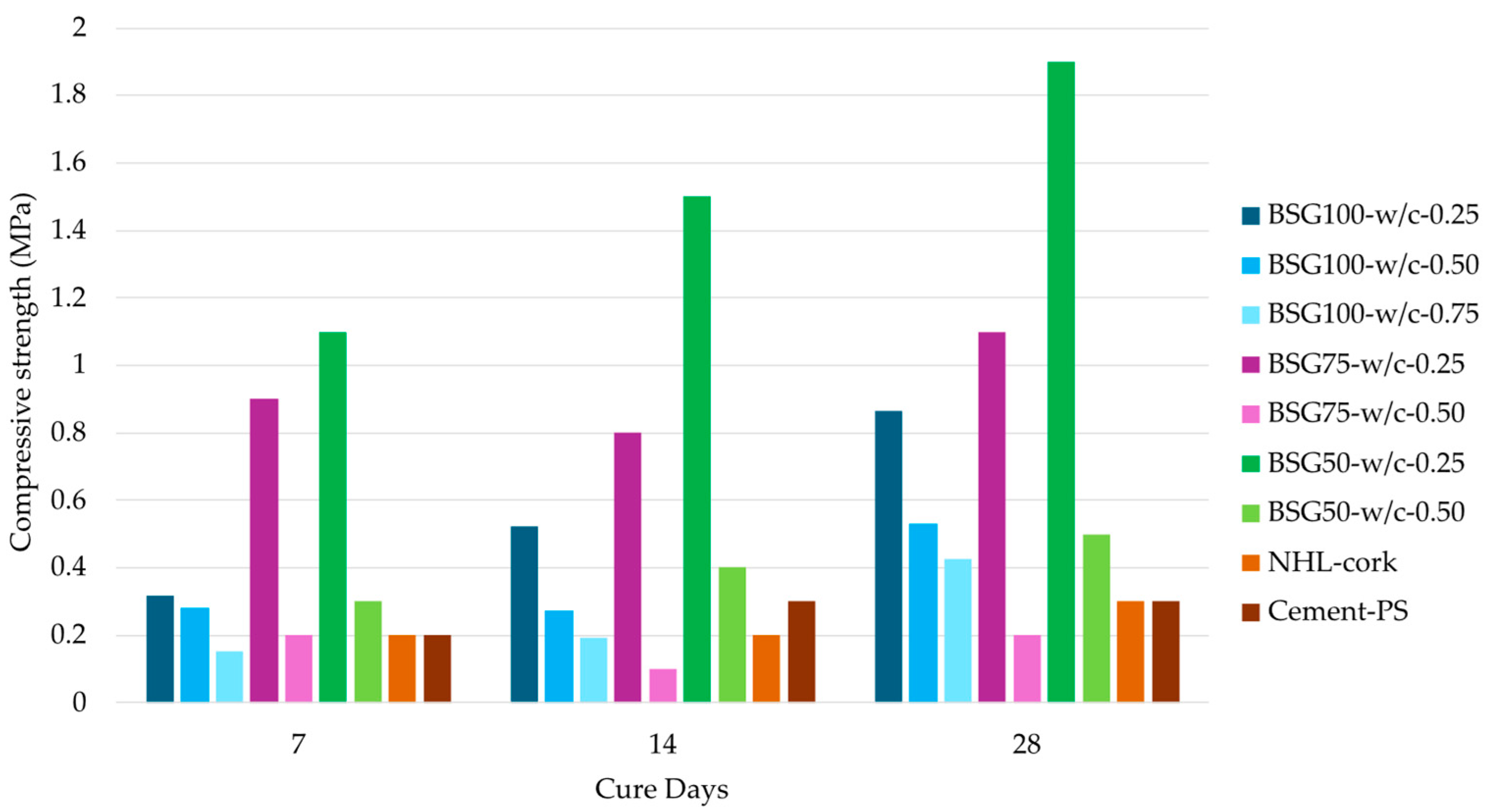

4.3.2. Mechanical Resistance

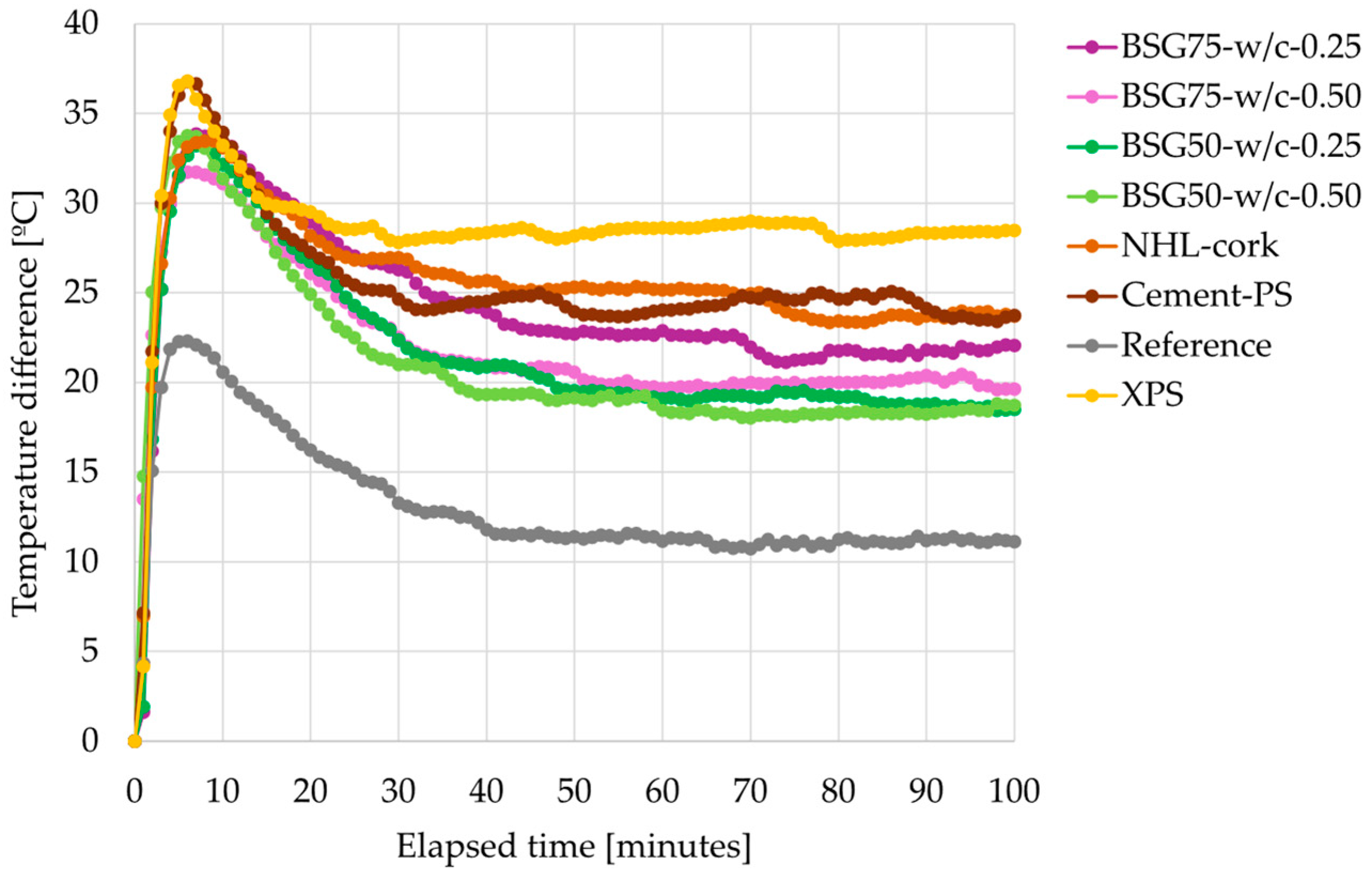

4.3.3. Thermal Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations Environment Programme. Global Status Report for Buildings and Construction—Beyond Foundations: Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- IPCC. Summary for Policymakers. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018; pp. 1–24. [Google Scholar] [CrossRef]

- Parvin, K.; Hossain, M.; Arsad, A.; Ker, P.J.; Hannan, M. Building energy technologies towards achieving net-zero pathway: A comprehensive review, challenges and future directions. J. Build. Eng. 2025, 100, 111795. [Google Scholar] [CrossRef]

- Ibrahim, M.; Harkouss, F.; Biwole, P.; Fardoun, F.; Ouldboukhitine, S. Building retrofitting towards net zero energy: A review. Energy Build. 2024, 322, 114707. [Google Scholar] [CrossRef]

- Shirinbakhsh, M.; Harvey, L.D. Net-zero energy buildings: The influence of definition on greenhouse gas emissions. Energy Build. 2021, 247, 111118. [Google Scholar] [CrossRef]

- Krajewska, A.; Siewczyńska, M. Circular Economy in the Construction Sector in Materials, Processes, and Case Studies: Research Review. Sustainability 2025, 17, 7029. [Google Scholar] [CrossRef]

- Bourbia, S.; Kazeoui, H.; Belarbi, R. A review on recent research on bio-based building materials and their applications. Mater. Renew. Sustain. Energy 2023, 12, 117–139. [Google Scholar] [CrossRef]

- Horn, P.A.; Pedron, N.B.; Junges, L.H.; Rebelo, A.M.; da Silva Filho, H.H.; Zeni, A.L.B. Antioxidant profile at the different stages of craft beers production: The role of phenolic compounds. Eur. Food Res. Technol. 2021, 247, 439–452. [Google Scholar] [CrossRef]

- Olajire, A.A. The brewing industry and environmental challenges. J. Clean. Prod. 2020, 256, 102817. [Google Scholar] [CrossRef]

- Heumann, A. Brewery’s Spent Grain: Market Situation and Example of Valorisation; B-Resilient, Co-Funded by the European Commission, Grant Agreement 101074621. Available online: https://pole-innovalliance.com/wp-content/uploads/2023/05/Brewerys-Spent-Grain-Market-situation-and-example-of-valorisation-1.pdf (accessed on 7 August 2025).

- Zeko-Pivač, A.; Tišma, M.; Žnidaršič-Plazl, P.; Kulisic, B.; Sakellaris, G.; Hao, J.; Planinić, M. The potential of brewer’s spent grain in the circular bioeconomy: State of the art and future perspectives. Front. Bioeng. Biotechnol. 2022, 10, 870744. [Google Scholar] [CrossRef] [PubMed]

- Allegretti, C.; Bellinetto, E.; D’Arrigo, P.; Griffini, G.; Marzorati, S.; Rossato, L.A.M.; Ruffini, E.; Schiavi, L.; Serra, S.; Strini, A. Towards a complete exploitation of brewers’ spent grain from a circular economy perspective. Fermentation 2022, 8, 151. [Google Scholar] [CrossRef]

- Duarte, L.C.; Esteves, M.P.; Carvalheiro, F.; Vicente, P.; Gírio, F.M. Os sub-produtos de natureza lenhocelulósica: Caracterização da situação portuguesa. Eng. Química 2007, 5, 56–62. [Google Scholar]

- Błaszak, B.; Demir, İ.E.; Długosz, A.; Kołaczyk, P.; Bąk, M.; Gozdecka, G.; Kaniewski, W.; Szulc, J. Sustainable Processing of Brewers’ Spent Grain for Plant-Based Yogurt Alternatives. Sustainability 2025, 17, 4087. [Google Scholar] [CrossRef]

- Chu, H.-Y.I.; Miri, T.; Onyeaka, H. Valorization of Bioactive Compounds Extracted from Brewer’s Spent Grain (BSG) for Sustainable Food Waste Recycling. Sustainability 2025, 17, 2477. [Google Scholar] [CrossRef]

- Ferraz, E.; Coroado, J.; Gamelas, J.; Silva, J.; Rocha, F.; Velosa, A. Spent brewery grains for improvement of thermal insulation of ceramic bricks. J. Mater. Civ. Eng. 2013, 25, 1638–1646. [Google Scholar] [CrossRef]

- Muthuminal, R.; Priya, R.M. Experimental investigation on utilization of brewers waste as fine aggregate in concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- El Haddaji, B.; Benzaama, M.-H.; Quiertant, M.; El Mendili, Y. Insight into the use of brewers’ spent grain as a low-carbon aggregate in building materials. Biomimetics 2024, 9, 781. [Google Scholar] [CrossRef]

- Alene, T.E.; Lemlemu, T.A.; Yifru, B.W. Study on the Effect of Partial Replacement of Cement by Breweries Dry Grain (Sorghum) Ash in Mortar Property. Adv. Mater. Sci. Eng. 2025, 2025, 5667403. [Google Scholar] [CrossRef]

- Costa, H. Betões Estruturais e Agregados Leves. Aplicações em Prefabricação e Reforço de Estruturas. Ph.D. Thesis, Universidade de Coimbra, Coimbra, Portugal, 2012. [Google Scholar]

- Coutinho, J.d.S. Agregados para Argamassas e Betões. 2002, pp. 105–125. Available online: https://civil.fe.up.pt/pub/apoio/ano1/cienciadosmateriais/apontamentos/teorica_20022003/JSC_105a125.pdf (accessed on 30 June 2025).

- Manso, M.; Castro-Gomes, J. Design of alkali-activated materials for a modular green wall and green roof system. MATEC Web Conf. 2019, 274, 04001. [Google Scholar] [CrossRef]

- Jerónimo, A.; Soares, C.; Aguiar, B.; Lima, N. Hydraulic lime mortars incorporating micro cork granules with antifungal properties. Constr. Build. Mater. 2020, 255, 119368. [Google Scholar] [CrossRef]

- Sousa, A. Aplicação de Argamassas Leves de Reboco e Assentamento em Alvenarias; Faculty of Engineering, University of Porto: Porto, Portugal, 2010. [Google Scholar]

- Morgado, A. Durabilidade de Argamassas Térmicas com Agregados Leves e Isolantes; Instituto Superior Técnico: Lisbon, Portugal, 2017. [Google Scholar]

- Thiedeitz, M.; Ostermaier, B.; Kränkel, T. Rice husk ash as an additive in mortar–Contribution to microstructural, strength and durability performance. Resour. Conserv. Recycl. 2022, 184, 106389. [Google Scholar] [CrossRef]

- Marques, B.; Almeida, J.; Tadeu, A.; António, J.; Santos, M.I.; de Brito, J.; Oliveira, M. Rice husk cement-based composites for acoustic barriers and thermal insulating layers. J. Build. Eng. 2021, 39, 102297. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Y.; Zhou, L.; Xu, L.; Diao, G.; Liu, G. Effects of hydroxyethyl methyl cellulose ether on the hydration and compressive strength of calcium aluminate cement. J. Therm. Anal. Calorim. 2020, 140, 545–553. [Google Scholar] [CrossRef]

- Badagliacco, D.; Sanfilippo, C.; Megna, B.; La Mantia, T.; Valenza, A. Mechanical and thermal properties of insulating sustainable mortars with Ampelodesmos mauritanicus and Pennisetum setaceum plants as aggregates. Appl. Sci. 2021, 11, 5910. [Google Scholar] [CrossRef]

- EN 998-1; Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar. European Committee for Standardization: Brussels, Belgium, 2016.

- EN 1097-5; Tests for Mechanical and Physical Properties of Aggregates—Part 5: Determination of the Water Content by Drying in a Ventilated Oven. European Committee for Standardization: Brussels, Belgium, 2008.

- EN 933-1; Tests of the Geometric Properties of Aggregates. Part 1. Particle Size Analysis. Sieving Method. European Committee for Standardization: Brussels, Belgium, 2014.

- EN 1097-3; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. European Committee for Standardization: Brussels, Belgium, 1998.

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization: Brussels, Belgium, 2006.

- EN 1015-18; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2002.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2019.

- Bamforth, C.W. Beer: Tap into the Art and Science of Brewing; Oxford University Press: New York, NY, USA, 2009; ISBN-10: 978-0195305425. [Google Scholar]

- Castro, L.E.N.; Colpini, L.M.S. All-around characterization of brewers’ spent grain. Eur. Food Res. Technol. 2021, 247, 3013–3021. [Google Scholar] [CrossRef]

- Lazera, R.F. Avaliação do Desempenho Mecânico de Argamassas Térmicas em Protótipos de Parede. Master’s Thesis, Instituto Superior Técnico, Universidade de Lisboa, Lisbon, Portugal, 2016. [Google Scholar]

- ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- ASTM C177-19; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM: West Conshohocken, PA, USA, 2019.

| By-Product | National Total (mg) | Water Content (%) |

|---|---|---|

| Brewer’s spent grain (BSG) | 97,536.2 | 50–80 |

| Grape pomace | 69,840.0 | 20 |

| Carob pulp | 40,000.0 | 10 |

| Rice husk | 34,535.7 | 13 |

| Tomato by-product | 30,768.9 | 70 |

| Olive pomace | 23,745.0 | 11 |

| Nut peel | 13,584.0 | 11 |

| Grape stalks | 9316.0 | 20 |

| Wine dregs | 8992.0 | - |

| Grape seed | 5400.0 | 10 |

| Sample | Volumetric Ratio | Binder | Aggregates | Water–Cement Ratio | |

|---|---|---|---|---|---|

| Cement | BSG | Fine Sand | |||

| BSG100-w/c-0.25 | 1:3 | 1 | 3 | - | 0.25 |

| BSG100-w/c-0.50 | 1:3 | 1 | 3 | - | 0.50 |

| BSG100-w/c-0.75 | 1:3 | 1 | 3 | - | 0.75 |

| BSG50-w/c-0.25 | 1:2:2 | 1 | 2 | 2 | 0.25 |

| BSG50-w/c-0.50 | 1:2:2 | 1 | 2 | 2 | 0.50 |

| BSG75-w/c-0.25 | 1:3:1 | 1 | 3 | 1 | 0.25 |

| BSG75-w/c-0.50 | 1:3:1 | 1 | 3 | 1 | 0.50 |

| Reference | 1:3 | 1 | - | 3 | 0.50 |

| NHL–cork | 2000 g (pre-dosed mixture) + 960 mL of water, density: 200 ± 50 kg/m3 | ||||

| Cement–PS | 2500 g (pre-dosed mixture) + 500 mL of water, density: 700 ± 50 kg/m3 | ||||

| BSG Analyzed | Water Content (%) |

|---|---|

| Dry BSG | 1.98 |

| Wet BSG—Test 1 | 37.44 |

| Wet BSG—Test 2 | 53.14 |

| Type of BSG | Density (kg/m3) |

|---|---|

| Dried BSG (60 °C for 24 h) | 190.1 |

| Air-dried BSG (room temperature) | 180.7 |

| Wet BSG (obtained from the production unit) | 513.5 |

| Saturated BSG (immersed in water for 2 h) | 534.1 |

| Water-to-Cement Ratio (w/c) | Spreading (mm) |

|---|---|

| 0.25 | 100 |

| 0.50 | 120 |

| 0.75 | 130 |

| Samples | Water Absorption Coefficient (kg/m2.min0.5) |

|---|---|

| BSG100-w/c-0.25 | 0.77 |

| BSG100-w/c-0.5 | 0.95 |

| BSG50-w/c-0.25 | 0.60 |

| BSG50-w/c-0.50 | 1.46 |

| BSG75-w/c-0.25 | 0.60 |

| BSG75-w/c-0.50 | 0.93 |

| Reference | 0.57 |

| NHL-cork | 0.37 |

| Cement-PS | 1.00 |

| Samples | ΔTf [°C] |

|---|---|

| XPS | 28.25 |

| Cement–PS | 24.18 |

| NHL–cork | 23.69 |

| BSG75-w/c-0.25 | 21.76 |

| BSG75-w/c-0.50 | 20.05 |

| BSG50-w/c-0.25 | 18.75 |

| BSG50-w/c-0.50 | 18.40 |

| Reference | 11.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manso, M.; Silva, J.; Antunes, V.; Ivo, I.; Canto, J.; Guerra, C. Potential Use of Brewer’s Spent Grain By-Product as a Component for Sustainable Thermal Mortars. Sustainability 2025, 17, 7557. https://doi.org/10.3390/su17167557

Manso M, Silva J, Antunes V, Ivo I, Canto J, Guerra C. Potential Use of Brewer’s Spent Grain By-Product as a Component for Sustainable Thermal Mortars. Sustainability. 2025; 17(16):7557. https://doi.org/10.3390/su17167557

Chicago/Turabian StyleManso, Maria, Joaquim Silva, Vítor Antunes, Isabel Ivo, João Canto, and Cristina Guerra. 2025. "Potential Use of Brewer’s Spent Grain By-Product as a Component for Sustainable Thermal Mortars" Sustainability 17, no. 16: 7557. https://doi.org/10.3390/su17167557

APA StyleManso, M., Silva, J., Antunes, V., Ivo, I., Canto, J., & Guerra, C. (2025). Potential Use of Brewer’s Spent Grain By-Product as a Component for Sustainable Thermal Mortars. Sustainability, 17(16), 7557. https://doi.org/10.3390/su17167557