Self-Healing Asphalt Mixtures Meso-Modelling: Impact of Capsule Content on Stiffness and Tensile Strength

Abstract

1. Introduction

2. Objectives

3. 3D DEM Model of Asphalt Mixtures

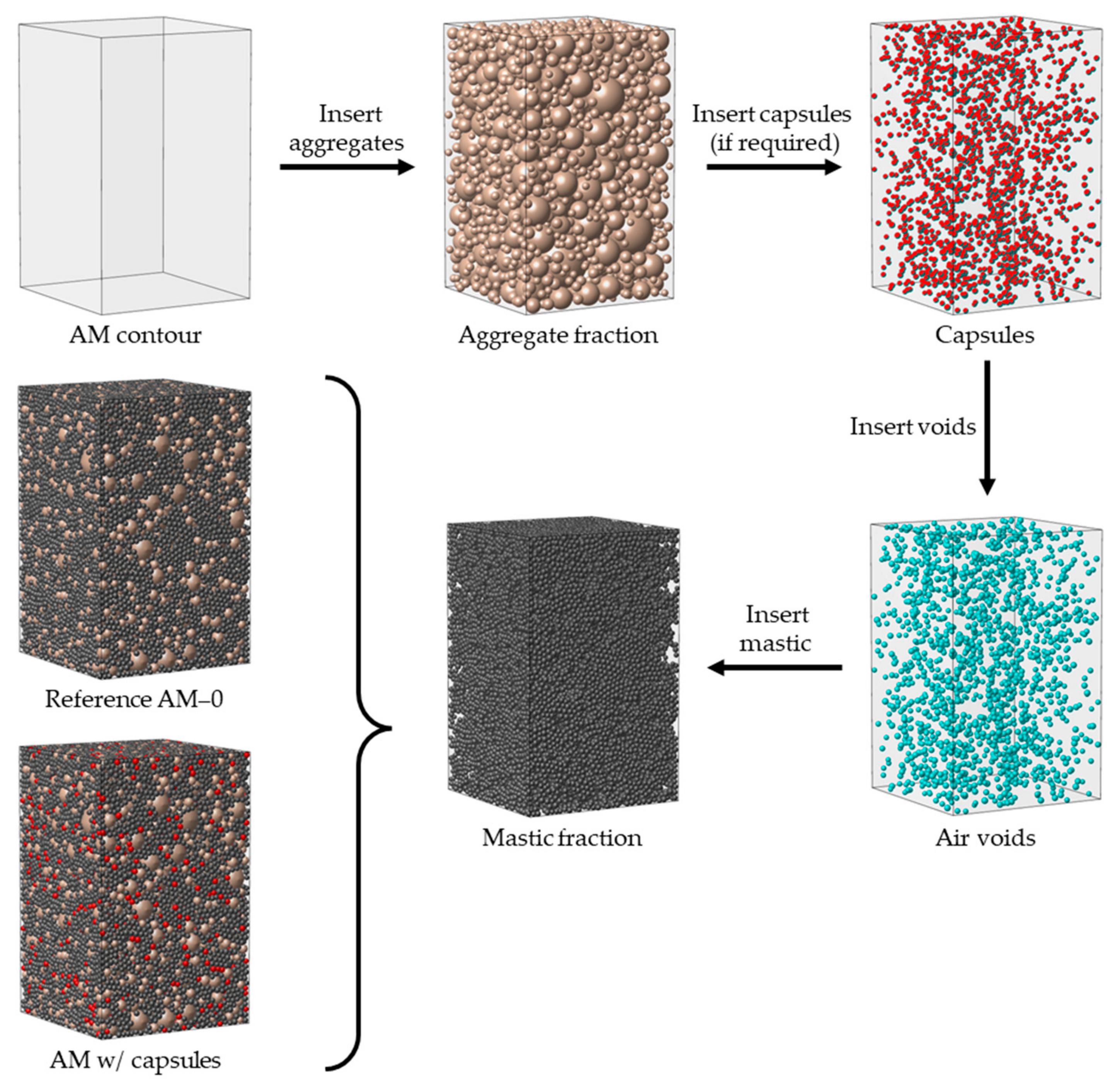

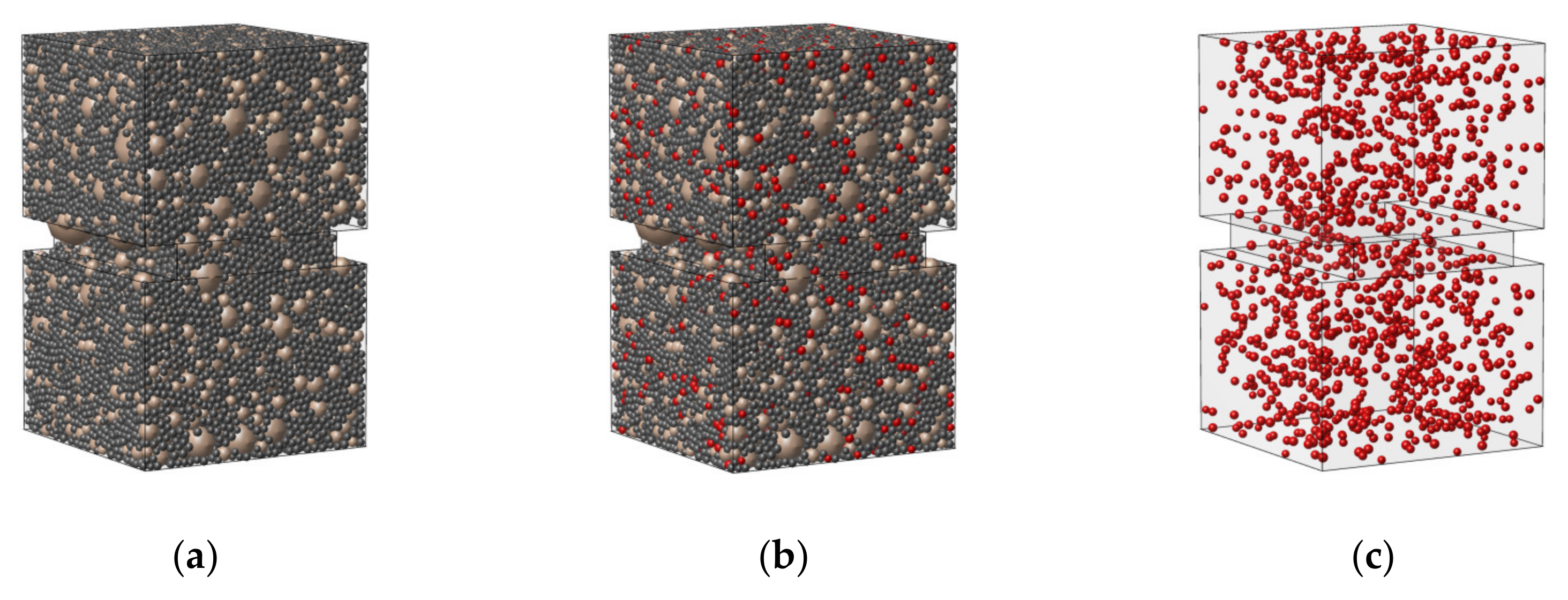

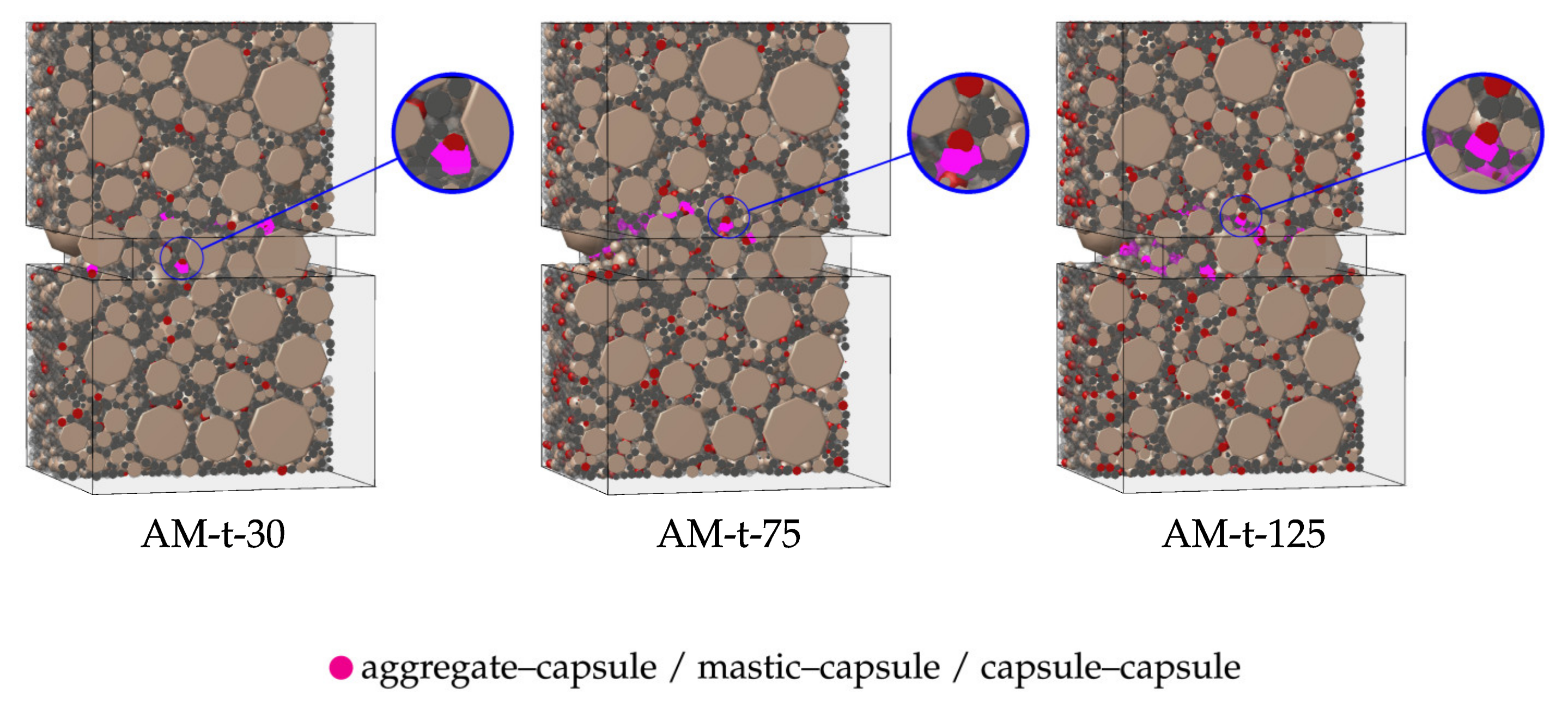

3.1. Numerical Specimen Generation

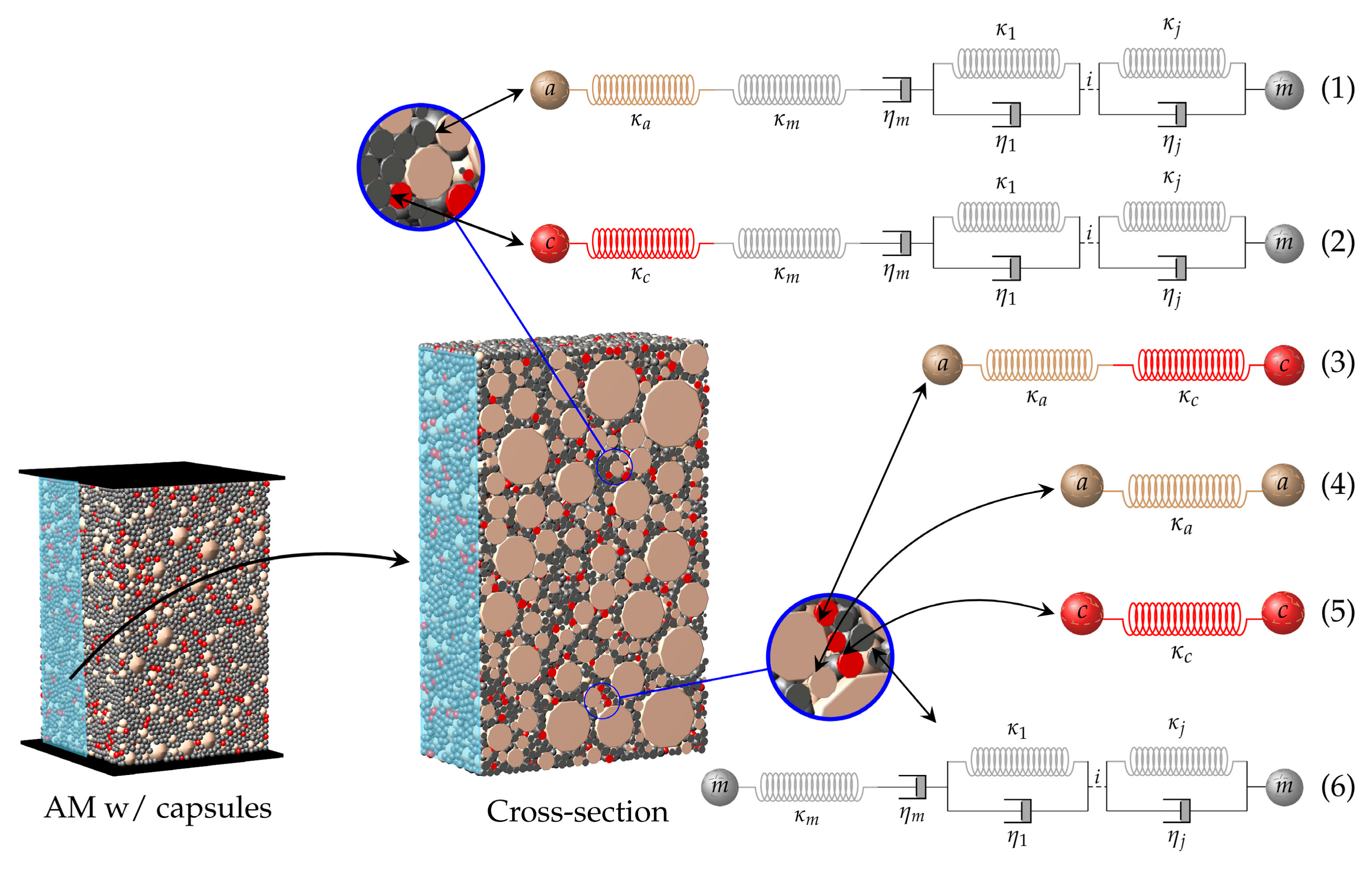

3.2. Contact Modelling Approach

3.2.1. Elastic Contact Model

3.2.2. Generalised Kelvin Contact Model

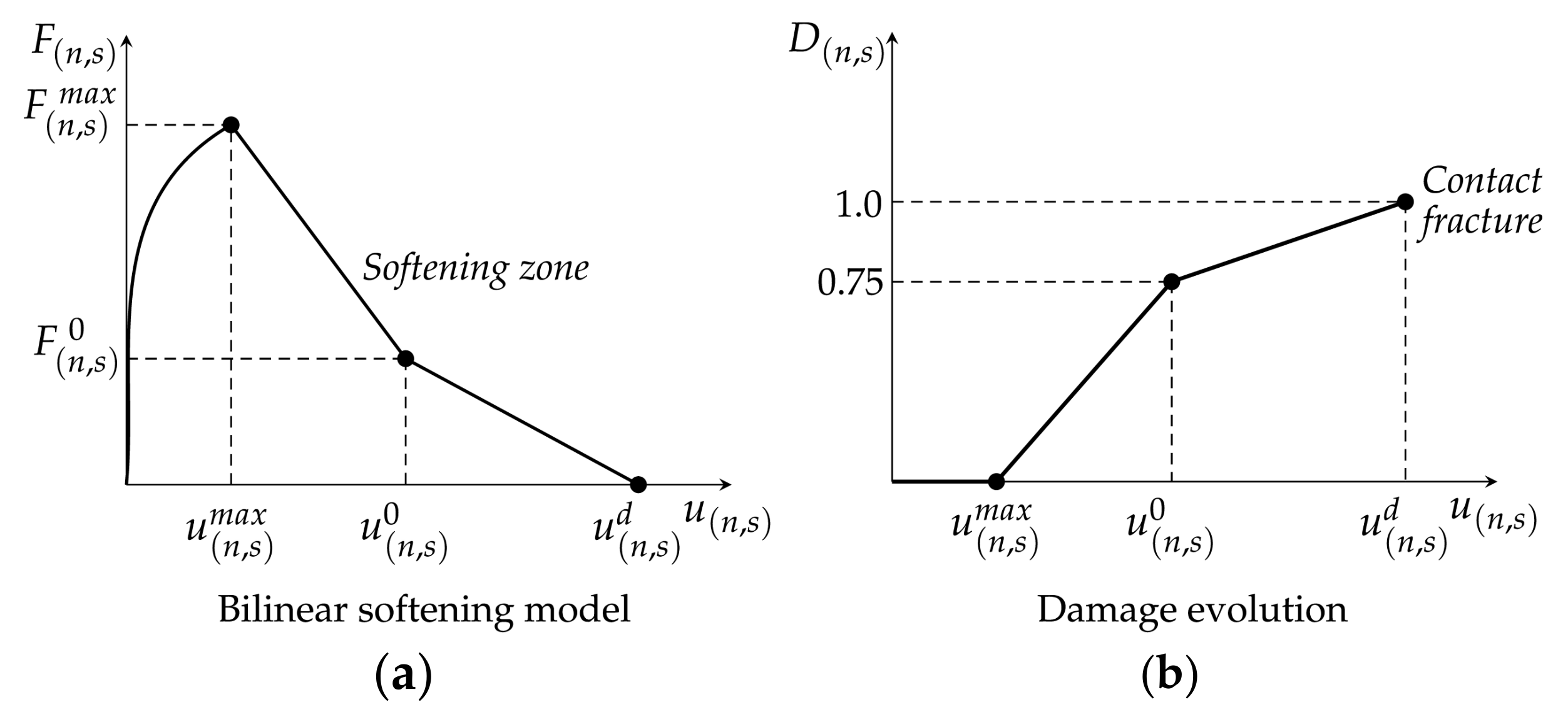

3.2.3. Bilinear Softening Damage Model

3.3. Contact Model Parameter Calibration

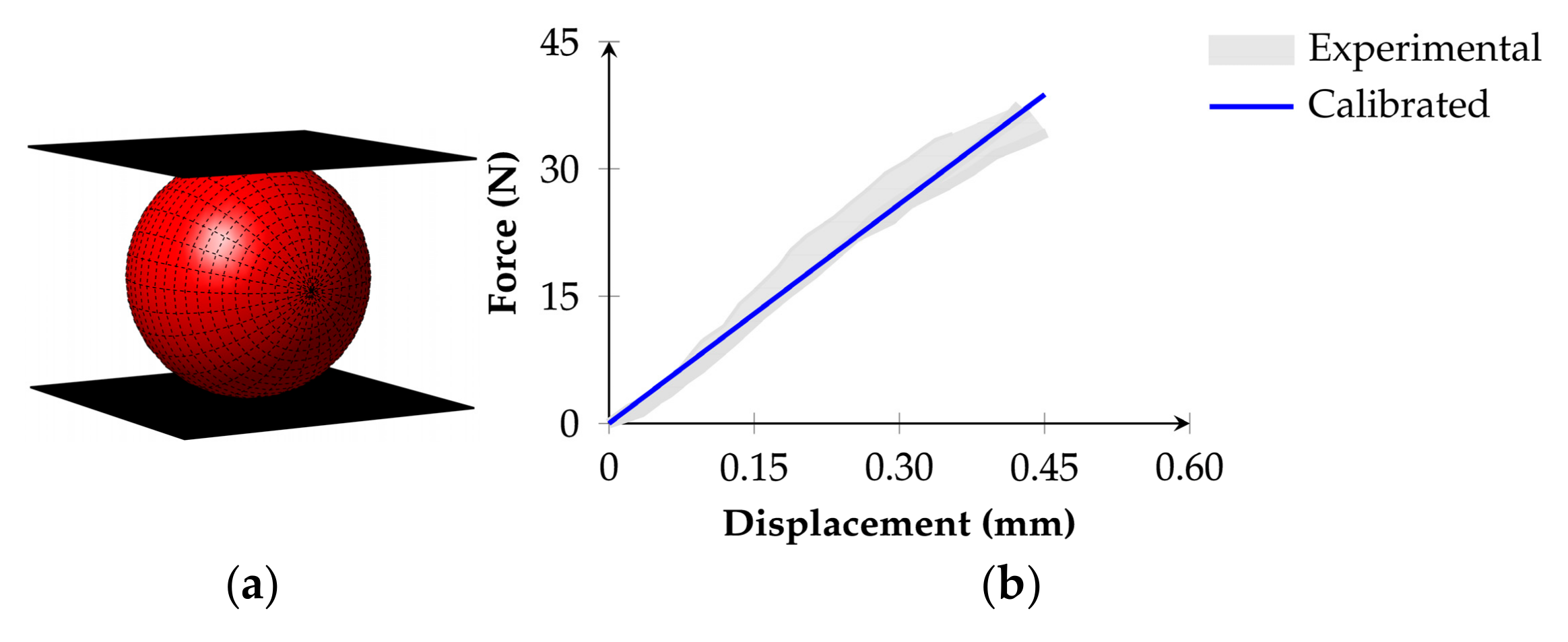

3.3.1. Elastic Model

3.3.2. Generalised Kelvin Contact Model

3.3.3. Bilinear Softening Model

4. Numerical Tests

5. Results and Discussion

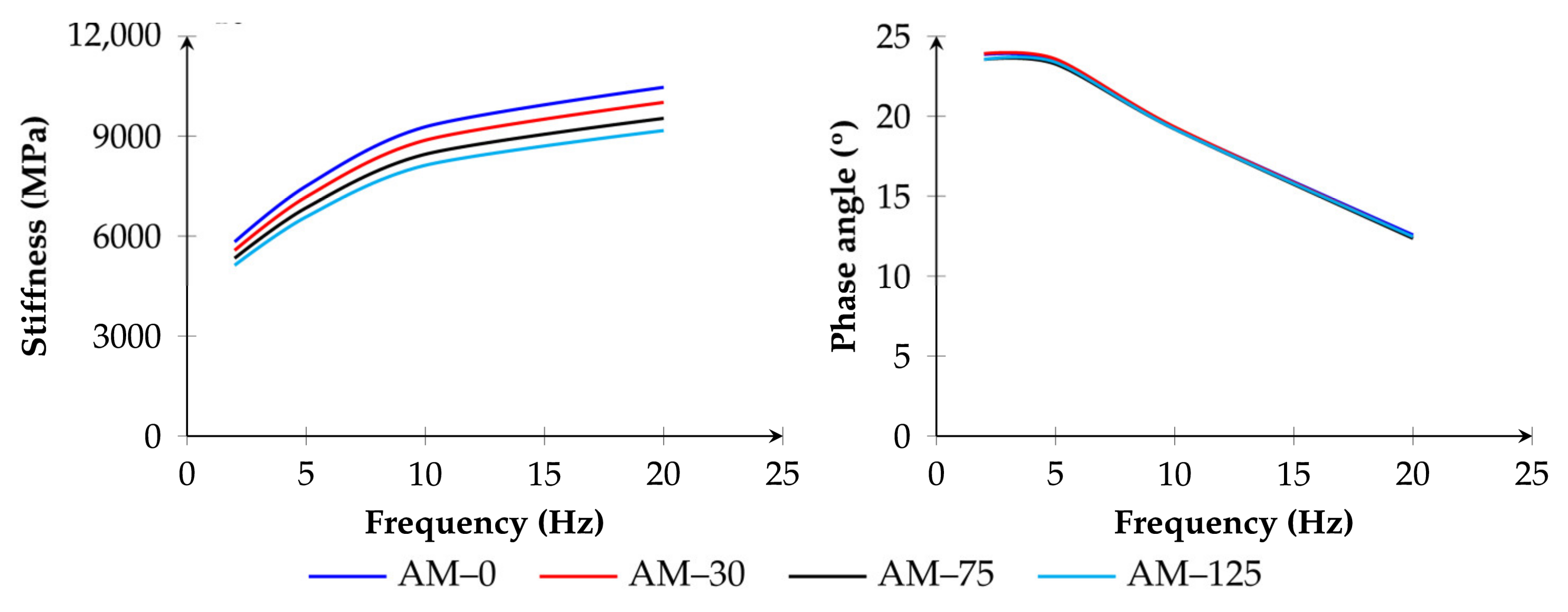

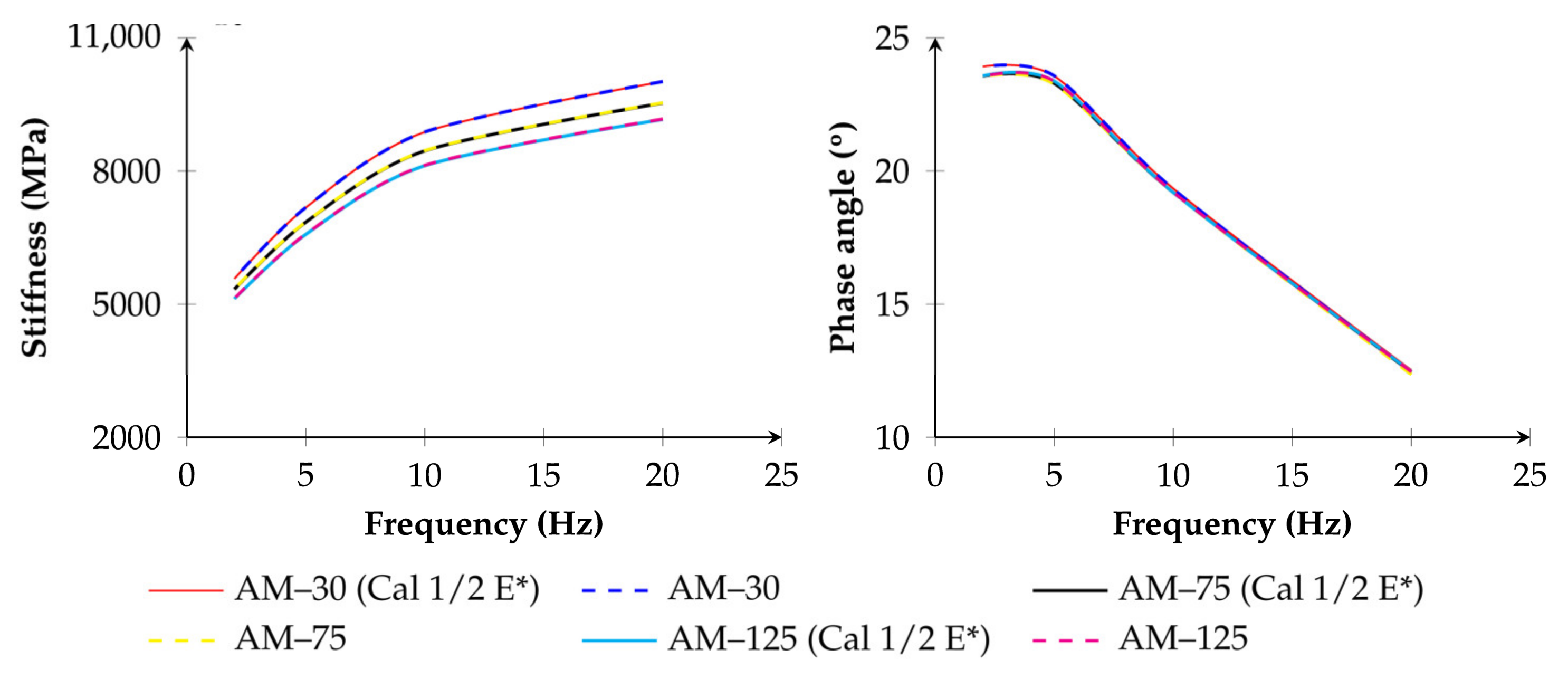

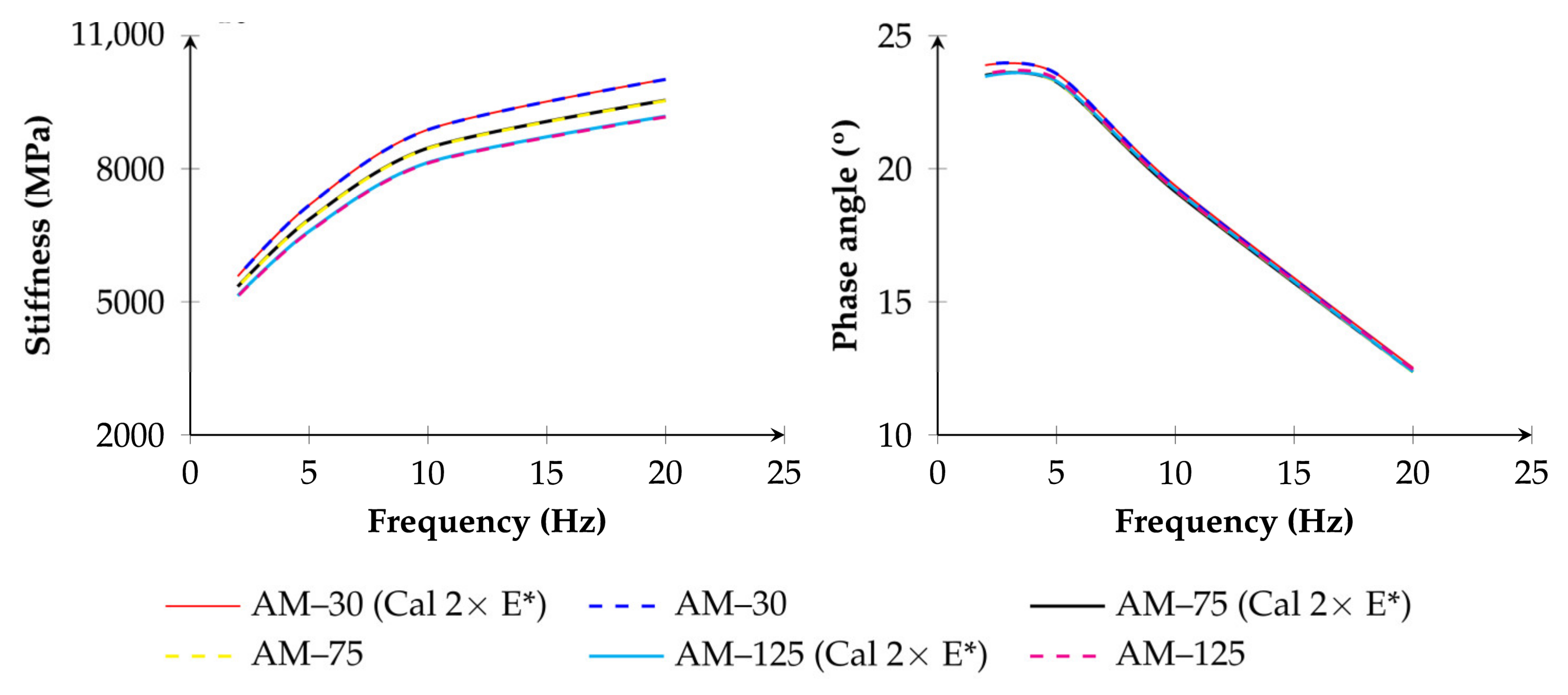

5.1. Tension–Compression Sinusoidal Test

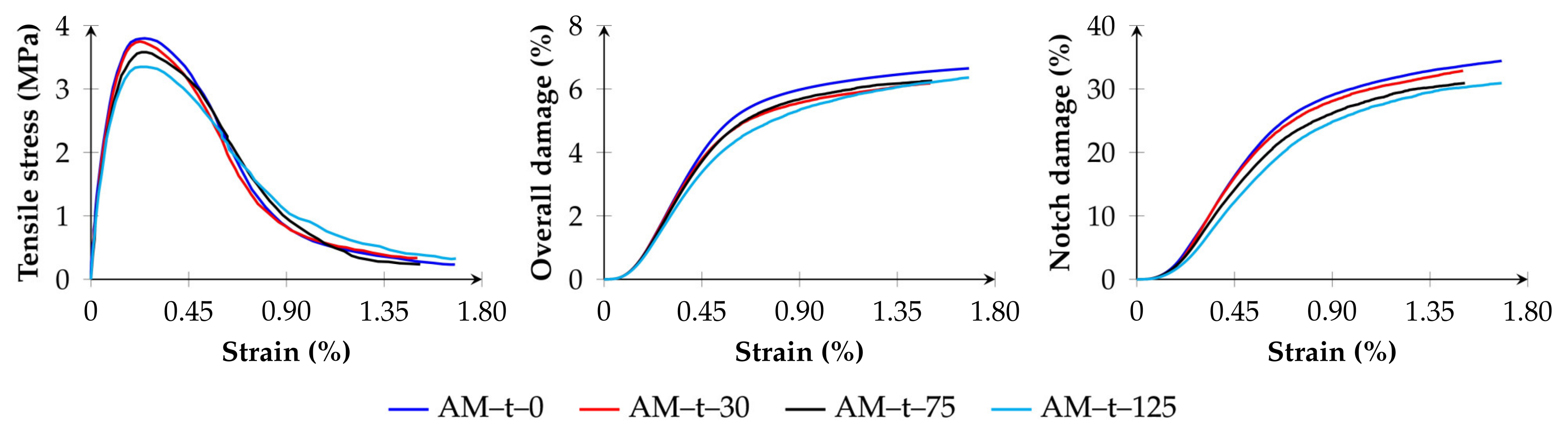

5.2. Tensile Strength Monotonic Test

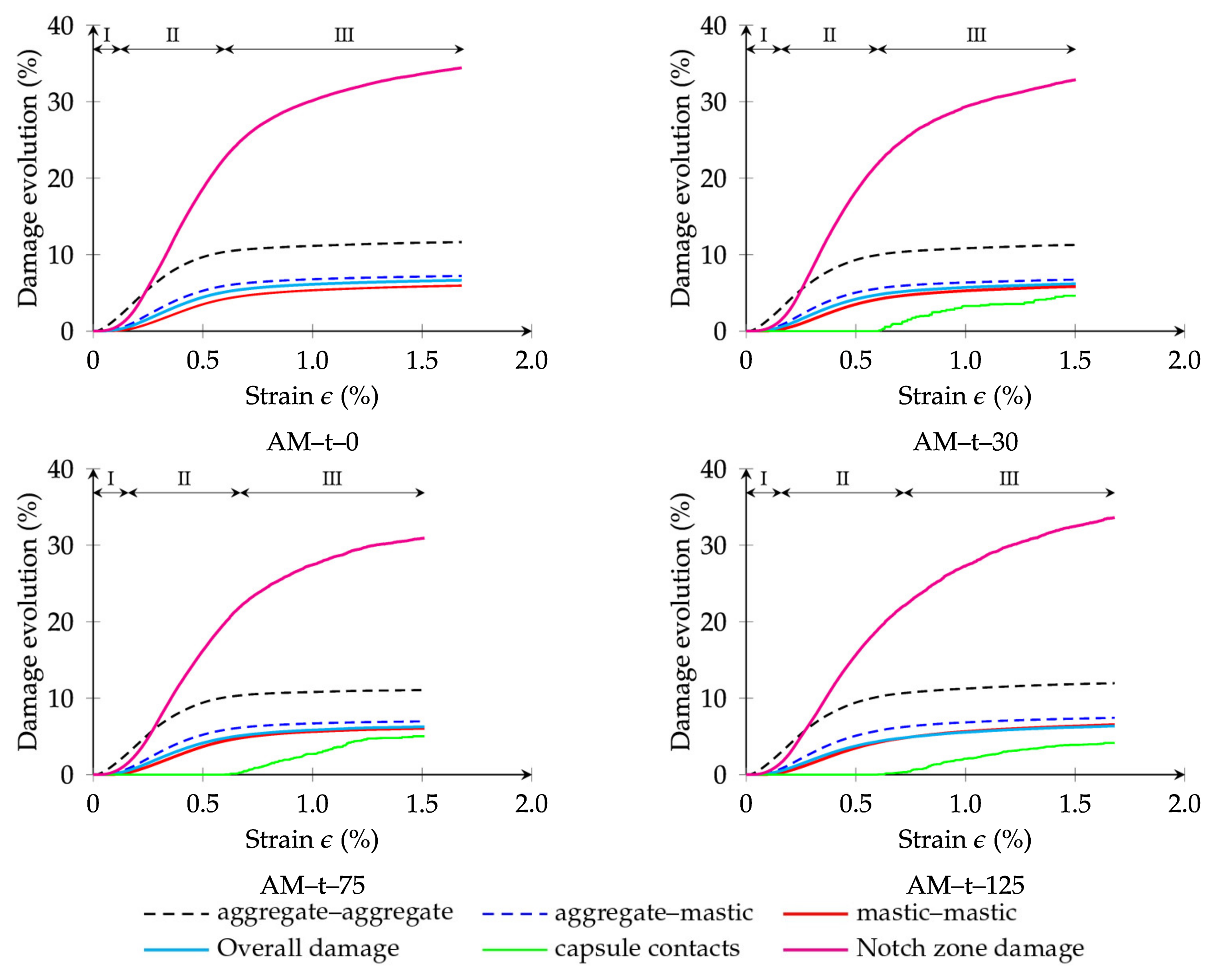

5.2.1. Contact Damage Evolution

- Stage 1: This stage (strain ε ≤ 0.12%) is characterised by the absence of contact damage in interactions involving mastic and capsules. The observed response primarily results from the initial rearrangement of the constituent materials in the asphalt mixtures in response to internal air voids and the deformability of the material phases. The elastic response from the contact models—either linear elastic or viscoelastic (GK model)—also dominates at this early point. During this stage, limited damage is observed exclusively between adjacent aggregates. However, because of the relatively low number of these interactions, this early damage has negligible influence on the overall damage progression.

- Stage 2: As tensile loading increases, contact damage begins to escalate, particularly in the vicinity of the notch tips (0.12% < ε ≤ 0.70%). This growth in damage predominantly occurs in aggregate–mastic and mastic–mastic interactions. At this point, the average overall contact damage reaches approximately 5.8%, while in the notch-tip region, damage rises to 24%, indicating a clear concentration of failure and a predisposition toward fracture initiation. In addition, interactions involving capsules remain unaffected during this stage. This observation suggests that the mechanical interactions involving capsules can withstand the initial loading stages, minimising the risk of premature activation—an important condition for self-healing applications.

- Stage 3: As shown in Figure 10, a trend of damage stabilisation is observed beyond this strain threshold (ε > 0.70%) for aggregate–aggregate, aggregate–mastic, and mastic–mastic contacts. Final average values for overall damage and notch-region damage reach approximately 6.31% and 33.24%, respectively. Among these interactions, aggregate–mastic contacts show a higher proportion of damaged interfaces when compared to mastic–mastic ones. This implies that while both types of interaction contribute to the damage process, aggregate–mastic contacts are more susceptible to failure, being a dominant role in the crack propagation mechanism. This finding highlights the importance of the bond between aggregates and mastic for the fracture resistance of mixtures—an observation corroborated by previous studies [8,27,36]. Damage to contacts involving capsules occurs only during this third stage, which supports their intended function in asphalt pavements. Capsules are designed to remain intact under initial loading and only become active once micro-cracking occurs in the surrounding asphalt binder. This simulated behaviour agrees with experimental findings, which suggest that capsules typically activate only after crack initiation [58].

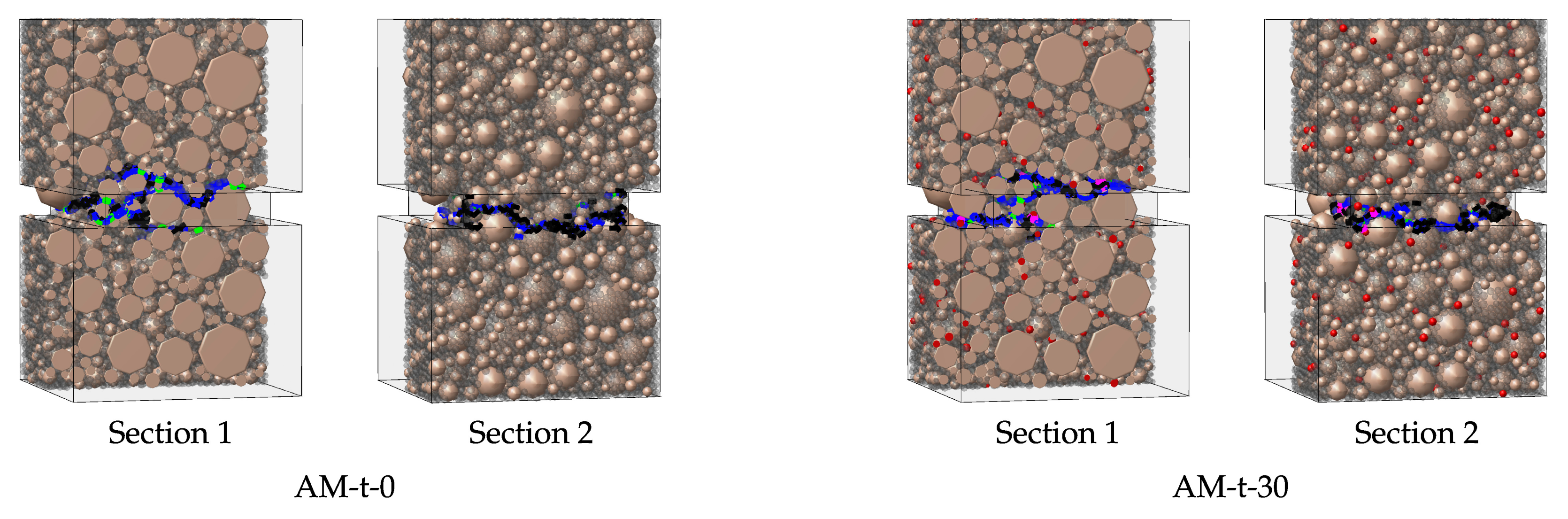

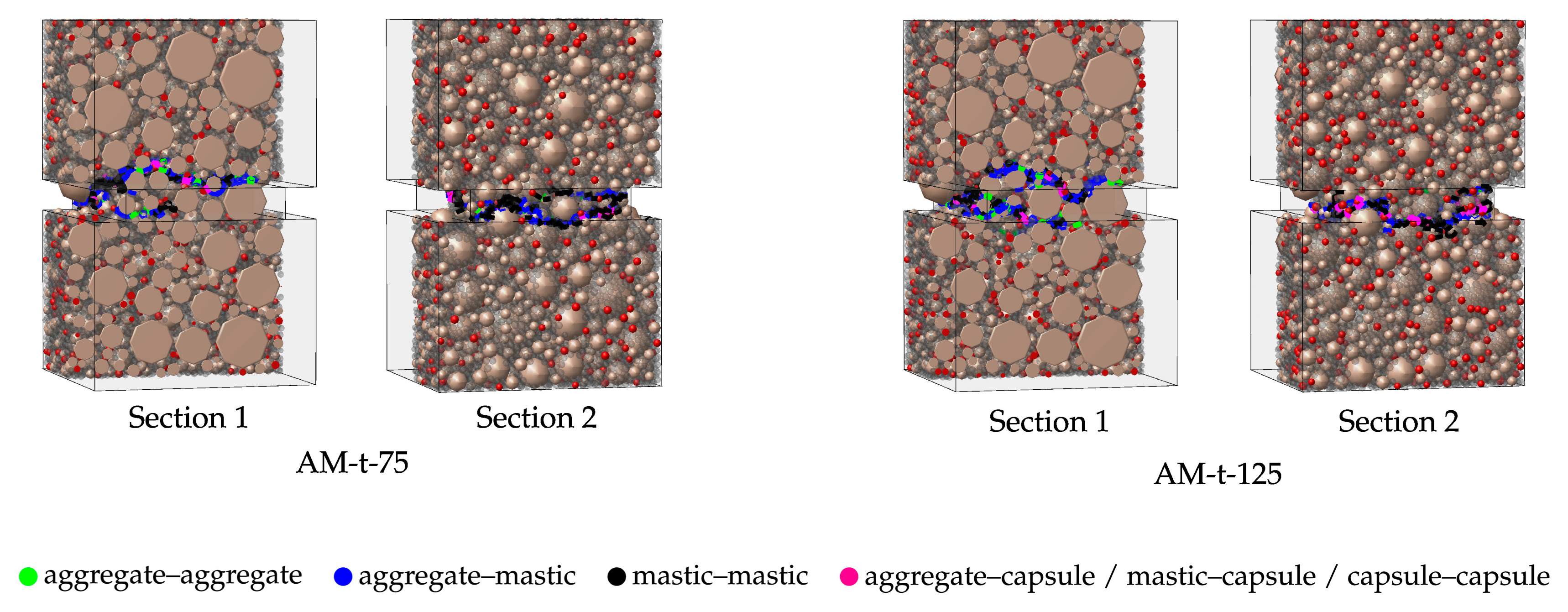

5.2.2. Contact Damage Patterns

5.2.3. Contact Damage Patterns—Capsule Behaviour

6. Modelling Limitations and Future Developments

7. Conclusions

- The three-dimensional DEM model effectively captured the behaviour of asphalt mixtures with capsules under different loading conditions and provided detailed insight into contact interactions and damage evolution.

- The addition of capsules led to a progressive reduction in stiffness modulus. On average, reductions of 4.3%, 8.7%, and 12.3% were verified for capsule contents of 0.30, 0.75, and 1.25 wt.%, respectively. The phase angle, however, remained unaffected across all frequencies and capsule ratios.

- The capsule continuum equivalent Young’s modulus, within the studied range (half and double of the calibrated value), had minimal influence on the overall rheological response. The most critical parameter affecting asphalt mixture stiffness was the capsule content, rather than the capsule stiffness itself.

- Under tensile loading, the presence of capsules reduced the peak tensile strength (up to 12.4% for the highest capsule content), but did not significantly affect the stress–strain and damage evolution of the specimens. Damage was highly localised around the notch tips, and the trends remained consistent among all capsule contents.

- Contacts involving capsules remained intact during early and intermediate loading stages and only fractured during the final damage stage, suggesting a delayed activation consistent with the design of healing systems. All these damaged contacts were localised within the notch-tip region, showing that simulations considering the rejuvenator effect would possibly influence the recovery of damaged asphalt mixtures.

- Capsules themselves have limited mechanical influence, particularly on damage evolution. The main mechanical benefit expected from their use is associated with the rejuvenator release mechanism.

- The numerical findings suggest that capsule contents of up to 0.75 wt.% can be incorporated without significant compromise to mechanical performance. Higher contents should be applied with caution due to the additional effect of rejuvenator in self-healing applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Buttlar, W.G. Three-Dimensional Micromechanical Pavement Model Development for the Study of Block Cracking. Constr. Build. Mater. 2019, 206, 35–45. [Google Scholar] [CrossRef]

- Li, Y.; Feng, J.; Yang, F.; Wu, S.; Liu, Q.; Bai, T.; Liu, Z.; Li, C.; Gu, D.; Chen, A.; et al. Gradient Aging Behaviors of Asphalt Aged by Ultraviolet Lights with Various Intensities. Constr. Build. Mater. 2021, 295, 123618. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, Y.; Liu, Y.; Wang, Z.; Ji, X. Study on the Cracking Behavior of Asphalt Mixture by Discrete Element Modeling with Real Aggregate Morphology. Constr. Build. Mater. 2023, 368, 130406. [Google Scholar] [CrossRef]

- Zhang, L.; Hoff, I.; Zhang, X.; Yang, C. Investigation of the Self-Healing and Rejuvenating Properties of Aged Asphalt Mixture Containing Multi-Cavity Ca-Alginate Capsules. Constr. Build. Mater. 2022, 361, 129685. [Google Scholar] [CrossRef]

- Wan, P.; Wu, S.; Liu, Q.; Xu, H.; Wang, H.; Peng, Z.; Rao, W.; Zou, Y.; Zhao, Z.; Chen, S. Self-Healing Properties of Asphalt Concrete Containing Responsive Calcium Alginate/Nano-Fe3O4 Composite Capsules via Microwave Irradiation. Constr. Build. Mater. 2021, 310, 125258. [Google Scholar] [CrossRef]

- Xu, X.; Yuan, L.; Cong, P.; Wang, Z.; Zhou, X.; Wang, J.; Liu, J. Self-Healing Microcapsule Properties Improvement Technology: Key Challenges and Solutions for Application in Asphalt Materials. Constr. Build. Mater. 2024, 439, 137298. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; Wan, P.; Liu, Q.; Xu, S.; Jiang, J.; Fan, L.; Tu, L. Healing Evaluation of Asphalt Mixtures with Polymer Capsules Containing Rejuvenator under Different Water Solutions. Sustainability 2023, 15, 15258. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Yalcin, E.; Garcia, A.; Al-Mansoori, T.; Yilmaz, M.; Hudson-Griffiths, R. Effect of Mixing and Ageing on the Mechanical and Self-Healing Properties of Asphalt Mixtures Containing Polymeric Capsules. Constr. Build. Mater. 2018, 175, 254–266. [Google Scholar] [CrossRef]

- Ding, X.; Cui, Y.; Ma, T.; Ye, F. Multiscale-Mechanical Analysis on Self-Healing Microcapsules under Asphalt Pavement. Constr. Build. Mater. 2024, 443, 137670. [Google Scholar] [CrossRef]

- Bao, S.; Liu, Q.; Li, H.; Zhang, L.; Maria Barbieri, D. Investigation of the Release and Self-Healing Properties of Calcium Alginate Capsules in Asphalt Concrete under Cyclic Compression Loading. J. Mater. Civ. Eng. 2021, 33, 04020401. [Google Scholar] [CrossRef]

- Sun, D.; Hu, J.; Zhu, X. Size Optimization and Self-Healing Evaluation of Microcapsules in Asphalt Binder. Colloid Polym. Sci. 2015, 293, 3505–3516. [Google Scholar] [CrossRef]

- Foroutan Mirhosseini, A.; Tahami, S.A.; Hoff, I.; Dessouky, S.; Ho, C.-H. Performance Evaluation of Asphalt Mixtures Containing High-RAP Binder Content and Bio-Oil Rejuvenator. Constr. Build. Mater. 2019, 227, 116465. [Google Scholar] [CrossRef]

- Garcia, A.; Jelfs, J.; Austin, C.J. Internal Asphalt Mixture Rejuvenation Using Capsules. Constr. Build. Mater. 2015, 101, 309–316. [Google Scholar] [CrossRef]

- Ozdemir, A.M.; Yilmaz, M.; Yalcin, E.; Kok, B.V.; Norambuena-Contreras, J.; Garcia, A. Effects of Capsules Containing Waste Oils on the Mechanical Properties of Hot Mix Asphalt: Experimental Approach. J. Mater. Civ. Eng. 2021, 33, 04021242. [Google Scholar] [CrossRef]

- Aguirre, M.A.; Hassan, M.M.; Shirzad, S.; Mohammad, L.N.; Cooper, S.; Negulescu, I.I. Laboratory Testing of Self-Healing Microcapsules in Asphalt Mixtures Prepared with Recycled Asphalt Shingles. J. Mater. Civ. Eng. 2017, 29, 04017099. [Google Scholar] [CrossRef]

- Kargari, A.; Arabani, M.; Mirabdolazimi, S.M. Effect of Palm Oil Capsules on the Self-Healing Properties of Aged and Unaged Asphalt Mixtures Gained by Resting Period and Microwave Heating. Constr. Build. Mater. 2022, 316, 125901. [Google Scholar] [CrossRef]

- Ruiz-Riancho, N.; Garcia, A.; Grossegger, D.; Saadoon, T.; Hudson-Griffiths, R. Properties of Ca-Alginate Capsules to Maximise Asphalt Self-Healing Properties. Constr. Build. Mater. 2021, 284, 122728. [Google Scholar] [CrossRef]

- Garcia, A.; Austin, C.J.; Jelfs, J. Mechanical Properties of Asphalt Mixture Containing Sunflower Oil Capsules. J. Clean. Prod. 2016, 118, 124–132. [Google Scholar] [CrossRef]

- Al-Mansoori, T.; Micaelo, R.; Artamendi, I.; Norambuena-Contreras, J.; Garcia, A. Microcapsules for Self-Healing of Asphalt Mixture without Compromising Mechanical Performance. Constr. Build. Mater. 2017, 155, 1091–1100. [Google Scholar] [CrossRef]

- Sun, D.; Li, B.; Ye, F.; Zhu, X.; Lu, T.; Tian, Y. Fatigue Behavior of Microcapsule-Induced Self-Healing Asphalt Concrete. J. Clean. Prod. 2018, 188, 466–476. [Google Scholar] [CrossRef]

- Quezada, J.C.; Chazallon, C. Discrete Element Modelling of Hot Mix Asphalt Complex Modulus Using Realistic Aggregate Shapes. Road Mater. Pavement Des. 2022, 23, 178–195. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, T.; Ling, M.; Zhang, D.; Huang, X. Predicting Dynamic Shear Modulus of Asphalt Mastics Using Discretized-Element Simulation and Reinforcement Mechanisms. J. Mater. Civ. Eng. 2019, 31, 04019163. [Google Scholar] [CrossRef]

- Zhu, X.; Yu, H.; Qian, G.; Yao, D.; Dai, W.; Zhang, H.; Li, J.; Zhong, H. Evaluation of Asphalt Mixture Micromechanical Behavior Evolution in the Failure Process Based on Discrete Element Method. Case Stud. Constr. Mater. 2023, 18, e01773. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Wang, S.; Liu, Q.; Yu, B.; Wang, Q. Use of X-Ray Computed Tomography to Evaluate the Gradual Behaviour of Air Voids in Asphalt Mixtures during Permanent Deformation. Int. J. Pavement Eng. 2023, 24, 2134570. [Google Scholar] [CrossRef]

- Peng, Y.; Gao, H. Comparative Modelling of Indirect Tensile Strength of Asphalt Mixtures with and without Considering Air Void Characteristics. Int. J. Pavement Eng. 2021, 22, 1601–1610. [Google Scholar] [CrossRef]

- Câmara, G.; Micaelo, R.; Monteiro Azevedo, N. 3D DEM Model Simulation of Asphalt Mastics with Sunflower Oil. Comput. Part. Mech. 2023, 10, 1569–1586. [Google Scholar] [CrossRef]

- Yin, H.; Li, Y.; Huang, H. Mesoscopic Study on Mechanical Properties and Dynamic Damage Characteristics of Self-Healing Microcapsule. Comput. Part. Mech. 2024, 11, 197–209. [Google Scholar] [CrossRef]

- Zhang, H.; Quan, W.; Wang, R. Study on Crack Resistance of Self-Healing Microcapsules in Asphalt Pavement by Multi-Scale Method. PLoS ONE 2024, 19, e0300178. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, T.; Li, C. Study on the Mechanical Behavior of Microcapsules during the Mixing Process of Asphalt Mixture. Constr. Build. Mater. 2024, 441, 137531. [Google Scholar] [CrossRef]

- Ge, H.; Quezada, J.C.; Le Houerou, V.; Chazallon, C.; Sha, A. From Macro to Micro: Investigation of Three-Dimensional Particle-Scale Responses of Asphalt Mixtures under Non-Uniform Rolling Tire Loads via Coupled FEM-DEM Simulations. Road Mater. Pavement Des. 2025, 1–30. [Google Scholar] [CrossRef]

- Hanna, J.; Elamin, A. Computational Fracture Modeling for Effects of Healed Crack Length and Interfacial Cohesive Properties in Self-Healing Concrete Using XFEM and Cohesive Surface Technique. Computation 2023, 11, 142. [Google Scholar] [CrossRef]

- Nian, T.; Ge, J.; Li, P.; Guo, R.; Li, J.; Wang, M. Improved Three-Dimensional Discrete Modeling Method and Anti-Cracking Properties of Asphalt Mixture. Constr. Build. Mater. 2022, 321, 126405. [Google Scholar] [CrossRef]

- Chen, X.; Ai, C.; Du, J.; He, H.; Huang, Y. Effect of Gradation Segregation on Low-Temperature Crack Resistance of Asphalt Pavement Using 3D DEM. Constr. Build. Mater. 2021, 274, 122060. [Google Scholar] [CrossRef]

- García, Á.; Schlangen, E.; van de Ven, M. Properties of Capsules Containing Rejuvenators for Their Use in Asphalt Concrete. Fuel 2011, 90, 583–591. [Google Scholar] [CrossRef]

- Câmara, G.; Azevedo, N.M.; Micaelo, R.; Silva, H. Generalised Kelvin Contact Models for DEM Modelling of Asphalt Mixtures. Int. J. Pavement Eng. 2023, 24, 2179625. [Google Scholar] [CrossRef]

- Câmara, G.; Micaelo, R.; Azevedo, N.M.; Silva, H. Incremental Viscoelastic Damage Contact Models for Asphalt Mixture Fracture Assessment. Infrastructures 2024, 9, 118. [Google Scholar] [CrossRef]

- Peng, C.; Wang, Z.; Zhu, C.; Kuang, D. 3D Reconstruction of Asphalt Mixture Based on 2D Images. Constr. Build. Mater. 2025, 462, 139938. [Google Scholar] [CrossRef]

- Du Plessis, A.; Boshoff, W.P. A Review of X-Ray Computed Tomography of Concrete and Asphalt Construction Materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Liu, Y.; Gong, F.; You, Z.; Wang, H. Aggregate Morphological Characterization with 3D Optical Scanner versus X-Ray Computed Tomography. J. Mater. Civ. Eng. 2018, 30, 04017248. [Google Scholar] [CrossRef]

- Ding, X.; Liu, F.; Ma, T.; Xiao, B. Effects of Coarse Aggregate Morphology on Asphalt Mixture’s Flowability: Parametric and Prediction Study. Case Stud. Constr. Mater. 2024, 21, e03735. [Google Scholar] [CrossRef]

- Peng, Y.; Xu, Y.; Zhang, X.; Meng, H.; Lu, X. Investigation on the Effects of Asphalt Mixes and Their Combinations on Asphalt Mix Shear Strength by 3D Discrete Element Method. Int. J. Pavement Eng. 2023, 24, 2251078. [Google Scholar] [CrossRef]

- Azevedo, N.M.; Farinha, M.L.B.; Oliveira, S. Assessment of Contact Laws Accounting for Softening in 3D Rigid Concrete Particle Models. Buildings 2024, 14, 801. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, D.; Zhang, Y.; Zhao, Y.; Huang, X. Effect of Air Voids on the High-Temperature Creep Behavior of Asphalt Mixture Based on Three-Dimensional Discrete Element Modeling. Mater. Des. 2016, 89, 304–313. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, X.; Si, B.; Zhang, Z.; Shao, D.; Zhu, S.; He, S. Investigation on Self-Healing Performance of Asphalt Mixture Containing Microcapsules and Survival Behaviour of Microcapsules. Int. J. Pavement Eng. 2023, 24, 2165657. [Google Scholar] [CrossRef]

- Xu, S.; Tabaković, A.; Liu, X.; Schlangen, E. Calcium Alginate Capsules Encapsulating Rejuvenator as Healing System for Asphalt Mastic. Constr. Build. Mater. 2018, 169, 379–387. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Q.; Li, H.; Norambuena-Contreras, J.; Wu, S.; Bao, S.; Shu, B. Synthesis and Characterization of Multi-Cavity Ca-Alginate Capsules Used for Self-Healing in Asphalt Mixtures. Constr. Build. Mater. 2019, 211, 298–307. [Google Scholar] [CrossRef]

- Câmara, G.; Azevedo, N.M.; Micaelo, R. Impact of Rejuvenator-Modified Mastic on Asphalt Mixture Stiffness: Meso-Scale Discrete Element Method Approach. Buildings 2023, 13, 3023. [Google Scholar] [CrossRef]

- Gong, F.; Liu, Y.; Zhou, X.; You, Z. Lab Assessment and Discrete Element Modeling of Asphalt Mixture during Compaction with Elongated and Flat Coarse Aggregates. Constr. Build. Mater. 2018, 182, 573–579. [Google Scholar] [CrossRef]

- Xie, S.; Yi, J.; Wang, H.; Yang, S.-H.; Xu, M.; Feng, D. Mechanical Response Analysis of Transverse Crack Treatment of Asphalt Pavement Based on DEM. Int. J. Pavement Eng. 2022, 23, 2206–2226. [Google Scholar] [CrossRef]

- Zhou, M.; Cao, W. Mesoscopic Analysis of Fatigue Damage Development in Asphalt Mixture Based on Modified Burgers Contact Algorithm in Discrete Element Modeling. Materials 2024, 17, 2025. [Google Scholar] [CrossRef]

- Ren, J.; Sun, L. Generalized Maxwell Viscoelastic Contact Model-Based Discrete Element Method for Characterizing Low-Temperature Properties of Asphalt Concrete. J. Mater. Civ. Eng. 2016, 28, 04015122. [Google Scholar] [CrossRef]

- Sun, L.; Ren, J.; Zhang, S. Fracture Characteristics of Asphalt Concrete in Mixed-Loading Mode at Low-Temperature Based on Discrete-Element Method. J. Mater. Civ. Eng. 2018, 30, 04018321. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Z.; Xue, J.; Xu, Y. Influence of the Mesoscopic Viscoelastic Contact Model on Characterizing the Rheological Behavior of Asphalt Concrete in the DEM Simulation. Adv. Civ. Eng. 2020, 2020, 5248267. [Google Scholar] [CrossRef]

- Liang, H.; Shi, L.; Wang, D.; Xiao, X.; Deng, K. Influence of Graded Coarse Aggregate Content and Specific Surface Area on the Fracture Properties of Asphalt Mixtures Based on Discrete Element Simulations and Indoor Tests. Constr. Build. Mater. 2021, 299, 123942. [Google Scholar] [CrossRef]

- Bai, X.; Wang, L. Study on Mesoscopic Model of Low-Temperature Cracking of Steel Slag Asphalt Mixture Based on Random Aggregate. Constr. Build. Mater. 2023, 364, 129974. [Google Scholar] [CrossRef]

- Shen, Z.; Xiao, Y.; Hou, K.; Chen, Y.; Meng, F. Investigating the Impact of Porous Steel Slag Aggregates on the Low-Temperature Crack Resistance of Asphalt Concrete. Constr. Build. Mater. 2024, 453, 138914. [Google Scholar] [CrossRef]

- Dan, H.-C.; Zhang, Z.; Chen, J.; Cao, W. Low-Temperature Fracture Characteristics of Asphalt Mixtures Using the Eccentric Single-Edge Notched Bend Test: A 3D Discrete Element Study. Constr. Build. Mater. 2022, 344, 128182. [Google Scholar] [CrossRef]

- Micaelo, R.; Freire, A.C.; Pereira, G. Asphalt Self-Healing with Encapsulated Rejuvenators: Effect of Calcium-Alginate Capsules on Stiffness, Fatigue and Rutting Properties. Mater. Struct. 2020, 53, 20. [Google Scholar] [CrossRef]

- Tabaković, A.; Braak, D.; Van Gerwen, M.; Copuroglu, O.; Post, W.; Garcia, S.J.; Schlangen, E. The Compartmented Alginate Fibres Optimisation for Bitumen Rejuvenator Encapsulation. J. Traffic Transp. Eng. Engl. Ed. 2017, 4, 347–359. [Google Scholar] [CrossRef]

- Derakhshan, M.; Ameri, M.; Aliha, M.; Shaker, H. Laboratory Evaluation of Self-Healing Capability of Warm-Mix Asphalt Containing Calcium Alginate Capsules under Aging Conditions. J. Mater. Civ. Eng. 2025, 37, 04024456. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, M.; Wu, J.; Wan, P.; Liu, Q. Self-Healing Properties of Asphalt Concrete with Calcium Alginate Capsules Containing Different Healing Agents. Materials 2022, 15, 5555. [Google Scholar] [CrossRef]

| Mineral Aggregates | Mastic | |||||

|---|---|---|---|---|---|---|

| Sieve size [mm] | 19.0 | 12.5 | 9.5 | 4.75 | 2.0 | >2.0 |

| AM–0 | ||||||

| Particles retained | - | 13 | 28 | 288 | 2184 | 22,861 |

| Volume [mm3] | - | 26,286.8 | 21,400.2 | 40,913.3 | 29,256.4 | 74,551.0 |

| AM–t–0 | ||||||

| Particles retained | - | 13 | 26 | 282 | 2117 | 22,168 |

| Volume [mm3] | - | 26,286.8 | 19,961.4 | 40,122.6 | 28,387.2 | 72,285.4 |

| Asphalt Mixture Model: AM (AM–t) | ||||

|---|---|---|---|---|

| Interaction type | AM–0 (AM–t–0) | AM–30 (AM–t–30) | AM–75 (AM–t–75) | AM–125 (AM–t–125) |

| Aggregate–aggregate | 4670 (4499) | 4667 (4493) | 4738 (4452) | 4670 (4499) |

| Aggregate–mastic | 55,108 (53,048) | 53,486 (51,522) | 51,710 (49,774) | 50,235 (48,354) |

| Mastic–mastic | 78,795 (76,073) | 73,689 (71,044) | 67,312 (65,032) | 62,497 (60,360) |

| Aggregate–capsule | – | 1284 (1236) | 2961 (2841) | 4873 (4694) |

| Mastic–capsule | – | 3877 (3730) | 9428 (9089) | 15,763 (15,203) |

| Capsule–capsule | – | 23 (21) | 143 (137) | 535 (510) |

| Aggregate–wall | 164 (164) | 163 (163) | 157 (157) | 164 (164) |

| Mastic–wall | 1373 (1373) | 1356 (1356) | 1299 (1299) | 1257 (1257) |

| Capsule-wall | – | 28 (28) | 86 (86) | 116 (116) |

| Chain Number | GK Macroscopic Component | Value |

|---|---|---|

| 1 | [kPa] | |

| [kPa∙s] | ||

| 2 | ||

| 3 | ||

| Maxwell components | [kPa] | |

| [kPa∙s] |

| Contact Parameter | Calibrated Value |

|---|---|

| Maximum contact tensile stress [MPa] | 6.12 |

| Maximum contact cohesion stress [MPa] | 24.48 |

| Contact fracture energy in mode I [N/mm] | 0.35 |

| Contact fracture energy in mode II [N/mm] | 56.44 |

| Asphalt Mixture | Variation in Stiffness (%) Min (Max) | Difference in Phase Angle (°) Min (Max) |

|---|---|---|

| AM–30 | 4.3 (4.4) | 0.02 (−0.11) |

| AM–75 | 8.4 (8.9) | −0.11 (−0.31) |

| AM–125 | 12.1 (12.4) | −0.10 (−0.31) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Câmara, G.; Azevedo, N.M.; Micaelo, R. Self-Healing Asphalt Mixtures Meso-Modelling: Impact of Capsule Content on Stiffness and Tensile Strength. Sustainability 2025, 17, 7502. https://doi.org/10.3390/su17167502

Câmara G, Azevedo NM, Micaelo R. Self-Healing Asphalt Mixtures Meso-Modelling: Impact of Capsule Content on Stiffness and Tensile Strength. Sustainability. 2025; 17(16):7502. https://doi.org/10.3390/su17167502

Chicago/Turabian StyleCâmara, Gustavo, Nuno Monteiro Azevedo, and Rui Micaelo. 2025. "Self-Healing Asphalt Mixtures Meso-Modelling: Impact of Capsule Content on Stiffness and Tensile Strength" Sustainability 17, no. 16: 7502. https://doi.org/10.3390/su17167502

APA StyleCâmara, G., Azevedo, N. M., & Micaelo, R. (2025). Self-Healing Asphalt Mixtures Meso-Modelling: Impact of Capsule Content on Stiffness and Tensile Strength. Sustainability, 17(16), 7502. https://doi.org/10.3390/su17167502