Scenario-Based Carbon Footprint of a Synthetic Liquid Fuel Vehicle

Abstract

1. Introduction

1.1. Life Cycle of Vehicles and Synthetic Liquid Fuel Vehicles

1.2. Related Studies on SLF-Vs

- Setting of scenarios that consider the options for H2 and CO2 production technologies and power source configurations used in WtW processes for each evaluation year.

- Evaluation of the life-cycle CO2 emissions of SLF-Vs for each scenario and comparison of the results with those for GVs, HEVs, and BEVs.

- Sensitivity and uncertainty analyses conducted to identify which processes in SLF production have the most impact on life-cycle CO2 emissions.

2. Materials and Methods

2.1. Scenario-Based Carbon Footprint

- Assessing the quality of both future scenarios and the LCA itself.

- Clearly defining the term “scenario”.

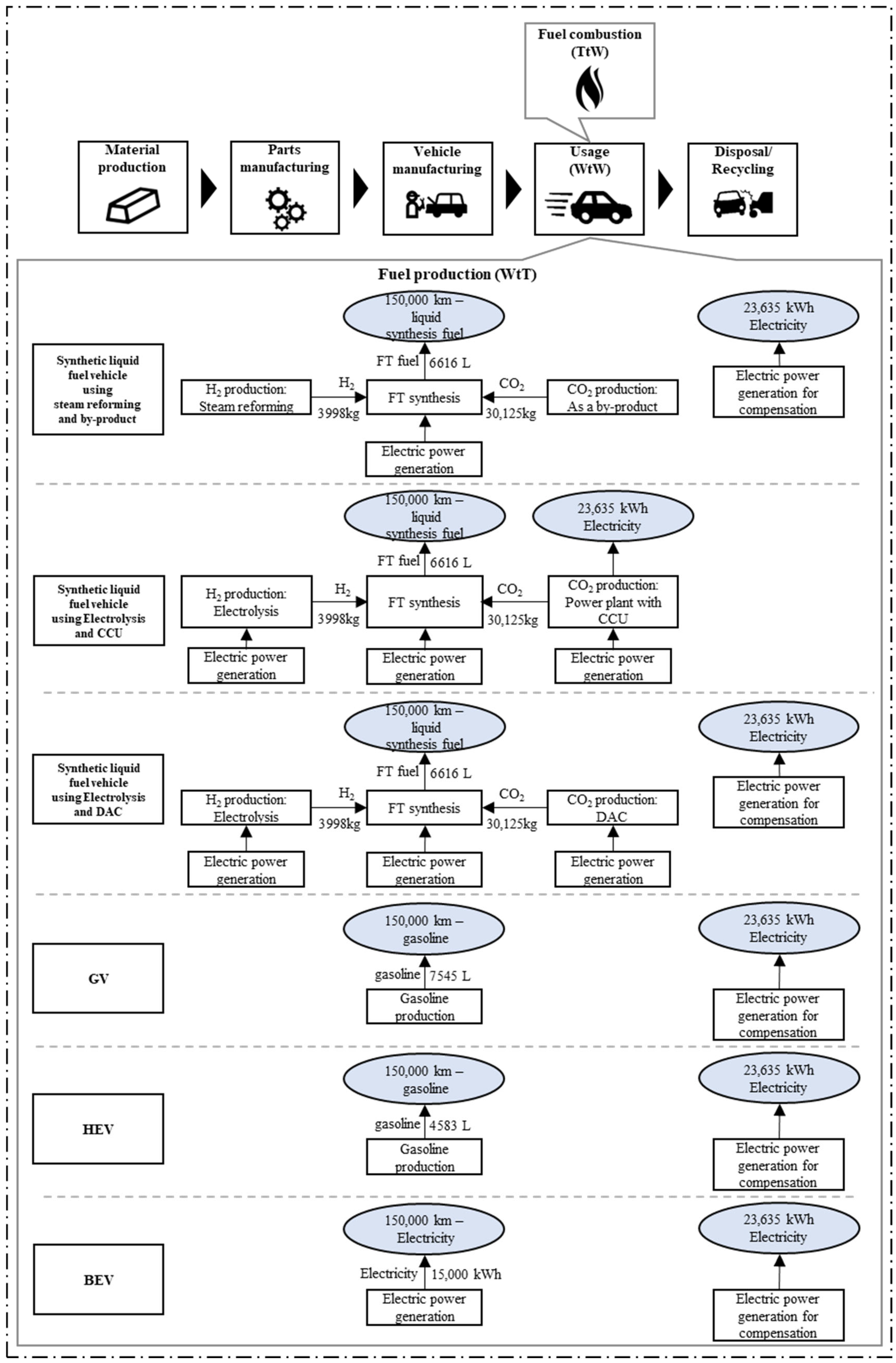

2.2. Functional Unit and System Boundary

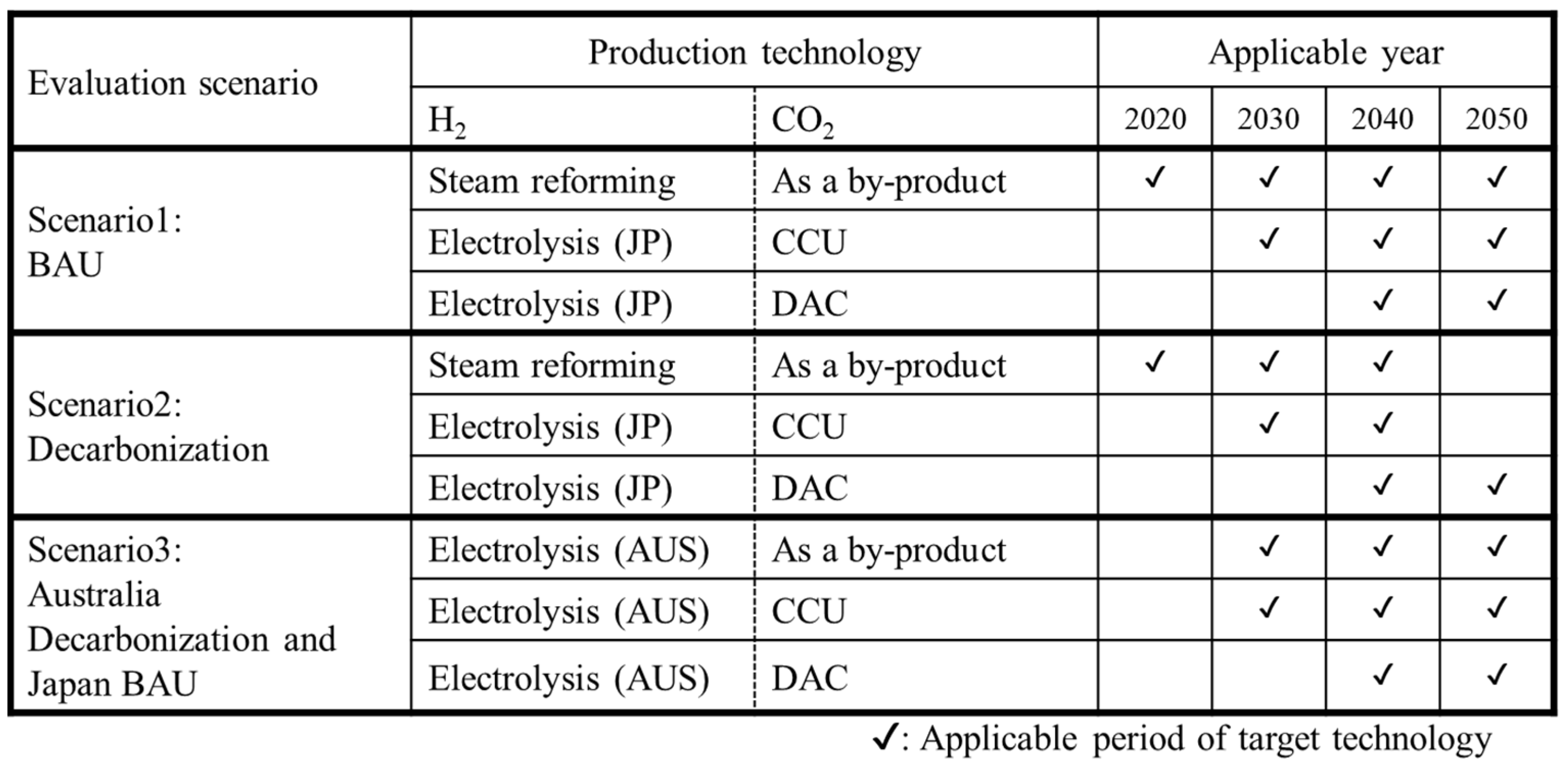

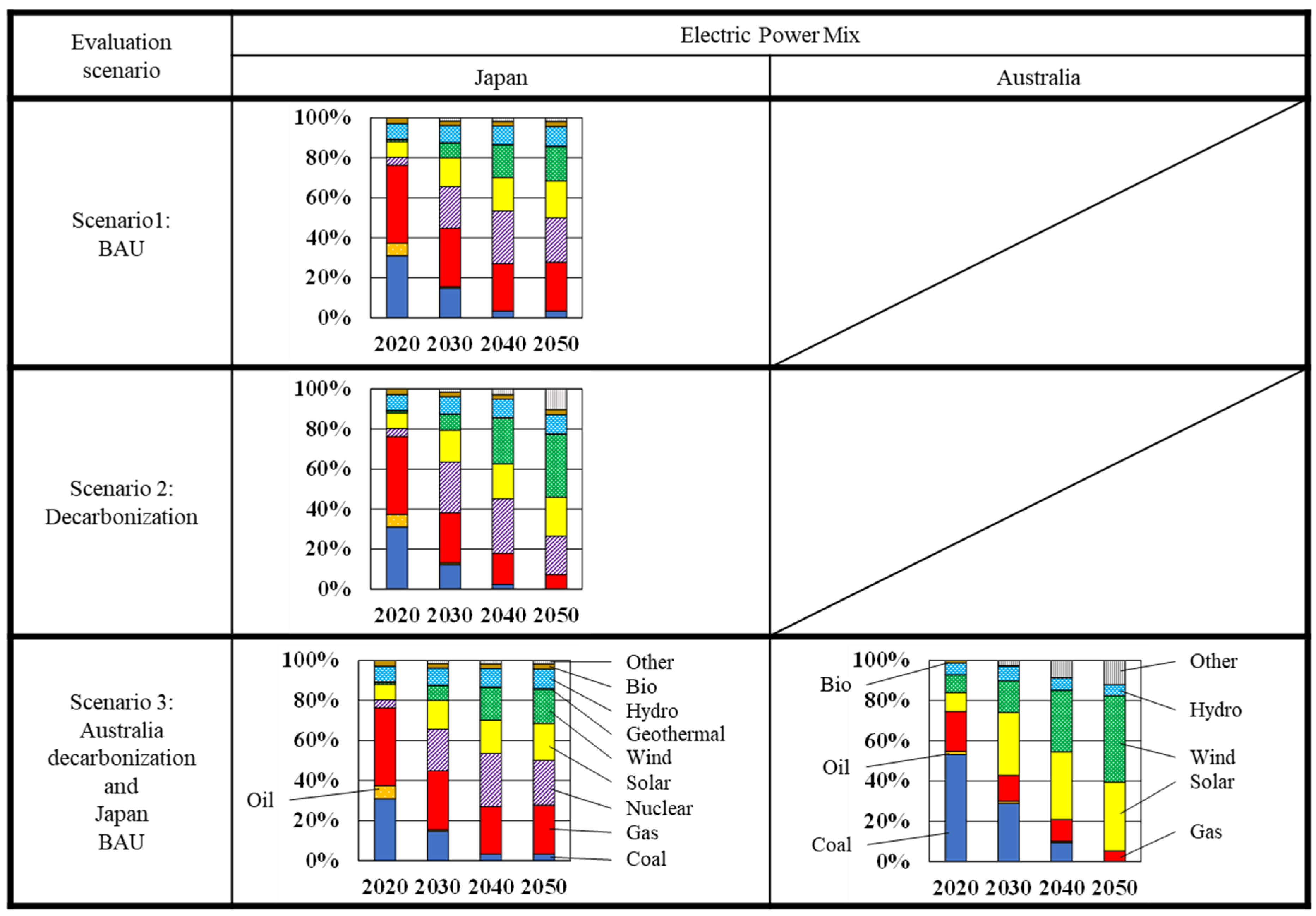

2.3. Scenario Setting

2.4. Life-Cycle Inventory

2.4.1. Vehicle Life Cycle

2.4.2. WtW

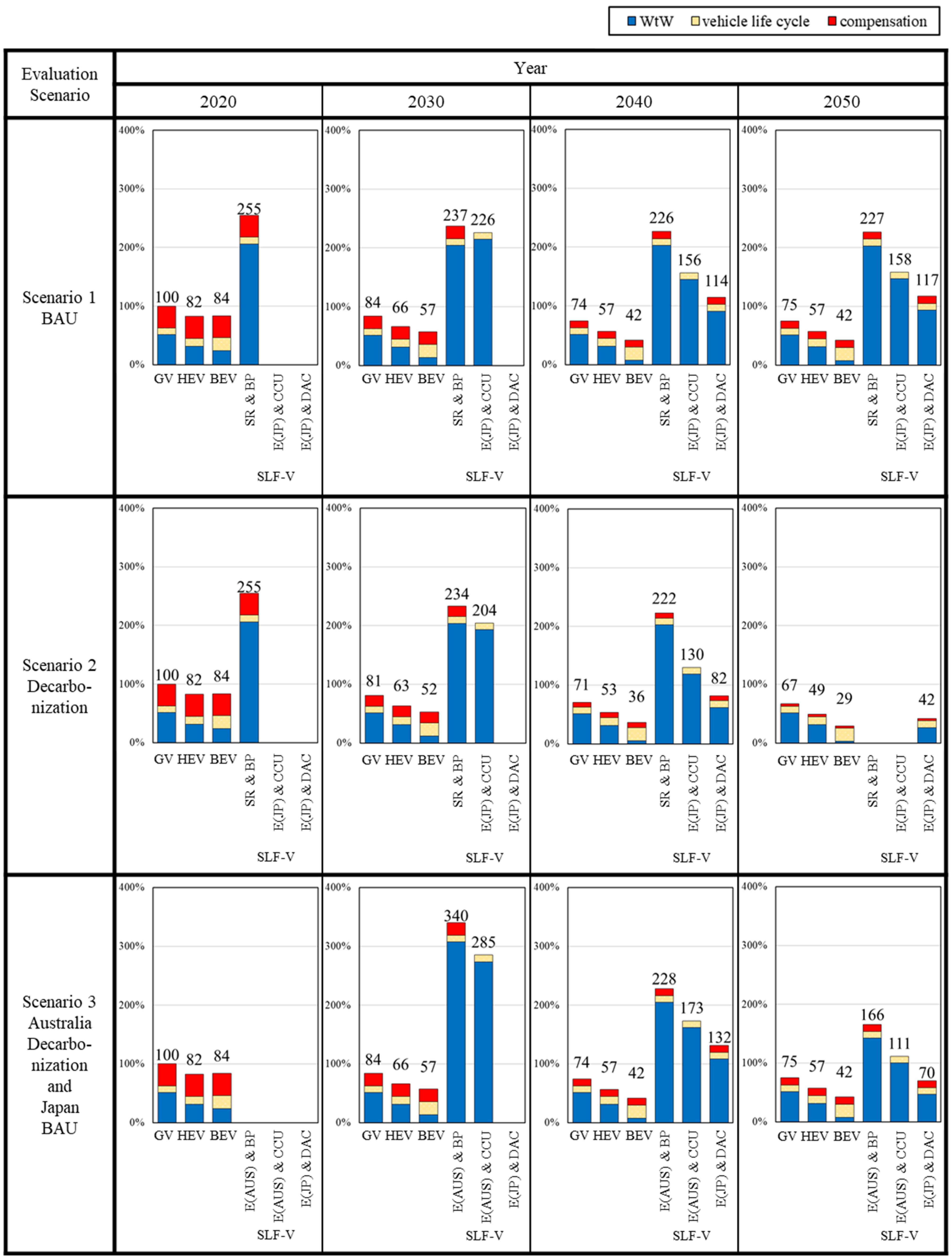

3. Results

4. Discussion

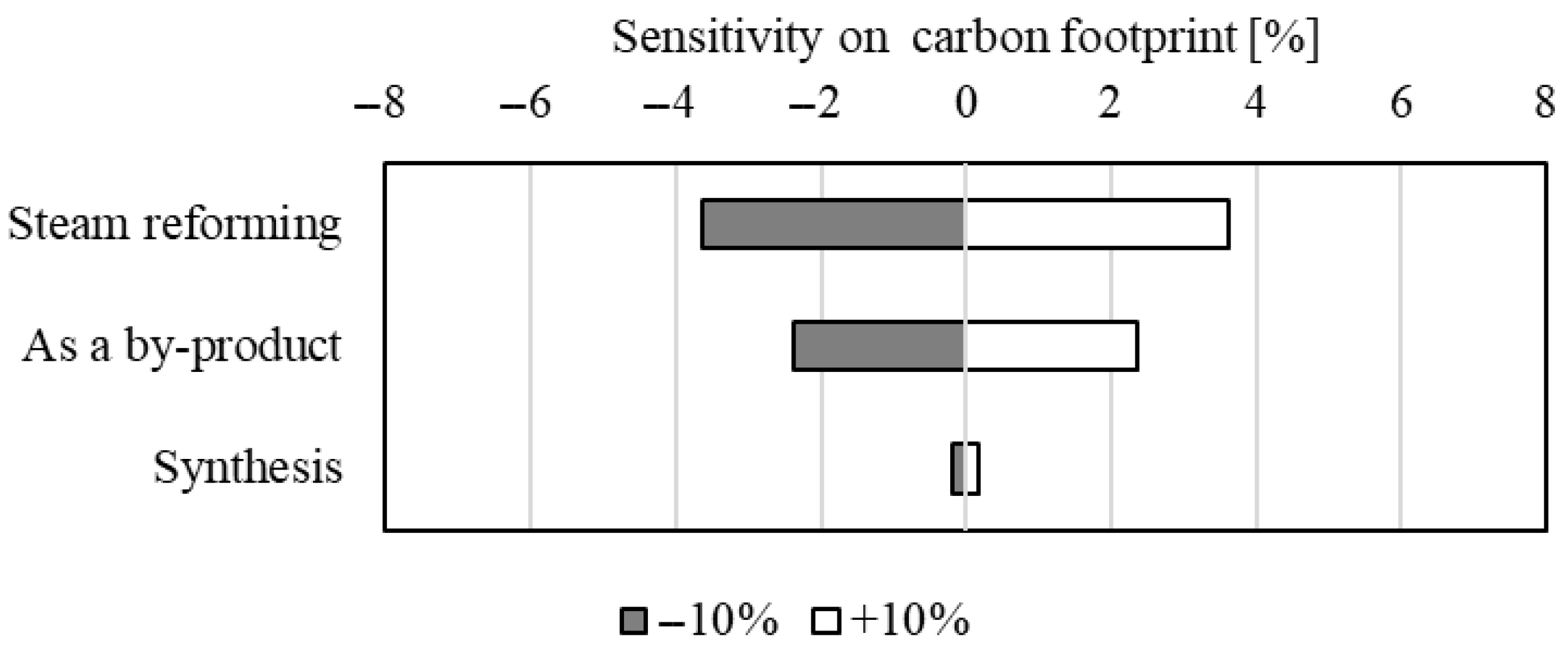

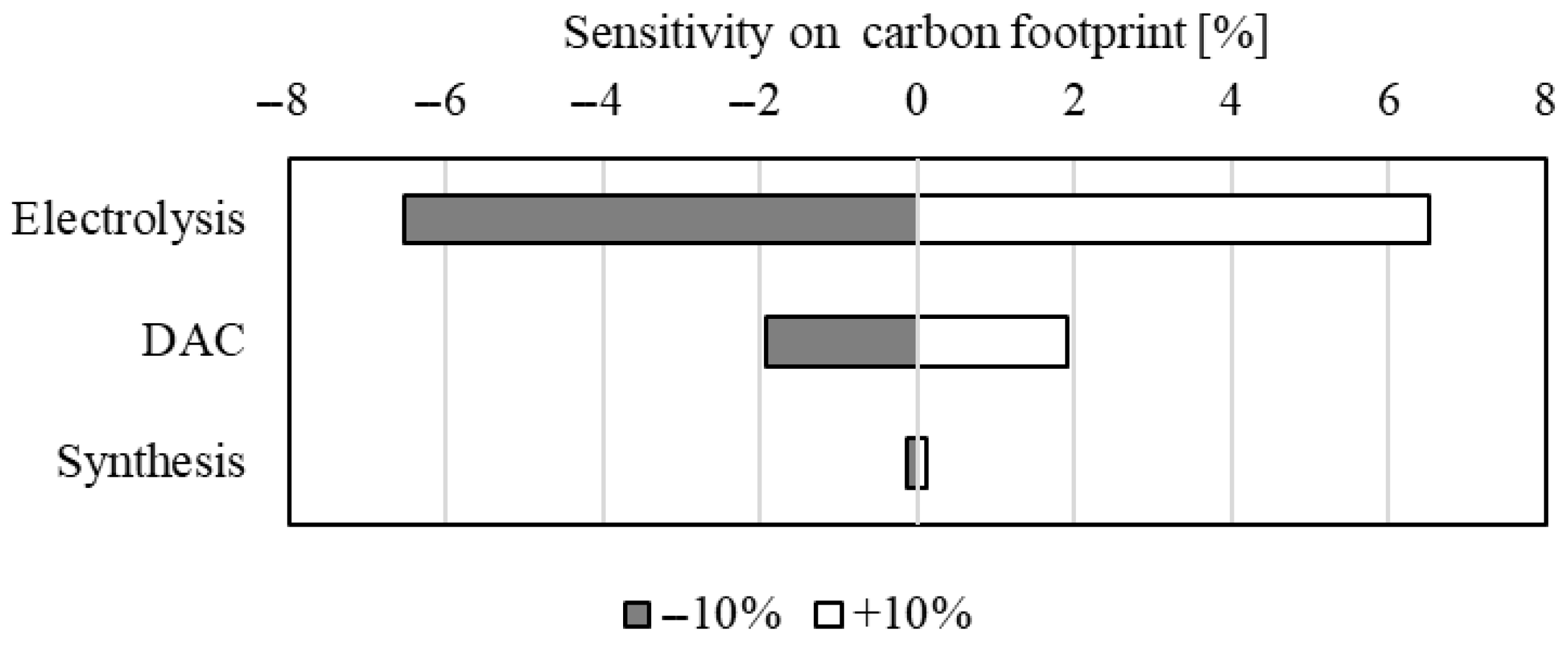

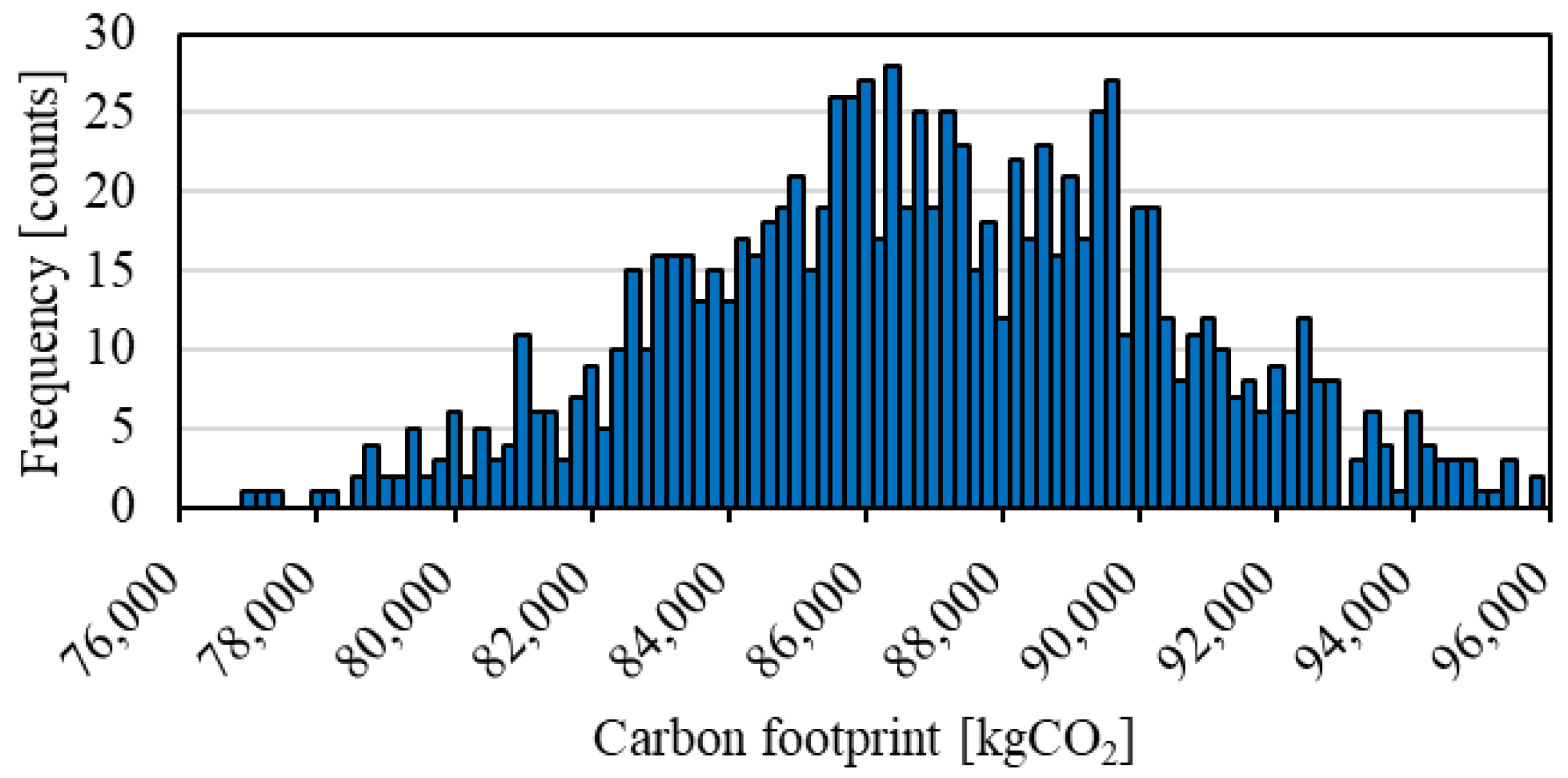

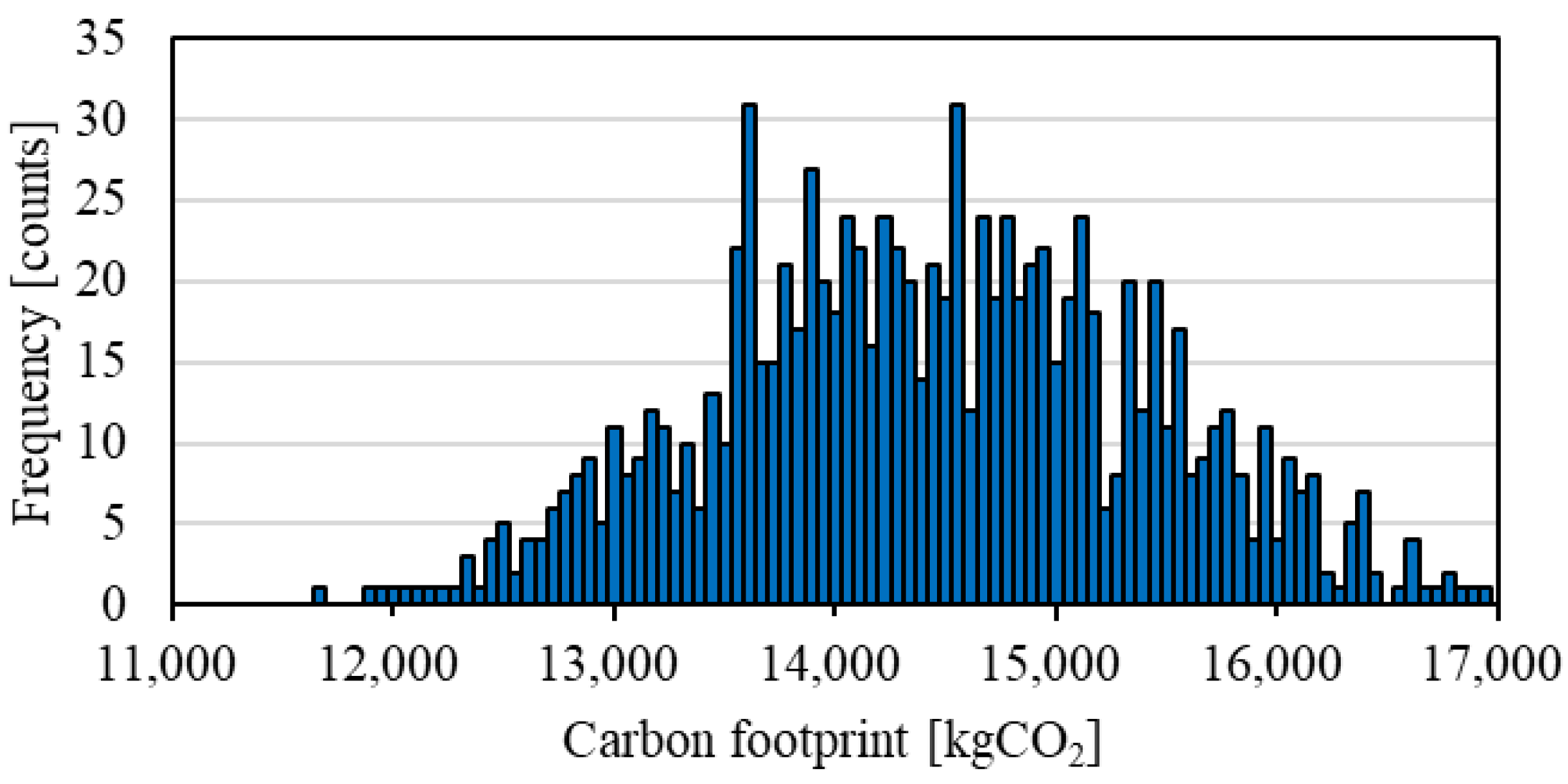

4.1. Sensitivity and Uncertainty Analyses

- Case 1.

- The 2020 SLF-Vs under the BAU scenario. The H2 production technology is steam reforming, and the CO2 production technology is as a by-product.

- Case 2.

- The 2050 SLF-Vs under the decarbonization scenario. The H2 production technology is electrolysis conducted in Japan, and the CO2 production technology is DAC.

4.2. Significance and Limitations

4.3. Future Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SLF-V | Synthetic liquid fuel vehicle |

| GV | Gasoline vehicle |

| HEV | Hybrid electric vehicle |

| BEV | Battery electric vehicle |

| ICEV | Internal combustion engine vehicle |

| TtW | Tank-to-wheel |

| WtT | Well-to-tank |

| WtW | Well-to-wheel |

| FT | Fischer–Tropsch |

| LCA | Life-cycle assessment |

| DAC | Direct air capture |

| CCU | Carbon capture and utilization |

| BAU | Business as usual |

References

- Lee, H.; Calvin, K.; Dasgupta, D.; Krinner, G.; Mukherji, A.; Thorne, P.; Trisos, C.; Romero, J.; Aldunce, P.; Barret, K. IPCC, 2023: Climate Change 2023: Synthesis Report, Summary for Policymakers. Contribution of Working Groups I, II and III to the Sixth Assessment Report on Climate Change on Governmental Panel of the Sixth Assessment Report; Core Writing Team, Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland, 2023. [Google Scholar]

- EDGAR. GHG Emissions of All World Countries—Report 2024; Publications Office of the European Union: Luxembourg, 2024. [Google Scholar]

- IEA. What Are the Main Sources of Global CO2 Emissions? Available online: https://www.iea.org/world/emissions#what-are-the-main-sources-of-global-co2-emissions/ (accessed on 28 July 2025).

- Knobloch, F.; Hanssen, S.V.; Lam, A.; Pollitt, H.; Salas, P.; Chewpreecha, U.; Huijbregts, M.A.J.; Mercure, J.-F. Net emission reductions from electric cars and heat pumps in 59 world regions over time. Nat. Sustain. 2020, 3, 437–447. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 emissions of internal combustion engine vehicle and battery electric vehicle using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- METI. Green Growth Strategy Through Achieving Carbon Neutrality in 2050. Available online: https://www.meti.go.jp/english/policy/energy_environment/global_warming/ggs2050/index.html (accessed on 18 July 2025).

- IEA. Global EV Outlook 2020 Entering the Decade of Electric Drive? IEA: Paris, France, 2023. [Google Scholar]

- Hanni, U.E.; Yamamoto, T.; Nakamura, T. An Analysis of Electric Vehicle Charging Intentions in Japan. Sustainability 2024, 16, 1177. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, X.; Sacchi, R.; You, F. Trade-off between critical metal requirement and transportation decarbonization in automotive electrification. Nat. Commun. 2023, 14, 1616. [Google Scholar] [CrossRef]

- Dell’Aversano, S.; Villante, C.; Gallucci, K.; Vanga, G.; Di Giuliano, A. E-fuels: A comprehensive review of the most promising technological alternatives towards an energy transition. Energies 2024, 17, 3995. [Google Scholar] [CrossRef]

- Uddin, M.N.; Wang, F. Fuelling a clean future: A systematic review of Techno-Economic and Life Cycle assessments in E-Fuel Development. Appl. Sci. 2024, 14, 7321. [Google Scholar] [CrossRef]

- METI. 2023/06/23 Carbon Recycling Roadmap Review Committee. 2023. Available online: https://www.meti.go.jp/shingikai/energy_environment/carbon_recycle_rm/pdf/20230623_03.pdf (accessed on 18 July 2025).

- Dieterich, V.; Buttler, A.; Hanel, A.; Spliethoff, H.; Fendt, S. Power-to-liquid via synthesis of methanol, DME or Fischer–Tropsch-fuels: A review. Energy Environ. Sci. 2020, 13, 3207–3252. [Google Scholar] [CrossRef]

- Panzone, C.; Philippe, R.; Chappaz, A.; Fongarland, P.; Bengaouer, A. Power-to-Liquid catalytic CO2 valorization into fuels and chemicals: Focus on the Fischer-Tropsch route. J. CO2 Util. 2020, 38, 314–347. [Google Scholar] [CrossRef]

- Schreiber, A.; Troy, S.; Weiske, S.; Samsun, R.C.; Peters, R.; Zapp, P.; Kuckshinrichs, W. Comparative well-to-tank life cycle assessment of methanol, dimethyl ether, and oxymethylene dimethyl ethers via the power-to-liquid pathway. J. CO2 Util. 2024, 82, 102743. [Google Scholar] [CrossRef]

- Hänggi, S.; Elbert, P.; Bütler, T.; Cabalzar, U.; Teske, S.; Bach, C.; Onder, C. A review of synthetic fuels for passenger vehicles. Energy Rep. 2019, 5, 555–569. [Google Scholar] [CrossRef]

- van der Giesen, C.; Kleijn, R.; Kramer, G.J. Energy and Climate Impacts of Producing Synthetic Hydrocarbon Fuels from CO2. Environ. Sci. Technol. 2014, 48, 7111–7121. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.M.; Sandhu, N.K.; McCoy, S.T.; Bergerson, J.A. A life cycle assessment of greenhouse gas emissions from direct air capture and Fischer–Tropsch fuel production. Sustain. Energy Fuels 2020, 4, 3129–3142. [Google Scholar] [CrossRef]

- Delgado, H.E.; Cappello, V.; Zang, G.; Sun, P.; Ng, C.; Vyawahare, P.; Elgowainy, A.A.; Wendt, D.S.; Boardman, R.D.; Marcinkoski, J. Techno-economic analysis and life cycle analysis of e-fuel production using nuclear energy. J. CO2 Util. 2023, 72. [Google Scholar] [CrossRef]

- Hombach, L.E.; Doré, L.; Heidgen, K.; Maas, H.; Wallington, T.J.; Walther, G. Economic and environmental assessment of current (2015) and future (2030) use of E-fuels in light-duty vehicles in Germany. J. Clean. Prod. 2019, 207, 153–162. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Wang, M. Technoeconomic and Life Cycle Analysis of Synthetic Methanol Production from Hydrogen and Industrial Byproduct CO2. Environ. Sci. Technol. 2021, 55, 5248–5257. [Google Scholar] [CrossRef]

- Richter, S.; Braun-Unkhoff, M.; Hasselwander, S.; Haas, S. Evaluation of the Applicability of Synthetic Fuels and Their Life Cycle Analyses. Energies 2024, 17, 981. [Google Scholar] [CrossRef]

- Sacchi, R.; Bauer, C.; Cox, B.; Mutel, C. When, where and how can the electrification of passenger cars reduce greenhouse gas emissions? Renew. Sustain. Energy Rev. 2022, 162, 112475. [Google Scholar] [CrossRef]

- Luo, L.; Wang, H.; Li, C.; Hu, Y. Life cycle assessment of methanol vehicles from energy, environmental and economic perspectives. Energy Rep. 2022, 8, 5487–5500. [Google Scholar] [CrossRef]

- Cabinet Secretariat. Growth Strategy Meeting (6th). Green Growth Strategy for Carbon Neutrality by 2050; Japan’s Ministry of Economy, Trade and Industry (METI): Tokyo, Japan, 2020. Available online: https://www.cas.go.jp/jp/seisaku/seicho/seichosenryakukaigi/dai6/siryou1.pdf (accessed on 18 July 2025).

- ANRE. How to Produce Hydrogen, the Next Generation Energy Source? 2021. Available online: https://www.enecho.meti.go.jp/about/special/johoteikyo/suiso_tukurikata.html (accessed on 18 July 2025).

- JIMGA. How Carbon Dioxide Is Produced. 2024. Available online: https://www.jimga.or.jp/gas/produce_co2/ (accessed on 18 July 2025).

- JETRO. Survey on the Hydrogen Industry in Australia. 2021. Available online: https://www.jetro.go.jp/world/reports/2021/01/82b3276826014c69.html (accessed on 18 July 2025).

- ISO 14040: 2006; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Wiedmann, T.; Minx, J. A definition of ‘carbon footprint’. Ecol. Econ. Res. Trends 2008, 1, 1–11. [Google Scholar]

- Schmidt, H.J. Carbon footprinting, labelling and life cycle assessment. Int. J. Life Cycle Assess. 2009, 14 (Suppl. S1), 6–9. [Google Scholar] [CrossRef]

- Bisinella, V.; Christensen, T.H.; Astrup, T.F. Future scenarios and life cycle assessment: Systematic review and recommendations. Int. J. Life Cycle Assess. 2021, 26, 2143–2170. [Google Scholar] [CrossRef]

- van der Giesen, C.; Cucurachi, S.; Guinée, J.; Kramer, G.J.; Tukker, A. A critical view on the current application of LCA for new technologies and recommendations for improved practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Fukushima, Y.; Hirao, M. A structured framework and language for scenario-based Life Cycle assessment. Int. J. Life Cycle Assess. 2002, 7, 317–329. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Environmental implications of large-scale adoption of wind power: A scenario-based life cycle assessment. Environ. Res. Lett. 2011, 6, 045102. [Google Scholar] [CrossRef]

- Rossi, F.; Zuffi, C.; Parisi, M.L.; Fiaschi, D.; Manfrida, G. Comparative scenario-based LCA of renewable energy technologies focused on the end-of-life evaluation. J. Clean. Prod. 2023, 405, 136931. [Google Scholar] [CrossRef]

- Kosamia, N.; Sanchez, A.; Rakshit, S. Scenario-based life cycle assessment and environmental monetary valuation of biosuccinic acid production from lignocellulosic biomass. Ind. Crop. Prod. 2023, 202, 117101. [Google Scholar] [CrossRef]

- von der Assen, N.; Jung, J.; Bardow, A. Life-cycle assessment of carbon dioxide capture and utilization: Avoiding the pitfalls. Energy Environ. Sci. 2013, 6, 2721–2734. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2012, 17, 53–64. [Google Scholar] [CrossRef]

- METI. Energy Supply and Demand Performance for Fiscal Year 2021 (Final Report). 2023. Available online: https://www.meti.go.jp/press/2023/04/20230421001/20230421001-1.pdf (accessed on 18 July 2025).

- Our World in Data. Australia: Energy Country Profile. 2023. Available online: https://ourworldindata.org/energy/country/australia (accessed on 18 July 2025).

- APEC. APEC Energy Demand and Supply Outlook 8th Edition 2022. Available online: https://view.officeapps.live.com/op/view.aspx?src=https%3A%2F%2Faperc.or.jp%2Ffile%2F2022%2F9%2F27%2FAPEC_Outlook_8th_Edition-Appendix.xlsx&wdOrigin=BROWSELINK (accessed on 18 July 2025).

- Mizuho Information & Research Institute, Inc. Research on Life Cycle Assessment of Stationary Fuel Cell Systems and Fuel Cell Vehicles; Mizuho Information & Research Institute, Inc.: Tokyo, Japan, 2008. [Google Scholar]

- Kosai, S.; Matsui, K.; Matsubae, K.; Yamasue, E.; Nagasaka, T. Natural resource use of gasoline, hybrid, electric and fuel cell vehicles considering land disturbances. Resour. Conserv. Recycl. 2021, 166, 105256. [Google Scholar] [CrossRef]

- AIST. LCI database IDEA version 2.3. 2020. Available online: https://sumpo.or.jp/consulting/lca/idea/ (accessed on 18 July 2025).

- CRIEPI. Hydrogen/Ammonia Power Generation Costs and Thermal Power Generation Costs with CCS. 2022. Available online: https://www.meti.go.jp/shingikai/energy_environment/ccs_choki_roadmap/pdf/002_03_00.pdf (accessed on 18 July 2025).

- CRIEPI. Comprehensive Assessment of Life Cycle CO2 Emissions from Power Generation Technologies in Japan. 2016. Available online: https://criepi.denken.or.jp/hokokusho/pb/reportDownload?reportNoUkCode=Y06&tenpuTypeCode=30&seqNo=1&reportId=871 (accessed on 18 July 2025).

- Concawe. E-Fuels: A Technoeconomic Assessment of European Domestic Production and Imports Towards 2050. 2022. Available online: https://www.concawe.eu/wp-content/uploads/Rpt_22-17.pdf (accessed on 18 July 2025).

- JWBA. GHG Emissions from Wood Biomass Power Generation Using Domestic Timber. 2022. Available online: https://www.meti.go.jp/shingikai/enecho/shoene_shinene/shin_energy/biomass_sus_wg/pdf/012_03_00.pdf (accessed on 18 July 2025).

- Dresp, S.; Dionigi, F.; Klingenhof, M.; Strasser, P. Direct electrolytic splitting of seawater: Opportunities and challenges. ACS Energy Lett. 2019, 4, 933–942. [Google Scholar] [CrossRef]

- ASTM D7566-23b; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM International: West Conshohocken, PA, USA, 2023. Available online: https://www.astm.org/ (accessed on 3 August 2025).

- Ueckerdt, F.; Bauer, C.; Dirnaichner, A.; Everall, J.; Sacchi, R.; Luderer, G. Potential and risks of hydrogen-based e-fuels in climate change mitigation. Nat. Clim. Change 2021, 11, 384–393. [Google Scholar] [CrossRef]

- Kumazawa, T.; Kobayashi, H. A simulation system to support the establishment of circulated business. Adv. Eng. Informatics 2006, 20, 127–136. [Google Scholar] [CrossRef]

- Umeda, Y.; Nonomura, A.; Tomiyama, T. Study on life-cycle design for the post mass production paradigm. Artif. Intell. Eng. Des. Anal. Manuf. 2000, 14, 149–161. [Google Scholar] [CrossRef]

| This Study | Sacchi et al. [23] | Schreiber et al. [15] | |

|---|---|---|---|

| Scope of Evaluation | Vehicle life cycle (manufacturing, usage, disposal/recycling). The usage phases encompasses both WtT and TtW. | Vehicle life cycle (manufacturing, usage, disposal/recycling, road). The encompasses both WtT and TtW. | WtT. |

| Target Vehicle Types | SLF-V (body/engine same as GV), GV, HEV, and BEV. | BEV and HEV (fossil gasoline and synthetic gasoline). | N/A (focus on fuel production). |

| Target Country | Japan. (H2 import from Australia in one scenario) | European countries, Brazil, China, India, Japan, and the United States. | Germany. |

| H2 Production Technology | Steam reforming, electrolysis (JP) and electrolysis (AUS) | Electrolysis | Electrolysis |

| CO2 Production Technology | By-product, CCU and DAC | DAC | CCU |

| Availability of each technology | Considered. | Not Considered. | Not Considered. |

| Fuel Synthesis Processes | FT synthesis. | Methanol to gasoline. | Methanol, dymethyl ether, and oxymethylene dimethyl ether. |

| Electricity Power Mixes | ”Japan’s BAU”, “Decarbonization”, and “Australia decarbonization and Japan BAU” scenarios (2020–2050). | Electricity mix in climate scenarios of “2 °C” and “3.5 °C” in each target country (2020–2050). | German electricity mixes (2021, 2030), and wind power. |

| Functional Unit | Life-cycle of one vehicle with a driving distance of 150,000 km and 23,635 kWh of power production (System Power Production). | GHG emissions per kilometer driven. | Supply of 1 L diesel-equivalent and 3.53 kWh of power production (System expansion). |

| Driving Distance in use phase | 150,000 km. | 200,000 km. | N/A (WtT scope). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamada, G.; Murata, H.; Kobayashi, H. Scenario-Based Carbon Footprint of a Synthetic Liquid Fuel Vehicle. Sustainability 2025, 17, 7500. https://doi.org/10.3390/su17167500

Yamada G, Murata H, Kobayashi H. Scenario-Based Carbon Footprint of a Synthetic Liquid Fuel Vehicle. Sustainability. 2025; 17(16):7500. https://doi.org/10.3390/su17167500

Chicago/Turabian StyleYamada, Gakuto, Hidenori Murata, and Hideki Kobayashi. 2025. "Scenario-Based Carbon Footprint of a Synthetic Liquid Fuel Vehicle" Sustainability 17, no. 16: 7500. https://doi.org/10.3390/su17167500

APA StyleYamada, G., Murata, H., & Kobayashi, H. (2025). Scenario-Based Carbon Footprint of a Synthetic Liquid Fuel Vehicle. Sustainability, 17(16), 7500. https://doi.org/10.3390/su17167500