Unlocking Circularity in Construction via Agile Methods and BIM

Abstract

1. Introduction

- How can CE, APM, and BIM be jointly applied in SME-led construction projects?

- What barriers arise in practice, and how do they manifest within EU/Mediterranean contexts?

- How can empirical insights inform a practical framework for SMEs?

2. Literature Review

2.1. CE and BIM Integration

2.2. APM and CE Synergies

2.3. BIM and APM: Technology Adoption and ERP Lessons

2.4. Current Gaps in Integrated CE–APM–BIM Approaches

- Resource-Based View: highlighting BIM’s role as a strategic digital resource enabling SME competitive advantage and sustainability transitions.

- Agile Management Theory: emphasizing iterative adaptability and responsiveness essential for dynamic circular economy practices.

- Systems Theory: underpinning the holistic integration of CE principles with digital and managerial methodologies to address systemic sustainability challenges.

3. Research Design and Methodology

3.1. Research Strategy and Data Sources

3.2. Survey Design and Execution

- Awareness and implementation of CE principles;

- Capacity for digital tools and BIM;

- Organizational agility and APM.

3.3. Analytical Approach and Ethical Considerations

4. Results

4.1. BLOOM Analysis

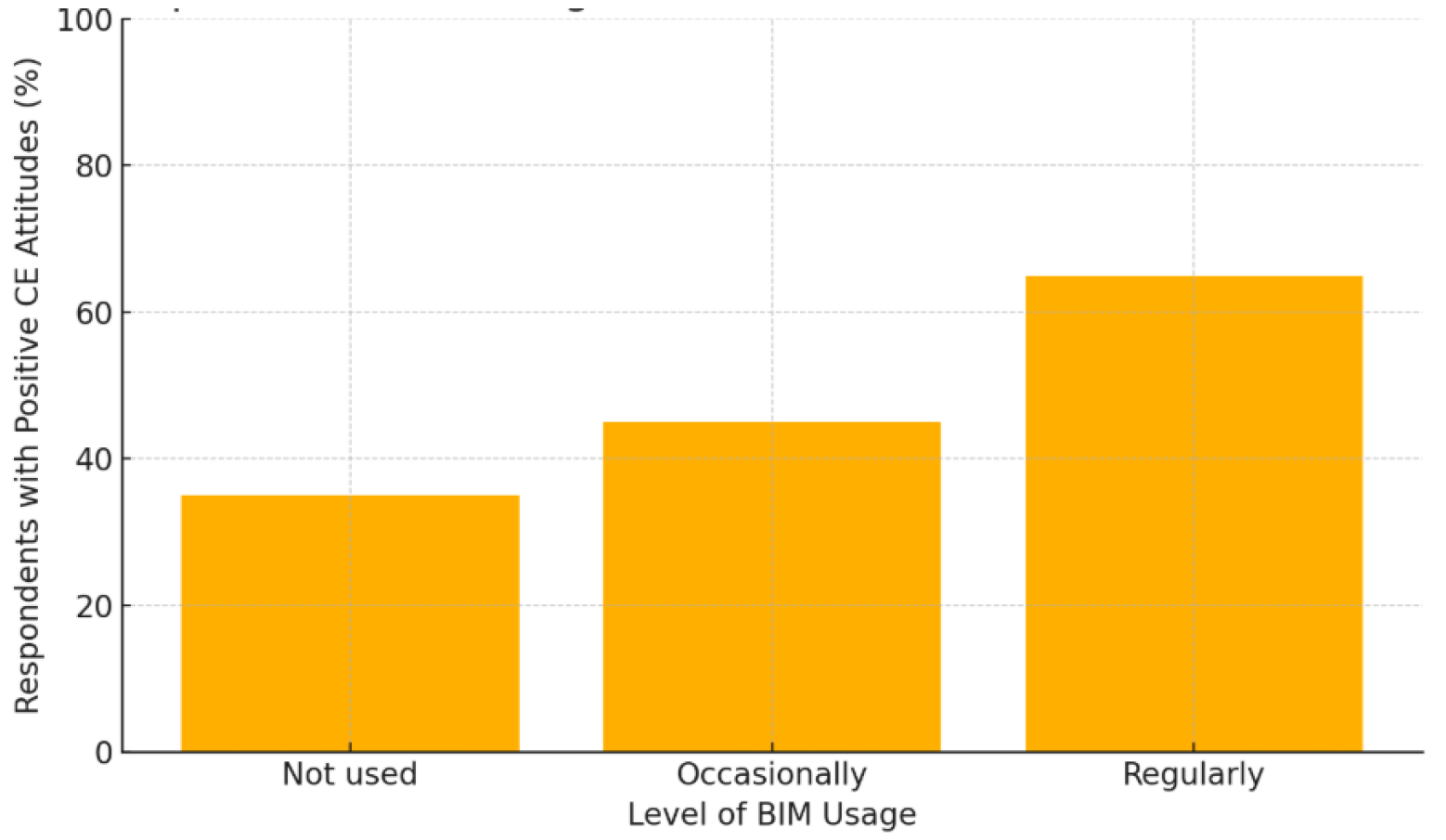

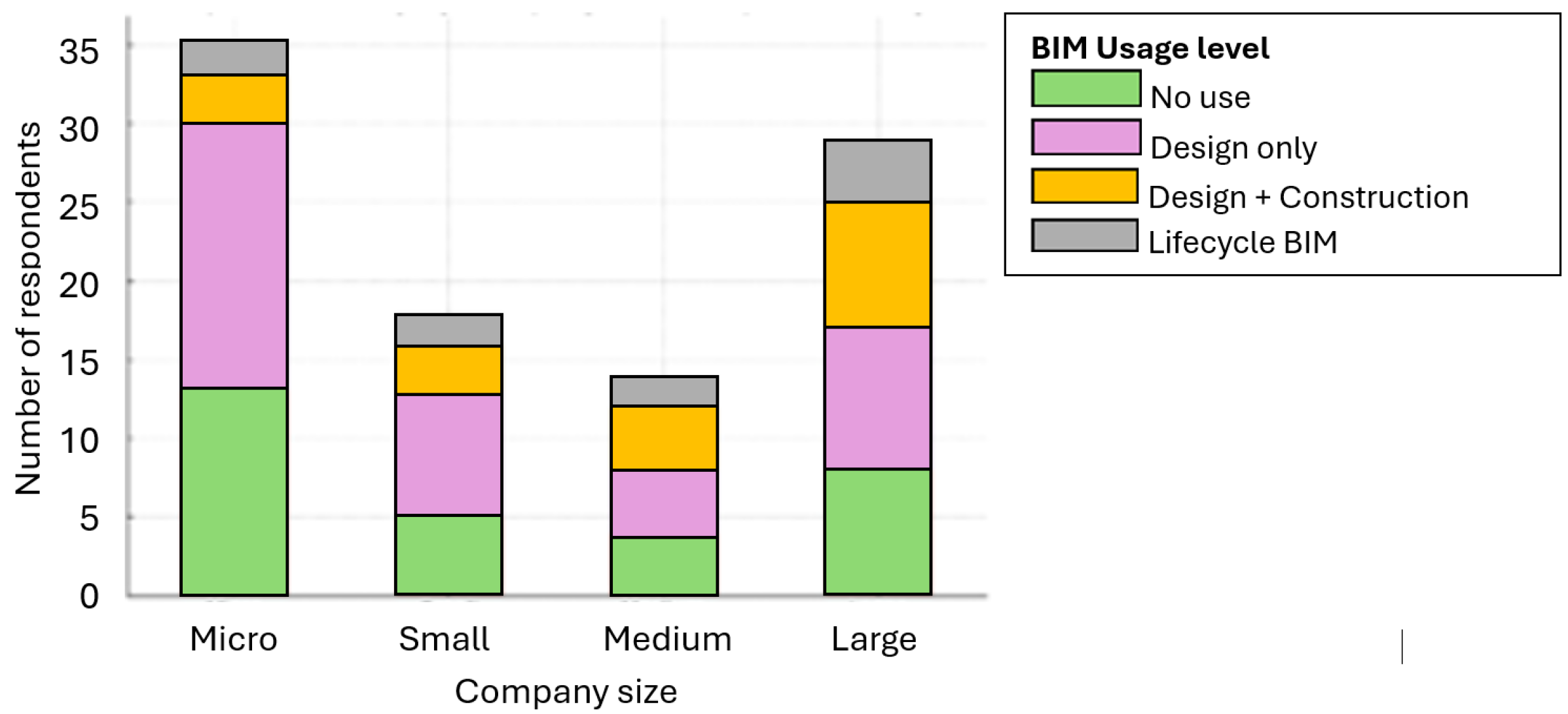

4.2. CE-APM-BIM Survey Findings

5. Discussion

- Accessible tools that simplify CE–BIM–APM application in real projects;

- Targeted, hands-on training rooted in practical scenarios and regional realities;

- A transparent regulatory framework that reduces uncertainty and aligns procurement criteria with CE goals;

- Pilot projects and demonstration sites that showcase feasible, scalable models of circular construction.

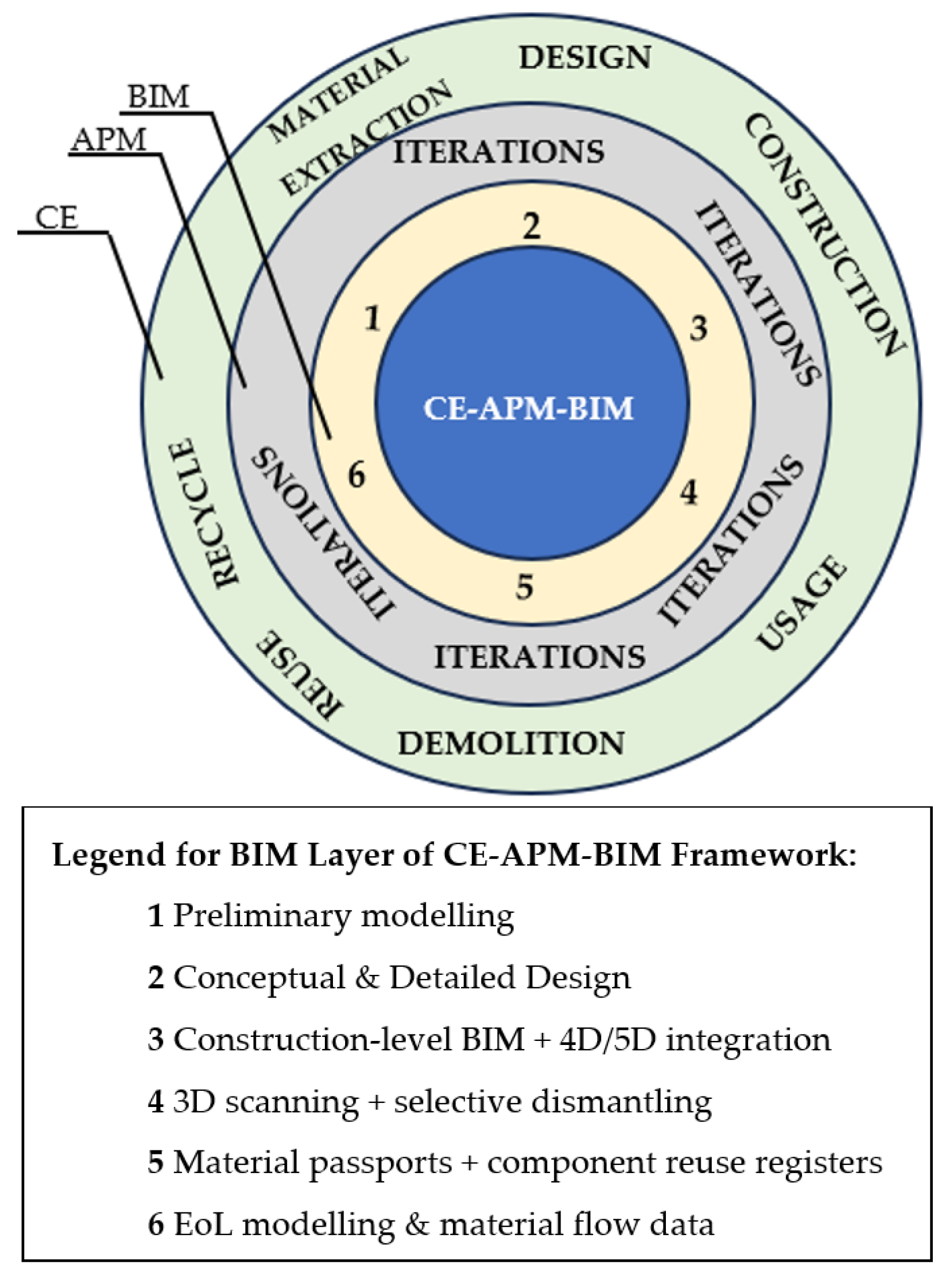

6. The CE-APM-BIM Integration Framework

- Strategy—embeds CE into organizational vision and business models.

- Processes with Methodology—operationalizing CE through agile project delivery, BIM-enabled workflows, and lean construction tools.

- Technology with Digital Infrastructure—deploys digital enablers (e.g., 4D/5D BIM, material passports, digital twins) to support circular data management and collaboration.

- Capabilities with Culture—fostering a multidisciplinary, empowered, and learning-oriented workforce through targeted training and inclusive governance.

- Governance with Policy—embedding CE criteria into procurement, aligning projects with regulatory mandates, and ensuring transparency through KPIs and performance feedback mechanisms.

- Material extraction: Iterative cycles involve evaluating alternative material sourcing strategies with lower environmental impact, integrating simulations of secondary material availability, and aligning with material passports through BIM platforms. Agile methods facilitate rapid testing of different procurement and reuse scenarios.

- Design: Iterations in the design phase are supported by BIM-enabled parametric modelling (e.g., 4D/5D BIM), which fosters real-time collaboration between architects, engineers, and contractors. Agile sprints promote rapid testing of CE strategies such as modularity, disassembly potential, and design for adaptability.

- Construction: During construction, iterative adjustments are driven by digital monitoring tools that enable real-time optimization of workflows. BIM models are updated continuously, and agile coordination ensures flexibility in execution plans as materials, site conditions, or CE constraints evolve.

- Usage: Iterations in the usage phase relate to continuous performance monitoring via digital twins and sensor-based systems. Feedback from building operation informs maintenance strategies aimed at extending the lifecycle of components and systems, in alignment with CE principles.

- Reuse: BIM models, enriched during the usage phase, enable identification of elements suitable for disassembly and reuse. Iterative cycles here involve feasibility assessments, market alignment, and logistic planning for the reintegration of components into new value chains.

- End of life (EoL: demolition, recycle, reuse): In the final phase, iterative assessments support decisions around selective demolition, sorting strategies, and material recovery optimization. BIM facilitates data-driven material inventories, while agile principles ensure adaptive decision making in response to site conditions and regulatory factors.

7. Conclusions

- Invest in targeted, hands-on training for BIM and agile management, tailored to real project environments.

- Initiate pilot projects applying circular principles and agile workflows, leveraging BIM for material tracking and performance measurement.

- Participate in peer-learning networks and regional hubs to exchange best practices and digital solutions.

- Engage with policymakers to promote the inclusion of CE criteria in procurement and regulatory frameworks.

- Leverage funding and incentive programs for digital and circular innovation, focusing on technology acquisition and workforce upskilling.

Limitations and Future Work

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEC | Architecture, Engineering and Construction |

| APM | Agile Project Management |

| BIM | Building Information Modelling |

| BLOOM | Project acronym: empowering construction SMEs for the circular economy; supported by the Norway Grants 2014–2021 under the Business Development and Innovation Croatia Programme |

| CDW | Construction and Demolition Waste |

| CE | Circular Economy |

| DfMA | Design for Manufacture and Assembly |

| EEA | European Economic Area |

| EoL | End of Life |

| ERP | Enterprise Resource Planning |

| ESG | Environmental, Social and Governance |

| EU | European Union |

| FF&E | Furniture, Fixtures and Equipment |

| IEA | International Energy Agency |

| ISO | International Organization for Standardization |

| KPI | Key Performance Indicator |

| LCA | Lifecycle Assessment |

| Minergie-ECO | Swiss building sustainability certification standard combining energy efficiency and ecological quality |

| RhinoCircular | A design tool for real-time circularity feedback based on Rhino/Grasshopper platform |

| SME | Small- and Medium-sized Enterprise |

| UNEP | United Nations Environment Programme |

References

- UNEP. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2022; Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 14 May 2025).

- IEA. Buildings: Tracking Clean Energy Progress; International Energy Agency: Paris, France, 2023; Available online: https://www.iea.org/reports/buildings (accessed on 23 May 2025).

- European Commission. The European Green Deal. COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 3 June 2025).

- European Commission. Circular Economy Action Plan: For a Cleaner and More Competitive Europe. COM(2020) 98 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 10 May 2025).

- European Commission. A Renovation Wave for Europe—Greening our Buildings, Creating Jobs, Improving Lives. COM(2020) 662 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0662 (accessed on 28 May 2025).

- European Commission. EU Taxonomy for Sustainable Activities; European Commission: Brussels, Belgium, 2021; Available online: https://finance.ec.europa.eu/sustainable-finance/tools-and-standards/eu-taxonomy-sustainable-activities_en (accessed on 17 June 2025).

- González, M.J.; García Navarro, J.; Mainini, A.G. BIM-based circular strategies for design and construction: A systematic review. Buildings 2022, 12, 339. [Google Scholar] [CrossRef]

- Kim, J.; Park, J.; Lee, S. Integration of BIM and material passports for circular construction: A case study. Buildings 2023, 13, 297. [Google Scholar] [CrossRef]

- Denicol, J.; Davies, A.; Krystallis, I. What are the causes and cures of poor megaproject performance? A systematic literature review and research agenda. Proj. Manag. J. 2020, 51, 328–345. [Google Scholar] [CrossRef]

- Vourc’h, A.; Sgaravatto, B.; Zimmermann, E. SMEs and Circular Economy: What Do We Know? A Literature Review. Buildings 2022, 12, 2106. [Google Scholar] [CrossRef]

- Eurostat. Generation of Waste by Economic Activity and Households; Eurostat: Luxembourg, 2023; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 19 June 2025).

- EEA and Norway Grants. The final conference of the BLOOM project: ’Circular Economy in Construction’; University of Zagreb Faculty of Civil Engineering: Zagreb, Croatia, 9 April 2024; Available online: https://www.grad.unizg.hr/en/news?@=2b1et (accessed on 18 June 2025).

- Martens, B.; Aelenei, D.; Silva, S.M. Agile BIM-based platform to support material reuse in circular construction. Sustainability 2022, 14, 13208. [Google Scholar] [CrossRef]

- Bjørberg, S.; Temeljotov Salaj, A. Development of a New Standard for Evaluation of Sustainable Refurbishment. Facilities 2023, 41, 372–388. [Google Scholar] [CrossRef]

- Koskela, L.; Howell, G. The underlying theory of project management is obsolete. In Proceedings of the PMI Research Conference, Seattle, Washington, USA, 14–17 July 2002; pp. 293–302. [Google Scholar]

- Enembreck, F.; Veras, A.L.M.; Sato, L.M.; Graciolli, O.D. Agile frameworks in circular built environments: Theoretical intersections and practice-led challenges. Sustainability 2024, 16, 1235. [Google Scholar] [CrossRef]

- Underwood, J.; Shelbourn, M.; Fleming, A.; Heywood, J.; Roberts, I. Streamlining a Design, Manufacture, and Fitting Workflow Within a UK Fit-Out SME: A BIM Implementation Case Study; IGI Global: Hershey, PA, USA, 2018; pp. 242–266. [Google Scholar] [CrossRef]

- Naneva, A. greenBIM, a BIM-based LCA integration using a circular approach based on the example of the Swiss sustainability standard Minergie-ECO. E3S Web Conf. 2022, 349, 10002. [Google Scholar] [CrossRef]

- Heisel, F.; McGranahan, J. Enabling Design for Circularity with Computational Tools; Springer Nature: Cham, Switzerland, 2024; pp. 97–110. [Google Scholar] [CrossRef]

- Kuzminykh, A.; Granja, J.; Parente, M.; Azenha, M. Promoting circularity of construction materials through demolition digitalisation at the preparation stage: Information requirements and openBIM-based technological implementation. Adv. Eng. Inform. 2024, 62, 102755. [Google Scholar] [CrossRef]

- Cruz, V.F.; Góes, T.M. Contribuição do BIM para o desenvolvimento da Economia Circular no ambiente construído: Uma revisão sistemática da literatura. Cad. Arquitetura Urban. 2021, 30, 1–17. [Google Scholar] [CrossRef]

- Jiang, L.; van den Berg, M.; Voordijk, H.; Adriaanse, A. Circularity assessment across construction project phases with Building Information Modelling. Dev. Built Environ. 2025, 22, 100663. [Google Scholar] [CrossRef]

- Kakkos, E.; Hischier, R. Paving the way towards circularity in the building sector. Empa’s Sprint Unit as a beacon of swift and circular construction. IOP Conf. Ser. 2022, 1078, 012009. [Google Scholar] [CrossRef]

- Ünal, E.; Ünal, E.; Urbinati, A.; Chiaroni, D.; Manzini, R. Value creation in circular business models: The case of a US small medium enterprise in the building sector. Resour. Conserv. Recycl. 2019, 146, 291–307. [Google Scholar] [CrossRef]

- Enembreck, F.L.P.; do Carmo Duarte Freitas, M.; Bragança, L.; Tavares, S.F. Potential Synergy Between Agile Management and the Mindset of Circular Economy in Construction Projects; Springer Nature: Cham, Switzerland, 2023; pp. 239–248. [Google Scholar] [CrossRef]

- Mamoghli, S.; Cassivi, L. Agile ERP Implementation: The Case of a SME. In Proceedings of the International Conference on Enterprise Information Systems (ICEIS), Heraklion, Crete, Greece, 3–5 May 2019; pp. 188–196. [Google Scholar] [CrossRef]

- Ribeiro, F.L.; Fernandes, M.T. Exploring agile methods in construction small and medium enterprises: A case study. J. Enterp. Inf. Manag. 2010, 23, 161–180. [Google Scholar] [CrossRef]

- Chai, C.; Tang, J.T.; Chan, S.; Lee, C.; Goh, K. BIM integration in Agile Scrum during the design phase. J. Eng. Sci. Technol. 2022, 4, 302–316. [Google Scholar]

- Omar, N. Enhancing Agile Application in Construction Projects Using BIM. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 2022. [Google Scholar]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Saka, A.B.; Chan, D.W.M.; Siu, F.M.F. Drivers of sustainable adoption of building information modelling (BIM) in the Nigerian construction small and medium-sized enterprises (SMEs). Sustainability 2020, 12, 3710. [Google Scholar] [CrossRef]

- Bosch-Sijtsema, P.; Isaksson, A.; Lennartsson, M.; Linderoth, H. Barriers and facilitators for BIM use among Swedish medium-sized contractors—“We wait until someone tells us to use it”. Vis. Eng. 2017, 5, 179. [Google Scholar] [CrossRef]

- Ahuja, R.; Sawhney, A.; Arif, M. Prioritizing BIM Capabilities of an Organization: An Interpretive Structural Modeling Analysis. Procedia Eng. 2017, 196, 2–10. [Google Scholar] [CrossRef]

- Saka, A.B.; Chan, D.W.M. A Scientometric Review and Metasynthesis of Building Information Modelling (BIM) Research in Africa. Buildings 2019, 9, 85. [Google Scholar] [CrossRef]

- Saka, A.B.; Chan, D.W.M. Profound barriers to building information modelling (BIM) adoption in construction SMEs: An interpretive structural modelling approach. Constr. Innov. 2020, 20, 261–284. [Google Scholar] [CrossRef]

- Pittri, H.; Godawatte, G.A.G.R.; Esangbedo, O.P.; Antwi-Afari, P.; Bao, Z. Exploring barriers to the adoption of digital technologies for circular economy practices in the construction industry in developing countries: A case of Ghana. Buildings 2025, 15, 1090. [Google Scholar] [CrossRef]

- Thirumal, S.; Udawatta, N.; Karunasena, G.; Al-Ameri, R. Barriers to adopting digital technologies to implement circular economy practices in the construction industry: A systematic literature review. Sustainability 2024, 16, 3185. [Google Scholar] [CrossRef]

- Qin, X.; Shi, Y.; Lyu, K.; Mo, Y. Using a TAM-TOE model to explore factors of Building Information Modelling (BIM) adoption in the construction industry. J. Civ. Eng. Manag. 2020, 26, 259–277. [Google Scholar] [CrossRef]

- Edirisinghe, R.; London, K. Comparative Analysis of International and National Level BIM Standardization Efforts and BIM Adoption; CIB W78: London, UK, 2015. [Google Scholar]

- Grassler, M. Circular Economy Good Practices in the Manufacturing Sector: When the Industry Fosters Opportunities to Positively Impact the World. CIRCULOOS Project Blog, 22 January 2024. Available online: https://circuloos.eu/circular-economy-good-practices-in-the-manufacturing-sector-when-the-industry-foster-opportunities-to-positively-impact-the-world/ (accessed on 1 August 2025).

- NBS. National BIM Report; NBS: Mandaluyong, Philippines, 2018. [Google Scholar]

- Marzani, G.; Tondelli, S.; Kuma, Y.; Cruz Rios, F.; Hu, R.; Bock, T.; Linner, T. Embedding Circular Economy in the Construction Sector Policy Framework: Experiences from EU, U.S., and Japan for Better Future Cities. Smart Cities 2025, 8, 48. [Google Scholar] [CrossRef]

- ISO 19650; Organization and Digitization of Information about Buildings and Civil Engineering Works, including Building Information Modelling (BIM) Information Management Using Building Information Modelling. International Organization for Standardization: Geneva, Switzerland, 2018–2023.

- Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings—Parts 1–3; Publications Office of the European Union: Luxembourg, 2020.

- United Nations (UN). Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

| Reference | Focus of the Study | Integration Type | SME Case Included |

|---|---|---|---|

| Underwood et al. (2018) [17] | Lean transformation and BIM in FF&E SME | BIM + Lean + DfMA | ✔ Yes |

| Naneva (2022) [18] | BIM–LCA integration aligned with Minergie-ECO | CE + BIM (LCA) | ✖ No |

| Heisel & McGranahan (2024) [19] | Computational tools and circularity indicators | CE (Design indicators) | ✖ No |

| Kuzminykh et al. (2024) [20] | Digital demolition planning with recyclable material focus | CE + BIM | ✖ No |

| Cruz & Góes (2021) [21] | BIM’s role in CE for built environment | CE + BIM (strategy) | ✖ No |

| Jiang et al. (2025) [22] | BIM-based circularity assessment tool, validated in renovation | CE + BIM (Tool) | ✖ No |

| Kakkos & Hischier (2022) [23] | LCA assessment of modular Sprint unit | CE + LCA | ✖ No |

| Ünal et al. (2019) [24] | Circular business model in US construction SME | CE (Business model) | ✔ Yes (non-EU) |

| Enembreck et al. (2023) [25] | Synergy between agile and circular thinking in construction | APM + CE (Theory) | ✖ No |

| Mamoghli & Cassivi (2019) [26] | Agile ERP implementation in Canadian SME | APM (ERP) | ✔ Yes (non-EU) |

| Ribeiro & Fernandes (2010) [27] | Agile methods in construction SMEs (Portugal) | APM (Practice) | ✔ Yes |

| Chai et al. (2022) [28] | BIM integration in Agile Scrum during design phase | BIM + APM | ✖ No |

| Omar (2022) [29] | Enhancing agile application in construction projects using BIM | BIM + APM | ✖ No |

| Martens et al. (2022) [13] | Agile BIM-based platform for material reuse | BIM + CE + APM | ✖ No |

| Bjørberg & Temeljotov Salaj (2023) [14] | Linking CE and agile principles in facility management | CE + APM | ✖ No |

| Enembreck et al. (2024) [16] | Agile frameworks in circular built environments | APM + CE | ✖ No |

| Denicol et al. (2020) [9] | Agile and project performance in construction | APM | ✖ No |

| Kim et al. (2023) [8] | BIM and material passports for circular construction | CE + BIM | ✖ No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nahod, M.-M. Unlocking Circularity in Construction via Agile Methods and BIM. Sustainability 2025, 17, 7497. https://doi.org/10.3390/su17167497

Nahod M-M. Unlocking Circularity in Construction via Agile Methods and BIM. Sustainability. 2025; 17(16):7497. https://doi.org/10.3390/su17167497

Chicago/Turabian StyleNahod, Maja-Marija. 2025. "Unlocking Circularity in Construction via Agile Methods and BIM" Sustainability 17, no. 16: 7497. https://doi.org/10.3390/su17167497

APA StyleNahod, M.-M. (2025). Unlocking Circularity in Construction via Agile Methods and BIM. Sustainability, 17(16), 7497. https://doi.org/10.3390/su17167497