1. Introduction

The transition toward more sustainable and circular construction practices is a critical challenge in the context of climate change and resource depletion. Traditional building materials, especially ordinary Portland cement (OPC), contribute significantly to global CO2 emissions and are associated with substantial energy consumption and waste generation. Consequently, the search for innovative materials with lower environmental impact has become a research priority and a policy driver, supported at both the European and national levels.

Among the emerging materials, alkali-activated and geopolymer systems have attracted increasing interest due to their ability to valorise industrial by-products and waste rich in aluminosilicates, such as fly ash, slag, ceramic residues, and demolition waste [

1,

2,

3]. These materials are obtained through a chemical activation process that leads to the formation of an amorphous, three-dimensional aluminosilicate network with ceramic-like properties, often achievable at ambient or moderate curing temperatures [

4].

Thanks to their compositional flexibility, geopolymers can be engineered to deliver excellent mechanical strength, thermal and fire resistance, chemical durability, and even acoustic insulation, making them suitable for a broad spectrum of construction applications. Moreover, their compatibility with additive manufacturing and digital design strategies, such as parametric modelling, opens new scenarios for advanced and customised architectural components [

5,

6].

Despite these advantages, several aspects still require further investigation, including the standardisation of precursor materials, long-term durability under real conditions, and the integration of these systems with other traditional or high-performance building materials. Furthermore, the environmental impact of geopolymer-based products must be assessed in terms of raw material sourcing and their full life cycle, recyclability, and adaptability to future uses.

In this review, the state of the art of geopolymer materials for sustainable building design, with a specific focus on prefabricated and customizable panel systems, is critically analysed. The paper explores the chemical, physical, and morphological characteristics of these materials and discusses their integration with design-driven digital tools, aiming to support performance-based and environmentally aware design choices.

2. Raw Materials and Synthesis of Geopolymers

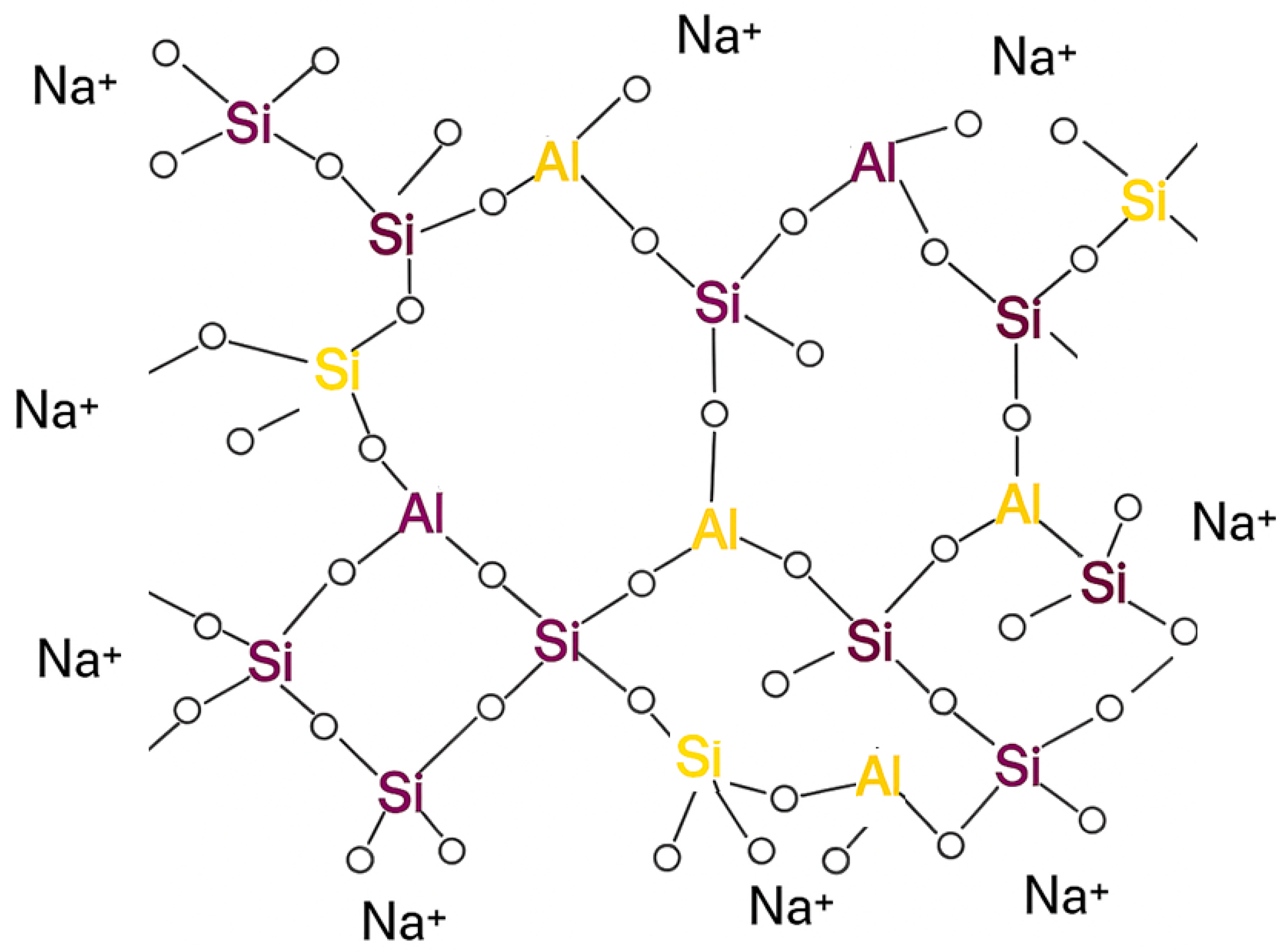

Geopolymers are a class of inorganic binders formed by the chemical activation of aluminosilicate-rich raw materials in highly alkaline environments. Unlike Portland cement, which relies on calcium silicate hydration, geopolymers develop their mechanical strength and cohesion through a polycondensation reaction that produces a three-dimensional amorphous or semi-crystalline aluminosilicate network (see

Figure 1), often designated as N-A-S-H (sodium aluminosilicate hydrate) or C-A-S-H (when calcium is present) [

7,

8].

The choice of raw materials plays a critical role in determining the final properties of geopolymer products. Common precursors include metakaolin, fly ash (class F or C), ground granulated blast furnace slag (GGBFS), ceramic waste, red mud, rice husk ash, and finely ground construction and demolition waste (CDW) [

9,

10]. These materials vary in terms of Si/Al ratio, amorphous content, particle morphology, and impurity levels, all of which influence reactivity and gel structure. Pre-treatment steps such as milling, sieving, and calcination may be required to improve the reactivity of some residues [

11].

In the context of prefabricated geopolymer panels, the synthesis must also consider workability, setting time, dimensional stability, and shrinkage behaviour. This requires optimised mix designs with tailored water-to-solid ratios, activator concentrations, and, in some cases, the use of admixtures (e.g., retarders, plasticisers, air entrainers) [

12].

The use of hybrid precursors, blending reactive ashes with inert fillers or recycled aggregates, can enhance performance while reducing cost and environmental impact [

13].

Curing methods are another key parameter. For panel production, controlled curing regimes (e.g., steam curing, oven curing at 60–80 °C) are often adopted to ensure rapid strength gain and microstructural homogeneity [

14]. When thermal curing is impractical, especially for large-scale production, alternative strategies involving sodium silicate gels or calcium-modified systems (slag-rich) may be employed to promote ambient temperature hardening [

15].

The scalability and processability of geopolymer mixtures make them particularly attractive for casting, extrusion, or 3D printing of architectural panels with complex geometries. In these applications, rheological behaviour and setting kinetics must be carefully balanced to ensure both printability and structural integrity [

16]. The ability to precisely shape fresh material opens new design avenues, where form and function can be seamlessly integrated with sustainability goals [

17].

Furthermore, recent research has demonstrated the feasibility of using fully waste-derived geopolymer systems for architectural panels, achieving both high performance and low carbon footprints. This includes systems based on waste glass powder, tile sludge, biomass ash, and CDW fines, which can be activated with alternative alkali sources such as spent alkaline solutions or industrial effluents, further contributing to resource circularity [

18,

19].

2.1. Synthesis Pathways and Reaction Mechanism

The geopolymerisation process transforms aluminosilicate precursors into a hardened inorganic polymer network via alkaline activation, typically with sodium or potassium hydroxide solutions, with or without silicate modifiers. In the first stage, the alkaline environment dissolves reactive silica (Si) and alumina (Al) species from the precursor, with dissolution rates governed by amorphous content, surface area, and mineralogy (see

Figure 2) [

20,

21].

Dissolved silicate and aluminate monomers then undergo hydrolysis and polycondensation, forming covalent Si–O–Al and Si–O–Si bonds within a three-dimensional gel network—N-A-S-H (sodium aluminosilicate hydrate) or, when calcium is present, C-A-S-H [

22]. This structural evolution depends on the Si/Al ratio, alkali type, and modifiers such as Ca

2+, Mg

2+, or Fe

3+ [

23,

24].

Finally, gelation and hardening occur as the network densifies, water is expelled, and interparticle bonds form. Curing conditions (temperature, humidity, time) control kinetics and properties, with moderate thermal curing (40–80 °C) enhancing reaction rates and uniformity for low-reactivity precursors [

25,

26]. Adjusting parameters such as Si/Al ratio, alkali concentration, activator ratio (SiO

2/Na

2O), and curing regime tailors performance. Reactive calcium sources promote C-A-S-H formation, improving early strength and densification [

27].

2.2. Raw Materials and Mix Design

The selection and formulation of geopolymer precursors are critical in determining the mechanical, chemical, and durability performance of the final product. Raw materials must be rich in amorphous silica (SiO2) and alumina (Al2O3), and capable of undergoing dissolution and polycondensation in alkaline media.

Natural precursors include metakaolin (a thermally treated kaolinite), kaolin, and volcanic tuffs. These materials are prized for their high purity and reactivity, particularly metakaolin, which is widely used in both research and commercial applications due to its well-defined composition and low impurity content. Industrial by-products or waste-derived precursors represent a sustainable alternative and include fly ash (class F and C), which is high in silica and alumina with variable calcium content; ground granulated blast furnace slag (GGBFS), which is calcium-rich and often blended to modify setting and strength; red mud, a by-product of alumina refining rich in iron and alkalis; ceramic waste and tile sludge; rice husk ash, palm ash, and sugarcane bagasse ash from biomass combustion; and construction and demolition waste (CDW), which can be used after fine grinding and, in some cases, thermal activation.

The reactivity of these materials depends on several factors, including the amorphous phase content, particle size distribution, specific surface area, and the presence of inert or interfering elements such as carbonates or iron oxides, which may hinder dissolution and polymerisation processes [

28,

29]. To improve the reactivity and homogenise the precursor, pre-treatment methods such as mechanical grinding, sieving, and, in some cases, thermal activation (calcination) are frequently adopted [

30].

The choice of alkaline activators is also fundamental and generally involves combinations of sodium or potassium hydroxide with sodium or potassium silicate solutions. The activator system influences not only the pH and ionic environment but also the kinetics of dissolution and gel formation. Consequently, the geopolymer mix design must be carefully tuned to achieve a balance between workability, setting kinetics, and mechanical performance. Crucial parameters to control include the Si/Al and Na/Si molar ratios, the solid-to-liquid and water-to-binder ratios, as well as the activator modulus, typically expressed as the SiO

2/Na

2O ratio [

31,

32].

In applications such as casting and 3D printing, fresh-state properties like rheology, yield stress, and thixotropy must be precisely managed to ensure printability and structural integrity. To this end, chemical admixtures, including plasticisers, setting retarders, and air-entraining agents, may be incorporated to tailor the fresh-state behaviour. Additionally, hybrid formulations, such as those combining fly ash with slag or ceramic waste with metakaolin, are frequently employed to optimise cost, improve reactivity, and enhance final properties, including durability, shrinkage resistance, and thermal stability [

33].

The incorporation of recycled aggregates (RA) from construction and demolition waste into geopolymer concretes offers additional environmental benefits by reducing the demand for virgin aggregates and diverting waste from landfills. Several studies have shown that RA can be successfully integrated into geopolymer matrices without a significant loss of mechanical performance, especially when using low-calcium precursors and optimised activator concentrations.

For instance, several experimental studies have demonstrated that geopolymer concretes containing up to 50% recycled aggregates can maintain, or even slightly exceed, the compressive strength of OPC concretes with the same RA content, while exhibiting lower water absorption and higher resistance to chemical ingress. These enhancements are generally attributed to the denser geopolymer matrix, which counteracts the higher porosity commonly associated with recycled aggregates.

2.3. Characterisation Techniques

A combination of physical, chemical, and microstructural characterisation techniques is essential to monitor geopolymer formation and assess the performance of the resulting materials. Among these, X-ray diffraction (XRD) is commonly employed to distinguish between amorphous and crystalline phases and to track the formation of zeolitic or other crystalline structures during curing. Fourier-transform infrared spectroscopy (FTIR) provides information on the evolution of Si–O–T (T = Si or Al) stretching vibrations, which reflect the degree of polymerisation and the nature of the aluminosilicate gel [

34].

Scanning electron microscopy (SEM), often coupled with energy-dispersive X-ray spectroscopy (EDS), allows the visualisation of surface morphology, porosity, and the spatial distribution of elements, offering insight into the homogeneity and compaction of the matrix [

35]. Nuclear magnetic resonance (NMR), especially

29Si and

27Al MAS-NMR, delivers detailed data on the coordination environment of silicon and aluminium atoms within the geopolymer network, enabling quantification of Q

4(nAl) species and gel connectivity [

36,

37].

Thermal techniques such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) are valuable for evaluating thermal stability, identifying water loss mechanisms, and detecting unreacted phases or post-curing transformations [

38]. Additionally, rheological measurements and setting time evaluations (e.g., Vicat apparatus) provide critical data for understanding the fresh-state behaviour of the material, particularly in the context of extrusion or 3D printing applications [

39,

40].

These techniques collectively support the correlation between mix design, processing conditions, and the resulting microstructural and mechanical performance of geopolymers.

2.4. Classification of Geopolymer Systems

Geopolymer materials can be broadly categorised based on several interdependent parameters, including the chemical and mineralogical nature of the precursor, the calcium content, the type of alkaline activation system employed, curing regime, and the resulting gel structure. Establishing a clear classification of geopolymer systems is essential not only for understanding their performance variability but also for facilitating targeted mix design, identifying suitable applications, and assessing environmental and scalability implications.

A fundamental distinction is often made between low-calcium and high-calcium systems, reflecting the influence of the precursor’s chemical composition on the polymerisation mechanism and the type of gel formed. Low-calcium systems, typically based on materials such as Class F fly ash, metakaolin, or volcanic tuffs, promote the formation of a predominantly N-A-S-H gel (sodium aluminosilicate hydrate), which imparts ceramic-like properties, high thermal resistance, and long-term chemical durability. These systems usually require thermal curing (between 60 and 80 °C) to activate polymerisation and to achieve early strength, especially when using precursors with low inherent reactivity [

11,

41].

In contrast, high-calcium systems, derived from Class C fly ash, ground granulated blast furnace slag (GGBFS), or hybrid blends, tend to form C-A-S-H gels (calcium-aluminosilicate hydrates), which resemble the binding phases of Portland cement but exhibit improved resistance to chemical degradation. These systems are generally more reactive at ambient temperatures and are increasingly used in precast elements, repair mortars, and one-part formulations, where rapid strength development is essential [

42,

43].

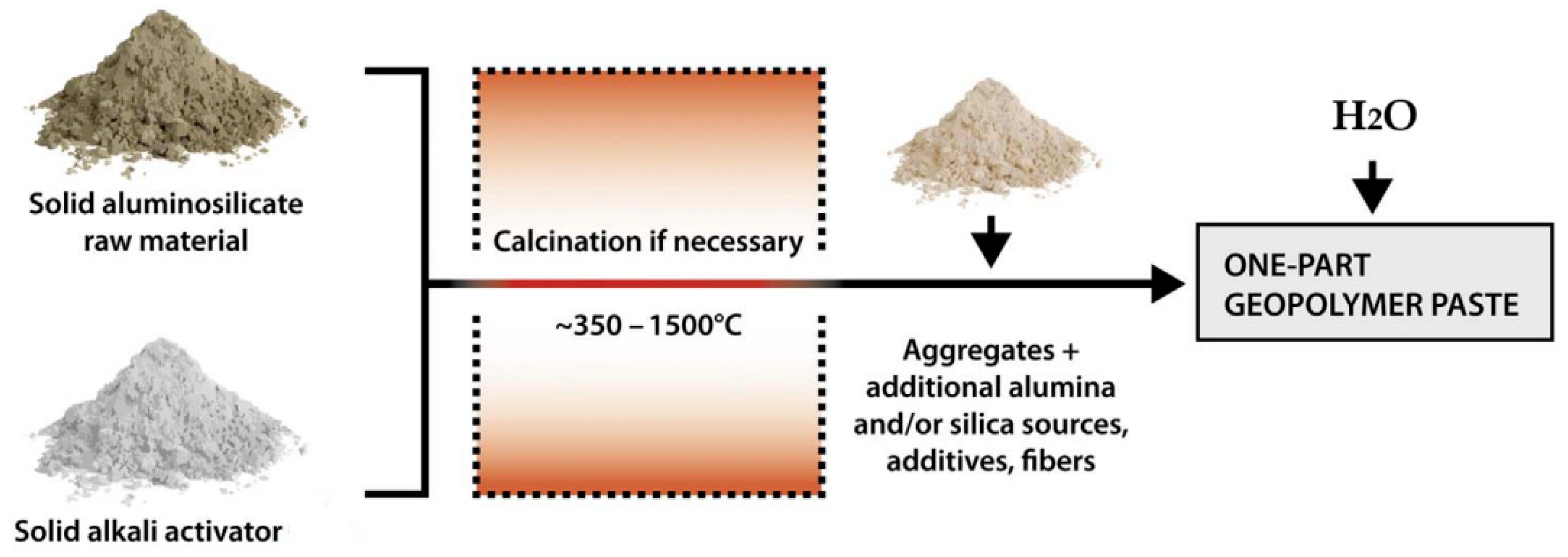

Beyond calcium content, geopolymers are classified according to the activation approach. Traditional formulations employ a two-part system, in which a liquid alkaline activator (typically a mixture of sodium or potassium hydroxide and silicate solution) is combined with the solid precursor just before use. While this approach allows precise control over reactivity and mix parameters, it poses logistical and handling challenges, particularly on construction sites. To address this, one-part systems, often referred to as “just add water” geopolymers, have been developed (see

Figure 3). These involve the dry blending of solid alkaline sources (e.g., sodium metasilicate powder) with the precursor, resulting in safer, more user-friendly formulations suitable for large-scale deployment [

44].

A further classification relates to curing conditions, which directly impact kinetics, microstructure, and application scenarios. Heat-cured geopolymers are generally favoured in laboratory or industrial settings, enabling consistent strength development and microstructural homogeneity. However, for in situ applications and prefabrication of large-scale components, ambient-cured systems are increasingly prioritised, especially when activated with GGBFS-rich blends or calcium-modified ashes [

44,

45,

46].

Moreover, emerging trends in geopolymer research have introduced a fourth classification dimension: precursor origin and sustainability. Natural precursors (e.g., metakaolin, zeolitic tuff) offer high purity but limited availability and higher cost, whereas waste-based systems, using fly ash, red mud, CDW fines, biomass ashes, or ceramic sludge, align with circular economy principles and carbon reduction targets. However, these latter systems often require pre-treatment or blending strategies to ensure sufficient reactivity and consistency, and their chemical variability presents challenges for large-scale standardisation [

47,

48].

Finally, some authors propose classification based on application context, distinguishing between geopolymers for structural use, insulating foams, 3D-printable pastes, environmental remediation binders, and high-performance composites. Each category involves specific rheological, mechanical, and durability requirements, further underlining the importance of a nuanced classification framework.

In this section, a comparative table (

Table 1) summarises the key properties and trade-offs associated with the most common geopolymer systems, providing a practical reference for researchers and practitioners engaged in sustainable material design and architectural applications.

From a matrix-type perspective, geopolymer materials can be classified into paste, mortar, and concrete. Geopolymer pastes, composed solely of binder and activator, are primarily used in fundamental studies and coatings, achieving compressive strengths of up to 60 MPa. Mortars, incorporating fine aggregates, deliver 20–60 MPa and improved dimensional stability, making them suitable for rendering and repair applications. Geopolymer concretes, containing both fine and coarse aggregates, typically reach 40–80 MPa, with durability exceeding that of OPC in aggressive environments. Each matrix type requires tailored workability and curing regimes to optimise performance.

2.5. Standardisation and Technical Barriers

Despite the growing body of research and the demonstrated performance of geopolymer materials, their widespread adoption in the construction sector remains significantly hindered by the lack of specific standards, regulatory frameworks, and certification protocols. This absence of harmonised technical specifications limits their integration into conventional design codes and building regulations, creating uncertainty for engineers, architects, and construction professionals.

Recent reviews have highlighted the delay in industrial uptake and the restriction on eligibility in public procurement or large-scale infrastructure projects due to the absence of established classification criteria, reference test methods, and performance benchmarks for geopolymer systems [

49,

50]. While traditional binders such as OPC benefit from decades of codified performance data and standardised durability tests (e.g., EN 197, ASTM C150) [

49,

50,

51], geopolymer formulations, being chemically diverse and highly dependent on precursor origin, lack unified reference procedures for critical properties such as compressive strength development, shrinkage, carbonation depth, or chloride ingress.

Moreover, variability in precursor composition, particularly for waste-derived materials such as fly ash or CDW, exacerbates this issue, making it difficult to define universally applicable mix designs or durability classes. Attempts to apply existing standards (e.g., those for OPC or blended cements) often prove inadequate or misleading when extended to alkali-activated systems due to their fundamentally different reaction mechanisms, pH profiles, and gel chemistry.

Some progress has been made at the national level. For instance, Australia (via Standards Australia and the CRC for Low Carbon Living) has proposed performance-based criteria for low-carbon cementitious materials. Similarly, RILEM TC 247-DTA and CEN Technical Committees are actively working on establishing guidelines and pre-normative documents for alkali-activated materials [

51]. Nonetheless, as of 2025, no international standard (ISO or EN) is fully dedicated to geopolymer materials for structural or architectural applications.

In addition to normative gaps, technical barriers such as inconsistent curing requirements, incompatibility with existing construction logistics, and limited availability of off-the-shelf activators further reduce market confidence. Safety concerns linked to the handling of highly alkaline solutions (e.g., NaOH, KOH) in two-part systems also pose limitations for on-site use, particularly in regions with stringent occupational health regulations [

52].

Addressing these issues requires a coordinated effort among research institutions, standardisation bodies, and industry stakeholders to

define robust performance-based standards applicable to geopolymer variability;

validate durability testing protocols under real-world conditions;

promote safe, scalable activator formulations (including one-part solutions); and

incorporate geopolymer-specific criteria into green building rating systems (e.g., LEED, BREEAM).

Overcoming these regulatory and technical barriers is essential to unlocking the full potential of geopolymer technology in sustainable construction and to positioning it as a credible, codified alternative to Portland cement.

Beyond the general absence of harmonised international standards, the standardisation process for geopolymers faces specific challenges. Raw material variability, particularly in waste-derived sources such as fly ash and CDW, leads to fluctuations in chemical composition, amorphous content, and reactivity, making it difficult to define universal mix designs. Inconsistent testing protocols, often adapted from OPC-based standards, further hinder the comparability of the results. Moreover, the lack of unified performance criteria (e.g., compressive strength thresholds, durability classes, workability parameters) across regions limits cross-market acceptance. National initiatives such as Standards Australia’s “Technical Specification for Low-Carbon Cementitious Materials” and RILEM TC 247-DTA’s [

51,

52] pre-normative recommendations offer promising starting points. A feasible pathway toward global standards could involve (i) establishing performance-based specifications that accommodate compositional variability, (ii) developing geopolymer-specific durability test methods, (iii) promoting the adoption of one-part systems to address safety and handling concerns, and (iv) integrating geopolymer criteria into mainstream construction rating systems (LEED, BREEAM, Green Star—Australia’s Green Building Council rating system for the environmental performance of buildings and communities). Such coordinated steps would facilitate both regulatory approval and industrial uptake.

In addition, several technical documents already provide partial coverage of geopolymer-related performance parameters. For instance, ASTM C1709-15 (“Standard Guide for Evaluation of Alternative Supplementary Cementitious Materials”) [

49,

51] includes guidance that can be applied to certain alkali-activated binders, while ASTM C1157-20 (“Standard Performance Specification for Hydraulic Cement”) offers a performance-based framework adaptable to geopolymer systems. RILEM TC 247-DTA [

49,

51] has produced pre-normative recommendations for mix design, curing, and durability testing, and Standards Australia has formalised criteria for low-carbon cementitious materials, including compressive strength, dimensional stability, and chemical resistance. Furthermore, CEN TC 351 [

49,

51] provides environmental assessment protocols that could be directly integrated into geopolymer specifications.

2.6. 3D Printing and Reinforcement Strategies for Geopolymer Materials

The integration of additive manufacturing technologies, particularly extrusion-based 3D printing, represents one of the most promising and transformative innovations in the field of geopolymer materials. Owing to their tunable rheology, rapid setting kinetics, and low environmental impact, geopolymer pastes are increasingly explored as sustainable alternatives to cementitious materials for digital construction. However, this emerging field faces several technical challenges that must be addressed to unlock its full potential.

A major issue in 3D-printed geopolymers concerns their relatively low tensile and flexural strength, which can compromise structural performance, especially in the context of horizontal layering and layer-to-layer adhesion. The anisotropy induced by the printing direction, combined with limited reinforcement options in the fresh state, often results in weak interfacial bonding between printed filaments. Consequently, 3D-printed geopolymer components may exhibit excellent compressive strength but fail prematurely under bending or shear stress [

53,

54,

55].

To mitigate these limitations, as reported by Ricciotti et al. [

55] (see

Figure 4), various reinforcement strategies have been explored. The inclusion of fibres, such as basalt, polypropylene, steel, or even natural fibres like flax or hemp, has shown significant improvements in crack control, flexural toughness, and post-peak ductility. Fibre content, length, orientation, and dispersion are all critical parameters that influence the effectiveness of reinforcement, particularly in printed components where nozzle size and flow rheology constrain fibre integration [

53,

54,

55].

Recent developments also include hybrid reinforcement systems, combining macrofibres and nanomaterials (e.g., carbon nanotubes, graphene oxide) to achieve multi-scale toughening effects. These approaches aim to enhance not only mechanical performance but also functional properties such as electrical conductivity, thermal regulation, and self-sensing capability, enabling the design of smart geopolymer composites for advanced architectural applications [

53,

54,

55].

Moreover, printing parameters, such as nozzle diameter, extrusion pressure, printing speed, and time between layers, have a direct impact on the mechanical anisotropy of the printed object. The optimisation of printing process parameters is thus essential to achieving consistent interlayer bonding and structural integrity. Several studies have introduced the use of chemical accelerators or thickeners to stabilise the extruded filament, reduce slump, and improve printability without compromising final strength [

53,

54,

55].

In parallel, rheological characterisation has become a crucial step in formulation development, particularly when targeting applications like prefabricated panels, vaults, or freeform structural elements. Controlling thixotropy, yield stress, and open time is necessary to prevent the collapse or deformation of successive layers during the build process [

53,

54,

55].

Altogether, 3D printing of geopolymer materials holds immense potential for resource-efficient, customisable, and low-carbon construction, especially when combined with reinforcement techniques that address mechanical limitations. Continued research is needed to establish structural design guidelines, durability benchmarks, and large-scale pilot projects that can demonstrate the feasibility and competitiveness of this technology in real architectural scenarios.

A comparative summary of the main differences between 3D-printed geopolymers, traditionally cast geopolymer systems, and 3D-printed Portland cement is provided in

Table 2. The table outlines key aspects such as mechanical performance, curing requirements, reinforcement strategies, durability, and environmental impact. This side-by-side comparison helps contextualise the opportunities and limitations of 3D printing within the broader landscape of sustainable construction materials, highlighting the specific strengths and current technical barriers of geopolymer-based solutions.

3. Properties and Applications of Geopolymers

Geopolymers exhibit a wide array of engineering properties that make them suitable for various structural and non-structural applications. Their mechanical strength, chemical and thermal resistance, environmental advantages, and ability to incorporate waste materials contribute to their growing role in sustainable construction and advanced functional materials.

3.1. Mechanical and Physical Properties

Geopolymers typically develop high early and long-term compressive strength, with reported values ranging from 20 to over 80 MPa, depending strongly on the type and reactivity of the precursor, the concentration and modulus of the activating solution, curing temperature, and mix proportions [

41,

42]. The development of strength is closely tied to the kinetics of dissolution and gel formation during the geopolymerisation process, as well as the formation of a dense, interconnected network of N-A-S-H gel. The incorporation of calcium-rich precursors such as ground granulated blast furnace slag (GGBFS) facilitates the co-formation of C-A-S-H gel alongside N-A-S-H, which accelerates early strength development and enhances the overall mechanical performance.

Flexural and tensile strengths are generally lower than compressive strength but can reach values sufficient for structural applications. The tensile strength of geopolymer mortars often ranges between 2–5 MPa, while flexural strength can vary from 4 to 10 MPa, depending on the formulation and presence of fibres or fine aggregates [

41]. Young’s modulus is typically in the range of 10–40 GPa and is comparable to that of conventional OPC systems, although it is slightly lower in low-calcium or porous matrices [

11].

Geopolymers also exhibit low total porosity and water absorption, thanks to their compact microstructure, which contributes to enhanced resistance to water ingress and chemical attack. These properties are particularly beneficial in aggressive environments, where resistance to chloride ion penetration, sulphate attack, and freeze–thaw cycles is critical for long-term durability [

42]. Moreover, their thermal conductivity can be tailored through the incorporation of lightweight aggregates, foamed precursors, or porous fillers, resulting in values as low as 0.2–0.5 W/m·K. This thermal insulation capacity makes them highly suitable for energy-efficient building envelopes and passive construction systems such as nZEB panels [

56].

Recent developments in nano-engineering have further enhanced geopolymer performance. The incorporation of nanosilica, carbon nanotubes, or nanoalumina can increase compressive strength by 5–20%, reduce total porosity, and improve fracture toughness. Additionally, certain nano-additives impart functional properties such as electrical conductivity, enabling self-sensing and structural health monitoring capabilities.

3.2. Thermal and Chemical Resistance

Geopolymers are widely recognised for their outstanding thermal stability and chemical durability, which stem from their inorganic polymeric structure and the absence of calcium hydroxide typically found in Portland cement systems. When exposed to elevated temperatures, geopolymer matrices retain their structural integrity and strength far beyond the limits of OPC-based materials. Studies have shown that well-formulated geopolymer composites can maintain their compressive strength and exhibit negligible cracking up to temperatures ranging from 800 to 1000 °C, and in some cases, even higher, depending on the precursor and additive content [

45,

46].

This behaviour is primarily attributed to the presence of a stable three-dimensional aluminosilicate network, which resists thermal decomposition and phase transitions. Unlike conventional cementitious materials, geopolymers do not suffer from the decomposition of portlandite or the breakdown of C–S–H phases at elevated temperatures. Instead, their structural densification can lead to improved ceramic-like behaviour when sintered, making them ideal for use in fire-resistant panels, refractory linings, and high-temperature insulation products for industrial applications such as metallurgy, cement kilns, and aerospace components [

47].

Moreover, geopolymer composites can be engineered with fillers or fibres, such as basalt, ceramic, or carbon, to further enhance their thermal shock resistance, dimensional stability, and post-heating mechanical properties. This tailoring potential opens new avenues for their deployment in environments requiring sustained exposure to thermal gradients or flame conditions.

From a chemical perspective, geopolymers exhibit remarkable resistance to aggressive agents, including acids, chlorides, and sulphates. Their low calcium content and lack of portlandite significantly reduce their vulnerability to acid leaching, ettringite formation, or sulphate-induced expansion. The dense microstructure and high chemical stability of the aluminosilicate gel contribute to minimal deterioration when exposed to pH values as low as 2, particularly when blended with slag or silica fume [

48].

These characteristics make geopolymers highly suitable for applications in wastewater treatment plants, marine structures, acid containment, and chemically aggressive industrial environments, where OPC-based systems often fail prematurely.

3.3. Environmental Performance and Circularity

Compared to traditional Portland cement, geopolymer systems have significant advantages in terms of environmental impact, primarily due to their lower carbon footprint and capacity to incorporate industrial residues as primary raw materials. The production of geopolymers does not involve high-temperature calcination or the formation of clinker, which are among the most energy- and carbon-intensive steps in the manufacture of OPC. As a result, LCA consistently shows that geopolymer concrete can reduce CO

2 emissions by 50–80%, depending on the source and treatment of the precursors and the formulation of the activator solution [

57,

58].

A key environmental benefit lies in the valorisation of waste and by-products such as fly ash, blast furnace slag, tile sludge, ceramic waste, red mud, biomass ash, and construction and demolition waste (CDW). These materials, when suitably treated, can be activated to form durable binders, contributing to waste minimisation and the diversion of such residues from landfills. Moreover, the use of alkaline activators can, in some cases, be substituted or partially replaced with industrial process effluents or recycled leachates, thereby promoting resource recovery and further reducing reliance on virgin chemicals [

59].

In alignment with the principles of the circular economy, geopolymer technology supports the closed-loop management of materials and energy flows. Geopolymer-based products can be tailored to meet green building criteria such as those imposed by LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), enhancing their attractiveness for sustainable construction practices [

60].

Several recent studies have explored the development of 100% waste-based geopolymers using synergistic blends of silico-aluminous industrial residues. These systems not only match or exceed the performance of conventional geopolymer formulations but also contribute to net reductions in embodied energy and carbon, particularly when used in prefabricated components or 3D-printed architectures optimised for material efficiency. Overall, geopolymer technology offers a viable route toward decarbonised construction and resilient material systems compatible with European climate targets and waste management directives.

3.4. Functional and Engineering Applications

Geopolymer materials have found increasing use across multiple sectors due to their versatility, durability, and environmental performance. In the construction sector, they have been applied to structural and non-structural elements, including concrete, masonry blocks, rendering mortars, and precast components. Their rapid setting time and high early strength make them particularly suitable for repair works, prefabricated systems, and time-sensitive infrastructures, such as airport pavements and highway overlays [

61].

In the field of digital fabrication, geopolymers are gaining momentum in extrusion-based 3D printing technologies. Their tunable rheology, combined with controllable setting kinetics, allows for the layer-by-layer construction of complex geometries without the need for conventional formwork. This makes them suitable for customised architectural elements, building envelopes, and structurally optimised forms, offering both material efficiency and aesthetic innovation. Research has demonstrated successful 3D printing of geopolymer formulations incorporating fly ash, slag, or tile waste, achieving excellent interlayer adhesion and dimensional stability [

62].

Another major area of application is the immobilisation and encapsulation of hazardous and radioactive wastes. The chemically stable and low-permeability aluminosilicate network of geopolymers enables the secure containment of toxic elements, including heavy metals, cesium, strontium, and chromates. These applications are being explored for industrial residues, mining waste, and nuclear decommissioning, providing an alternative to vitrification and cement-based solidification systems [

63].

Geopolymers have also been employed in environmental remediation, particularly for water purification and advanced oxidation processes. Functionalised or composite geopolymers incorporating iron oxides, titanium dioxide, or bio-based fillers have shown promising results as adsorbents and photocatalytic supports for removing organic pollutants, dyes, and heavy metals from aqueous systems [

64].

Thermal insulating and fire-resistant panels are another emerging application, especially for use in buildings, tunnels, transport systems, and naval infrastructure. Their inherent fire resistance, low thermal conductivity, and non-combustibility offer clear advantages over polymer-based insulation. Composite formulations with foaming agents or lightweight aggregates can achieve additional thermal and acoustic performance.

In recent developments, geopolymers have been hybridised with natural or synthetic fibres (e.g., flax, basalt, carbon) and functional additives such as phase change materials (PCMs) or graphene oxide (see

Figure 5). These composites aim to impart multifunctionality by combining mechanical toughness, energy storage, self-sensing capabilities, and thermal regulation in a single material platform. This makes them attractive for next-generation green buildings, infrastructure resilience, and adaptive envelope systems [

65].

In addition to building-scale applications, geopolymers have potential in large-scale infrastructure such as bridges, dams, and high-rise buildings. Their high compressive strength, superior chemical resistance, and thermal stability make them suitable for precast bridge segments, spillway linings, and façade panels in tall structures. Pilot projects in Australia and the Netherlands have demonstrated structural performance comparable to OPC systems, with reduced maintenance requirements over service life.

3.5. Long-Term Durability and Service Performance

As outlined in

Section 3.1, durability mechanisms such as carbonation, chloride ingress, and sulphate attack are critical for assessing long-term performance. Geopolymers have demonstrated enhanced resistance to acidic and sulphate environments, reduced chloride permeability, and good freeze–thaw stability compared to OPC systems [

66,

67,

68,

69,

70,

71,

72,

73,

74,

75,

76]. For example, fly ash-based binders can retain over 60% of their compressive strength after 18 weeks of exposure to 2% H

2SO

4, while OPC systems often lose more than 40% under similar conditions [

66,

69,

70]. Freeze–thaw testing has shown negligible mass loss and minimal strength reduction after 300 cycles, whereas OPC requires air entrainment to achieve comparable results [

67,

71,

72]. Carbonation depth in geopolymers can be greater than in OPC, necessitating careful curing to maintain reinforcement passivation [

66,

73,

76]. Long-term field studies (>5 years) remain limited, but available data report >85% strength retention for geopolymer concretes exposed to marine or industrial environments, with lower maintenance requirements than OPC [

74,

75]. In summary, recent research demonstrates that properly formulated geopolymers can match or surpass OPC in chemical resistance, freeze–thaw durability, and even carbonation resilience, especially when slag is included, curing is thorough, and fibre reinforcements are applied. Yet, fully realising their potential requires expanded field testing, standardised durability protocols, and targeted development of classification systems. Bridging these gaps will be critical to positioning geopolymers as reliable, sustainable alternatives for long-term architectural applications [

75,

76]. A comparative summary of the main durability characteristics of geopolymer materials versus traditional OPC systems is provided in

Table 3.

While promising short- to medium-term durability data exist, the number of long-term (>5 years) field exposure studies remains limited. To strengthen confidence in service performance, extended monitoring of full-scale elements, covering carbonation, freeze–thaw, chloride ingress, and mechanical stability, is essential. Large-scale pilot projects in marine, industrial, and extreme-climate contexts would provide critical empirical validation, complementing accelerated laboratory tests and enabling the formulation of geopolymer-specific design codes.

4. Geopolymer-Based Multilayer and Sandwich Panels for Sustainable Envelopes

4.1. Innovation and Circular Approaches in the Construction Sector

This section outlines the conceptual framework underpinning sustainability and circular economy principles in the development of geopolymer-based construction systems, emphasising their role in promoting resource efficiency and reducing environmental impact.

In light of the growing and evolving challenges faced by the construction sector, such as climate change, the need for carbon neutrality, resource circularity, and environmental quality, building envelopes are increasingly recognised as strategic systems. These systems are not only essential from an aesthetic, structural, and functional standpoint, but also serve as critical tools for reducing environmental footprints [

55].

Sustainable construction is fundamentally defined as a set of design and building solutions that incorporate environmental awareness from the earliest stages of the process. To meet this ambition, it is necessary to adopt design approaches that minimise environmental impacts across the entire life cycle of a building. This includes the use of innovative materials and construction processes that optimise the use of raw materials and facilitate recyclability [

56]. Emphasis is thus placed on the need to enhance production and construction supply chains in a manner that ensures that materials retain their value even at the end of a building’s life. This is made possible through the adoption of highly industrialised, dry-assembly construction methods that support disassembly and reuse or high-quality recycling [

57].

The development of circular design strategies enables a rethinking of systems and products within an integrated and multi-scalar vision. This supports the transition toward more resilient and ecologically performing living environments [

56]. The present research aligns with this paradigm, adopting a systemic and interdisciplinary methodological approach and embracing the three guiding principles of the circular economy: the elimination of waste and pollution, the circulation of products and materials at their highest value, and the regeneration of natural systems [

57].

To effectively implement these principles in operational practice, a significant shift in vision is required, particularly one that favours dry construction techniques. Such techniques offer greater control over waste generation and facilitate high-quality reuse or recycling of building components after deconstruction [

57].

In this context, the experimentation and application of geopolymer-based materials, which are emerging among innovative and sustainable construction materials, clearly reflect the above principles. Their notable characteristics include the use of natural matrices and industrial by-products, as well as the ability to harden at much lower temperatures than conventional materials through environmentally friendly chemical reactions. This even enables their production directly on site [

55].

Furthermore, geopolymers have significant advantages in terms of their compatibility with digital fabrication technologies. These technologies allow for material optimisation, reduced construction times, and cost-efficiency when compared to traditional construction [

54]. Of particular relevance is the potential for geopolymers to replace cement as a binder in concrete, leading to notable environmental benefits, including the use of recycled inputs and lower production temperatures, with corresponding reductions in CO

2 emissions [

47,

48,

55].

Such strategies, as discussed in [

57], demonstrate how circularity and environmental efficiency can be embedded within material development and construction workflows.

Figure 6 provides a representative example of a geopolymer composite production process incorporating plastic waste, designed to minimise environmental impacts across all stages of preparation.

4.2. Circular Design Strategies for Envelope Systems

In the context of sustainable construction, envelope systems are increasingly understood not only as static barriers but also as active and strategic components that contribute to energy performance, material efficiency, and circularity. The shift from monolithic to stratified and modular envelopes allows for greater functional integration and adaptability. Such approaches respond to the demands of climate neutrality, recyclability, demountability, and user well-being [

55,

56].

Circular design principles encourage the use of materials with low embodied energy, high durability, and the capacity for disassembly or reuse. Geopolymer materials, owing to their low carbon footprint and compatibility with recycled raw materials, offer a promising solution for realising these principles. Their adaptability in terms of rheology and curing conditions enables the design of multilayer components via both traditional casting and digital fabrication techniques [

16,

52,

55].

The following discussion focuses on specific technological solutions for implementing circular design strategies in geopolymer-based envelope systems, with attention to manufacturing techniques, reinforcement options, and performance optimisation.

4.3. Structural and Functional Design of Geopolymer Sandwich Panels

The following discussion addresses the conceptual aspects of mechanical and physical performance, focusing on how geopolymer composites align with structural and functional requirements in the built environment.

As summarised in

Table 4, various geopolymer-based sandwich panel systems have been developed using different core materials, each offering specific advantages in terms of thermal conductivity, density, and functional performance.

Sandwich panels typically consist of two stiff outer faces (“skins”) and a lightweight core, engineered to maximise the ratio between structural performance and mass. In geopolymer-based panels, outer layers are formulated with dense metakaolin- or waste-based matrices, while the core may include lightweight foamed geopolymers or inert aggregates. This configuration can significantly improve the thermal, acoustic, and fire resistance properties of the component [

57].

Innovative sandwich panel designs have incorporated expanded clay, perlite, cork granules, and geopolymer foams as cores, achieving thermal conductivity values compatible with nZEB requirements [

58,

59]. Moreover, these panels are compatible with dry assembly methods and can be tailored for prefabrication or 3D extrusion-based printing.

4.4. Integration of Foamed and Lightweight Cores

This section presents the conceptual basis for thermal and acoustic performance in geopolymer-based elements, highlighting their relevance for comfort, energy efficiency, and compliance with building regulations [

55,

56].

From a technological perspective, the integration of specific aggregate types, optimised mix designs, and structural configurations are discussed as means to enhance thermal and acoustic performance in practical applications.

The incorporation of foamed geopolymer cores has demonstrated several advantages: reduced density (400–800 kg/m

3), improved thermal insulation, and enhanced fire resistance. Different foaming strategies, physical (air, gas release) or chemical (H

2O

2, aluminium powders), have been explored, with promising results in terms of pore control and mechanical stability [

46,

61].

In comparative studies, sandwich panels with foamed cores showed improved specific stiffness and reduced thermal bridges compared to homogeneous geopolymer panels. These solutions also contribute to circularity by enabling the integration of industrial by-products such as fly ash, slag, or recycled ceramic waste [

55,

57].

Overall, the combination of lightweight cores and geopolymer matrices offers a pathway to producing prefabricated components that meet stringent energy performance requirements while reducing embodied carbon and promoting the reuse of secondary raw materials [

55,

57].

4.5. Environmental and Thermal Performance Considerations

Conceptual perspective. Geopolymer sandwich panels offer competitive performance in terms of thermal insulation and fire resistance, with values of thermal conductivity between 0.08 and 0.18 W/mK depending on the core composition and porosity [

47,

60]. The use of mineral-based binders also ensures superior fire resistance (Euroclass A1) and low smoke emissions compared to organic-based systems.

Technological perspective. From an environmental standpoint, LCA has highlighted the benefits of geopolymer panels in reducing CO

2 emissions and embodied energy, especially when combined with recycled raw materials and optimised production processes [

60]. The capacity to manufacture panels at near-ambient temperatures further reduces energy demand. For instance, Ciobanu et al. [

77] (see

Figure 7) developed lightweight geopolymer panels using fly ash and perlite aggregates, achieving a density of approximately 580 kg/m

3 and a thermal conductivity of 0.10 W/mK. These values demonstrate the suitability of such panels for integrated thermal insulation and load-bearing performance, with compressive strengths exceeding 6 MPa.

4.6. Recyclability, Modular Assembly, and Circular Potential

Conceptual perspective. Geopolymer-based multilayer systems align closely with circular economy objectives. Their mineral composition facilitates inert recycling, while their modular configuration promotes design for disassembly. These characteristics make them particularly suitable for dry-assembled façades and temporary structures where reversibility and reuse are desirable. Moreover, their compatibility with additive manufacturing technologies enables the creation of highly customised envelope components with minimal material waste and high geometric flexibility.

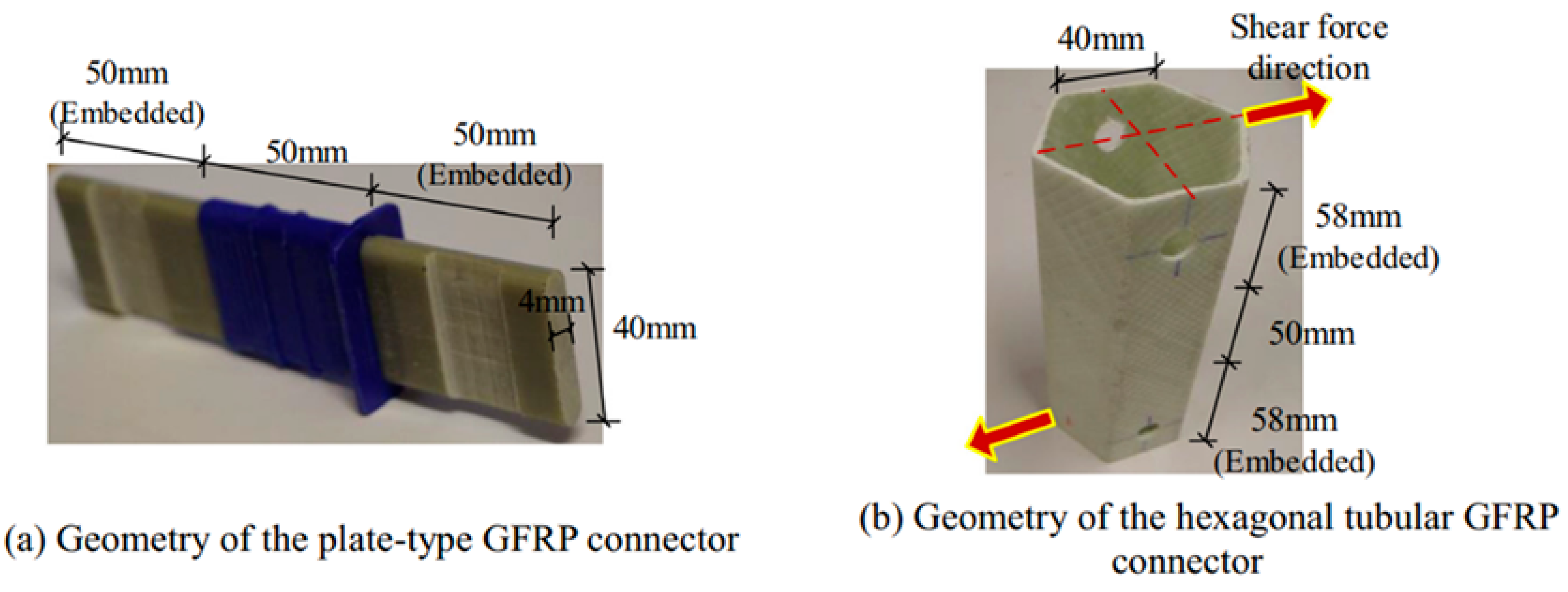

Technological perspective. Recent studies also demonstrate that the structural performance of these modular panels can be enhanced through the use of fibre-reinforced polymer (FRP) connectors. In particular, precast geopolymer-based sandwich panels have achieved flexural capacities exceeding 8 kN/m with minimal interfacial delamination, confirming their suitability for mechanically efficient dry-assembly solutions [

78] (see

Figure 8).

Furthermore, the compatibility of geopolymer materials with additive manufacturing technologies opens the door to highly customised envelope components with minimal material waste and high geometric flexibility. Ongoing research is investigating the integration of BIM tools for parametric design and life cycle monitoring of these panels, supporting a systemic approach to sustainability in architecture. These findings highlight not only the promising mechanical and thermal performance of geopolymer-based panels but also their compatibility with evolving regulatory frameworks and digital design environments such as BIM, thus reinforcing their potential integration into high-performance, sustainable building envelopes.

4.7. Parametric Modelling and BIM in the Design and Prototyping of Geopolymer Panels

Conceptual perspective. This section outlines the conceptual framework underpinning the integration of BIM and parametric modelling into geopolymer-based construction, focusing on their role in design optimisation and interdisciplinary collaboration.

Parametric modelling, unlike purely geometric modelling, has increasingly emerged in recent years as a vital support tool across the design process at multiple scales. It establishes intrinsic and extrinsic relationships among the various elements of a model, enabling not only the generation of alternative solutions through the manipulation of key parameters but also the potential to automate processes in line with contemporary digital fabrication protocols. In this regard, experimentation involving the application of geopolymer materials in the construction of panel systems finds digital modelling an essential ally for validating design choices.

The parametric nature of such models allows for the integration of data beyond mere geometry and dimensions, thereby avoiding redundancy and inconsistency. Parametric rules ensure that object geometries and dimensions are automatically updated when modifications or associations are applied within the model. In the present study, this aspect was explored through a review of the scientific literature concerning both the spatial and formal configurations of panels, as well as their digital prototyping scenarios. The first component is more closely tied to the design of the panel itself and involves the analysis of analogous case studies in which parametric design has been used to develop planar and spatial aggregations of modular components. The second component focuses more specifically on the manufacturing of these panels through digital fabrication systems to explore potential production pathways.

Technological perspective. The existing literature on this topic reveals a diverse range of applications of parametric modelling across various scales. In some cases, the emphasis is on structural aspects, drawing on the stiffness properties provided by aggregated geometries; in others, the focus is on material performance to model and digitise such characteristics for predictive evaluation.

In terms of geometric tessellation, the identification and classification of forms that are capable of either filling a plane or generating three-dimensional surfaces is crucial. While the origins of geometric tiling can be traced back to Sumerian wall and floor decorations [

79], the technique has been adopted across cultures and historical periods for primarily decorative and aesthetic purposes. However, examples of structural applications where form and construction are inherently integrated can be found in the geodesic domes and curved surfaces developed by Richard Buckminster Fuller in the early twentieth century [

80]. These were based on rigid geometric principles and his philosophy of “doing more and more with less and less.” His work inspired numerous architects, including Shigeru Ban [

81], who integrated Fuller’s geometric foundations with the advantages of new materials and parametric design tools.

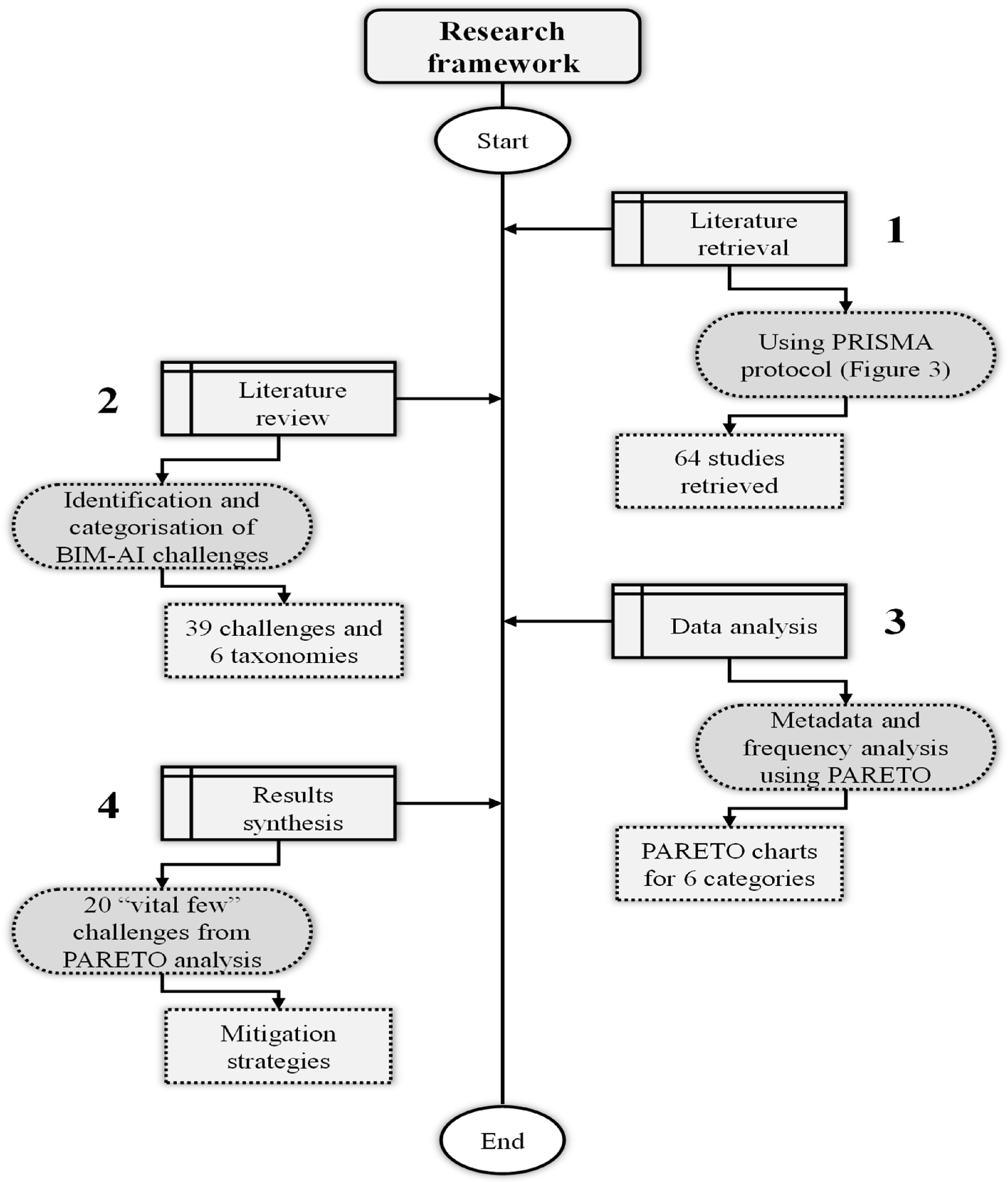

Building upon these precedents, the literature review undertaken in this study drew from searches within the Web of Science, Scopus, and ScienceDirect databases, initially using keywords such as “geometric tessellation,” “parametric design,” and “modular panels.” This was followed by the application of more refined filters and thematic constraints.

Interestingly, some authors have explored the integration of geometric patterns with environmental performance, particularly in the context of building facades. These investigations often rely on algorithmic frameworks that span from conceptual research to evaluation and physical prototyping [

82] (see

Figure 9).

Similarly, Dastoum et al. [

83] conducted a systematic review of geometric pattern applications for optimising daylighting and thermal performance. Their classification distinguishes between traditional and modern configurations, with hexagonal modules being among the most frequently used due to their geometric simplicity, whereas more intricate patterns inspired by Islamic art are less common due to their complex articulation.

These findings are echoed by Bande et al. [

84], who incorporated generative design algorithms into computational workflows that take into account contextual variables such as social and climatic conditions. Their work demonstrates how advanced digital tools can support responsive and place-specific architectural solutions.

The review further revealed that triangular, quadrilateral, and hexagonal planar shapes are the most commonly employed due to their capacity to fill a surface using repeated units. More complex patterns, such as rosettes or stellated forms, which rely on symmetrical arrangements, are also explored for their aesthetic and structural potential. Additionally, some studies have investigated the use of Voronoi diagrams, which fill space through the aggregation of irregular polygons. However, their application in geopolymer prototyping is limited due to the lack of uniformity between individual components. Other approaches involving non-planar tessellations, based on folded surfaces or origami techniques, offer three-dimensional configuration possibilities and may allow for the spatial aggregation of panels or volumetric modules.

It should be noted that for this review, tessellation studies focusing on perforated elements or systems alternating solid and void spaces were excluded, as were fully dynamic or kinetic systems typically used for solar shading purposes [

85]. These approaches are less aligned with the material behaviour and construction logic of geopolymer components.

In relation to digital material modelling, parametric design, when integrated with building information modelling (BIM) in the Architecture, Engineering and Construction (AEC) sector, offers significant potential for anticipating the behaviour of innovative materials and validating their applications. According to Scotti et al., this type of digital experimentation can drastically reduce both cost and time, although industrial uptake remains limited due to a degree of scepticism [

86]. Other authors highlight how BIM enhances material management through simulations of physical and mechanical properties, lifecycle scenarios, and even end-of-life waste strategies [

87].

In several cases, parametric design has led to the development of plug-ins and tools that can interface with BIM platforms, enriching material databases and fostering sustainability-led design decisions. Notably, Jayasinghe and Waldmann describe a BIM-integrated web tool functioning as a materials and components bank aimed at supporting circular construction [

88].

Overall, the incorporation of parametric design and BIM into the workflow of geopolymer panel development offers a robust, data-driven framework for innovation. It bridges the gap between experimental materials and real-world implementation, facilitating informed decision-making, adaptive design, and integrated sustainability from concept to construction.

4.8. BIM-Integrated LCA Approaches in Geopolymer-Based Construction

Conceptual perspective. The following discussion addresses specific technological solutions for implementing BIM in the manufacturing and installation of geopolymer panels, including software platforms, data management protocols, and interoperability standards.

The integration of building information modelling (BIM) with LCA represents a powerful methodology for supporting evidence-based decisions in sustainable construction. When applied to geopolymer-based materials and components, BIM–LCA integration enables a quantitative evaluation of environmental performance across the entire building life cycle, from raw material sourcing and panel production to installation, use, and end-of-life phases.

Technological perspective. Recent studies have demonstrated how BIM–LCA tools can be effectively used to compare geopolymer concrete with Portland cement-based systems, revealing significant advantages in terms of CO

2 reduction and embodied energy savings. For example, a case study by Rezaei et al. using Autodesk Revit (version 2024) and OneClick LCA (version 3.9) showed that substituting OPC with fly ash–slag–based geopolymer concrete in a mid-rise building reduced embodied carbon emissions by approximately 42%, with 30% lower total energy consumption over a 50-year life span [

89] (see

Figure 10). Another study, conducted on a school building in the Netherlands and reported by bimLCA.eu (2024) (available online:

https://www.bimlca.eu, accessed on 1 July 2025), quantified a 35–60% reduction in global warming potential (GWP) when geopolymer panels replaced standard precast concrete in the façade envelope, also resulting in improved circularity scores [

90].

These outcomes are largely due to the absence of clinker, low-temperature processing, and the use of industrial by-products such as fly ash or CDW. BIM platforms enriched with Environmental Product Declarations (EPDs) and LCA data libraries allow designers to simulate different envelope configurations and compare environmental impacts in real time, adjusting parameters such as material thickness, thermal conductivity, transportation distances, or maintenance cycles.

The application of BIM-integrated LCA is particularly valuable in the early design phase, where decisions regarding material selection and modular configuration can be optimised based on multi-criteria assessment, including not only environmental factors (GWP, non-renewable energy demand) but also cost, durability, and disassembly potential. Parametric design models further enhance this process by enabling scenario analysis across multiple design alternatives with varying geometric and material attributes.

Nonetheless, certain limitations persist. Current BIM–LCA tools are often calibrated for traditional materials and may lack accurate datasets for geopolymer-based products, especially those based on regional or non-standardised formulations. Moreover, the interoperability between architectural design software (e.g., Revit, ArchiCAD version 2024) and LCA databases (e.g., GaBi, SimaPro, ecoinvent) remains a critical issue, requiring improved standardisation and user-friendly interfaces.

To support wider adoption, emerging platforms such as bimLCA.eu, OneClick LCA, and Tally are increasingly incorporating geopolymer-specific EPDs and carbon accounting modules. Pilot projects in Northern Europe and Australia have shown the feasibility of fully BIM-integrated workflows for low-carbon construction using geopolymer-based prefabricated panels, achieving LEED Gold or BREEAM Excellent certifications [

90,

91,

92]. A further example is provided by Müller et al., who developed a fully 3D-printed envelope system using a ceramic waste-based geopolymer formulation, demonstrating substantial reductions in embodied carbon and energy demand when compared to standard precast solutions [

93].

A comparative overview of life cycle carbon footprints for selected geopolymer systems and OPC systems across different case studies is summarised in

Table 5.

In summary, the BIM–LCA integration framework offers a compelling route to quantify and optimise the environmental performance of geopolymer materials within building envelopes. Further development of geopolymer-specific databases and design plugins is essential to fully leverage this potential and align with digital sustainability goals in architecture and construction.

Beyond digital integration, LCA studies consistently show that geopolymer concretes can achieve embodied carbon reductions of 35–60% and embodied energy savings of 20–40% compared with OPC systems. These benefits are particularly pronounced when industrial by-products such as fly ash or slag are used and when production and curing occur at ambient temperature.

Environmental impact assessments also highlight reductions in acidification potential (up to 40%), eutrophication potential (up to 35%), and water footprint (up to 25%) relative to OPC-based concretes. Such reductions support compliance with international green building certifications and contribute to broader sustainability targets.

A selection of real-world case studies comparing geopolymer-based and OPC-based materials through BIM–LCA workflows is summarised in

Table 6, highlighting the potential environmental benefits, energy savings, and modelling tools adopted in sustainable architectural applications.

4.9. Artificial Intelligence and Machine Learning in Geopolymer Mix Design

Conceptual perspective. In recent years, the application of artificial intelligence (AI) and machine learning (ML) techniques in materials science has opened new frontiers in the optimisation of geopolymer formulations. These data-driven approaches allow for the rapid prediction of key performance indicators, such as compressive strength, setting time, porosity, and durability, based on complex input parameters, including precursor type, Si/Al ratio, activator modulus, curing temperature, and fibre content.

Traditional mix design in geopolymer research relies heavily on empirical testing and trial-and-error procedures, which are time-consuming and resource-intensive due to the large compositional variability of raw materials, particularly when using industrial by-products or local waste streams. ML algorithms offer an efficient alternative by analysing existing experimental datasets and developing predictive models capable of identifying non-linear relationships and multivariate dependencies among mixed variables. This enables the formulation of optimised recipes with fewer iterations and better performance targeting.

Technological perspective. Recent studies published in 2025 have demonstrated the effectiveness of algorithms such as Artificial Neural Networks (ANNs), Support Vector Machines (SVMs), and Gradient Boosting Decision Trees (GBDT) in forecasting mechanical and rheological properties of alkali-activated materials with high accuracy (R

2 > 0.9) [

94,

95]. These tools are particularly useful in hybrid systems or formulations involving recycled aggregates, nanomaterials, or multiple activator sources.

Moreover, feature importance analyses conducted within ML frameworks can provide insights into the most influential parameters affecting performance, often revealing counterintuitive trends that may not emerge through classical regression. For example, some models have identified the activator modulus as a more decisive factor than curing temperature in early strength development for fly ash–slag blends, while others have shown that fibre dosage exhibits threshold effects depending on binder viscosity [

94,

96].

The integration of AI-based predictive models into BIM workflows is also being explored, enabling real-time feedback on material performance during the digital design phase. This convergence of materials informatics, digital construction, and sustainability-driven design represents a transformative opportunity for the next generation of geopolymer-based technologies [

97] (see

Figure 11).

However, challenges remain, including the limited availability of large, standardised datasets, the need for robust validation of model generalisability across different precursor sources, and the integration of uncertainty quantification in AI predictions. To overcome these issues, collaborative databases and open-access repositories are being proposed, along with explainable AI techniques to ensure transparency and reliability [

98].

In summary, the adoption of AI and ML in geopolymer mix design holds the potential to accelerate innovation, reduce development time, and support performance-based design in sustainable construction, particularly when aligned with circular economy objectives and digital design platforms. A comparative overview of traditional and AI-driven methodologies for geopolymer mix design is provided in

Table 7, highlighting the benefits, limitations, and emerging synergies with digital design platforms.

5. Conclusions

This review has comprehensively addressed the state-of-the-art, emerging trends, and critical barriers in the development and application of geopolymer-based materials for sustainable architectural design and construction. By investigating their chemical nature, formulation strategies, durability, digital fabrication techniques, and environmental assessment methodologies, it is evident that geopolymers represent one of the most promising classes of materials for reducing the environmental impact of the built environment. Their intrinsic advantages, including the absence of clinker, low-temperature processing, and the valorisation of industrial waste, make them strategically aligned with climate-neutral and circular construction goals.

Among the most promising applications are modular multilayer panels, which offer a unique combination of mechanical strength, thermal insulation, and design flexibility. These systems facilitate disassembly and reuse and are well suited for dry assembly and prefabricated construction. Their integration with 3D printing technologies and fibre-reinforced solutions further enhances performance and customisation, enabling tailored responses to architectural and structural requirements. However, certain technical challenges persist, particularly in terms of interlayer adhesion, shrinkage behaviour, and anisotropy in printed structures. These aspects demand further optimisation at both the material and process levels.

At a broader scale, the use of BIM-integrated life cycle assessment (BIM–LCA) has proven effective in supporting the environmental benchmarking and performance simulation of geopolymer-based components. Case studies have demonstrated that replacing Portland cement with geopolymer systems can lead to CO2 reductions of up to 60%, with significant energy savings across the life cycle. These digital tools not only support early-stage decision-making, but also promote transparency and comparability in sustainable design workflows. Nonetheless, the adoption of BIM–LCA methodologies for geopolymers remains limited by the scarcity of standardised datasets, environmental product declarations (EPDs), and user-friendly integration into common design platforms.

In parallel, the integration of artificial intelligence (AI) and machine learning (ML) in geopolymer research is opening new frontiers in predictive mix design. These approaches enable data-driven optimisation, accelerating the development of new formulations and improving material performance with fewer experimental cycles. AI-based models also support the identification of critical variables influencing strength, durability, and rheology, offering valuable insights into the complex behaviour of multi-component systems. However, to fully exploit these capabilities, larger and more consistent experimental datasets are required, along with open-access repositories and the incorporation of uncertainty modelling into AI frameworks.

Despite these advances, the widespread adoption of geopolymer technology still faces several barriers. One of the most critical issues is the absence of harmonised technical standards and design codes, which limits market acceptance, regulatory approval, and construction-scale implementation. Many formulations remain context-specific, and their performance depends heavily on the local availability and variability of raw materials. In addition, long-term durability data, particularly under variable climate conditions and in aggressive environments, are still limited when compared to Portland cement-based systems. This hampers confidence among engineers, designers, and contractors.

Furthermore, there are economic and logistical challenges. The cost-effectiveness of geopolymers is highly dependent on proximity to suitable waste sources, existing industrial symbiosis frameworks, and the availability of alkaline activators. In some regions, regulatory barriers or a lack of awareness among practitioners prevent large-scale experimentation and procurement. Finally, manufacturing and curing processes must be further adapted for industrial scalability, automation, and integration with prefabrication chains.

Future Perspectives and Recommendations

To overcome these limitations and fully harness the potential of geopolymers, a series of coordinated actions is required. First, standardisation efforts must be intensified at national and international levels, promoting the development of performance-based codes tailored to geopolymer behaviour. Second, the creation of validated EPDs, LCA datasets, and digital libraries integrated into BIM environments will enable wider adoption and facilitate compliance with sustainability certification schemes (e.g., LEED, BREEAM, CAM).

From a research perspective, further studies are needed to explore the long-term performance of geopolymer structures under real exposure conditions (e.g., freeze–thaw, sulphate attack, carbonation), and to assess their structural compatibility with conventional reinforcement systems. The synergy between digital design tools, advanced manufacturing, and smart material modelling (including AI and digital twins) offers exciting opportunities to embed geopolymers into intelligent construction ecosystems.

Finally, effective technology transfer and multi-stakeholder collaboration are essential to bridge the gap between laboratory research and market uptake. Demonstration projects, public procurement policies favouring low-carbon materials, and targeted education and training for architects and engineers will be key enablers in the transition towards more sustainable, circular, and digitally integrated building practices.