1. Introduction

In the context of global sustainability challenges, the transition from a linear to a circular economic model has emerged as a central strategy [

1]. The fundamental objective of the circular economy (CE) concept is to minimize waste and optimize resource efficiency by extending product life cycles and closing material loops [

2]. Within the given context, reverse logistics (RL) plays a crucial role by enabling the return of products or materials from end-users back into supply chains, thus enabling them to be re-used, re-manufactured, or recycled [

3].

Whilst large enterprises are increasingly integrating CE and RL into their operations, small and medium-sized enterprises (SMEs) encounter considerable obstacles. These factors encompass restricted financial and technological resources, an absence of specialized personnel, and an inadequate understanding of circular strategies [

4,

5]. Concurrently, SMEs are vital components of regional economies. They possess the capability of making substantial contributions to sustainable production and consumption, provided that appropriate support mechanisms and infrastructures are in place [

6].

Despite the proliferation of studies on the CE and RL, the specific success factors and challenges for SMEs remain under-explored, particularly from an empirical perspective. Unlike previous studies, which have relied predominantly on literature, this study systematically incorporates insights from six expert interviews in order to contextualize and prioritize the findings. The present study aims to address this research gap by identifying the key drivers and barriers to RL implementation in SMEs operating within the CE framework. Whereas previous research often remains at a conceptual level or focuses on large enterprises, this paper concentrates on the operational, financial, technological, and regulatory conditions under which SMEs can—or cannot—implement reverse logistics processes. The analysis provides a context-sensitive view of the current barriers to implementation and the factors that enable it, and builds on existing research by incorporating categories that have received little attention to date, such as regulatory ambiguity and limited customer involvement. The present study employs a mixed-methods approach, integrating a systematic literature review (SLR) with qualitative expert interviews. The design was selected to encompass both academic insights and practitioner-based perspectives, thereby facilitating a more nuanced understanding of RL integration in the SME context.

The structure of the paper is as follows: In

Section 2, the theoretical foundations of RL and CE are introduced, and their interdependencies are outlined.

Section 3 of the text presents research design and methodology.

Section 4 of the text provides a synthesis of the key findings from the SLR and the interviews.

Section 5 of the text is dedicated to the discussion of practical implications and recommendations for future research.

2. Theoretical Background

2.1. Reverse Logistics

RL can be defined as the process of moving materials and information in the opposite direction of the value chain. In addition to the return of products that have not been utilized or have remained unsold, the process encompasses the recycling and disposal of said products. The term “reverse logistics” is frequently compared with “disposal logistics”, as the latter also deals with processes for the return, utilization, and disposal of residual materials. In principle, reverse logistics encompasses various types of return and return transport, and focuses on three task areas: disposal logistics, returns logistics, and container logistics [

7].

In the event of a product being returned to the company by the consumer, the product may undergo one or all the return process steps. It is generally accepted that the measures above, which are implemented in conjunction with a product or material undergoing a circular process, are collectively referred to as the reverse logistics process steps [

8].

2.2. Circular Economy

The concept of a CE has existed for many generations, as the natural world can be understood as a circular concept. Objects or concepts that are of no importance to some individuals can be viewed as a valuable resource by others [

9]. In the contemporary era, adhering to the principles of the CE is imperative, as the concept of finite resource availability has become firmly entrenched in the public consciousness. Consequently, alternative solutions, such as the recycling or reuse of products, are gaining increasing significance. Several advantages are associated with this, including the reduction of the ecological footprint of each individual, the minimization of resource consumption, and the reduction of waste [

10].

In principle, the CE is predicated on the conservation of resources, the protection of the climate and the environment, and the promotion of human health. Mineral resources, biomass, land, air, and water are all natural resources provided to humans. Greater emphasis must be placed on the judicious utilization of these resources and their consumption, both in the present and in the future, to minimize the wasteful use of resources. The comprehensive utilization of CE concepts is instrumental in ensuring the disposal of waste in a manner that is both climate-friendly and environmentally sustainable. This approach entails the systematic removal of pollutants from these cycles, thereby ensuring their effective elimination. It can be concluded that the measures under discussion should already be considered during the product design stage. These measures include the extension of the service life, the conservation of raw materials, and the utilization of recyclable materials in production. Moreover, the CE facilitates the prolonged utilization of specific raw materials, thereby generating a favorable economic impact through the retention of product value over an extended period [

11].

2.3. Dependencies Between RL and the CE

RL and the CE are closely intertwined, especially in returning and reintegrating products, materials, and waste into the economic cycle. RL provides the operational framework that makes the practical implementation of CE strategies, such as reuse, reprocessing, and recycling, possible.

A key link between the two concepts is their shared goal. Both concepts aim to extend product and material lifecycles to foster a more sustainable economic system. While the CE provides the strategic framework focused on resource conservation and waste prevention, RL translates these objectives into actionable return and recovery processes [

12].

Integrating RL effectively into CE systems is critical for achieving closed-loop material flows. Only through well-coordinated RL processes can materials be efficiently reintegrated to generate ecological and economic value [

13].

In terms of resource management, both approaches support reducing primary resource use by extending product lifespans and incorporating recyclable and renewable materials. This helps to minimize dependency on critical raw materials and supports the reduction of emissions and the adoption of sustainable production practices [

14].

The interactions between RL and the CE have a positive impact on both systems through mutual influences. These include efficiency improvements, innovations, and new designs, as well as economic and ecological benefits. Enhancements in one area lead to positive effects in the other. Higher efficiency in RL is reflected in well-organized processes, optimized products, and increased machine utilization. Additionally, reducing inventory levels optimizes resource use [

14].

Innovation and product design play a key role in enabling reuse and recycling. The choice of materials and how they are processed affect product lifespan and the possibility of later refurbishment [

2,

11].

There are also economic and ecological aspects. RL can reduce costs and increase profitability, while the reuse of secondary raw materials can provide financial benefits. Ecologically, it reduces emissions and conserves resources, thereby supporting the promotion of a sustainable circular system [

15].

3. Methodology

The present study employs a two-stage research design, combining secondary and primary data analysis. The initial stage of the research involves conducting an SLR to establish a theoretical foundation regarding the role of RL within the CE and to identify related success factors and challenges in SMEs. The SLR was selected as a methodological approach due to its structured, transparent, and replicable nature, following the guidelines outlined by Töpfer (2012) [

16]. This process entailed systematic identification, screening, categorization, and evaluation of relevant academic studies within the defined research domain [

16].

The selection of Scopus as the database for the literature search was made based on its comprehensive interdisciplinary coverage and alignment with SLR standards. Preliminary comparisons with other databases revealed no significant discrepancies in retrieved publications, thereby providing a robust rationale for the exclusive utilization of Scopus. A comprehensive keyword combination was developed to capture all relevant aspects of the topic. The precise search terms and parameters are enumerated in

Table 1.

In the second stage, the findings of the SLR were complemented by primary data collected through semi-structured expert interviews. These interviews furnished practical perspectives and industry-specific insights, thereby enriching the theoretical results with empirical validation and contributing to a more comprehensive understanding of RL in the context of CE implementation in SMEs.

To reduce the volume of literature relevant to the forward search, the period over which data was collected was limited to the years 2018 to 2024. The scientific literature from the last six years, therefore, forms the basis for the following literature analysis. In conducting the present literature search, the following document types were utilized: conference papers, individual book chapters, and articles. Furthermore, the following categories were defined for the search: “engineering”, “environmental sciences”, “economics”, “econometrics and finance”, and “economics, management and accounting”.

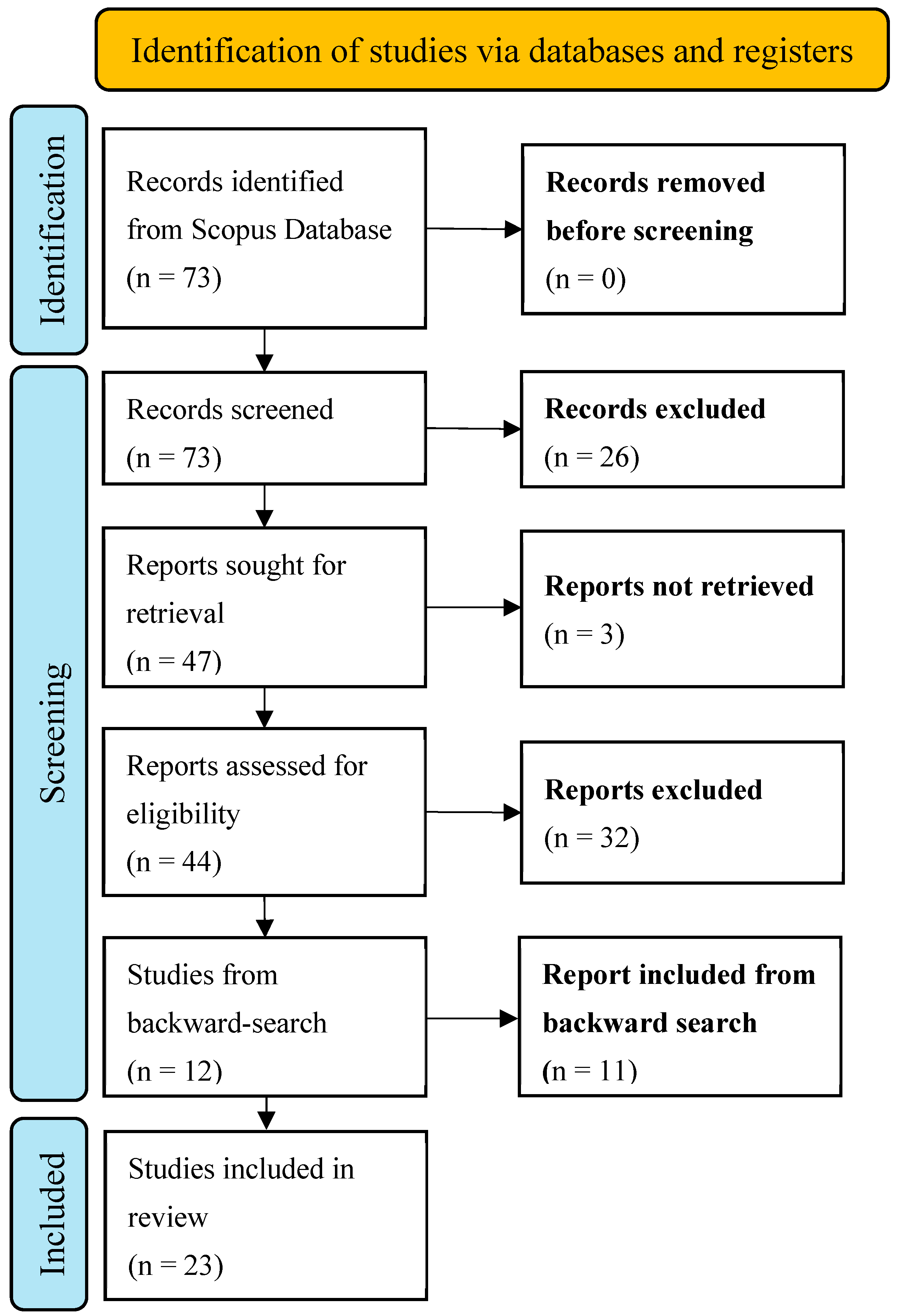

The search string includes the keywords “circular economy”, “barriers”, “success factors”, and “SME” as well as the corresponding synonyms for each of these terms. The analysis showed that a total of 73 sources could be assigned to the search string. In addition, a backward search was carried out to extend the theoretical scope and to enable a detailed analysis of the topic of RE about the challenges and success factors for SMEs. The visualization of the selection process according to PRISMA is shown in

Figure 1 [

17].

The initial assessment of the literature was based on the title and abstract. To ensure internal validity, each author conducted the assessment independently. Based on the screening of titles and abstracts, and the inclusion and exclusion criteria in

Table 2, 41 articles were initially classified as “suitable”, 6 articles as “possibly suitable”, and 26 studies as “not suitable”. After re-examination, the 6 articles previously rated as “possibly suitable” were categorized as “suitable”. For the full-text analysis, 47 publications were classified as “suitable”, although 3 of these had to be excluded because the files could not be accessed. Finally, 44 articles were analyzed using full text analysis, and 12 sources were identified as “suitable”, meeting the criteria in

Table 2. In the final stage, a backward search was conducted, which resulted in the identification of a further 11 research papers. After the final analysis, a total of 23 sources were used for content analysis. The selection was also based on the previously defined inclusion and exclusion criteria, which are listed in

Table 2.

The implementation of the SLR and the subsequent evaluation of the relevant literature form the basis for the empirical part of this paper. To make a reliable statement about the challenges and success factors for SMEs in the field of RL and the CE, expert interviews were conducted. Before participating, all respondents were informed about the purpose of the study and gave their verbal consent. It was also ensured that the respondents were informed of the anonymity of the survey.

Six interviews were conducted with experts, which were described as semi-structured, and the Kuckartz method was used to ensure optimal data analysis in this thesis. This type of analysis is also referred to as content structuring and qualitative content analysis. This qualitative analysis focuses primarily on the text, which means that the content of the statements is particularly relevant and essential for processing and presentation. Following Kuckartz’s method of structured qualitative content analysis, consistency between coders was ensured through the following procedures: First, the category system was developed collaboratively. Second, selected interview excerpts were coded jointly. Third, all discrepancies were discussed and resolved until complete agreement was reached. This approach is based on methodological transparency and conceptual alignment, which are central to the logic of qualitative research.

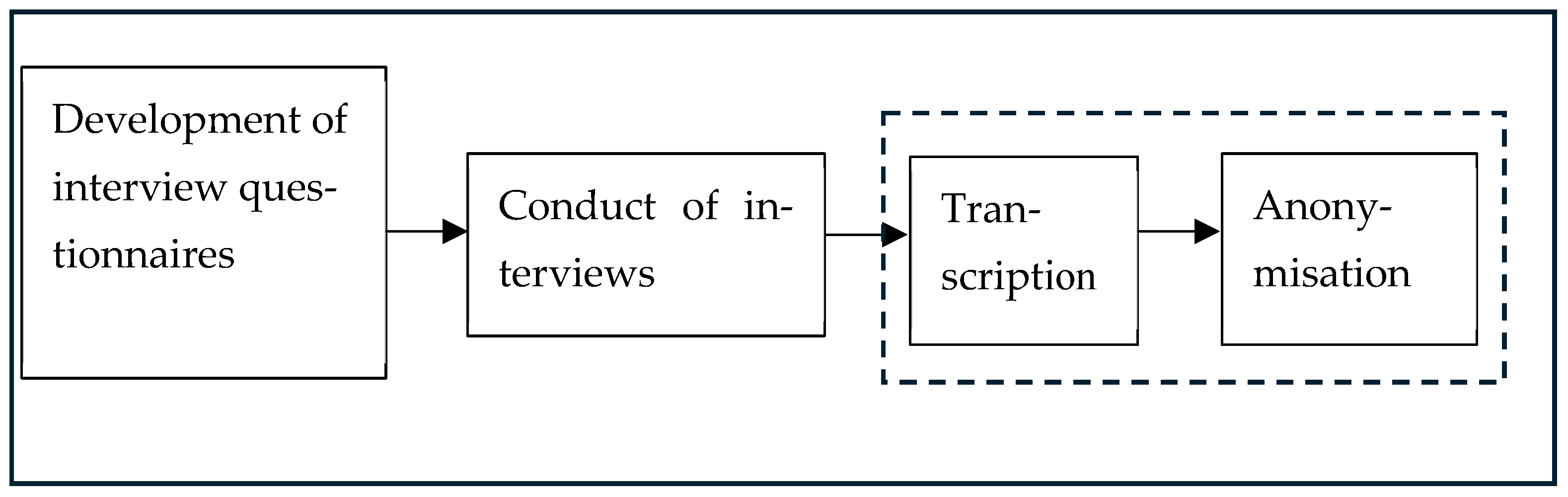

Figure 2 and

Figure 3 show the process according to Kuckartz, including the preparation for the interviews and the subsequent content-structuring qualitative content analysis [

18].

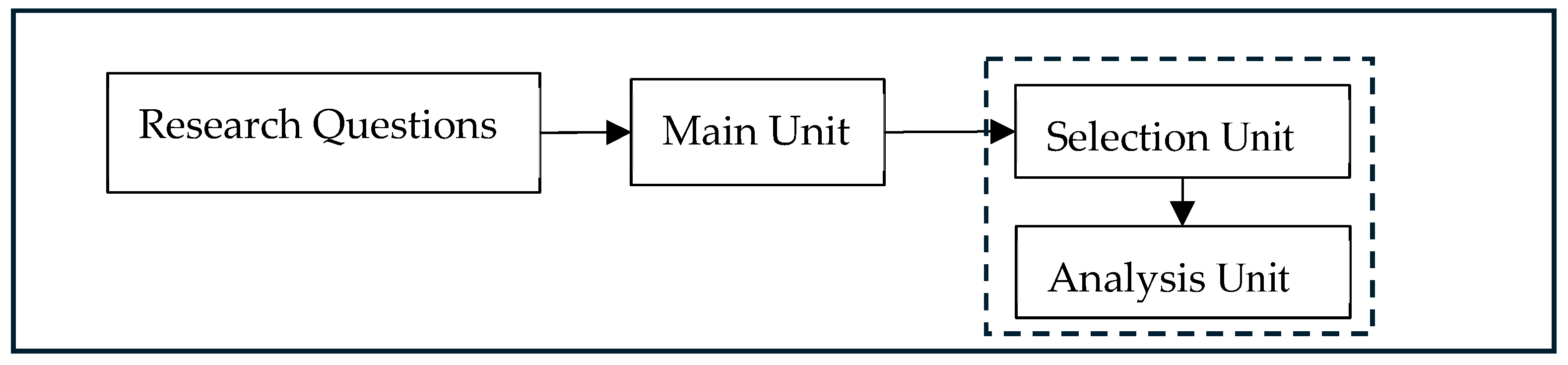

The planning stage involves defining the research questions and determining the population, the unit of analysis, and the unit of selection. The population is defined as the total number of interviewees relevant to the topic. In this specific case, a unit of selection is the number of all selected interviewees; six experts were chosen for this research. The unit of analysis in an interview study is an individual interview. The sum of all units of analysis is called the unit of selection [

18].

After this preparation, the questionnaire for the experts is drawn up, and the interviews are conducted. The individual interviews are then transcribed and anonymized [

18].

The interview guide covered topics such as strategic orientation, operational processes, technological readiness, collaboration practices, financial considerations, legal issues, and internal competencies. The six interviewees were all from SMEs, with four from the manufacturing sector, one from logistics, and one from environmental services. All the interviewees were senior professionals from SMEs who had decision-making authority. Each interview began with open-ended questions about the current state of reverse logistics within the SME, allowing the interviewees to elaborate on perceived barriers and success factors. Follow-up questions were then used to encourage clarification and provide examples. Interviews continued until thematic saturation was reached, as evidenced by the recurrence of core themes and the absence of new codes in the final two interviews.

The number of expert interviews conducted is consistent with prior qualitative research in the contexts of SME logistics and sustainability (e.g., Reefke and Sundaram, 2016; Govindan et al., 2024) [

19,

20]. In these studies, in-depth perspectives from a small, purposefully selected sample provide valuable insight into practical phenomena [

19,

20].

4. Content Analysis

The subsequent section will analyze the publications and interviews. The challenges and success factors of RL in SMEs are identified based on the studies. The challenges are categorized into the following: strategic, operational, financial, technological, and human resource challenges. The factors contributing to success can also be divided into the same categories. This categorization was defined in consultation and discussion with two other researchers.

4.1. Challenges Relevant to the Company

4.1.1. Strategic

Kolpinski et al. (2023) [

21] demonstrate in their study that the adaptation or expansion of processes frequently results in challenges in practice, as SMEs frequently possess limited capacity for implementing change. In this context, the absence of decision-makers who can make clear decisions regarding the use and sale of secondary materials has resulted in a problem. It is evident that the decision of SMEs to discontinue the utilization of RL within their operations is predominantly influenced by a paucity of incentives and the imposition of superfluous requirements [

21].

4.1.2. Operational

SMEs face many challenges when it comes to recycling and RL. According to Palombi et al. (2024), difficulties arise in waste management because waste, secondary, and by-products are often poorly defined [

22]. This applies to both pre-consumer and post-consumer waste. In addition, the necessary infrastructure for recycling and disposal is often lacking, which SMEs can hardly manage without external support, e.g., from public authorities [

23].

Another problem is the additional time and labor required for RL processes, as recent research shows. Many SMEs rely on external service providers to take back products [

24]. In this context, Howard et al. (2022) [

25] stress the importance of cooperation with stakeholders along the value chain. This cooperation is necessary for the successful implementation of recycling, recovery, or disposal [

26]. However, the willingness of customers to return waste is often insufficient, making implementation difficult. Although the integration of RL processes can, in principle, create value, the success of these measures depends heavily on the return behavior of customers [

25].

In addition, many SMEs lack appropriate recycling structures, especially for specialized products, which makes implementation more difficult [

24]. Dey et al. (2020) also point out that there is often a lack of financial and technological resources to set up comprehensive recycling and take-back logistics processes [

27]. In practice, therefore, SMEs often rely on mixed recycling approaches: on the one hand, waste is processed internally, and on the other hand, external processes are used, which in turn can lead to logistical challenges [

28].

Although optimized waste management and greener logistics could, in principle, help reduce emissions, these changes often prove problematic in practice. High emissions and transport costs are particularly challenging for SMEs, which means that conscious environmental protection is not always feasible in such cases [

24].

4.1.3. Technological

While new technologies offer opportunities for SMEs to develop, they also pose risks, as the necessary infrastructure for effective implementation is often lacking [

25]. Efficient waste collection and logistics processes are central to future technological developments. However, the speed with which technological adjustments need to be made poses significant challenges for SMEs. Material recycling requires high investment costs that are difficult for many SMEs to bear. Existing disposal processes, such as waste incineration, are increasingly being replaced by advanced recycling technologies to promote sustainability [

29].

4.1.4. Financial

Financial challenges compound existing problems. Cost is a key factor for SMEs and has a particular impact on processing and recycling. Palombi et al. (2024) highlight the high initial investment costs [

22]. In addition, there is often a lack of sufficient operating budgets, especially for reused, refurbished, or recycled products [

30].

4.1.5. Human Resources

In addition to the technological and financial aspects, the human factor is also a challenge. Rizos et al. (2016) point out that a lack of technical knowledge leads to internal problems [

31]. García-Quevedo et al. (2020) add that a lack of technical skills makes it challenging to implement reuse, recycling, and material recovery [

32]. Other studies also show that limited expertise and financial constraints hinder the implementation of recycling and RL [

33]. This lack of expertise is often due to a lack of education and training programs. Without targeted training, employees are often insufficiently prepared for the requirements of RL, leading to internal difficulties [

22]. An Italian study also confirms that a lack of knowledge makes it challenging to implement new take-back processes [

34].

4.2. Company-Relevant Success Factors

4.2.1. Strategic

By combining practices such as RL, waste management, and product reuse, SMEs can achieve comprehensive strategic value creation [

35]. In particular, according to Dey et al. (2019), lean approaches aimed at waste prevention contribute to waste reduction and enable cost savings [

36].

4.2.2. Operational

RL plays a central role in the sustainability of SMEs by enabling recovery, reuse, and recycling of products and materials. The CE can reduce environmental impacts and strengthen sustainability [

37]. It also raises awareness among SMEs and their customers, encouraging, for example, the return of old products and the reduction of packaging materials [

35]. An Italian study showed that customers are willing to participate in processes such as joint maintenance and disposal if this creates shared value [

38].

Progress in material recycling is seen as positive for SMEs because of the focus on sustainability. In particular, more environmentally friendly recycling methods are needed, as much waste is still incinerated, which, although efficient, is environmentally problematic [

29]. SMEs rely most on the recovery of raw materials as well as on adaptations and repairs [

39]. To ensure that products are disposed of in an environmentally sound manner at the end of their life cycle, SMEs need to provide their customers with comprehensive information and set up special take-back schemes [

37].

To make the return of products more attractive, SMEs offer waste management services and fee incentives to encourage customers to return their old products instead of disposing of them as waste [

24]. Examples include the collection of cardboard packaging or plastic film and the recycling of clothing by offering discounts as an incentive [

38]. Customer interest in the reuse of production waste has also increased by the use of secondary raw materials [

22]. This is also reflected in a study by Rizos et al. (2015), which confirms that the collection of old products increases customer awareness [

40].

Cooperation between customers and SMEs plays a key role in the joint disposal and return of products, leading to increased value added through RL activities [

38]. Targeted communication with customers should raise their awareness of recycling and reuse [

41]. Networking between SMEs in the same sector and cooperation along with the supply chain help to make RL more effective. This includes collecting used materials from customers, processing them by partner companies, and returning them to suppliers for reuse as secondary raw materials [

31,

38]. To promote these processes, technological integration and the provision of information are needed to incentivize the intensive use of reverse processes [

23].

4.2.3. Technological

The introduction of new technologies, such as RL, is a key factor in supporting activities along the value chain [

37]. The use of such technologies and the necessary expertise contribute significantly to the success of SMEs by expanding infrastructure and increasing efficiency [

21]. Industry 4.0 applications, which enable the intelligent networking of products, machines, and people, improve processes through optimized system networking [

35,

42].

The development of communication platforms along the value chain promotes exchange and collaboration between stakeholders and supports processes such as RL [

35]. According to Dey et al. (2020) and Prieto-Sandoval et al. (2021), Industry 4.0, IoT, big data, and cloud computing are crucial for comprehensive data management and integration of material flows [

27,

43]. Advanced technologies enable more efficient waste disposal and recycling processes, while virtual communication and employee training further facilitate implementation [

39].

4.2.4. Financial

SMEs can benefit from the recycling of discarded products and materials by reusing, refurbishing, or repairing them after their first use cycle. The recovery of materials and the use of repair and refurbishment facilities can generate new revenues. Return loops, which include different process steps such as repair, preparation for reuse, and material recycling, contribute to this. Although value creation in SMEs is often focused on cost reduction, a comprehensive approach can be helpful in the long term, primarily through the reuse and recovery of products. This requires a rethink along the entire value chain, including adjustments in supply chains and product design [

25]. According to Salvioni et al. (2022) [

34], operating costs can be reduced through internal material recovery and the purchase of recycled materials. Examples include the reuse of production waste, packaging, waste recycling, and incineration of residues for energy recovery [

34].

4.2.5. Human Resources

Well-trained staff is a key success factor for SMEs in implementing operational and strategic changes in the CE [

22]. Training promotes understanding of RL activities, such as the return of old and used products, and motivates employees to support them actively [

35].

Dey et al. (2020) emphasize the importance of comprehensive training to improve the knowledge of employees throughout the supply chain and to promote practices such as reuse, recycling, and waste reduction [

27]. Targeted training and the use of appropriate technologies have also significantly reduced production waste in SMEs [

23].

The next phase of the analysis involves a category-based examination of the expert interviews, focusing on the main categories. The main categories and subcategories were developed based on the content structure of the qualitative content analysis. Each of the two main categories was subdivided into subcategories, as all the main categories proved to be heterogeneous in content. The categorization and naming of the subcategories are based on the results of the systematic literature review. In addition, a new subcategory was added to the existing subcategories of enterprise-related challenges. This subcategory is called regulatory requirements. No additional subcategory was created for the enterprise success factors. The authors consider it more efficacious to reproduce the coded text of the interviews in tabular form (

Table 3), as this facilitates the presentation of the essentials of the subcategories in a transparent manner.

Table 3 shows the challenges and success factors relevant to the company, as identified in the interview study.

SMEs face strategic, operational, financial, technological, and human resource challenges in the context of RL and the CE. Strategically, there is a lack of process integration and sustainability awareness, while, operationally, complex take-back processes and a lack of customer buy-in make implementation difficult. Financial barriers include high investment costs and a lack of profitability, while technologically outdated systems and a lack of AI infrastructure are problematic. Staff training and awareness are needed. Success factors are a clear strategic focus; operationally, a robust supply chain and financial incentives; technologically, the implementation of new technologies; and well-trained, motivated staff. Regulatory requirements are not mentioned as a success factor.

In terms of the relative emphasis placed on themes in the expert interviews, operational and strategic challenges emerged most prominently, with 26 and 23 coded segments, respectively. Technological and human resource-related barriers were each mentioned ten times, while financial and regulatory issues were referenced seven times each. In terms of success factors, effective internal coordination, precise strategic alignment, and early planning were the most frequently highlighted enablers, followed by practical elements such as staff training, cross-functional collaboration, and customer incentives. This distribution highlights the particular importance of internal structures and planning capabilities for the successful implementation of reverse logistics in SMEs. This frequency-based approach provides an estimate of the relative importance of the most critical challenges and enablers, as perceived by practitioners.

5. Discussion

The results of the SLR are compared below with the results of the expert interviews. From a strategic perspective, both the SLR and the experts identified a lack of integration of RL processes. In contrast, from an operational standpoint, the lack of customer readiness and the complexity of RL processes are problematic. High investment costs, outdated technologies, and a lack of AI infrastructure are among the financial and technological challenges. On the human resources side, a lack of skilled labor and expertise is an obstacle. Strategic success factors include a clear focus on objectives; operationally, resilient supply chains; financially, value creation through returns; and technologically, the use of new technologies. Training and a motivated workforce are also seen as essential. Regulatory barriers are only relevant for challenges. The table below shows the comparison (

Table 4).

Based on our findings, several implications arise. Firstly, policymakers should focus on targeted funding and regulatory clarity to lower the entry barriers for SMEs engaging in reverse logistics. Companies could start by implementing low-cost, scalable solutions, such as simple take-back programs and digital tracking tools, while strengthening their cooperation within regional networks. Future research should explore how different policy environments influence the adoption of RL and evaluate the long-term impact of RL activities on SME performance across sectors.

While several categories, such as a lack of technical expertise or financial constraints, were commonly reported in both the literature and the expert interviews, notable differences emerged in other areas. For instance, practitioners emphasized regulatory ambiguity more strongly, whereas the academic literature often framed regulation more abstractly. Similarly, experts highlighted limited customer engagement as a significant obstacle, a topic that has received less attention in previous studies. These discrepancies may stem from the fact that the literature focuses on generalizable constructs, whereas SMEs face context-specific operational realities.

6. Conclusions

This study explored the barriers to, and enablers of, SMEs implementing RL within the CE. A dual-method approach of a SLR and expert interviews was used to capture both theoretical insights and practical realities.

The SLR revealed consistent challenges in the areas of strategy, operations, finance, technology, and human resources. Common themes included the insufficient integration of RL into a business strategy, limited financial capacity, outdated infrastructure, and a lack of employee expertise. The expert interviews confirmed these categories, but also revealed additional, more practical concerns, such as customer reluctance to participate in return systems and the administrative burden posed by regulatory frameworks.

Conversely, both methods highlighted similar success factors, such as strategic sustainability orientation, investment in digital tools, and stakeholder engagement. However, practitioners placed greater emphasis on adaptive management, internal collaboration, and informal knowledge flows—elements that are less present in academic literature.

This study provides valuable insights into the practices of reverse logistics in SMEs, although it is essential to consider the limitations of the study. The present study is qualitative and is based on six expert interviews. The results obtained from this particular methodology do not lend themselves to generalization. The opinions of the experts reflect the practical circumstances in the selected SMEs and thus contribute to enriching the results with nuanced knowledge from practice. Nevertheless, the limited scope of the sample and the geographical focus on German-speaking countries may impede the generalizability of the findings to other sectors or international contexts. Moreover, given the cross-sectional nature of the study, temporal developments cannot be considered. However, using a two-method approach enabled a thorough and well-founded analysis, which could form the basis for more extensive future research. As the sample is limited to German-speaking experts, predominantly from manufacturing and logistics sectors, future research should aim to include cross-regional comparisons, including underrepresented service industries, and potentially adopt longitudinal designs to capture change over time. Furthermore, excluding sectors such as agriculture and food, which face distinct RL conditions, could affect the generalizability of the results. Future research should explore cross-regional differences and expand sectoral coverage to improve our understanding of the context-specific dynamics of RL implementation in SMEs.

This contrast illustrates the importance of aligning theoretical models with SME-specific operational constraints to develop more effective RL strategies. Future research should examine sectoral and regional variations in RL practices and consider how regulatory conditions impact the ability of SMEs to implement circular processes. Comparative legal analyses could provide valuable insights into supportive versus restrictive policy environments. The study also highlights regulatory complexity as a cross-cutting challenge but does not distinguish between different types of regulatory influence. Future research could explore how various policy instruments, such as mandates, subsidies, or reporting requirements, affect the adoption of RL in SMEs differently. Comparative policy studies could also shed light on how supportive versus restrictive regulatory environments influence circular economy practices in different regions or sectors. Furthermore, the potential of artificial intelligence and digital platforms to facilitate RL, particularly in settings with limited resources, warrants further investigation. Studying incentive mechanisms, the behavioral aspects of product returns, and the long-term impact of RL on business resilience and sustainability performance would also contribute to a more nuanced understanding of circular transition pathways for SMEs.