1.1. Background and Motivation

Driven by the goal of “double carbon”, energy structure transformation and the construction of new power system have become the core of national strategy. While renewable energy sources, such as photovoltaic (PV) and wind power, are connected to the power grid on a large scale, their volatility poses a serious challenge to the flexible regulation of the system. Carbon-oriented energy system integration is increasingly becoming an important means of promoting the consumption of renewable energy [

1], among which virtual power plant (VPP), as a key carrier for aggregating distributed resources, urgently needs to integrate low-carbon technologies to support the cleaner operation of power grids [

2]. Oxy-fuel combustion capture (OCC) is a high-efficiency carbon reduction technology, which can realize fuller combustion by increasing the oxygen concentration in the combustion zone, reduce the emission of pollutants such as carbon monoxide, significantly reduce the nitrogen content in the flue gas, significantly increase the carbon dioxide concentration, greatly simplify the subsequent carbon capture process, and reduce energy costs. In addition, this technology is compatible with the existing coal-fired power plant infrastructure, with low retrofit cost and high thermal efficiency, which is one of the key technology paths to realize deep decarbonization in the industrial sector [

3,

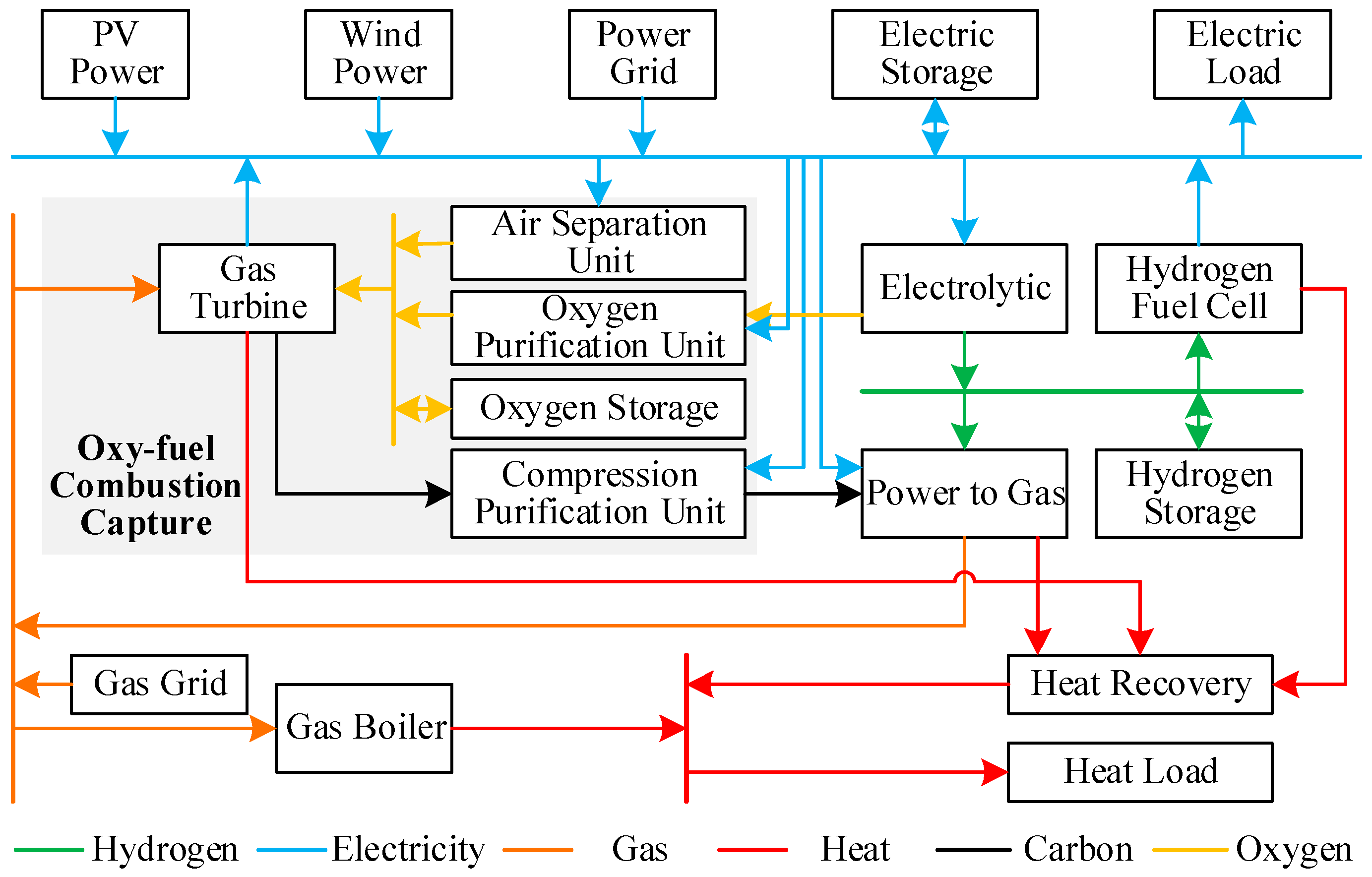

4]. Therefore, introducing OCC into VPP and constructing OCC-VPP is an important technological path to build a low-carbon and high-efficiency energy system, and its optimized operation has important engineering value to realize the strategic goal of energy transition.

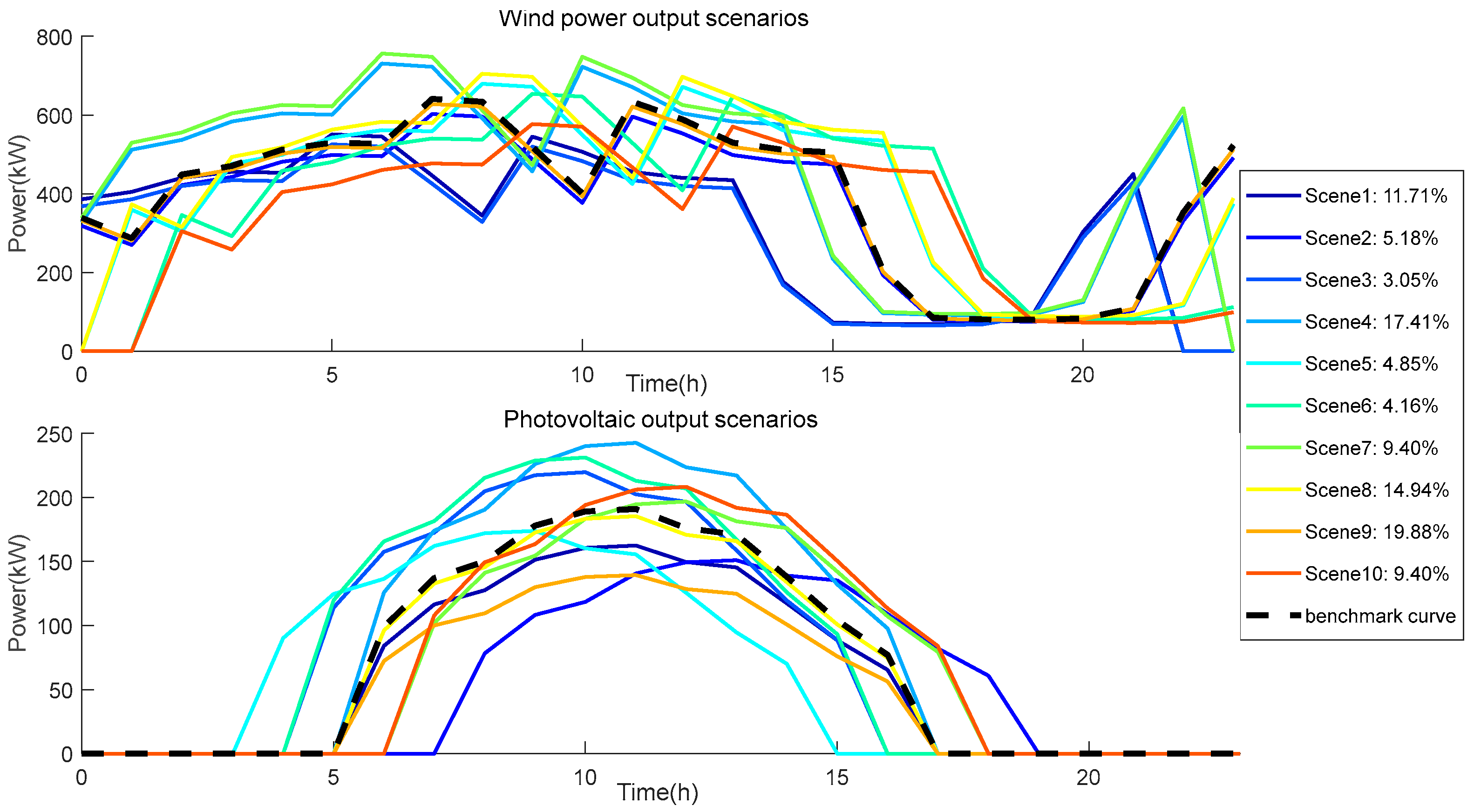

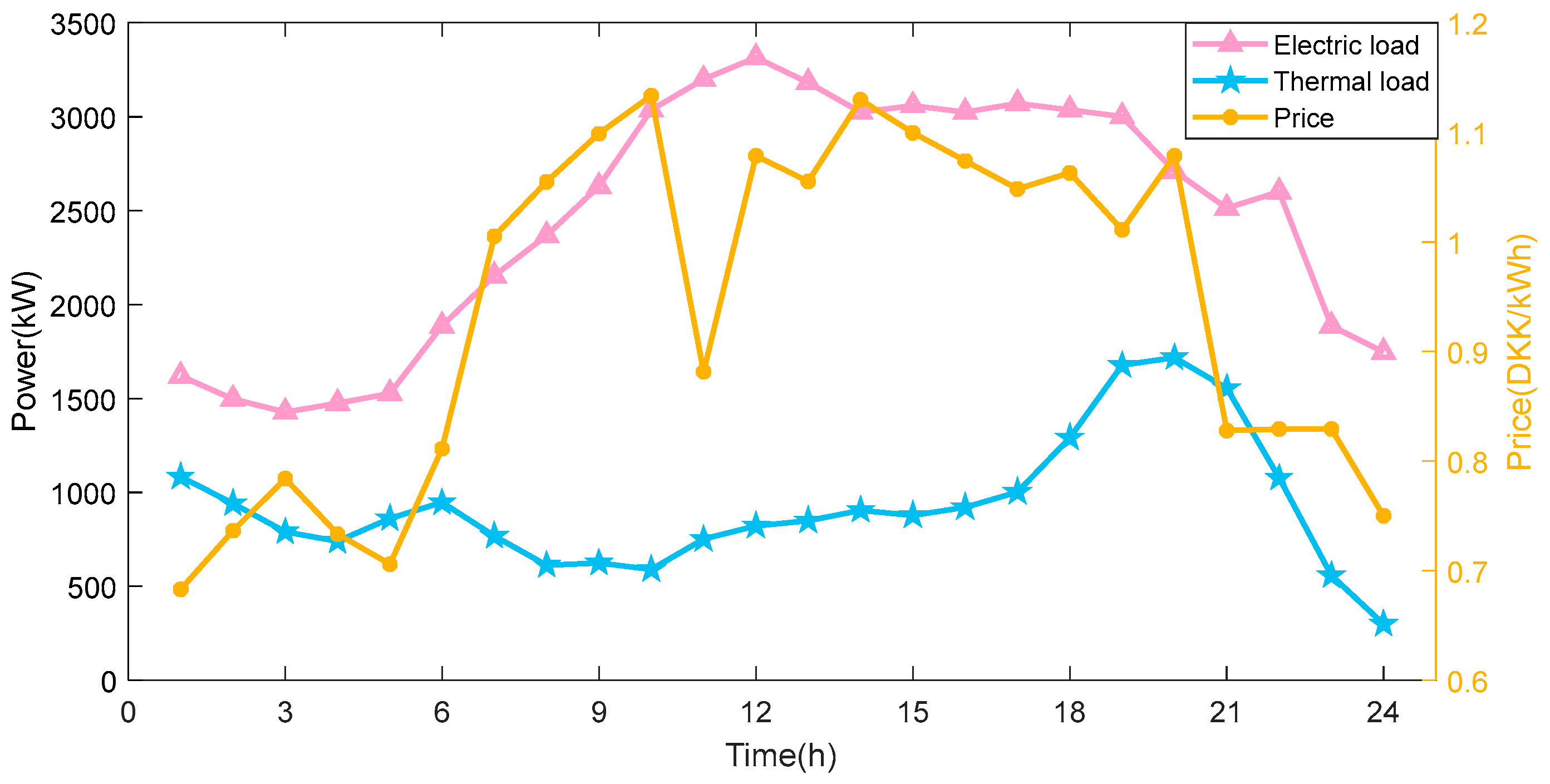

However, the actual scheduling of VPP faces a complex environment with multiple uncertainties superimposed. On the one hand, the uncertainty of source (wind power) and load (electricity/heat load) prediction deviation and electricity price fluctuation can easily lead to the deviation of the traditional deterministic optimization results from the reality, which can lead to the risk of wind abandonment, light abandonment, or imbalance of energy supply [

5,

6]; on the other hand, the carbon-emission cost under carbon trading has a direct influence on the system economy, but there is not yet a consensus on the form of carbon-emissions trading. Traditional stochastic optimization relies on the exact probability distribution, which is inefficient; robust optimization is overly conservative, which sacrifices too much in terms of economy. In this regard, there is an urgent need to establish a scheduling framework that takes into account both robustness and economy, and provides a scientific decision basis for the scientific and efficient operation of VPP by coupling the cost of carbon trading and finely modeling the multiple uncertainties in the source–charge–electricity price.

1.2. Literature Review

As the core carrier of integrating distributed energy resources, the research progress of VPP is mainly reflected in three aspects, namely, composition structure expansion, operation optimization model deepening, and an uncertainty handling method. In terms of composition structure, early research mainly focuses on the aggregation and dispatch of conventional resources such as wind, light, and storage, and in recent years, it gradually extends to the direction of multi-energy complementarity and decarbonization. Some scholars have explored the structure of VPP containing renewable energy sources such as wind and light and energy storage, which enhances the capacity of renewable energy consumption through energy-storage regulation. Heredia et al. combined wind power with large-scale energy storage to form a VPP, which transforms uncertain wind power generation into dispatchable output [

7]. Abdullah et al. combined the energy-storage system, wind power, photovoltaic, and small-scale conventional power plant combination to form a VPP and explored the techno-economics of this type of VPP in Malaysia [

8]. Dadashi et al. combined several wind farms and energy-storage systems in the form of a VPP and studied its strategy to participate in the market [

9]. Morcilla and Enano combined PV power-generation systems and centralized battery-storage systems in community residences to form a VPP, and investigated the impact on the distribution network reliability [

10]. Rodrigues et al. introduced electric-to-hydrogen conversion into a conventional VPP, and analyzed the impact of power to hydrogen (P2H) on the autonomous operation of the VPP and carbon-emission reduction [

11]. Yang et al. integrated distributed power generation, energy storage, and flexible loads for residential buildings to form a VPP, which provides a new energy solution to improve the renewable energy consumption capacity of residences [

12].

With the development of carbon capture technology, the introduction of carbon capture-generating units (CCUS) in VPPs, which can balance low carbon and controllable output, is increasingly garnering attention. Chen et al. introduced CCUS in a VPP to promote the economic and low carbon synergy of the VPP [

13]. Jin et al. coupled wind power, PV, cogeneration system, CCUS, and power to gas (P2G) to form a VPP which can cope with the uncertainty of wind power and PV output and achieve better environmental benefits [

14]. Ju et al. integrated wind power, PV, biomass power generation, and CCUS to form a VPP for rural areas, which provides a new technological pathway for the green and low-carbon transformation of energy sources in rural areas [

15]. Lin et al. proposed a multi-energetic VPP architecture integrating P2G, CCUS, and energy storage that optimizes renewable energy consumption and multi-market trading strategies through hydrogen-power coupling [

16]. Current carbon-capture units in VPPs mostly use traditional amine capture technology, which has high energy consumption and insufficient flexibility. In contrast, OCC has become an emerging research direction due to its ability to significantly reduce capture energy consumption, compatibility with existing gas facilities, and near-zero emissions. By supplying oxygen as a byproduct of hydrogen production through electrolytic cells to the OCC unit, it replaces some forms of producing oxygen through air separation with high energy consumption. At the same time, hydrogen is used for fuel-cell heating and methane conversion reactions, forming a closed-loop collaborative mechanism of renewable energy hydrogen production, oxygen recycling, and CO

2 resource utilization. For example, He et al. proposed a VPP structure considering oxygen-enriched combustion (OEC) and power-to-ammonia (P2A), aiming to achieve low-carbon economy of the VPP [

17]. Huang et al. constructed a VPP that combines wind power, photovoltaic, oxygen-enriched combustion, gas turbine, waste-heat recovery and utilization system, and proton-exchange membrane electrolysis (PEMEL), and the VPP can be utilized through multi-energy complementation and energy gradient utilization to achieve low-carbon and economic operation of VPP [

18]. Compared with existing research that commonly uses high-energy-consumption amine-based carbon-capture technology (such as CCS), the OCC-VPP design in this paper can reduce carbon-capture energy consumption and utilize oxygen storage tanks to achieve cross-period oxygen–carbon collaborative scheduling, providing a new technological path for VPP that combines deep decarbonization and multi-energy complementarity characteristics.

In the field of operation optimization, the existing research results are relatively abundant, which lays a good foundation for this paper. Earlier optimization models had economics as a single objective, and scheduling was achieved by minimizing the cost of purchased electricity/gas or the penalty for wind and light abandonment. Huang et al. constructed an scheduling model for VPPs by considering interval forecasting of loads and outputs, and with the objective of cost minimization [

19]. Zhu et al. proposed a two-tiered economic scheduling method for VPPs by considering the different interests of VPPs and system operators [

20]. Park et al. considered the network conditions of the distribution system operator, proposed a scheduling model by maximizing VPP’s profit, and the simulation results show that the proposed model improves VPP’s profit by 1.6% compared to the traditional method [

21]. Michael et al. considered the electrical parameter uncertainty and proposed a scheduling model by maximizing the revenue of VPP in the market, emphasizing the importance of the collaborative operation of VPP and demand response [

22]. Hou et al. developed a two-phase economic scheduling method for a multi-energy VPP in response to uncertainty of demand and response of flexible resources, and the simulation results revealed that the proposed method was superior in reducing the balancing cost caused by parameter deviations and improving the VPP economics [

23].

With the promotion of the carbon-trading mechanism, some studies have started to introduce carbon cost-related factors in VPP scheduling. Liu et al. proposed an optimal scheduling model for VPP covering demand response resources and photovoltaics by considering the carbon-emissions trading mechanism [

24]. Liu considered multiple energy sources complementing each other and the decarbonization of energy sources, and with the goal of maximizing the operational efficiency of the carbon-containing trading, he established a multi-VPP optimal scheduling model, and proposed a multi-region cooperative scheduling strategy for VPP [

25]. Zhang et al. analyzed the VPP operation mode under carbon-trading and green certificate trading mechanisms, and incorporated them into the scheduling model of VPP, in order to balance economy and environment [

26]. Li et al. evaluated the limitations of traditional energy sources, the unpredictability of renewable energy output, and the constraints faced by energy-storage devices in VPPs, and constructed a dispatch model of VPPs guided by the carbon tax framework, and the simulation results showed that the cooperation between VPP and storage brought mutual benefits to both the operator and the storage provider, and the carbon emissions are significantly reduced [

27]. Xie et al. constructed a VPP cluster cooperative operation optimization model by considering the carbon-emission constraints, and the results show the operating costs and carbon emissions of the three VPPs are reduced after VPP clusters operate [

28]. Zhou et al. analyzed the mode of VPP participating in the electricity and carbon markets, and constructed a scheduling strategy optimization model for multiple VPPs participating in the joint market, and the results showed the carbon emissions decreased by 31.3% through the cooperation, and at the same time, the total profit of the alliance increased [

29].

Since renewable energy (like wind power and PV) are usually included in VPPs, and load demand also exists in some VPPs, the source–load uncertainty problem is inevitably faced in VPP scheduling [

30,

31,

32]. For uncertainty optimization methods, stochastic optimization (SO) and robust optimization (RO) are the current mainstream frameworks. Stochastic optimization relies on an accurate description of the probability distribution of the scenery load, which requires a large number of scenarios to be generated to ensure the accuracy, and leads to a disaster in the solution dimension, making it difficult to meet the timeliness demand of the day-ahead scheduling [

33,

34]; robust optimization requires only the uncertainty set to describe the fluctuation boundaries of the scenery load, which ensures the feasibility of scheduling scheme under the worst scenarios but does not increase economical performance due to the over-protection of the guards [

35,

36]. In order to balance the two, distributionally robust optimization (DRO) describes the probability distribution uncertainty through the ambiguity set, but most of the existing studies are limited to a single source of uncertainty (e.g., only wind power or load), and the lack of joint modeling of the multiple uncertainties of “source-load-price” [

37,

38].

In summary, the following gaps exist in the existing studies: firstly, most of the existing VPPs adopt the energy-consuming traditional amine carbon-capture technology (e.g., CCUS), which has limited regulating capability, and the synergistic scheduling mechanism of OCC in VPPs has not yet been fully investigated, although it is highly energy-efficient; secondly, most of the existing dispatch models are limited to a single source of uncertainty, and lack the synergistic modeling of multiple source–load–price uncertainties, which makes it difficult for the optimization results to cope with the complex environment of overlapping fluctuations in practice.