Socio-Economic Benefits of Different Indonesian Crops: Opportunities for Sago Starch in Bioplastic Development

Abstract

1. Introduction

2. Materials and Methods

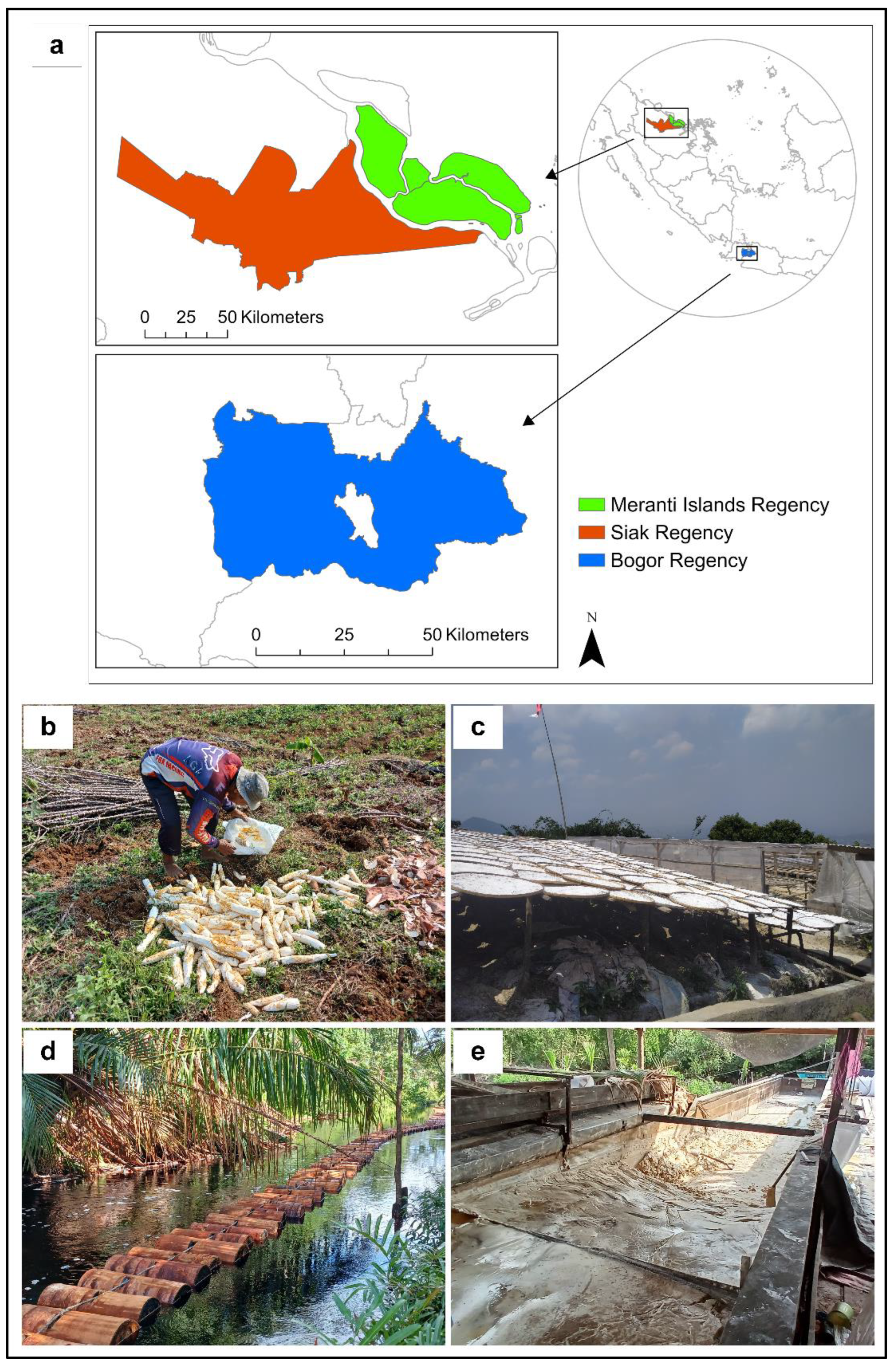

2.1. Study Areas

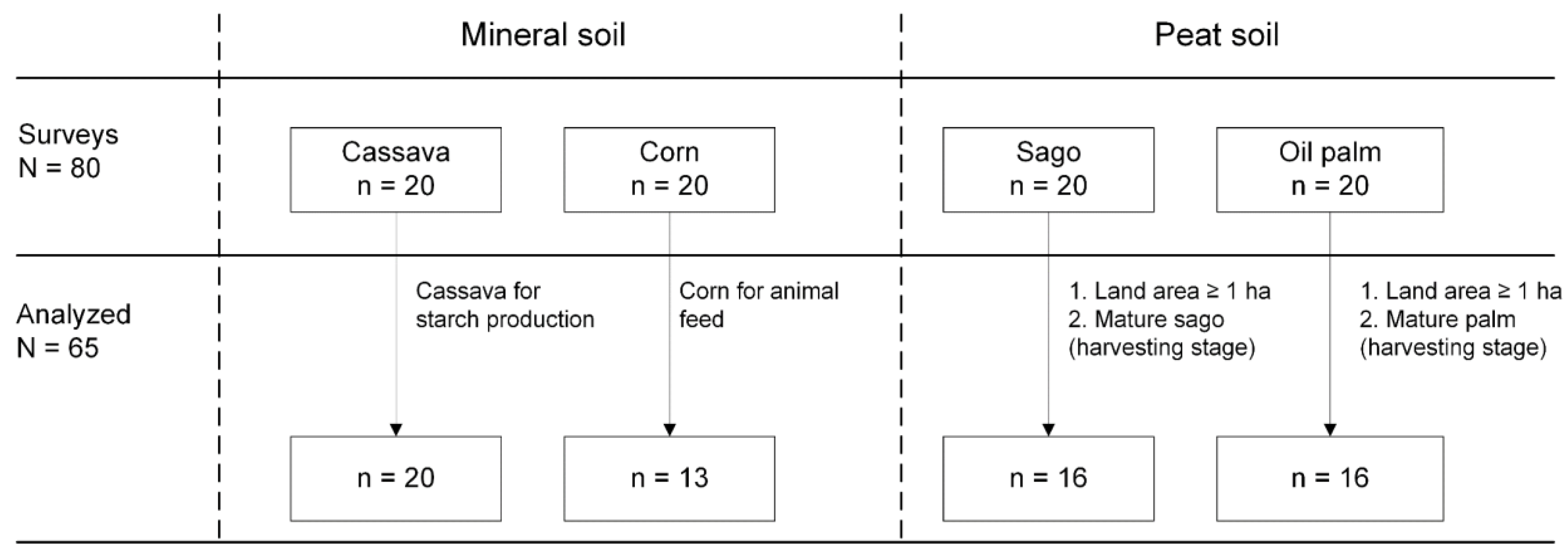

2.2. Data Collection

2.3. Analysis Framework

2.4. Analysis of Benefits Received by Farmers at the Farm Level

2.5. Analysis of the Social Cost of Carbon Dioxide (SC-CO2)

2.6. Value Added and Net Societal Benefit

2.7. Optimum Yield Scenarios of Sago and Oil Palm Farm-Level Benefits

3. Results

3.1. Costs and Revenues at the Farm Level

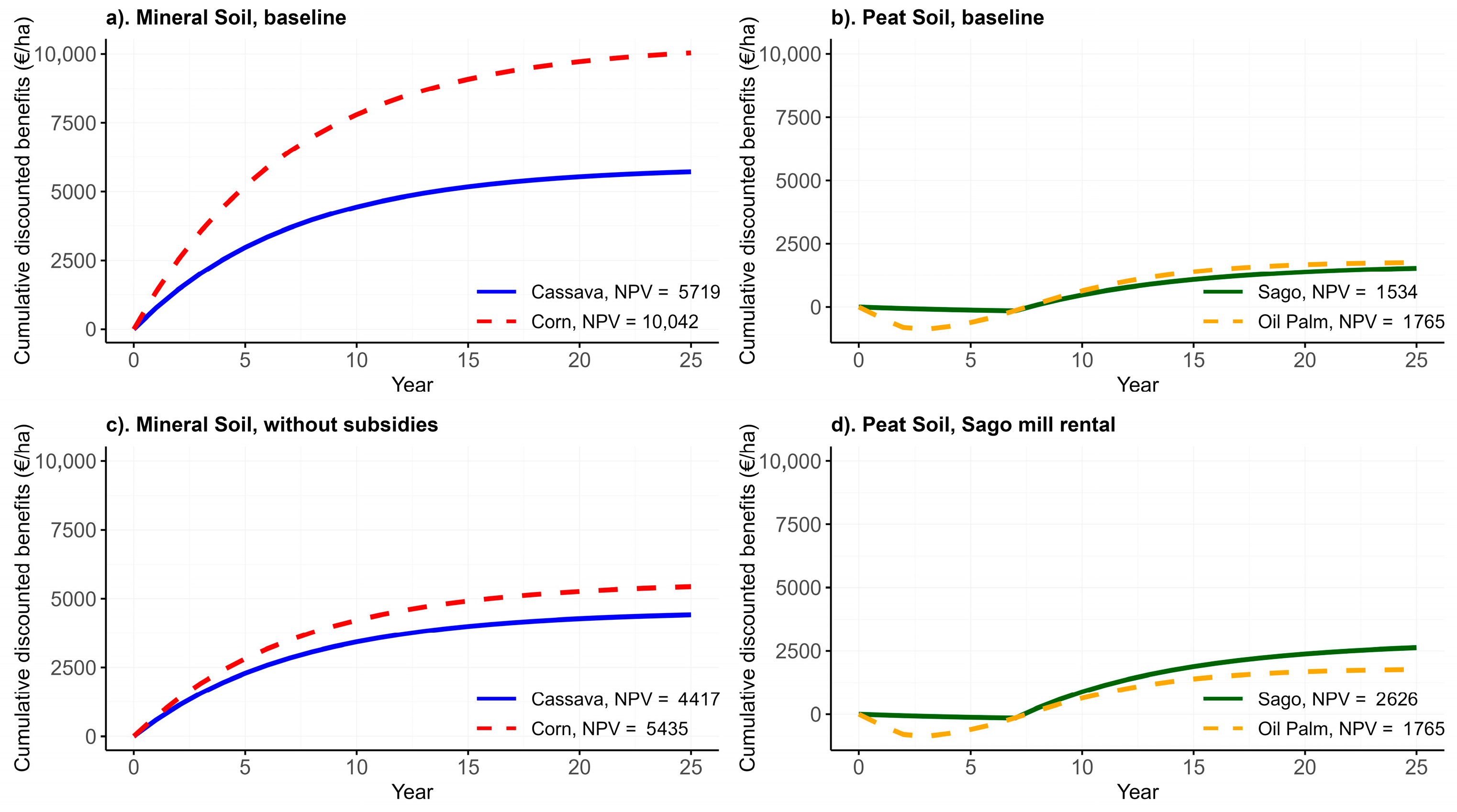

3.2. Benefits Received by Farmers at the Farm Level

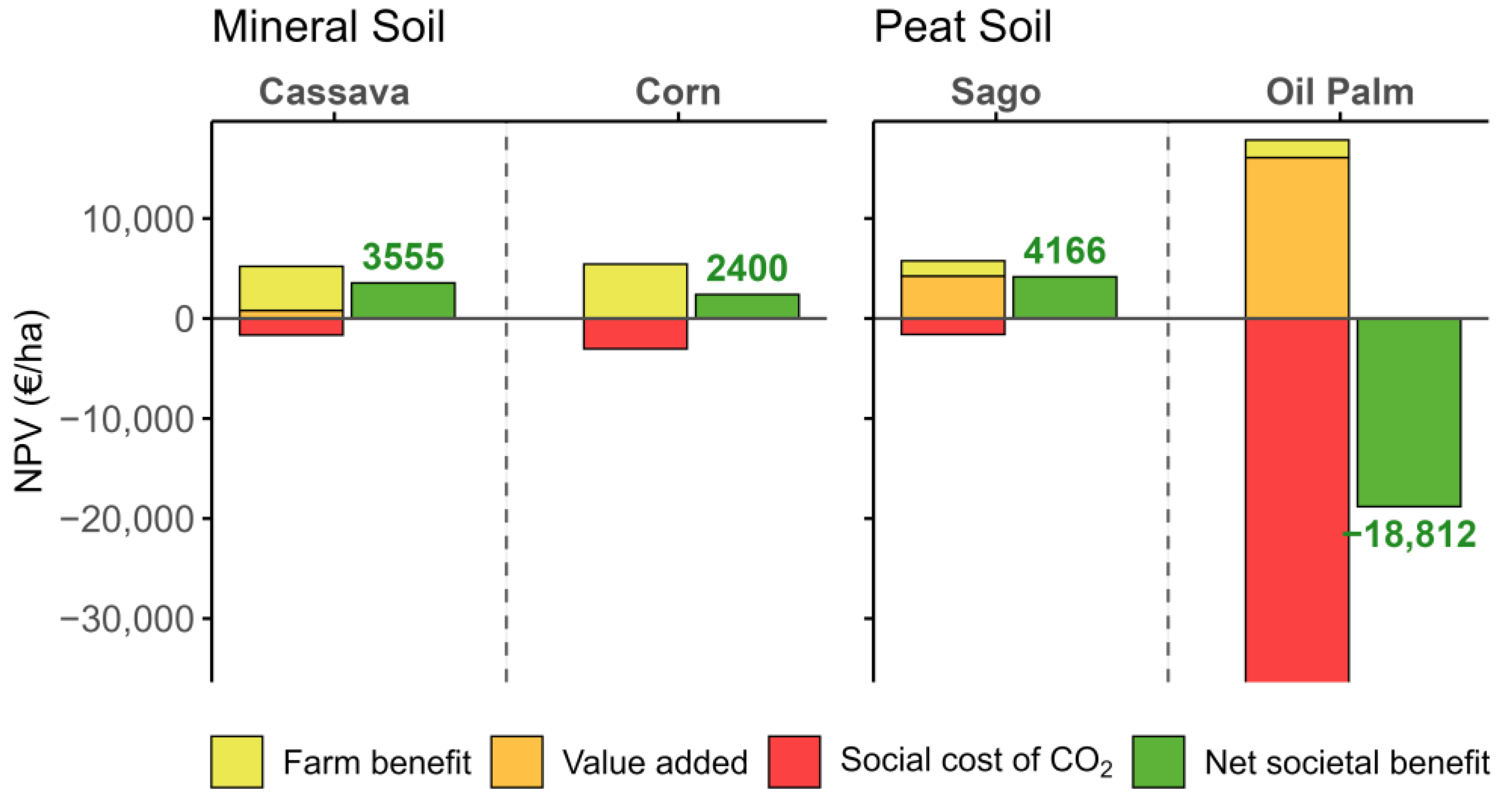

3.3. Social Cost of Carbon

3.4. Value Added Created and Net Societal Benefit

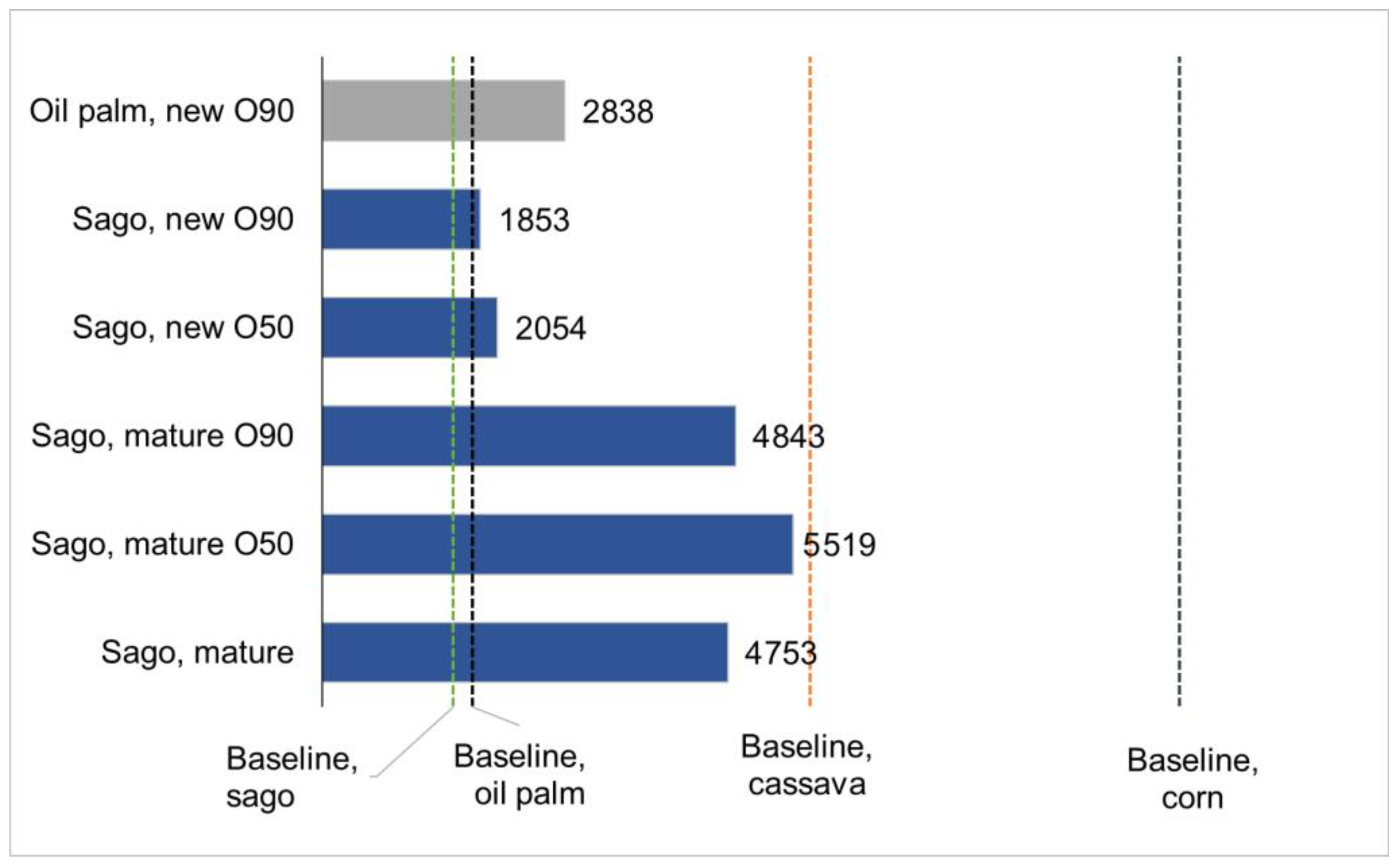

3.5. Optimum Yield Scenario of Sago and Oil Palm Farm Level Benefits

4. Discussion

4.1. Uncertainties and Limitations

4.2. Opportunity for Sago Starch Utilization as Bioplastic Feedstock

4.3. Policy Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CPO | Crude palm oil |

| FFB | Fresh fruit bunch |

| GHG | Greenhouse gas |

| NPV | Net present value |

| PK | Palm kernel |

| SC-CO2 | Social cost of carbon dioxide |

| US EPA | United States Environmental Protection Agency |

| YAP | Year after planting |

References

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-Sourced Polymers as Alternatives to Conventional Food Packaging Materials: A Review. Trends Food Sci. Technol. 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Langeveld, H.; Meeusen, M.; Sanders, J. The Biobased Economy: Biofuels, Materials and Chemicals in the Post-Oil Era; Earthscan: London, UK, 2010; ISBN 9781849774802. [Google Scholar]

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and Compostable Alternatives to Conventional Plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic Waste Inputs from Land into the Ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Lebreton, L.C.M.; van der Zwet, J.; Damsteeg, J.-W.; Slat, B.; Andrady, A.; Reisser, J. River Plastic Emissions to the World’s Oceans. Nat. Commun. 2017, 8, 15611. [Google Scholar] [CrossRef] [PubMed]

- Alexander, I.; Putri, M.M.W.; Simatupang, R.; Soepardjo, T. Plastic and Recycling Industry Outlook in Indonesia: An Assessment on Capacity and Capability; USAID/Indonesia: Jakarta, Indonesia, 2022.

- Narancic, T.; Verstichel, S.; Reddy Chaganti, S.; Morales-Gamez, L.; Kenny, S.T.; De Wilde, B.; Babu Padamati, R.; O’Connor, K.E. Biodegradable Plastic Blends Create New Possibilities for End-of-Life Management of Plastics but They Are Not a Panacea for Plastic Pollution. Environ. Sci. Technol. 2018, 52, 10441–10452. [Google Scholar] [CrossRef] [PubMed]

- Karjoko, L.; Handayani, I.; Jaelani, A.K.; Hayat, M.J. Indonesia’s Sustainable Development Goals Resolving Waste Problem: Informal to Formal Policy. Int. J. Sustain. Dev. Plan. 2022, 17, 649–658. [Google Scholar] [CrossRef]

- BPS National Export Import Data. Available online: https://www.bps.go.id/en/exim (accessed on 30 March 2025).

- Bakkalapulo, M. Can Bioplastics Turn the Tide on Indonesia’s Waste Problem? Available online: https://www.wbur.org/hereandnow/2018/10/24/indonesia-plastic-pollution (accessed on 14 February 2023).

- Mediatama, G. Kantong Singkong Naik Kelas. Available online: https://insight.kontan.co.id/news/kantong-singkong-naik-kelas (accessed on 15 February 2024).

- Yamamoto, Y. Evaluation and Development of Sago Palm as a Natural Starch Resource in the Tropics. Sago Palm 2019, 26, 44–52. [Google Scholar]

- van der Meer, P.J.; Tata, H.; Rachmanadi, D.; Arifin, Y.F.; Suwarno, A.; van Arensbergen, P. Developing Sustainable and Profitable Solutions for Peatland Restoration. IOP Conf. Ser. Earth Environ. Sci. 2021, 914, 012032. [Google Scholar] [CrossRef]

- Wardis, G. Socio-Economic Factors That Have Influenced the Decline of Sago Consumption in Small Islands: A Case in Rural Maluku, Indonesia. South Pac. Stud. 2014, 34, 99–116. [Google Scholar]

- Sidiq, F.F.; Coles, D.; Hubbard, C.; Clark, B.; Frewer, L.J. Sago and the Indigenous Peoples of Papua, Indonesia: A Review. J. Agric. Appl. Biol. 2021, 2, 138–149. [Google Scholar] [CrossRef]

- Amni, C.; Ismet; Aprilia, S. Mariana Study on Biodegradable Plastic from Sago with Addition of Glycerol and Serbitor. IOP Conf. Ser. Earth Environ. Sci. 2019, 365, 012052. [Google Scholar] [CrossRef]

- Ismail, H.; Zaaba, N.F. Tensile Properties, Degradation Behavior, and Water Absorption of Sago Starch Plastic Films. J. Vinyl Addit. Technol. 2012, 18, 235–240. [Google Scholar] [CrossRef]

- Ismail, H.; Zaaba, N.F. The Mechanical Properties, Water Resistance and Degradation Behaviour of Silica-Filled Sago Starch/PVA Plastic Films. J. Elastomers Plast. 2014, 46, 96–109. [Google Scholar] [CrossRef]

- de Léis, C.M.; Nogueira, A.R.; Kulay, L.; Tadini, C.C. Environmental and Energy Analysis of Biopolymer Film Based on Cassava Starch in Brazil. J. Clean. Prod. 2017, 143, 76–89. [Google Scholar] [CrossRef]

- Molenveld, K.; Post, W.; Ferreira, S.F.; de Sévaux, G.; Hartstra, M. Paving the Way for Biobased Materials: A Roadmap for the Market Introduction of PHAs; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2022. [Google Scholar]

- Anda, M.; Ritung, S.; Suryani, E.; Sukarman; Hikmat, M.; Yatno, E.; Mulyani, A.; Subandiono, R.E. Suratman Husnain Revisiting Tropical Peatlands in Indonesia: Semi-Detailed Mapping, Extent and Depth Distribution Assessment. Geoderma 2021, 402, 115235. [Google Scholar] [CrossRef]

- Mattila, T.J. The Role of Peatlands in Carbon Footprints of Countries and Products. Sci. Total Environ. 2024, 947, 174552. [Google Scholar] [CrossRef] [PubMed]

- Hooijer, A.; Page, S.; Canadell, J.G.; Silvius, M.; Kwadijk, J.; Wösten, H.; Jauhiainen, J. Current and Future CO2 Emissions from Drained Peatlands in Southeast Asia. Biogeosciences 2010, 7, 1505–1514. [Google Scholar] [CrossRef]

- UNEP Global Peatlands Assessment—The State of the World’s Peatlands: Evidence for Action Toward the Conservation, Restoration, and Sustainable Management of Peatlands; Global Peatlands Initiative; United Nations Environment Programme: Nairobi, Kenya, 2022.

- Budiman, I.; Bastoni; Sari, E.N.; Hadi, E.E.; Asmaliyah; Siahaan, H.; Januar, R.; Hapsari, R.D. Progress of Paludiculture Projects in Supporting Peatland Ecosystem Restoration in Indonesia. Glob. Ecol. Conserv. 2020, 23, e01084. [Google Scholar] [CrossRef]

- Monda, Y.; Kuwahara, S.; Aoki, Y.; Suzuki, H.; Kaneko, T.; Kozan, O.; Muhammad, A.; Susanti, R.; Gunawan, H.; Kanzaki, M. Productivity of Sago Palms on Smallholder Plantations after Rewetting in Previously Drained Peatland: A Case Study on Tebing Tinggi Island, Riau Province, Indonesia. Tropics 2022, 31, 11–32. [Google Scholar] [CrossRef]

- Pazli, P.; Pardhana, F. Crude Oil, Palm Oil and Sago Riau: For the Capitalists or the Residents to Stay? J. Econ. Coop. Dev. 2023, 44, 51–78. [Google Scholar]

- Uda, S.K.; Hein, L.; Adventa, A. Towards Better Use of Indonesian Peatlands with Paludiculture and Low-Drainage Food Crops. Wetl. Ecol. Manag. 2020, 28, 509–526. [Google Scholar] [CrossRef]

- Jabar, P. Produksi Ubi Kayu Berdasarkan Kabupaten/Kota Di Jawa Barat. Available online: https://opendata.jabarprov.go.id/id/dataset/produksi-ubi-kayu-berdasarkan-kabupatenkota-di-jawa-barat (accessed on 28 March 2023).

- Jong, F.S. An Overview of Sago Industry Development, 1980s–2015. In Sago Palm: Multiple Contributions to Food Security and Sustainable Livelihoods; Ehara, H., Toyoda, Y., Johnson, D.V., Eds.; Springer: Singapore, 2018; pp. 75–89. ISBN 978-981-10-5269-9. [Google Scholar]

- Swastiwi, A.W. Sagu Lingga: Kebijakan Ketahanan Pangan Masa Lalu dan Warisannya. J. Sos. Dan Sains 2021, 1, 1.423–1.435. [Google Scholar] [CrossRef]

- Muliany, P.H. Pusat Data Dan Sistem Informasi Pertanian; Ministry of Agriculture RI: Jakarta, Indonesia, 2021; p. 3.

- Schuiling, D.L. Growth and Development of True Sago Palm (Metroxylon Sagu Rottbøll) with Special Reference to Accumulation of Starch in the Trunk: A Study on Morphology, Genetic Variation and Ecophysiology, and Their Implications for Cultivation. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2009. [Google Scholar]

- Butler, R.A.; Koh, L.P.; Ghazoul, J. REDD in the Red: Palm Oil Could Undermine Carbon Payment Schemes. Conserv. Lett. 2009, 2, 67–73. [Google Scholar] [CrossRef]

- Calvo Buendia, E.; Tanabe, K.; Kranjc, A.; Baasansuren, J.; Fukuda, M.; Ngarize, S.; Osako, A.; Pyrozhenko, Y.; Shermanau, P.; Federici, S. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Leconte, M.C.; Mazzarino, M.J.; Satti, P.; Iglesias, M.C.; Laos, F. Co-Composting Rice Hulls and/or Sawdust with Poultry Manure in NE Argentina. Waste Manag. 2009, 29, 2446–2453. [Google Scholar] [CrossRef]

- Hooijer, A.; Page, S.; Jauhiainen, J.; Lee, W.A.; Lu, X.X.; Idris, A.; Anshari, G. Subsidence and Carbon Loss in Drained Tropical Peatlands. Available online: https://bg.copernicus.org/articles/9/1053/2012/ (accessed on 3 August 2023).

- IPCC. IPCC Fourth Assessment Report. IPCC Geneva 2007, 2007, 044023. [Google Scholar]

- Suswatiningsih, T.E.; Yulistiana, E.; Sayekti, A.A.S. Struktur biaya dan penentuan harga angkut TBS kelapa sawit oleh kontraktor. Agritech J. Fak. Pertan. Univ. Muhammadiyah Purwok. 2021, 23, 84–90. [Google Scholar] [CrossRef]

- Orentlicher, N. Carbon, Palms and Peat: Assessing the Environmental and Economic Sustainability of Sago. Master’s Thesis, Wageningen University & Research, Wageningen, The Netherlands, 2019. [Google Scholar]

- Jong, F.S.; Flach, M. The Sustainability of Sago Palm (Metroxylon Sagu) Cultivation on Deep Peat in Sarawak. Sago Palm 1995, 3, 13–20. [Google Scholar]

- RSPO. RSPO Smallholder Peat Best Management Practices Handbooks and Flood Risk Assessment Template; Roundtable on Sustainable Palm Oil: Kuala Lumpur, Malaysia, 2022. [Google Scholar]

- Woittiez, L.S.; van Wijk, M.T.; Slingerland, M.; van Noordwijk, M.; Giller, K.E. Yield Gaps in Oil Palm: A Quantitative Review of Contributing Factors. Eur. J. Agron. 2017, 83, 57–77. [Google Scholar] [CrossRef]

- Khasanah, N.; van Noordwijk, M. Subsidence and Carbon Dioxide Emissions in a Smallholder Peatland Mosaic in Sumatra, Indonesia. Mitig. Adapt. Strateg. Glob. Change 2019, 24, 147–163. [Google Scholar] [CrossRef] [PubMed]

- Castellanos-Navarrete, A.; Tobar-Tomás, W.V.; López-Monzón, C.E. Development without Change: Oil Palm Labour Regimes, Development Narratives, and Disputed Moral Economies in Mesoamerica. J. Rural Stud. 2019, 71, 169–180. [Google Scholar] [CrossRef]

- Hiraishi, T.; Krug, T.; Tanabe, K.; Srivastava, N.; Baasansuren, J.; Fukuda, M.; Troxler, T.G. (Eds.) IPCC 2013 Supplement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories: Wetlands; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- YKHI. Studi Rantai Pasok TBS Petani Kelapa Sawit Swadaya; Yayasan Keanekaragaman Hayati Indonesia: Jakarta, Indonesia, 2019. [Google Scholar]

- Harahap, F.; Silveira, S.; Khatiwada, D. Cost Competitiveness of Palm Oil Biodiesel Production in Indonesia. Energy 2019, 170, 62–72. [Google Scholar] [CrossRef]

- Simangunsong, B.C.H.; Fidela; Sitanggang, V.J.; Manurung, E.G.T.; Tambunan, A.H. Economic Value of Fresh Fruit Bunch from Oil Palm Plantation as Feedstock for Bioenergy in Indonesia. J. Jpn. Inst. Energy 2019, 98, 144–148. [Google Scholar] [CrossRef]

- MPOB Malaysia Prices of Crude Palm Oil 2023, Malaysian Palm Oil Board. Available online: https://bepi.mpob.gov.my/admin2/price_local_daily_view_cpo_msia.php?more=Y&jenis=1Y&tahun=2023 (accessed on 17 December 2024).

- Disbun Riau Harga TBS 2023, Dinas Perkebunan Riau. Available online: https://disbun.riau.go.id/rekap_harga_tbs (accessed on 17 December 2024).

- Carletto, C.; Gourlay, S.; Murray, S.; Zezza, A. Land Area Measurement in Household Surveys: Empirical Evidence and Practical Guidance for Effective Data Collection; World Bank: Washington, DC, USA, 2024. [Google Scholar]

- de Vos, R.E.; Nurfalah, L.; Tenorio, F.A.; Lim, Y.L.; Monzon, J.P.; Donough, C.R.; Sugianto, H.; Dwiyahreni, A.A.; Winarni, N.L.; Mulani, N.; et al. Shortening Harvest Interval, Reaping Benefits? A Study on Harvest Practices in Oil Palm Smallholder Farming Systems in Indonesia. Agric. Syst. 2023, 211, 103753. [Google Scholar] [CrossRef]

- Beegle, K.; Carletto, C.; Himelein, K. Reliability of Recall in Agricultural Data. J. Dev. Econ. 2012, 98, 34–41. [Google Scholar] [CrossRef]

- Kosmowski, F.; Chamberlin, J.; Ayalew, H.; Sida, T.; Abay, K.; Craufurd, P. How Accurate Are Yield Estimates from Crop Cuts? Evidence from Smallholder Maize Farms in Ethiopia. Food Policy 2021, 102, 102122. [Google Scholar] [CrossRef] [PubMed]

- Rennert, K.; Errickson, F.; Prest, B.C.; Rennels, L.; Newell, R.G.; Pizer, W.; Kingdon, C.; Wingenroth, J.; Cooke, R.; Parthum, B.; et al. Comprehensive Evidence Implies a Higher Social Cost of CO2. Nature 2022, 610, 687–692. [Google Scholar] [CrossRef] [PubMed]

- Tol, R.S.J. Social Cost of Carbon Estimates Have Increased over Time. Nat. Clim. Change 2023, 13, 532–536. [Google Scholar] [CrossRef]

- Couwenberg, J.; Hooijer, A. Towards Robust Subsidence-Based Soil Carbon Emission Factors for Peat Soils in South-East Asia, with Special Reference to Oil Palm Plantations. Mires Peat 2013, 12, 1–13. [Google Scholar]

- Evans, C.D.; Callaghan, N.; Jaya, A.; Grinham, A.; Sjogersten, S.; Page, S.E.; Harrison, M.E.; Kusin, K.; Kho, L.K.; Ledger, M.; et al. A Novel Low-Cost, High-Resolution Camera System for Measuring Peat Subsidence and Water Table Dynamics. Front. Environ. Sci. 2021, 9, 630752. [Google Scholar] [CrossRef]

- Mankong, P.; Fantke, P.; Ghose, A.; Soheilifard, F.; Oginah, S.A.; Phenrat, T.; Mungkalasiri, J.; Gheewala, S.H.; Prapaspongsa, T. Assessing Life Cycle Impacts from Toxic Substance Emissions in Major Crop Production Systems in Thailand. Sustain. Prod. Consum. 2024, 46, 717–732. [Google Scholar] [CrossRef]

- Boschiero, M.; De Laurentiis, V.; Caldeira, C.; Sala, S. Comparison of Organic and Conventional Cropping Systems: A Systematic Review of Life Cycle Assessment Studies. Environ. Impact Assess. Rev. 2023, 102, 107187. [Google Scholar] [CrossRef]

- Yusuf, M.A.; Romli, M.; Suprihatin, S.; Wiloso, E.I. Carbon Footprint of Semi-Mechanical Sago Starch Production. J. Ecol. Eng. 2019, 20, 159–166. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Knudsen, M.T.; Cederberg, C. Towards Better Representation of Organic Agriculture in Life Cycle Assessment. Nat. Sustain. 2020, 3, 419–425. [Google Scholar] [CrossRef]

- Hein, L.; Sumarga, E.; Quiñones, M.; Suwarno, A. Effects of Soil Subsidence on Plantation Agriculture in Indonesian Peatlands. Reg. Environ. Change 2022, 22, 121. [Google Scholar] [CrossRef]

- Sumarga, E.; Hein, L.; Hooijer, A.; Vernimmen, R. Hydrological and Economic Effects of Oil Palm Cultivation in Indonesian Peatlands. Ecol. Soc. 2016, 21, 52. [Google Scholar] [CrossRef]

- Taufik, M.; Setiawan, B.I.; Van Lanen, H.A. Increased Fire Hazard in Human-Modified Wetlands in Southeast Asia. Ambio 2019, 48, 363–373. [Google Scholar] [CrossRef] [PubMed]

- Wösten, J.H.M.; Van Den Berg, J.; Van Eijk, P.; Gevers, G.; Giesen, W.; Hooijer, A.; Idris, A.; Leenman, P.; Rais, D.S.; Siderius, C. Interrelationships between Hydrology and Ecology in Fire Degraded Tropical Peat Swamp Forests. Water Resour. Dev. 2006, 22, 157–174. [Google Scholar] [CrossRef]

- Hein, L.; Spadaro, J.V.; Ostro, B.; Hammer, M.; Sumarga, E.; Salmayenti, R.; Boer, R.; Tata, H.; Atmoko, D.; Castañeda, J.-P. The Health Impacts of Indonesian Peatland Fires. Environ. Health 2022, 21, 62. [Google Scholar] [CrossRef]

- Kiely, L.; Spracklen, D.V.; Arnold, S.R.; Papargyropoulou, E.; Conibear, L.; Wiedinmyer, C.; Knote, C.; Adrianto, H.A. Assessing Costs of Indonesian Fires and the Benefits of Restoring Peatland. Nat. Commun. 2021, 12, 7044. [Google Scholar] [CrossRef]

- Newby, J.; Smith, D.; Cramb, R.; Delaquis, E.; Yadav, L. Cassava Value Chains and Livelihoods in South-East Asia; ACIAR Proceedings Series, No. 148; Australian Centre for International Agricultural Research: Canberra, Australia, 2020; p. 114.

- Budidarsono, S.; Rahmanulloh, A.; Sofiyuddin, M. Economics Assessment of Palm Oil Production; Palm Oil Series; World Agroforestry Centre (ICRAF): Bogor, Indonesia, 2012; p. 6. [Google Scholar]

- Trisia, M.A.; Tachikawa, M.; Ehara, H. The Role of the Sago Supply Chain for Rural Development in Indonesia: A Review and Perspective. Rev. Agric. Sci. 2021, 9, 143–156. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Yoshida, T.; Goto, Y.; Nitta, Y.; Kakuda, K.; Jong, F.S.; Hilary, L.B.; Hassan, A.H. Differences in Growth and Starch Yield of Sago Palms (Metroxylon Sagu Rottb.) among Soil Types in Sarawak, Malaysia. Jpn. J. Trop. Agric. 2003, 47, 250–259. [Google Scholar]

- Euler, M.; Hoffmann, M.P.; Fathoni, Z.; Schwarze, S. Exploring Yield Gaps in Smallholder Oil Palm Production Systems in Eastern Sumatra, Indonesia. Agric. Syst. 2016, 146, 111–119. [Google Scholar] [CrossRef]

- Adriani, D.; Yazid, M.; Riswani; Damayanthy, D.; Choi, E.; Yang, H. Livelihood Alternatives in Restored Peatland Areas in South Sumatra Province, Indonesia. Land 2024, 13, 643. [Google Scholar] [CrossRef]

- FAO. Beje Aquaculture and Inland Fishery in Tropical Peatland of Indonesia; Mitigation of Climate Change in Agriculture (MICCA) Programme of FAO; Food and Agriculture Organization of the United Nations: Rome, Italy, 2016. [Google Scholar]

- do Val Siqueira, L.; Arias, C.I.L.F.; Maniglia, B.C.; Tadini, C.C. Starch-Based Biodegradable Plastics: Methods of Production, Challenges and Future Perspectives. Curr. Opin. Food Sci. 2021, 38, 122–130. [Google Scholar] [CrossRef]

- Satya, A.; Amalia, A.; Armanto, A.N.; Mutaqin, D.J.; Afriyanti, D.; Priyanto, E.B.; Prasetio, H.; Nasution, M.I.; Lusiana, S.; Gumilang, R.S. National Strategy on Wetland Management: Peatland Ecosystems and Mangroves; Ministry of National Development Planning of the Republic of Indonesia: Jakarta, Indonesia, 2022.

- Henning, F.G.; Ito, V.C.; Demiate, I.M.; Lacerda, L.G. Non-Conventional Starches for Biodegradable Films: A Review Focussing on Characterisation and Recent Applications in Food Packaging. Carbohydr. Polym. Technol. Appl. 2022, 4, 100157. [Google Scholar] [CrossRef]

- Seung, D. Amylose in Starch: Towards an Understanding of Biosynthesis, Structure and Function. New Phytol. 2020, 228, 1490–1504. [Google Scholar] [CrossRef]

- Jha, P.; Dharmalingam, K.; Nishizu, T.; Katsuno, N.; Anandalakshmi, R. Effect of Amylose–Amylopectin Ratios on Physical, Mechanical, and Thermal Properties of Starch—based Bionanocomposite Films Incorporated with CMC and Nanoclay. Starch—Stärke 2020, 72, 1900121. [Google Scholar] [CrossRef]

- Karim, A.A.; Tie, A.P.L.; Manan, D.M.A.; Zaidul, I.S.M. Starch from the Sago (Metroxylon Sagu) Palm Tree—Properties, Prospects, and Challenges as a New Industrial Source for Food and Other Uses. Compr. Rev. Food Sci. Food Saf. 2008, 7, 215–228. [Google Scholar] [CrossRef]

- Ahmad, F.B.; Williams, P.A.; Doublier, J.-L.; Durand, S.; Buleon, A. Physico-Chemical Characterisation of Sago Starch. Carbohydr. Polym. 1999, 38, 361–370. [Google Scholar] [CrossRef]

- Ismail, H.; Zaaba, N. Effect of Unmodified and Modified Sago Starch on Properties of (Sago Starch)/Silica/PVA Plastic Films. J. Vinyl Addit. Technol. 2014, 20, 185–192. [Google Scholar] [CrossRef]

- Sistem Informasi Pengelolaan Sampah Nasional, National Waste Management Information System. Available online: https://sipsn.menlhk.go.id/sipsn/ (accessed on 1 November 2024).

- Global Plastic Action Partnership and National Plastic Action Partnership. Radically Reducing Plastic Pollution in Indonesia: A Multistakeholder Action Plan; World Economic Forum: Cologny, Switzerland; Geneva, Switzerland, 2020. [Google Scholar]

- Cordova, M.R.; Nurhati, I.S. Major Sources and Monthly Variations in the Release of Land-Derived Marine Debris from the Greater Jakarta Area, Indonesia. Sci. Rep. 2019, 9, 18730. [Google Scholar] [CrossRef]

- Purba, N.P.; Faizal, I.; Christie, D.; Pratama, M.B.; Valino, D.A.; Martasuganda, M.K.; Herawati, T.; Wulandari, A.; Utami, S.T.; Aryanto, N.C.D.; et al. Mapping the Sources and Strands of Marine Debris via Particle Modelling and In-Situ Sampling Approaches in Archipelagic Countries. Sci. Rep. 2024, 14, 25804. [Google Scholar] [CrossRef] [PubMed]

- Dohong, A.; Abdul Aziz, A.; Dargusch, P. A Review of Techniques for Effective Tropical Peatland Restoration. Wetlands 2018, 38, 275–292. [Google Scholar] [CrossRef]

- Kalhori, A.; Wille, C.; Gottschalk, P.; Li, Z.; Hashemi, J.; Kemper, K.; Sachs, T. Temporally Dynamic Carbon Dioxide and Methane Emission Factors for Rewetted Peatlands. Commun. Earth Environ. 2024, 5, 62. [Google Scholar] [CrossRef]

- Afriyanti, D.; Hein, L.; Kroeze, C.; Zuhdi, M.; Saad, A. Scenarios for Withdrawal of Oil Palm Plantations from Peatlands in Jambi Province, Sumatra, Indonesia. Reg. Environ. Change 2019, 19, 1201–1215. [Google Scholar] [CrossRef]

- Winrock Protecting Peatlands While Shifting Toward Sustainable Palm Oil Production. Available online: https://winrock.org/protecting-peatlands-while-shifting-toward-sustainable-palm-oil-production/ (accessed on 28 July 2025).

- GEF Working Together to Conserve the Irreplaceable Peat Forests of Borneo. Available online: https://www.thegef.org/newsroom/feature-stories/working-together-conserve-irreplaceable-peat-forests-borneo (accessed on 28 July 2025).

- Zulkamaini, Z.; Nasution, M.S.; Rinto, R.; Meiwanda, G.; Bedasari, H. Public Private Partnerships in Peatland Management: A Design for Sustainable Practices; EDP Sciences: Les Ulis, France, 2024; Volume 506, p. 08001. [Google Scholar] [CrossRef]

- Miller, M.A.; Tonoto, P.; Taylor, D. Sustainable Development of Carbon Sinks? Lessons from Three Types of Peatland Partnerships in Indonesia. Sustain. Dev. 2022, 30, 241–255. [Google Scholar] [CrossRef]

- Anshari, G.Z.; Gusmayanti, E.; Afifudin, M.; Ruwaimana, M.; Hendricks, L.; Gavin, D.G. Carbon Loss from a Deforested and Drained Tropical Peatland over Four Years as Assessed from Peat Stratigraphy. Catena 2022, 208, 105719. [Google Scholar] [CrossRef]

- Mishra, S.; Page, S.E.; Cobb, A.R.; Lee, J.S.H.; Jovani-Sancho, A.J.; Sjögersten, S.; Jaya, A.; Aswandi; Wardle, D.A. Degradation of Southeast Asian Tropical Peatlands and Integrated Strategies for Their Better Management and Restoration. J. Appl. Ecol. 2021, 58, 1370–1387. [Google Scholar] [CrossRef]

| Revenue or Cost | Cassava | Corn | Sago ** | Oil Palm ** | ||

|---|---|---|---|---|---|---|

| a | b | a | b | |||

| Revenues | 1905.2 | 1905.2 | 3085.5 | 3085.5 | 887.3 | 1346.3 |

| Fixed costs | ||||||

| Land clearing or preparation | 287.6 | 287.6 | 127.5 * | 248.8 | 1.3 *** | 16.9 *** |

| Tool | 14.7 | 14.7 | 14.6 * | 15.6 | 3.7 | 5.8 |

| Membership | 0 | 0 | 11.6 | 0 | 0 | 0 |

| Tool maintenance | 0 | 0 | 0 | 0 | 0 | 3.4 |

| Land rental | 73.0 | 73.0 | 120.4 | 120.4 | 0 | 0 |

| Variable costs | ||||||

| Seed/seedling + planting | 70.1 | 70.1 | 30.6 * | 215.2 | 2.3 *** | 17.6 *** |

| Fertilizer | 330.7 * | 532.0 | 286.9 * | 912.8 | 0 | 205.7 |

| Pesticide | 29.5 | 29.5 | 79.3 * | 101.1 | 0 | 50.6 |

| Maintenance labor | 215.0 | 215.0 | 230.2 | 230.2 | 29.2 | 193.2 |

| Harvesting + post-harvesting | 0 | 0 | 500.2 | 500.2 | 119.2 | 233.7 |

| Fuel | 0 | 0 | 45.9 | 45.9 | 0 | 0 |

| Transport | 0 | 0 | 84.8 | 84.8 | 0 | 0 |

| Emissions Source | Unit | Cassava | Corn | Sago | Oil Palm |

|---|---|---|---|---|---|

| Manure | t CO2eq/ha | 0.5 | 1.0 | 0 | 0.0 |

| Urea | t CO2eq/ha | 1.5 | 2.3 | 0 | 0.5 |

| NPK | t CO2eq/ha | 0.2 | 0.8 | 0 | 0.2 |

| Dolomite | t CO2eq/ha | 0 | 0 | 0 | 0.1 |

| Peat oxidation | t CO2eq/ha | - | - | 2.2 | 48.6 |

| Total emissions | t CO2eq/ha | 2.2 | 3.6 | 2.2 | 49.5 |

| SC-CO2 | EUR/ha | 95.1 | 174.3 | 91.7 | 2105.0 |

| Initial Costs | Fixed Costs | Variable Costs | Output | Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cassava starch processing | ||||||||||||

| Building | EUR | 15,170 | Fuel and maintenance | EUR/year | 615 | Cassava input | kg/year | 480,000 | Starch output | kg/year | 120,000 | This study |

| Washing machine | EUR | 152 | Starch transport | EUR/year | 1129 | Cassava price | EUR/kg | 0.10 | Starch price | EUR/kg | 0.55 | |

| Rasping and sieving machines | EUR | 379 | Mill’s operation | EUR/year | 4733 | |||||||

| Grinding machine | EUR | 440 | Cassava peeling and carrying | EUR/year | 7565 | |||||||

| Whitener | EUR/year | 328 | ||||||||||

| Starch bag | EUR/year | 386 | ||||||||||

| Sago starch processing | ||||||||||||

| Building, machines | EUR | 15,777 | Maintenance | EUR/year | 728 | Sago log input | trunk/year | 2808 | Wet starch output | kg/year | 640,224 | This study |

| Mill operation | EUR/year | 6022 | Sago log cost | EUR/trunk | 24.43 | Wet starch price | EUR/kg | 0.18 | ||||

| Fuel | EUR/year | 2314 | Wet starch transport | EUR/year | 1942 | |||||||

| Rental scenario cost | EUR/year | 10,295 | ||||||||||

| Log peeling | EUR/year | 2726 | ||||||||||

| Log handling | EUR/year | 1363 | ||||||||||

| Wet starch packing | EUR/year | 2758 | ||||||||||

| CPO processing | ||||||||||||

| Building, machines | EUR | 5,662,830 | Production costs | EUR/year | 2,461,485 | FFB input | kg/year | 150,000,000 | CPO output | kg/year | 36,000,000 | [48,49,50,51] |

| FFB cost | EUR/kg | 0.14 | CPO price | EUR/kg | 0.78 | |||||||

| PK output | kg/year | 7,050,000 | ||||||||||

| PK price | EUR/kg | 0.33 | ||||||||||

| FFB collection and transport | ||||||||||||

| Operation and maintenance | EUR/year | 30 | FFB quantity | kg/year | 15,426 | FFB selling price | EUR/kg | 0.14 | [39] | |||

| Transport costs | EUR/year | 84 | FFB buying price | EUR/kg | 0.09 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sutawijaya, I.B.G.; Suwarno, A.; Hein, L. Socio-Economic Benefits of Different Indonesian Crops: Opportunities for Sago Starch in Bioplastic Development. Sustainability 2025, 17, 7351. https://doi.org/10.3390/su17167351

Sutawijaya IBG, Suwarno A, Hein L. Socio-Economic Benefits of Different Indonesian Crops: Opportunities for Sago Starch in Bioplastic Development. Sustainability. 2025; 17(16):7351. https://doi.org/10.3390/su17167351

Chicago/Turabian StyleSutawijaya, Ida Bagus Gede, Aritta Suwarno, and Lars Hein. 2025. "Socio-Economic Benefits of Different Indonesian Crops: Opportunities for Sago Starch in Bioplastic Development" Sustainability 17, no. 16: 7351. https://doi.org/10.3390/su17167351

APA StyleSutawijaya, I. B. G., Suwarno, A., & Hein, L. (2025). Socio-Economic Benefits of Different Indonesian Crops: Opportunities for Sago Starch in Bioplastic Development. Sustainability, 17(16), 7351. https://doi.org/10.3390/su17167351