An Experimental Study of Permeable Asphalt Pavement Incorporating Recycled Concrete Coarse Aggregates

Abstract

1. Introduction

2. Experimental Methodologies and Material Properties

2.1. Development of Recycled Coarse Aggregates

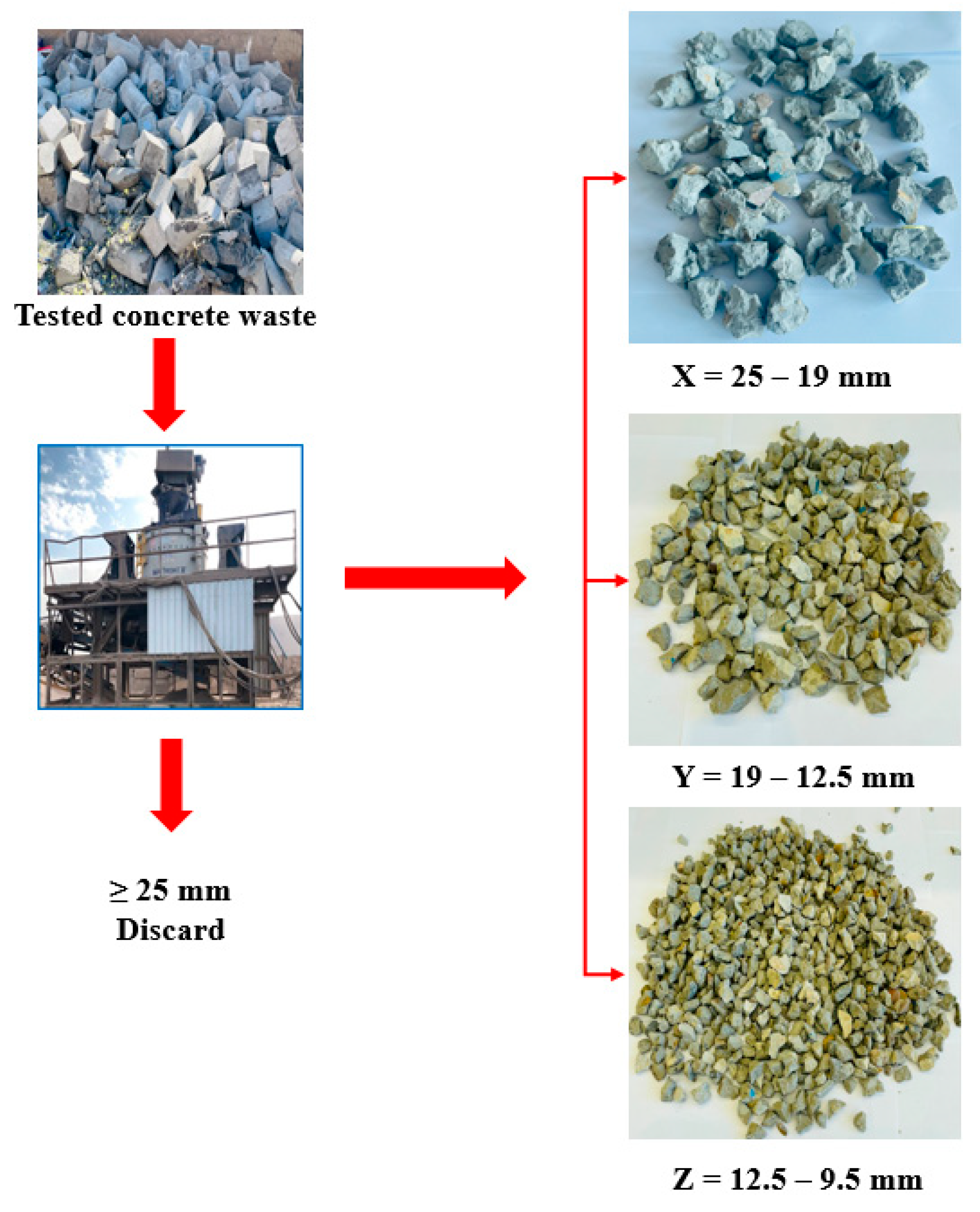

2.1.1. Preparation of Recycled Coarse Aggregate from Tested Concrete Waste

2.1.2. Properties of Graded Recycled Coarse Aggregate

2.1.3. Sieve Analysis Tests on Developed Recycled Coarse Aggregate

2.2. Properties of Asphalt and Optimal Binder Content

2.3. Design Criteria, Mix Types, and Formulating Permeable Asphalt Mixtures

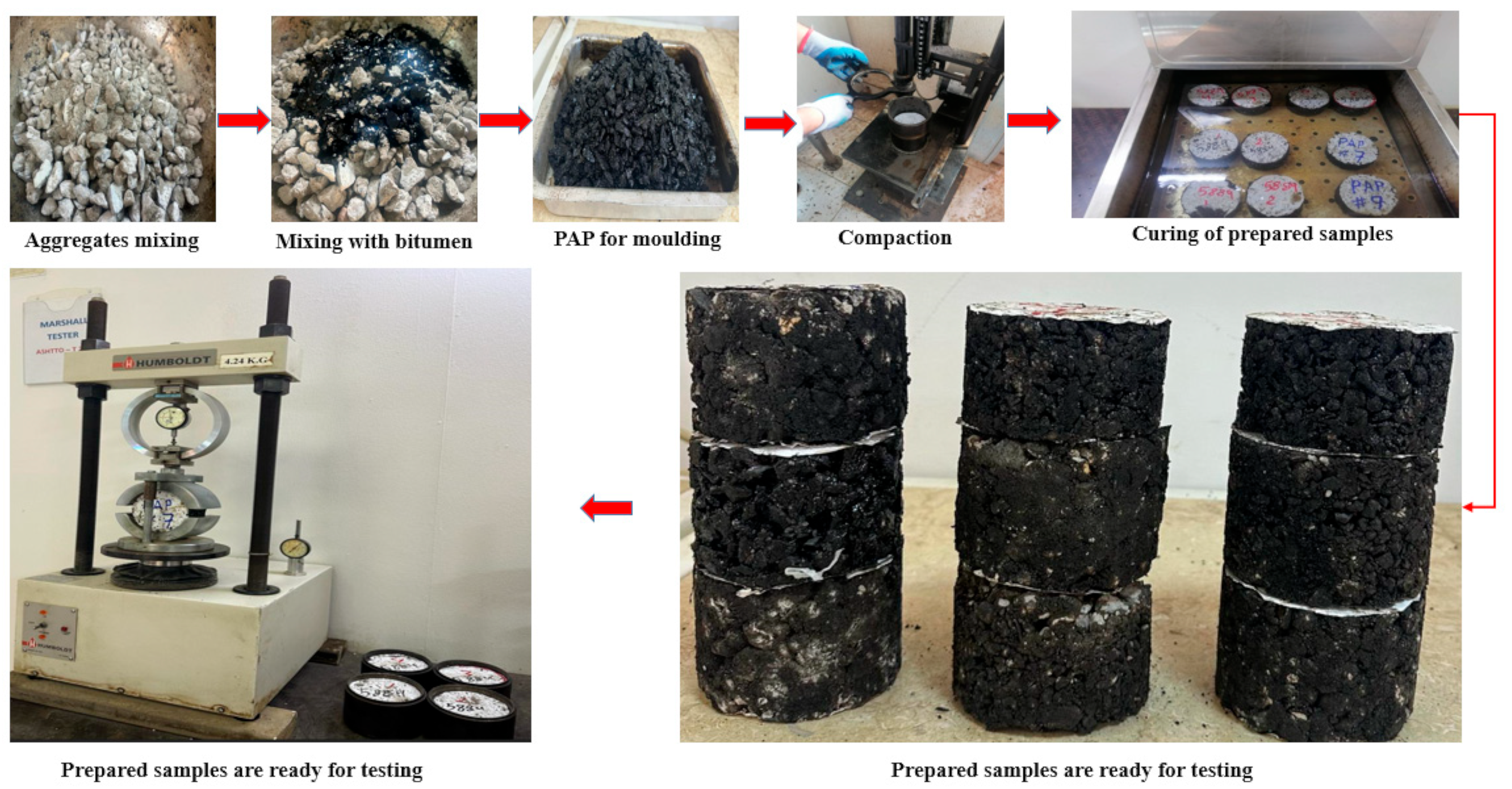

2.4. Fabrication of PAP Blend Specimens

2.5. Marshall Stability Method

3. Results and Discussion

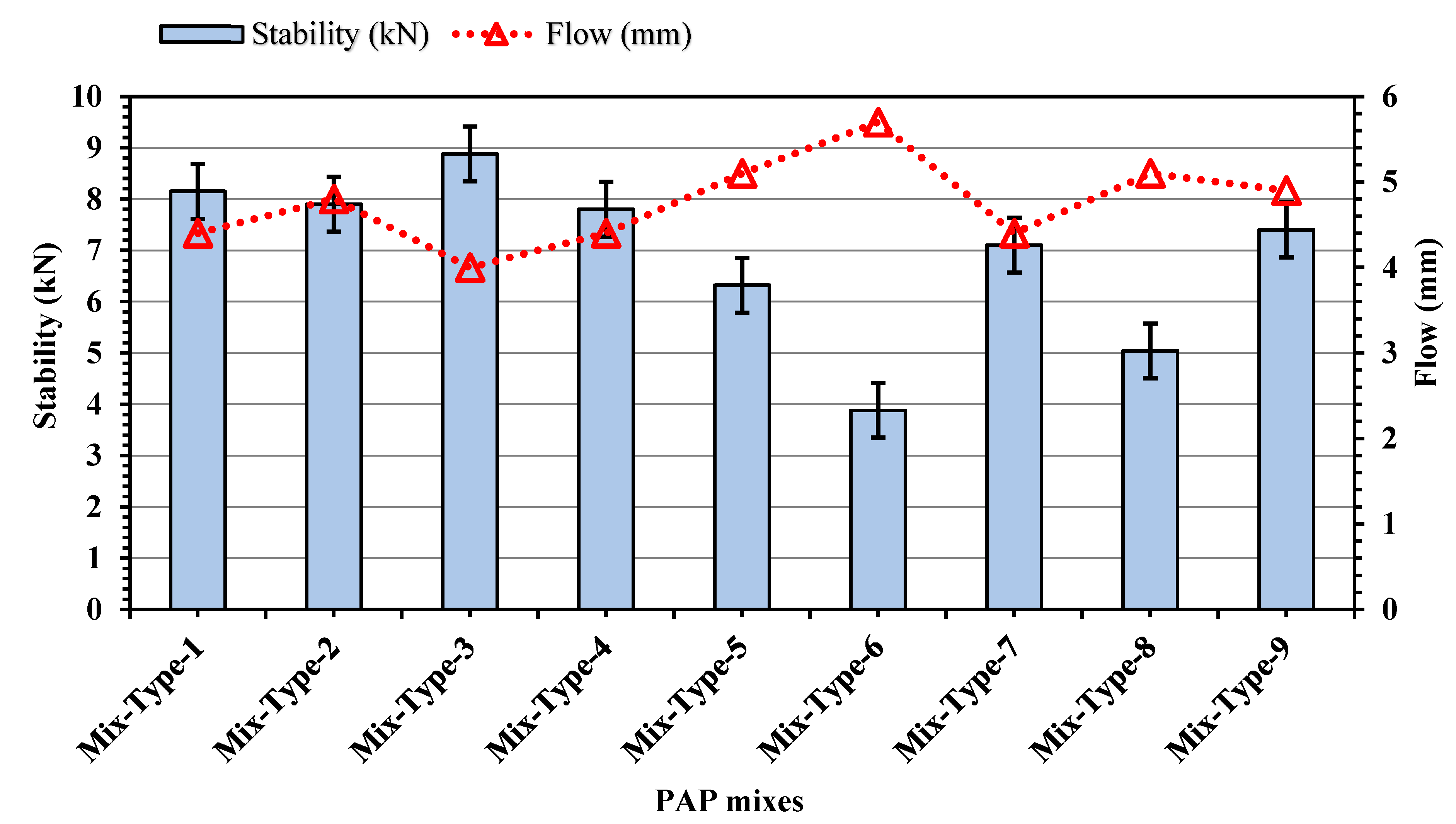

3.1. Stability and Flow Relationship

3.2. Stability Loss Analysis

- RSR = Remaining strength ratio;

- = Post-immersion stability after 24 h;

- = Pre-immersion stability.

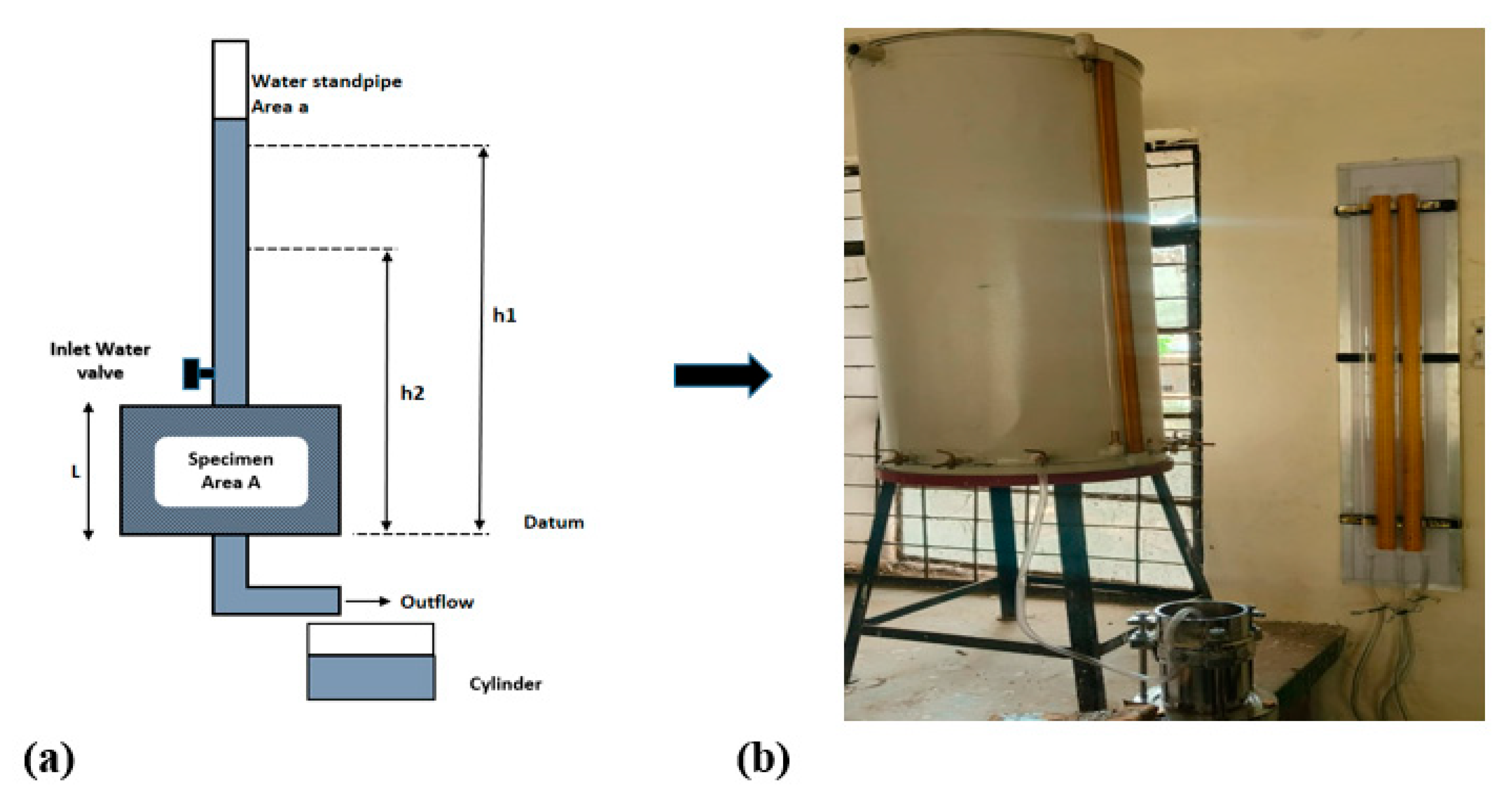

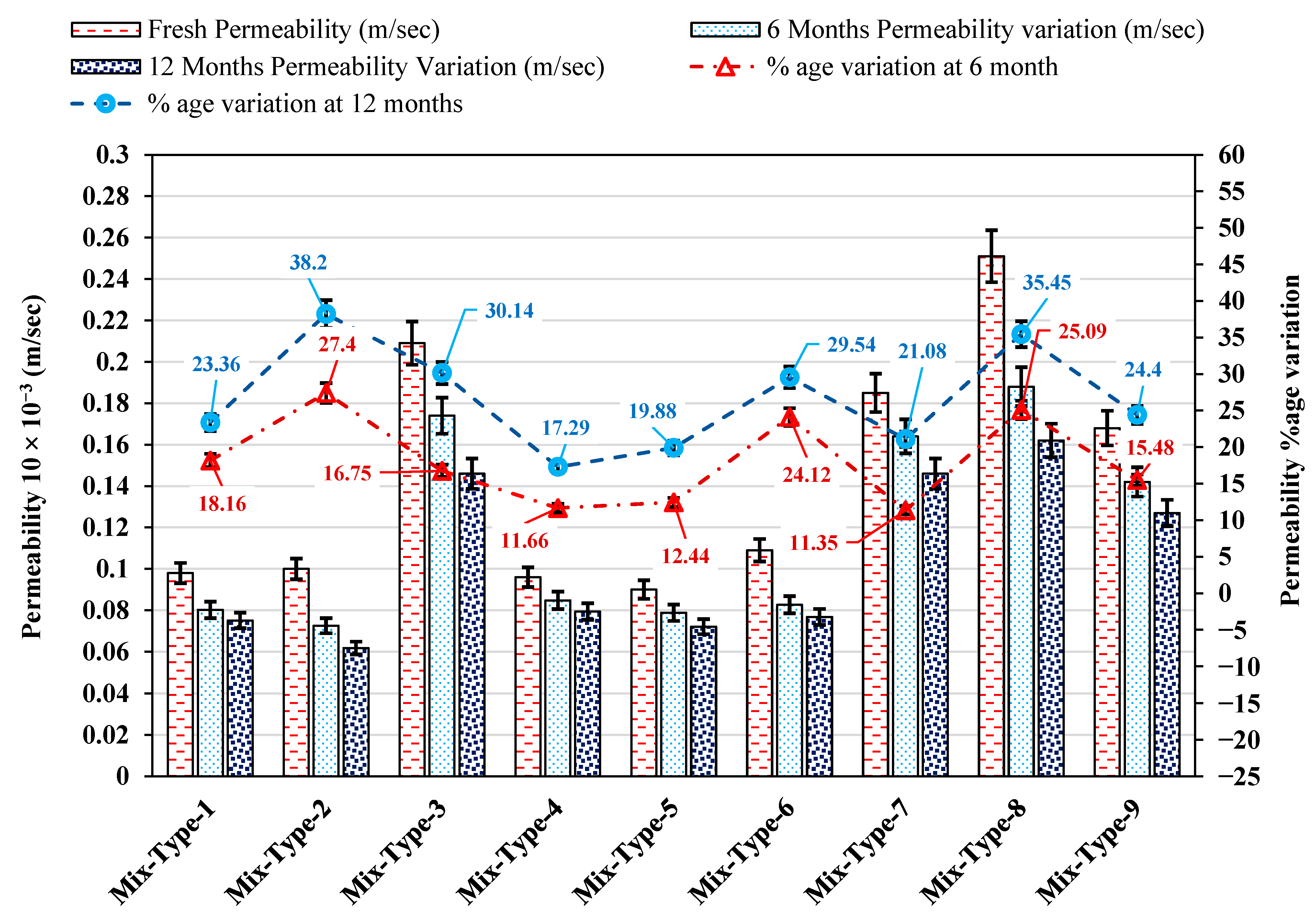

3.3. Permeability Coefficient (k)

3.3.1. Permeability (Mix-Type-1 to Mix-Type-9) Mixes

3.3.2. Correlation Analysis Between Permeability and Stability

4. Significance, Limitations, and Prospective

4.1. Significance

4.2. Limitations

4.3. Prospective Avenues for Further Investigation

5. Conclusions

- The developed RCA from tested laboratory cubes and cylindrical concrete waste produced successful experimental results in designing PAP mixes.

- The OBC for the PAP mixes of this study was reported to be 6%, which is slightly higher than that of natural aggregates.

- The highest Marshal stability, 8.88 kN, and lowest flow, 4.0, were reported in Mix-Type-3 with the optimal gradations of X = 1, Y = 1, and Z = 0.5, respectively.

- The highest permeability value was observed in the freshly mixed samples. After 6 months and 12 months, the core samples showed a reduction in permeability.

- It has been concluded that the most effective PAP mix in the study was Mix-Type-3. The mix has reported the highest stability and good permeability at the tested time of fresh samples. In the long term, 6 and 12 months also achieved the acceptable limits of DOTMNC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Al-Shamrani, A.M.; Jameel, M.; Khan, N.A.; Ibrahim, Z.; Akhtar, J. Stability and permeability characteristics of porous asphalt pavement: An experimental case study. Case Stud. Constr. Mater. 2021, 15, e00591. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Albatayneh, O.; Akhtar, J.N.; Koting, S. Porous asphalt pavement design by incorporating recycled coarse aggregate for sustainable urban drainage: An experimental study. Results Eng. 2025, 25, 103751. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. Environmental optimization of warm mix asphalt (WMA) design with recycled concrete aggregates (RCA) inclusion through artificial intelligence (AI) techniques. Results Eng. 2023, 17, 100984. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Bani-Hani, K.A.; Malkawi, D.A.H.; Malkawi, A.I.H. Porous Asphalt Mix Design Pavement by Incorporating a Precise Proportion of Recycled Coarse Aggregate. Int. J. Pavement Res. Technol. 2023, 25, 1–12. [Google Scholar] [CrossRef]

- Kusumawardani, D.; Wong, Y. Assessment of packing structure of porous asphalt mixture (PAM) based on image-based analysis. Int. J. Pavement Res. Technol. 2023, 16, 1158–1167. [Google Scholar] [CrossRef]

- Drake, J.; Bradford, A.; Van Seters, T. Stormwater quality of spring–summer-fall effluent from three partial-infiltration permeable pavement systems and conventional asphalt pavement. J. Environ. Manag. 2014, 139, 69–79. [Google Scholar] [CrossRef]

- Kusumawardani, D.; Wong, Y. Effect of Coarse Aggregate Surface Texture on Performance of Porous Asphalt Mixture (PAM). Int. J. Pavement Res. Technol. 2022, 15, 1498–1508. [Google Scholar] [CrossRef]

- Hajiabadi, M.; Shirgir, B.; Delnavaz, M. Evaluation of Urban Runoff Quality Passing from Pervious Concrete Pavements Containing Limestone Powder. Int. J. Pavement Res. Technol. 2023, 16, 1101–1112. [Google Scholar] [CrossRef]

- Liu, Q.; Cao, D. Research on material composition and performance of porous asphalt pavement. J. Mater. Civ. Eng. 2009, 21, 135–140. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Muda, M.M.; Legese, A.M.; Urgessa, G.; Boja, T. Strength, Porosity and Permeability Properties of Porous Concrete Made from Recycled Concrete Aggregates. Constr. Mater. 2023, 3, 81–92. [Google Scholar] [CrossRef]

- Shah, M.M.; Khalid, U.; Mujtaba, H.; Naqvi, S.A.Z.; Masood, S. Environmental impacts and performance assessment of recycled fine aggregate concrete. Environ. Sci. Pollut. Res. 2024, 31, 36938–36957. [Google Scholar] [CrossRef]

- Akhtar, M.; Khan, M.; Akhtar, J. Use of the falling-head method to assess permeability of fly ash based roof tiles with waste polythene fibre. Int. J. Sci. Eng. Res. 2014, 5, 476–483. [Google Scholar]

- Jaya, R.P. Porous concrete pavement containing nanosilica from black rice husk ash. In New Materials in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 493–527. [Google Scholar]

- Abdulwahid, A.; Al-Shafi’i, N.; Al-Busaltan, S.F. Evaluating the effect of porous concrete pavement characteristics on beneath pavement layers. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012064. [Google Scholar]

- Atul Narayan, S.; Murali Krishnan, J.; Little, D.; Rajagopal, K. Mechanical behaviour of asphalt binders at high temperatures and specification for rutting. Int. J. Pavement Eng. 2017, 18, 916–927. [Google Scholar] [CrossRef]

- Suresha, S.; Varghese, G.; Ravi Shankar, A.U. Laboratory and theoretical evaluation of clogging behaviour of porous friction course mixes. Int. J. Pavement Eng. 2010, 11, 61–70. [Google Scholar] [CrossRef]

- Al-Jumaili, M.A.H. Laboratory evaluation of modified porous asphalt mixtures. Appl. Res. J. 2016, 8, 2–3. [Google Scholar]

- Putri, E.E.; Vasilsa, O. Improve the Marshall stability of porous asphalt pavement with HDPE addition. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; p. 03005. [Google Scholar]

- Nakanishi, H.; Hamzah, M.; Hasan, M.M.; Karthigeyan, P.; Shaur, O. Mix design and application of porous asphalt pavement using Japanese technology. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012026. [Google Scholar]

- Hardiman, H. Application of packing theory on grading design for porous asphalt mixtures. Civ. Eng. Dimens. 2004, 6, 57–63. [Google Scholar]

- Yu, L.; Chen, T.; Wen, B.; Dong, W.; Lei, B. Sustainable Pavement Solutions: A Study of the Performance of Permeable Asphalt Mixtures Incorporating Steel Slag and Recycled Concrete Aggregate. J. Mater. Civ. Eng. 2025, 37, 04025220. [Google Scholar] [CrossRef]

- Elmagarhe, A.; Lu, Q.; Alamri, M.; Alharthai, M.; Elnihum, A. Laboratory performance evaluation of porous asphalt mixture containing recycled concrete aggregate and fly ash. Case Stud. Constr. Mater. 2024, 20, e02849. [Google Scholar] [CrossRef]

- ACI-211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. ACI Committee 211: Farmington Hills, MI, USA, 1991.

- ACI 214R-11; Guide to Evaluation of Strength Test Results of Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- ASTM-C33; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003.

- Baladi, G.Y.; Lyles, R.W.; Harichandran, R.S. Asphalt Mix Design: An Innovative Approach; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1988. [Google Scholar]

- Asphalt Institute. MS-2 Asphalt Mix Design Methods, 7th ed.; Asphalt Institute: Lexington, KY, USA, 2009. [Google Scholar]

- Asphalt Institute. Mix Design Methods of Asphalt Concrete and Other Hot Mix Types, 6th ed.; Asphalt Institute: Lexington, KY, USA, 1993. [Google Scholar]

- American Association of State Highway and Transportation Officials. Standard Specification for Performance-Graded Asphalt Binder; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1998. [Google Scholar]

- Saoud, H.A.A.; Sprynskyy, M.; Pashaei, R.; Kawalec, M.; Pomastowski, P.; Buszewski, B. Diatom biosilica: Source, physical-chemical characterization, modification, and application. J. Sep. Sci. 2022, 45, 3362–3376. [Google Scholar] [CrossRef]

- Jin, D.; Ge, D.; Zhou, X.; You, Z. Asphalt mixture with scrap tire rubber and nylon fiber from waste tires: Laboratory performance and preliminary ME design analysis. Buildings 2022, 12, 160. [Google Scholar] [CrossRef]

- Duan, K.; Wang, C.; Liu, J.; Song, L.; Chen, Q.; Chen, Y. Research progress and performance evaluation of crumb-rubber-modified asphalts and their mixtures. Constr. Build. Mater. 2022, 361, 129687. [Google Scholar] [CrossRef]

- ASTM D5581-06; Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 1989.

- Weatherbee, S. 321216-Attachment A-Porous Asphalt Pavement and Infiltration Beds; University of New Hampshire: Durham, New Hampshire, 2013. [Google Scholar]

- Wahhab, H.A.A.; Asi, I.; Ali, S.; Al-Swailmi, S.; Al-Nour, A. Stripping on Saudi Arabian Roads–Prediction and Prevention. In Proceedings of the 6th Saudi Engineering Conference, Dhahran, Saudi Arabia, 14–17 December 2002. [Google Scholar]

- Standard Specifications and Code of Practice for Construction of Concrete Roads, 3rd ed.; The Indian Roads Congress: New Delhi, India, 2002.

- Putman, B.J.; Kline, L.C. Comparison of mix design methods for porous asphalt mixtures. J. Mater. Civ. Eng. 2012, 24, 1359–1367. [Google Scholar] [CrossRef]

- Król, J.B.; Khan, R.; Collop, A.C. The study of the effect of internal structure on permeability of porous asphalt. Road Mater. Pavement Des. 2018, 19, 935–951. [Google Scholar] [CrossRef]

- Chiranjeevi, G.; Shankar, S. Influence of Aggregate Gradation and Pore Structure on Porous Asphalt Mixture Permeability and Resilient Modulus. J. Rehabil. Civ. Eng. 2026, 14, 2027. [Google Scholar]

- Vardanega, P. State of the art: Permeability of asphalt concrete. J. Mater. Civ. Eng. 2014, 26, 54–64. [Google Scholar] [CrossRef]

- Abdullah, W.S.; Obaidat, M.T.; Abu-Sa’da, N.M. Influence of aggregate type and gradation on voids of asphalt concrete pavements. J. Mater. Civ. Eng. 1998, 10, 76–85. [Google Scholar] [CrossRef]

- Nataatmadja, A. The use of hyperbolic function for predicting critical permeability of asphalt. In Proceedings of the ARRB Conference, 24th, 2010ARRB, Melbourne, Australia, 12–15 September 2010. [Google Scholar]

- Eleyedath, A.; Becerril, E.G., Jr.; Ali, A.; Mehta, Y. Development of a framework for the structural design of long-lasting porous asphalt pavement for high-traffic volume roadways. Constr. Build. Mater. 2025, 470, 140638. [Google Scholar] [CrossRef]

| Tests | Standards | Minimum (%) | Maximum (%) | Results |

|---|---|---|---|---|

| ASTM C29/C29M | _ | _ | ||

| Bulk density (BD) | 2.656 | |||

| Saturated surface density (SSD) | 2.707 | |||

| Apparent surface density (ASD) | 2.759 | |||

| Percentage of water absorption | 1.90% < 2 | |||

| RCA abrasion | ASTM C131 | - | 30% | |

| X | 14.2% | |||

| Y | 16.7% | |||

| Z | 19.3% | |||

| Soundness | ASTM C88 | |||

| Sodium Sulfate | - | 10 | 7.1 | |

| X | - | 7.5 | ||

| Y | 7.9 | |||

| Z | ||||

| Elongation and& Flakiness Index | ASTM D4791 | - | 10% | |

| X | - | 10% | 5.3% | |

| Y | 6.8% | |||

| Z | 7.9% | |||

| Fractured Faces | ASTM D5821 | - | ||

| 2ff | 90% | - | 100% | |

| 1ff | 100% | 100% |

| Experimental Values | Study’s Results | 60–70 Grade Recommended Values | Standards |

|---|---|---|---|

| Penetration at 25 °C, 100 g, 5 s | 65 | 60–70 (1/10 mm) | AASHTO T 49, 2019 |

| Flash point, Cleveland Open Cup | 258 | Min 232 °C | AASHTO T 48, 2015 |

| Ductility at 25 °C, cm | 118 | Min 100 cm | AASHTO T 51, 2018 |

| Solubility in trichloroethylene | 106 | Min 99.0% | AASHTO T 44, 2014 |

| Thin film oven 3.2 mm, 163 °C, 5 h loss on heating | 0.7 | Max 0.75% | AASHTO T 179, 2009 |

| Penetration of the residual % of the original | 64 | Min 54% | AASHTO T 49, 2019 |

| Ductility of residue at 25 °C, 5 cm/min | 62 | Min 50 cm | AASHTO T 51, 2018 |

| Viscosity, at 60 °C, poise, min | 2605 | Min 2400 poise | AASHTO T 202, 2019, 2000 |

| Kinematic viscosity (centistokes) at 135 °C | 270 | Max 400 centistokes | AASHTO T 201, 2015 |

| The softening point, ring, and ball apparatus | 47 | 46–54 °C | AASHTO T 53 |

| PAP Mixes | Prepared Recycled Aggregate Gradation for This Study | Recycled Aggregate Proportion | RCFP (75-2μ) | SF | WPF | CR | Binder | Total Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X | Y | Z | ||||||||||

| X = 19 mm | Y = 12.5 mm | Z = 9.5 mm | % | % | % | % | % | % | % | % | % | |

| g | g | g | g | g | g | g | g | g | ||||

| Mix-Type-1 | 0.5 | 1 | 1 | 17.70 | 35.40 | 35.40 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 212.40 | 424.8 | 424.8 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-2 | 1 | 0.5 | 1 | 35.40 | 17.70 | 35.40 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 424.8 | 212.4 | 424.8 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-3 | 1 | 1 | 0.5 | 35.40 | 35.40 | 17.7 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 424.8 | 424.8 | 212.4 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-4 | 0 | 1 | 1 | 0.0 | 44.25 | 44.25 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 0.0 | 531 | 531 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-5 | 1 | 0 | 1 | 44.25 | 0.00 | 44.25 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 531 | 0.0 | 531 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-6 | 1 | 1 | 0 | 44.25 | 44.25 | 0.0 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 531 | 531 | 0.0 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-7 | 0 | 2 | 1 | 0.0 | 55.32 | 33.18 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 0.0 | 663.84 | 398.16 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-8 | 2 | 0 | 1 | 55.32 | 0.0 | 33.18 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 663.84 | 0.0 | 398.16 | 12 | 12 | 6 | 36 | 72 | 1200 | ||||

| Mix-Type-9 | 0 | 1 | 2 | 0.0 | 33.18 | 55.32 | 1 | 1 | 0.5 | 3 | 6 | 100 |

| 0.0 | 398.16 | 663.84 | 12 | 12 | 12 | 36 | 72 | 1200 | ||||

| Types of Porous Asphalt Mixes | Percentage of Voids | Mixes Stability (kN) | Loss of Stability (%) | Mixes Flow (mm) | |

|---|---|---|---|---|---|

| After 30 min, Stability | After 24 h of Stability | ||||

| Mix-Type-1 | 19.64 | 8.15 | 4.38 | 46.26 | 4.4 |

| Mix-Type-2 | 18.60 | 7.9 | 4.26 | 44.81 | 4.8 |

| Mix-Type-3 | 17.90 | 8.88 | 5.44 | 38.74 | 4 |

| Mix-Type-4 | 18.75 | 7.8 | 4.38 | 43.85 | 4.4 |

| Mix-Type-5 | 20.05 | 6.32 | 3.35 | 46.99 | 5.1 |

| Mix-Type-6 | 21.52 | 3.88 | 1.58 | 59.28 | 5.7 |

| Mix-Type-7 | 18.88 | 7.1 | 4.05 | 42.96 | 4.4 |

| Mix-Type-8 | 21.09 | 5.04 | 2.66 | 46.82 | 5.1 |

| Mix-Type-9 | 19.70 | 7.4 | 3.86 | 47.43 | 4.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nejem, J.K.; Akhtar, M.N. An Experimental Study of Permeable Asphalt Pavement Incorporating Recycled Concrete Coarse Aggregates. Sustainability 2025, 17, 7323. https://doi.org/10.3390/su17167323

Nejem JK, Akhtar MN. An Experimental Study of Permeable Asphalt Pavement Incorporating Recycled Concrete Coarse Aggregates. Sustainability. 2025; 17(16):7323. https://doi.org/10.3390/su17167323

Chicago/Turabian StyleNejem, Jamal K., and Mohammad Nadeem Akhtar. 2025. "An Experimental Study of Permeable Asphalt Pavement Incorporating Recycled Concrete Coarse Aggregates" Sustainability 17, no. 16: 7323. https://doi.org/10.3390/su17167323

APA StyleNejem, J. K., & Akhtar, M. N. (2025). An Experimental Study of Permeable Asphalt Pavement Incorporating Recycled Concrete Coarse Aggregates. Sustainability, 17(16), 7323. https://doi.org/10.3390/su17167323