1. Introduction

Major earthquakes—including the 1994 Northridge earthquake, the 1999 Kocaeli and Düzce earthquakes, the 2011 Christchurch and Tohoku-Oki earthquakes, the 2016 Kumamoto earthquake, the 2017 Puebla earthquake (Mexico), the 2018 Sulawesi earthquake (Indonesia), the 2020 Aegean Sea earthquake (Turkey and Greece), and the 2023 Kahramanmaraş earthquake (Turkey and Syria)—have caused widespread damage and loss of life, exposing critical vulnerabilities in buildings and infrastructure across diverse seismic regions. These events are notable not only for their impact on urban environments but also for the attention they have drawn to the limitations of conventional structural systems. In many cases, they have accelerated the development, implementation, or revision of seismic protection technologies, including base isolation and energy dissipation devices, as part of resilience-focused design strategies. Seismic design codes have been crucial in preventing collapses and saved countless lives. However, over the past two decades, particularly in developed nations, damage to non-structural components and loss of functionality, resulting in business interruptions, have been the primary sources of economic losses from earthquakes [

1,

2,

3,

4]. For instance, in the 1994 Northridge earthquake, non-structural damage accounted for approximately 50% of the total estimated loss of

$18.5 billion [

5]. Today’s modern buildings house sensitive and expensive equipment that is essential for business, commerce, education, and healthcare. Often, the value of these building contents exceeds that of the buildings themselves. According to Taghavi and Miranda [

4], financial losses from non-structural damage can account for up to 70% of total costs, while the structural system only represents 18% of the investment. Therefore, in a future earthquake similar to the 1994 Northridge event, total losses could surpass previous estimates due to the high cost of non-structural components (such as electrical and architectural components, building contents), and business interruptions. This paper focuses specifically on passive seismic protection systems, such as base isolation and energy dissipation devices, which are commonly adopted in international design codes and widely implemented in practice. Active and semi-active control systems are not covered in this review. Given that the primary goal of seismic risk mitigation is to minimize casualties, economic loss, and service disruption, the design of new structures and the retrofitting of existing ones must address not only life safety but also post-earthquake functionality.

Historical events like the 1994 Northridge and 2011 Tohoku-Oki earthquakes revealed that much of the economic loss stemmed from damage to non-structural components and business interruptions, despite buildings remaining structurally safe. To address this, advanced seismic protection systems, such as base isolation and energy dissipation devices, are being increasingly adopted for their ability to preserve both structural and operational performance during and after seismic events.

The standards for designing and analyzing isolation systems have undergone considerable advancements. As emphasized by Peng et al. [

6] and Al-Janabi and Topkaya [

7], international design codes play a fundamental role in shaping the safety, reliability, and implementation strategies of seismic protection systems, particularly base isolation and energy dissipation devices, whose integration pathways are illustrated in

Figure 1 (adapted from [

8]). These codes provide standardized guidelines for designing, testing, and modeling structures to withstand earthquakes, tailored to the specific seismic risks of each region. By establishing performance-based criteria, international codes like ASCE 7 (US) [

9], GB 50011 (China) [

10], and NZS 1170.5 (New Zealand) [

11] ensure that buildings and infrastructure are resilient to after strong earthquake shaking. Design codes not only provide a legal and technical framework for seismic protection but also play a key role in enabling the integration of innovative technologies such as base isolation and energy dissipation devices. For instance, Wang et al. [

12,

13] noted that modern codes can promote innovation when coupled with rigorous testing protocols, while Borchiellini et al. [

14] discussed the regulatory role of codes in ensuring accountability and reducing structural risk. Additionally, Song and Zheng [

15] underscored the importance of international code harmonization in advancing knowledge-sharing and resilience-building, particularly in the face of emerging global challenges like climate change and urbanization.

A closer examination of major international seismic design codes reveals both the historical development, and the current scope of provisions related to seismic isolation. In the United States, base isolation was formally addressed in the Uniform Building Code (UBC) in the early 1990s, and has since been incorporated and expanded in ASCE/SEI 7 and the International Building Code (IBC). In Europe, Eurocode 8 includes specific guidelines for base-isolated structures, with national annexes providing further adaptation. Japan, a pioneer in seismic isolation research and application, integrated isolation technologies into its Building Standard Law following the 1995 Kobe earthquake, leading to rapid adoption in both public and private construction. In China, seismic isolation provisions are included in GB 50011-2010, with increasing emphasis on high-rise and essential infrastructure. Canada also includes isolation system guidelines in the National Building Code of Canada (NBCC), particularly through references to CSA standards. These codes vary in their scope and specificity, but all contribute to standardizing isolation design, defining performance levels, and enabling broader adoption of energy dissipation and base isolation technologies worldwide.

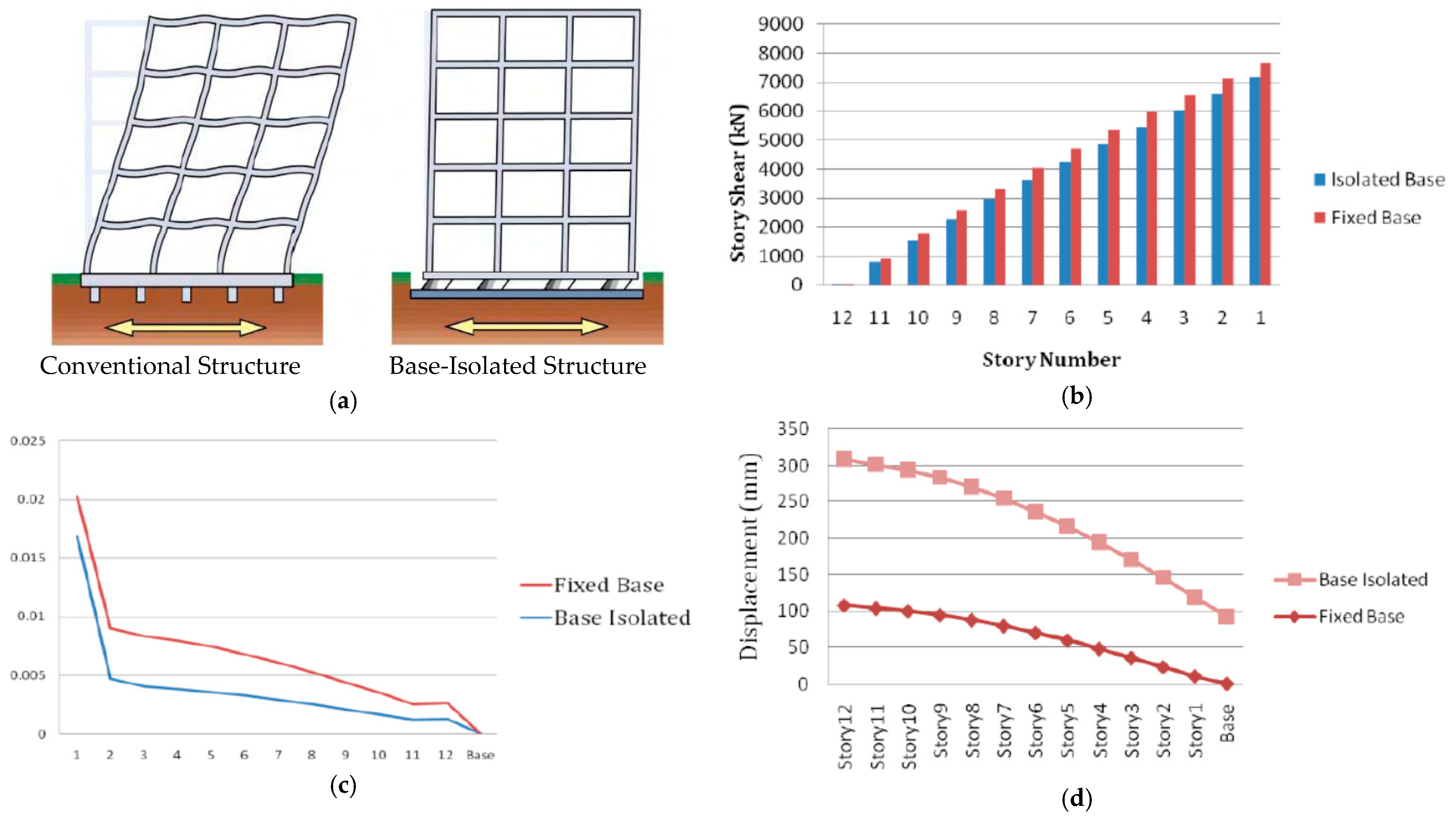

Recent advancements in seismic engineering have led to the development of tools and analytical methods capable of detecting potential failure modes in isolation systems under extreme seismic events that exceed design-level ground motions [

16]. These innovations significantly enhance the predictive accuracy of structural response analyses and contribute to more reliable and robust isolation system designs [

17]. As shown in

Figure 2 (adapted from [

8]), the implementation of seismic isolation effectively reduces structural acceleration and displacement demands during ground shaking. Additionally,

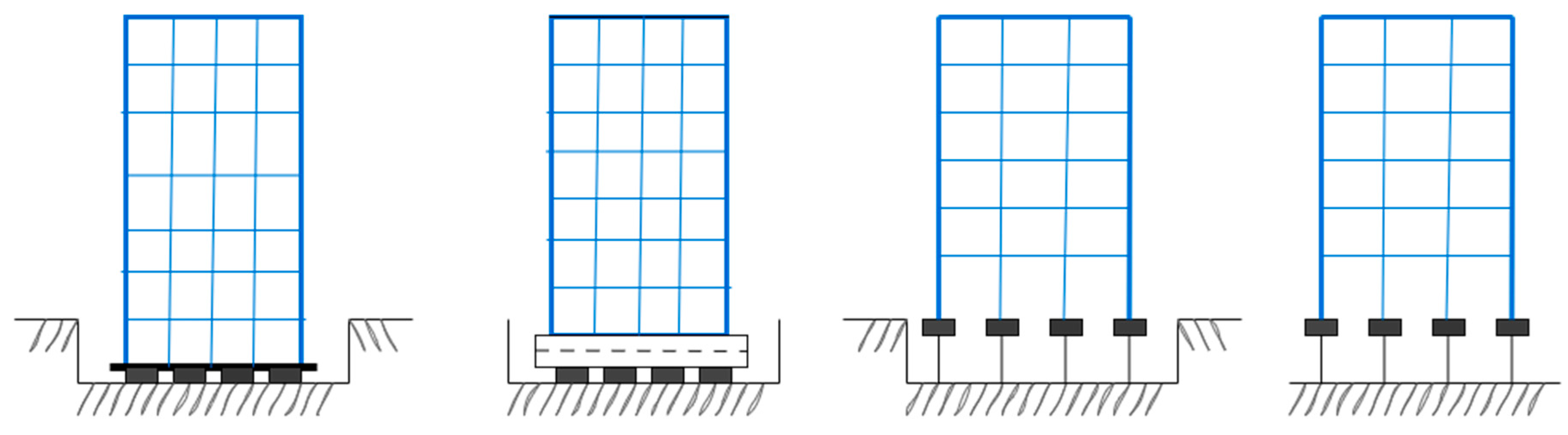

Figure 3 presents common configurations and strategic placement options for seismic isolation devices within building structures, which are essential for maximizing system performance [

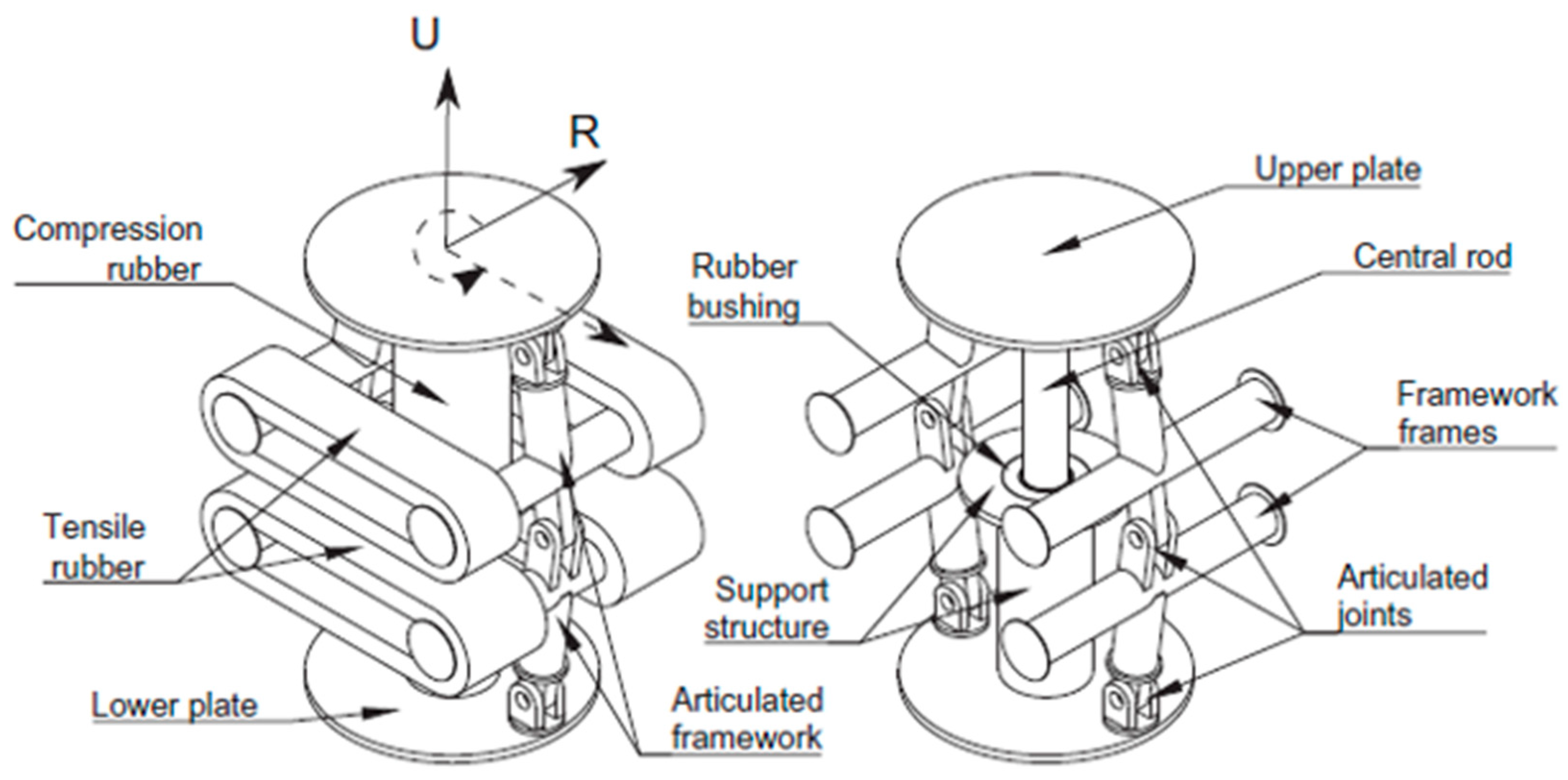

17]. Seismic isolation is a vital technique used in structural engineering to enhance the performance of buildings during earthquakes. According to Warn and Ryan [

18], seismic isolation works by significantly lengthening the natural period of a structure—typically to two to four seconds—through the use of flexible isolation devices at its base. In many design practices, including those outlined in U.S. and Canadian codes, the isolated period is often targeted to be approximately three times longer than the fixed-base period, to effectively reduce seismic demand. These devices effectively decouple the structure from ground motion during seismic events, thereby reducing the transmission of seismic forces [

19]. By shifting the natural period, seismic isolation minimizes the acceleration experienced by the floors and reduces inter-story drifts compared to non-isolated structures [

20]. Consequently, the demands placed on the building’s superstructure, the portion above the isolation system, are significantly lowered, allowing it to remain elastic or nearly so, even under design-level earthquake conditions. This approach ultimately enhances the resilience and safety of structures in seismic-prone regions. In addition, the reduced demands help protect displacement-sensitive and acceleration-sensitive equipment, non-structural components, and building contents from potential damage [

21]. However, this shift in the natural period leads to increased displacement concentrated at the isolation interface, which must be managed by the seismic isolation devices. Despite this, Alhan and Şahin [

22] noted that seismic isolation is highly effective in simultaneously reducing both acceleration and drift demands, making it one of the most effective strategies for achieving “Operational” or “Fully Operational” performance following a large, infrequent earthquake.

Several sources have offered thorough reviews covering different aspects of the development, theory, and application of seismic isolation technology. Early reviews were particularly comprehensive. For example, Kelly [

23] provided a historical overview, tracing seismic isolation technology from its early rudimentary stages and presenting a detailed timeline of research and development. Buckle and Mayes [

24] also offered an insightful historical perspective, along with an extensive list of early applications that contributed to the technology’s acceptance and wider use. Taylor et al. [

25] focused on elastomers in seismic isolation bearings, highlighting their long-term performance. A mid-1990s report further explored various subtopics, including the theory, experimental research, and application of sliding bearings, hybrid testing, and developments across several countries [

26]. In the last two decades, as the body of knowledge on seismic isolation has expanded rapidly, comprehensive reviews have become less frequent, although several specialized reviews have emerged. Kunde and Jangid [

27] provided an in-depth review focused on seismic isolation in bridges, covering analytical, experimental, and parametric studies. Symans et al. [

28] examined the challenges of applying seismic isolation and damping systems to wood-frame structures, which are difficult to isolate due to their flexibility and lighter mass. A recent primer from the American society of civil engineers [

29] outlines the theory, hardware, analysis, design, and testing requirements for seismic isolation in the United States. Additionally, a report by the International Council for Research and Innovation in Building and Construction (CIB) Task Group 44 [

30], compiled by international experts, compares devices, design codes, and the current state of seismic isolation practices across countries leading in its adoption.

Over the past decades, base isolation has emerged as a leading seismic protection strategy. However, despite its widespread application, existing literature lacks a unified and in-depth review that critically evaluates design methodologies, international standards, and emerging innovations. This review addresses this gap by systematically comparing base isolation technologies, testing approaches, and global implementation.

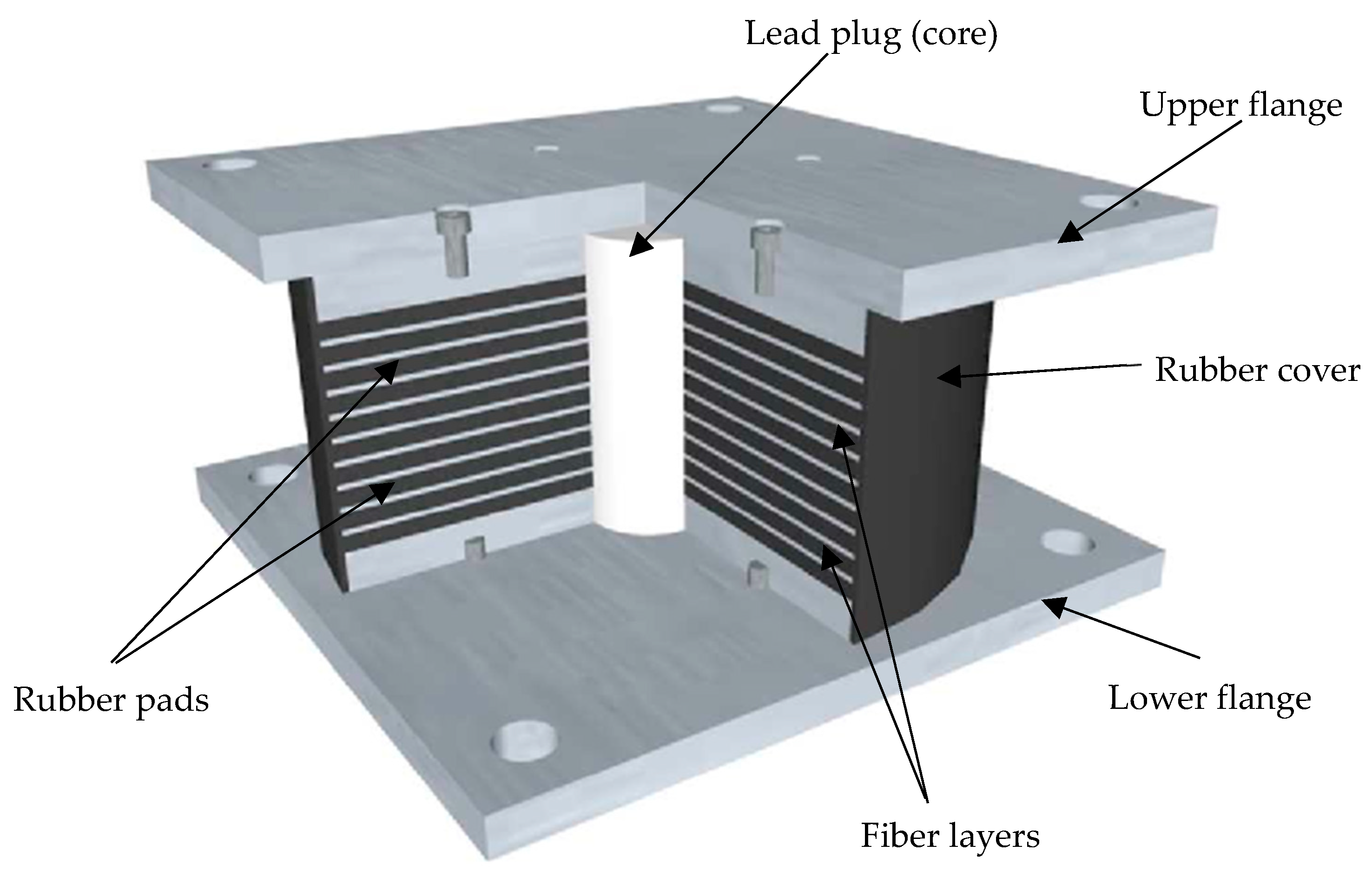

The development of seismic isolation technology has progressed through several key milestones. Theoretically, early concepts of period elongation and decoupling from ground motion were formalized in the 1960s and 1970s, leading to the development of practical isolator models. Material innovations followed, including the introduction of lead-rubber bearings (LRBs) in the late 1970s by Bill Robinson and the subsequent use of high-damping rubber compounds in HDRBs. The 1980s and 1990s saw a surge in experimental testing and real-world implementation, especially in Japan, the U.S., and New Zealand. This progress prompted the integration of isolation provisions into major design codes, starting with the Uniform Building Code (UBC) in the U.S. in the early 1990s, and similar code updates in Europe, Japan, and China. These milestones have collectively shaped modern seismic isolation practices.

Given the extensive number of existing review papers on seismic isolation technology, it is essential to clarify the unique contributions of this study. The key novel aspects of this review include:

- -

A structured and comparative analysis of base isolation techniques and their effectiveness under varying seismic conditions, across different international standards, identifying key strengths and gaps in each approach;

- -

A critical review of international seismic design codes, with a detailed comparative assessment of regulatory frameworks;

- -

A comprehensive discussion on the latest advancements in energy dissipation technologies and their potential integration into modern seismic design;

- -

An in-depth case study-based evaluation of base isolation applications, assessing their real-world performance;

- -

Future research insights and challenges from the perspective of practical implementation, integrating expert viewpoints.

The paper is structured as follows: in

Section 2, a comparison and discussion of base-isolation systems is presented;

Section 3 and

Section 4 compare international seismic design codes on seismic energy dissipation devices and seismic isolation, respectively;

Section 5 and

Section 6 examine experimental testing and numerical modeling approaches, respectively;

Section 7 discusses case studies on the application of seismic isolation;

Section 8 discusses challenges and future directions;

Section 9 summarizes conclusions and future research needs.

3. Design and Standards of Seismic Energy Dissipation Devices

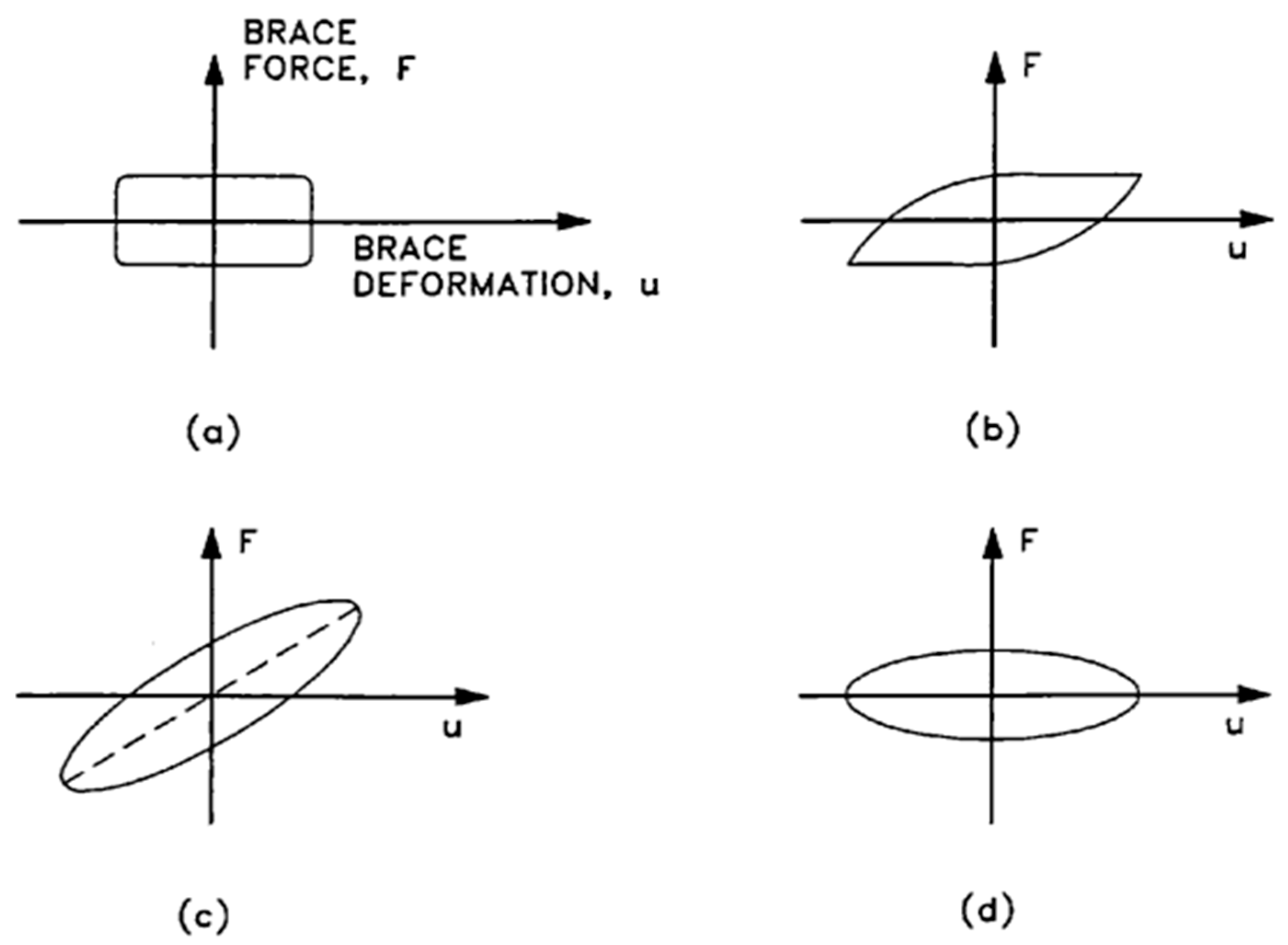

This section examines the performance of various energy dissipation devices in the context of seismic resilience and evaluates the design standards that govern their use across different seismic zones. Energy dissipation devices are fundamental in enhancing the resilience of structures exposed to seismic activity. By dissipating energy, these devices reduce the seismic forces exerted on primary structural components, thereby decreasing damage and extending the life of buildings, particularly in high-risk earthquake zones. The effectiveness of these devices lies in their ability to absorb and dissipate seismic energy, thereby reducing the impact on the primary structure [

91]. Almajhali [

91] further explains that several types of energy dissipation devices are commonly implemented, each chosen based on its mechanism and configuration within the structural system, making them suitable for different types of structures and seismic demands. Viscous dampers are frequently employed due to their predictable, linear force–displacement behavior, which makes them adaptable to both low and high seismic intensities. These dampers generate resistance through fluid viscosity, making them a reliable choice in both new constructions and retrofits [

26]. Additional insights are provided by Constantinou and Symans [

92], including experimental validation of their performance in seismic applications (refer to

Figure 10). Friction dampers, on the other hand, rely on controlled sliding friction, offering simplicity and consistent performance, particularly in retrofit applications where spatial constraints are present [

93]. Metallic yielding dampers absorb seismic energy through inelastic deformation, providing robust energy absorption for high-seismic regions, with effectiveness that extends through multiple aftershocks [

94,

95]. Typical configurations of energy dissipation devices vary based on their mechanism and intended function. Fluid viscous dampers (FVDs) are commonly installed diagonally between floors, beams, or braces and consist of a piston moving through a viscous fluid. As the structure displaces during seismic excitation, the relative movement produces resistance proportional to velocity, thereby damping the motion. Metallic yielding dampers are usually placed at intersections of bracing systems or within beam-column joints, where specially shaped steel elements (such as X-shaped or U-shaped plates) undergo stable plastic deformation to absorb energy. Their reliability, simplicity, and reusability make them especially suitable for critical infrastructure in high seismic zones. These configurations allow engineers to tailor dissipation behavior based on location, displacement demand, and structural system type, improving performance without heavily modifying the primary structure. Chang et al. [

96] explained that viscoelastic dampers combine elasticity with viscous behavior, allowing them to maintain stiffness while dissipating energy, making them particularly suitable for flexible structures such as tall buildings. Naeim and Kelly [

33] demonstrated that tuned mass dampers (TMDs), although not strictly energy dissipators, reduce motion by dynamically counteracting seismic forces. These devices are commonly used in tall buildings and bridges, particularly in regions with high wind or seismic activity.

The performance of energy dissipation devices is strongly influenced by key mechanical parameters that govern their force-deformation behavior:

Viscous Dampers: The damping force F = c⋅ depends on the damping coefficient c and relative velocity . High-damping coefficients are effective in reducing peak accelerations and inter-story drifts, especially in flexible structures. However, their performance is sensitive to temperature and loading frequency.

Friction Dampers: These rely on a predefined slip force Fs = μ⋅N, where μ is the friction coefficient and N is the normal force. Performance is determined by how consistently the damper can maintain sliding without stick-slip behavior. Excessive variation in friction can lead to unpredictable responses under seismic loading.

Metallic Yielding Dampers: Governed by their yield strength and hysteretic shape, these devices dissipate energy through stable plastic deformation. Key parameters include yield force and post-yield stiffness, which determine energy absorption capacity and re-centering behavior. A balance is needed to avoid excessive residual deformation.

Viscoelastic Dampers: These exhibit combined elastic and viscous behavior, with stiffness and damping highly dependent on strain rate and material formulation. Their effectiveness is defined by the storage modulus (elastic) and loss modulus (dissipative), which must be optimized for both frequency and amplitude of seismic input.

International guidelines establish specific performance, testing, and durability criteria tailored to regional seismic demands. These ensure that the selected energy dissipation devices are not only effective in general but are appropriate for the intensity and frequency of seismic events expected in each geographic area. In the United States, ASCE 7-16 includes provisions for energy dissipation systems, requiring rigorous testing to verify their performance over time [

97]. The IBC similarly mandates that energy dissipators meet specific performance standards, especially in high-seismic regions [

98]. Eurocode 8, the European standard, addresses the mechanical properties of dissipators, such as strength and deformation capacity, ensuring that they can withstand both design-based and maximum-considered earthquakes [

99]. Japanese standards, established by the JSSI and JBD, prioritize durability within the core structure of tall buildings, considering the high probability of aftershocks in the region [

100]. China’s GB50011 standard outlines stringent testing and inspection protocols for energy dissipation devices, especially for public infrastructure [

10]. In Canada, the NBC and CSA S832 standard emphasize material quality and installation specifics to ensure effectiveness in high-seismic regions [

85]. These standards ensure energy dissipation devices perform effectively under seismic stress, emphasizing testing, durability, and maintenance for protection in seismic-prone regions [

101].

Table 4 summarized the differences between analysis of seismic energy dissipation device standards and design requirements across the United States, China, Japan, Canada, and New Zealand, highlighting regional differences in seismic zones, applicable standards, and testing protocols.

In addition, a systematic analysis of other international seismic isolation standards is presented in

Table 5, highlighting key provisions, strengths, and gaps in each framework.

While

Table 5 presents a clause-based comparison of U.S., Chinese, and Japanese standards, the rationale for these differences reflects deeper regional and practical considerations:

U.S. codes (ASCE 7, FEMA guidelines) are rooted in performance-based design philosophies, prioritizing flexibility and efficiency across a wide range of structures. Emphasis is placed on dynamic response reduction and modularity in device selection.

Japanese standards adopt a more conservative stance due to frequent high-magnitude earthquakes. This results in rigorous full-scale testing, stricter fatigue and strain-based performance validation, and broader adoption of dampers in both public and private sectors.

China’s GB standards reflect lessons learned from recent major earthquakes and aim to rapidly standardize and enforce damping technologies for emerging urban infrastructure. These codes prioritize material aging, cyclic performance, and structural redundancy, particularly for hospitals, transportation hubs, and high-rise buildings.

4. Design Standards for Seismic Isolation and Energy Dissipation Devices

This section synthesizes key design standards across regions and compares their provisions to highlight regulatory strengths, gaps, and integration challenges for both base isolation and energy dissipation systems. A comparative evaluation of the regulatory frameworks in countries such as the U.S., China, Japan, Canada, and New Zealand is presented to highlight how local seismic conditions shape the design criteria, testing protocols, and integration strategies for both base isolation and energy dissipation devices. Design standards for seismic isolation and energy dissipation across regions like the U.S., China, Japan, Canada, and New Zealand provide essential guidelines for enhancing structural resilience to earthquakes. These standards offer provisions for base-isolation systems and energy dissipation devices, tailored to local seismic risks [

102].

Table 6 provides a comprehensive comparison of the seismic isolation and energy dissipation design standards and codes.

Harmonizing international seismic codes is challenging due to differences in seismic risk, construction practices, and national priorities [

103]. Countries like Japan, New Zealand, and the United States have developed seismic codes based on their unique earthquake histories, leading to varying approaches in modeling and testing base-isolation systems and energy dissipation devices. For example, Japan’s guidelines emphasize advanced simulation techniques due to high seismic activity, while the U.S. focuses on performance-based design [

97,

104]. Differences in structural design philosophies, modeling techniques, and regulatory environments further complicate standardization. Efforts to align codes, such as those by PEER, aim to bridge these gaps, though full harmonization remains complex [

105].

Table 6.

Comparative analysis of seismic isolation standards.

Table 6.

Comparative analysis of seismic isolation standards.

| Region | Design Standard | Key Design Provisions for Base-Isolation Systems | Energy Dissipation Integration | Additional Design Considerations |

|---|

| United States | ASCE 7 [97], AASHTO [106] | Provisions for base-isolation systems focus on designing for high seismic loads, including guidelines for both elastomeric bearings and sliding systems. ASCE 7 includes specific load requirements | ASCE 7 includes provisions for energy dissipation devices (viscous dampers, friction dampers, etc.) as supplemental seismic protection for structures | Seismic load determination methods are detailed, including force-based and displacement-based designs. AASHTO provides specific provisions for bridges, incorporating both base isolation and energy dissipation |

| China | GB 50011 [10], JGJ/T [107] | Base isolation guidelines focus on earthquake-resistant measures for buildings, bridges, and public infrastructures, with detailed specifications for elastomeric bearings and sliding bearings | Chinese standards specify the use of energy dissipation devices in seismic designs to improve the performance of structures. Primarily applied to critical infrastructure | Detailed installation and inspection requirements for isolators and dampers. Post-event assessment guidelines are included |

| Japan | JRA Guidelines [108], AIJ Guidelines [109] | Extensive guidelines for base-isolation in high-rise buildings and critical infrastructure, with provisions for long-term durability, considering post-event performance | Energy dissipation is incorporated with seismic isolation, including guidelines for dampers in both new builds and retrofits to accommodate aftershock events | Japan’s seismic codes include provisions for retrofitting existing structures, ensuring long-term resilience, particularly in high-risk zones like Tokyo and Osaka |

| Canada | NBCC [85], CSA S832 [110] | Provisions for base isolation in high seismic regions, with a focus on advanced materials and the integration of bearings in new construction and retrofits for improved safety | Integration of energy dissipation devices such as viscous dampers and friction dampers, typically for high-seismic zones like Vancouver, where active seismic risks exist | Detailed provisions for quality control during installation and post-event evaluation. Includes provisions for design flexibility and adaptability to different seismic intensities |

| New Zealand | NZS 1170.5 [11], NZSEE Guidelines [111] | Base isolation provisions are specifically aimed at protecting structures in high-risk seismic regions, with detailed recommendations for elastomeric and sliding bearings | Energy dissipation devices are used in conjunction with base isolation to enhance building resilience, especially for high-rise buildings in Christchurch and Wellington | The NZSEE guidelines provide extensive recommendations for building types and seismic performance requirements, including post-event inspections and assessment criteria |

In addition to this horizontal comparison, examining how codes have evolved over time within each country offers valuable context. In the United States, seismic isolation provisions were first formalized in the 1991 Uniform Building Code (UBC), mainly for essential structures. Later editions of ASCE 7, particularly from 2005 onward, introduced non-linear modeling, broader applicability, and performance-based verification. The 2022 edition continues to expand this flexibility.

In Japan, the devastating 1995 Kobe Earthquake prompted major updates to seismic codes. The JIS standards were revised to include full-scale testing, inspection requirements, and fatigue criteria. Over time, low-damping devices and advanced dampers were also incorporated into national specifications.

In China, GB 50011 introduced seismic isolation guidelines in 2001 following the Chi-Chi and Wenchuan earthquakes. The 2010 update added cyclic testing and long-term performance criteria. More recent revisions, including drafts from 2021, reflect a growing shift toward resilience and life-cycle-based seismic design.

This historical evolution illustrates a shared global trend: the movement from purely prescriptive, life-safety-based approaches to more flexible, performance-based frameworks that encourage innovation and system-level reliability.

Recent advances in seismic protection go beyond conventional elastomeric bearings and viscous dampers. Emerging technologies include semi-active magneto-rheological (MR) dampers, which adjust damping characteristics in real time; shape memory alloy (SMA)-based isolators with self-centering capacity; hybrid base-isolation systems that integrate energy dissipation and re-centering; and variable stiffness devices capable of adapting to displacement demands. These systems show strong potential in high-performance seismic design, though their integration into current codes remains limited. Further development of design guidelines is needed to facilitate their widespread adoption.

5. Experimental Testing

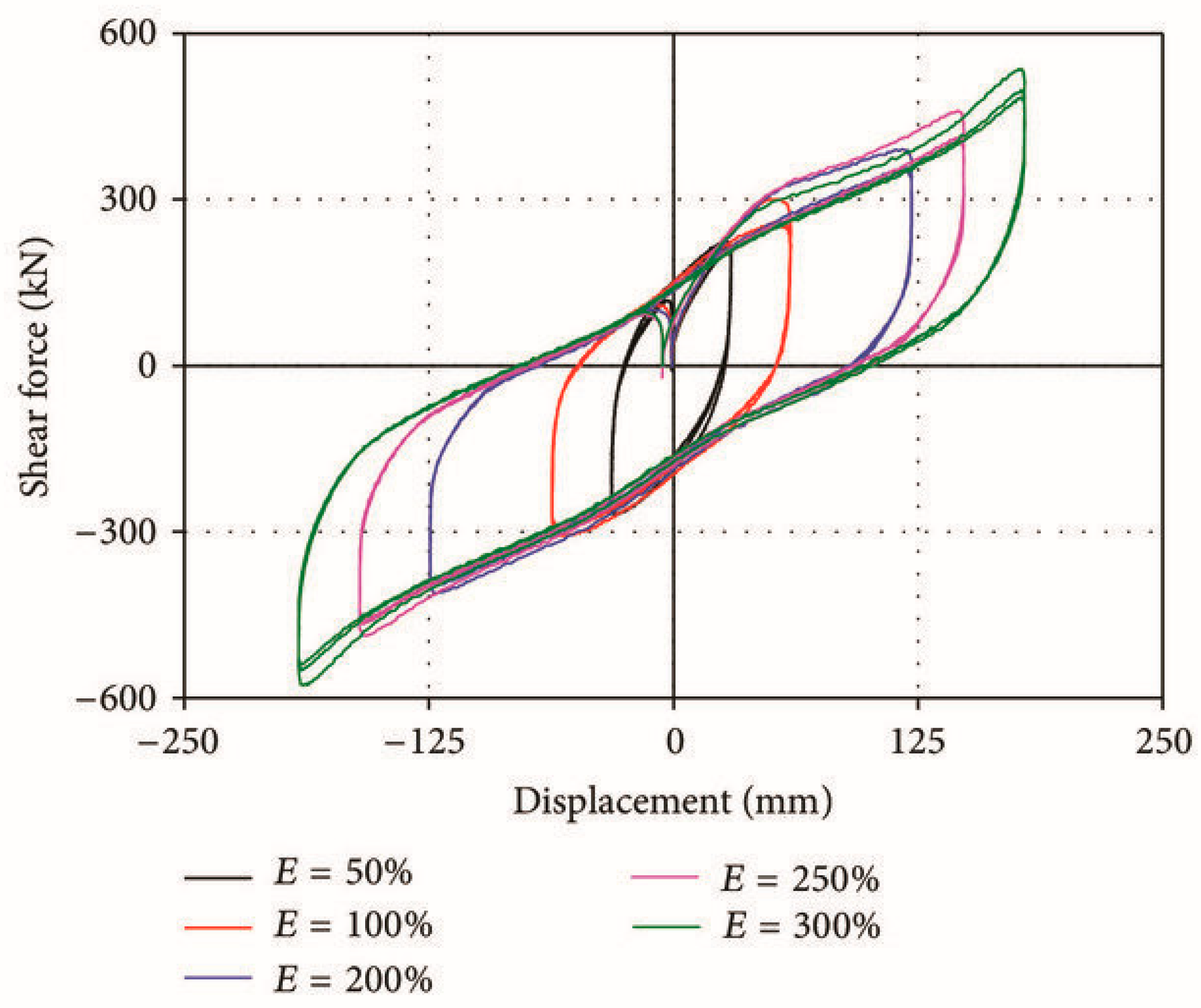

Experimental testing of base-isolation and energy dissipation systems is a fundamental step in ensuring these technologies’ effectiveness in real-world seismic events. Rasool et al. [

112] (2024) stated that rigorous protocols evaluate the effectiveness of isolation and dissipation devices in reducing building motion and absorbing energy. Key experimental methods include cyclic loading, shake table tests, hybrid simulations, and quasi-static tests, each targeting specific aspects of system performance [

112,

113]. Cyclic loading tests are essential for examining the force-displacement behavior of energy dissipators, such as metallic yielding dampers, friction dampers, and viscous dampers [

92,

114]. The test setup involves applying repeated cyclic forces of increasing amplitude to devices, such as metallic yielding dampers, which are tested for their inelastic deformation and stable hysteretic response. Friction dampers are evaluated for consistent slip forces, ensuring performance reliability under dynamic conditions [

114]. Shake table tests simulate intense ground motion to analyze the isolation system’s ability to reduce seismic forces. Elastomeric isolators and lead-rubber bearings are tested under varying axial loads, with geometries including different diameters and rubber thicknesses. These tests reveal significant reductions in peak structural accelerations and inter-story drifts for systems using high-damping isolators. Shake table setups often incorporate scaled models of buildings or bridges to mimic realistic structural behavior under seismic excitations [

113]. Hybrid simulations combine physical testing with computational modeling, offering high-fidelity insights into the dynamic behavior of isolation and damping systems. In such setups, devices like lead-core rubber bearings or fluid viscous dampers are physically tested while computational models simulate the surrounding structure. These simulations provide detailed information on non-linearity, load transfer mechanisms, and potential failure modes under complex seismic scenarios [

104]. Quasi-static tests are commonly used to analyze the behavior of viscoelastic dampers under slow, cyclic loading. Parameters such as damping ratio and stiffness are measured, with the test geometry focusing on the thickness and properties of the viscoelastic material. Findings confirm that viscoelastic dampers exhibit predictable and efficient energy dissipation across a range of strain rates, ensuring suitability for varying seismic intensities.

Each testing method serves specific structural and seismic contexts:

Cyclic loading tests are typically used in laboratory conditions for small-to-medium-scale dampers and isolators. They are especially useful in early-stage validation of device hysteresis and durability for mid-rise buildings in moderate seismic zones.

Shake table tests simulate real earthquake ground motions and are essential for large-scale validation of base-isolated buildings, bridges, or critical infrastructure. They are preferred in high-seismic-risk zones and are crucial when testing displacement-sensitive systems.

Hybrid simulations combine physical testing of key components with computational modeling of the full structure. These are best suited for high-rise or complex structures, especially when evaluating system performance under long-duration or multi-event earthquake scenarios.

Quasi-static tests are often applied to viscoelastic and metallic dampers used in low- to mid-rise buildings. They are ideal for understanding material behavior under slow cyclic loads and validating simplified models in low-to-moderate seismic zones.

Testing requirements for base isolation and energy dissipation systems vary across different national codes, reflecting regional seismicity and building practices. In the United States, ASCE 7 and AASHTO establish guidelines for testing procedures, including cyclic tests for damping devices and performance criteria for isolators under maximum-considered earthquakes. Cyclic tests for lead-rubber bearings have demonstrated stable hysteretic behavior and significant energy dissipation over repeated cycles, ensuring compliance with U.S. performance-based design standards [

97,

115]. Chinese standards, specifically GB50011 and JGJ/T, mandate extensive testing for base isolators and energy dissipators, focusing on durability and cyclic performance. Shake table tests for base-isolated buildings in high-risk regions, such as Sichuan, highlight the superior performance of hybrid isolation systems under mainshock–aftershock sequences [

10,

107]. Japanese standards, including the JRA and AIJ guidelines, emphasize advanced experimental techniques for isolators due to the country’s frequent earthquakes and aftershocks [

104]. These standards incorporate hybrid simulations, which combine physical and computational models to assess system resilience across multiple earthquake events. In particular, damping devices are tested for strain-rate dependency and cyclic energy dissipation to meet Japan’s requirements for seismic safety in dense urban settings [

100]. In Canada, the NBCC and CSA S832 set forth testing protocols that emphasize material properties and isolation device durability, incorporating shake table tests to verify isolators’ capacity to limit seismic forces in critical facilities. Experimental results show that base-isolated hospitals can maintain operational functionality even under maximum-considered earthquakes [

85]. New Zealand NZS 1170.5 and NZSEE guidelines recommend testing that simulates both design-level and maximum-considered earthquakes, reflecting the country’s high seismicity. Specific tests include cyclic loading of steel yielding dampers and quasi-static testing of high-damping rubber bearings to verify their energy dissipation efficiency and resilience under extreme conditions [

11]. This comprehensive testing approach ensures that base-isolation and energy dissipation systems meet severe performance standards and are resilient under diverse seismic conditions worldwide.

Table 7 summarizes the key differences in the testing methodologies and standards across different countries.

6. Numerical Modeling Approaches

Guerreiro et al. [

116] highlighted that numerical modeling is a crucial tool in the design and analysis of base-isolation systems and energy dissipation devices, as it enables the prediction of their behavior under seismic loads, evaluation of their performance, and optimization of their design before physical implementation. Base-isolation systems are commonly analyzed using non-linear time-history analysis, which effectively captures the hysteretic behavior of isolators under seismic loading [

117]. Typical modeling techniques for base-isolation systems include the lumped-mass model, which simplifies the structure by reducing it to a system of masses and springs, and the distributed-mass model, which more accurately represents the continuous nature of the structure [

26]. These models are used to simulate the interaction between the building and the isolation system, taking into account factors such as stiffness, damping, and the non-linear behavior of isolators. Additionally, advanced approaches like finite element models (FEM) are increasingly employed to perform more detailed simulations, particularly for complex structures like tall buildings [

118]. FEM enables the analysis of both the isolation system and structural components in greater detail, accounting for the non-linear properties of isolation bearings, such as elastomeric bearings, sliding bearings, and viscous dampers.

The choice of modeling technique depends on the type of structure, its complexity, and the seismic design objective:

Lumped mass models are ideal for simplified, preliminary analysis of low- to mid-rise regular buildings, especially in moderate seismic regions. They are often used when the goal is to estimate global structural response (e.g., base shear or floor acceleration) without high computational cost.

Distributed mass models are more appropriate for mid- to high-rise structures or those with irregular mass or stiffness distribution. They allow better representation of dynamic characteristics like higher-mode effects and torsional behavior, which become significant in taller buildings or asymmetric layouts.

Finite element models (FEM) are necessary for complex structures such as bridges, high-rise buildings, or critical facilities with coupled damping and isolation systems. FEM is preferred in performance-based seismic design when non-linear material behavior, local stress concentrations, or soil–structure interaction must be captured under severe seismic scenarios.

Almajhali [

91] explained that simulating energy dissipation devices, such as viscous dampers, friction dampers, and metallic yielding dampers, involves modeling their behavior under seismic loads to evaluate their energy absorption capacities and their interaction with the surrounding structure. For viscous dampers, the viscous damping force model is typically used, where the damper force is proportional to the velocity of relative motion between the connected parts [

26]. In contrast, friction dampers are modeled using a frictional force model, which incorporates the Coulomb friction law, accounting for the sliding resistance between two surfaces [

93]. Moreschi and Singh [

94] demonstrated that metallic yielding dampers, which absorb energy through inelastic deformation, are typically modeled using hysteretic models that define the force–displacement relationship as a series of loops, representing the energy dissipation during cyclic loading. Additionally, advanced hybrid models, which combine physical testing and computational simulations, have gained popularity for accurately simulating the behavior of energy dissipation devices in real-world scenarios [

119].

The modeling approaches for base-isolation systems and energy dissipation devices in various countries, based on their seismic design codes, are outlined in

Table 8. It compares the use of non-linear dynamic analysis, finite-element modeling, and hybrid simulations, emphasizing how the guidelines of each region address different levels of structural complexity and seismic conditions.

The assumptions listed in

Table 8 significantly influence simulation outcomes:

Lumped vs. distributed mass modeling affects higher-mode participation and the accuracy of dynamic response prediction. Lumped mass models may underestimate story accelerations in tall or irregular structures.

Linear vs. non-linear isolator behavior influences base displacement predictions under large seismic excitations. Linear models simplify analysis but may fail to capture stiffness degradation or post-yield behavior under near-fault ground motions.

Viscous damping vs. hysteretic damping assumptions can alter peak force estimations. Hysteretic damping better captures energy dissipation in metallic devices but requires more detailed material modeling.

Simplified soil–structure interaction (SSI) assumptions may neglect foundation uplift or rocking effects, which can be critical in soft soils or isolated bridges.

7. Case Studies

This section synthesizes key design standards across regions and compares their provisions to highlight regulatory strengths, gaps, and integration challenges for both base isolation and energy dissipation systems. Base-isolation and energy dissipation systems have been implemented globally in critical infrastructure to mitigate seismic risks and enhance building resilience [

120]. In the United States, these systems are widely used in bridges, hospitals, and government buildings, such as the retrofitting of San Francisco City Hall with base-isolation bearings resulted in a substantial reduction in seismic forces. Post-retrofit simulations and instrumentation data indicated a reduction in peak floor acceleration by approximately 60% and inter-story drift by over 70% compared to a fixed-base equivalent, ensuring both life safety and operational continuity [

97], and the integration of dampers in the Alaska Way Viaduct Replacement Tunnel to reduce ground shaking effects [

115]. These systems were designed according to the non-linear dynamic analysis methods specified in the ASCE 7 and AASHTO codes to ensure structural integrity under various seismic loads. The evaluations focused on the ability of base-isolation systems to reduce building motion and energy dissipation devices to absorb seismic energy. Testing methods, such as cyclic loading and shake table tests, have simulated real-world seismic events to assess the durability and energy absorption capabilities of isolators and dampers [

115]. In China, base-isolation has been implemented in high-rise buildings and bridges, such as the Shanghai Tower, where isolation bearings and damping devices were used to mitigate the effects of strong earthquakes [

10]. The country’s seismic design codes, GB 50011 and JGJ/T, promoted the use of hybrid simulations combining physical and computational tests to model base-isolation and energy dissipation devices more accurately. The performance evaluations combined static and dynamic analyses with specific guidelines for verifying the energy dissipation efficiency of isolators and dampers under cyclic and quasi-static conditions [

121]. Hybrid simulations were increasingly used to assess system resilience under multiple earthquake events, ensuring performance standards are met across various seismic scenarios [

10]. Japan, with its frequent seismic events, has extensively adopted base-isolation systems in both residential and commercial buildings, including the Tokyo Skytree which incorporates oil dampers and tuned mass dampers (TMDs) capable of dissipating up to 40% of seismic energy during major ground shaking. During the 2011 Tohoku earthquake, real-time monitoring data showed that base acceleration was reduced by approximately 50%, and maximum displacement remained within elastic limits, confirming the effectiveness of the integrated damping system [

104]. The Japan Road Association (JRA) and the Architectural Institute of Japan (AIJ) guidelines emphasized hybrid simulations and finite-element models for energy dissipation devices to ensure structures remain resilient during repeated seismic events. In Canada, critical infrastructure such as hospitals and emergency response centers, including the BC Place Stadium in Vancouver, uses base-isolation and energy dissipation systems to withstand seismic forces [

85]. National Building Code of Canada (NBCC) advocated for finite-element modeling to accurately analyze interactions between structural components and damping devices. In New Zealand, where seismic activity is prevalent, base-isolation systems have been employed in hospitals like Wellington Hospital and Auckland City Hospital to ensure the resilience of life-saving infrastructure [

111]. The base-isolated foundation system implemented at Christchurch Hospital reduced seismic demands on the superstructure by up to 65% in simulated strong-motion events, according to testing aligned with NZS 1170.5. Instrumented post-earthquake monitoring confirmed performance remained within the ‘fully operational’ performance objective. New Zealand’s seismic design guidelines, including NZS 1170.5 and NZSEE, recommend non-linear dynamic analysis to model these systems and ensure they meet stringent earthquake resilience standards, particularly for the maximum-considered earthquake scenario [

11].

These global case studies highlight the practical effectiveness of base-isolation and energy dissipation technologies, while also revealing regional preferences and performance variations based on seismic demand, regulatory environment, and design philosophy.

Table 9 summarizes additional case studies.

8. Challenges and Future Directions in Seismic Design Codes and Practical Implementation

While international codes offer essential guidance for seismic design, practical implementation often faces challenges related to harmonization, emerging technologies, and long-term performance verification. This section discusses these obstacles and outlines future directions to improve both code development and field application. Base-isolation and energy dissipation systems are essential for enhancing the seismic resilience of structures, but the current design codes face several challenges and limitations. Mayes et al. [

102] stated that a major issue is the lack of standardization among different national and regional seismic codes. For example, the U.S. codes [

97,

115] emphasize performance-based design, while countries like China and Japan adopt hybrid simulation techniques [

10,

104]. These discrepancies hinder international consistency and the exchange of best practices, making it difficult for multinational projects to adopt uniform standards. Moreover, many codes still rely on simplified or static models, which may not fully capture the complex behavior of base-isolation systems under dynamic seismic forces [

138]. While hybrid simulations and advanced finite element models are recommended in some codes [

10], they are not universally applied, leaving gaps in accurately predicting performance in real-world scenarios, particularly for innovative materials and technologies. The adaptation of codes to emerging technologies, such as smart materials and active control systems, is another challenge [

103]. Although technologies like shape-memory alloys and magnetorheological dampers are gaining traction, they are not fully integrated into existing seismic standards [

26,

139], leaving gaps in their implementation.

To bridge the observed performance gaps across regions, there is a pressing need for a unified international framework that standardizes performance-based assessment protocols. This framework should support the adoption of emerging technologies such as smart materials, adaptive isolation systems, and real-time health monitoring, which remain underrepresented in current standards despite their demonstrated potential.

In addition, the following insights into the evolution of design standards and future trends can be stated as follows:

The current variation in international seismic codes makes standardization difficult. A unified global framework should be developed to ensure consistency in isolation system performance assessment;

Advanced computational models should be incorporated into seismic codes to improve predictive accuracy and real-time monitoring of isolators;

Seismic codes must adapt to emerging technologies, such as AI-driven adaptive isolators and smart damping systems.

Recent advancements in seismic protection systems have extended beyond conventional passive devices to include smart and hybrid technologies that offer enhanced adaptability, control precision, and long-term resilience. Among these, shape memory alloy (SMA)-based isolators demonstrate superelasticity and self-centering capabilities, contributing to reduced residual displacements and improved post-earthquake functionality. Hybrid isolation systems, combining base isolators with energy dissipation or re-centering mechanisms, have also shown promising performance across a broader spectrum of ground motion characteristics. Additionally, passive systems integrated with real-time structural health monitoring are emerging, enabling adaptive response strategies based on observed performance during and after seismic events. Although these technologies remain in the early stages of implementation and are not yet included in most design codes, they align closely with the principles of performance-based seismic design and are likely candidates for future codification.

As seismic design continues to emphasize resilience and service continuity, the long-term behavior of isolation and damping devices is gaining critical importance. Aging-related factors, such as thermal degradation in lead-core bearings, oil leakage or viscosity loss in fluid viscous dampers, and fatigue in smart damping materials, can significantly affect performance over the service life of a structure. While current design codes address durability indirectly through material quality controls and periodic inspection guidelines, they generally lack provisions for detailed deterioration modeling or predictive maintenance. Future revisions should consider incorporating lifecycle-based design criteria and performance monitoring frameworks to ensure that protective systems remain reliable and effective under long-term operational and environmental demands.